tire pressure FORD F650/750 2021 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2021, Model line: F650/750, Model: FORD F650/750 2021Pages: 390, PDF Size: 5.16 MB

Page 15 of 390

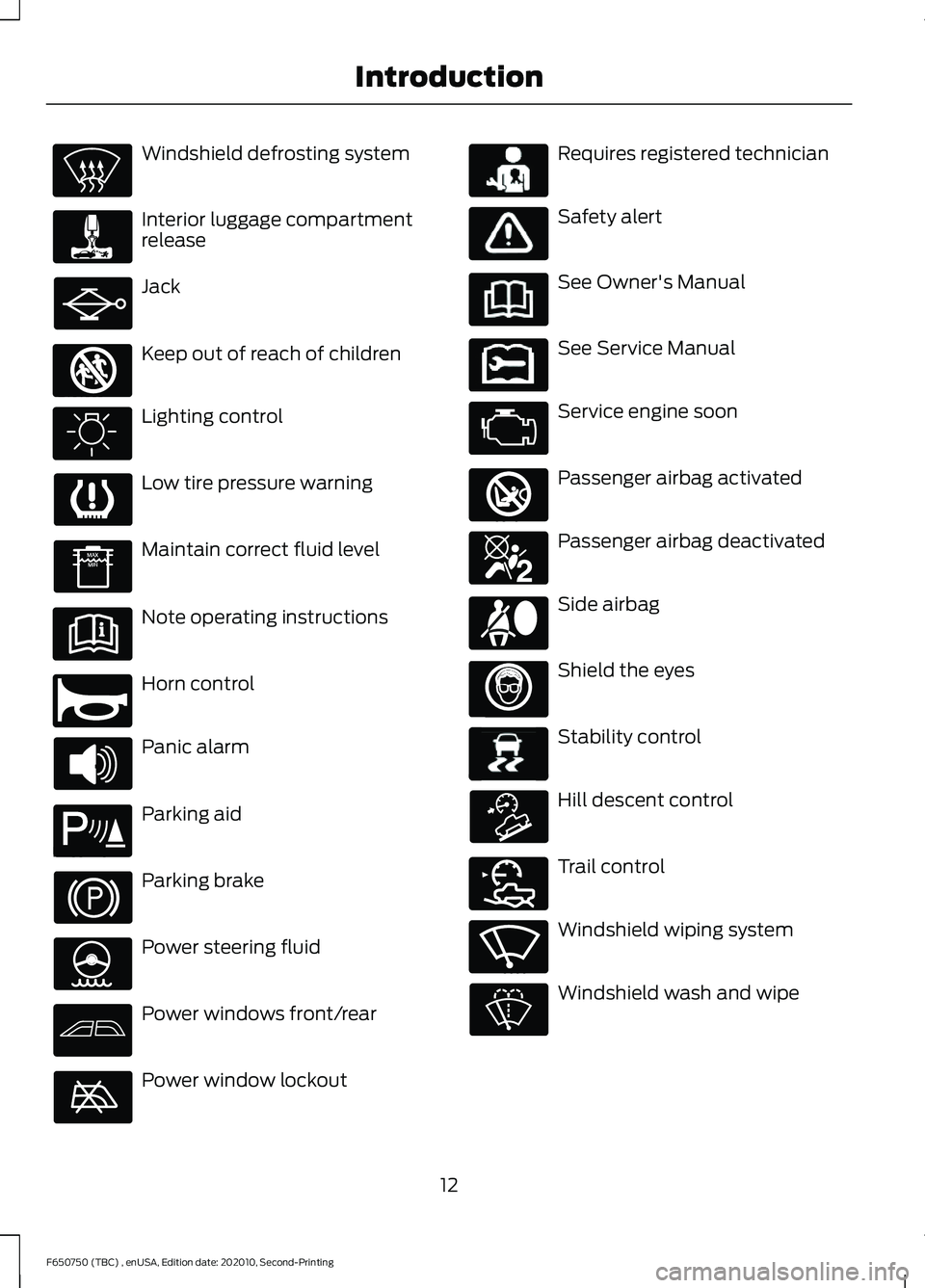

Windshield defrosting system

Interior luggage compartment

release

Jack

Keep out of reach of children

Lighting control

Low tire pressure warning

Maintain correct fluid level

Note operating instructions

Horn control

Panic alarm

Parking aid

Parking brake

Power steering fluid

Power windows front/rear

Power window lockout Requires registered technician

Safety alert

See Owner's Manual

See Service Manual

Service engine soon

Passenger airbag activated

Passenger airbag deactivated

Side airbag

Shield the eyes

Stability control

Hill descent control

Trail control

Windshield wiping system

Windshield wash and wipe

12

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Introduction E161353 E270945 E139213 E231159 E231158 E270849 E270850 E167012 E138639 E163957 E272858 E270969

