ABS FORD F650/750 2019 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2019, Model line: F650/750, Model: FORD F650/750 2019Pages: 387, PDF Size: 4.78 MB

Page 65 of 387

Powertrain Malfunction/Reduced

Power/Electronic Throttle Control

(If Equipped)

Illuminates in the event of a

powertrain fault. Contact an

authorized dealer as soon as

possible.

Service Engine Soon If it illuminates when the engine

is running this indicates a

malfunction. The On Board

Diagnostics system has detected a

malfunction of the vehicle emission control

system.

If it flashes, engine misfire may be

occurring. Increased exhaust gas

temperatures could damage the catalytic

converter or other vehicle components.

Drive in a moderate fashion (avoid heavy

acceleration and deceleration) and have

your vehicle immediately serviced.

It illuminates when you switch the ignition

on prior to engine start to check the bulb

and to indicate whether your vehicle is

ready for Inspection and Maintenance

(I/M) testing.

Normally, it illuminates until the engine is

cranked and automatically turns off if no

malfunctions are present. However, if after

15 seconds it flashes eight times, this

indicates that your vehicle is not ready for

Inspection and Maintenance (I/M) testing.

See Catalytic Converter (page 103).

Stability Control and Traction

Control Indicator

(If Equipped) Flashes during operation. If it does not illuminate when you switch

the ignition on, or remains on when the

engine is running, this indicates a

malfunction. Have your vehicle checked

as soon as possible (Air brakes only).

Traction Control

(If Equipped) Flashes slowly when you disable

traction control. It rapidly flashes

during a traction control event

(Hydraulic brakes only).

Traction Control System Off

(If

Equipped) Illuminates when you switch the

system off (Air brakes only).

Trailer Anti-Lock Brake System

(ABS) Illuminates briefly when you

switch on the ignition, and only

when a PLC trailer or a PLC

diagnostic tool is connected. If the light

fails to illuminate, remains on after you

start the vehicle or continues to flash, have

the system serviced immediately.

Transmission Tow/Haul

(If Equipped) Illuminates when you switch on

the tow/haul feature. If the light

flashes steadily, have the system

serviced immediately, damage to the

transmission could occur.

Two Speed Axle

(If Equipped) The Two Speed Axle indicator

comes on when you switch the

low axle range on.

62

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Instrument Cluster E138639 E138639 E194301 E209040 E161509 E208809

