service FORD F650/750 2019 Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2019, Model line: F650/750, Model: FORD F650/750 2019Pages: 387, PDF Size: 4.78 MB

Page 107 of 387

Illumination of the service engine soon

indicator, charging system warning light or

the temperature warning light, fluid leaks,

strange odors, smoke or loss of engine

power could indicate that the emission

control system is not working properly.

An improperly operating or damaged

exhaust system may allow exhaust to

enter the vehicle. Have a damaged or

improperly operating exhaust system

inspected and repaired immediately.

Do not make any unauthorized changes to

your vehicle or engine. By law, vehicle

owners and anyone who manufactures,

repairs, services, sells, leases, trades

vehicles, or supervises a fleet of vehicles

are not permitted to intentionally remove

an emission control device or prevent it

from working. Information about your

vehicle

’s emission system is on the Vehicle

Emission Control Information Decal

located on or near the engine. This decal

also lists engine displacement.

Please consult your warranty information

for complete details.

On-Board Diagnostics (OBD-II)

Your vehicle has a computer known as the

on-board diagnostics system (OBD-II) that

monitors the engine ’s emission control

system. The system protects the

environment by making sure that your

vehicle continues to meet government

emission standards. The OBD-II system

also assists a service technician in properly

servicing your vehicle. When the service engine soon

indicator illuminates, the OBD-II

system has detected a

malfunction. Temporary malfunctions may

cause the service engine soon indicator to

illuminate. Examples are: 1. Your vehicle has run out of fuel

—the

engine may misfire or run poorly.

2. Poor fuel quality or water in the fuel —the engine may misfire or run

poorly.

3. The fuel fill inlet may not have closed properly. See Refueling (page 97).

4. Driving through deep water —the

electrical system may be wet.

You can correct these temporary

malfunctions by filling the fuel tank with

good quality fuel, properly closing the fuel

fill inlet or letting the electrical system dry

out. After three driving cycles without these

or any other temporary malfunctions

present, the service engine soon indicator

should stay off the next time you start the

engine. A driving cycle consists of a cold

engine startup followed by mixed city and

highway driving. No additional vehicle

service is required.

If the service engine soon indicator remains

on, have your vehicle serviced at the first

available opportunity. Although some

malfunctions detected by the OBD-II may

not have symptoms that are apparent,

continued driving with the service engine

soon indicator on can result in increased

emissions, lower fuel economy, reduced

engine and transmission smoothness and

lead to more costly repairs.

Readiness for Inspection and

Maintenance (I/M) Testing

Some state and provincial and local

governments may have

Inspection/Maintenance (I/M) programs

to inspect the emission control equipment

on your vehicle. Failure to pass this

inspection could prevent you from getting

a vehicle registration. If the service engine soon

indicator is on or the bulb does

not work, your vehicle may need

service. See On-Board Diagnostics.

104

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Engine Emission Control

Page 108 of 387

Your vehicle may not pass the I/M test if

the service engine soon indicator is on or

not working properly (bulb is burned out),

or if the OBD-II system has determined

that some of the emission control systems

have not been properly checked. In this

case, the vehicle is not ready for I/M

testing.

If the vehicle

’s engine or transmission has

just been serviced, or the battery has

recently run down or been replaced, the

OBD-II system may indicate that the

vehicle is not ready for I/M testing. To

determine if the vehicle is ready for I/M

testing, turn the ignition key to the on

position for 15 seconds without cranking

the engine. If the service engine soon

indicator blinks eight times, it means that

the vehicle is not ready for I/M testing; if

the service engine soon indicator stays on

solid, it means that your vehicle is ready

for I/M testing.

The OBD-II system checks the emission

control system during normal driving. A

complete check may take several days.

If the vehicle is not ready for I/M testing,

you can perform the following driving cycle

consisting of mixed city and highway

driving:

1. 15 minutes of steady driving on an expressway or highway followed by 20

minutes of stop-and-go driving with at

least four 30-second idle periods.

2. Allow your vehicle to sit for at least eight hours with the ignition off. Then,

start the vehicle and complete the

above driving cycle. The vehicle must

warm up to its normal operating

temperature. Once started, do not turn

off the vehicle until the above driving

cycle is complete.

If the vehicle is still not ready for I/M

testing, you need to repeat the above

driving cycle. SELECTIVE CATALYTIC

REDUCTANT SYSTEM - DIESEL

Your vehicle may have a selective catalytic

reduction system. The system helps reduce

emission levels of oxides of nitrogen from

the exhaust system. The system

automatically injects diesel exhaust fluid

into the exhaust system to enable correct

selective catalytic reduction system

function.

Note:

Selective catalytic reduction systems

are not fitted to vehicles in markets where

only high-sulfur diesel fuel is available.

Diesel Exhaust Fluid Level

In order for the system to operate correctly

you must maintain the diesel exhaust fluid

level.

A warning message appears in the

information display when the diesel

exhaust fluid level is low. If a warning

message appears, refill the diesel exhaust

fluid tank as soon as possible. See

Information Messages (page 67).

Filling the Diesel Exhaust Fluid

Tank WARNING:

Keep diesel exhaust

fluid out of reach of children. Avoid

contact with skin, eyes or clothing. In

case of contact with your eyes, flush

immediately with water and get prompt

medical attention. In case of contact

with your skin, clean immediately with

soap and water. If you swallow any

diesel exhaust fluid, drink plenty of

water, call a physician immediately.

