check engine FORD F750 2000 10.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2000, Model line: F750, Model: FORD F750 2000 10.GPages: 208, PDF Size: 1.08 MB

Page 145 of 208

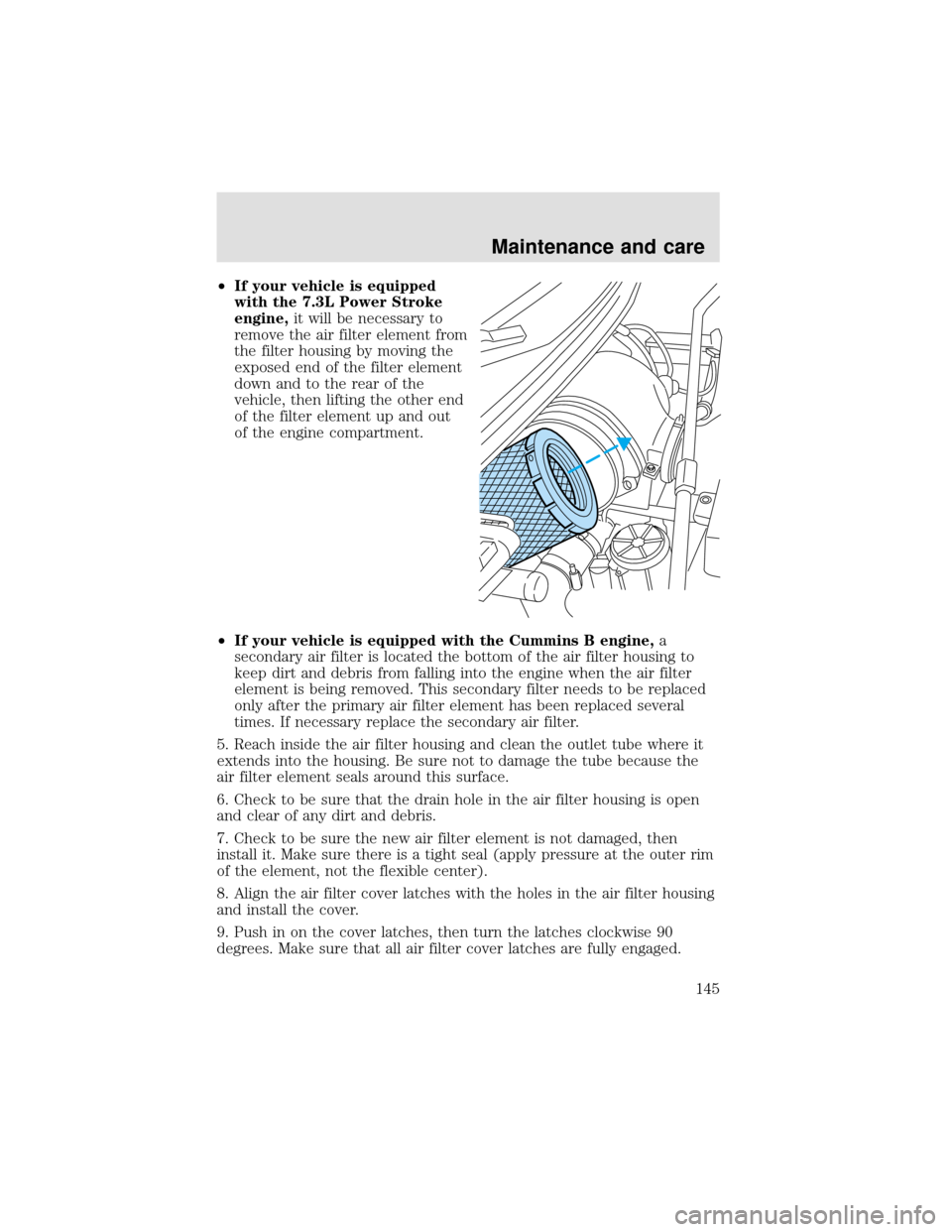

•If your vehicle is equipped

with the 7.3L Power Stroke

engine,it will be necessary to

remove the air filter element from

the filter housing by moving the

exposed end of the filter element

down and to the rear of the

vehicle, then lifting the other end

of the filter element up and out

of the engine compartment.

•If your vehicle is equipped with the Cummins B engine,a

secondary air filter is located the bottom of the air filter housing to

keep dirt and debris from falling into the engine when the air filter

element is being removed. This secondary filter needs to be replaced

only after the primary air filter element has been replaced several

times. If necessary replace the secondary air filter.

5. Reach inside the air filter housing and clean the outlet tube where it

extends into the housing. Be sure not to damage the tube because the

air filter element seals around this surface.

6. Check to be sure that the drain hole in the air filter housing is open

and clear of any dirt and debris.

7. Check to be sure the new air filter element is not damaged, then

install it. Make sure there is a tight seal (apply pressure at the outer rim

of the element, not the flexible center).

8. Align the air filter cover latches with the holes in the air filter housing

and install the cover.

9. Push in on the cover latches, then turn the latches clockwise 90

degrees. Make sure that all air filter cover latches are fully engaged.

