cooling FORD F650/750 2019 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2019, Model line: F650/750, Model: FORD F650/750 2019Pages: 387, PDF Size: 4.78 MB

Page 12 of 387

If these modified engine performance

characteristics persist for an extended

period and either the service engine soon

or powertrain malfunction, reduced power,

electronic throttle control light is

illuminated, have the system checked by

an authorized dealer.

Service engine soon

Powertrain malfunction, reduced

power, electronic throttle control

Diesel Lubrication System

It is important to change the engine oil at

the recommended service intervals or

when indicated by the information display

to maintain oil viscosity. Extending the oil

and filter change interval beyond the

recommended interval can negatively

affect engine performance, fuel economy

and engine life. See Engine Oil Check

(page 192).

Engine and secondary cooling system

The cooling system contains a primary

cooling loop to cool the engine and a

secondary cooling loop to cool the

transmission, charge air, and fuel. The

coolant serves three primary purposes: to

provide heat transfer, freeze point

protection, and corrosion protection using

additives.

Vehicles with diesel engines typically are

used to carry heavy loads and accumulate

mileage rapidly. These two factors may

cause the additives in the coolant to wear

out in a shorter time. You can find more

information about coolant additives and

coolant change intervals in the coolant

chapter. See

General Maintenance

Information (page 322). Operating the

engine with insufficient coolant or coolant

additive can cause severe engine damage. Selective catalytic reduction system

Your vehicle is equipped with a selective

catalytic reduction system designed to

reduce emission levels of nitrogen oxides

from the exhaust of your diesel engine. This

system relies on the use of Diesel Exhaust

Fluid (DEF) that you must replenish at

certain intervals. Failure to maintain proper

DEF levels or if the DEF becomes

contaminated will result in vehicle speed

limitations or result in your vehicle entering

an idle-only mode. See

Selective

Catalytic Reductant System (page 105).

Minor Troubleshooting Guide

If the engine won ’t crank WARNING:

Battery posts,

terminals and related accessories

contain lead and lead compounds. Wash

hands after handling.

Turn on the headlights. If the lights are dim,

do not go on at all or when the ignition is

turned to the start position, the lights

become dim or go out, the battery

connections may be loose or corroded, or

the battery may be discharged. If there is

a clicking or stuttering sound coming from

the engine compartment when you turn

the key to the start position, this may also

indicate a loose or corroded battery

connection.

Check the battery connections at the

battery posts, cable connection to the

engine grounding point and at the starter

connection.

If you suspect a discharged battery, have

it checked and corrected.

9

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Introduction

Page 13 of 387

•

The gearshift lever must be in P (Park)

or N (Neutral) in order for the starter

to operate.

• Try operating the starter switch several

times. This operation may clean

potentially corroded contacts or make

the switch temporarily operable until

you can reach the dealer.

• If all electrical connections are tight

and you need assistance to start, See

Jump Starting the Vehicle (page 156

).

If engine cranks but won ’t start

Prolonged starter cranking (in excess of 10

seconds) could cause damage to the

starter motor or the high-pressure fuel

pump.

• Check the fuel gauge. You may be out

of fuel. If the gauge shows that there

is fuel in the tank, the trouble may be

in the electrical system or the fuel

system. If equipped with an auxiliary

tank, be sure that the tank control

switch is set for the tank with fuel and

not on an empty tank.

• Leaving your ignition key turned to on

for over two minutes without starting

may make starting difficult because

the glow plugs will cease activation.

Reset the system by turning the ignition

key to off and then back to on again.

Note: If the system is out of fuel and the

engine will not start, do not continue

cranking the engine. Continued cranking can

damage the high-pressure fuel pump.

If the engine runs hot

The following could cause the engine to

overheat:

• Lack of coolant

• Dirty cooling system.

• Plugged radiator fins, A/C condenser

and/or oil cooler

• Malfunctioning fan drive •

Driving with frozen coolant

• Sticking thermostat

• Overloading or pulling heavy trailers

during hot weather

• Grill or radiator air blockage

• Slipping or missing drive belt

• Plugged or very dirty air filter

If fuses burn out WARNING:

Replacement fuses

and circuit breakers must always be the

same rating as the original equipment

shown. Never replace a fuse or circuit

breaker with one of a higher rating.

