check oil FORD F750 2003 10.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2003, Model line: F750, Model: FORD F750 2003 10.GPages: 248, PDF Size: 2.54 MB

Page 7 of 248

Interior Luggage

Compartment Release

Symbol

Panic Alarm

Engine OilEngine Coolant

Engine Coolant

TemperatureDo Not Open When Hot

BatteryAvoid Smoking, Flames,

or Sparks

Battery AcidExplosive Gas

Fan WarningPower Steering Fluid

Maintain Correct Fluid

LevelMAX

MIN

Emission System

Engine Air FilterPassenger Compartment

Air Filter

JackCheck fuel cap

Low tire warning

Introduction

7

Page 16 of 248

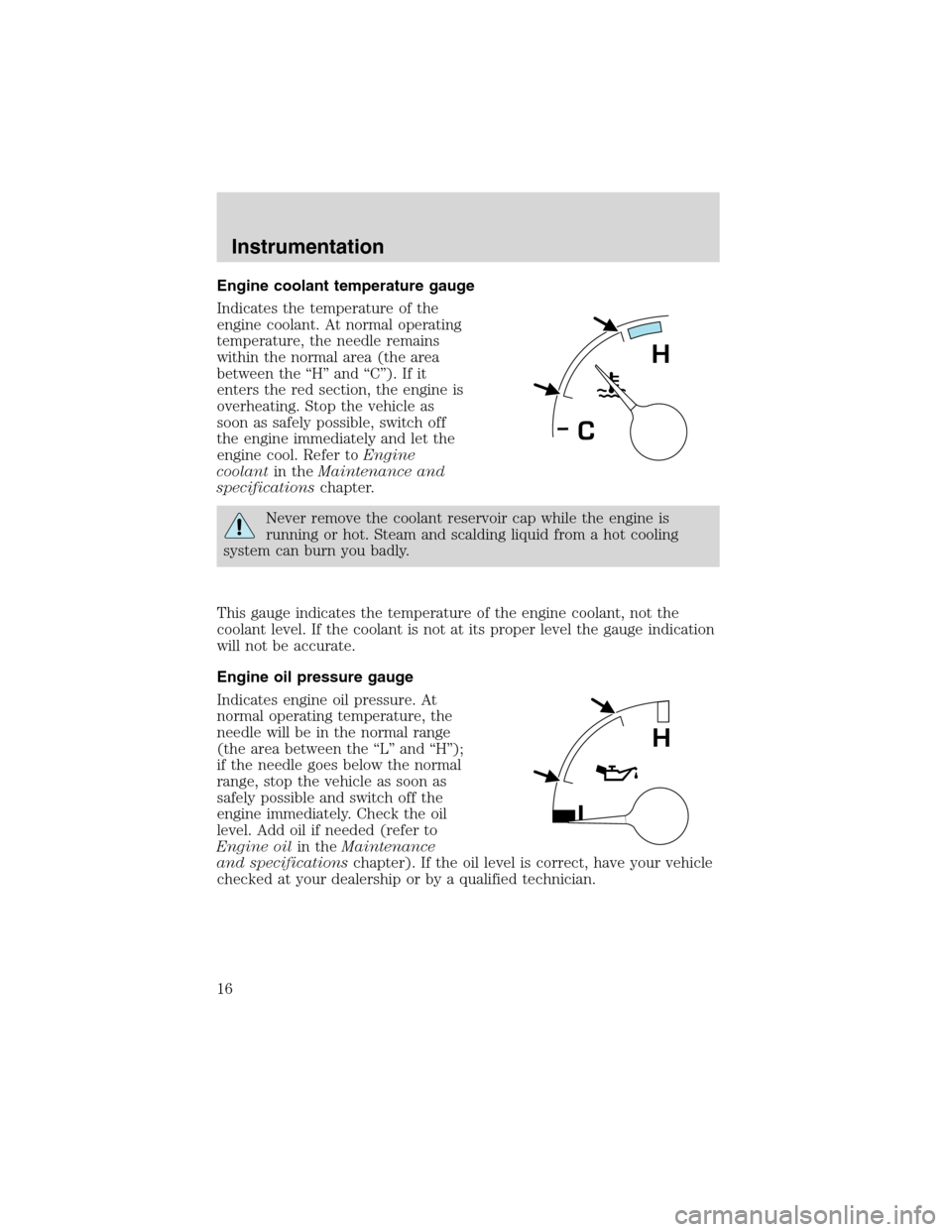

Engine coolant temperature gauge

Indicates the temperature of the

engine coolant. At normal operating

temperature, the needle remains

within the normal area (the area

between the“H”and“C”). If it

enters the red section, the engine is

overheating. Stop the vehicle as

soon as safely possible, switch off

the engine immediately and let the

engine cool. Refer toEngine

coolantin theMaintenance and

specificationschapter.

