maintenance reset FORD F650/750 2021 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2021, Model line: F650/750, Model: FORD F650/750 2021Pages: 390, PDF Size: 5.16 MB

Page 7 of 390

Fuses

Fuse Specification Chart

..........................193

Changing a Fuse ..........................................

201

Vehicle Inspection Guide

Vehicle Inspection Information .............

203

Maintenance

General Information ....................................

212

Opening and Closing the Hood ..............

213

Under Hood Overview - 6.7L Diesel ......

215

Under Hood Overview - 7.3L ....................

216

Engine Oil Dipstick - 7.3L ...........................

217

Engine Oil Dipstick - 6.7L Diesel .............

217

Engine Oil Check - 7.3L ...............................

217

Engine Oil Check - 6.7L Diesel ................

218

Changing the Engine Oil and Oil Filter ........................................................................\

.

219

Oil Change Indicator Reset .....................

220

Changing the Engine Air Filter - 6.7L Diesel ............................................................

221

Changing the Engine Air Filter - 7.3L .....

223

Draining the Fuel Filter Water Trap - 6.7L Diesel ...........................................................

225

Engine Coolant Check - 7.3L ...................

226

Engine Coolant Check - 6.7L Diesel ......

231

Automatic Transmission Fluid Check ........................................................................\

236

Brake Fluid Check ........................................

237

Power Steering Fluid Check ....................

238

Changing the 12V Battery ........................

239

Adjusting the Headlamps .......................

240

Washer Fluid Check ...................................

242

Fuel Filter - 7.3L ............................................

242

Checking the Wiper Blades .....................

242

Changing the Wiper Blades ....................

242

Removing a Headlamp .............................

243

Changing a Bulb ..........................................

243Changing the Engine-Mounted and

Diesel Fuel Conditioner Module Fuel

Filters - 6.7L Diesel .................................

244

Electrical System Inspection ..................

247

Air Induction System Inspection ...........

247

Exhaust System Inspection ....................

248

Brake System Inspection .........................

248

Axle Inspection .............................................

251

Steering System Inspection ....................

252

Suspension System Inspection .............

252

Frame and Tow Hook Inspection ..........

253

Rear Axle Fluid Check ................................

253

Spring U-Bolt Check ..................................

253

Vehicle Care

General Information ..................................

255

Cleaning Products ......................................

255

Cleaning the Exterior .................................

256

Waxing .............................................................

257

Cleaning the Engine ...................................

257

Cleaning the Windows and Wiper Blades ........................................................................\

257

Cleaning the Interior ..................................

258

Cleaning the Instrument Panel and Instrument Cluster Lens ......................

258

Repairing Minor Paint Damage .............

259

Cleaning the Wheels .................................

259

Vehicle Storage ...........................................

260

Wheels and Tires

Tire Care .........................................................

262

Using Snow Chains .....................................

277

Changing a Road Wheel ...........................

277

Technical Specifications ..........................

279

Capacities and Specifications

Engine Specifications - 6.7L Diesel .......

281

Engine Specifications - 7.3L ....................

282

Motorcraft Parts - 6.7L Diesel ................

283

4

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Table of Contents

Page 16 of 390

DATA RECORDING

WARNING: Do not connect

wireless plug-in devices to the data link

connector. Unauthorized third parties

could gain access to vehicle data and

impair the performance of safety related

systems. Only allow repair facilities that

follow our service and repair instructions

to connect their equipment to the data

link connector.

We respect your privacy and are

committed to protecting it. The

information contained in this publication

was correct at the time of going to print,

but as technology rapidly changes, we

recommend that you visit the regional Ford

website for the latest information.

Your vehicle has electronic control units

that have data recording functionality and

the ability to permanently or temporarily

store data. This data could include

information on the condition and status of

your vehicle, vehicle maintenance

requirements, events and malfunctions.

The types of data that can be recorded are

described in this section. Some of the data

recorded is stored in event logs or error

logs.

Note: Error logs are reset following a service

or repair.

Note: We may provide information in

response to requests from law enforcement,

other government authorities and third

parties acting with lawful authority or

through a legal process. Such information

could be used by them in legal proceedings. Data recorded includes, for example:

•

Operating states of system

components, for example, fuel level,

tire pressure and battery charge level.

• Vehicle and component status, for

example, wheel speed, deceleration,

lateral acceleration and seatbelt

status.

• Events or errors in essential systems,

for example, headlamps and brakes.