Maintenance and care

145

Page 147 of 208

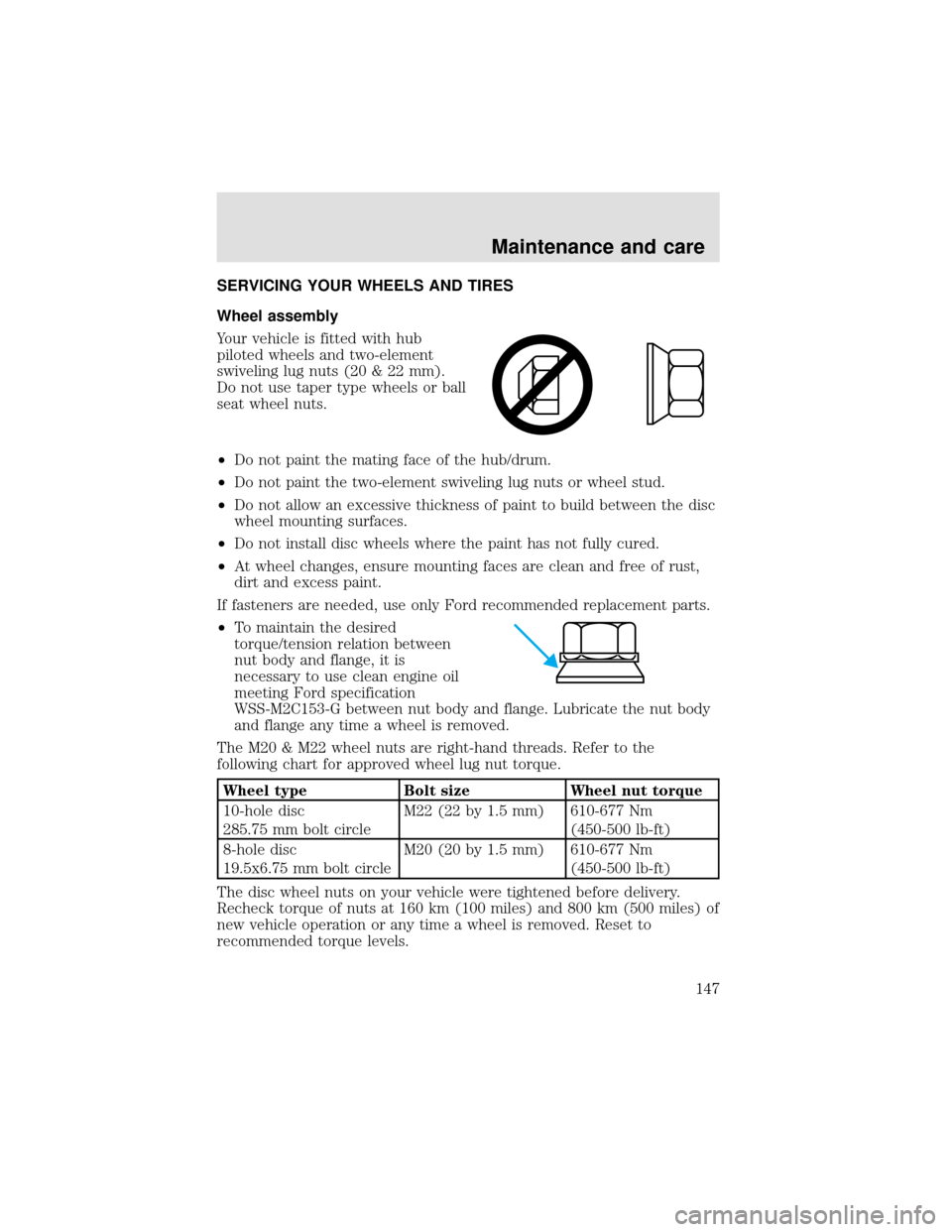

SERVICING YOUR WHEELS AND TIRES

Wheel assembly

Your vehicle is fitted with hub

piloted wheels and two-element

swiveling lug nuts (20 & 22 mm).

Do not use taper type wheels or ball

seat wheel nuts.

•Do not paint the mating face of the hub/drum.

•Do not paint the two-element swiveling lug nuts or wheel stud.

•Do not allow an excessive thickness of paint to build between the disc

wheel mounting surfaces.

•Do not install disc wheels where the paint has not fully cured.

•At wheel changes, ensure mounting faces are clean and free of rust,

dirt and excess paint.

If fasteners are needed, use only Ford recommended replacement parts.

•To maintain the desired

torque/tension relation between

nut body and flange, it is

necessary to use clean engine oil

meeting Ford specification

WSS-M2C153-G between nut body and flange. Lubricate the nut body

and flange any time a wheel is removed.

The M20 & M22 wheel nuts are right-hand threads. Refer to the

following chart for approved wheel lug nut torque.

Wheel type Bolt size Wheel nut torque

10-hole disc

285.75 mm bolt circleM22 (22 by 1.5 mm) 610-677 Nm

(450-500 lb-ft)

8-hole disc

19.5x6.75 mm bolt circleM20 (20 by 1.5 mm) 610-677 Nm

(450-500 lb-ft)

The disc wheel nuts on your vehicle were tightened before delivery.

Recheck torque of nuts at 160 km (100 miles) and 800 km (500 miles) of

new vehicle operation or any time a wheel is removed. Reset to

recommended torque levels.

Maintenance and care

147

Page 155 of 208

Draining the fuel filter/water separator—Cummins B engine

Refer to your engine operator’s manual for service procedures.