Never remove the coolant reservoir cap while the engine is

running or hot. Steam and scalding liquid from a hot cooling

system can burn you badly.

This gauge indicates the temperature of the engine coolant, not the

coolant level. If the coolant is not at its proper level the gauge indication

will not be accurate.

Engine oil pressure gauge

Indicates engine oil pressure. At

normal operating temperature, the

needle will be in the normal range

(the area between the“L”and“H”);

if the needle goes below the normal

range, stop the vehicle as soon as

safely possible and switch off the

engine immediately. Check the oil

level. Add oil if needed (refer to

Engine oilin theMaintenance

and specificationschapter). If the oil level is correct, have your vehicle

checked at your dealership or by a qualified technician.

H

C

L

H

Instrumentation

16

Page 111 of 248

To prevent electrical shock, do not use your heater with

ungrounded electrical systems or two-pronged (cheater)

adapters.

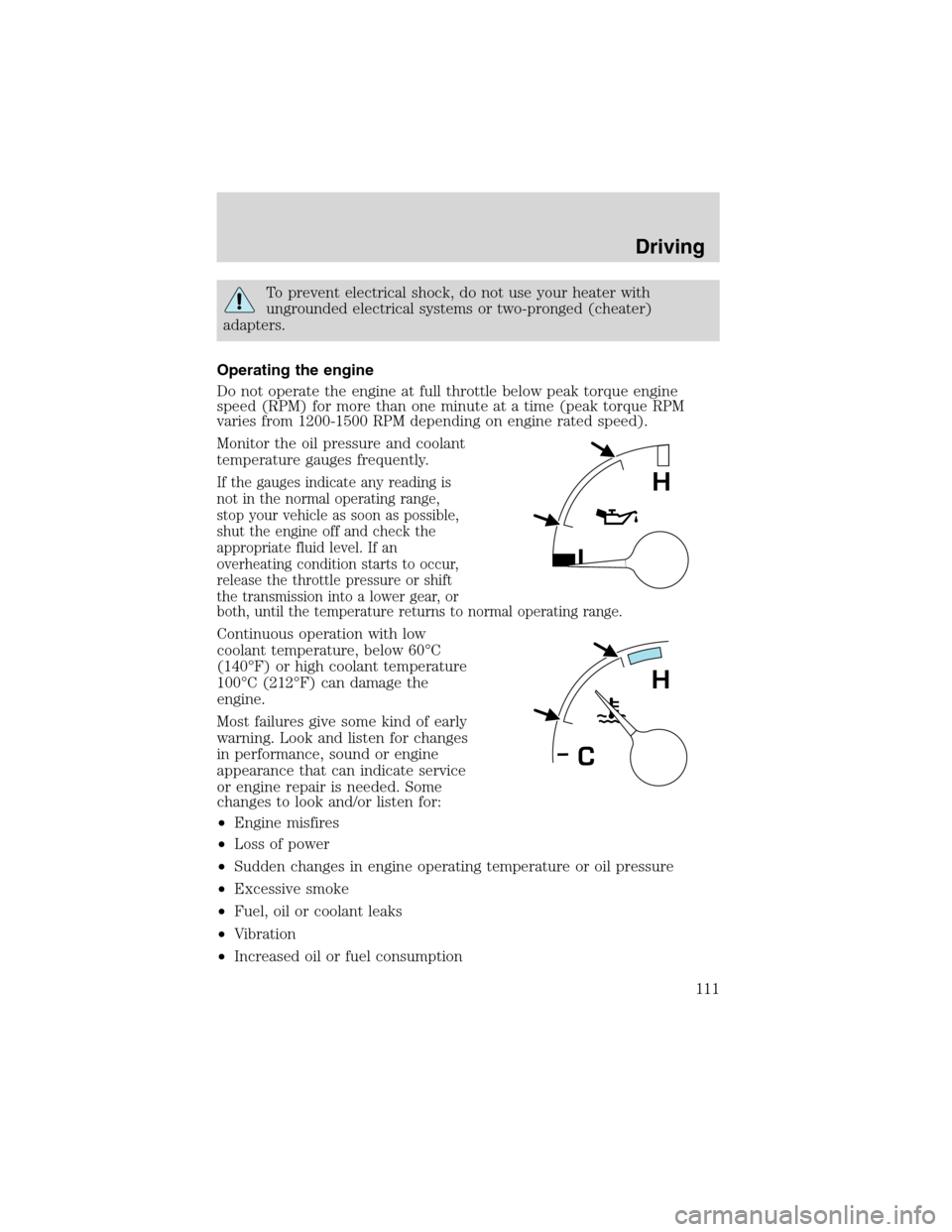

Operating the engine

Do not operate the engine at full throttle below peak torque engine

speed (RPM) for more than one minute at a time (peak torque RPM

varies from 1200-1500 RPM depending on engine rated speed).