Page 79 of 387

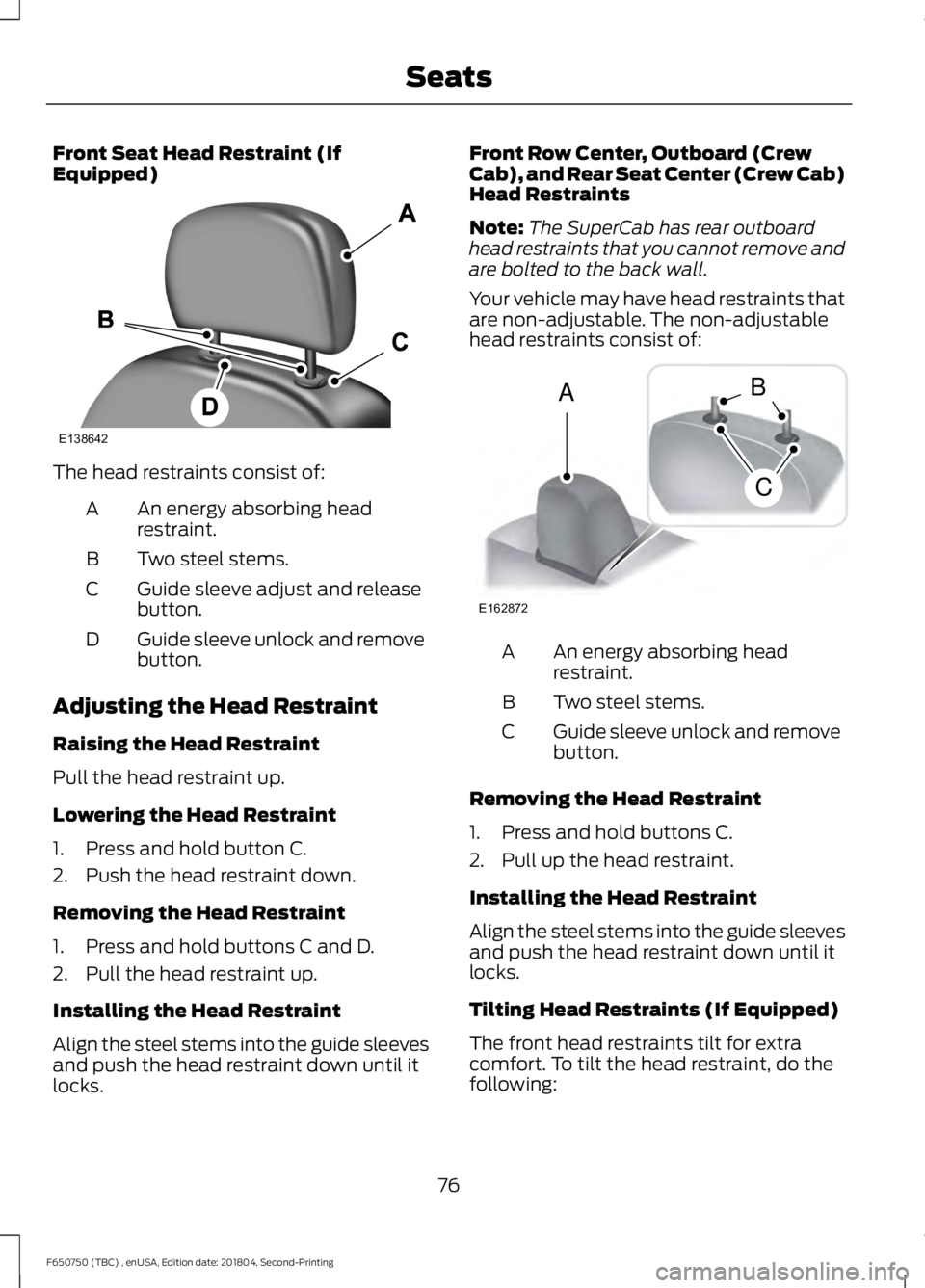

Front Seat Head Restraint (If

Equipped)

The head restraints consist of:

An energy absorbing head

restraint.

A

Two steel stems.

B

Guide sleeve adjust and release

button.

C

Guide sleeve unlock and remove

button.

D

Adjusting the Head Restraint

Raising the Head Restraint

Pull the head restraint up.

Lowering the Head Restraint

1. Press and hold button C.

2. Push the head restraint down.

Removing the Head Restraint

1. Press and hold buttons C and D.

2. Pull the head restraint up.

Installing the Head Restraint

Align the steel stems into the guide sleeves

and push the head restraint down until it

locks. Front Row Center, Outboard (Crew

Cab), and Rear Seat Center (Crew Cab)

Head Restraints

Note:

The SuperCab has rear outboard

head restraints that you cannot remove and

are bolted to the back wall.

Your vehicle may have head restraints that

are non-adjustable. The non-adjustable

head restraints consist of: An energy absorbing head

restraint.

A

Two steel stems.

B

Guide sleeve unlock and remove

button.

C

Removing the Head Restraint

1. Press and hold buttons C.

2. Pull up the head restraint.

Installing the Head Restraint

Align the steel stems into the guide sleeves

and push the head restraint down until it

locks.

