FORD F750 2007 11.G Owners Manual

Manufacturer: FORD, Model Year: 2007, Model line: F750, Model: FORD F750 2007 11.GPages: 280, PDF Size: 1.93 MB

Page 101 of 280

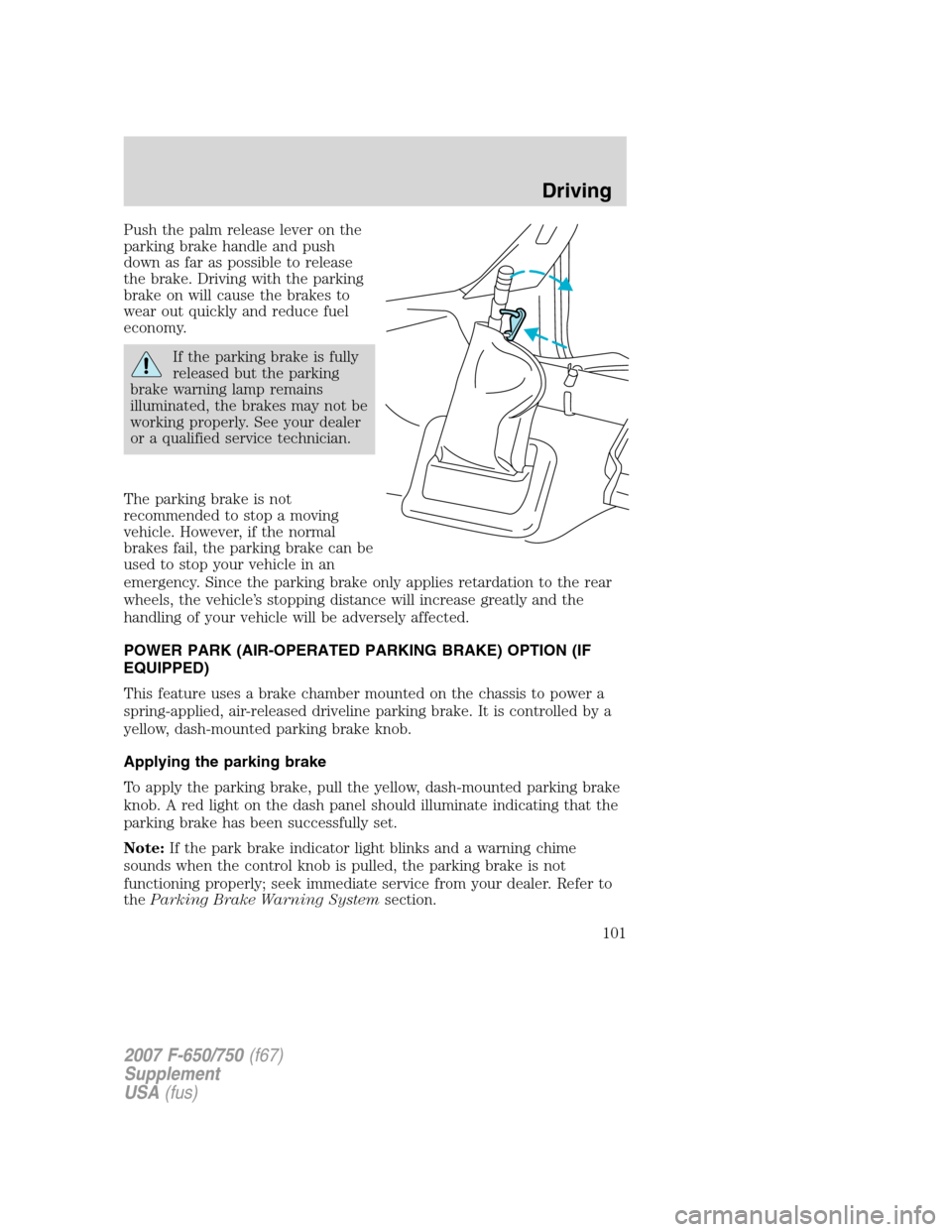

Push the palm release lever on the

parking brake handle and push

down as far as possible to release

the brake. Driving with the parking

brake on will cause the brakes to

wear out quickly and reduce fuel

economy.

If the parking brake is fully

released but the parking

brake warning lamp remains

illuminated, the brakes may not be

working properly. See your dealer

or a qualified service technician.

The parking brake is not

recommended to stop a moving

vehicle. However, if the normal

brakes fail, the parking brake can be

used to stop your vehicle in an

emergency. Since the parking brake only applies retardation to the rear

wheels, the vehicle’s stopping distance will increase greatly and the

handling of your vehicle will be adversely affected.

POWER PARK (AIR-OPERATED PARKING BRAKE) OPTION (IF

EQUIPPED)

This feature uses a brake chamber mounted on the chassis to power a

spring-applied, air-released driveline parking brake. It is controlled by a

yellow, dash-mounted parking brake knob.

Applying the parking brake

To apply the parking brake, pull the yellow, dash-mounted parking brake

knob. A red light on the dash panel should illuminate indicating that the

parking brake has been successfully set.

Note:If the park brake indicator light blinks and a warning chime

sounds when the control knob is pulled, the parking brake is not

functioning properly; seek immediate service from your dealer. Refer to

theParking Brake Warning Systemsection.

2007 F-650/750(f67)

Supplement

USA(fus)

Driving

101

Page 102 of 280

Releasing the parking brake

Note:Read and understand the following steps and perform them

whenever you prepare to drive the vehicle.