Higher rated fuses or circuit breakers

could allow circuit overloading in the

event of a circuit malfunction, resulting

in severe vehicle damage or personal

injury due to fire.

Burned-out or blown fuses usually indicate

an electrical short-circuit, although a fuse

may occasionally burn out from vibration.

Insert a second fuse. If this fuse

immediately burns out and you cannot

locate the cause, return your vehicle to

your dealer for a circuit check. See

Changing a Fuse

(page 176).

Selective catalytic reduction system

speed limit and Idle-only modes

If the vehicle ’s speed is limited or in an

idle-only mode, the selective catalytic

reduction system may be limiting the

vehicle ’s functions due to low or

contaminated DEF. Check the DEF. See

Selective Catalytic Reductant System

(page

105).

SYMBOLS GLOSSARY

These are some of the symbols you may

see on your vehicle.

10

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Introduction

Page 19 of 387

PROTECTING THE

ENVIRONMENT

You should play your part in protecting the

environment. Correct vehicle usage and

the authorized disposal of waste, cleaning

and lubrication materials are significant

steps toward this aim.

For details about Ford Motor

Company's sustainability progress and

initiatives visit:

Web Address

www.sustainability.ford.com

NOISE POLLUTION CONTROL

In order to keep to the federal exterior

noise regulations, your vehicle may be

equipped with noise emission items.

Depending on your vehicle configuration,

it may have all or some of the following

items:

Air Intake System

Inspect the air cleaner. Do not alter its

location. Do not alter inlet and outlet

piping.

Body

Inspect wheel well splash shields, cab

shields and under hood insulation for

deterioration, dislocation and orientation.

Cooling System

• Inspect the fan for blade damage. If

you find any damage, replace with the

recommended parts. Inspect for

fan-to-shroud interference and any

damage to shroud, such as cracks and

holes.

• Do not change fan ratio or alter fan

spacer dimensions and positions. •

Inspect fan clutch for proper operation.

Make sure the fan is disengaged when

cooling of the engine is not required.

• Inspect radiator shutters (if equipped)

for proper operation. The shutters

should be open during normal

operating temperatures.

Engine

Valve covers and block covers damp-out

engine mechanical noise. If they need

replacing, make sure to replace them with

the recommended parts. Check for

mechanical isolations.

Transmission Enclosure

Inspect for cracks, holes and tears. Clean

any deposits, such as oil, dirt and stones.

Exhaust System

• Inspect for leaks at various joint

connections and loose clamps.

• Perform a visual inspection for cracks

or holes in the muffler and tail pipe.

• Always use the recommended

replacement parts.

• Do not change the tail pipe elbow or

offset tail pipe orientation from the

standard position as originally received.

• To avoid abnormal changes in vehicle

sound levels, it is necessary for the

owner to perform inspections and

necessary maintenance at specified

intervals. See Scheduled

Maintenance (page 322).

