oil FORD F750 2011 12.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: F750, Model: FORD F750 2011 12.GPages: 290, PDF Size: 1.96 MB

Page 2 of 290

Seating and Safety Restraints 69

Seating 69

Safety restraints 80

Child restraints 88

Driving 104

Starting 104

Brakes 111

Air suspension 132

Transmission operation 134

Vehicle loading 147

Roadside Emergencies 153

Hazard flasher switch 154

Fuses and relays 154

Jump starting 162

Wrecker towing 166

Customer Assistance 170

Getting assistance outside the U.S. and Canada 172

Reporting safety defects (U.S. only) 174

Reporting safety defects (Canada only) 174

Cleaning 175

Underbody preservation 181

Maintenance and Specifications 182

Hood 190

Engine oil 193

Battery 193

Engine coolant 196

Fuel information 197

Diesel Exhaust Fluid (DEF) 201

Wheel lug nut torque 229

Tire information 229

Lubricant specifications 237

Refill capacities 250

Table of Contents

2

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 9 of 290

ENTERING, EXITING AND/OR CLIMBING ON THIS VEHICLE

You must be careful and deliberate to minimize the possibility of personal

injury from a slip and fall when entering, exiting and/or climbing on this

vehicle. Always use the steps and assist handles before climbing. Do not

skip any steps or assist handles. Use three point contact at all times with

at least two feet and one hand or two hands and one foot firmly placed

during all phases of entering, exiting and/or climbing. Always keep your

shoe soles and hands clean. Keep the steps and assist handles free of

snow, ice, oil, grease, substances or debris. Be sure to use extra care in

bad weather. Avoid wearing thick gloves. Always perform trailer hook-up

while standing on the ground.

WARNING:Do not carry items while entering, exiting, and/or

climbing. Make sure you keep a firm grip. Always FACE the

VEHICLE STEP and HANDLE SYSTEM while climbing up and down.

Do not climb behind the cab unless you have three point contact with

a step and handle system at all times.