Monitor the oil pressure and coolant

temperature gauges frequently.

If the gauges indicate any reading is

not in the normal operating range,

stop your vehicle as soon as possible,

shut the engine off and check the

appropriate fluid level. If an

overheating condition starts to occur,

release the throttle pressure or shift

the transmission into a lower gear, or

both, until the temperature returns to normal operating range.

Continuous operation with low

coolant temperature, below 60°C

(140°F) or high coolant temperature

100°C (212°F) can damage the

engine.

Most failures give some kind of early

warning. Look and listen for changes

in performance, sound or engine

appearance that can indicate service

or engine repair is needed. Some

changes to look and/or listen for:

•Engine misfires

•Loss of power

•Sudden changes in engine operating temperature or oil pressure

•Excessive smoke

•Fuel, oil or coolant leaks

•Vibration

•Increased oil or fuel consumption

L

H

H

C

Driving

111

Page 112 of 248

Excessive full throttle operation below peak torque RPM will shorten

engine life to overhaul and can cause serious engine damage. Operation

of the engine below peak torque RPM can occur during gear shifting due

to difference of gear ratios.

Engine shutdown system (if equipped)

This system is designed to help prevent engine damage that could result

from operating the engine during a prolonged period of low engine oil

pressure, high engine coolant temperature or low coolant level. If any of

these conditions occur, a warning light will illuminate and a chime will

sound warning the operator that the engine will shutdown in 30 seconds.

This is to allow time for the operator to move the vehicle off the road. If

additional time is required, the engine can be restarted and run each

time for approximately 30 seconds.

Do not attempt to use this restarting feature to drive the vehicle, serious

engine damage could result.

Exhaust fumes

Never idle the engine in closed areas. Never sit in a parked or

stopped vehicle for any amount of time with engine running.

If you ever smell exhaust fumes of any kind inside your vehicle,

have your dealer inspect and fix your vehicle immediately. Do

not drive if you smell exhaust fumes. These fumes are harmful and

could kill you.

In order to guard against fumes entering your vehicle, the exhaust

system and body ventilation system should be checked by a qualified

technician:

•Each time the vehicle is raised for service.

•Whenever a change in exhaust system noise is noted.

•Whenever the vehicle has been damaged by impact from another

vehicle, object or road obstruction.

In order to afford proper operation, all air inlet vents should be kept

clear of snow, leaves and other debris.

If you run the engine while stopped (idled) in an unconfined area, open

the windows at least 2.5 cm (one inch) and adjust the heating or air

conditioning to draw outside air into the vehicle as follows:

•If your vehicle has outside air control vents, open them fully.