Note:The parking brake will not disengage unless sufficient system air

pressure is available.

For vehicles with automatic transmissions - dash-mounted push

button (Allison 3000 Series) and steering column-mounted (Allison

2200 and 2500) gear selection:

1. With the engine running, depress and hold the service brake pedal.

2. Wait until system air pressure is above 100 psi (690 kPa).

3. Select the appropriate drive gear.

4. Push the yellow, dash-mounted parking brake knob.

For vehicles with manual transmissions - (TTC 7–speed,

Eaton/Fuller 5–speed and 6–speed):

1. With the engine running, depress and hold the service brake pedal.

2. Wait until system air pressure is above 100 psi (690 kPa).

3. Depress and hold the clutch pedal.

4. Select the appropriate drive gear.

5. Push the yellow, dash-mounted parking brake knob.

Hold the brake pedal down while moving the gearshift lever from

position to position. If the brake pedal is not held down, the

vehicle may move unexpectedly resulting in property damage, personal

injury or death.

Parking brake light illumination due to low air pressure

If at any time during vehicle operation air pressure is too low, the

parking brake may apply and the parking brake light will turn on.

If the parking brake is applied due to low air pressure, immediate service

is required to the parking brake system.

Parking brake warning system

If the park brake light blinks and a chime sounds when pulling the yellow

control knob out, this indicates the parking brake is not functioning

properly; seek service for the parking brake immediately.

The light will blink and the chime will sound until the yellow control

knob is pushed in or approximately eight minutes have passed. If the

2007 F-650/750(f67)

Supplement

USA(fus)

Driving

102

Page 103 of 280

yellow control knob is pulled out again, the light will blink and the chime

will sound as a reminder that immediate service is required to the

parking brake system.

Releasing spring manually

Do not attempt to disassemble the parking brake chamber under

any circumstances. The high spring load may cause serious

injury.

If air pressure is released from the spring brake chamber the power

spring applies the brake and, unless air pressure can be re-established,

the spring brake must be released as follows in order to move the

vehicle.

Block the wheels to help prevent the vehicle from moving.

Unexpected and possibly sudden vehicle movement may occur if

these precautions are not taken.

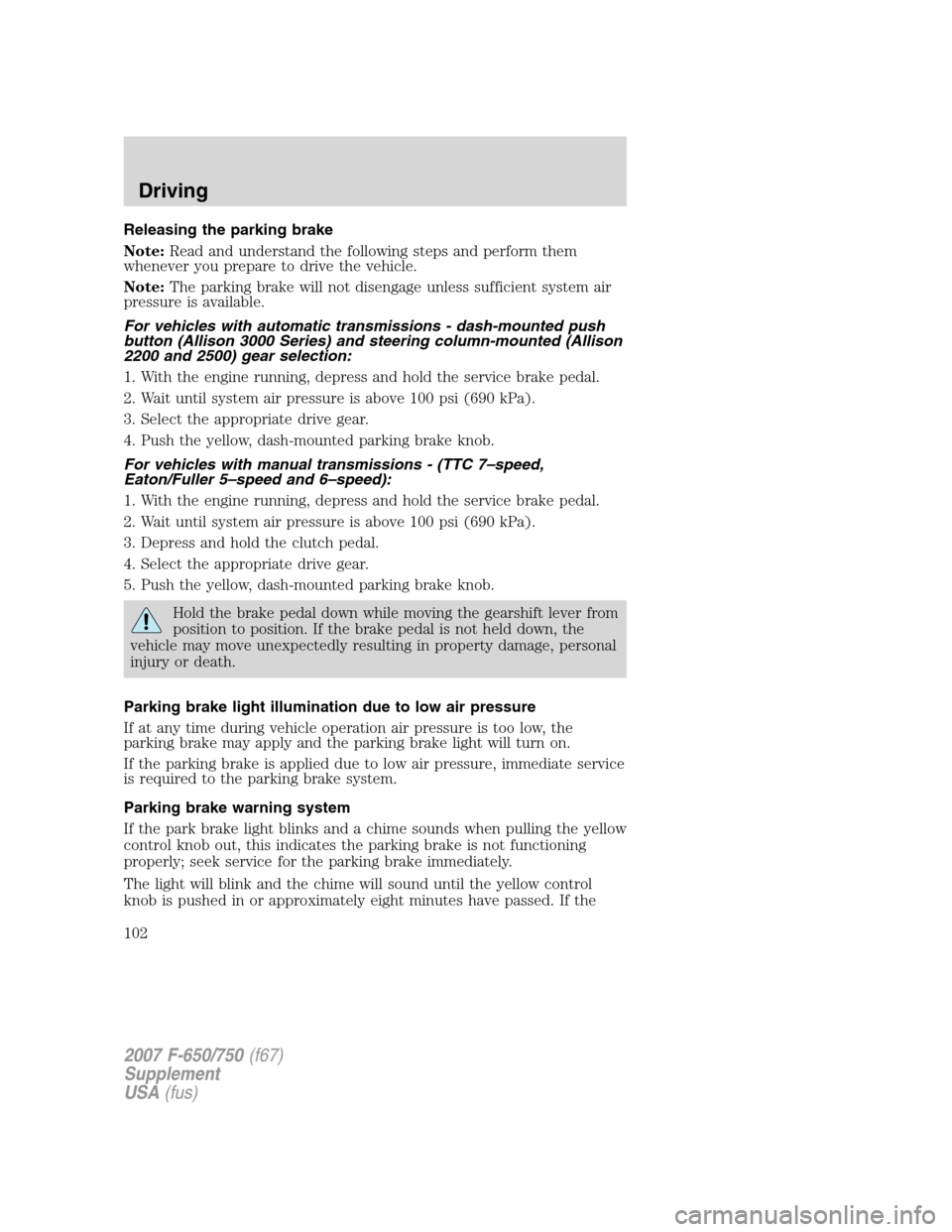

Loosen the jam nut (1) and un-thread the adjustment rod (2) from the

chamber to reduce tension on the cable (3). Continue to un-thread the

adjustment rod all the way and remove it from the chamber. The nut and

shaft are metric.