• System responses to driving situations,

for example, airbag deployment and

stability control.

• Environmental conditions, for example,

temperature.

Some of this data, when used in

combination with other information, for

example, an accident report, damage to a

vehicle or eyewitness statements, could

be associated with a specific person.

Service Data

Service data recorders in your vehicle are

capable of collecting and storing

diagnostic information about your vehicle.

This potentially includes information about

the performance or status of various

systems and modules in the vehicle, such

as engine, throttle, steering or brake

systems. In order to properly diagnose and

service your vehicle, Ford Motor Company

(Ford of Canada in Canada), and service

and repair facilities may access or share

among them vehicle diagnostic

information received through a direct

connection to your vehicle when

diagnosing or servicing your vehicle.

Additionally, Ford Motor Company (Ford

of Canada, in Canada) may, where

permitted by law, use vehicle diagnostic

information for vehicle improvement or

with other information we may have about

you, for example, your contact information,

to offer you products or services that may

interest you. Data may be provided to our

13

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Introduction

Page 74 of 390

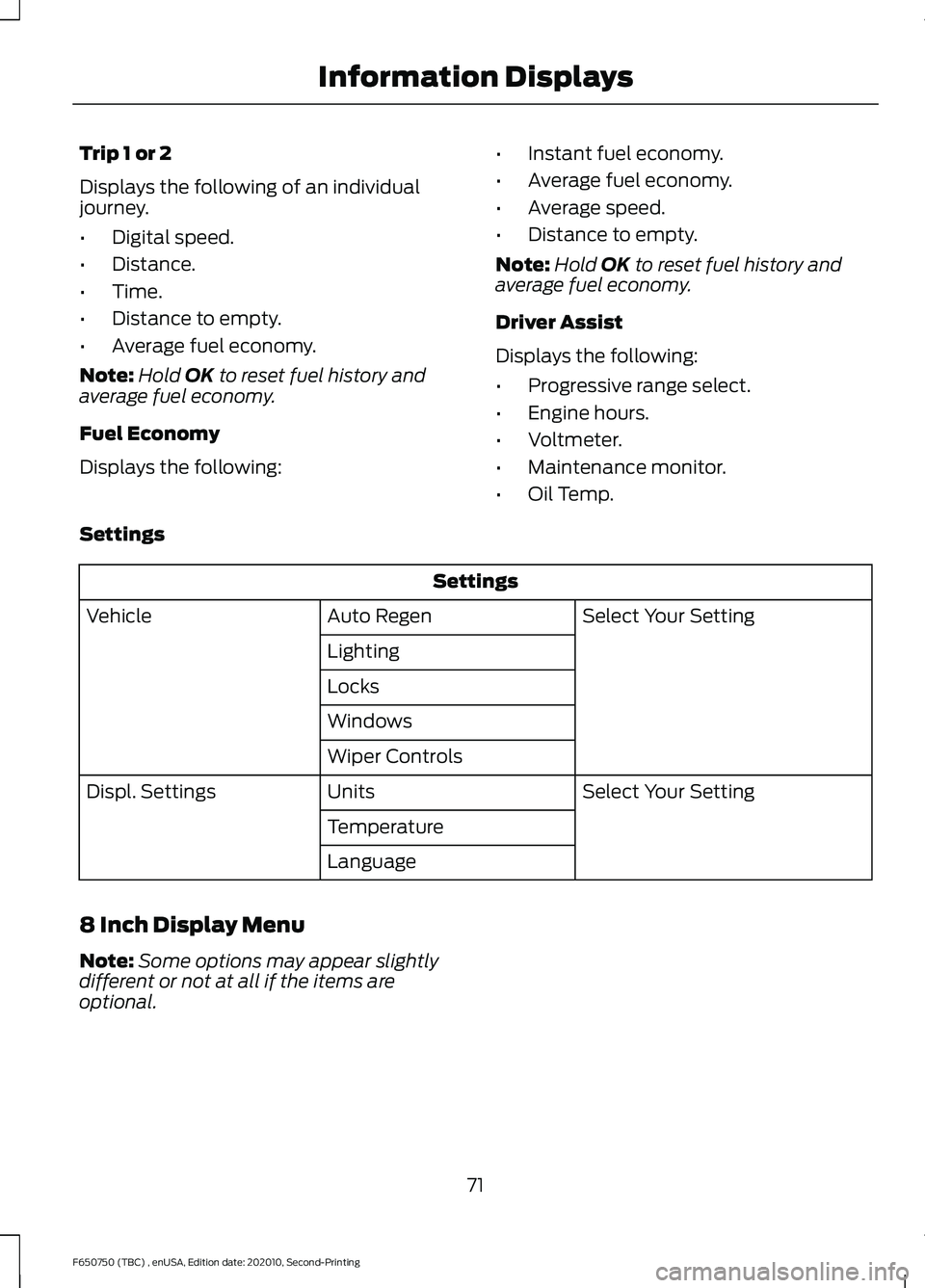

Trip 1 or 2

Displays the following of an individual

journey.

•

Digital speed.

• Distance.

• Time.

• Distance to empty.

• Average fuel economy.

Note: Hold OK to reset fuel history and

average fuel economy.

Fuel Economy

Displays the following: •

Instant fuel economy.

• Average fuel economy.

• Average speed.

• Distance to empty.

Note: Hold

OK to reset fuel history and

average fuel economy.

Driver Assist

Displays the following:

• Progressive range select.

• Engine hours.

• Voltmeter.

• Maintenance monitor.

• Oil Temp.

Settings Settings

Select Your Setting

Auto Regen

Vehicle

Lighting

Locks

Windows

Wiper Controls Select Your Setting

Units

Displ. Settings

Temperature

Language

8 Inch Display Menu

Note: Some options may appear slightly

different or not at all if the items are

optional.