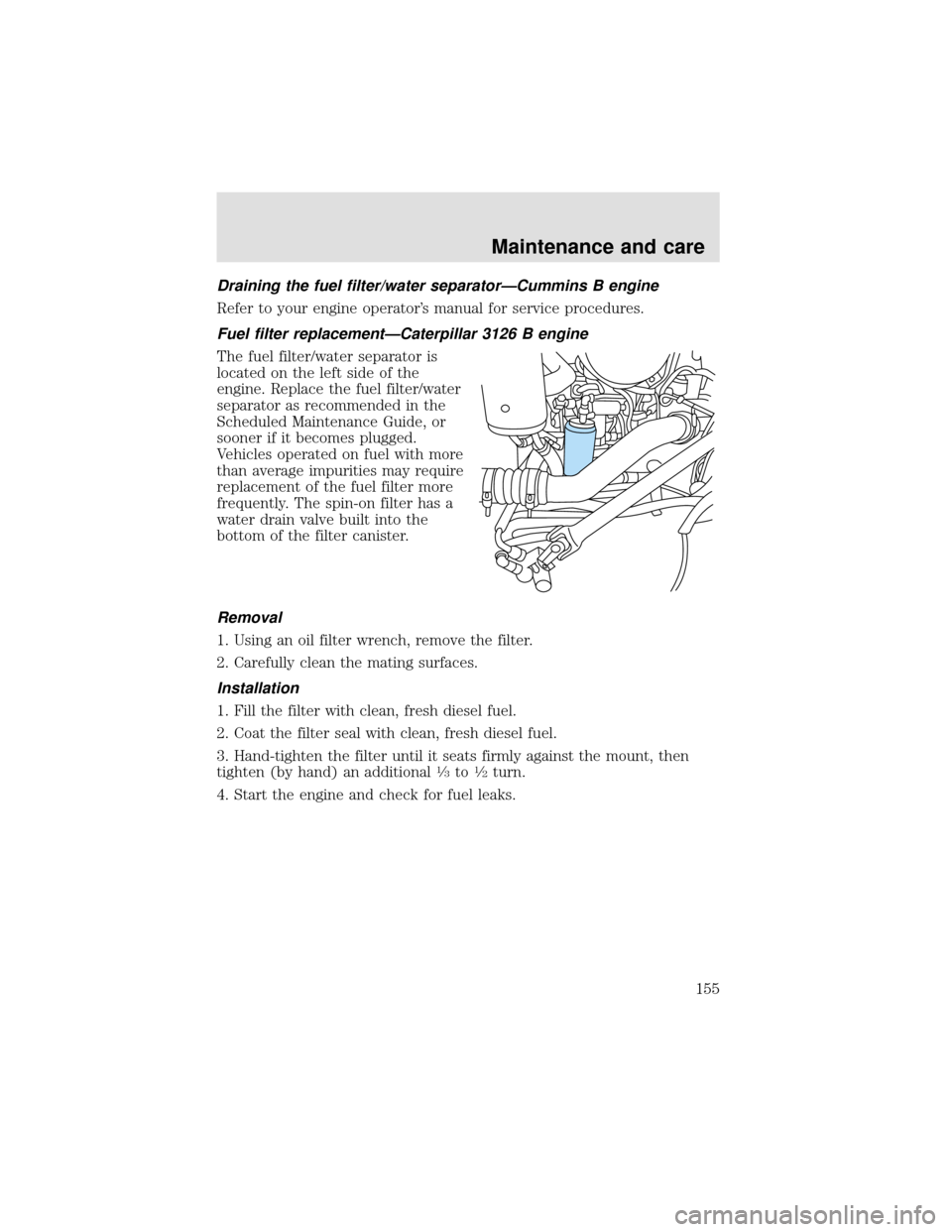

Fuel filter replacement—Caterpillar 3126 B engine

The fuel filter/water separator is

located on the left side of the

engine. Replace the fuel filter/water

separator as recommended in the

Scheduled Maintenance Guide, or

sooner if it becomes plugged.

Vehicles operated on fuel with more

than average impurities may require

replacement of the fuel filter more

frequently. The spin-on filter has a

water drain valve built into the

bottom of the filter canister.

Removal

1. Using an oil filter wrench, remove the filter.

2. Carefully clean the mating surfaces.

Installation

1. Fill the filter with clean, fresh diesel fuel.

2. Coat the filter seal with clean, fresh diesel fuel.

3. Hand-tighten the filter until it seats firmly against the mount, then

tighten (by hand) an additional

1⁄3to1⁄2turn.

4. Start the engine and check for fuel leaks.

Maintenance and care

155

Page 157 of 208

Installation

The engine will not run properly if the fuel filter is not installed

in housing.

1. Apply a coating of clean diesel fuel to the new bevel gasket and install

it onto the fuel filter housing.

2. Install the new fuel filter element onto the cap. Place the new fuel

filter element and cap into the fuel filter housing. Allow fuel to soak into

the fuel filter element.

3. Tighten cap onto the fuel filter housing until cap contacts the housing.

4. Start the engine and check for fuel leaks.

After changing the fuel filter, the engine will purge the trapped air as it

runs. Engine may run roughly and smoke until the air is completely

eliminated.

Fuel filter replacement—Cummins B engine

Refer to your engine operator’s manual for service intervals and

procedures.

ESSENTIALS OF GOOD FUEL ECONOMY

Measuring techniques

Your best source of information about actual fuel economy is you, the

driver. You must gather information as accurately and consistently as

possible. Fuel expense, frequency of fillups or fuel gauge readings are

NOT accurate as a measure of fuel economy. We do not recommend

taking fuel economy measurements during the first 1 600 km (1 000

miles) of driving (engine break-in period). You will get a more accurate

measurement after 3 000 km–5 000 km (2 000 miles-3 000 miles).