Driving

112

Page 180 of 248

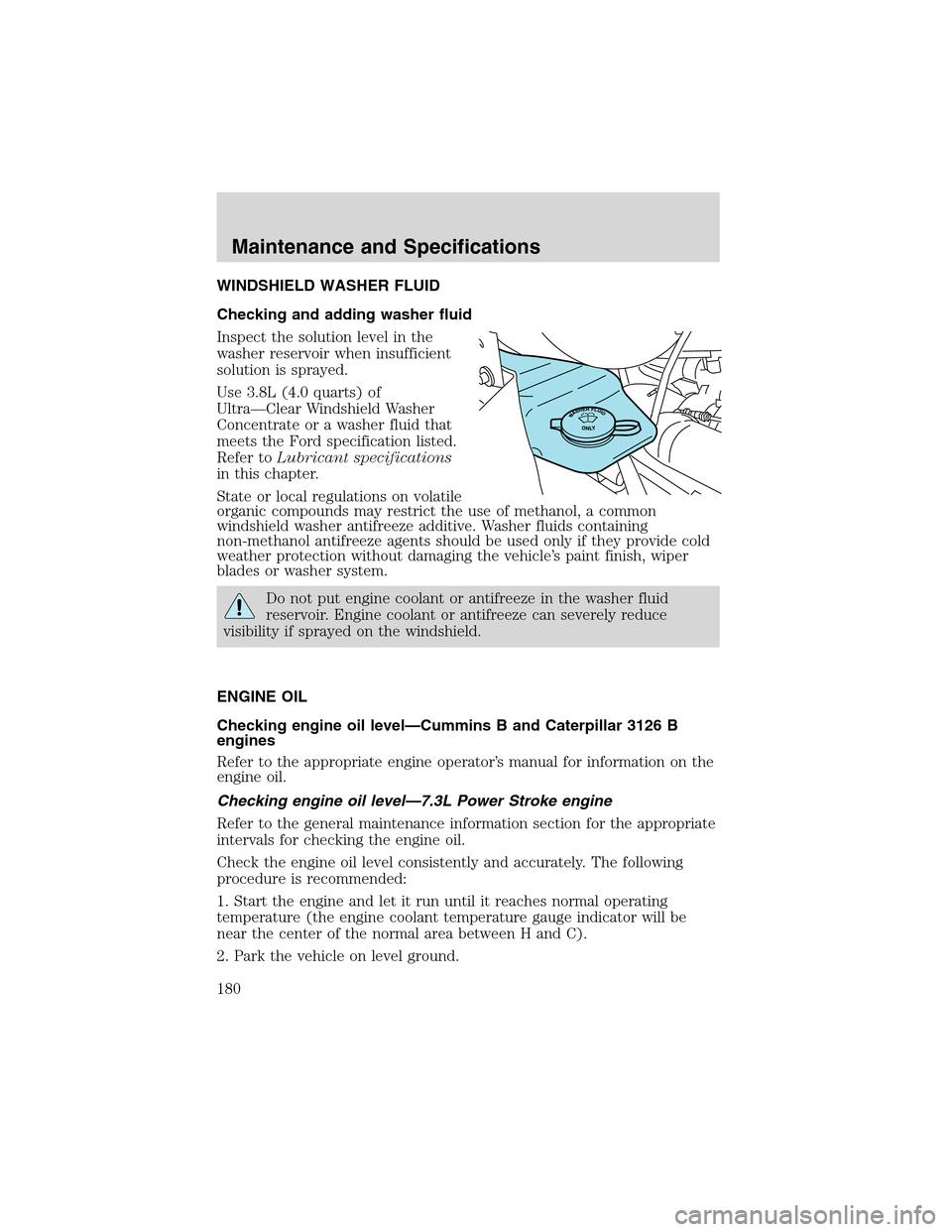

WINDSHIELD WASHER FLUID

Checking and adding washer fluid

Inspect the solution level in the

washer reservoir when insufficient

solution is sprayed.

Use 3.8L (4.0 quarts) of

Ultra—Clear Windshield Washer

Concentrate or a washer fluid that

meets the Ford specification listed.

Refer toLubricant specifications

in this chapter.

State or local regulations on volatile

organic compounds may restrict the use of methanol, a common

windshield washer antifreeze additive. Washer fluids containing

non-methanol antifreeze agents should be used only if they provide cold

weather protection without damaging the vehicle’s paint finish, wiper

blades or washer system.

Do not put engine coolant or antifreeze in the washer fluid

reservoir. Engine coolant or antifreeze can severely reduce

visibility if sprayed on the windshield.

ENGINE OIL

Checking engine oil level—Cummins B and Caterpillar 3126 B

engines

Refer to the appropriate engine operator’s manual for information on the

engine oil.

Checking engine oil level—7.3L Power Stroke engine

Refer to the general maintenance information section for the appropriate

intervals for checking the engine oil.

Check the engine oil level consistently and accurately. The following

procedure is recommended:

1. Start the engine and let it run until it reaches normal operating

temperature (the engine coolant temperature gauge indicator will be

near the center of the normal area between H and C).

2. Park the vehicle on level ground.

Maintenance and Specifications

180

Page 186 of 248

Battery posts, terminals and related accessories contain lead and

lead compounds. Wash hands after handling.

ENGINE COOLANT

Checking engine coolant

The concentration and level of engine coolant should be checked at the

mileage intervals listed in the general maintenance information section.

The coolant concentration should be maintained at 50/50 coolant and

water, which equates to a freeze point of -36°C (-34°F). Coolant

concentration testing is possible with a hydrometer or antifreeze tester

(such as the Rotunda Battery and Antifreeze Tester, 014–R1060). The

level of coolant should be maintained at the“cold full”of“cold fill range”

level in the coolant reservoir. If the level falls below, add coolant per the

instructions in theAdding Engine Coolantsection.