71

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Information Displays

Page 76 of 390

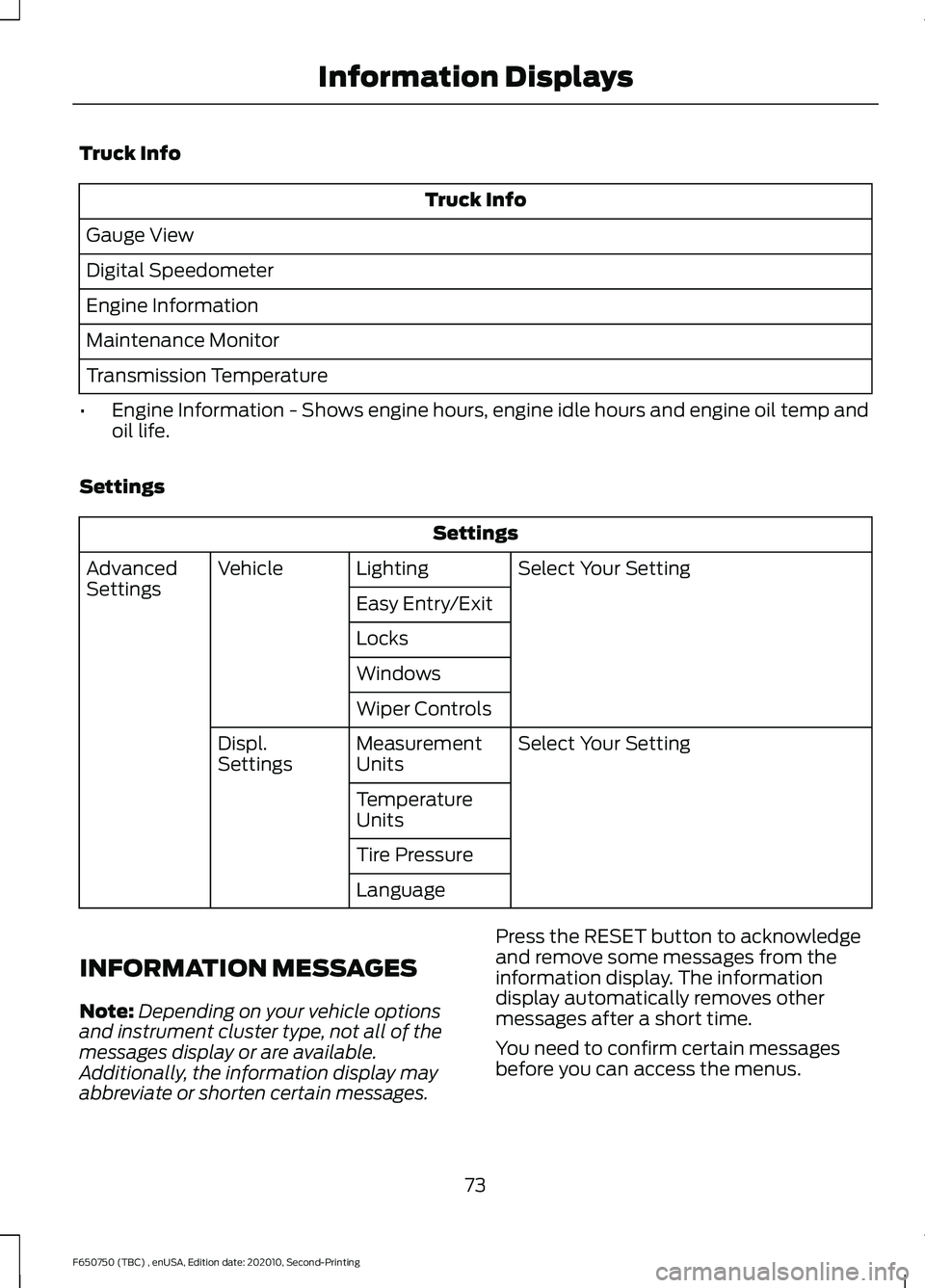

Truck Info

Truck Info

Gauge View

Digital Speedometer

Engine Information

Maintenance Monitor

Transmission Temperature

• Engine Information - Shows engine hours, engine idle hours and engine oil temp and

oil life.

Settings Settings

Select Your Setting

Lighting

Vehicle

Advanced

Settings

Easy Entry/Exit

Locks

Windows

Wiper Controls

Select Your Setting

Measurement

Units

Displ.

Settings

Temperature

Units

Tire Pressure

Language

INFORMATION MESSAGES

Note: Depending on your vehicle options

and instrument cluster type, not all of the

messages display or are available.

Additionally, the information display may

abbreviate or shorten certain messages. Press the RESET button to acknowledge

and remove some messages from the

information display. The information

display automatically removes other

messages after a short time.

You need to confirm certain messages

before you can access the menus.

73

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Information Displays

Page 223 of 390

5. For diesel engines, you need to reset

the Intelligent Oil Life Monitor™. See

Information Displays (page 70).

Engine lubrication for severe

service operation

The following conditions define severe

operation for which engine operation with

SAE 5W-40 API CJ-4 is recommended. Oil

and oil filter change intervals will be

determined by the Intelligent Oil Life

Monitor™ as noted previously.

• Frequent or extended idling (over 10

minutes per hour of normal driving).

• Low-speed operation/stationary use.

• If vehicle is operated in sustained

ambient temperatures below

-9°F

(-23°C) or above 100°F (38°C).

• Frequent low-speed operation,

consistent heavy traffic less than

25 mph (40 km/h)

.

• Operating in severe dust conditions.