105

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Engine Emission Control

Page 112 of 387

•

The system has a diesel exhaust fluid

quality sensor. Dilution of diesel

exhaust fluid or use of any other liquid

in the SCR system leads to a diesel

exhaust fluid system fault, eventually

leading to the vehicle only operating in

idle-only mode.

• Do not dilute diesel exhaust fluid with

water or any other liquid.

• An ammonia odor may be smelled

when the cap is removed or during

refill. Refill diesel exhaust fluid in a well

ventilated area.

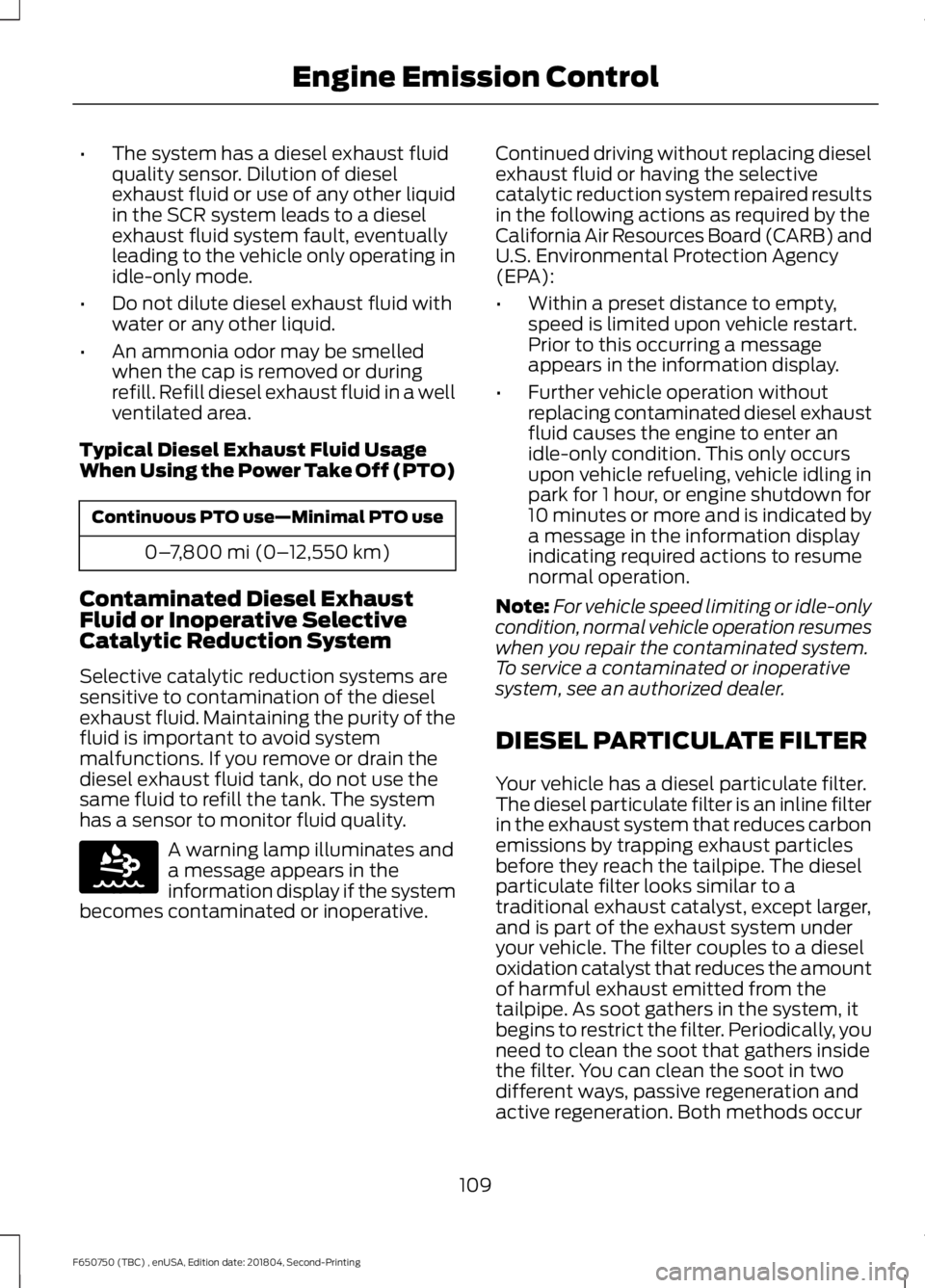

Typical Diesel Exhaust Fluid Usage

When Using the Power Take Off (PTO) Continuous PTO use—Minimal PTO use

0–7,800 mi (0– 12,550 km)

Contaminated Diesel Exhaust

Fluid or Inoperative Selective

Catalytic Reduction System

Selective catalytic reduction systems are

sensitive to contamination of the diesel

exhaust fluid. Maintaining the purity of the

fluid is important to avoid system

malfunctions. If you remove or drain the

diesel exhaust fluid tank, do not use the

same fluid to refill the tank. The system

has a sensor to monitor fluid quality. A warning lamp illuminates and

a message appears in the

information display if the system

becomes contaminated or inoperative. Continued driving without replacing diesel

exhaust fluid or having the selective

catalytic reduction system repaired results

in the following actions as required by the

California Air Resources Board (CARB) and

U.S. Environmental Protection Agency

(EPA):

•

Within a preset distance to empty,

speed is limited upon vehicle restart.

