jump start terminals FORD F650 2017 13.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: F650, Model: FORD F650 2017 13.GPages: 382, PDF Size: 5.18 MB

Page 154 of 382

Note:

Use only a 12-volt supply to start your

vehicle.

Note: Do not disconnect the battery of the

disabled vehicle as this could damage the

vehicle electrical system.

Park the booster vehicle close to the hood

of the disabled vehicle, making sure the

two vehicles do not touch.

Connecting the Jumper Cables WARNINGS

Do not attach the cables to fuel lines,

engine rocker covers, the intake

manifold or electrical components

as grounding points. Stay clear of moving

parts. To avoid reverse polarity

connections, make sure that you correctly

identify the positive (+) and negative (-)

terminals on both the disabled and booster

vehicles before connecting the cables. Do not attach the end of the positive

cable to the studs or L-shaped eyelet

located above the positive (+)

terminal of your vehicle ’s battery. High

current may flow through and cause

damage to the fuses. Do not connect the end of the

second cable to the negative (-)

terminal of the battery to be jumped.

A spark may cause an explosion of the

gases that surround the battery. Note:

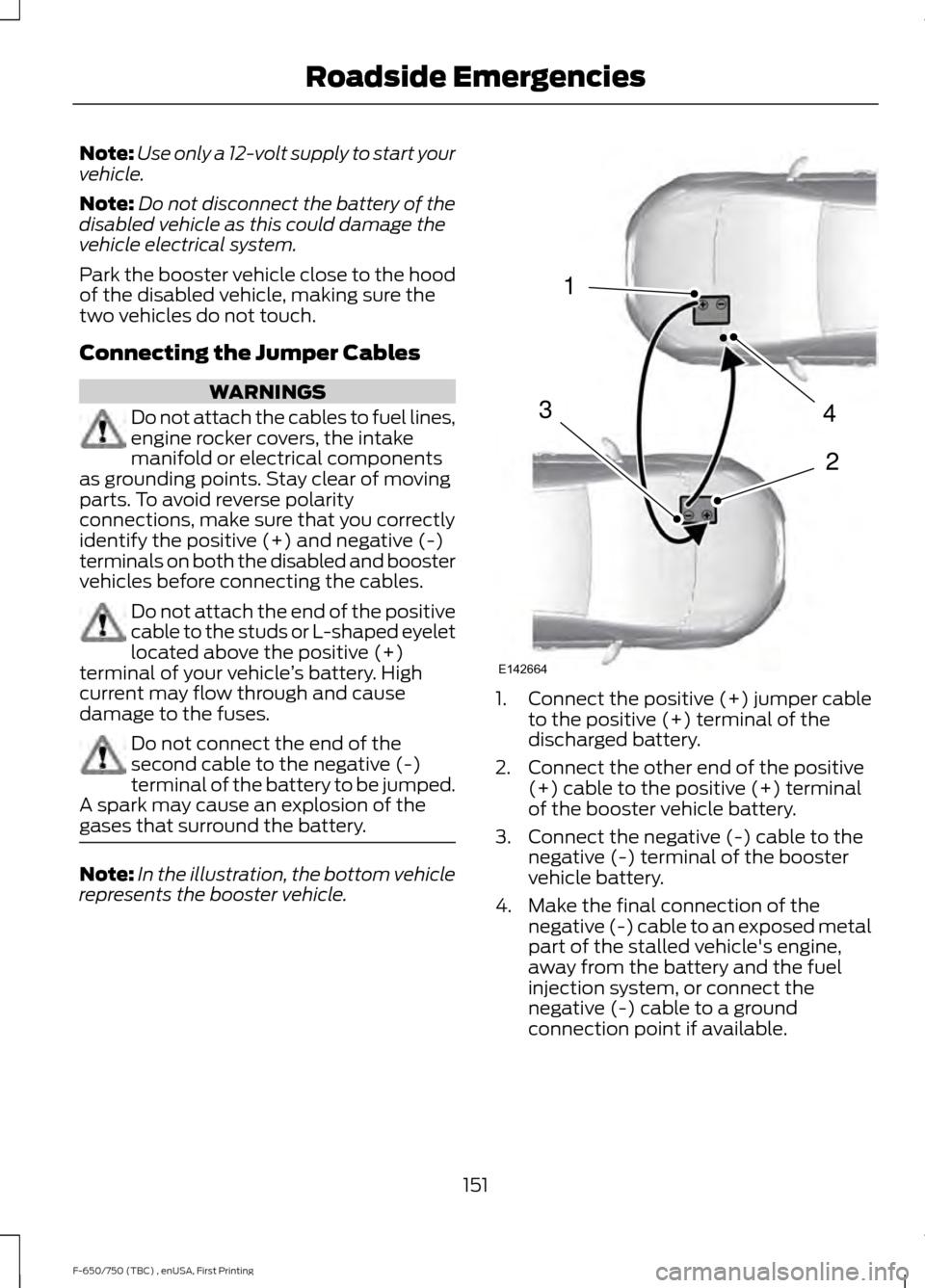

In the illustration, the bottom vehicle

represents the booster vehicle. 1.

Connect the positive (+) jumper cable

to the positive (+) terminal of the

discharged battery.

2. Connect the other end of the positive (+) cable to the positive (+) terminal

of the booster vehicle battery.

3. Connect the negative (-) cable to the negative (-) terminal of the booster

vehicle battery.

4. Make the final connection of the negative (-) cable to an exposed metal

part of the stalled vehicle's engine,

away from the battery and the fuel

injection system, or connect the

negative (-) cable to a ground

connection point if available.