• Operating the vehicle off road.

• Towing a trailer over

1,000 mi

(1,600 km).

• Sustained, high-speed driving at Gross

Vehicle Weight Rating (maximum

loaded weight for vehicle operation).

• Use of fuels with sulfur content other

than ultra-low sulfur diesel (ULSD).

• Use of high-sulfur diesel fuel.

OIL CHANGE INDICATOR

RESET

Base Cluster

Use the information display controls on

the steering wheel to reset the oil change

indicator. From the main menu scroll to: Action and Description

Message

Press the right arrow button,

then from this menu scroll

to the following message.

Settings

Press the down arrow

button, then from this menu

scroll to the following

message.

Vehicle

Press the right arrow button,

then from this menu scroll

to the following message.

Oil Life

Reset

Press and hold the

OK

button until the instrument

cluster displays the

following message.

Oil Life

Hold to

Reset

Press and hold the

OK

button until the instrument

cluster displays the

following message.

Oil Life

Hold OK

to Reset

Reset Complete

If the instrument cluster

displays the following

message, repeat the

process.

Reset Cancelled

High Series Cluster

Use the information display controls on

the steering wheel to reset the oil change

indicator.

220

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Maintenance

Page 224 of 390

From the main menu scroll to:

Action and Description

Message

Press the down arrow

button, then from this menu

scroll to the following

message.

Truck Info

Press the OK button.

Mainten-

ance

Monitor

Press the down arrow

button, then from this menu

scroll to the following

message.

Oil Life:

xxx%

Press the

OK button.

Oil Life

Press and hold the

OK

button until the instrument

cluster displays the

following message.

Oil Life

Hold OK to

Reset

Oil Life: 100%

When the oil change indic-

ator resets, the instrument

cluster displays 100%.

