FORD F750 2001 10.G Owners Manual

Manufacturer: FORD, Model Year: 2001, Model line: F750, Model: FORD F750 2001 10.GPages: 240, PDF Size: 1.3 MB

Page 211 of 240

SCHEDULED MAINTENANCE SERVICES

Maintenance service adjustments must conform to specifications

contained in this manual, and those shown on the Important Engine

Information Decal. The following services are to be performed at

scheduled intervals because they are considered essential to the life and

performance of your vehicle. Ford recommends that you perform

maintenance on all designated items to achieve best vehicle operation.

Scheduled maintenance beyond 160 930 km (100 000 miles) should be

continued as before 160 930 km (100 000 miles).

SPECIAL OPERATING CONDITIONS

If your driving habitsfrequentlyinclude one or more the following

conditions:

²Short trips oflessthan 16 km (ten miles) when outside temperatures

remain below freezing.

²Operating duringhot weatherin stop-and-go ªrush hourº traffic.

²Operating in severe dust conditions.

²Extensive idling, or low speed operation such as door-to-door delivery

service.

²High speed operation with a fully loaded vehicle (max. GVW).

²Snowplowing.

Perform the following:

²Change engine oil and oil filter every three months, 8 000 km

(5 000 miles) or 125 hours of engine service.

²If operating in severe dust conditions, replace the air cleaner filter

more often than regular intervals as determined by the air filter

restriction indicator. Make sure that the air filter restriction indicator

is in good working order.

²Lube the manual transmission and the rear axle every 48 279 km

(30 000 miles) or 6 months, whichever comes first.

²See the Allison, Cummins and Caterpillar Operator's Manual.

General maintenance information

211

Page 212 of 240

AIR BRAKE ADJUSTMENT

Failure to maintain proper air brake adjustment can result in

reduction or loss of braking ability.

Air brake inspection and adjustment should be performed by a qualified

service technician in accordance with the instructions in the Ford Truck

Service Manual.

Cam brakes - automatic slack adjusters

Inspect standard air brakes equipped with automatic slack adjusters for

proper brake adjustment every four months or 32 000 km (20 000 miles)

whichever occurs first.

However, more frequent inspection is required if your vehicle's brakes

are subjected to heavy use or adverse operating conditions such as:

²Frequent brake applications while fully loaded.

²Operation on hilly or mountainous terrain.

²Frequent operation on dirt, gravel or mud.

Some aftermarket brake linings also require more frequent inspections.

General maintenance information

212

Page 213 of 240

SCHEDULED MAINTENANCE GUIDE

MAINTENANCE SERVICES AND RECORD RETENTION

The maintenance record form which follows is for your convenience. In addition to recording the services performed, you should

retain copies of your receipts for the services. You also should keep records of any emission control systems maintenance

services performed on your vehicle.

Maintenance Record

Warranty

Start Date ______________________________________ Engine Displacement ______________________________________

Vehicle

Identification

Number _________________________________________ Owner Name ___________________________________________

IMPORTANT — This document should remain with the vehicle at all times.