Your vehicle was factory-filled with a 50/50 engine coolant and water

concentration. If the concentration of coolant falls below 40% or above

60%, the engine parts could become damaged or not work properly.A

50–50 mixture of coolant and water provides the following:

•freeze protection down to -36°C (-34°F).

•boiling protection up to 129°C (265°F).

•protection against rust and other forms of corrosion.

•enables calibrated guages to work properly.

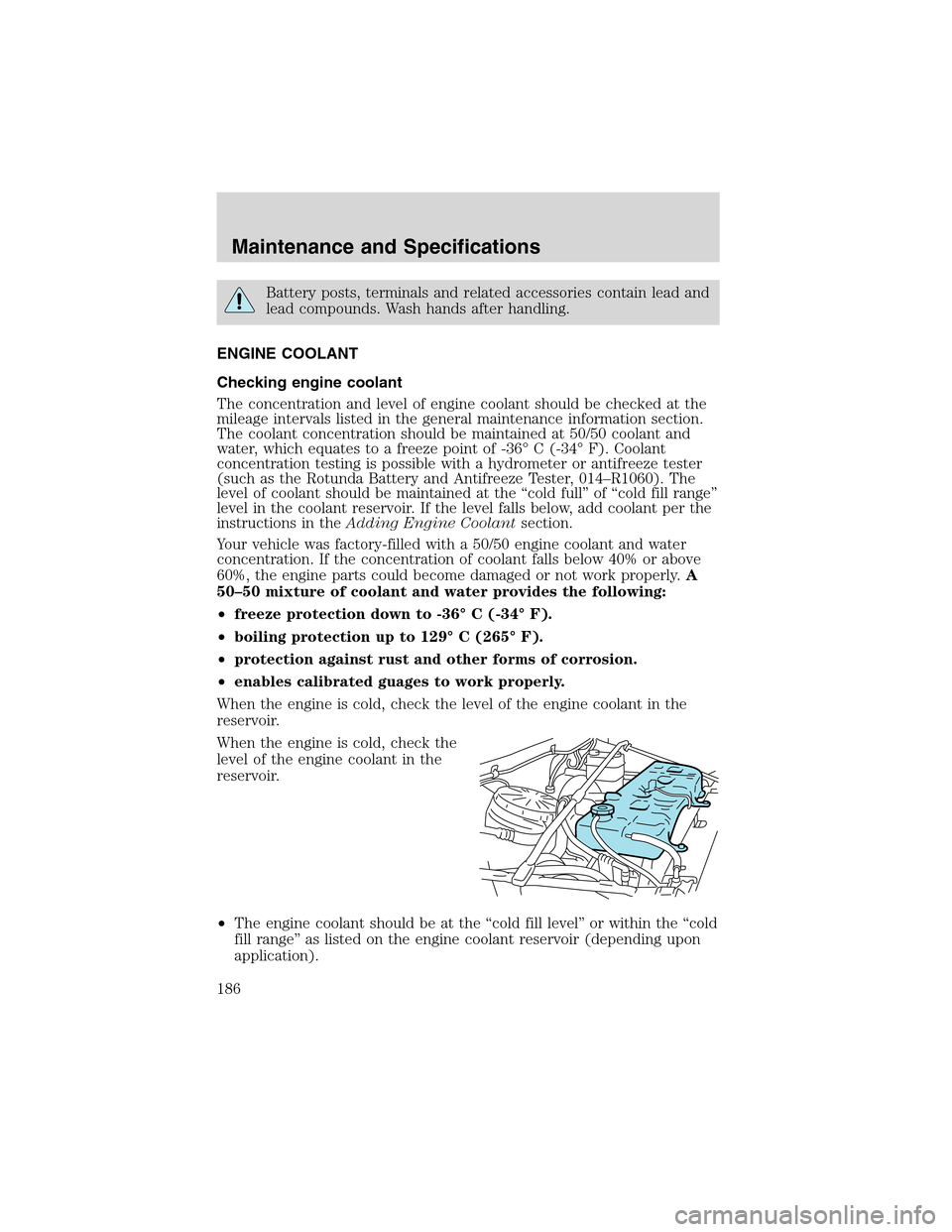

When the engine is cold, check the level of the engine coolant in the

reservoir.

When the engine is cold, check the

level of the engine coolant in the

reservoir.

•The engine coolant should be at the“cold fill level”or within the“cold

fill range”as listed on the engine coolant reservoir (depending upon

application).

Maintenance and Specifications

186

Page 189 of 248

1. Before you begin, turn the engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the coolant

pressure relief cap on the coolant reservoir (an opaque plastic bottle).

Slowly turn cap counterclockwise (left) until pressure begins to release.