Repeat the process if the oil

change indicator does not

reset.

CHANGING THE ENGINE AIR

FILTER - 6.7L DIESEL

Air Filter Restriction Gauge WARNING:

To reduce the risk of

vehicle damage and personal burn

injuries, do not start your engine with the

air cleaner removed and do not remove

it while the engine is running. Note:

Operating your vehicle in heavy

snowfall or extreme rain conditions may

allow excessive amounts of snow or water

into the air intake system. This could plug

or soak the air filter and cause the engine to

lose power or shut down. The restriction gauge, on the upper housing

of the air filter assembly, measures the

vacuum inside the air filter. The more the

air filter is dirty or clogged, the higher the

vacuum reading.

Check the air filter restriction gauge

whenever you open the hood to perform

general engine maintenance or at least

every 7,500 mi (12,000 km). If you operate

your vehicle in extremely dusty conditions,

check and reset the gauge at least every

500 mi (800 km), or two weeks, whichever

comes first. Change the air filter when the

restriction gauge reads near the change

filter line and the gauge is yellow. If you

allow the restriction gauge to reach

maximum restriction, you can affect your

engine performance and fuel economy.

Note:

Do not blow out the air filter element

with compressed air since the compressed

air could damage the filter paper.

Note: Do not rely on filter appearance

alone. A filter which appears to be dirty may

have several thousand miles (kilometers)

of life remaining.