16

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Environment

Page 75 of 387

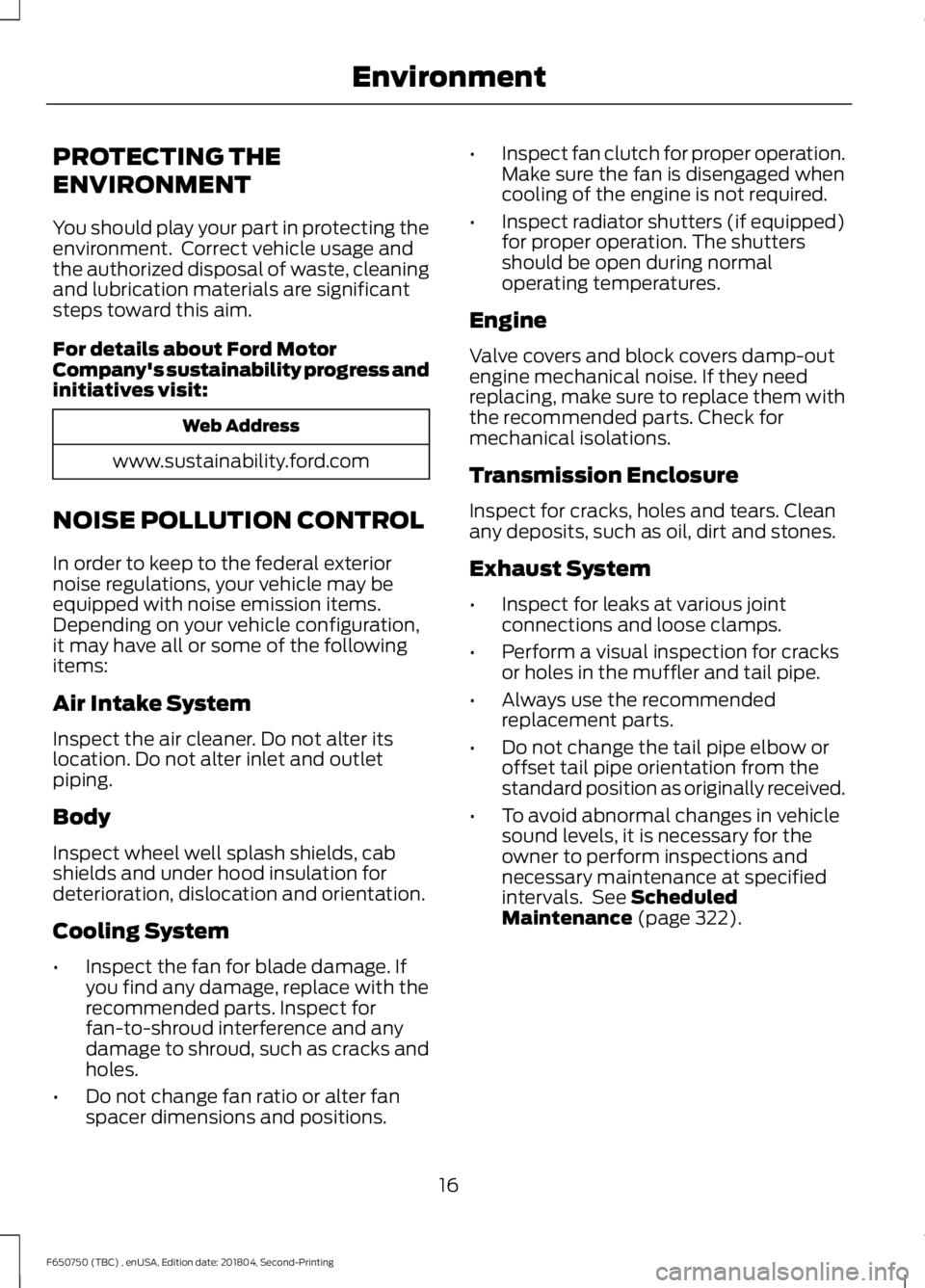

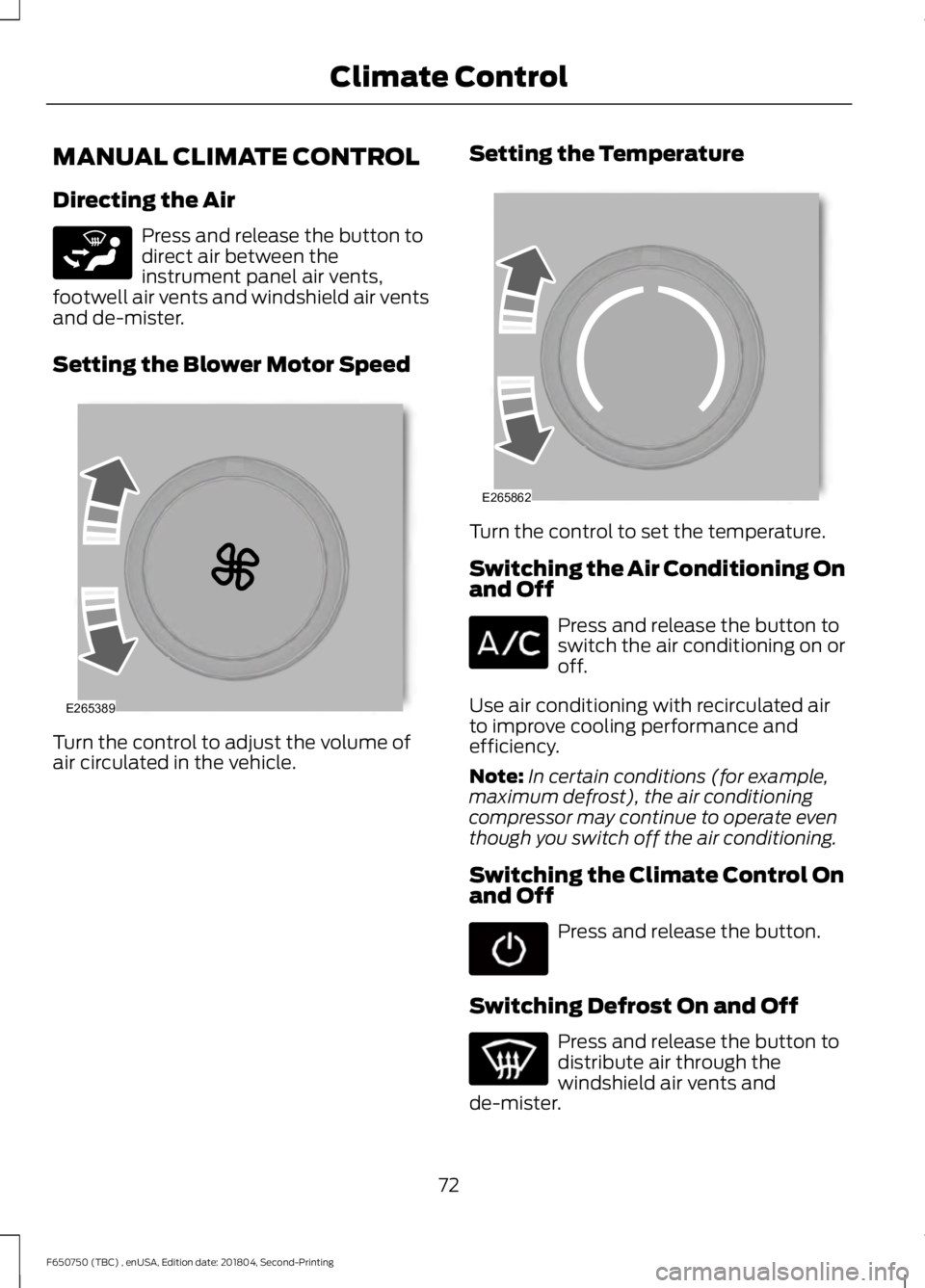

MANUAL CLIMATE CONTROL

Directing the Air

Press and release the button to

direct air between the

instrument panel air vents,

footwell air vents and windshield air vents

and de-mister.

Setting the Blower Motor Speed Turn the control to adjust the volume of

air circulated in the vehicle. Setting the Temperature Turn the control to set the temperature.

Switching the Air Conditioning On

and Off

Press and release the button to

switch the air conditioning on or

off.

Use air conditioning with recirculated air

to improve cooling performance and

efficiency.

Note: In certain conditions (for example,

maximum defrost), the air conditioning

compressor may continue to operate even

though you switch off the air conditioning.

Switching the Climate Control On

and Off Press and release the button.

Switching Defrost On and Off Press and release the button to

distribute air through the

windshield air vents and

de-mister.

72

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Climate ControlE265283 E265389 E265862

Page 76 of 387

Air directed to the instrument panel and

footwell air vents turns off. You can also

use this setting to defog and clear the

windshield of a thin covering of ice.

Switching Maximum Air

Conditioning On and Off

Press and release the button for

maximum cooling.

The left-hand and right-hand settings set

to LO, recirculated air flows through the

instrument panel air vents, air conditioning

turns on and the blower motor adjusts to

the highest speed.

Switching Recirculated Air On and

Off Press and release the button to

switch between outside air and

recirculated air.

The air currently in the passenger

compartment recirculates. This may

reduce the time needed to cool the interior

(when used with A/C) and reduce

unwanted odors from entering your vehicle.

Note: Recirculated air may turn off (or

prevent you from switching on) in all air flow

modes except MAX A/C to reduce the risk

of fogging. Recirculation may also turn on

and off in various air distribution control

combinations during hot weather in order

to improve cooling efficiency.

HINTS ON CONTROLLING THE

INTERIOR CLIMATE

General Hints

Note: Prolonged use of recirculated air may

cause the windows to fog up.