3. Step back while the pressure releases.

4. When you are sure that all the pressure has been released, use the

cloth to turn it counterclockwise and remove the cap.

5. Fill the coolant reservoir slowly with the proper coolant mixture (see

above), to within the“cold fill range”or the“cold full”level on the

reservoir. If you removed the radiator cap in an overflow system, fill the

radiator until the coolant is visible and radiator is almost full.

6. Replace the cap. Turn until tightly installed. (Cap must be tightly

installed to prevent coolant loss.)

After any coolant has been added, check the coolant concentration see

Checking Engine Coolant section). If the concentration is not 50/50

(protection to–34°F/–36°C), drain some coolant and adjust the

concentration. It may take several drains and additions to obtain a 50/50

coolant concentration.

Whenever coolant has been added, the coolant level in the coolant

reservoir should be checked the next few times you drive the vehicle. If

necessary, add enough 50/50 concentration of engine coolant and

distilled water to bring the liquid level to the proper level.

If you have to add more than 1.0 liter (1.0 quart) of engine coolant per

month, have your dealer check the engine cooling system. Your cooling

system may have a leak. Operating an engine with a low level of coolant

can result in engine overheating and possible engine damage.

Replacing coolant

A coolant mixture of 50% coolant concentrate and 50% water is

recommended to maintain best overall performance. To avoid damaging

the engine and radiator, the coolant concentrate should not exceed 60%.

When refilling the coolant system either as part of the regular

maintenance (refer to the general maintenance information section), or

due to service performed, adhere to the following instructions:

1. Drain and flush the cooling system to remove dirt deposits, oil, rust

particles.

Note:

When filling the system with Motorcraft Premium Engine Coolant

(green-colored) or equivalent meeting Ford specification ESE-M97B44–A, a

supplemental coolant additive is required. Refer toAdding Coolantsection

Maintenance and Specifications

189

Page 196 of 248

Fuel filter replacement—Caterpillar 3126 B engine

The fuel filter/water separator is

located on the left side of the

engine. Replace the fuel filter/water

separator as recommended in the

general maintenance information

section, or sooner if it becomes

plugged. Vehicles operated on fuel

with more than average impurities

may require replacement of the fuel

filter more frequently. The spin-on

filter has a water drain valve built

into the bottom of the filter canister.

Removal

1. Using an oil filter wrench, remove the filter.

2. Carefully clean the mating surfaces.

Installation

1. Fill the filter with clean, fresh diesel fuel.

2. Coat the filter seal with clean, fresh diesel fuel.

3. Hand-tighten the filter until it seats firmly against the mount, then

tighten (by hand) an additional

1⁄3to1⁄2turn.

4. Start the engine and check for fuel leaks.

Maintenance and Specifications

196

Page 210 of 248

11. Inspect the air induction system for loose fitting, damaged or missing

components and repair as necessary.

