alternator FORD F750 2004 11.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2004, Model line: F750, Model: FORD F750 2004 11.GPages: 264, PDF Size: 1.47 MB

Page 9 of 264

To be sure your vehicle is ready to operate, conduct a pre-trip inspection

at the beginning of each work period. Follow the steps listed in this

section to assure a proper vehicle inspection procedure. The pages in

this section may be produced locally and used on a regular basis.

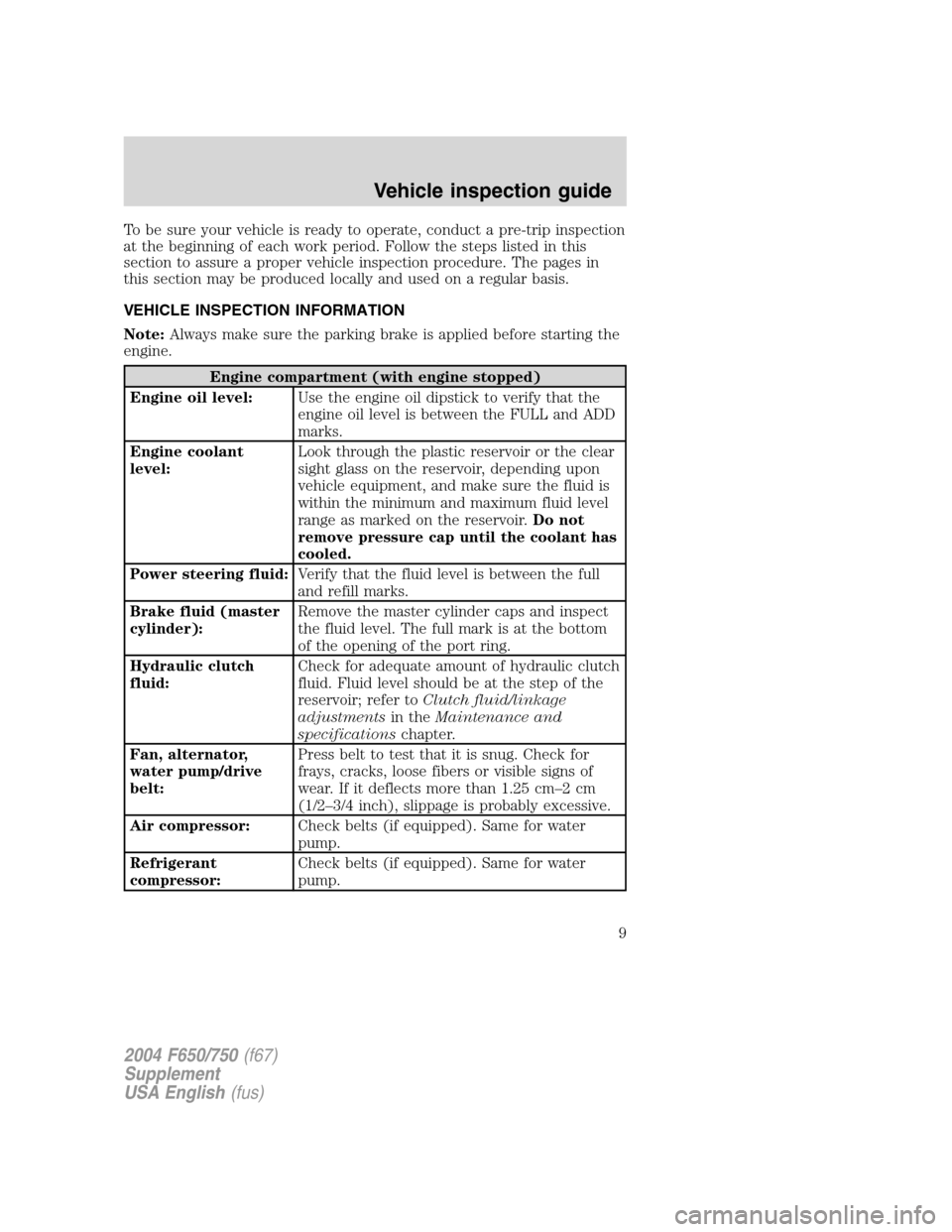

VEHICLE INSPECTION INFORMATION

Note:Always make sure the parking brake is applied before starting the

engine.