Prior to this occurring a message

appears in the information display.

• Further vehicle operation without

replacing contaminated diesel exhaust

fluid causes the engine to enter an

idle-only condition. This only occurs

upon vehicle refueling, vehicle idling in

park for 1 hour, or engine shutdown for

10 minutes or more and is indicated by

a message in the information display

indicating required actions to resume

normal operation.

Note: For vehicle speed limiting or idle-only

condition, normal vehicle operation resumes

when you repair the contaminated system.

To service a contaminated or inoperative

system, see an authorized dealer.

DIESEL PARTICULATE FILTER

Your vehicle has a diesel particulate filter.

The diesel particulate filter is an inline filter

in the exhaust system that reduces carbon

emissions by trapping exhaust particles

before they reach the tailpipe. The diesel

particulate filter looks similar to a

traditional exhaust catalyst, except larger,

and is part of the exhaust system under

your vehicle. The filter couples to a diesel

oxidation catalyst that reduces the amount

of harmful exhaust emitted from the

tailpipe. As soot gathers in the system, it

begins to restrict the filter. Periodically, you

need to clean the soot that gathers inside

the filter. You can clean the soot in two

different ways, passive regeneration and

active regeneration. Both methods occur

109

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Engine Emission ControlE163176

Page 115 of 387

Before you start operator commanded

regeneration, do the following:

•

Shift into park (P) or if you have an

RNDM selector shift into neutral (N)

and apply the parking and or air brake,

on stable, level ground.

• Park your vehicle outside of any

structure.

• Park your vehicle 10– 15 ft (3–5 m)

away from any obstructions and away

from materials that can easily combust

or melt, for example paper, leaves,

petroleum products, fuels, plastics and

other dry organic material.

• Make sure there is a minimum of 1/8

tank of fuel.

• Make sure all fluids are at proper levels.

How to Start Operator Commanded

Regeneration WARNING:

Stay clear of the

exhaust tailpipe during regeneration. Hot

exhaust gases can burn you badly.

Note: You cannot use the operator

commanded regeneration until the diesel

particulate filter load percentage has

reached 100%. The diesel particulate filter

load percentage fluctuates up and down

when driving your vehicle due to active and

passive regenerations.

Note: During the use of operator

commanded regeneration, you may observe

a light amount of white smoke. This is

normal. You may not be able to use

operator commanded

regeneration if the service engine

soon warning lamp appears in the

information display Information Display Procedure

Start your vehicle engine and when it has

reached the normal operating temperature,

press the information display control

button on the steering wheel until Exhaust

Filter XX%/FULL is displays. Operator

commanded regeneration can only be

initiated when FULL

See Information

Display Control (page 47). If a message

advising that the exhaust filter is full

appears in the information display, press

the down arrow button to set the display

to

Y. Answer yes to this prompt and then

follow the next prompts regarding exhaust

position required to initiate operator

commanded regeneration. Be sure to

understand each prompt. If you are not

sure what is being asked by each prompt,

contact an authorized dealer. The display

confirms the operation has started and

when it has finished.

If the diesel particulate filter is near or at

saturation, a message requesting

permission to initiate filter cleaning

appears in the information display only if

viewing the Exhaust Filter Status message.

See

Information Messages (page 67).

Answer yes to this prompt and then follow

the next prompts regarding exhaust

position required to initiate operator

commanded regeneration. Be sure to

understand each prompt. If you are not

sure what is being asked by each prompt,

contact an authorized dealer. The display

confirms the operation has started and

when it has finished. You can also drive to

clean the filter. When the system is at the point

of oversaturation, the service

engine warning lamp illuminates

and a message appears in the information

display. You cannot initiate filter cleaning.

You must have your vehicle checked as

soon as possible.

112

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Engine Emission Control

Page 116 of 387

Once operator commanded regeneration

starts, engine speed increases to

approximately 2000 rpm and the cooling

fan speed increases. You will hear a

change in audible sound due to engine

speed and cooling fan speed increases.

It is not necessary to open the hood on the

engine compartment. Once operator

commanded regeneration completes, the

engine speed returns to normal idling. The

exhaust system remains very hot for

several minutes even after regeneration is

complete. Do not reposition the vehicle

over materials that could burn until the

exhaust system has had sufficient time to

cool. Depending on the amount of soot

collected by the diesel particulate filter,

ambient temperature and altitude,

operator commanded regeneration lasts

approximately 30 minutes.

Operator Commanded Regeneration

with Automatic Regeneration Control

(If Equipped)

If your vehicle is operated with significant

stationary operation, low speed drive

cycles less than 25 mph (40 km/h), short

drive cycles, drive time less than 15 minutes

or the vehicle does not fully warm up,

passive and active regeneration may not

sufficiently clean the diesel particulate

filter system. You can switch off automatic

regeneration until better driving conditions

are available, for example steady high

speed driving. You can then switch

automatic regeneration back on to clean

the diesel particulate filter.