2007 F-650/750(f67)

Supplement

USA(fus)

Driving

103

Page 104 of 280

AIR BRAKES (IF EQUIPPED)

General air brake information

After starting the engine, give the air compressor time to build up the air

pressure to 60 psi (414 kPa) before moving the vehicle.

Do not drive or continue to drive if the low air pressure buzzer

is sounding or the brake warning light is lit. These warnings

indicate that air pressure is not to normal operating level. Continued

use of the vehicle could result in loss of braking ability.

Avoid repeated light application of the brake pedal. This will

deplete air pressure faster and could result in loss of braking

capability.

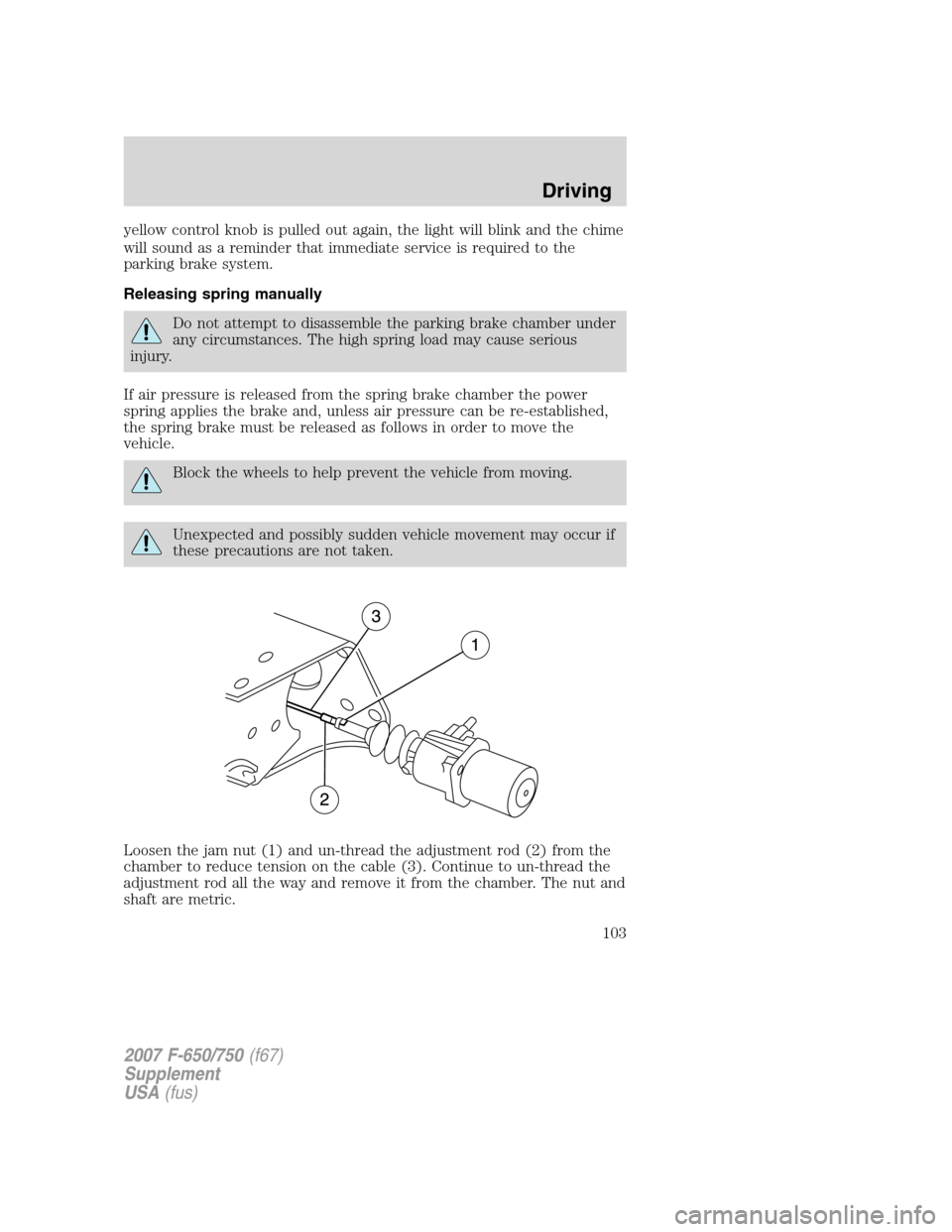

Periodically check the air pressure

gauge while driving. Pressure should

range between approximately

100–125 psi (690–862 kPa). The air

compressor governor cut-in and

cut-out pressure settings are preset

at the factory and are not

adjustable.