151

F-650/750 (TBC) , enUSA, First Printing Roadside Emergencies4

2

1

3

E142664

Page 220 of 382

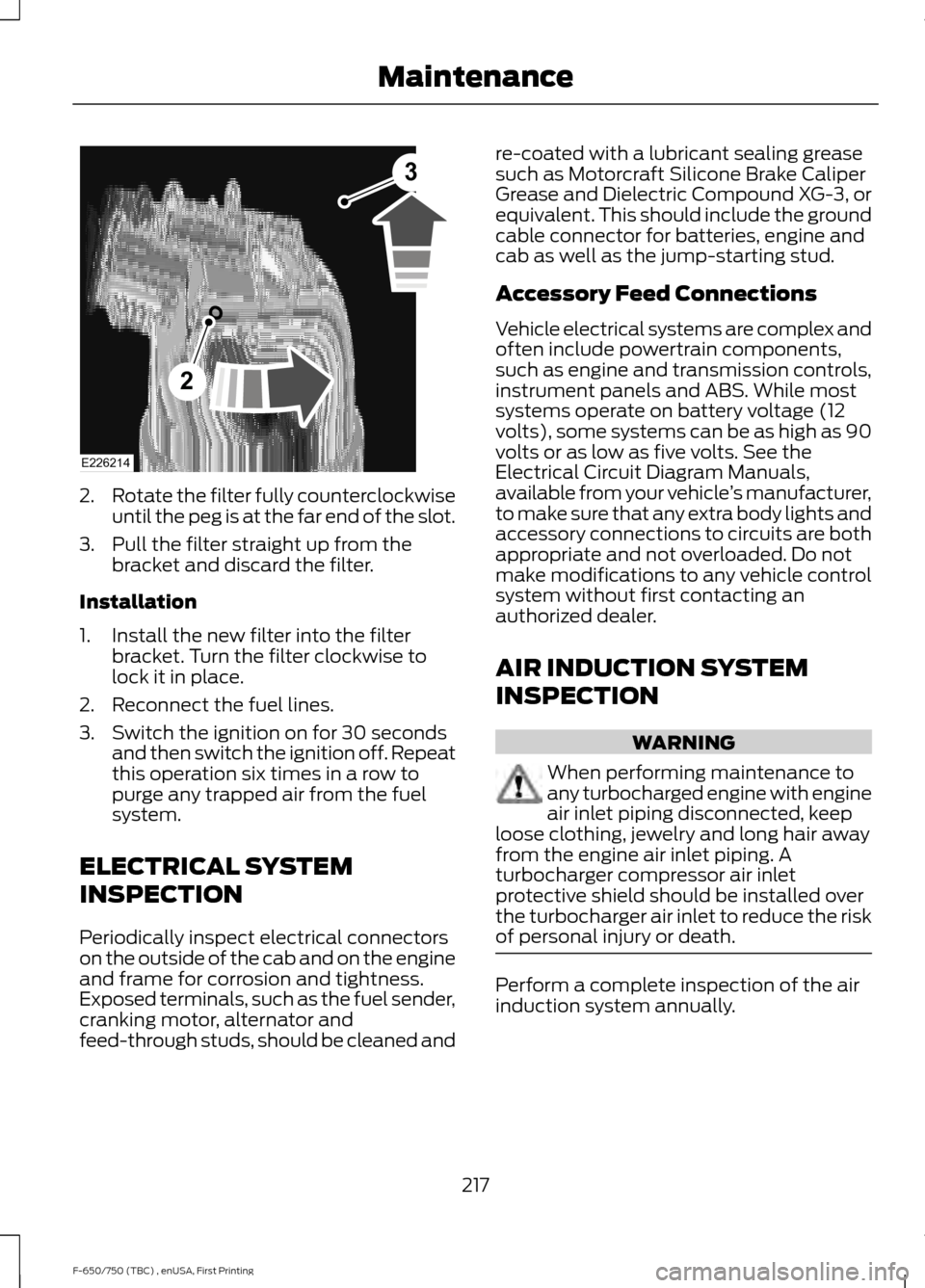

2.

Rotate the filter fully counterclockwise

until the peg is at the far end of the slot.

3. Pull the filter straight up from the bracket and discard the filter.

Installation

1. Install the new filter into the filter bracket. Turn the filter clockwise to

lock it in place.

2. Reconnect the fuel lines.

3. Switch the ignition on for 30 seconds and then switch the ignition off. Repeat

this operation six times in a row to

purge any trapped air from the fuel

system.

ELECTRICAL SYSTEM

INSPECTION

Periodically inspect electrical connectors

on the outside of the cab and on the engine

and frame for corrosion and tightness.

Exposed terminals, such as the fuel sender,

cranking motor, alternator and

feed-through studs, should be cleaned and re-coated with a lubricant sealing grease

such as Motorcraft Silicone Brake Caliper

Grease and Dielectric Compound XG-3, or

equivalent. This should include the ground

cable connector for batteries, engine and

cab as well as the jump-starting stud.

Accessory Feed Connections

Vehicle electrical systems are complex and

often include powertrain components,

such as engine and transmission controls,

instrument panels and ABS. While most

systems operate on battery voltage (12

volts), some systems can be as high as 90

volts or as low as five volts. See the

Electrical Circuit Diagram Manuals,

available from your vehicle

’s manufacturer,

to make sure that any extra body lights and

accessory connections to circuits are both

appropriate and not overloaded. Do not

make modifications to any vehicle control

system without first contacting an

authorized dealer.

AIR INDUCTION SYSTEM

INSPECTION WARNING

When performing maintenance to

any turbocharged engine with engine

air inlet piping disconnected, keep

loose clothing, jewelry and long hair away

from the engine air inlet piping. A

turbocharger compressor air inlet

protective shield should be installed over

the turbocharger air inlet to reduce the risk

of personal injury or death. Perform a complete inspection of the air

induction system annually.

217

F-650/750 (TBC) , enUSA, First Printing MaintenanceE226214

2

3