Note: You may feel a small amount of air

from the footwell air vents regardless of the

air distribution setting. Note:

To reduce humidity build-up inside

your vehicle, do not drive with the system

switched off or with recirculated air always

switched on.

Note: Do not place objects under the front

seats as this may interfere with the airflow

to the rear seats.

Note: Remove any snow, ice or leaves from

the air intake area at the base of the

windshield.

Note: To improve the time to reach a

comfortable temperature in hot weather,

drive with the windows open until you feel

cold air through the air vents.

Quickly Heating the Interior

1. Adjust the blower motor speed to the highest speed setting.

2. Adjust the temperature control to the highest setting.

3. Direct air to the footwell air vents.

Recommended Settings for

Heating

1. Adjust the blower motor speed to the center setting.

2. Adjust the temperature control to the midway point of the hot settings.

3. Direct air to the footwell air vents.

Quickly Cooling the Interior

1. Select MAX A/C.

2. Drive with the windows open for a short

period of time.

Recommended Settings for

Cooling

1. Adjust the blower motor speed to the center setting.

2. Adjust the temperature control to the midway point of the cold settings.

73

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Climate Control

Page 116 of 387

Once operator commanded regeneration

starts, engine speed increases to

approximately 2000 rpm and the cooling

fan speed increases. You will hear a

change in audible sound due to engine

speed and cooling fan speed increases.

It is not necessary to open the hood on the

engine compartment. Once operator

commanded regeneration completes, the

engine speed returns to normal idling. The

exhaust system remains very hot for

several minutes even after regeneration is

complete. Do not reposition the vehicle

over materials that could burn until the

exhaust system has had sufficient time to

cool. Depending on the amount of soot

collected by the diesel particulate filter,

ambient temperature and altitude,

operator commanded regeneration lasts

approximately 30 minutes.

Operator Commanded Regeneration

with Automatic Regeneration Control

(If Equipped)

If your vehicle is operated with significant

stationary operation, low speed drive

cycles less than 25 mph (40 km/h), short

drive cycles, drive time less than 15 minutes

or the vehicle does not fully warm up,

passive and active regeneration may not

sufficiently clean the diesel particulate

filter system. You can switch off automatic

regeneration until better driving conditions

are available, for example steady high

speed driving. You can then switch

automatic regeneration back on to clean

the diesel particulate filter.

Switching Automatic Regeneration

Control On and Off

To switch operator commanded

regeneration on and off, use the

information display control on the steering

wheel. See Information Display Control

(page

47). Scroll to the exhaust cleaning

message and then select Y or N to switch

it On or Off. How to Interrupt or Cancel Operator

Commanded Regeneration

If you need to cancel the operator

commanded regeneration, pressing the

brake, accelerator or switching the engine

off stops the procedure. Depending on the

amount of time you allowed the operator

commanded regeneration to operate, soot

may not have had sufficient time to be fully

eliminated, but the exhaust system and

exhaust gas may still be hot. If you shut

your vehicle off during operator

commanded regeneration, you may notice

turbo flutter. This is a normal consequence

caused by shutting off a diesel engine

during boosted operation and is considered

normal.

Filter Service and Maintenance

Over time, a slight amount of ash builds

up in the diesel particulate filter, which is

not removed during the regeneration

process. The filter may need to be replaced

with a new or remanufactured part at

approximately 250,000 mi (400,000 km).

Actual mileage varies depending on engine

and vehicle operating conditions.

If filter service is required, the

engine control system warning

lamp illuminates in the

information display. If there are any issues with the

diesel particulate filter system,

the engine control system

warning lamp and a service

engine soon warning lamp

illuminate to inform you that

your vehicle requires service. Have your

vehicle checked as soon as possible.