221

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing MaintenanceE163372

Page 225 of 390

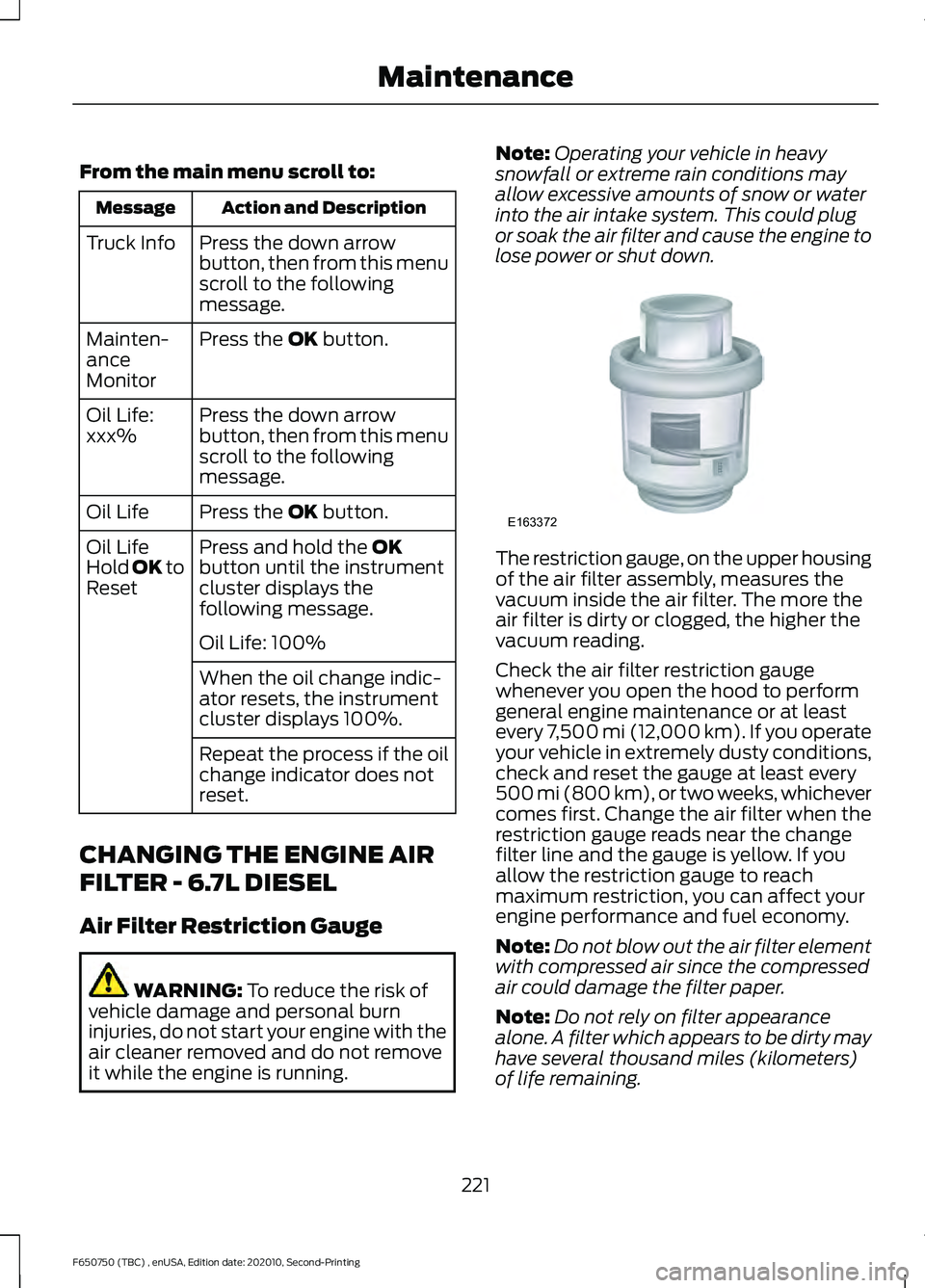

After installation of the new filter element,

reset the gauge by pressing the reset

button on top of the gauge.

We recommend the following actions after

operating the vehicle up to 200 mi

(320 km) in heavy snowfall or extreme

rain:

• Snow: At the earliest opportunity, open

the hood and clear all the snow and ice

from the air filter housing inlet. Do NOT

remove the foam filter and reset the

air filter restriction gauge.

• Extreme rain: The air filter dries after

about 15– 30 minutes at highway

speeds. At the earliest opportunity,

open the hood and reset the air filter

restriction gauge.

Air Filter Replacement

When replacing the air filter element, use

a Motorcraft® air filter element. See

Motorcraft Parts

(page 283).