Switching Automatic Regeneration

Control On and Off

To switch operator commanded

regeneration on and off, use the

information display control on the steering

wheel. See Information Display Control

(page

47). Scroll to the exhaust cleaning

message and then select Y or N to switch

it On or Off. How to Interrupt or Cancel Operator

Commanded Regeneration

If you need to cancel the operator

commanded regeneration, pressing the

brake, accelerator or switching the engine

off stops the procedure. Depending on the

amount of time you allowed the operator

commanded regeneration to operate, soot

may not have had sufficient time to be fully

eliminated, but the exhaust system and

exhaust gas may still be hot. If you shut

your vehicle off during operator

commanded regeneration, you may notice

turbo flutter. This is a normal consequence

caused by shutting off a diesel engine

during boosted operation and is considered

normal.

Filter Service and Maintenance

Over time, a slight amount of ash builds

up in the diesel particulate filter, which is

not removed during the regeneration

process. The filter may need to be replaced

with a new or remanufactured part at

approximately 250,000 mi (400,000 km).

Actual mileage varies depending on engine

and vehicle operating conditions.

If filter service is required, the

engine control system warning

lamp illuminates in the

information display. If there are any issues with the

diesel particulate filter system,

the engine control system

warning lamp and a service

engine soon warning lamp

illuminate to inform you that

your vehicle requires service. Have your

vehicle checked as soon as possible.

113

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Engine Emission Control

Page 122 of 387

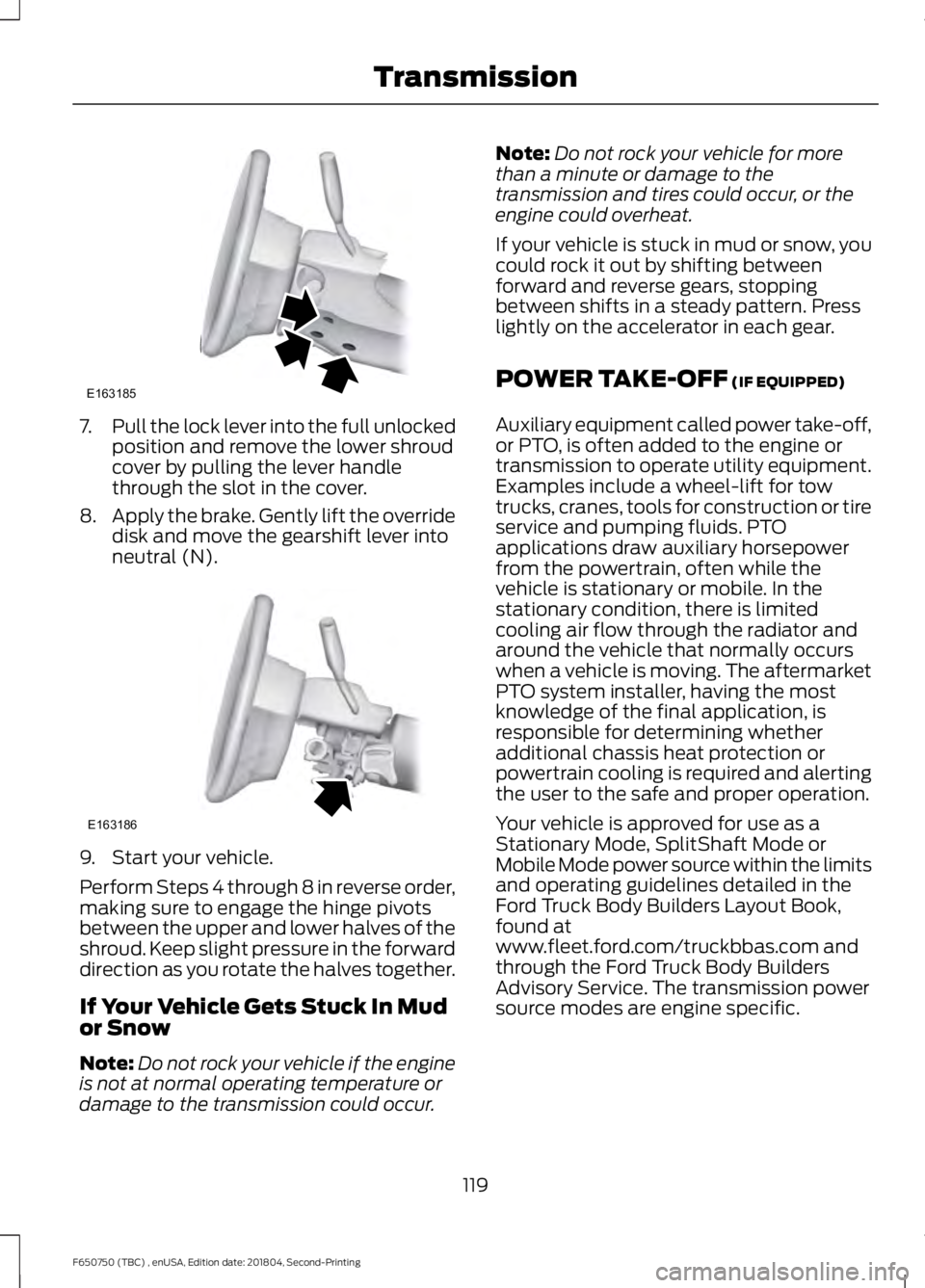

7.

Pull the lock lever into the full unlocked

position and remove the lower shroud

cover by pulling the lever handle

through the slot in the cover.

8. Apply the brake. Gently lift the override

disk and move the gearshift lever into

neutral (N). 9. Start your vehicle.