Page 16 of 390

DATA RECORDING

WARNING: Do not connect

wireless plug-in devices to the data link

connector. Unauthorized third parties

could gain access to vehicle data and

impair the performance of safety related

systems. Only allow repair facilities that

follow our service and repair instructions

to connect their equipment to the data

link connector.

We respect your privacy and are

committed to protecting it. The

information contained in this publication

was correct at the time of going to print,

but as technology rapidly changes, we

recommend that you visit the regional Ford

website for the latest information.

Your vehicle has electronic control units

that have data recording functionality and

the ability to permanently or temporarily

store data. This data could include

information on the condition and status of

your vehicle, vehicle maintenance

requirements, events and malfunctions.

The types of data that can be recorded are

described in this section. Some of the data

recorded is stored in event logs or error

logs.

Note: Error logs are reset following a service

or repair.

Note: We may provide information in

response to requests from law enforcement,

other government authorities and third

parties acting with lawful authority or

through a legal process. Such information

could be used by them in legal proceedings. Data recorded includes, for example:

•

Operating states of system

components, for example, fuel level,

tire pressure and battery charge level.

• Vehicle and component status, for

example, wheel speed, deceleration,

lateral acceleration and seatbelt

status.

• Events or errors in essential systems,

for example, headlamps and brakes.

• System responses to driving situations,

for example, airbag deployment and

stability control.

• Environmental conditions, for example,

temperature.

Some of this data, when used in

combination with other information, for

example, an accident report, damage to a

vehicle or eyewitness statements, could

be associated with a specific person.

Service Data

Service data recorders in your vehicle are

capable of collecting and storing

diagnostic information about your vehicle.

This potentially includes information about

the performance or status of various

systems and modules in the vehicle, such

as engine, throttle, steering or brake

systems. In order to properly diagnose and

service your vehicle, Ford Motor Company

(Ford of Canada in Canada), and service

and repair facilities may access or share

among them vehicle diagnostic

information received through a direct

connection to your vehicle when

diagnosing or servicing your vehicle.