When air pressure is insufficient

(below 60 psi [414 kPa]), a warning

light illuminates and a buzzer

sounds when the ignition is in the

ON position.

This condition may be caused by excessive brake applications depleting

the system air pressure. If this condition occurs, stop driving the vehicle

until the compressor has fully recharged the air system.

Do not move the vehicle when the air pressure is insufficient

because the brake system may be inoperative.

Select a gear ratio to help slow your vehicle before descending grades.

Supplement with brakes as required to safely slow the vehicle and avoid

overspeeding the engine.

0 30 12090 60

150AIR

PRESSUREPSI

2007 F-650/750(f67)

Supplement

USA(fus)

Driving

104

Page 105 of 280

Air chamber stroke indication

Air chamber push rods have orange stroke indicator markers that warn

when the braking system requires adjustment or repair. The orange

stripe is painted on the air chamber push rod at the slack adjuster stroke

dimension which requires service when visible during brake application.

Air brake inspection and adjustment or repairs should be performed by a

qualified service technician in accordance with the instructions in the

service manual.

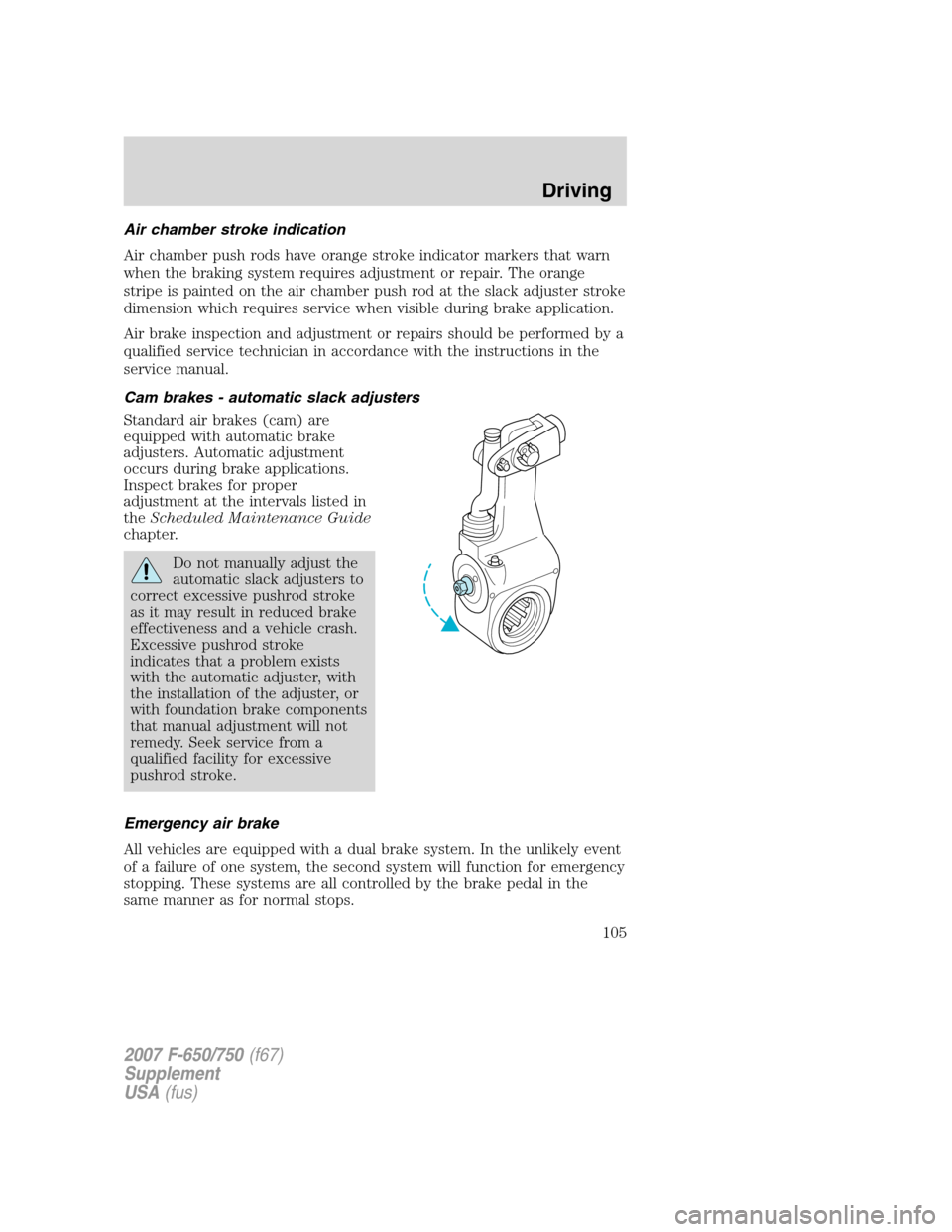

Cam brakes - automatic slack adjusters

Standard air brakes (cam) are

equipped with automatic brake

adjusters. Automatic adjustment

occurs during brake applications.

Inspect brakes for proper

adjustment at the intervals listed in

theScheduled Maintenance Guide

chapter.

Do not manually adjust the

automatic slack adjusters to

correct excessive pushrod stroke

as it may result in reduced brake

effectiveness and a vehicle crash.

Excessive pushrod stroke

indicates that a problem exists

with the automatic adjuster, with

the installation of the adjuster, or

with foundation brake components

that manual adjustment will not

remedy. Seek service from a

qualified facility for excessive

pushrod stroke.