Perform Steps 4 through 8 in reverse order,

making sure to engage the hinge pivots

between the upper and lower halves of the

shroud. Keep slight pressure in the forward

direction as you rotate the halves together.

If Your Vehicle Gets Stuck In Mud

or Snow

Note:

Do not rock your vehicle if the engine

is not at normal operating temperature or

damage to the transmission could occur. Note:

Do not rock your vehicle for more

than a minute or damage to the

transmission and tires could occur, or the

engine could overheat.

If your vehicle is stuck in mud or snow, you

could rock it out by shifting between

forward and reverse gears, stopping

between shifts in a steady pattern. Press

lightly on the accelerator in each gear.

POWER TAKE-OFF (IF EQUIPPED)

Auxiliary equipment called power take-off,

or PTO, is often added to the engine or

transmission to operate utility equipment.

Examples include a wheel-lift for tow

trucks, cranes, tools for construction or tire

service and pumping fluids. PTO

applications draw auxiliary horsepower

from the powertrain, often while the

vehicle is stationary or mobile. In the

stationary condition, there is limited

cooling air flow through the radiator and

around the vehicle that normally occurs

when a vehicle is moving. The aftermarket

PTO system installer, having the most

knowledge of the final application, is

responsible for determining whether

additional chassis heat protection or

powertrain cooling is required and alerting

the user to the safe and proper operation.

Your vehicle is approved for use as a

Stationary Mode, SplitShaft Mode or

Mobile Mode power source within the limits

and operating guidelines detailed in the

Ford Truck Body Builders Layout Book,

found at

www.fleet.ford.com/truckbbas.com and

through the Ford Truck Body Builders

Advisory Service. The transmission power

source modes are engine specific.

119

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing TransmissionE163185 E163186

Page 125 of 387

GENERAL INFORMATION

WARNING: Do not apply the brake

pedal and accelerator pedal

simultaneously. Applying both pedals

simultaneously for more than a few

seconds will limit engine performance,

which may result in difficulty maintaining

speed in traffic and could lead to serious

injury.

Note: Occasional brake noise is normal. If

a metal-to-metal, continuous grinding or

continuous squeal sound is present, the

brake linings may be worn-out. Have the

system checked as soon as possible. If your

vehicle has continuous vibration or shudder

in the steering wheel while braking, have it

checked by an authorized dealer.

All standard equipment brakes are

self-adjusting. Automatic adjustment,

when required, occurs whenever you apply

and release the brakes during forward or

reverse operation.

Know the required stopping distances for

all driving conditions you may encounter.

For longer brake lining life, take full

advantage of engine braking power when

coming to a stop.

Wet brakes result in reduced braking

efficiency. Gently press the brake pedal a

few times when driving from a car wash or

standing water to dry the brakes.

If the brakes do not grip well:

• Check brake adjustment.

• Check the brake linings for excessive

wear.

• Check the system air pressure on

vehicles with air brakes. •

Let the brakes cool if you have been

using them excessively, as in mountain

driving or after several fast, high-speed

stops.

• If you have been driving through deep

water, gently apply the brakes several

times while your vehicle is moving

slowly.

Brake Over Accelerator

In the event the accelerator pedal

becomes stuck or entrapped, apply steady

and firm pressure to the brake pedal to

slow the vehicle and reduce engine power.

If you experience this condition, apply the

brakes and bring your vehicle to a safe

stop. Move the transmission to park (P),

switch the engine off and apply the parking

brake. Inspect the accelerator pedal for

any interference. If none are found and the

condition persists, have your vehicle towed

to the nearest authorized dealer

Anti-lock Brake System

This system helps you maintain steering

control during emergency stops by keeping

the brakes from locking. This lamp momentarily

illuminates when you switch the

ignition on. If the light does not

illuminate during start up, remains on or

flashes, the system may be disabled. Have

the system checked by an authorized

dealer. If you connect a PLC trailer with

the ignition on, the trailer ABS

light also illuminates. If the light

fails to illuminate, if it remains on after you

start the vehicle or continues to flash, have

the system serviced immediately.

See

Warning Lamps and Indicators

(page 60).

122

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Brakes E210335

Page 126 of 387

If the system is disabled, normal

braking is still effective. If the

brake warning lamp illuminates

when you release the parking brake, have

the system checked by an authorized

dealer. It also illuminates momentarily

when you switch the ignition on to confirm

the lamp is functional. If it does not

illuminate when you switch the ignition on,

or begins to flash at any time, have the

system checked by an authorized dealer.

HINTS ON DRIVING WITH

ANTI-LOCK BRAKES

The anti-lock braking system does not

eliminate the risks when:

• You drive too closely to the vehicle in

front of you.

• Your vehicle is hydroplaning.

• You take corners too fast.

• The road surface is poor.

Note: If the system activates, the brake

pedal may pulse and may travel further.

Maintain pressure on the brake pedal. You

may also hear a noise from the system. This

is normal.

PARKING BRAKE

Hydraulic Brakes (If Equipped) WARNING:

Always set the parking

brake and leave your vehicle with the

transmission in park (P). WARNING:

This control is for

parking only. Do not leave the vehicle

unattended after setting the parking

brake without placing the transmission

in park (P). We recommend using wheel

chocks for hilly or off-road

circumstances. WARNING:

Unexpected and

possibly sudden vehicle movement may

occur if you do not take these

precautions. WARNING:

If the parking brake is

fully released, but the brake warning

lamp remains illuminated, the brakes

may not be working properly. Have your

vehicle checked as soon as possible.