113

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Engine Emission Control

Page 122 of 387

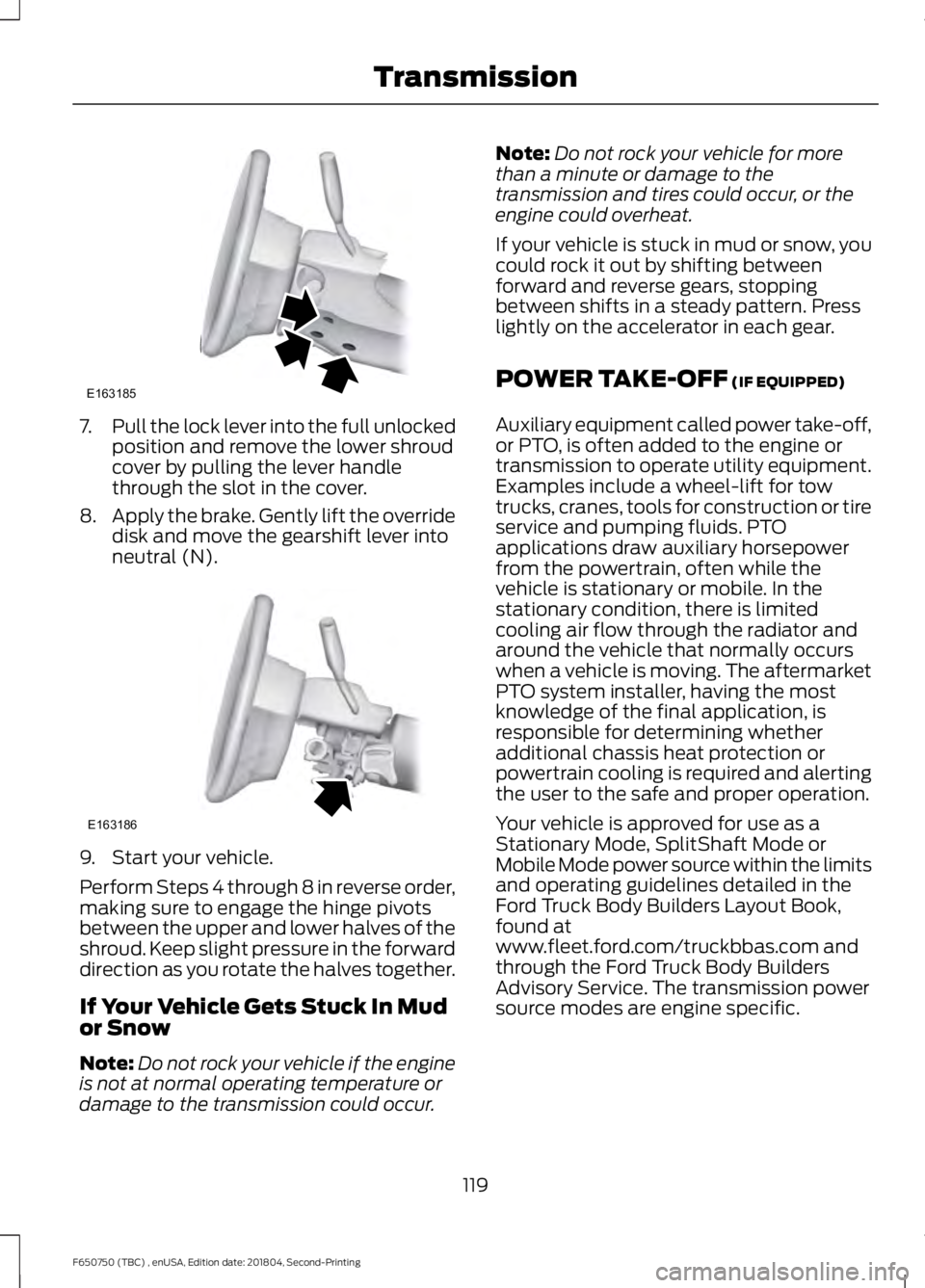

7.

Pull the lock lever into the full unlocked

position and remove the lower shroud

cover by pulling the lever handle

through the slot in the cover.

8. Apply the brake. Gently lift the override

disk and move the gearshift lever into

neutral (N). 9. Start your vehicle.

Perform Steps 4 through 8 in reverse order,

making sure to engage the hinge pivots

between the upper and lower halves of the

shroud. Keep slight pressure in the forward

direction as you rotate the halves together.

If Your Vehicle Gets Stuck In Mud

or Snow

Note:

Do not rock your vehicle if the engine

is not at normal operating temperature or

damage to the transmission could occur. Note:

Do not rock your vehicle for more

than a minute or damage to the

transmission and tires could occur, or the

engine could overheat.