The advertised fuel capacity of the fuel tank(s) on your vehicle is equal

to the rated refill capacity of the fuel tank(s) as listed inFuel Tank

Capacitiesin theCapacities and Specificationschapter. The

advertised capacity is the amount of the Indicated Capacity and the

Empty Reserve combined. Indicated Capacity is the difference in the

amount of fuel in a full tank and a tank when the fuel gauge indicates

empty. Empty Reserve is the small amount of usable fuel remaining in

the fuel tank after the fuel gauge indicates empty.

Maintenance and care

157

Page 163 of 208

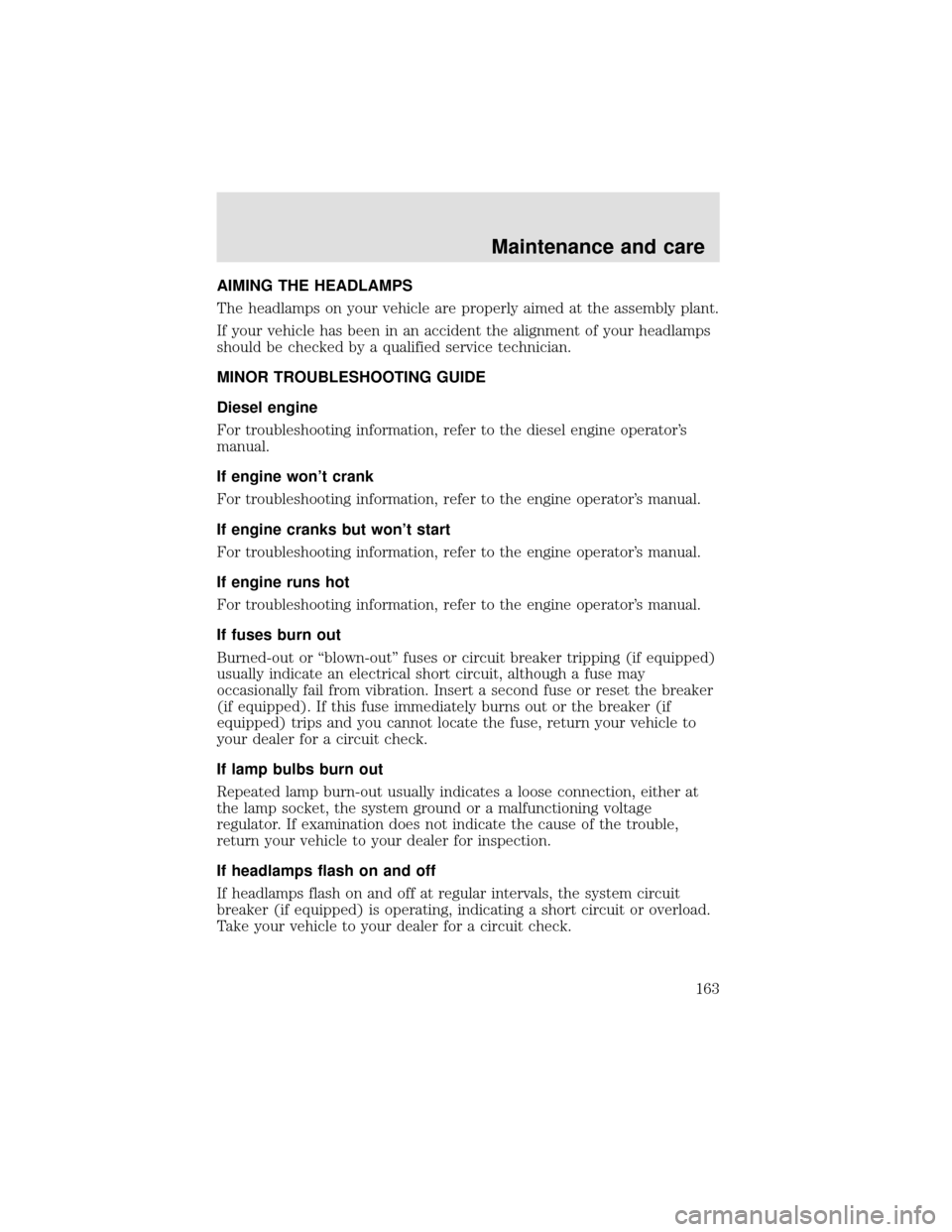

AIMING THE HEADLAMPS

The headlamps on your vehicle are properly aimed at the assembly plant.

If your vehicle has been in an accident the alignment of your headlamps

should be checked by a qualified service technician.

MINOR TROUBLESHOOTING GUIDE

Diesel engine

For troubleshooting information, refer to the diesel engine operator’s

manual.

If engine won’t crank

For troubleshooting information, refer to the engine operator’s manual.

If engine cranks but won’t start

For troubleshooting information, refer to the engine operator’s manual.

If engine runs hot

For troubleshooting information, refer to the engine operator’s manual.

If fuses burn out

Burned-out or“blown-out”fuses or circuit breaker tripping (if equipped)

usually indicate an electrical short circuit, although a fuse may

occasionally fail from vibration. Insert a second fuse or reset the breaker

(if equipped). If this fuse immediately burns out or the breaker (if

equipped) trips and you cannot locate the fuse, return your vehicle to

your dealer for a circuit check.

If lamp bulbs burn out

Repeated lamp burn-out usually indicates a loose connection, either at

the lamp socket, the system ground or a malfunctioning voltage

regulator. If examination does not indicate the cause of the trouble,

return your vehicle to your dealer for inspection.

If headlamps flash on and off

If headlamps flash on and off at regular intervals, the system circuit

breaker (if equipped) is operating, indicating a short circuit or overload.

Take your vehicle to your dealer for a circuit check.