General maintenance information

213

Page 214 of 240

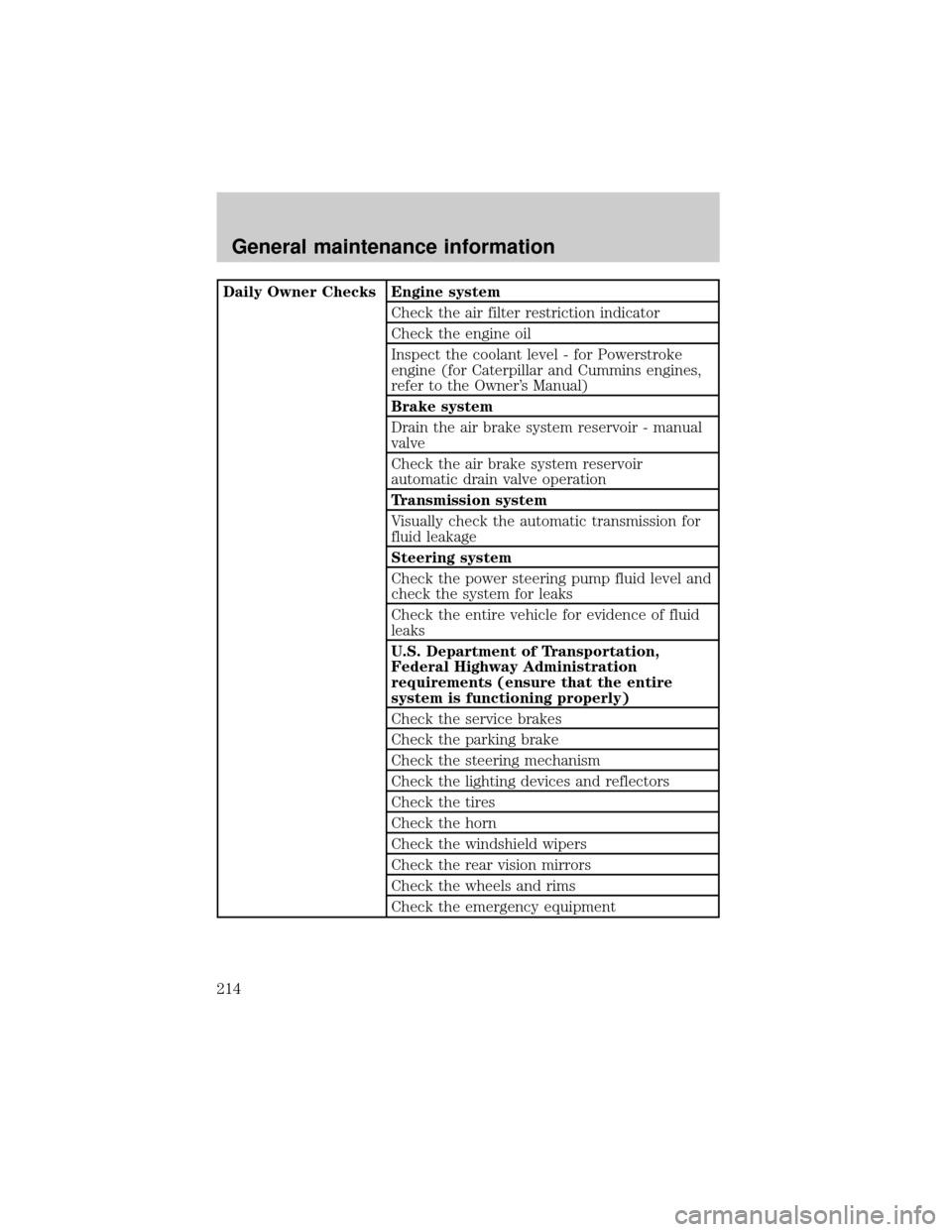

Daily Owner Checks Engine system

Check the air filter restriction indicator

Check the engine oil

Inspect the coolant level - for Powerstroke

engine (for Caterpillar and Cummins engines,

refer to the Owner's Manual)

Brake system

Drain the air brake system reservoir - manual

valve

Check the air brake system reservoir

automatic drain valve operation

Transmission system

Visually check the automatic transmission for

fluid leakage

Steering system

Check the power steering pump fluid level and

check the system for leaks

Check the entire vehicle for evidence of fluid

leaks

U.S. Department of Transportation,

Federal Highway Administration

requirements (ensure that the entire

system is functioning properly)