SERVICING YOUR WHEELS AND TIRES

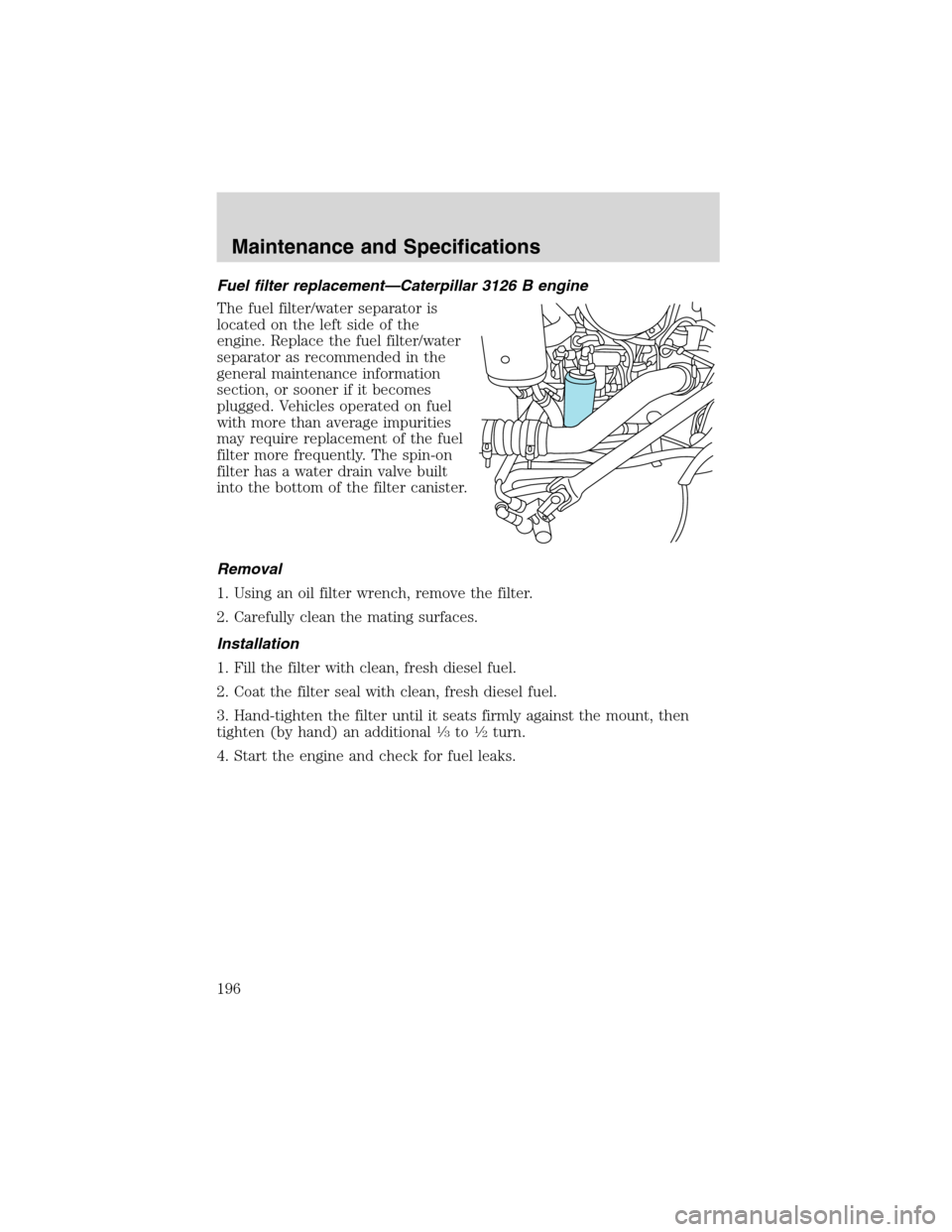

Wheel assembly

Your vehicle is fitted with hub

piloted wheels and two-element

swiveling lug nuts (20 & 22 mm).

Do not use taper type wheels or ball

seat wheel nuts.

•Do not paint the mating face of the hub/drum.

•Do not paint the two-element swiveling lug nuts or wheel stud.

•Do not allow an excessive thickness of paint to build between the disc

wheel mounting surfaces.

•Do not install disc wheels where the paint has not fully cured.

•At wheel changes, ensure mounting faces are clean and free of rust,

dirt and excess paint.

If fasteners are needed, use only Ford recommended replacement parts.