Engine compartment (with engine stopped)

Engine oil level:Use the engine oil dipstick to verify that the

engine oil level is between the FULL and ADD

marks.

Engine coolant

level:Look through the plastic reservoir or the clear

sight glass on the reservoir, depending upon

vehicle equipment, and make sure the fluid is

within the minimum and maximum fluid level

range as marked on the reservoir.Do not

remove pressure cap until the coolant has

cooled.

Power steering fluid:Verify that the fluid level is between the full

and refill marks.

Brake fluid (master

cylinder):Remove the master cylinder caps and inspect

the fluid level. The full mark is at the bottom

of the opening of the port ring.

Hydraulic clutch

fluid:Check for adequate amount of hydraulic clutch

fluid. Fluid level should be at the step of the

reservoir; refer toClutch fluid/linkage

adjustmentsin theMaintenance and

specificationschapter.

Fan, alternator,

water pump/drive

belt:Press belt to test that it is snug. Check for

frays, cracks, loose fibers or visible signs of

wear. If it deflects more than 1.25 cm–2cm

(1/2–3/4 inch), slippage is probably excessive.

Air compressor:Check belts (if equipped). Same for water

pump.

Refrigerant

compressor:Check belts (if equipped). Same for water

pump.

2004 F650/750(f67)

Supplement

USA English(fus)