Additionally, Ford Motor Company (Ford

of Canada, in Canada) may, where

permitted by law, use vehicle diagnostic

information for vehicle improvement or

with other information we may have about

you, for example, your contact information,

to offer you products or services that may

interest you. Data may be provided to our

13

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Introduction

Page 76 of 390

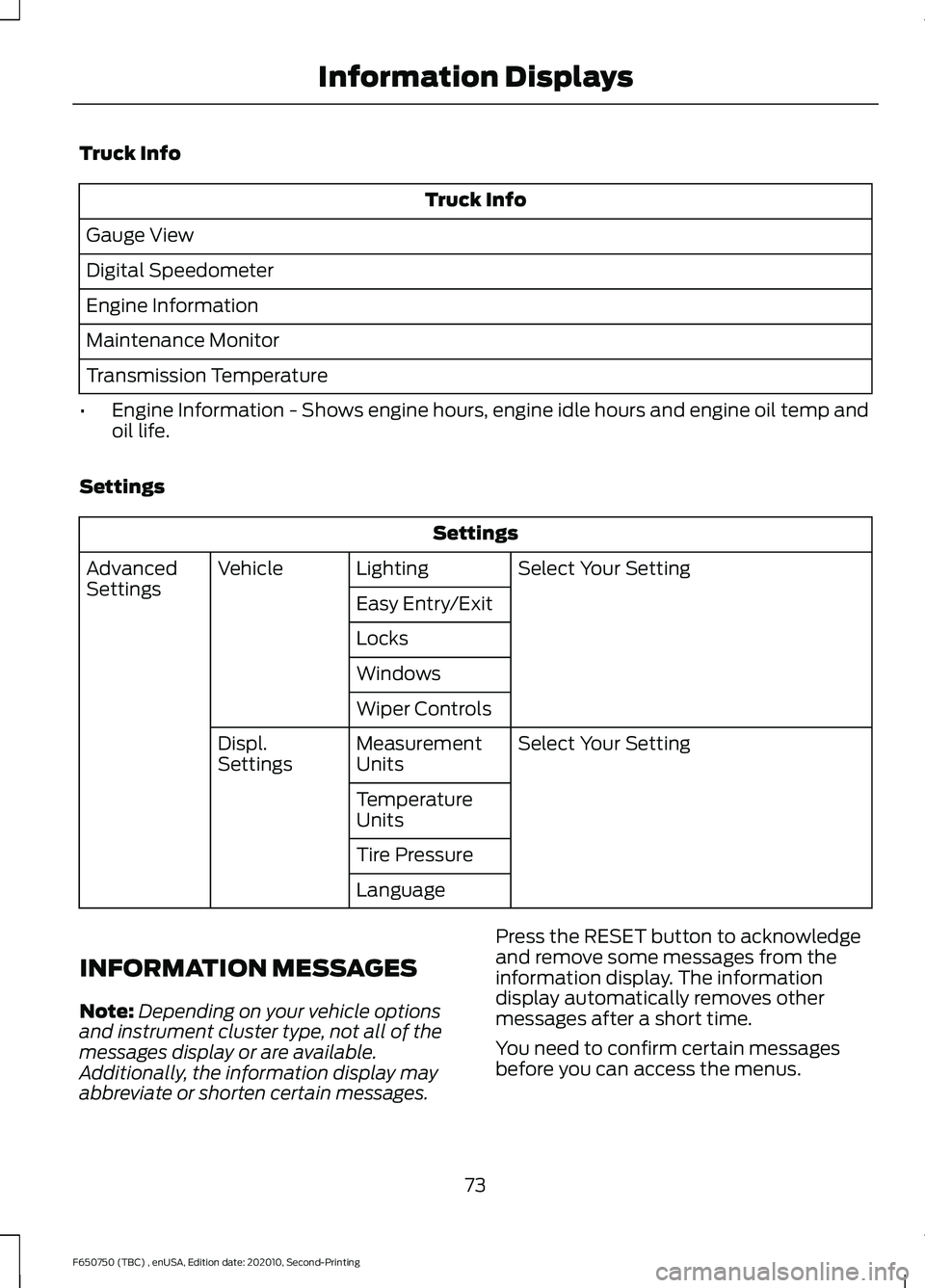

Truck Info

Truck Info

Gauge View

Digital Speedometer

Engine Information

Maintenance Monitor

Transmission Temperature

• Engine Information - Shows engine hours, engine idle hours and engine oil temp and

oil life.

Settings Settings

Select Your Setting

Lighting

Vehicle

Advanced

Settings

Easy Entry/Exit

Locks

Windows

Wiper Controls

Select Your Setting

Measurement

Units

Displ.

Settings

Temperature

Units

Tire Pressure

Language

INFORMATION MESSAGES

Note: Depending on your vehicle options

and instrument cluster type, not all of the

messages display or are available.

Additionally, the information display may

abbreviate or shorten certain messages. Press the RESET button to acknowledge

and remove some messages from the

information display. The information

display automatically removes other

messages after a short time.

You need to confirm certain messages

before you can access the menus.