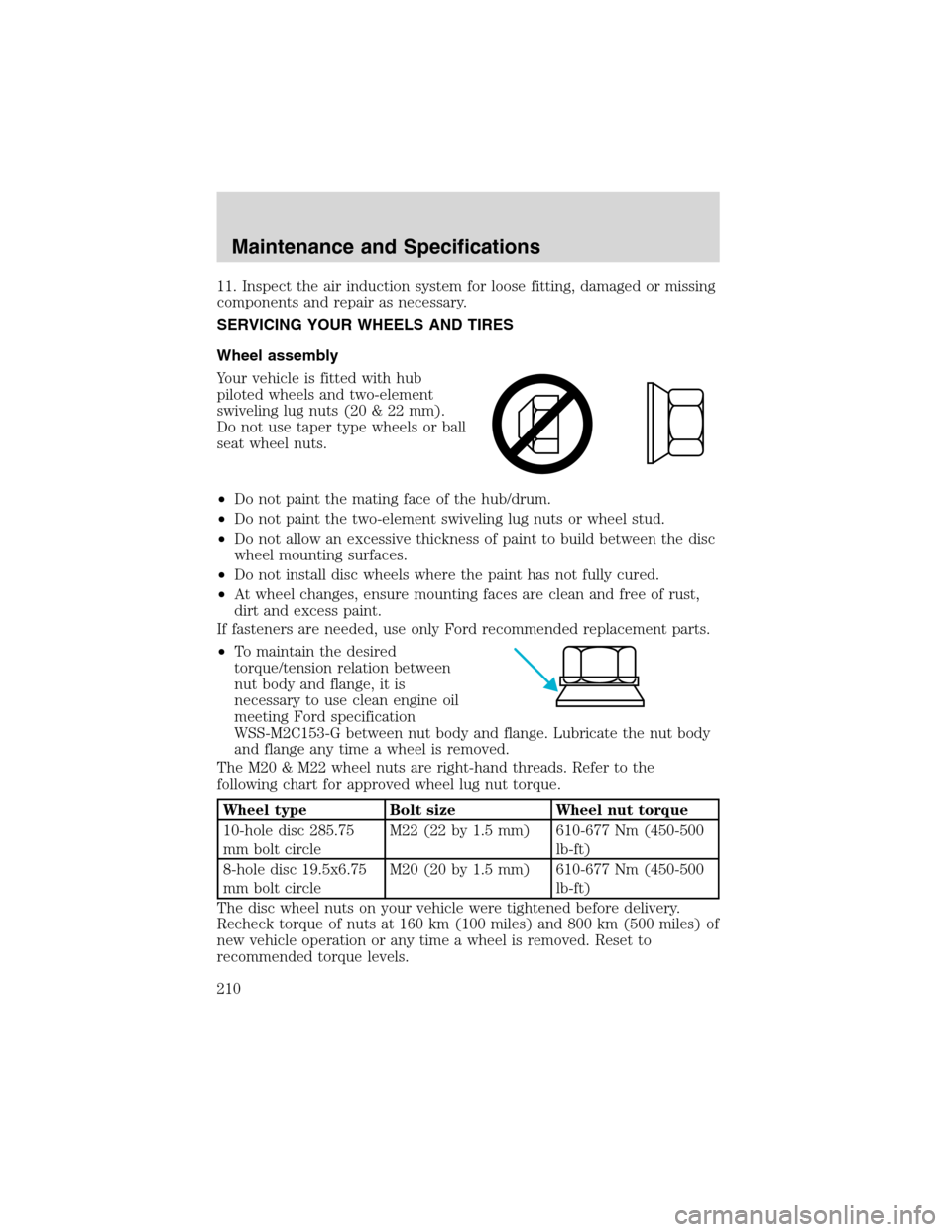

•To maintain the desired

torque/tension relation between

nut body and flange, it is

necessary to use clean engine oil

meeting Ford specification

WSS-M2C153-G between nut body and flange. Lubricate the nut body

and flange any time a wheel is removed.

The M20 & M22 wheel nuts are right-hand threads. Refer to the

following chart for approved wheel lug nut torque.

Wheel type Bolt size Wheel nut torque

10-hole disc 285.75

mm bolt circleM22 (22 by 1.5 mm) 610-677 Nm (450-500

lb-ft)

8-hole disc 19.5x6.75

mm bolt circleM20 (20 by 1.5 mm) 610-677 Nm (450-500

lb-ft)

The disc wheel nuts on your vehicle were tightened before delivery.

Recheck torque of nuts at 160 km (100 miles) and 800 km (500 miles) of

new vehicle operation or any time a wheel is removed. Reset to

recommended torque levels.

Maintenance and Specifications

210

Page 213 of 248

An inflated tire and rim can be very dangerous if improperly

used, serviced or maintained. To avoid serious injury, never

attempt to re-inflate a tire which has been run flat or seriously

under-inflated without first removing the tire from the wheel assembly

for inspection. Do not attempt to add air to tires or replace tires or

wheels without first taking precautions to protect persons and

property.

Refer to the Ford Service Manual or the regulations of the Occupational

Safety and Health Administration (OSHA) for appropriate procedures

and cautions.

Tire inflation pressure must not exceed the recommendations of

the axle, tire and/or wheel rim manufacturer for the specific

load, speed and application. The inflation pressures on the tire sidewall

do not take the wheel rim capabilities into consideration.

Never use a rim of different manufacture or any different size or

type than original rims.

Try to replace tires in pairs on the same axle shaft. Tires larger or

smaller than originally installed may affect the accuracy of the

speedometer. Consult your dealer about the need to change the switch

setting on the back of the speedometer.

Front wheel alignment

If abnormal tire wear or ride and handling characteristics such as vehicle

lead or wander are experienced with properly inflated tires, the front

end alignment should be checked.

Wheel bearing care

Front and rear wheel bearings are adjustable to correct for bearing and

spindle wear. Long bearing life depends upon proper adjustment and

correct lubrication. If bearings are adjusted too tightly (preloaded) they

will overheat and wear rapidly. Loose adjustment will cause pounding

and will contribute to uneven tire wear, steering difficulties and

inefficient brake operation.

Refer to the Ford Service Manual applicable to your vehicle for proper

tightening procedures and torque specifications.

Periodically check the oil level on oil filled front bearing hubs. If

necessary, add oil through the filler plug so the oil level is between the

Maintenance and Specifications

213