Check the service brakes

Check the parking brake

Check the steering mechanism

Check the lighting devices and reflectors

Check the tires

Check the horn

Check the windshield wipers

Check the rear vision mirrors

Check the wheels and rims

Check the emergency equipment

General maintenance information

214

Page 215 of 240

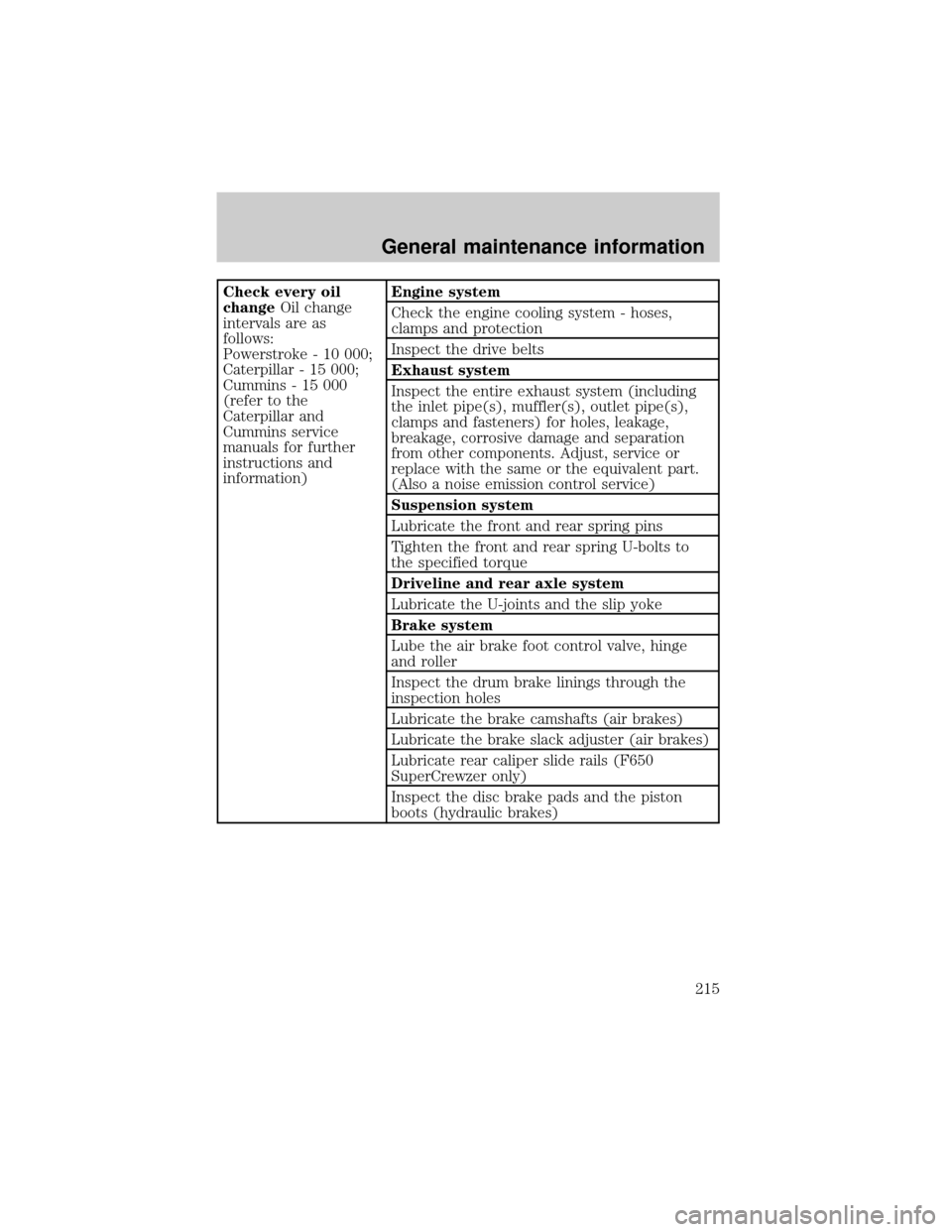

Check every oil

changeOil change

intervals are as

follows:

Powerstroke - 10 000;

Caterpillar - 15 000;

Cummins - 15 000

(refer to the

Caterpillar and

Cummins service

manuals for further

instructions and

information)Engine system

Check the engine cooling system - hoses,

clamps and protection

Inspect the drive belts

Exhaust system

Inspect the entire exhaust system (including

the inlet pipe(s), muffler(s), outlet pipe(s),

clamps and fasteners) for holes, leakage,

breakage, corrosive damage and separation

from other components. Adjust, service or

replace with the same or the equivalent part.

(Also a noise emission control service)

Suspension system

Lubricate the front and rear spring pins

Tighten the front and rear spring U-bolts to

the specified torque

Driveline and rear axle system

Lubricate the U-joints and the slip yoke

Brake system

Lube the air brake foot control valve, hinge

and roller

Inspect the drum brake linings through the

inspection holes

Lubricate the brake camshafts (air brakes)

Lubricate the brake slack adjuster (air brakes)

Lubricate rear caliper slide rails (F650

SuperCrewzer only)

Inspect the disc brake pads and the piston

boots (hydraulic brakes)