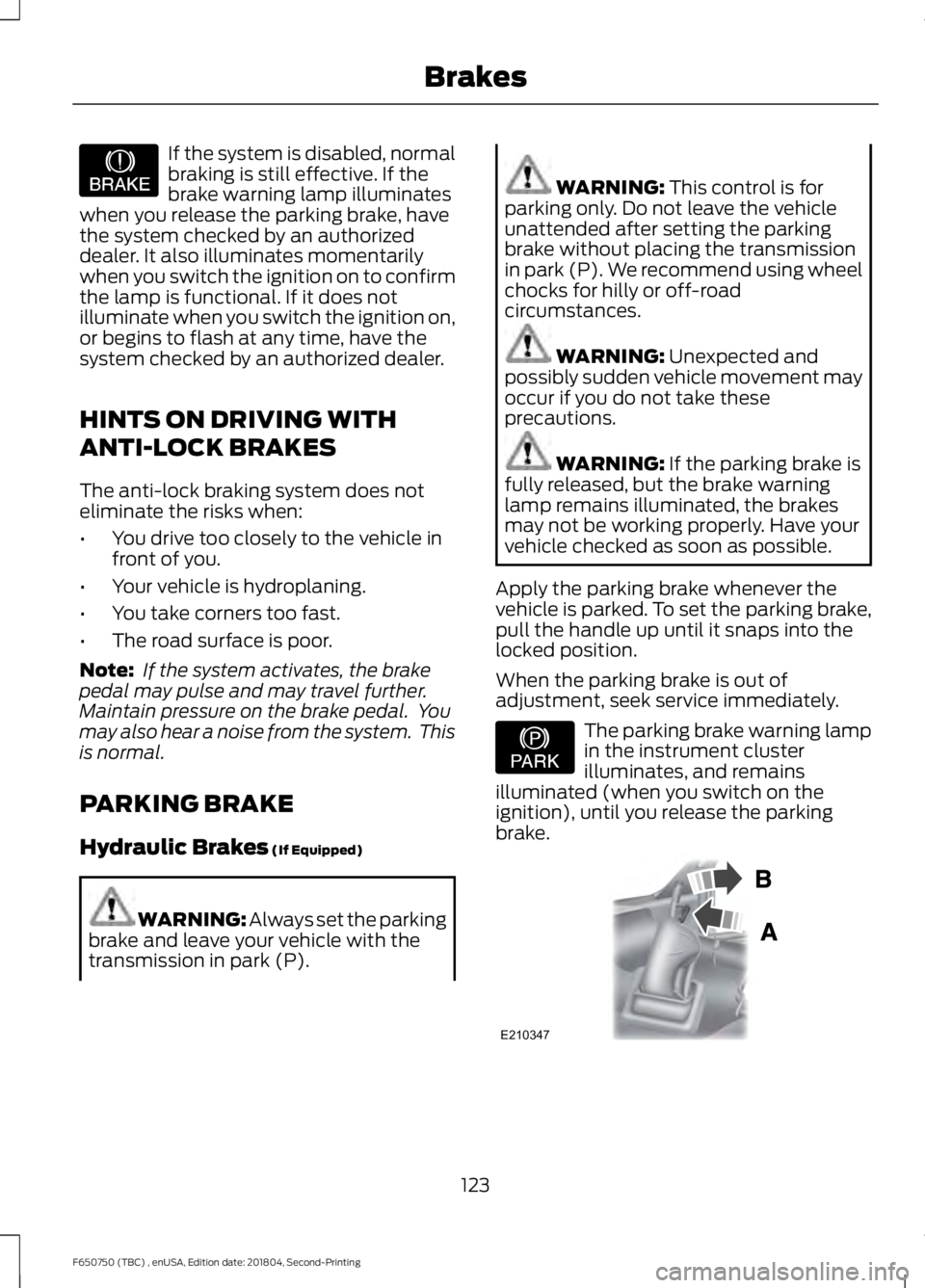

Apply the parking brake whenever the

vehicle is parked. To set the parking brake,

pull the handle up until it snaps into the

locked position.

When the parking brake is out of

adjustment, seek service immediately. The parking brake warning lamp

in the instrument cluster

illuminates, and remains

illuminated (when you switch on the

ignition), until you release the parking

brake. 123

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing BrakesE209041 E208810 E210347

Page 127 of 387

Push the palm release lever (A) on the

parking brake handle (B) and push down

as far as possible to release the brake.

Driving with the parking brake on causes

the brakes to wear out quickly and reduces

fuel economy.

We recommend you not use the parking

brake to stop a moving vehicle. However,

if the normal brakes fail, you can use the

parking brake to stop your vehicle in an

emergency. Since the parking brake only

applies retardation to the rear wheels, the

vehicle's stopping distance increases

greatly and the handling of your vehicle is

adversely affected.

Releasing Spring Manually

WARNING: Do not attempt to

disassemble the parking brake air

chamber under any circumstances as

this may cause serious injury. WARNING:

Block the wheels to

help prevent the vehicle from moving. WARNING:

Unexpected and

possibly sudden vehicle movement may

occur if you do not take these

precautions.