Vehicle inspection guide

Vehicle inspection guide

9

Page 11 of 264

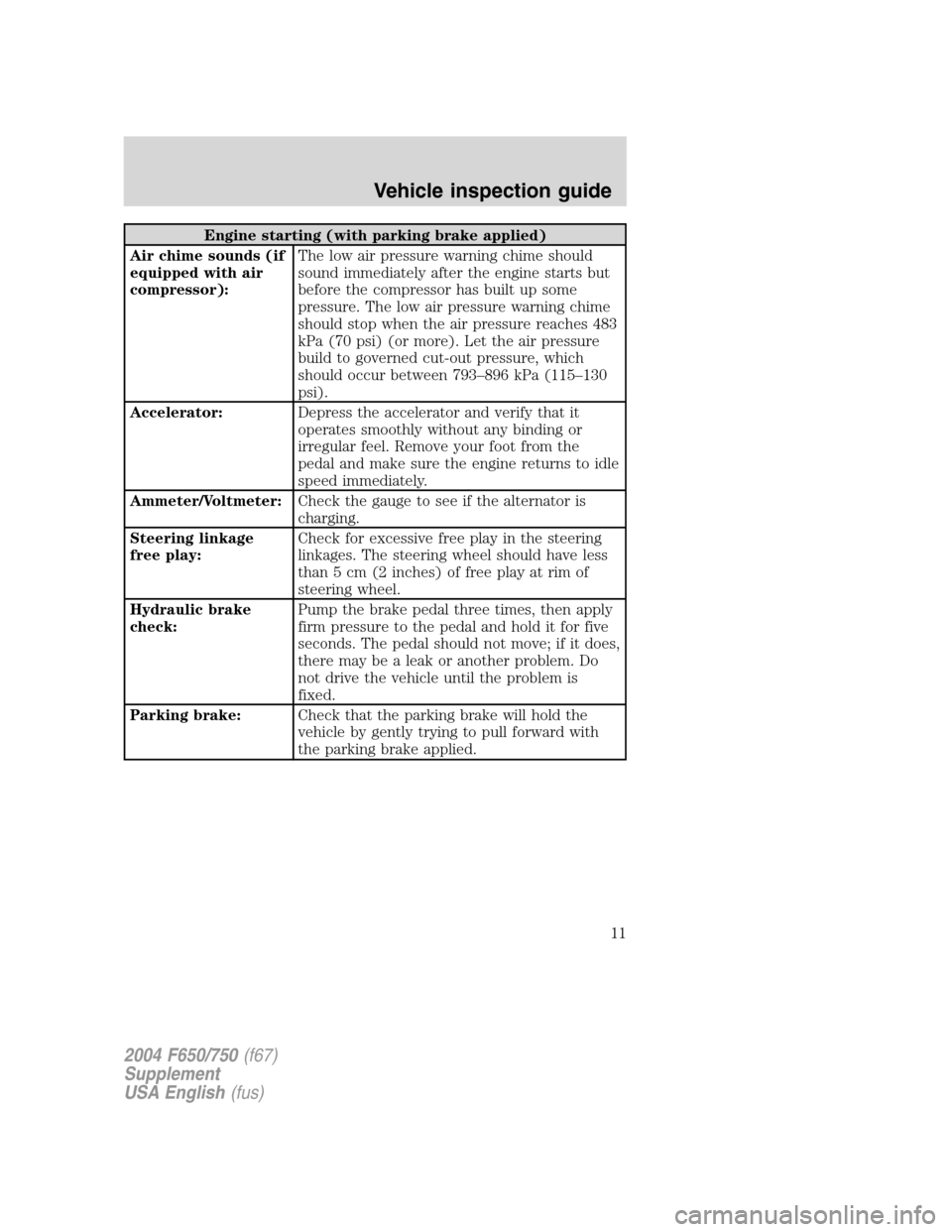

Engine starting (with parking brake applied)

Air chime sounds (if

equipped with air

compressor):The low air pressure warning chime should

sound immediately after the engine starts but

before the compressor has built up some

pressure. The low air pressure warning chime

should stop when the air pressure reaches 483

kPa (70 psi) (or more). Let the air pressure

build to governed cut-out pressure, which

should occur between 793–896 kPa (115–130

psi).

Accelerator:Depress the accelerator and verify that it

operates smoothly without any binding or

irregular feel. Remove your foot from the

pedal and make sure the engine returns to idle

speed immediately.

Ammeter/Voltmeter:Check the gauge to see if the alternator is

charging.

Steering linkage

free play:Check for excessive free play in the steering

linkages. The steering wheel should have less

than 5 cm (2 inches) of free play at rim of

steering wheel.

Hydraulic brake

check:Pump the brake pedal three times, then apply

firm pressure to the pedal and hold it for five

seconds. The pedal should not move; if it does,

there may be a leak or another problem. Do

not drive the vehicle until the problem is

fixed.

Parking brake:Check that the parking brake will hold the

vehicle by gently trying to pull forward with

the parking brake applied.

2004 F650/750(f67)

Supplement

USA English(fus)