General maintenance information

215

Page 216 of 240

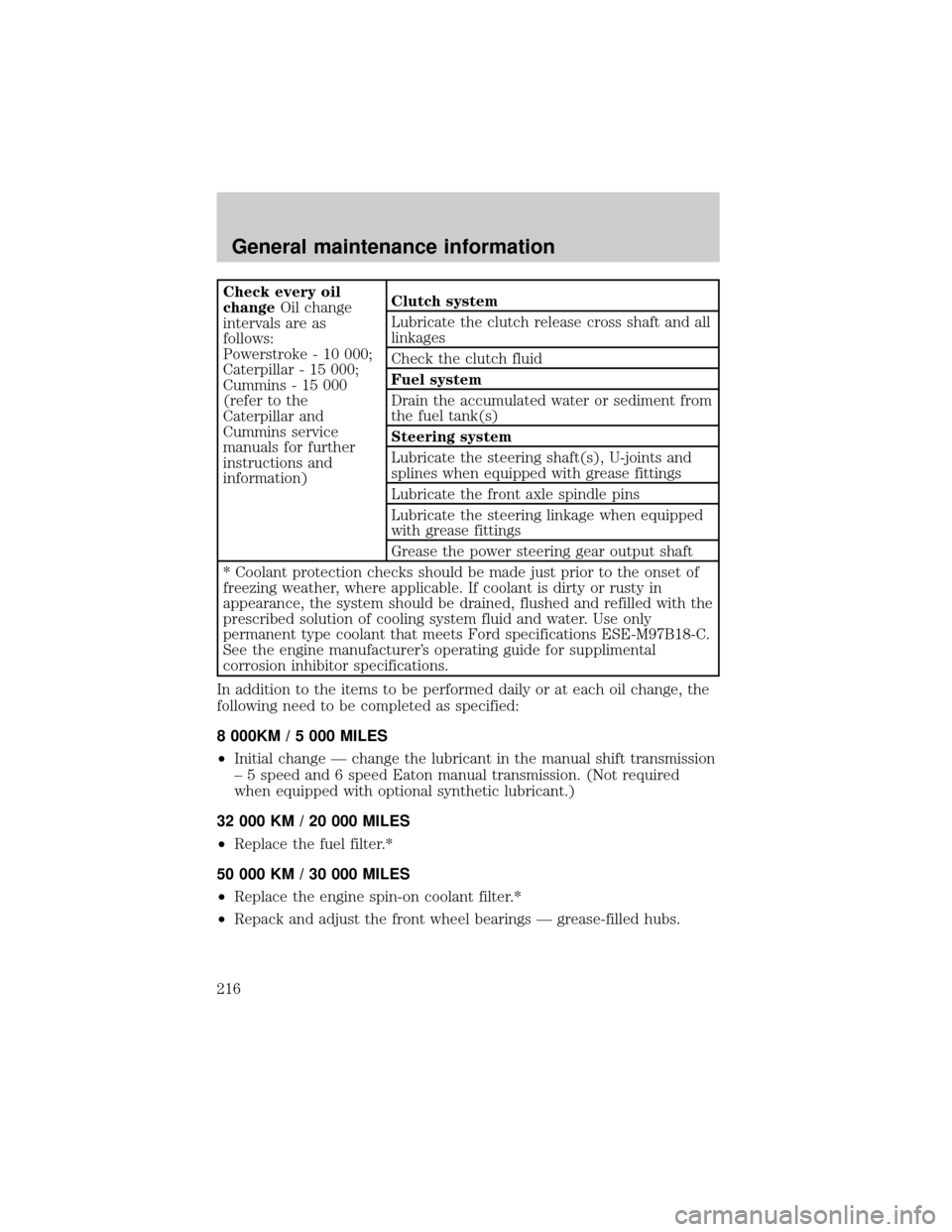

Check every oil

changeOil change

intervals are as

follows:

Powerstroke - 10 000;

Caterpillar - 15 000;

Cummins - 15 000

(refer to the

Caterpillar and

Cummins service

manuals for further

instructions and

information)Clutch system

Lubricate the clutch release cross shaft and all

linkages

Check the clutch fluid

Fuel system

Drain the accumulated water or sediment from

the fuel tank(s)

Steering system

Lubricate the steering shaft(s), U-joints and

splines when equipped with grease fittings

Lubricate the front axle spindle pins

Lubricate the steering linkage when equipped

with grease fittings

Grease the power steering gear output shaft

* Coolant protection checks should be made just prior to the onset of

freezing weather, where applicable. If coolant is dirty or rusty in

appearance, the system should be drained, flushed and refilled with the

prescribed solution of cooling system fluid and water. Use only

permanent type coolant that meets Ford specifications ESE-M97B18-C.

See the engine manufacturer's operating guide for supplimental

corrosion inhibitor specifications.

In addition to the items to be performed daily or at each oil change, the

following need to be completed as specified:

8 000KM / 5 000 MILES

²Initial change Ð change the lubricant in the manual shift transmission

± 5 speed and 6 speed Eaton manual transmission. (Not required

when equipped with optional synthetic lubricant.)

32 000 KM / 20 000 MILES

²Replace the fuel filter.*

50 000 KM / 30 000 MILES

²Replace the engine spin-on coolant filter.*

²Repack and adjust the front wheel bearings Ð grease-filled hubs.