Maintenance and care

163

Page 168 of 208

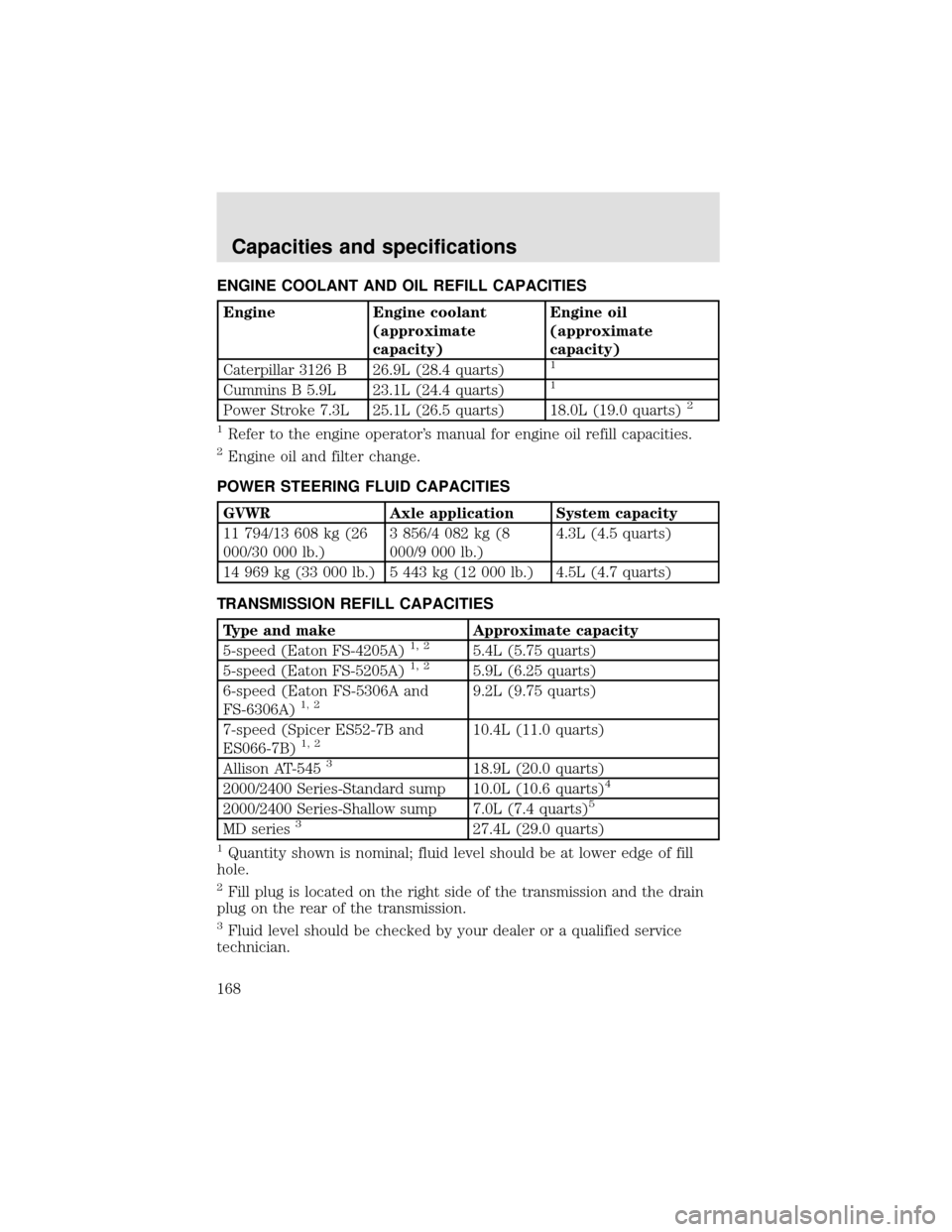

ENGINE COOLANT AND OIL REFILL CAPACITIES

Engine Engine coolant

(approximate

capacity)Engine oil

(approximate

capacity)

Caterpillar 3126 B 26.9L (28.4 quarts)

1

Cummins B 5.9L 23.1L (24.4 quarts)1

Power Stroke 7.3L 25.1L (26.5 quarts) 18.0L (19.0 quarts)2

1

Refer to the engine operator’s manual for engine oil refill capacities.

2Engine oil and filter change.

POWER STEERING FLUID CAPACITIES

GVWR Axle application System capacity

11 794/13 608 kg (26

000/30 000 lb.)3 856/4 082 kg (8

000/9 000 lb.)4.3L (4.5 quarts)

14 969 kg (33 000 lb.) 5 443 kg (12 000 lb.) 4.5L (4.7 quarts)

TRANSMISSION REFILL CAPACITIES

Type and make Approximate capacity

5-speed (Eaton FS-4205A)1, 25.4L (5.75 quarts)

5-speed (Eaton FS-5205A)1, 25.9L (6.25 quarts)

6-speed (Eaton FS-5306A and

FS-6306A)

1, 29.2L (9.75 quarts)

7-speed (Spicer ES52-7B and

ES066-7B)

1, 210.4L (11.0 quarts)

Allison AT-545

318.9L (20.0 quarts)

2000/2400 Series-Standard sump 10.0L (10.6 quarts)4

2000/2400 Series-Shallow sump 7.0L (7.4 quarts)5

MD series327.4L (29.0 quarts)

1Quantity shown is nominal; fluid level should be at lower edge of fill

hole.

2Fill plug is located on the right side of the transmission and the drain

plug on the rear of the transmission.

3Fluid level should be checked by your dealer or a qualified service

technician.