If your vehicle is stuck in mud or snow, you

could rock it out by shifting between

forward and reverse gears, stopping

between shifts in a steady pattern. Press

lightly on the accelerator in each gear.

POWER TAKE-OFF (IF EQUIPPED)

Auxiliary equipment called power take-off,

or PTO, is often added to the engine or

transmission to operate utility equipment.

Examples include a wheel-lift for tow

trucks, cranes, tools for construction or tire

service and pumping fluids. PTO

applications draw auxiliary horsepower

from the powertrain, often while the

vehicle is stationary or mobile. In the

stationary condition, there is limited

cooling air flow through the radiator and

around the vehicle that normally occurs

when a vehicle is moving. The aftermarket

PTO system installer, having the most

knowledge of the final application, is

responsible for determining whether

additional chassis heat protection or

powertrain cooling is required and alerting

the user to the safe and proper operation.

Your vehicle is approved for use as a

Stationary Mode, SplitShaft Mode or

Mobile Mode power source within the limits

and operating guidelines detailed in the

Ford Truck Body Builders Layout Book,

found at

www.fleet.ford.com/truckbbas.com and

through the Ford Truck Body Builders

Advisory Service. The transmission power

source modes are engine specific.

119

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing TransmissionE163185 E163186

Page 149 of 387

ESSENTIAL TOWING CHECKS

See Load limits in the Load Carrying

chapter for load specification terms found

on the tire label and Safety Compliance

label and instructions on calculating your

vehicle's load.

Remember to account for the trailer

tongue weight as part of your vehicle load

when calculating the total vehicle weight.

Hitches

Do not use a hitch that either clamps onto

the bumper or attaches to the axle. You

must distribute the load in your trailer so

that 10-15% of the total weight of the

trailer is on the tongue.

Safety Chains

Note: Do not attach safety chains to the

bumper.

Always connect the safety chains to the

frame or hook retainers of your vehicle

hitch.

To connect the safety chains, cross the

chains under the trailer tongue and allow

enough slack for turning tight corners. Do

not allow the chains to drag on the ground.

Trailer Brakes WARNING:

Do not connect a

trailer's hydraulic brake system directly

to your vehicle's brake system. Your

vehicle may not have enough braking

power and your chances of having a

collision greatly increase.

Electric brakes and manual, automatic or

surge-type trailer brakes are safe if you

install them properly and adjust them to

the manufacturer's specifications. The

trailer brakes must meet local and federal

regulations. The rating for the tow vehicle's braking

system operation is at the gross vehicle

weight rating, not the gross combined

weight rating.

Trailer Lamps

WARNING:

Never connect any

trailer lamp wiring to the vehicle's tail

lamp wiring; this may damage the

electrical system resulting in fire. Contact

your authorized dealer as soon as

possible for assistance in proper trailer

tow wiring installation. Additional

electrical equipment may be required.

Trailer lamps are required on most towed

vehicles. Make sure all running lights, brake

lights, turn signals and hazard lights are

working.

Before Towing a Trailer

Practice turning, stopping and backing up

to get the feel of your vehicle-trailer

combination before starting on a trip.

When turning, make wider turns so the

trailer wheels clear curbs and other

obstacles.

When Towing a Trailer

• Check your hitch, electrical connections

and trailer wheel lug nuts thoroughly

after you have traveled

50 mph

(80 km/h).

• When stopped in congested or heavy

traffic during hot weather, place the

transmission in park (P) or neutral (N)

to aid engine and transmission cooling

and to help air conditioning

performance.

• Turn off the speed control with heavy

loads or in hilly terrain. The speed

control may turn off automatically

when you are towing on long, steep

grades.

146

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Towing

Page 150 of 387

•

Shift to a lower gear when driving down

a long or steep hill. Do not apply the

brakes continuously, as they may

overheat and become less effective.

• If your transmission is equipped with

the Tow/Haul feature, use this feature

when towing. This provides engine

braking and helps eliminate excessive

transmission shifting for optimum fuel

economy and transmission cooling.

• Allow more distance for stopping with

a trailer attached. Anticipate stops and

brake gradually.