General maintenance information

216

Page 217 of 240

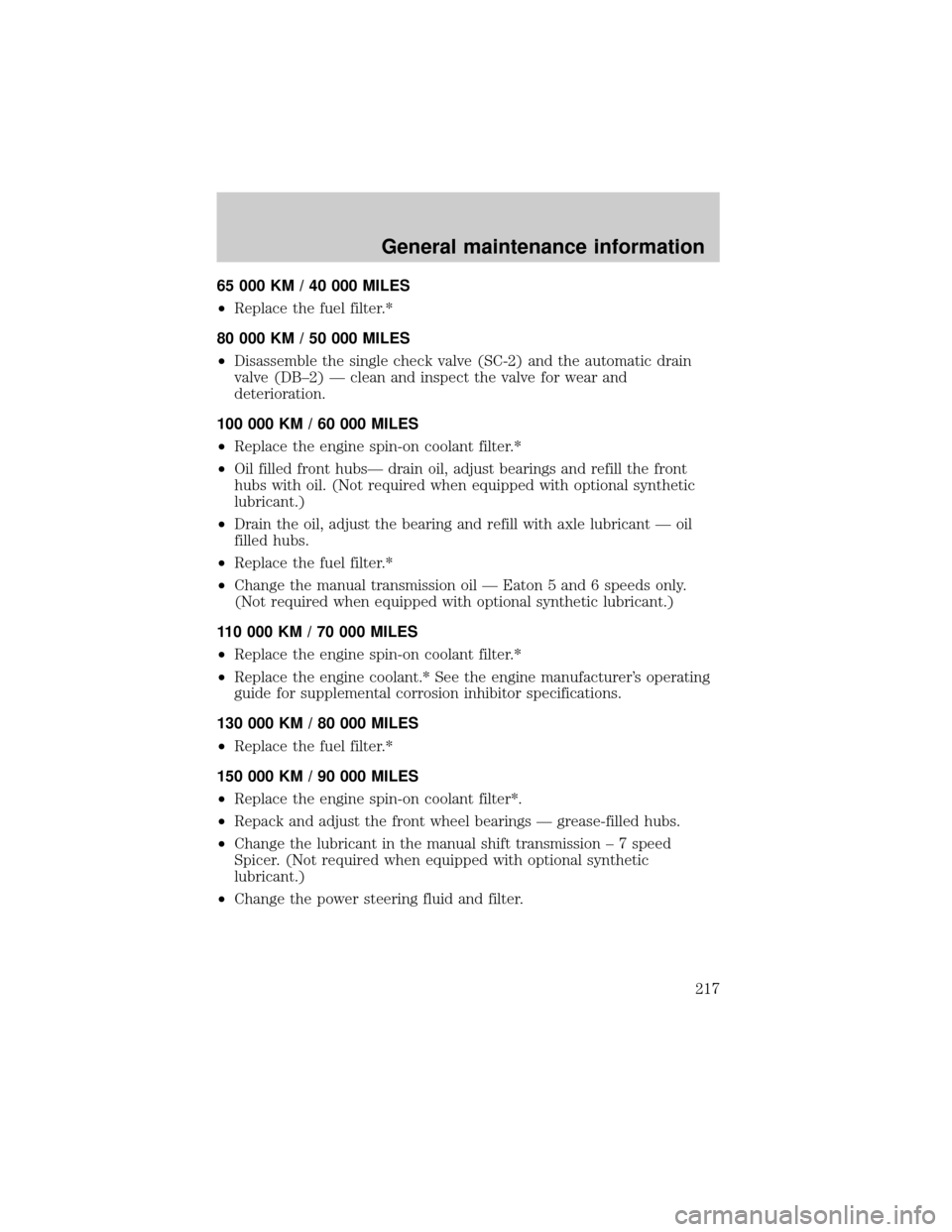

65 000 KM / 40 000 MILES

²Replace the fuel filter.*

80 000 KM / 50 000 MILES

²Disassemble the single check valve (SC-2) and the automatic drain

valve (DB±2) Ð clean and inspect the valve for wear and

deterioration.

100 000 KM / 60 000 MILES

²Replace the engine spin-on coolant filter.*

²Oil filled front hubsÐ drain oil, adjust bearings and refill the front

hubs with oil. (Not required when equipped with optional synthetic

lubricant.)

²Drain the oil, adjust the bearing and refill with axle lubricant Ð oil

filled hubs.

²Replace the fuel filter.*

²Change the manual transmission oil Ð Eaton 5 and 6 speeds only.

(Not required when equipped with optional synthetic lubricant.)

110 000 KM / 70 000 MILES

²Replace the engine spin-on coolant filter.*

²Replace the engine coolant.* See the engine manufacturer's operating

guide for supplemental corrosion inhibitor specifications.

130 000 KM / 80 000 MILES

²Replace the fuel filter.*

150 000 KM / 90 000 MILES

²Replace the engine spin-on coolant filter*.

²Repack and adjust the front wheel bearings Ð grease-filled hubs.

²Change the lubricant in the manual shift transmission ± 7 speed

Spicer. (Not required when equipped with optional synthetic

lubricant.)

²Change the power steering fluid and filter.