Tilting Head Restraints (If Equipped)

The front head restraints tilt for extra

comfort. To tilt the head restraint, do the

following:

76

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing SeatsE138642 E162872

A

C

B

Page 95 of 387

SAFETY PRECAUTIONS

WARNING: Do not overfill the fuel

tank. The pressure in an overfilled tank

may cause leakage and lead to fuel spray

and fire. WARNING:

The fuel system may

be under pressure. If you hear a hissing

sound near the fuel filler inlet, do not

refuel until the sound stops. Otherwise,

fuel may spray out, which could cause

serious personal injury. WARNING:

Fuels can cause

serious injury or death if misused or

mishandled. WARNING:

Gasoline may contain

benzene, which is a cancer-causing

agent. WARNING: When refueling always

shut the engine off and never allow

sparks or open flames near the fuel tank

filler valve. Never smoke or use a cell

phone while refueling. Fuel vapor is

extremely hazardous under certain

conditions. Avoid inhaling excess fumes. WARNING:

Flow of fuel through

a fuel pump nozzle can produce static

electricity. This can cause a fire if you are

filling an ungrounded fuel container. WARNING:

Stop refueling after

the fuel pump nozzle automatically

shuts off for the second time. Failure to

follow this will fill the expansion space

in the fuel tank and could lead to fuel

overflowing. Observe the following guidelines when

handling automotive fuel:

•

Extinguish all smoking materials and

any open flames before refueling your

vehicle.

• Automotive fuels can be harmful or

fatal if swallowed. Fuel such as

gasoline is highly toxic and if

swallowed can cause death or

permanent injury. If swallowed, call a

physician immediately, even if no

symptoms are immediately apparent.

The toxic effects of fuel may not be

visible for hours.

• Avoid inhaling fuel vapors. Inhaling too

much fuel vapor of any kind can lead

to eye and respiratory tract irritation.

In severe cases, excessive or prolonged

breathing of fuel vapor can cause

serious illness and permanent injury.

• Avoid getting fuel liquid in your eyes. If

you splash fuel in your eyes, remove

contact lenses (if worn), flush with

water for 15 minutes and seek medical

attention. Failure to seek proper

medical attention could lead to

permanent injury.

• Fuels can also be harmful if absorbed

through the skin. If you splash fuel on

your skin, clothing or both, promptly

remove contaminated clothing and

wash your skin thoroughly with soap

and water. Repeated or prolonged skin

contact with fuel liquid or vapor causes

skin irritation.

• Be particularly careful if you are taking

“Antabuse ” or other forms of disulfiram

for the treatment of alcoholism.

Breathing gasoline vapors, or skin

contact could cause an adverse

reaction. In sensitive individuals, serious

92

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Fuel and Refueling

Page 105 of 387

EMISSION LAW

WARNING: Do not remove or alter

the original equipment floor covering or

insulation between it and the metal floor

of the vehicle. The floor covering and

insulation protect occupants of the

vehicle from the engine and exhaust

system heat and noise. On vehicles with

no original equipment floor covering

insulation, do not carry passengers in a

manner that permits prolonged skin

contact with the metal floor. Failure to

follow these instructions may result in

fire or personal injury.

U.S. federal laws and certain state laws

prohibit removing or rendering inoperative

emission control system components.

Similar federal or provincial laws may

apply in Canada. We do not approve of any

vehicle modification without first

determining applicable laws. Tampering with emissions

control systems including

related sensors or the Diesel

Exhaust Fluid system can result in reduced

engine power and the illumination of the

service engine soon light. Tampering With a Noise Control

System

Federal laws prohibit the following acts:

•

Removal or rendering inoperative by

any person other than for purposes of

maintenance.

• Repair or replacement of any device or

element of the design incorporated into

a new vehicle for the purpose of noise

control prior to its sale or delivery to

the ultimate purchaser or while it is in

use.

• The use of the vehicle after any person

removes or renders inoperative any

device or element of the design.

The U.S. Environmental Protection Agency

may presume to constitute tampering as

follows:

• Removal of hood blanket, fender apron

absorbers, fender apron barriers,

underbody noise shields or acoustically

absorptive material.

• Tampering or rendering inoperative the

engine speed governor, to allow engine

speed to exceed manufacturer

specifications.

If the engine does not start, runs rough,

experiences a decrease in engine

performance, experiences excess fuel

consumption or produces excessive

exhaust smoke, check for the following:

• A plugged or disconnected air inlet

system hose.

• A plugged engine air filter element.