Capacities and specifications

168

Page 175 of 208

GENERAL MAINTENANCE INFORMATION

The Scheduled Maintenance Services listed in this section are required

because they are considered essential to the life and performance of

your vehicle.

Ford Motor Company recommends you perform the Owner Maintenance

Services listed in this section. These services are matters of day-to-day

care that are important to the proper operation of your vehicle. In

addition to the conditions described in the Owner Maintenance Checklist,

be alert for any unusual noise, vibration or other indication that your

vehicle may need service and attend to it promptly.

Use only recommended fuels, lubricants, fluids and service parts

conforming to Ford specifications. Motorcraft parts are designed and

built for best performance in your vehicle. Using these parts for

replacement is your assurance that Ford-Built quality stays in your

vehicle.

SCHEDULED MAINTENANCE

The maintenance or replacement of the emission control devices (or

systems) in your new Ford Motor Company vehicle (or engine) may be

performed at your expense. These services may be performed by any

automotive repair establishment or individual using automotive parts

equivalent to those with which your vehicle or engine was originally

equipped. If any parts other than Ford, Motorcraft, or Ford authorized,

remanufactured parts are used for maintenance replacements (or for the

service) of components effecting the emission control, the owner should

be assured that such parts are warranted by their manufacturer to be

equivalent to genuine Ford Motor Company Parts in performance and

durability. Please consult your warranty information booklet for complete

warranty information.

Authorized dealer maintenance

Your authorized dealer specializes in knowing all about Ford Motor

Company vehicles rather than knowing a little about all makes.

There are Ford or Ford of Canada dealer service shops ready to serve

you wherever you drive in the U.S. or Canada. They stock Ford and

Motorcraft parts, and Ford Chemicals and lubricants. You can be

confident that these meet the same exacting design and quality

standards as those used to build the vehicle originally. Dealer Service

Technicians have available training in the latest product developments

and service techniques.

General maintenance information

175

Page 178 of 208

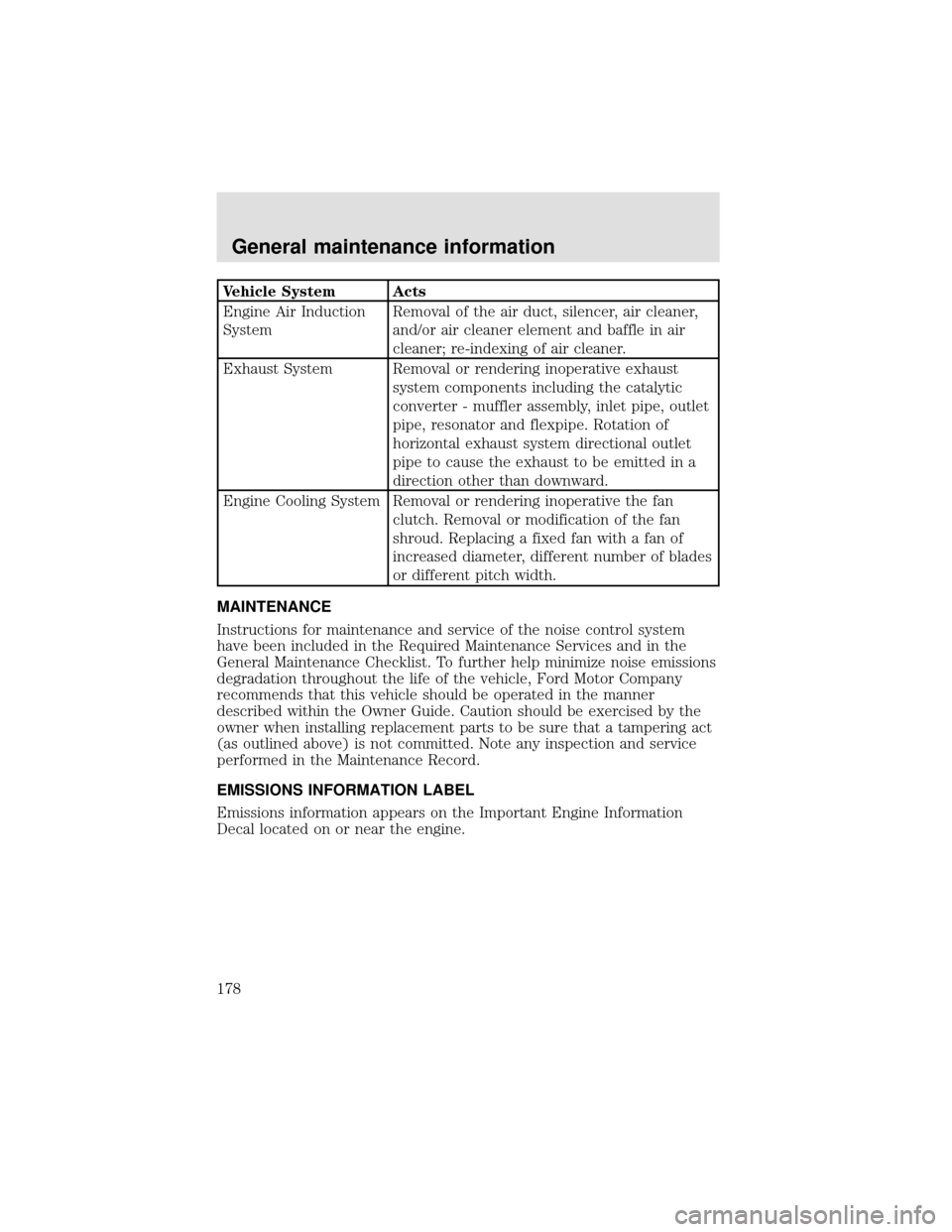

Vehicle System Acts

Engine Air Induction

SystemRemoval of the air duct, silencer, air cleaner,

and/or air cleaner element and baffle in air

cleaner; re-indexing of air cleaner.