If you release hydraulic pressure from the

spring brake chamber, the power spring

applies the brake. If the hydraulic pressure

can be re-established, you must release

the spring brake in order to move your

vehicle. Air Brakes

(If Equipped) WARNING:

This control is for

parking only. Do not leave the vehicle

unattended after setting the parking

brake without placing the transmission

in park (P). We recommend using wheel

chocks for hilly or off-road

circumstances.

If the service brakes fail to operate while

your vehicle is moving, you can make an

emergency stop with the parking brake.

Since the parking brake only applies

stopping power to the rear wheels, your

vehicle ’s stopping distance greatly

increases and the handling of your vehicle

is adversely affected. Make repairs

immediately to an inoperative air brake

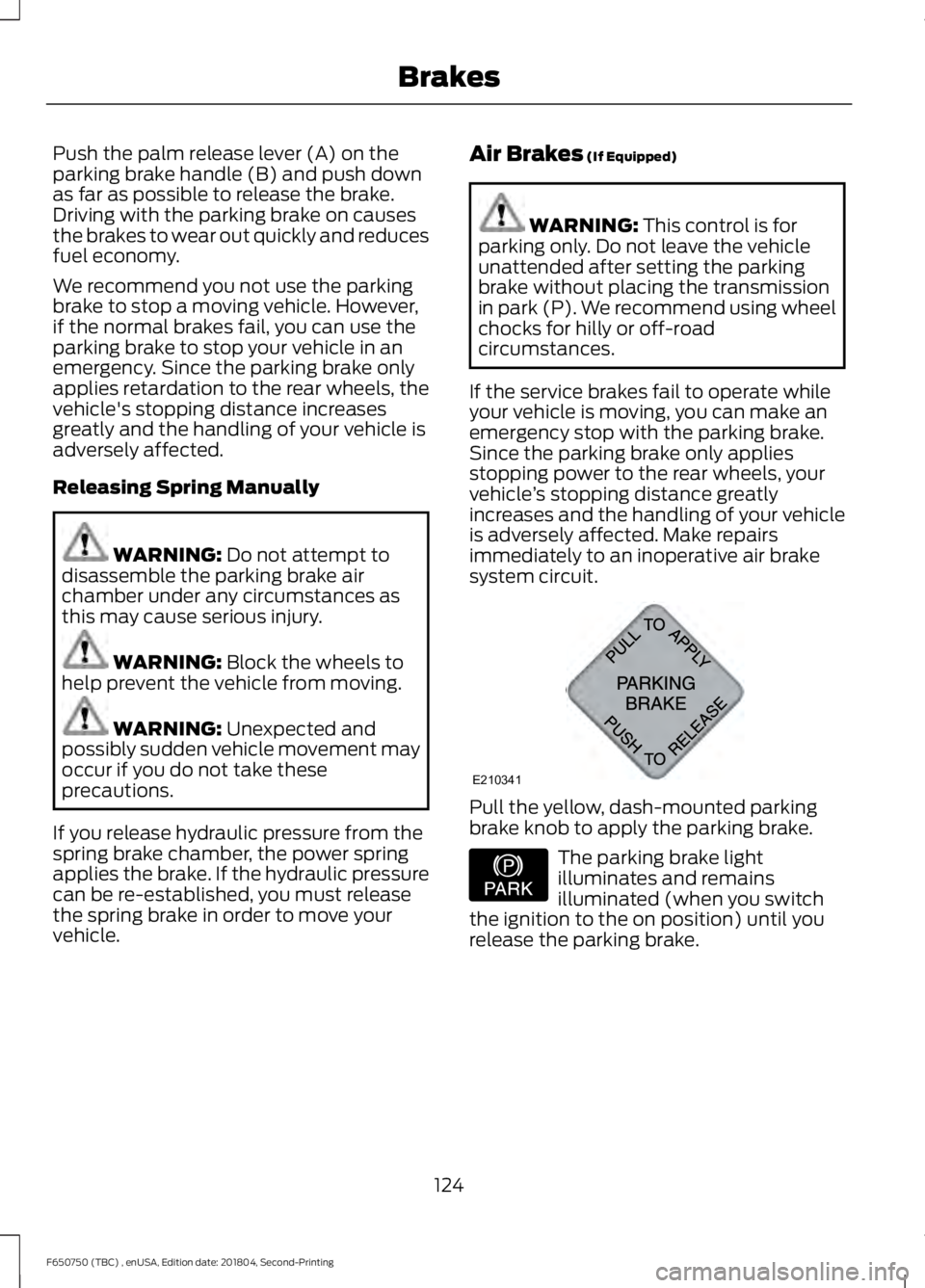

system circuit. Pull the yellow, dash-mounted parking

brake knob to apply the parking brake.

The parking brake light

illuminates and remains

illuminated (when you switch

the ignition to the on position) until you

release the parking brake.

124

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing BrakesE210341 E208810

Page 128 of 387

Releasing the Parking Brake

WARNING: When your vehicle is

stationary, keep the brake pedal fully

pressed when shifting gears. Failure to

follow this instruction could result in

personal injury, death or property

damage.

Note: Read and understand the following

steps and perform them whenever you

prepare to drive the vehicle.

Note: The parking brake does not disengage

unless sufficient system air pressure is

available.

1. Press and hold the service brake pedal

while the engine is running.