• Water in the fuel filter and water

separator.

• A clogged fuel filter.

• Contaminated fuel.

• Air in the fuel system, due to loose

connections.

• An open or pinched sensor hose.

• Incorrect engine oil level.

102

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Engine Emission Control

Page 106 of 387

•

Incorrect fuel for climatic conditions.

• Incorrect engine oil viscosity for

climactic conditions.

Note: Some vehicles have a lifetime fuel

filter that is integrated with the fuel tank.

Regular maintenance or replacement is not

needed.

Note: If these checks do not help you

correct the concern, have your vehicle

checked as soon as possible.

Noise Emissions Warranty,

Prohibited Tampering Acts and

Maintenance

On January 1, 1978, Federal regulation

became effective governing the noise

emission on trucks over 10,000 lb

(4,536 kg) Gross Vehicle Weight Rating

(GVWR). The preceding statements

concerning prohibited tampering acts and

maintenance, and the noise warranty

found in the Warranty Guide, are

applicable to complete chassis cabs over

10,000 lb (4,536 kg)

GVWR.

CATALYTIC CONVERTER WARNING:

Do not park, idle or

drive your vehicle on dry grass or other

dry ground cover. The emission system

heats up the engine compartment and

exhaust system, creating the risk of fire. WARNING:

The normal operating

temperature of the exhaust system is

very high. Never work around or attempt

to repair any part of the exhaust system

until it has cooled. Use special care when

working around the catalytic converter.

The catalytic converter heats up to a very

high temperature after only a short

period of engine operation and stays hot

after the engine is switched off. WARNING:

Exhaust leaks may

result in entry of harmful and potentially

lethal fumes into the passenger

compartment. If you smell exhaust

fumes inside your vehicle, have your

vehicle inspected immediately. Do not

drive if you smell exhaust fumes.

Your vehicle has various emission control

components and a catalytic converter that

enables it to comply with applicable

exhaust emission standards.

To make sure that the catalytic converter

and other emission control components

continue to work properly:

• Do not crank the engine for more than

10 seconds at a time.

• Do not run the engine with a spark plug

lead disconnected.

• Do not push-start or tow-start your

vehicle. Use booster cables. See Jump

Starting the Vehicle

(page 156).

• Use only the specified fuel listed.

• Do not switch the ignition off when your

vehicle is moving.

• Avoid running out of fuel.

• Have the items listed in scheduled

maintenance information performed

according to the specified schedule.

Note: Resulting component damage may

not be covered by the vehicle Warranty.

The scheduled maintenance items listed

in scheduled maintenance information are

essential to the life and performance of

your vehicle and to its emissions system.

If you use anything other than Ford,

Motorcraft or Ford-authorized parts for

maintenance replacements or for service

of components affecting emission control,

such non-Ford parts should be equivalent

to genuine Ford Motor Company parts in

performance and durability.

103

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Engine Emission Control

Page 125 of 387

GENERAL INFORMATION

WARNING: Do not apply the brake

pedal and accelerator pedal

simultaneously. Applying both pedals

simultaneously for more than a few

seconds will limit engine performance,

which may result in difficulty maintaining

speed in traffic and could lead to serious

injury.

Note: Occasional brake noise is normal. If

a metal-to-metal, continuous grinding or

continuous squeal sound is present, the

brake linings may be worn-out. Have the

system checked as soon as possible. If your

vehicle has continuous vibration or shudder

in the steering wheel while braking, have it

checked by an authorized dealer.

All standard equipment brakes are

self-adjusting. Automatic adjustment,

when required, occurs whenever you apply

and release the brakes during forward or

reverse operation.

Know the required stopping distances for

all driving conditions you may encounter.

For longer brake lining life, take full

advantage of engine braking power when

coming to a stop.

Wet brakes result in reduced braking

efficiency. Gently press the brake pedal a

few times when driving from a car wash or

standing water to dry the brakes.

If the brakes do not grip well:

• Check brake adjustment.

• Check the brake linings for excessive

wear.