Vehicle inspection guide

11

Page 178 of 264

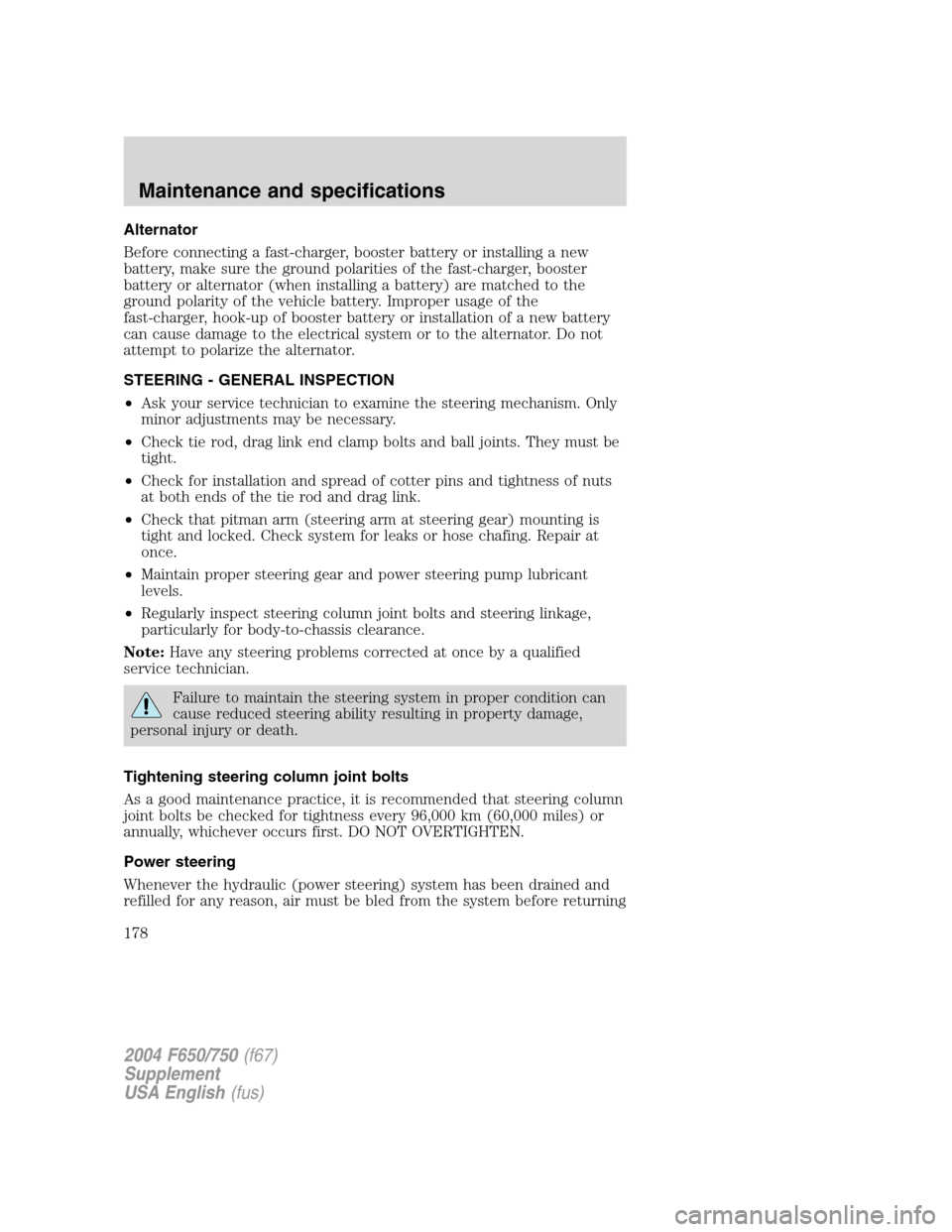

Alternator

Before connecting a fast-charger, booster battery or installing a new

battery, make sure the ground polarities of the fast-charger, booster

battery or alternator (when installing a battery) are matched to the

ground polarity of the vehicle battery. Improper usage of the

fast-charger, hook-up of booster battery or installation of a new battery

can cause damage to the electrical system or to the alternator. Do not

attempt to polarize the alternator.

STEERING - GENERAL INSPECTION

•Ask your service technician to examine the steering mechanism. Only

minor adjustments may be necessary.

•Check tie rod, drag link end clamp bolts and ball joints. They must be

tight.

•Check for installation and spread of cotter pins and tightness of nuts

at both ends of the tie rod and drag link.

•Check that pitman arm (steering arm at steering gear) mounting is

tight and locked. Check system for leaks or hose chafing. Repair at

once.

•Maintain proper steering gear and power steering pump lubricant

levels.

•Regularly inspect steering column joint bolts and steering linkage,

particularly for body-to-chassis clearance.

Note:Have any steering problems corrected at once by a qualified

service technician.

Failure to maintain the steering system in proper condition can

cause reduced steering ability resulting in property damage,

personal injury or death.

Tightening steering column joint bolts

As a good maintenance practice, it is recommended that steering column

joint bolts be checked for tightness every 96,000 km (60,000 miles) or

annually, whichever occurs first. DO NOT OVERTIGHTEN.

Power steering

Whenever the hydraulic (power steering) system has been drained and

refilled for any reason, air must be bled from the system before returning

2004 F650/750(f67)

Supplement

USA English(fus)