Note: Failure to use the correct air filter

element may result in severe engine

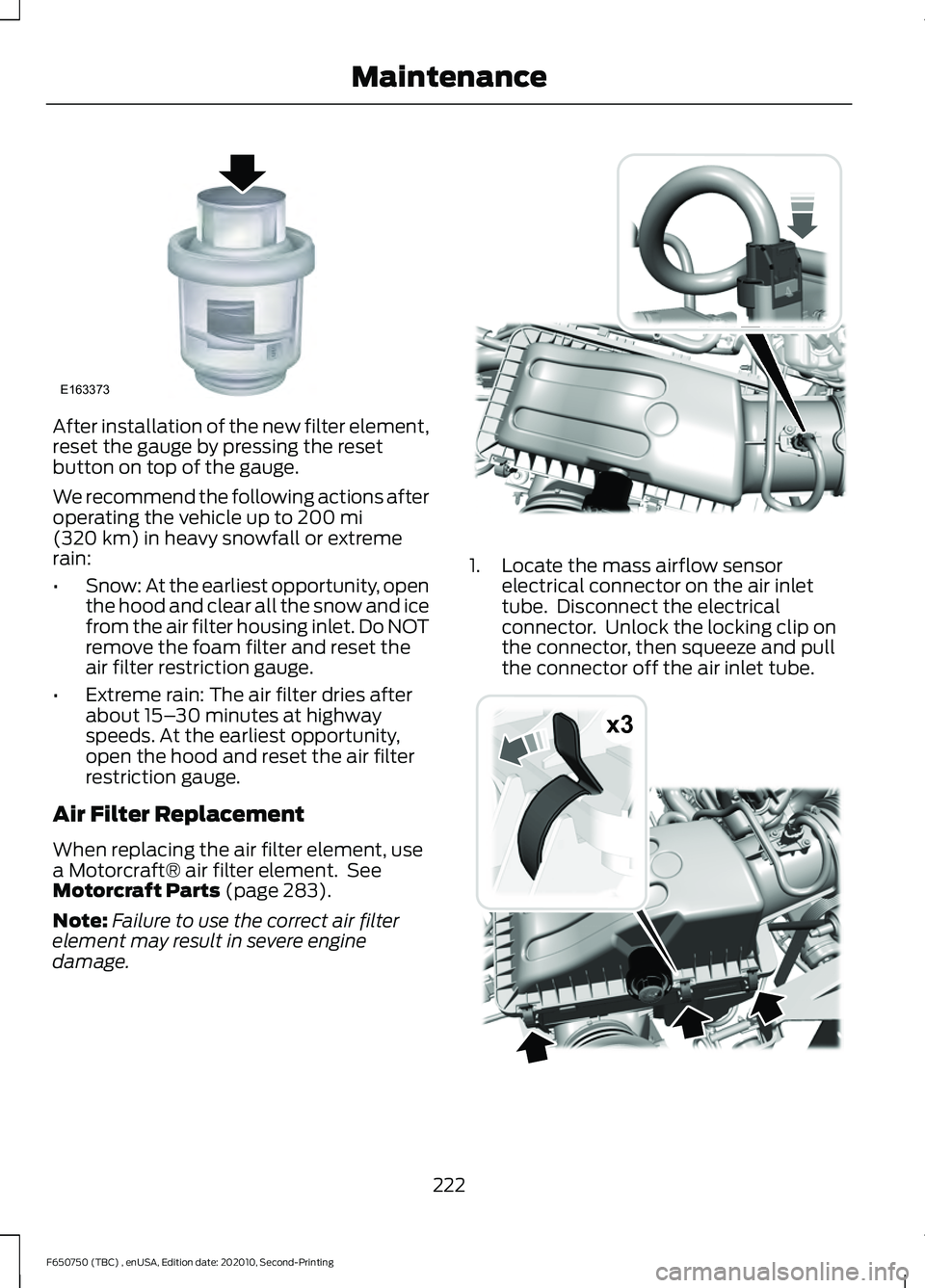

damage. 1. Locate the mass airflow sensor

electrical connector on the air inlet

tube. Disconnect the electrical

connector. Unlock the locking clip on

the connector, then squeeze and pull

the connector off the air inlet tube. 222

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing MaintenanceE163373 E317651 x3E317652

Page 232 of 390

Coolant Change

Change the coolant at specific mileage

intervals as listed in the scheduled

maintenance information. The information

display may display a message to change

coolant at this time. Add prediluted

coolant approved to the correct

specification. See Capacities and

Specifications (page 281).

Engine-driven Cooling Fan (Fan

Clutch)

Your vehicle comes with an engine driven

cooling fan drive, also called a fan clutch.

This fan drive changes the fan speed to

match the vehicle ’s changing cooling air

flow requirements. Fan speed, fan noise

level and fuel consumption all will increase

based on the driving conditions that

include trailer towing, hill climbing, heavy

loads, high speed and high ambient

temperature, individually or in combination.

The fan drive is designed to provide the

minimum fan speed, and resulting

minimum fan noise and fuel consumption

required to meet the ever changing vehicle

cooling air flow requirements. You will hear

the amount of fan noise increasing and

decreasing as the engine power

requirements and vehicle driving conditions

change as you drive. This is to be expected

as being normal to the operation of your

vehicle. High levels of fan noise might also

be heard when your engine is first started,

and should normally decrease after driving

for a short time.

Fail-Safe Cooling

Fail-safe cooling allows you to temporarily

drive your vehicle before any incremental

component damage occurs. The fail-safe

distance depends on ambient

temperature, vehicle load and terrain. How Fail-Safe Cooling Works

If the engine begins to overheat, the

coolant temperature gauge moves toward

the red zone: A warning lamp illuminates and

a message may appear in the

information display.

If the engine reaches a preset

over-temperature condition, the engine

switches to alternating cylinder operation.

Each disabled cylinder acts as an air pump

and cools the engine.

When this occurs, your vehicle still

operates, however:

• Engine power is limited.

• The air conditioning system turns off.

Continued operation increases the engine

temperature, causing the engine to

completely shut down. Your steering and

braking effort increases in this situation.

When the engine temperature cools, you

can re-start the engine. Have your vehicle

checked as soon as possible to minimize

engine damage.

When Fail-Safe Mode Is Activated WARNING:

Fail-safe mode is for

use during emergencies only. Operate

your vehicle in fail-safe mode only as

long as necessary to bring your vehicle

to rest in a safe location and seek

immediate repairs. When in fail-safe

mode, your vehicle will have limited

power, will not be able to maintain

229

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Maintenance

Page 243 of 390

5. Turn the air conditioning (if equipped)

on and allow the engine to idle for at

least one minute.

6. Release the parking brake. With your foot on the brake pedal and with the

air conditioning on, put the vehicle in

drive (D) and allow the engine to idle

for at least one minute.

•If you do not allow the engine to

relearn its idle trim, the idle quality

of your vehicle may be adversely

affected until the idle trim is

eventually relearned.