73

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Information Displays

Page 129 of 390

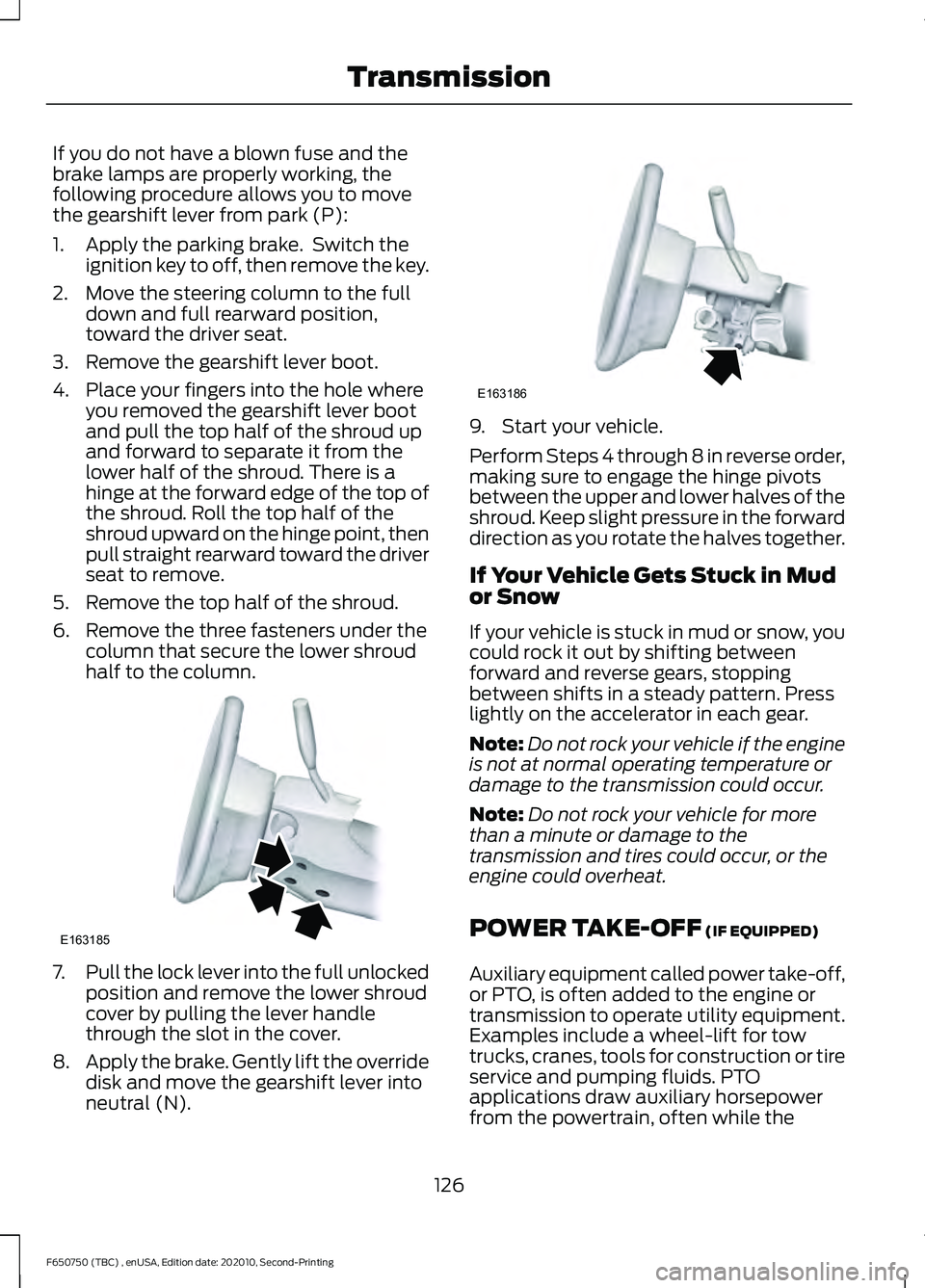

If you do not have a blown fuse and the

brake lamps are properly working, the

following procedure allows you to move

the gearshift lever from park (P):

1. Apply the parking brake. Switch the

ignition key to off, then remove the key.

2. Move the steering column to the full down and full rearward position,

toward the driver seat.

3. Remove the gearshift lever boot.

4. Place your fingers into the hole where you removed the gearshift lever boot

and pull the top half of the shroud up

and forward to separate it from the

lower half of the shroud. There is a

hinge at the forward edge of the top of

the shroud. Roll the top half of the

shroud upward on the hinge point, then

pull straight rearward toward the driver

seat to remove.

5. Remove the top half of the shroud.

6. Remove the three fasteners under the column that secure the lower shroud

half to the column. 7.

Pull the lock lever into the full unlocked

position and remove the lower shroud

cover by pulling the lever handle

through the slot in the cover.

8. Apply the brake. Gently lift the override

disk and move the gearshift lever into

neutral (N). 9. Start your vehicle.

Perform Steps 4 through 8 in reverse order,

making sure to engage the hinge pivots

between the upper and lower halves of the

shroud. Keep slight pressure in the forward

direction as you rotate the halves together.

If Your Vehicle Gets Stuck in Mud

or Snow

If your vehicle is stuck in mud or snow, you

could rock it out by shifting between

forward and reverse gears, stopping

between shifts in a steady pattern. Press

lightly on the accelerator in each gear.

Note:

Do not rock your vehicle if the engine

is not at normal operating temperature or

damage to the transmission could occur.

Note: Do not rock your vehicle for more

than a minute or damage to the

transmission and tires could occur, or the

engine could overheat.

POWER TAKE-OFF (IF EQUIPPED)

Auxiliary equipment called power take-off,

or PTO, is often added to the engine or

transmission to operate utility equipment.