General maintenance information

217

Page 218 of 240

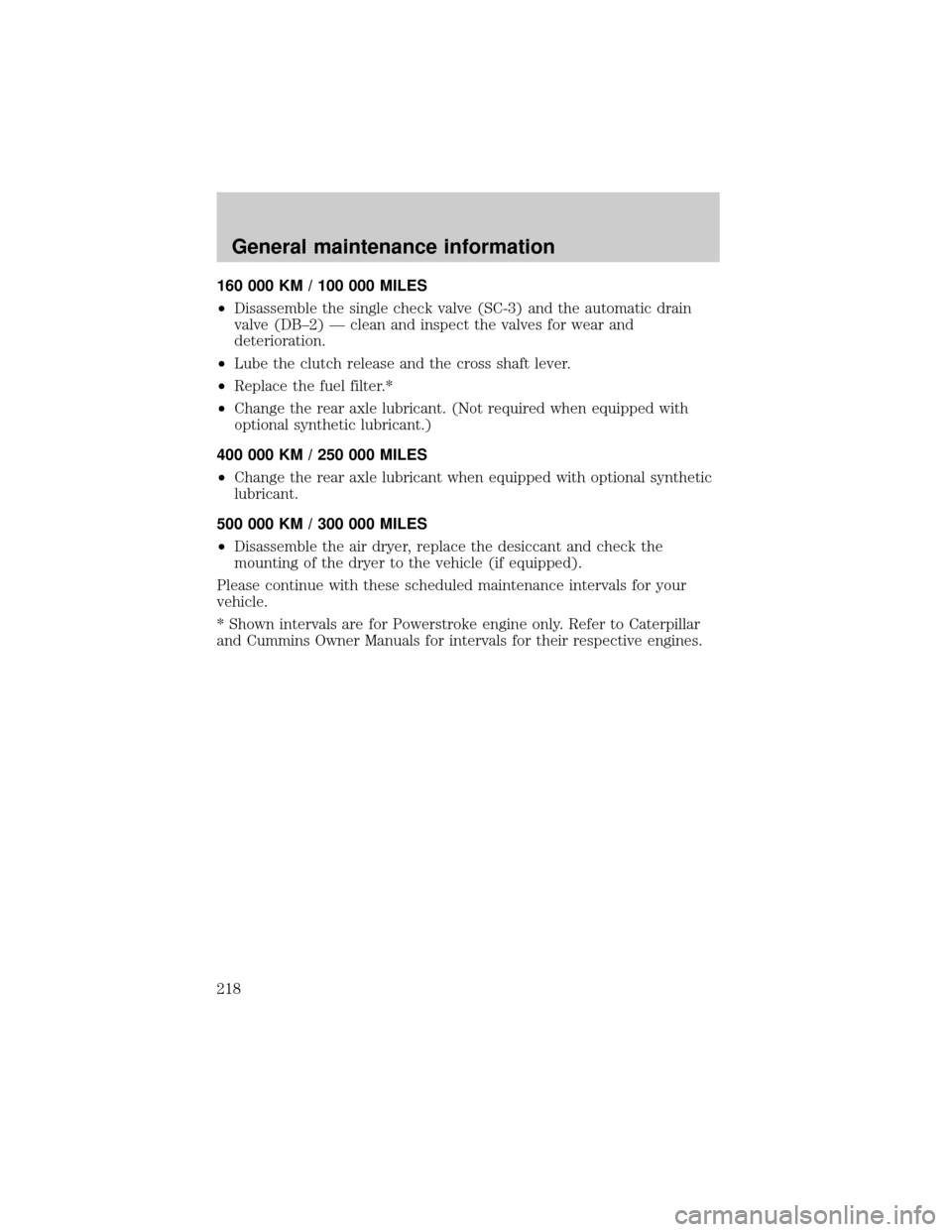

160 000 KM / 100 000 MILES

²Disassemble the single check valve (SC-3) and the automatic drain

valve (DB±2) Ð clean and inspect the valves for wear and

deterioration.

²Lube the clutch release and the cross shaft lever.

²Replace the fuel filter.*

²Change the rear axle lubricant. (Not required when equipped with

optional synthetic lubricant.)

400 000 KM / 250 000 MILES

²Change the rear axle lubricant when equipped with optional synthetic

lubricant.

500 000 KM / 300 000 MILES

²Disassemble the air dryer, replace the desiccant and check the

mounting of the dryer to the vehicle (if equipped).

Please continue with these scheduled maintenance intervals for your

vehicle.

* Shown intervals are for Powerstroke engine only. Refer to Caterpillar

and Cummins Owner Manuals for intervals for their respective engines.