Maintenance and specifications

178

Page 195 of 264

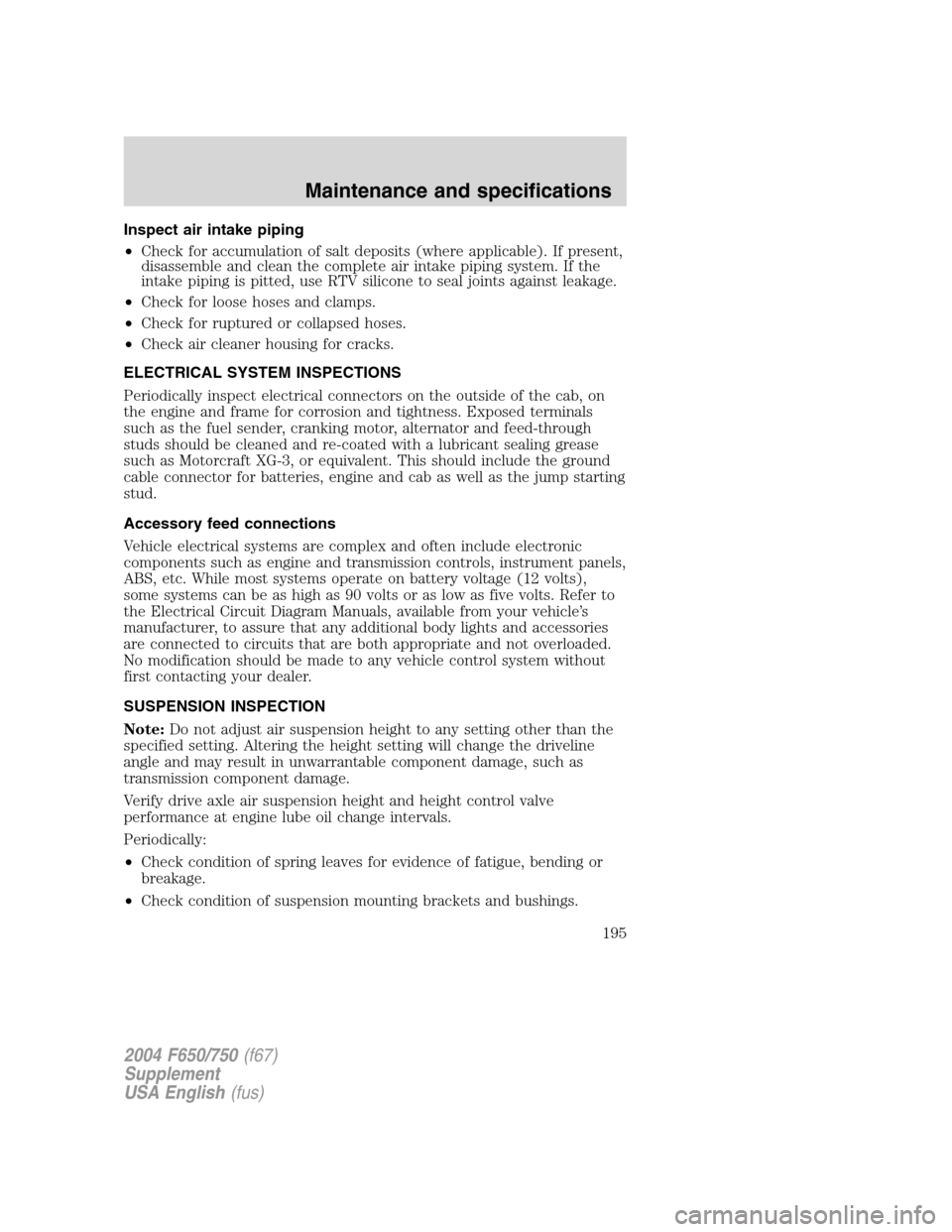

Inspect air intake piping

•Check for accumulation of salt deposits (where applicable). If present,

disassemble and clean the complete air intake piping system. If the

intake piping is pitted, use RTV silicone to seal joints against leakage.

•Check for loose hoses and clamps.

•Check for ruptured or collapsed hoses.

•Check air cleaner housing for cracks.

ELECTRICAL SYSTEM INSPECTIONS

Periodically inspect electrical connectors on the outside of the cab, on

the engine and frame for corrosion and tightness. Exposed terminals

such as the fuel sender, cranking motor, alternator and feed-through

studs should be cleaned and re-coated with a lubricant sealing grease

such as Motorcraft XG-3, or equivalent. This should include the ground

cable connector for batteries, engine and cab as well as the jump starting

stud.

Accessory feed connections

Vehicle electrical systems are complex and often include electronic

components such as engine and transmission controls, instrument panels,

ABS, etc. While most systems operate on battery voltage (12 volts),

some systems can be as high as 90 volts or as low as five volts. Refer to

the Electrical Circuit Diagram Manuals, available from your vehicle’s

manufacturer, to assure that any additional body lights and accessories

are connected to circuits that are both appropriate and not overloaded.

No modification should be made to any vehicle control system without

first contacting your dealer.

SUSPENSION INSPECTION

Note:Do not adjust air suspension height to any setting other than the

specified setting. Altering the height setting will change the driveline

angle and may result in unwarrantable component damage, such as

transmission component damage.

Verify drive axle air suspension height and height control valve

performance at engine lube oil change intervals.

Periodically:

•Check condition of spring leaves for evidence of fatigue, bending or

breakage.

•Check condition of suspension mounting brackets and bushings.

2004 F650/750(f67)

Supplement

USA English(fus)

Maintenance and specifications

195