Examples include a wheel-lift for tow

trucks, cranes, tools for construction or tire

service and pumping fluids. PTO

applications draw auxiliary horsepower

from the powertrain, often while the

126

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing TransmissionE163185 E163186

Page 131 of 390

GENERAL INFORMATION

WARNING: Exceeding these ratings

by overloading can cause component

failure resulting in property damage,

personal injury or death.

Fluid Temperature

If the operating temperature exceeds

250°F (121°C), the rate of axle lubrication

oxidation increases and shortens the life

of the lubricant and seals, requiring axle

lubrication changes to become more

frequent to preserve the axle. Do not

consistently run extreme pressure (EP)

lubricants above

250°F (121°C).

Axle Conversions WARNING:

When operating a

loaded vehicle, the driver must keep all

adjustable axles on the ground at all

times, supporting their share of the

vehicle ’s load. Failure to do so can

overload other axles, tires, wheels,

springs, steering components, brakes

and frames, resulting in early component

failure, loss of vehicle control, possible

property damage and personal injury.

We do not recommend, or approve,

performing axle conversions. However, we

understand that, on occasion, others install

aftermarket add-on axles on the truck

chassis that allow operator control for

weight transfer from other axles (such as

air lift axles). ELECTRONIC LOCKING

DIFFERENTIAL

(IF EQUIPPED)

Driver-Controlled Electronic

Locking Differential

Note: Never use the differential lock at

vehicle speeds above

25 mph (40 km/h).

Some drive axles have a driver-controlled

differential lock. The differential lock can

lock or unlock the differential when your

vehicle is moving or stopped. When you

require extra traction, the differential lock

provides full power to both wheels.

When you lock the differential, your

vehicle ’s turning radius increases

(under-steer).

Take care to avoid sudden accelerations

when both drive wheels are on a slippery

surface. WARNING:

Sudden acceleration

on slippery surfaces could cause the

wheels to spin, the vehicle to turn

sideways on a crowned road surface or

in a turn, possibly resulting in loss of

vehicle control and personal injury.

Activating the Electronic Locking

Differential

You can lock and unlock the differential

when your vehicle is moving at a constant

speed of less than 25 mph (40 km/h) and

while the wheels are not slipping. Do not

lock the differential when your vehicle is

traveling down steep grades and when

traction is minimal.

The differential lock and differential lock

light automatically disengage at speeds

above

25 mph (40 km/h). The differential

lock remains off until either you restart your

vehicle, or you turn the differential lock

switch off then back on.

128

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Rear Axle

Page 172 of 390

AIR SUSPENSION (IF EQUIPPED)

Note: Do not operate your vehicle without

air in the suspension springs. Operating your

vehicle without air in the suspension springs

damages the suspension, degrades ride

performance and may cause property

damage.

The air suspension system automatically

adjusts to different loads to maintain a

constant frame height, allows for ease of

vehicle loading, provides improved vehicle

ride, and increased driver comfort.

Air Suspension Dump Button Note:

The suspension dumps air when the

ignition is in the accessory or on position,

but fills only when the ignition is in the on

position.

A button located on the instrument panel

controls the system. It operates only when

the ignition is in the accessory or on

position and the air tanks have sufficient

pressure to fill the air springs. When you

turn off the ignition, the suspension

remains in whatever state it was last set.

Pressing and holding the button for two

seconds exhausts air from the air springs,

lowering the frame for loading. Pressing

and holding the button for two seconds

fills the air springs so your vehicle remains

at normal ride height. System Indicator Light

The air suspension indicator light

illuminates when using the button to

release air pressure in the rear air springs.

Never drive your vehicle when the warning

lamp is illuminated and there is low (or no)

air pressure in the springs.

Connecting and Disconnecting a

Trailer with Air Suspension and Air

Suspension Dump Button

When connecting to a trailer:

•

Press and hold the button for two

seconds to exhaust air from the air

suspension system.

• Press and hold the button for two

seconds, and then raise the landing

gear after making the connection to

the trailer.

When disconnecting the trailer:

• Lower the landing gear, and then press

and hold the button for two seconds.

• Disconnect the brake hoses, trailer-side

and rear light connectors, then pull the

release lever on the fifth wheel.

You must fill the air springs before

operating with a trailer or operating in the

bobtail mode.