General maintenance information

218

Page 219 of 240

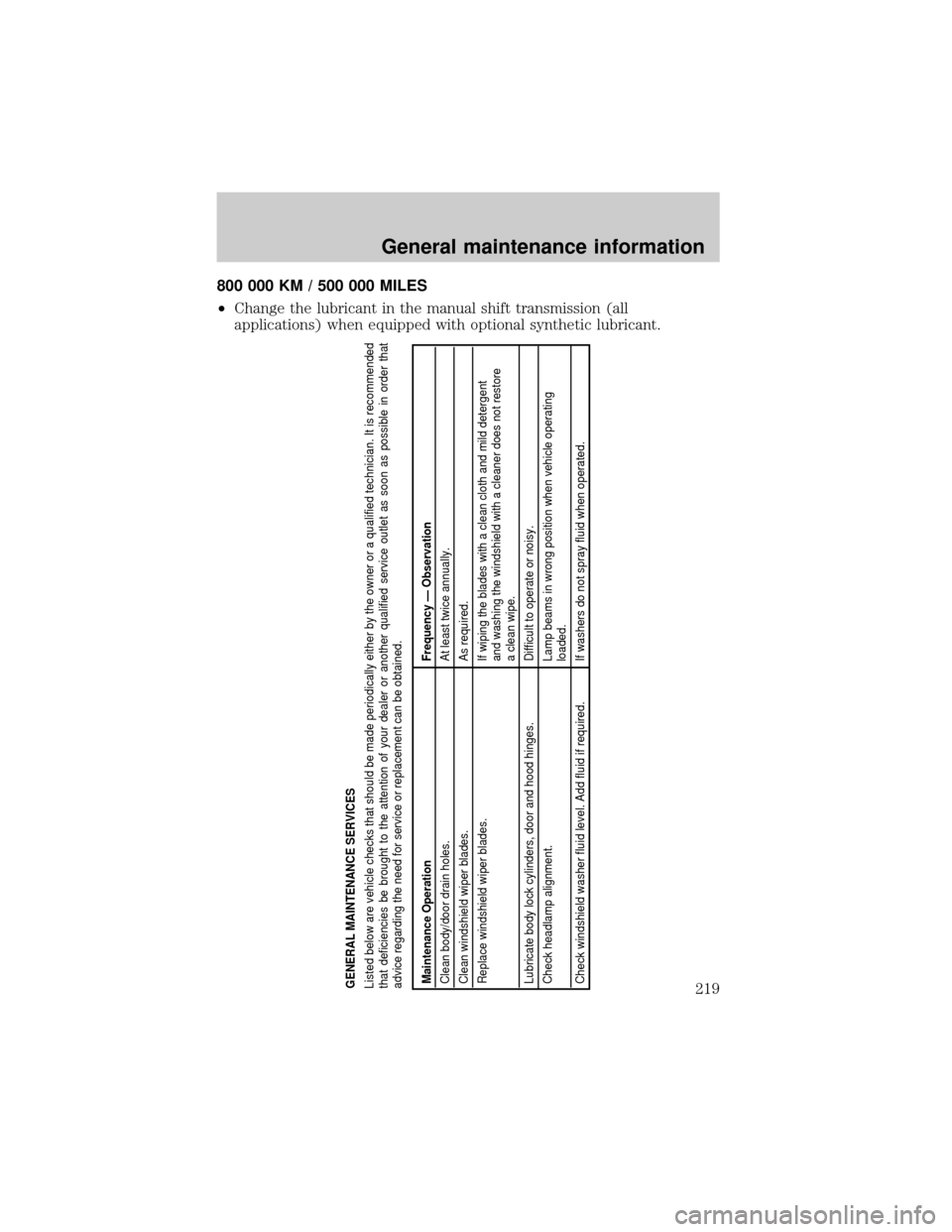

800 000 KM / 500 000 MILES

²Change the lubricant in the manual shift transmission (all

applications) when equipped with optional synthetic lubricant.

Maintenance Operation Frequency — ObservationClean body/door drain holes.

Clean windshield wiper blades.

Replace windshield wiper blades.

Lubricate body lock cylinders, door and hood hinges.

Check headlamp alignment.

Check windshield washer fluid level. Add fluid if required.At least twice annually.

As required.

If wiping the blades with a clean cloth and mild detergent

and washing the windshield with a cleaner does not restore

a clean wipe.

Difficult to operate or noisy.

Lamp beams in wrong position when vehicle operating

loaded.

If washers do not spray fluid when operated. GENERAL MAINTENANCE SERVICES

Listed below are vehicle checks that should be made periodically either by the owner or a qualified technician. It is recommended

that deficiencies be brought to the attention of your dealer or another qualified service outlet as soon as possible in order that

advice regarding the need for service or replacement can be obtained.