Exhaust System Removal or rendering inoperative exhaust

system components including the catalytic

converter - muffler assembly, inlet pipe, outlet

pipe, resonator and flexpipe. Rotation of

horizontal exhaust system directional outlet

pipe to cause the exhaust to be emitted in a

direction other than downward.

Engine Cooling System Removal or rendering inoperative the fan

clutch. Removal or modification of the fan

shroud. Replacing a fixed fan with a fan of

increased diameter, different number of blades

or different pitch width.

MAINTENANCE

Instructions for maintenance and service of the noise control system

have been included in the Required Maintenance Services and in the

General Maintenance Checklist. To further help minimize noise emissions

degradation throughout the life of the vehicle, Ford Motor Company

recommends that this vehicle should be operated in the manner

described within the Owner Guide. Caution should be exercised by the

owner when installing replacement parts to be sure that a tampering act

(as outlined above) is not committed. Note any inspection and service

performed in the Maintenance Record.

EMISSIONS INFORMATION LABEL

Emissions information appears on the Important Engine Information

Decal located on or near the engine.

General maintenance information

178

Page 182 of 208

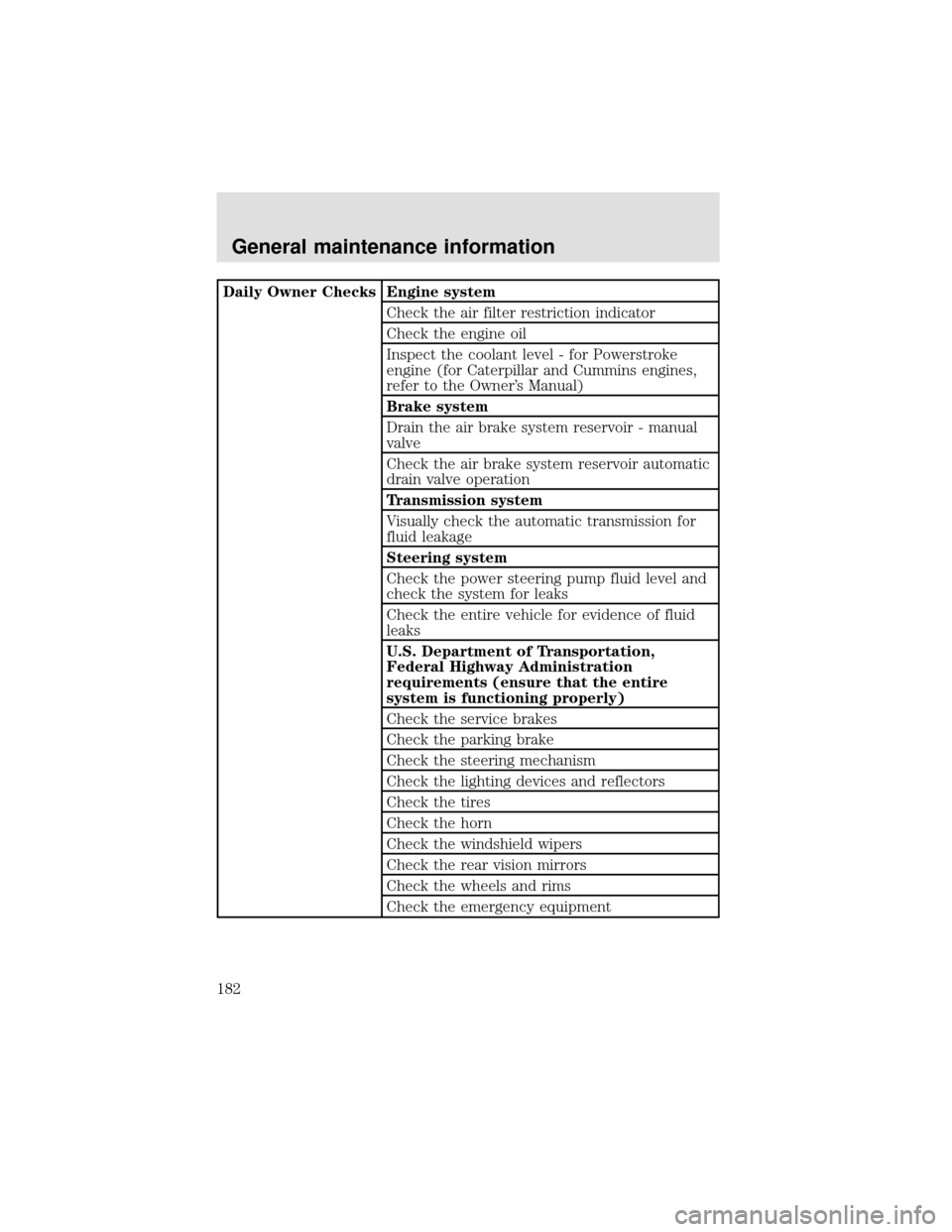

Daily Owner Checks Engine system

Check the air filter restriction indicator

Check the engine oil

Inspect the coolant level - for Powerstroke

engine (for Caterpillar and Cummins engines,

refer to the Owner’s Manual)