7. Drive the vehicle to complete the relearning process

•The vehicle may need to be driven

10 mi (16 km) or more to relearn the

idle and fuel trim strategy along

with the ethanol content for flexible

fuel vehicles.

If the battery has been disconnected or a

new battery has been installed, the clock

and radio settings must be reset once the

battery is reconnected.

Always dispose of automotive

batteries in a responsible manner.

Follow your local authorized standards

for disposal. Call your local authorized

recycling center to find out more about

recycling automotive batteries.

Battery Management System (If

Equipped)

The battery management system (BMS)

monitors battery conditions and takes

actions to extend battery life. If excessive

battery drain is detected, the system may

temporarily disable certain electrical

features to protect the battery. Those

electrical accessories affected include the

rear defrost, heated/cooled seats, climate

control fan, heated steering wheel, audio

and navigation system. A message may be

shown in the information displays to alert the driver that battery protection actions

are active. These messages are only for

notification that an action is taking place,

and not intended to indicate an electrical

problem or that the battery requires

replacement.

Electrical accessory installation

To ensure proper operation of the BMS,

any electrical devices that are added to

the vehicle should not have their ground

connection made directly at the negative

battery post. A connection at the negative

battery post can cause inaccurate

measurements of the battery condition

and potential incorrect system operation.

Note:

Electrical or electronic accessories

added to the vehicle by the dealer or the

owner may adversely affect battery

performance and durability, and may also

affect the performance of other electrical

systems in the vehicle.

When a battery replacement is required,

the battery should only be replaced with

a Ford recommended replacement battery

which matches the electrical requirements

of the vehicle. After battery replacement,

or in some cases after charging the battery

with the external charger, the BMS requires

eight hours of vehicle sleep time (key off

with doors closed) to relearn the new

battery state of charge. Prior to relearning

the state of charge, the BMS may disable

electrical features (to protect the battery)

earlier than normal.

ADJUSTING THE HEADLAMPS

Vertical Aim Adjustment

The headlamps on your vehicle are

properly aimed at the assembly plant. If

your vehicle has been in an accident, the

alignment of your headlamps should be

checked by your authorized dealer.

240

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Maintenance

Page 252 of 390

Air Brakes

WARNING: Do not manually adjust

the automatic slack adjusters to correct

excessive push rod stroke as it may result

in reduced brake effectiveness and a

vehicle crash. Excessive push rod stroke

indicates that a problem exists with the

automatic adjuster, with the installation

of the adjuster, or with foundation brake

components that manual adjustment

does not remedy. Seek service from a

qualified facility for excessive push rod

stroke.

Inspection and Adjustment

Establish a regular schedule for periodic

cleaning, lubrication and adjustment

inspection based on vehicle use. Exact

maintenance intervals are difficult to

predetermine due to vehicle applications

and operating conditions. If you are

uncertain of the proper schedule for your

vehicle, contact an authorized dealer.

Regular inspections should include:

• Periodic checking (every service

interval) of push rod travel or brake

adjustment. This is essential for

effective braking. Brake chamber push

rods on original equipment chambers

now incorporate an orange paint

marker near the base of the push rod as a stroke indicator to aid in

adjustment checks. If the push rod is

clean and the brakes are out of

adjustment, you can see the orange

marker protruding from the chamber

when the brakes are applied.

• Checking the brake lining (every service

interval). When brake linings or blocks

wear within 0.063 in (1.6 mm) they

must be replaced.

• Periodic checking (every service

interval) of the air compressor filter.

Check the filter minder and when the

indicator is near or on the red line

marked

Service, replace the filter and

reset the service filter minder.

Do not back off or disconnect the front

brakes so that they are less effective,

letting the rear brakes do all the stopping

of your vehicle. Do not overlook the brakes

on the trailer either. Brake condition on the

trailer is just as important as the tractor.

Proper brake balance on trucks and

tractor-trailers is essential for effective

braking.

Once a year, inspect the entire brake

system:

• Rubber components for deterioration.

A qualified technician should inspect

these components and replace them

as necessary. Replacement intervals

vary according to the severity and

length of vehicle service.

• Condition of brake drums, brake

chambers and slack adjusters.

• System for air leaks.

• Hose or pipes for rust, damage and

deterioration.

• Operation of service and parking

brakes.

Periodically inspect parts such as air brake

chamber diaphragm, air compressor and

air cleaner. Replace any parts if you can

consider them unserviceable.

249

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Maintenance