Emergency air brake

All vehicles are equipped with a dual brake system. In the unlikely event

of a failure of one system, the second system will function for emergency

stopping. These systems are all controlled by the brake pedal in the

same manner as for normal stops.

2007 F-650/750 (f67)

Supplement

USA (fus)

Driving

105

Page 106 of 280

Do not continue to operate the vehicle with a failure of one of

the systems. Take the vehicle to your dealer for service

immediately.

Air brake reservoir draining

Failure to drain air brake reservoirs can result in a reduction or

loss of braking ability due to fluid accumulation in the reservoir

and/or possible freeze-up during cold weather.

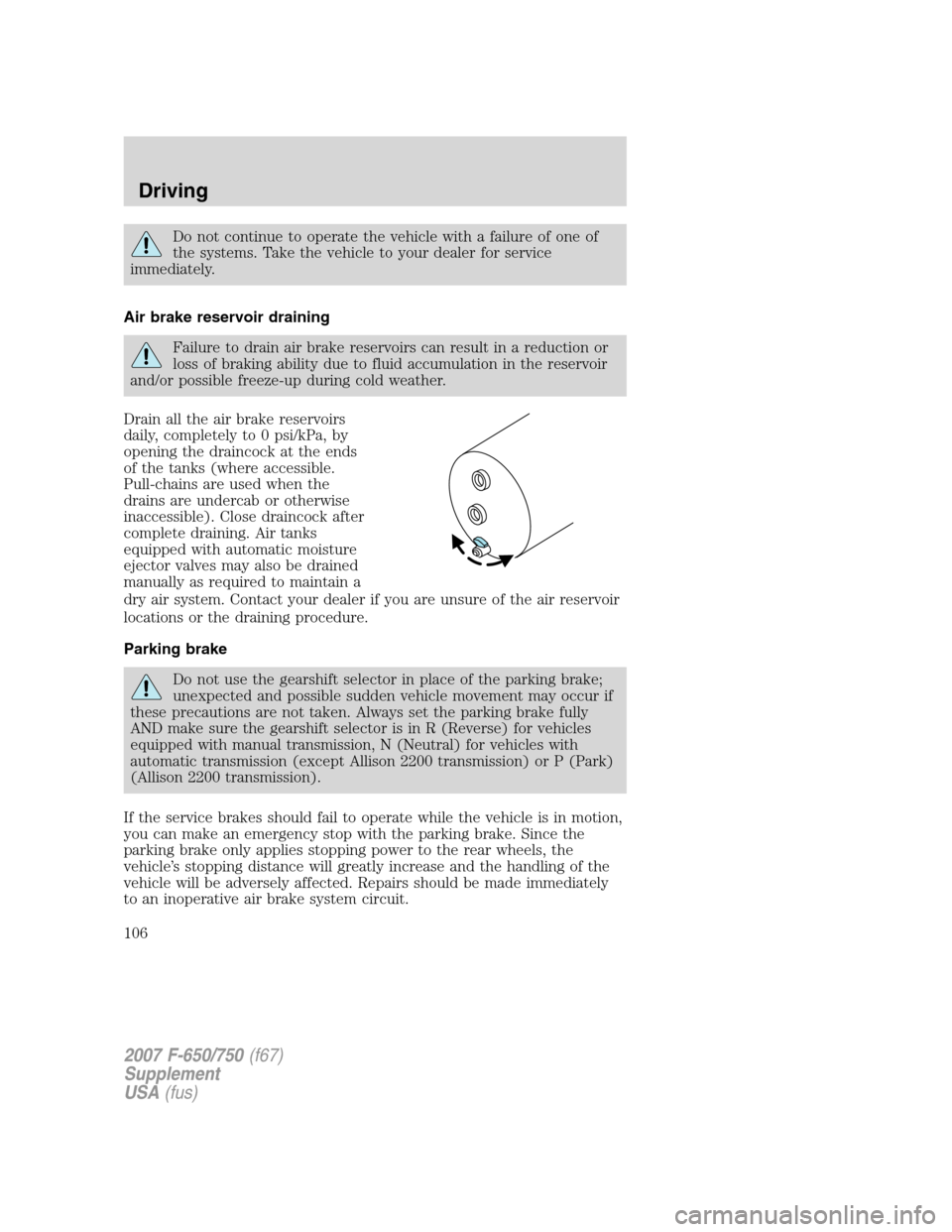

Drain all the air brake reservoirs

daily, completely to 0 psi/kPa, by

opening the draincock at the ends

of the tanks (where accessible.

Pull-chains are used when the

drains are undercab or otherwise

inaccessible). Close draincock after

complete draining. Air tanks

equipped with automatic moisture

ejector valves may also be drained

manually as required to maintain a

dry air system. Contact your dealer if you are unsure of the air reservoir

locations or the draining procedure.

Parking brake

Do not use the gearshift selector in place of the parking brake;

unexpected and possible sudden vehicle movement may occur if

these precautions are not taken. Always set the parking brake fully

AND make sure the gearshift selector is in R (Reverse) for vehicles

equipped with manual transmission, N (Neutral) for vehicles with

automatic transmission (except Allison 2200 transmission) or P (Park)

(Allison 2200 transmission).