Brake system

Drain the air brake system reservoir - manual

valve

Check the air brake system reservoir automatic

drain valve operation

Transmission system

Visually check the automatic transmission for

fluid leakage

Steering system

Check the power steering pump fluid level and

check the system for leaks

Check the entire vehicle for evidence of fluid

leaks

U.S. Department of Transportation,

Federal Highway Administration

requirements (ensure that the entire

system is functioning properly)

Check the service brakes

Check the parking brake

Check the steering mechanism

Check the lighting devices and reflectors

Check the tires

Check the horn

Check the windshield wipers

Check the rear vision mirrors

Check the wheels and rims

Check the emergency equipment

General maintenance information

182

Page 183 of 208

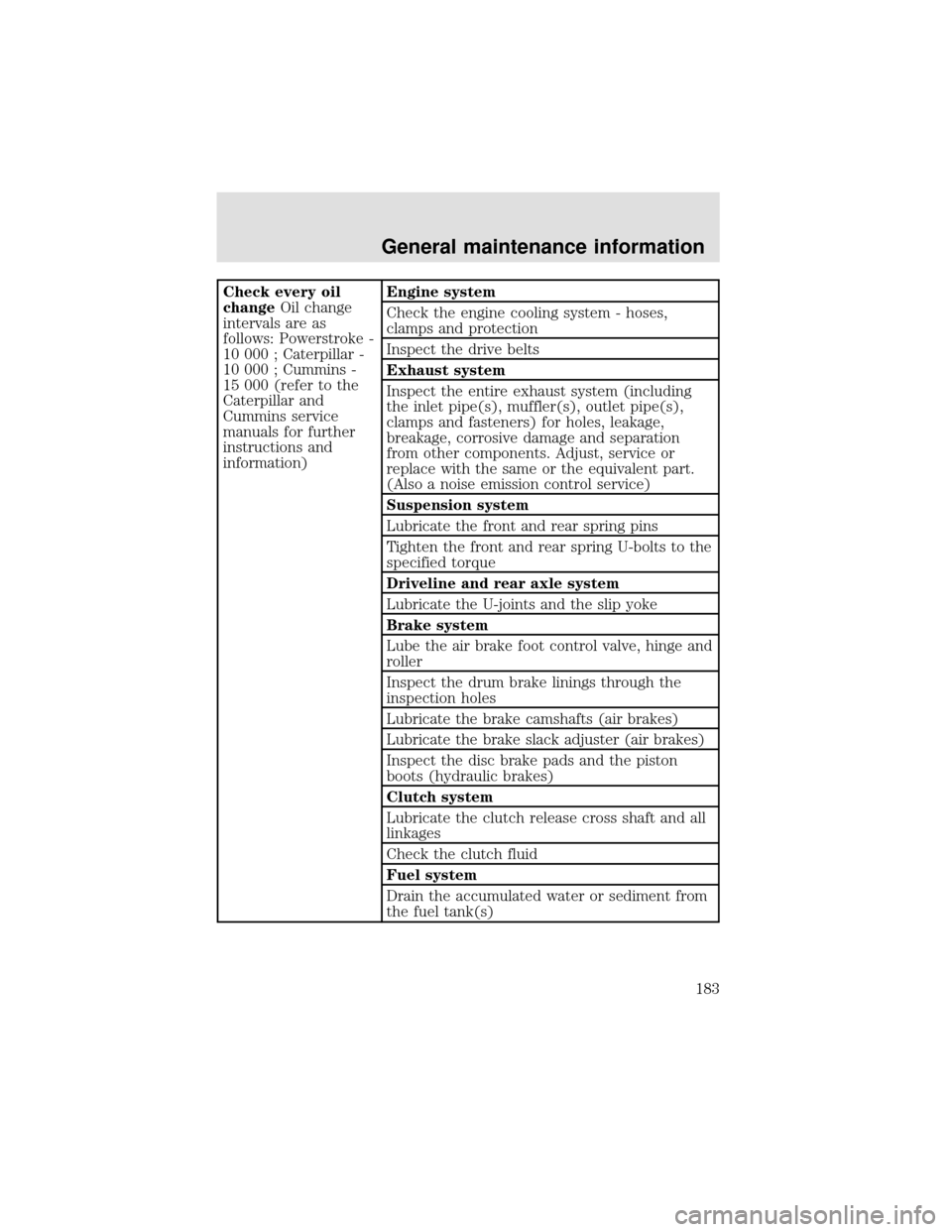

Check every oil

changeOil change

intervals are as

follows: Powerstroke -

10 000 ; Caterpillar -

10 000 ; Cummins -

15 000 (refer to the

Caterpillar and

Cummins service

manuals for further

instructions and

information)Engine system

Check the engine cooling system - hoses,

clamps and protection

Inspect the drive belts

Exhaust system

Inspect the entire exhaust system (including

the inlet pipe(s), muffler(s), outlet pipe(s),

clamps and fasteners) for holes, leakage,

breakage, corrosive damage and separation

from other components. Adjust, service or

replace with the same or the equivalent part.

(Also a noise emission control service)

Suspension system

Lubricate the front and rear spring pins

Tighten the front and rear spring U-bolts to the

specified torque

Driveline and rear axle system

Lubricate the U-joints and the slip yoke

Brake system

Lube the air brake foot control valve, hinge and

roller

Inspect the drum brake linings through the

inspection holes

Lubricate the brake camshafts (air brakes)

Lubricate the brake slack adjuster (air brakes)

Inspect the disc brake pads and the piston

boots (hydraulic brakes)

Clutch system

Lubricate the clutch release cross shaft and all

linkages

Check the clutch fluid

Fuel system

Drain the accumulated water or sediment from

the fuel tank(s)

General maintenance information

183