• Check the system air pressure on

vehicles with air brakes. •

Let the brakes cool if you have been

using them excessively, as in mountain

driving or after several fast, high-speed

stops.

• If you have been driving through deep

water, gently apply the brakes several

times while your vehicle is moving

slowly.

Brake Over Accelerator

In the event the accelerator pedal

becomes stuck or entrapped, apply steady

and firm pressure to the brake pedal to

slow the vehicle and reduce engine power.

If you experience this condition, apply the

brakes and bring your vehicle to a safe

stop. Move the transmission to park (P),

switch the engine off and apply the parking

brake. Inspect the accelerator pedal for

any interference. If none are found and the

condition persists, have your vehicle towed

to the nearest authorized dealer

Anti-lock Brake System

This system helps you maintain steering

control during emergency stops by keeping

the brakes from locking. This lamp momentarily

illuminates when you switch the

ignition on. If the light does not

illuminate during start up, remains on or

flashes, the system may be disabled. Have

the system checked by an authorized

dealer. If you connect a PLC trailer with

the ignition on, the trailer ABS

light also illuminates. If the light

fails to illuminate, if it remains on after you

start the vehicle or continues to flash, have

the system serviced immediately.

See

Warning Lamps and Indicators

(page 60).

122

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Brakes E210335

Page 184 of 387

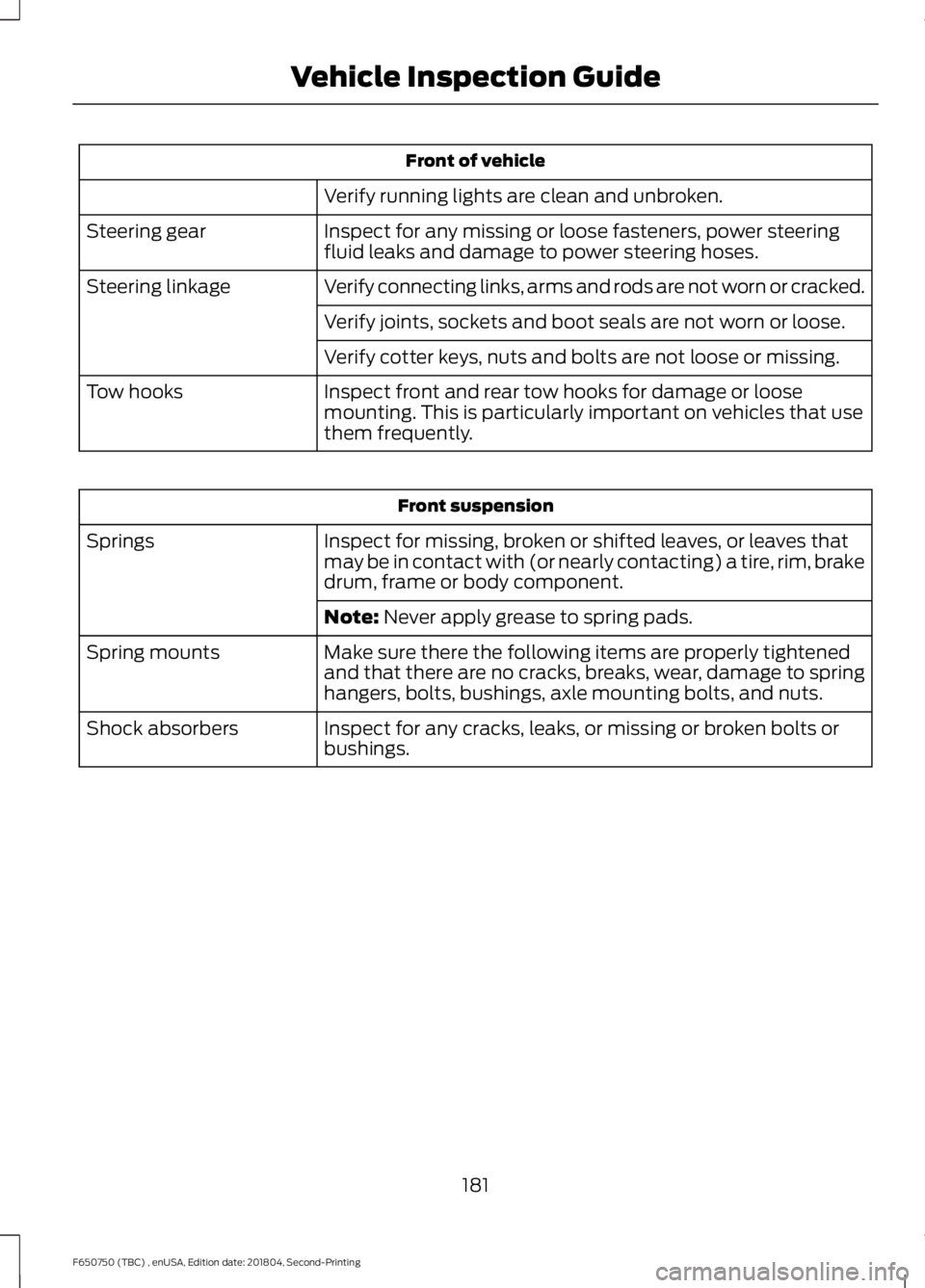

Front of vehicle

Verify running lights are clean and unbroken.

Inspect for any missing or loose fasteners, power steering

fluid leaks and damage to power steering hoses.

Steering gear

Verify connecting links, arms and rods are not worn or cracked.

Steering linkage

Verify joints, sockets and boot seals are not worn or loose.

Verify cotter keys, nuts and bolts are not loose or missing.

Inspect front and rear tow hooks for damage or loose

mounting. This is particularly important on vehicles that use

them frequently.

Tow hooks Front suspension

Inspect for missing, broken or shifted leaves, or leaves that

may be in contact with (or nearly contacting) a tire, rim, brake

drum, frame or body component.

Springs

Note: Never apply grease to spring pads.

Make sure there the following items are properly tightened

and that there are no cracks, breaks, wear, damage to spring

hangers, bolts, bushings, axle mounting bolts, and nuts.

Spring mounts

Inspect for any cracks, leaks, or missing or broken bolts or

bushings.