General maintenance information

219

Page 220 of 240

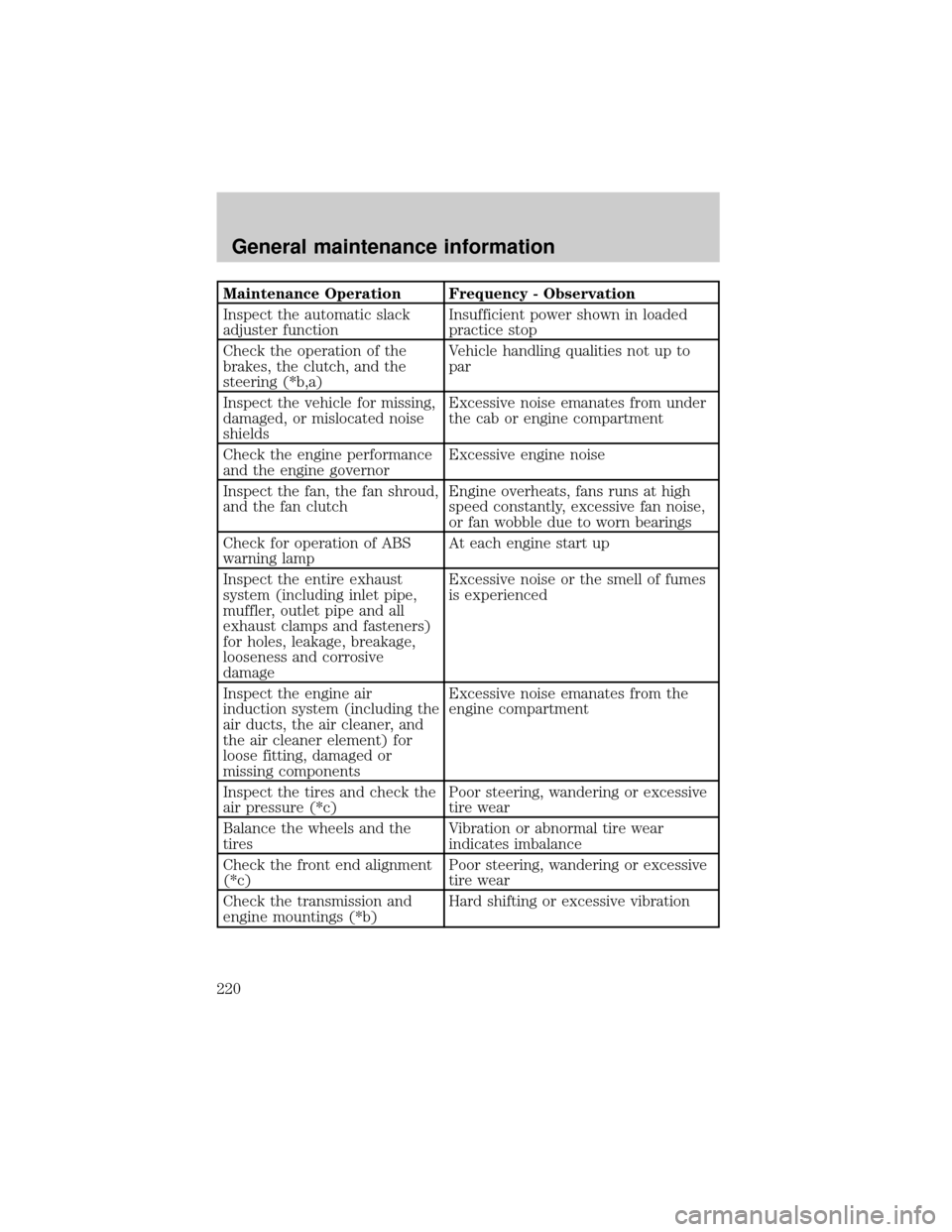

Maintenance Operation Frequency - Observation

Inspect the automatic slack

adjuster functionInsufficient power shown in loaded

practice stop

Check the operation of the

brakes, the clutch, and the

steering (*b,a)Vehicle handling qualities not up to

par

Inspect the vehicle for missing,

damaged, or mislocated noise

shieldsExcessive noise emanates from under

the cab or engine compartment

Check the engine performance

and the engine governorExcessive engine noise

Inspect the fan, the fan shroud,

and the fan clutchEngine overheats, fans runs at high

speed constantly, excessive fan noise,

or fan wobble due to worn bearings

Check for operation of ABS

warning lampAt each engine start up

Inspect the entire exhaust

system (including inlet pipe,

muffler, outlet pipe and all

exhaust clamps and fasteners)

for holes, leakage, breakage,

looseness and corrosive

damageExcessive noise or the smell of fumes

is experienced

Inspect the engine air

induction system (including the

air ducts, the air cleaner, and

the air cleaner element) for

loose fitting, damaged or

missing componentsExcessive noise emanates from the

engine compartment

Inspect the tires and check the

air pressure (*c)Poor steering, wandering or excessive

tire wear

Balance the wheels and the

tiresVibration or abnormal tire wear

indicates imbalance

Check the front end alignment

(*c)Poor steering, wandering or excessive

tire wear

Check the transmission and

engine mountings (*b)Hard shifting or excessive vibration

General maintenance information

220