FIFTH WHEEL OPERATION WARNING: Failure to follow the

fifth wheel manufacturer ’s instructions

for hooking and unhooking as well as

sliding the fifth wheel could result in an

accident, personal injury or death. WARNING:

When the tractor and

trailer are parked unattended, the trailer

brake hand control should never be used

to apply the brake, since air may leak

from the system, allowing vehicle

movement, resulting in possible property

damage, personal injury or death.

Before hook-up, make sure:

• The fifth wheel jaws are fully open.

• The fifth wheel is fully tilted back to

prevent body damage when the tractor

is backed under a trailer.

• You block the trailer wheels and adjust

and apply the trailer spring brakes.

Never chase a trailer.

• The brake hoses and light cords are

clear of the fifth wheel. Hook-up

1. Back the tractor squarely under the

trailer, engaging the fifth-wheel jaws

on the kingpin. Always back up slowly;

make sure the trailer is neither too high

nor too low. Avoid backing under the

trailer from an angle.

2. Connect the service and emergency brake hoses and trailer light connector.

3. Inspect the jaws of the fifth wheel to be sure they have fully closed on the

trailer kingpin and the trailer plate is

resting securely on the fifth wheel.

4. Make sure the coupler release lever is in the locked position.

5. Charge the trailer brake system. Set the trailer brakes, with either the hand

valve or tractor protection valve. Pull

against the trailer for an extra check of

proper hook-up. Do not pull hard

enough to damage or strain the

equipment.

6. Set the tractor parking brakes and fully

raise the trailer landing gear.

7. Check the operation of all trailer lights

and correct any lights that may be

faulty.

Un-hook

1. Try to keep the tractor and trailer in a straight line.

2. Apply the parking brakes.

3. Lower the trailer landing gear, making sure it is on solid, level ground. The

weight of the trailer is to be on the

landing gear.

4. Block the trailer wheels.

5. Disconnect the brake hoses and light cords. Be sure hoses and cords are

clear.

6. Pull coupler release lever to disengage

the fifth wheel jaws.

147

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Towing

Page 155 of 387

In order to operate the engine in

temperatures of 32°F (0°C) or lower, read

the following instructions:

•

Make sure that the batteries are of

sufficient size and are fully charged.

Check other electrical components to

make sure they are in optimum

condition

• Use the proper coolant solution at the

concentration recommended

protecting the engine against damage

from freezing

• Try to keep the fuel tank full as much

as possible at the end of operation to

prevent condensation in the fuel

system

• Make sure you use proper cold weather

engine oil and that it is at its proper

level. Also, if necessary, make sure to

follow the engine oil and filter change

schedule found under the Special

operating conditions section listed in

the scheduled maintenance

information

• At temperatures of -9°F (-23°C) or

below, it is recommended that you use

an engine block heater to improve cold

engine starting

• If operating in arctic temperatures of

-20°F (-29°C)

or lower, consult your

truck dealer for information about

special cold weather equipment and

precautions

The following cold weather idling

guidelines are recommended:

• You can use Motorcraft® cetane

improvers or non-alcohol-based

cetane improvers from a reputable

manufacturer as needed.

• Maintain the engine cooling system

properly. •

Avoid shutting the engine down after

an extensive idling period. Drive your

vehicle for several miles with the

engine at normal operating

temperatures under a moderate load.

• Consider using an engine block heater.

• For extended idle times use an

approved idle speed increase device.

Winter Operating Tips for Arctic

Operation -20°F (-29°C) and

Below

The following information is a guideline

only and is not to be the only source of

possible solutions in resolving extreme

cold temperature issues.

Starting Aids WARNING:

Do not use starting

fluid, such as ether, in the air intake

system (see air filter decal). Such fluid

could cause immediate explosive

damage to the engine and possible

personal injury.

The use of the factory engine block heater

assists in engine starting in extreme cold

ambient temperatures. See

Engine Block

Heater (page 90).

Idle Control

Your vehicle may have a factory option for

a stationary elevated idle control through

dash-mounted upfitter switches that

allows the operator to elevate the idle rpm

for extended idle periods, as well as

aftermarket equipment such as PTO

operation. You must configure this feature

even if ordered from the factory. See your

authorized dealer for required upfitting.

152

F650750 (TBC) , enUSA, Edition date: 201804, Second-Printing Driving Hints