2. Select the appropriate drive gear.

3. Push and hold the yellow dash-mounted parking brake knob until

the parking brake light turns off, then

release.

Parking Brake Light Illumination Due

to Low Air Pressure

If the air pressure becomes too low at any

time during vehicle operation, the parking

brake may apply and the parking brake

light turns on.

If the parking brake applies due to low air

pressure, immediate service is required to

the parking brake system.

Releasing Spring Brake with Air

Pressure

The air system in all vehicles with

spring-actuated rear wheel parking brakes

has a valve on the governor for connection

to an outside air supply. The valve lets you

recharge the system with air from an

outside source, releasing the

spring-actuated parking brakes. Your

vehicle is now ready to tow in an

emergency. You can only use an outside air source if

the protected system is in operating

condition. If you cannot restore air pressure

in the protected air system, you must

release the spring-actuated brakes

manually.

Releasing Spring Manually

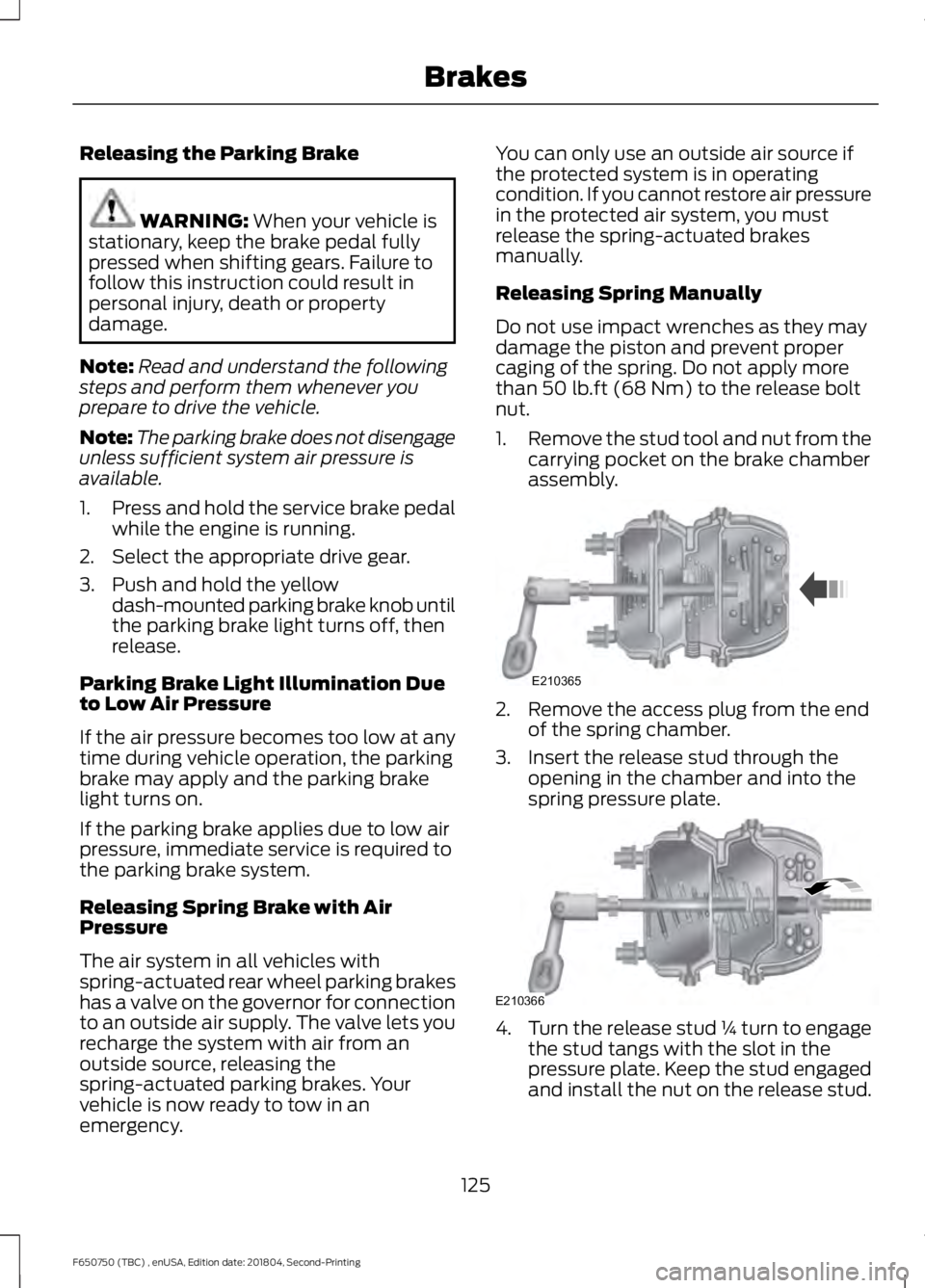

Do not use impact wrenches as they may

damage the piston and prevent proper

caging of the spring. Do not apply more

than

50 lb.ft (68 Nm) to the release bolt

nut.

1. Remove the stud tool and nut from the

carrying pocket on the brake chamber

assembly. 2. Remove the access plug from the end

of the spring chamber.

3. Insert the release stud through the opening in the chamber and into the

spring pressure plate. 4.

Turn the release stud ¼ turn to engage

the stud tangs with the slot in the

pressure plate. Keep the stud engaged

and install the nut on the release stud.

125

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing BrakesE210365 E210366