Suspension Conversions WARNING:

When operating a

loaded vehicle, the driver must keep all

adjustable axles on the ground at all

times, supporting their share of the

vehicle ’s load. Failure to do so can

overload other axles, tires, wheels,

springs, steering components, brakes

and frames, resulting in early component

failure, loss of vehicle control, possible

property damage and personal injury.

169

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Load CarryingE213409

Page 180 of 390

ECONOMICAL DRIVING

Your fuel economy is affected by several

things, such as how you drive, the

conditions you drive under, and how you

maintain your vehicle.

You may improve your fuel economy by

keeping these things in mind:

•

Accelerate and slow down in a smooth,

moderate fashion.

• Drive at steady speeds without

stopping.

• Anticipate stops; slowing down may

eliminate the need to stop.

• Close the windows for high-speed

driving.

• Drive at reasonable speeds. Traveling

at 55 mph (90 km/h) uses 15% less

fuel than traveling at 65 mph

(105 km/h).

• Keep the tires properly inflated and use

only the recommended size.

• Use the recommended engine oil.

• Perform all regularly scheduled

maintenance.

Avoid these actions; they reduce your fuel

economy:

• Sudden accelerations or hard

accelerations.

• Warm up your vehicle on cold

mornings.

• Use the air conditioner.

• Use the speed control in hilly terrain.

• Rest your foot on the brake pedal while

driving.

• Carry unnecessary weight.

Approximately 1 mpg [0.4 km/L] is lost

for every

400 lb (180 kg) of weight

carried.

• Driving with the wheels out of

alignment. Conditions

•

Adding certain accessories to your

vehicle may reduce fuel economy. For

example bug deflectors, rollbars, light

bars, running boards, ski racks or

luggage racks.

• Using fuel blended with alcohol may

lower fuel economy.

• Fuel economy may decrease with lower

temperatures during the first

5–10 mi

(12 –16 km) of driving.

• Driving on flat terrain offers improved

fuel economy as compared to driving

on hilly terrain.

• Transmissions give their best fuel

economy when operated in the top

cruise gear and with steady pressure

on the gas pedal.

COLD WEATHER

PRECAUTIONS

Note: Idling in cold weather does not heat

the engine to its normal operating

temperature. Long periods of idling,

especially in cold weather, can cause a

buildup of deposits which can cause engine

damage.

Changing to a lighter grade engine oil also

makes starting easier under these

conditions. Refer to Engine oil

specifications. See

Capacities and

Specifications (page 288).

Diesel fuel is adjusted seasonally for cold

temperatures. Diesel fuel which has not

been properly formulated for the ambient

conditions may gel which can clog the fuel

filters. One indication that the fuel filter(s)