If the service brakes should fail to operate while the vehicle is in motion,

you can make an emergency stop with the parking brake. Since the

parking brake only applies stopping power to the rear wheels, the

vehicle’s stopping distance will greatly increase and the handling of the

vehicle will be adversely affected. Repairs should be made immediately

to an inoperative air brake system circuit.

2007 F-650/750 (f67)

Supplement

USA (fus)

Driving

106

Page 107 of 280

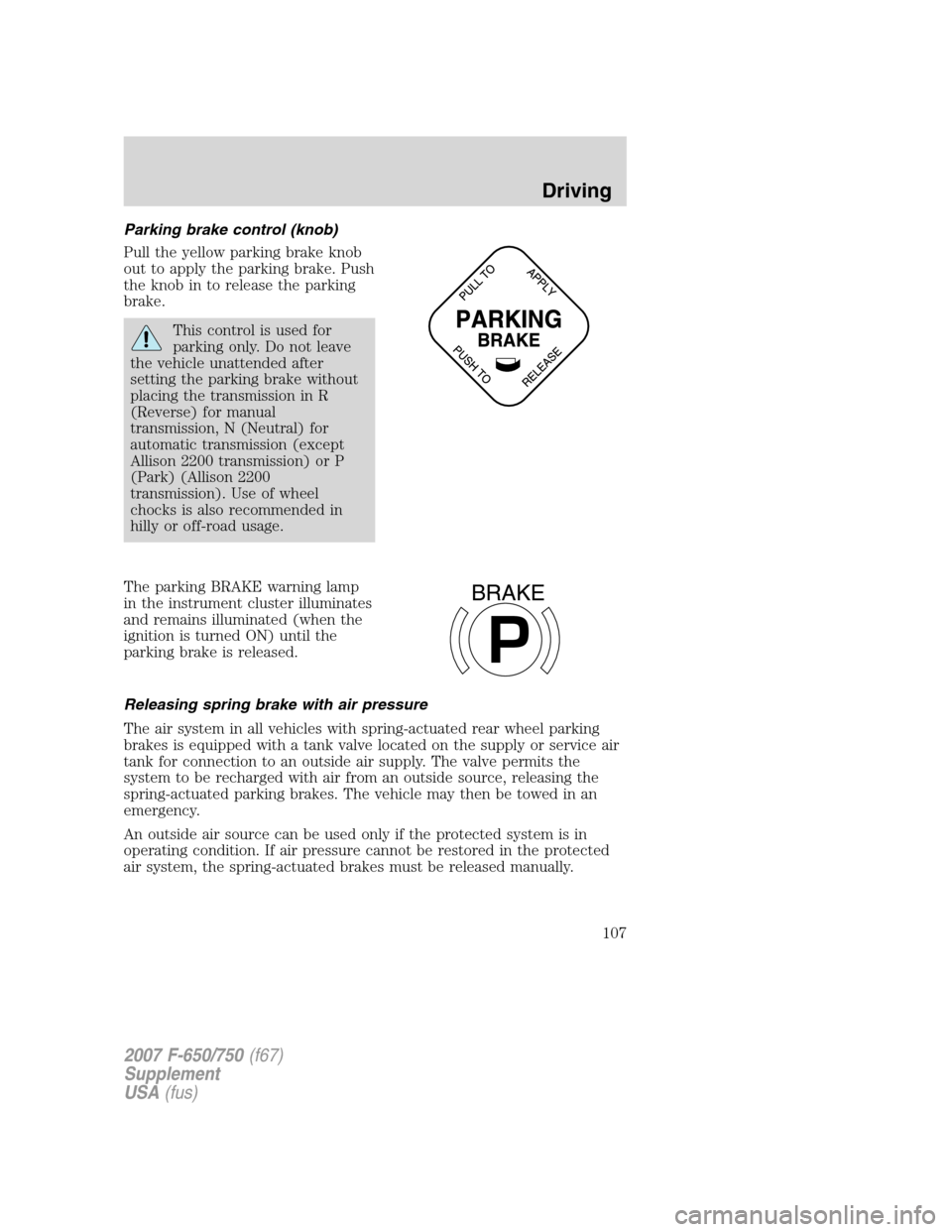

Parking brake control (knob)

Pull the yellow parking brake knob

out to apply the parking brake. Push

the knob in to release the parking

brake.

This control is used for

parking only. Do not leave

the vehicle unattended after

setting the parking brake without

placing the transmission in R

(Reverse) for manual

transmission, N (Neutral) for

automatic transmission (except

Allison 2200 transmission) or P

(Park) (Allison 2200

transmission). Use of wheel

chocks is also recommended in

hilly or off-road usage.

The parking BRAKE warning lamp

in the instrument cluster illuminates

and remains illuminated (when the

ignition is turned ON) until the

parking brake is released.

Releasing spring brake with air pressure

The air system in all vehicles with spring-actuated rear wheel parking

brakes is equipped with a tank valve located on the supply or service air

tank for connection to an outside air supply. The valve permits the

system to be recharged with air from an outside source, releasing the

spring-actuated parking brakes. The vehicle may then be towed in an

emergency.

An outside air source can be used only if the protected system is in

operating condition. If air pressure cannot be restored in the protected

air system, the spring-actuated brakes must be released manually.