Shock absorbers

181

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Vehicle Inspection Guide

Page 187 of 387

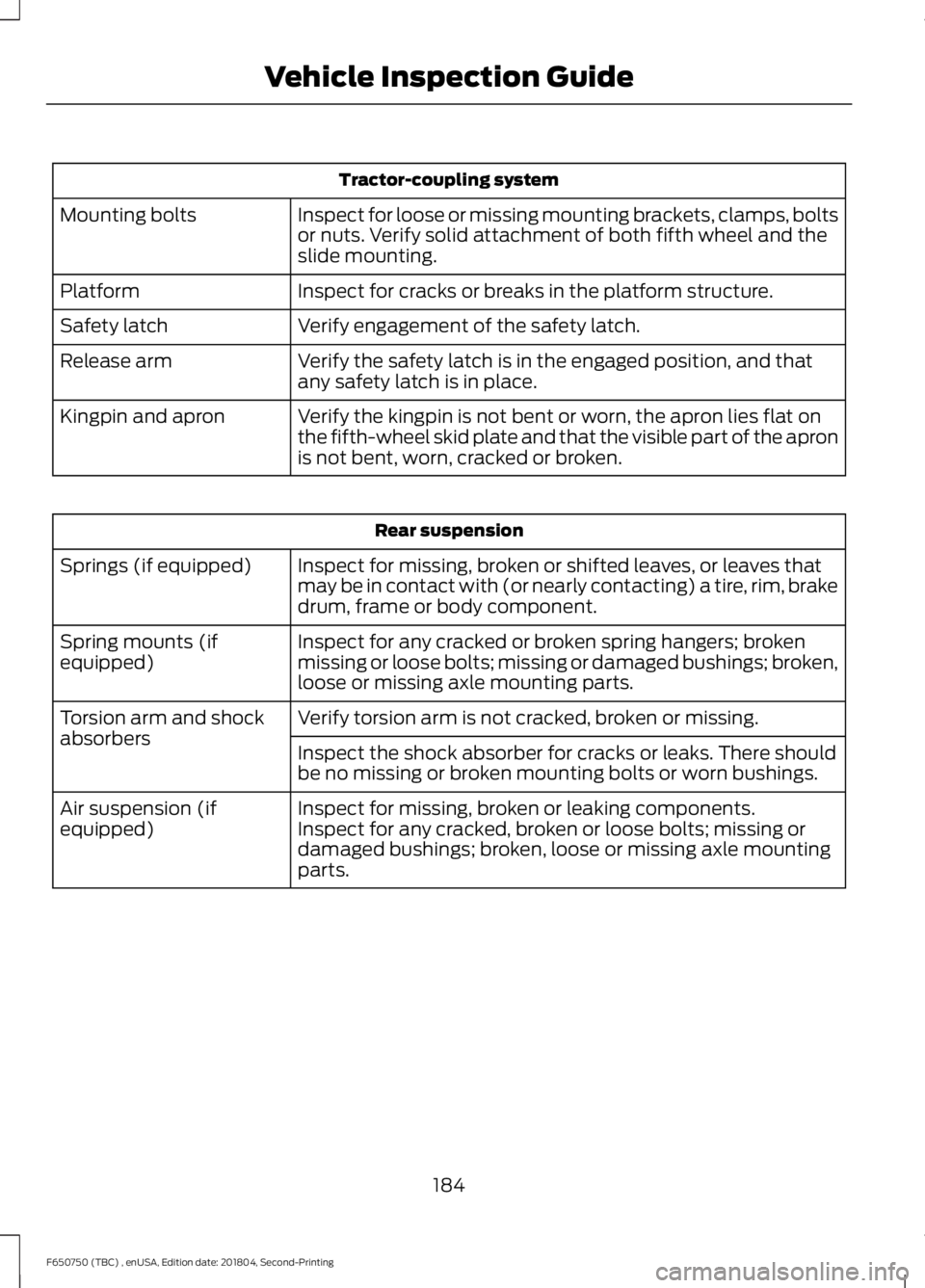

Tractor-coupling system

Inspect for loose or missing mounting brackets, clamps, bolts

or nuts. Verify solid attachment of both fifth wheel and the

slide mounting.

Mounting bolts

Inspect for cracks or breaks in the platform structure.

Platform

Verify engagement of the safety latch.

Safety latch

Verify the safety latch is in the engaged position, and that

any safety latch is in place.

Release arm

Verify the kingpin is not bent or worn, the apron lies flat on

the fifth-wheel skid plate and that the visible part of the apron

is not bent, worn, cracked or broken.

Kingpin and apron Rear suspension

Inspect for missing, broken or shifted leaves, or leaves that

may be in contact with (or nearly contacting) a tire, rim, brake

drum, frame or body component.

Springs (if equipped)

Inspect for any cracked or broken spring hangers; broken

missing or loose bolts; missing or damaged bushings; broken,

loose or missing axle mounting parts.

Spring mounts (if

equipped)

Verify torsion arm is not cracked, broken or missing.

Torsion arm and shock

absorbers

Inspect the shock absorber for cracks or leaks. There should

be no missing or broken mounting bolts or worn bushings.

Inspect for missing, broken or leaking components.

Air suspension (if

equipped) Inspect for any cracked, broken or loose bolts; missing or

damaged bushings; broken, loose or missing axle mounting

parts.

184

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Vehicle Inspection Guide

Page 196 of 387

To top up the engine oil level do the

following:

1. Clean the area surrounding the engine

oil filler cap before you remove it.

2. Remove the engine oil filler cap. See Under Hood Overview (page 190).

Turn it counterclockwise and remove

it.

3. Add engine oil of the proper viscosity and grade that meets Ford

specifications. See

Capacities and

Specifications (page 261). You may

have to use a funnel to pour the engine

oil into the opening.

4. Recheck the oil level.

5. If the oil level is correct, replace the dipstick and make sure it is fully seated.

6. Replace the engine oil filler cap. Turn it clockwise until you feel a strong

resistance.