may be clogged is if the engine starts, stalls

after a short time, and then does not

restart. If you have been using biodiesel,

you may need to use a fuel with lower

biodiesel content, try another brand, or

discontinue using biodiesel. Do not use

177

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Driving Hints

Page 206 of 390

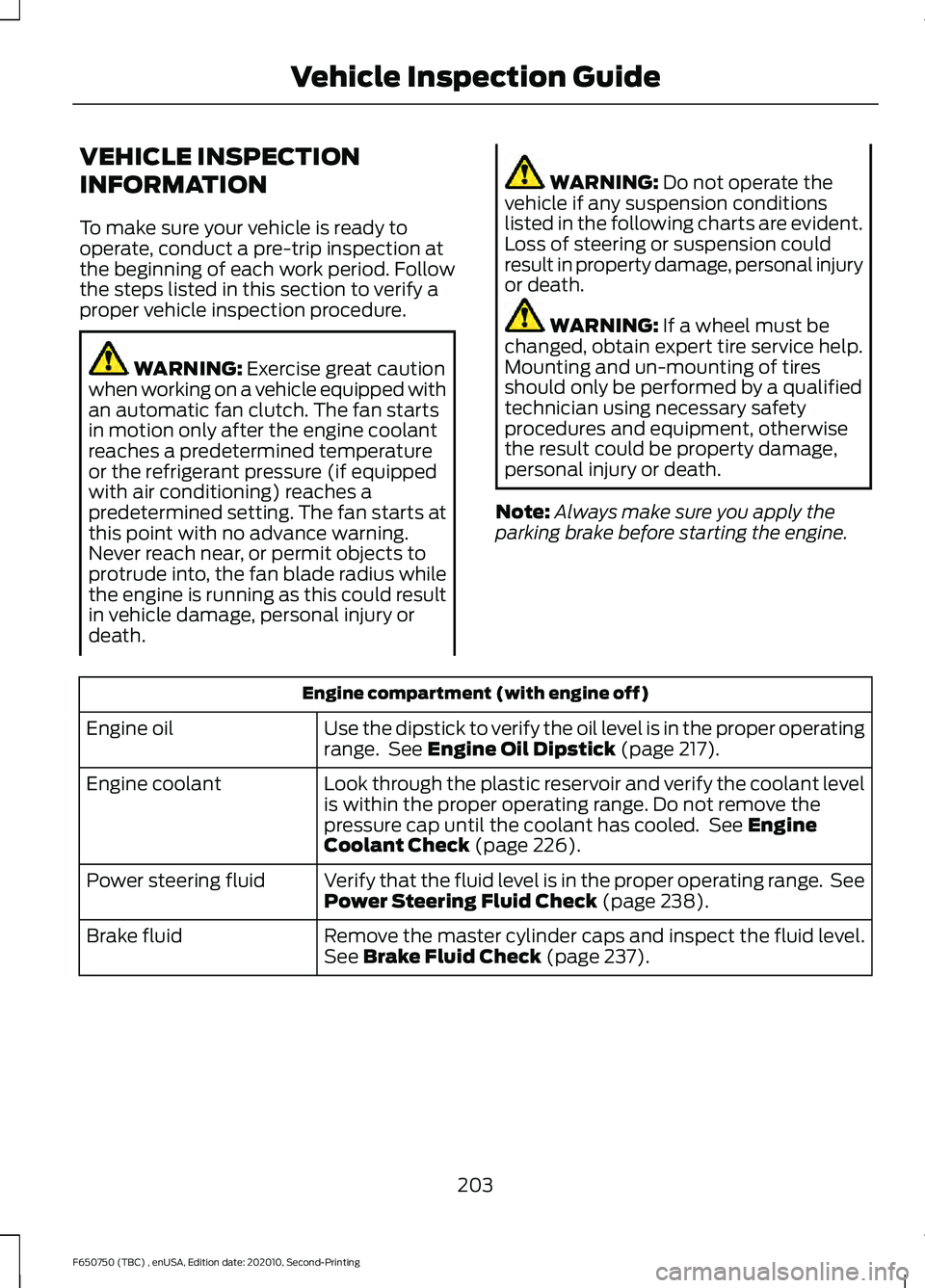

VEHICLE INSPECTION

INFORMATION

To make sure your vehicle is ready to

operate, conduct a pre-trip inspection at

the beginning of each work period. Follow

the steps listed in this section to verify a

proper vehicle inspection procedure.

WARNING: Exercise great caution

when working on a vehicle equipped with

an automatic fan clutch. The fan starts

in motion only after the engine coolant

reaches a predetermined temperature

or the refrigerant pressure (if equipped

with air conditioning) reaches a

predetermined setting. The fan starts at

this point with no advance warning.

Never reach near, or permit objects to

protrude into, the fan blade radius while

the engine is running as this could result

in vehicle damage, personal injury or

death. WARNING:

Do not operate the

vehicle if any suspension conditions

listed in the following charts are evident.

Loss of steering or suspension could

result in property damage, personal injury

or death. WARNING:

If a wheel must be

changed, obtain expert tire service help.

Mounting and un-mounting of tires

should only be performed by a qualified

technician using necessary safety

procedures and equipment, otherwise

the result could be property damage,

personal injury or death.

Note: Always make sure you apply the

parking brake before starting the engine. Engine compartment (with engine off)

Use the dipstick to verify the oil level is in the proper operating

range. See

Engine Oil Dipstick (page 217).

Engine oil

Look through the plastic reservoir and verify the coolant level

is within the proper operating range. Do not remove the

pressure cap until the coolant has cooled. See

Engine

Coolant Check (page 226).

Engine coolant

Verify that the fluid level is in the proper operating range. See

Power Steering Fluid Check

(page 238).

Power steering fluid

Remove the master cylinder caps and inspect the fluid level.

See

Brake Fluid Check (page 237).

Brake fluid

203

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Vehicle Inspection Guide

Page 236 of 390

3. Refill with prediluted coolant as soon

as possible.

Water alone, without prediluted coolant,

can cause engine damage from corrosion,

overheating or freezing.

Do not use the following as a coolant

substitute:

• Alcohol.

• Methanol.

• Brine.

• Any coolant mixed with alcohol or

methanol antifreeze.