P

BRAKE

2007 F-650/750(f67)

Supplement

USA(fus)

Driving

107

Page 108 of 280

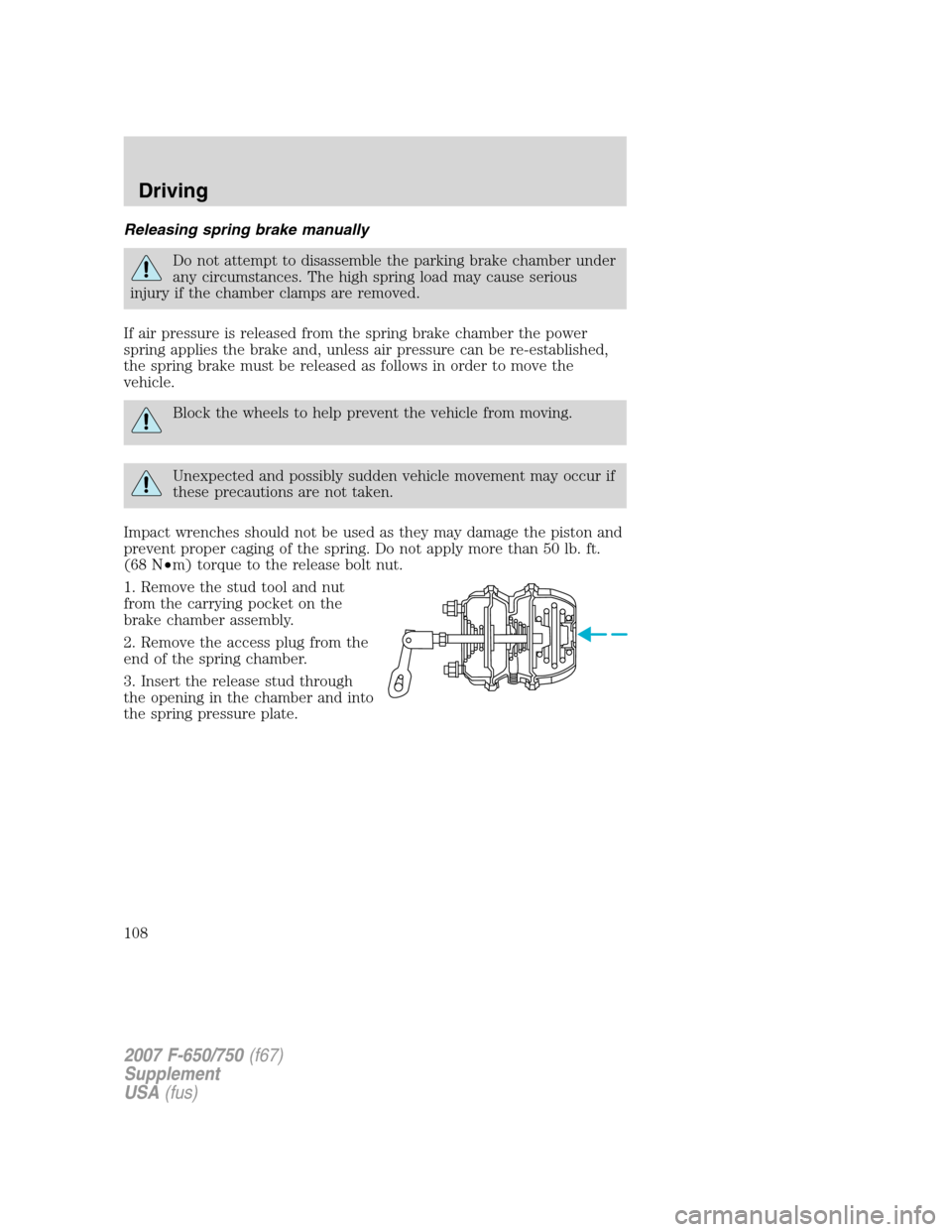

Releasing spring brake manually

Do not attempt to disassemble the parking brake chamber under

any circumstances. The high spring load may cause serious

injury if the chamber clamps are removed.

If air pressure is released from the spring brake chamber the power

spring applies the brake and, unless air pressure can be re-established,

the spring brake must be released as follows in order to move the

vehicle.

Block the wheels to help prevent the vehicle from moving.

Unexpected and possibly sudden vehicle movement may occur if

these precautions are not taken.

Impact wrenches should not be used as they may damage the piston and

prevent proper caging of the spring. Do not apply more than 50 lb. ft.

(68 N•m) torque to the release bolt nut.

1. Remove the stud tool and nut

from the carrying pocket on the

brake chamber assembly.

2. Remove the access plug from the

end of the spring chamber.

3. Insert the release stud through

the opening in the chamber and into

the spring pressure plate.

2007 F-650/750(f67)

Supplement

USA(fus)