Note: Do not add oil further than the

maximum mark. Oil levels above the

maximum mark may cause engine damage.

Note: Make sure you install the oil filler cap

correctly.

Note: Soak up any spillage with an

absorbent cloth immediately.

Engine lubrication for severe

service operation

The following conditions define severe

operation for which engine operation with

SAE 5W-40 oil which meets Ford

specification, WSS-M2C171-F1, is

recommended. Oil and oil filter change

intervals will be determined by the

Intelligent Oil Life Monitor™ as noted

previously.

ENGINE OIL CHECK - 6.8L

To check the engine oil level consistently

and accurately, do the following: 1.

Make sure the parking brake is on. Make

sure the transmission is in park (P) or

neutral (N).

2. Run the engine until it reaches normal operating temperature.

3. Make sure that your vehicle is on level ground.

4. Switch the engine off and wait 15 minutes for the oil to drain into the oil

pan. Checking the engine oil level too

soon after you switch the engine off

may result in an inaccurate reading.

5. Open the hood. See

Maintenance

(page 187).

6. Remove the dipstick and wipe it with a clean, lint-free cloth. See

Maintenance

(page 187).

7. Replace the dipstick and remove it again to check the oil level. See

Maintenance

(page 187).

8. Make sure that the oil level is between

the maximum and minimum marks. If

the oil level is at the minimum mark,

add oil immediately. See

Capacities

and Specifications (page 255).

9. If the oil level is correct, replace the dipstick and make sure it is fully seated.

Note: Do not remove the dipstick when the

engine is running.

Note: If the oil level is between the

maximum and minimum marks, the oil level

is acceptable. Do not add oil.

Note: The oil consumption of new engines

reaches its normal level after approximately

3,000 mi (5,000 km)

.

Adding Engine Oil WARNING:

Do not remove the

filler cap when the engine is running.

193

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Maintenance

Page 197 of 387

Do not use supplemental engine oil

additives because they are unnecessary

and could lead to engine damage that may

not be covered by the vehicle Warranty.

Only use oils certified for gasoline engines

by the American Petroleum Institute (API).

An oil with this trademark symbol

conforms to the current engine and

emission system protection standards and

fuel economy requirements of the

International Lubricants Specification

Advisory Committee (ILSAC).

To top up the engine oil level do the

following:

1. Clean the area surrounding the engine

oil filler cap before you remove it.

2. Remove the engine oil filler cap.

3. Add engine oil that meets the correct specification.

4. Recheck the oil level.

5. If the oil level is correct, replace the dipstick and make sure it is fully seated.

6. Replace the engine oil filler cap. Turn it clockwise until you feel a strong

resistance.

Note: Do not add oil further than the

maximum mark. Oil levels above the

maximum mark may cause engine damage.

Note: Make sure you install the oil filler cap

correctly. Note:

Soak up any spillage with an

absorbent cloth immediately.

CHANGING THE ENGINE OIL

AND OIL FILTER WARNING: Do not handle a hot

oil filter with bare hands. WARNING:

Continuous contact

with used motor oil has caused cancer

in laboratory mice. Protect your skin by

washing with soap and water.

If your vehicle is equipped with a diesel

engine, an Intelligent Oil Life Monitor™

calculates the proper oil change service

interval. When the information display

indicates: OIL CHANGE REQUIRED, change

the engine oil and oil filter. See

Information Displays

(page 64).

The engine oil filter protects your engine

by filtering harmful, abrasive or sludge

particles and particles significantly smaller

than most available will-fit filters. See

Motorcraft Parts

(page 258).

1. Unscrew the oil filter and oil pan drain plug and wait for the oil to drain.

2. Replace the filter.

3. Reinstall the oil pan drain plug.

4. Refill the engine with new oil. See Capacities and Specifications (page

261

).

5. For diesel engines, you need to reset the Intelligent Oil Life Monitor™. See

Information Displays

(page 64).

194

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing MaintenanceE142732