Alcohol and other liquids can cause engine

damage from overheating or freezing.

Do not add extra inhibitors or non-specified

additives to the coolant. These can be

harmful and compromise the corrosion

protection of the coolant.

Engine and Secondary Cooling

System Refill Procedure

The following procedure should be used

when refilling the engine or secondary

cooling systems after it has been drained

or become extremely low:

1. Before you remove the cap, turn the engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the cap. Slowly turn cap

counterclockwise until pressure begins

to release.

3. Step back when the pressure releases.

4. When you are sure that all the pressure

has been released, use the cloth to turn

the cap counterclockwise and then

remove it.

5. Slowly add prediluted engine coolant to the coolant reservoir until the

coolant level is within the minimum

and maximum range as listed on the

reservoir.

6. Reinstall the pressure relief cap. 7. Start and run the engine at 2000 rpm

for 2 minutes.

8. Shut engine off, and remove the pressure relief cap as previously

outlined.

9. If required, add prediluted engine coolant to the coolant reservoir until

the coolant level is within the minimum

and maximum range as listed on the

reservoir.

10. Engine cooling system: Repeat steps

5 through 9 until the coolant level has

stabilized (is no longer dropping after

each step) and the upper radiator

hose at the radiator is warm to the

touch (indicating that the engine

thermostat is open and coolant is

flowing through the radiator).

11. Check the secondary cooling system.

Repeat steps 1 through 10 until the

coolant level has stabilized (is no

longer dropping after each step) and

the lower passenger side of the

secondary radiator is warm to the

touch (indicating secondary

thermostat is open and coolant is

flowing through the entire system).

12. Check the coolant level in both systems before you drive your vehicle

the next few times.

13. If necessary, add prediluted engine coolant to the coolant reservoirs until

the coolant level is within the

minimum and maximum range as

listed on the reservoir. After any

coolant has been added, check the

coolant concentration.

Recycled Coolant

We do not recommend the use of recycled

coolant as an approved recycling process

is not yet available.

233

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Maintenance

Page 254 of 390

inspection and keep to instructions

provided by the service manual.

Hydraulic brake systems are

power-assisted. There is a great

reduction in braking capabilities

without engine assist.

• Proper fluid level. The level should be

at the bottom edge of the ring on each

reservoir fill port. Do not fill the master

cylinder to the top of the reservoir. If

fluid level requires attention to

maintain a proper master cylinder level,

this is an indication of either severe

operation (pad wear) or fluid leakage.

A more frequent and thorough brake

inspection is required.

• Brake lines, hoses and fittings. Repair

or replace brake line tubes, hoses or

fittings as required. Inspect these

components every 4,000 mi

(6,000 km) for the following.

• Lines for kinks, dents, corrosion or

rupture.

• Hoses for abrasions, kinks, soft

spots or rupture, collapse, cracks,

twists or loose frame supports.

When replacing a hose, be sure

there is adequate clearance to the

hose to avoid an abrasion to the

new hose.

• All connections for leaks.

Driveline Parking Brake WARNING: Use wheel chocks and

exercise caution when inspecting under

the vehicle. A vehicle roll-away could

result in property damage, personal injury

or death.

A qualified technician should adjust the

parking brake and keep to the instructions

in the service manual. AXLE INSPECTION

Front Axle

Maintaining the front axle alignment to

specifications is very important. A qualified

technician should check and maintain the

alignment.

Regular inspections should include:

•

Toe-in inspection and adjustment (if

necessary), particularly with radial

tires.

• Checking for proper tightness of axle

mounting U-bolt nuts, attaching or

mounting bolts and nuts.

• Checking the axle for damage, binding,

worn parts and adequate lubrication.

• Checking the kingpins for excessive

wear. Also, perform this check during

other scheduled maintenance, for

example as tire rotation or service,

wheel bearing service and alignment.

See the workshop manual for proper

procedures.

Toe-in

It is essential to maintain correct toe-in

and tire pressure for optimum tire wear.

Inspecting steer axle tires in the first

3,000– 10,000 mi (5,000– 16,000 km)

generally shows if tires are wearing

normally.

Rapid outside shoulder wear on both tires

indicates too much toe-in.

Rapid inside shoulder wear on both tires

indicates too much toe-out.

In P&D-type service, there can be a

left-to-right steer tire tread life differential

up to 40% depending on routes and other

variables.

251

F650750 (TBC) , enUSA, Edition date: 202010, Second-Printing Maintenance