Driving

108

Page 109 of 280

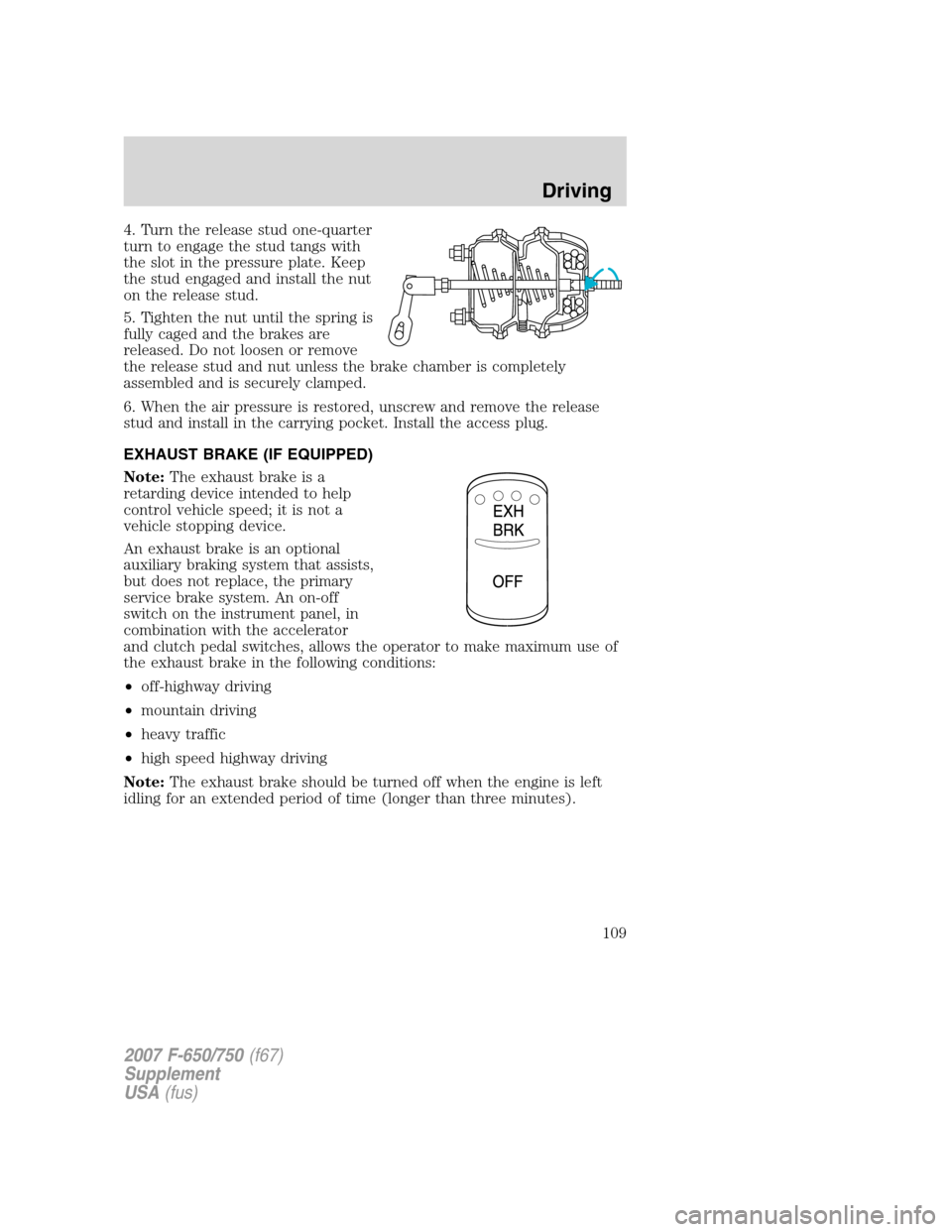

4. Turn the release stud one-quarter

turn to engage the stud tangs with

the slot in the pressure plate. Keep

the stud engaged and install the nut

on the release stud.

5. Tighten the nut until the spring is

fully caged and the brakes are

released. Do not loosen or remove

the release stud and nut unless the brake chamber is completely

assembled and is securely clamped.

6. When the air pressure is restored, unscrew and remove the release

stud and install in the carrying pocket. Install the access plug.

EXHAUST BRAKE (IF EQUIPPED)

Note:The exhaust brake is a

retarding device intended to help

control vehicle speed; it is not a

vehicle stopping device.

An exhaust brake is an optional

auxiliary braking system that assists,

but does not replace, the primary

service brake system. An on-off

switch on the instrument panel, in

combination with the accelerator

and clutch pedal switches, allows the operator to make maximum use of

the exhaust brake in the following conditions:

•off-highway driving

•mountain driving

•heavy traffic

•high speed highway driving

Note:The exhaust brake should be turned off when the engine is left

idling for an extended period of time (longer than three minutes).

2007 F-650/750(f67)

Supplement

USA(fus)

Driving

109

Page 110 of 280

The exhaust brake is a butterfly

type valve mounted in the exhaust

pipe. When the operator’s foot is not

on the accelerator pedal and the

exhaust brake switch is in the ON

position, an air cylinder shuts the

butterfly valve, restricting the flow

of exhaust gases and retarding the

engine. This retarding action is

carried through the engine and drivetrain, slowing the vehicle and

reducing the need for frequent service brake applications.

Exhaust brakes are not intended for use as the primary braking system

during vehicle operation.

Operation

Push the rocker switch up to turn

the exhaust brake on. The switch

will illuminate in the ON position.

Push the switch down to turn the

brake off.

Starting engine

Before starting the engine, make sure that the exhaust brake switch is in

the OFF position. Do not turn the exhaust brake on until the engine has

reached normal operating temperatures.

Driving downhill

While approaching a steep grade, make sure that the exhaust brake

switch is in the ON position. The exhaust brake actuates as soon as you

remove your foot from the accelerator pedal. While going down the

grade, use a low enough gear to descend safely with a minimum

application of the service brakes. As a general guideline, use the same

gear as you would to ascend the hill.

Before descending a hill or steep grade always select the proper gear. If

the transmission is taken out of gear while descending it is possible that

you will not be able to select another gear because of maximum RPM

being governed.

2007 F-650/750(f67)

Supplement

USA(fus)

Driving

110