Introduction

9

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 11 of 290

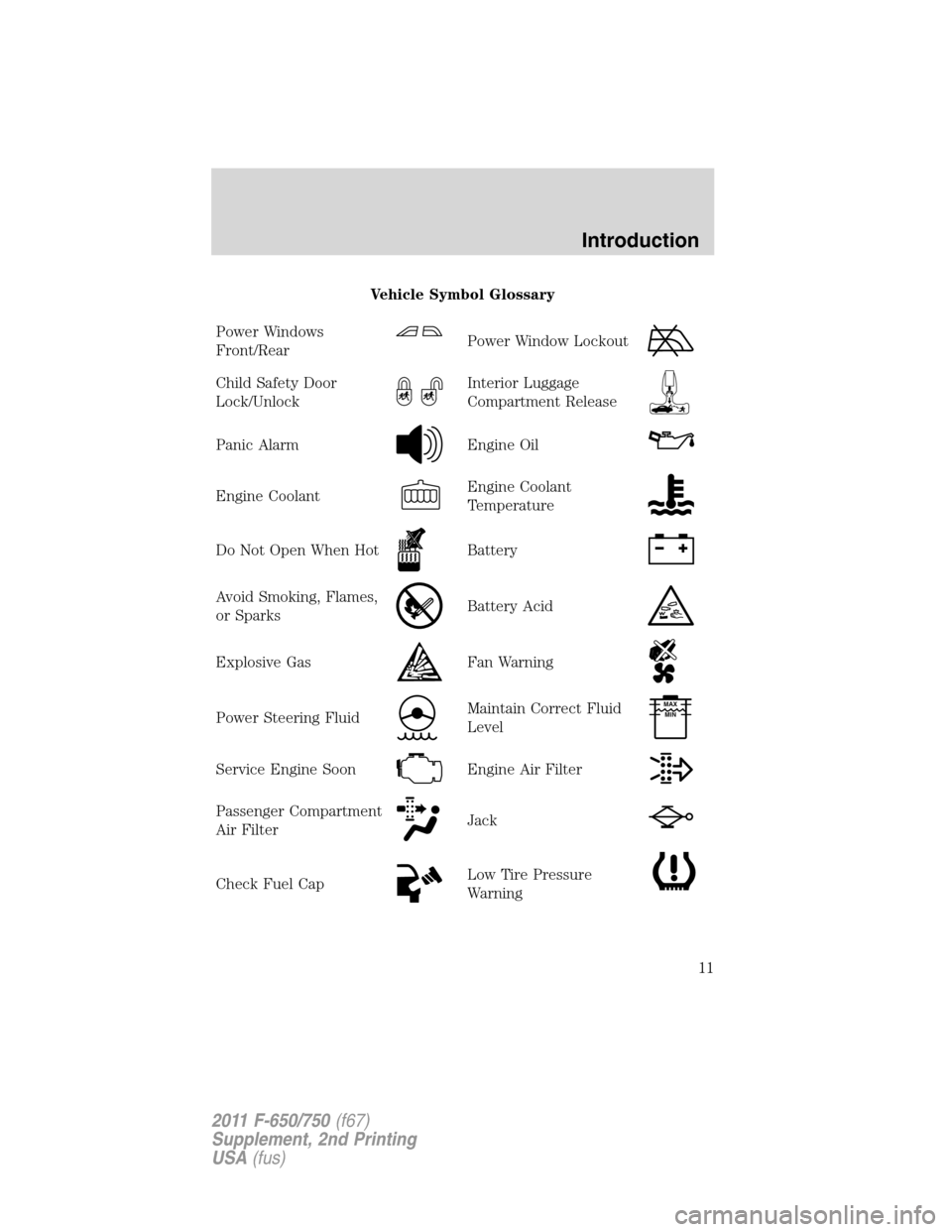

Vehicle Symbol Glossary

Power Windows

Front/Rear

Power Window Lockout

Child Safety Door

Lock/UnlockInterior Luggage

Compartment Release

Panic AlarmEngine Oil

Engine CoolantEngine Coolant

Temperature

Do Not Open When HotBattery

Avoid Smoking, Flames,

or SparksBattery Acid

Explosive GasFan Warning

Power Steering FluidMaintain Correct Fluid

LevelMAX

MIN

Service Engine SoonEngine Air Filter

Passenger Compartment

Air FilterJack

Check Fuel CapLow Tire Pressure

Warning

Introduction

11

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 12 of 290

To be sure your vehicle is ready to operate, conduct a pre-trip inspection

at the beginning of each work period. Follow the steps listed in this

section to ensure a proper vehicle inspection procedure. The pages in

this section may be produced locally and used on a regular basis.

VEHICLE INSPECTION INFORMATION

Note:Always make sure the parking brake is applied before starting the

engine.

Engine compartment (with engine stopped)

Engine oil level:Use the engine oil dipstick to verify that the

engine oil level is between the ADD and

OPERATING RANGE marks.

Engine coolant

level:Look through the plastic reservoir or the clear

sight glass on the reservoir, depending upon

vehicle equipment, and make sure the fluid is

within the minimum and maximum fluid level

range as marked on the reservoir.Do not

remove pressure cap until the coolant has

cooled.

Power steering fluid:Verify that the fluid level is in the proper

operating range. Refer toPower steering

fluidin theMaintenance and Specifications

chapter.

Brake fluid (master

cylinder):Remove the master cylinder caps and inspect

the fluid level. The full mark is at the bottom

of the opening of the fluid ports.

Hydraulic clutch

fluid:Check for adequate amount of hydraulic clutch

fluid. Fluid level should be at the step of the

reservoir; refer toClutch fluid/linkage

adjustmentsin theMaintenance and

Specificationschapter.

Belts (Fan,

alternator, water

pump and A/C

compressor):Check for glazing, fraying or cracking. There

should be no more than five-seven cracks per

rib, per inch (2.5 cm).

Vehicle Inspection Guide

12

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 14 of 290

Engine starting (parking brake applied)

Safety/Emergency

equipment:Prior to entering the cab, verify that the

vehicle is equipped with spare electrical fuses

(if used), three red reflective triangles, a

properly charged and rated fire extinguisher

and wheel chocks. Walk around the vehicle

and check that all steps and grab handles,

inside and out as well as behind, are tight and

clean. Use extreme caution and a three-point

stance at all times. Check door latches for

positive closing, latching and locking.

Starting the engine:Verify the parking brake is set. Press the

clutch (if equipped with a manual

transmission) and verify the transmission is in

neutral. Vehicles equipped with an automatic

transmission should be in N (Neutral) or P

(Park) if equipped with a park position.

Turn the key to the on position. When the

indicator light in the instrument cluster turns

off, turn the key to start.

Oil pressure builds:Make sure engine oil pressure is building to

normal operating range.

Air chime sounds (if

equipped with air

compressor):The low air pressure warning chime should

sound immediately after the engine starts but

before the compressor has built up pressure.

The low air pressure warning chime should

stop when the air pressure reaches 70 psi

(483 kPa) (or more). Let the air pressure

build to governed cut-out pressure, which

should occur between 115–130 psi

(793–896 kPa).

Vehicle Inspection Guide

14

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 18 of 290

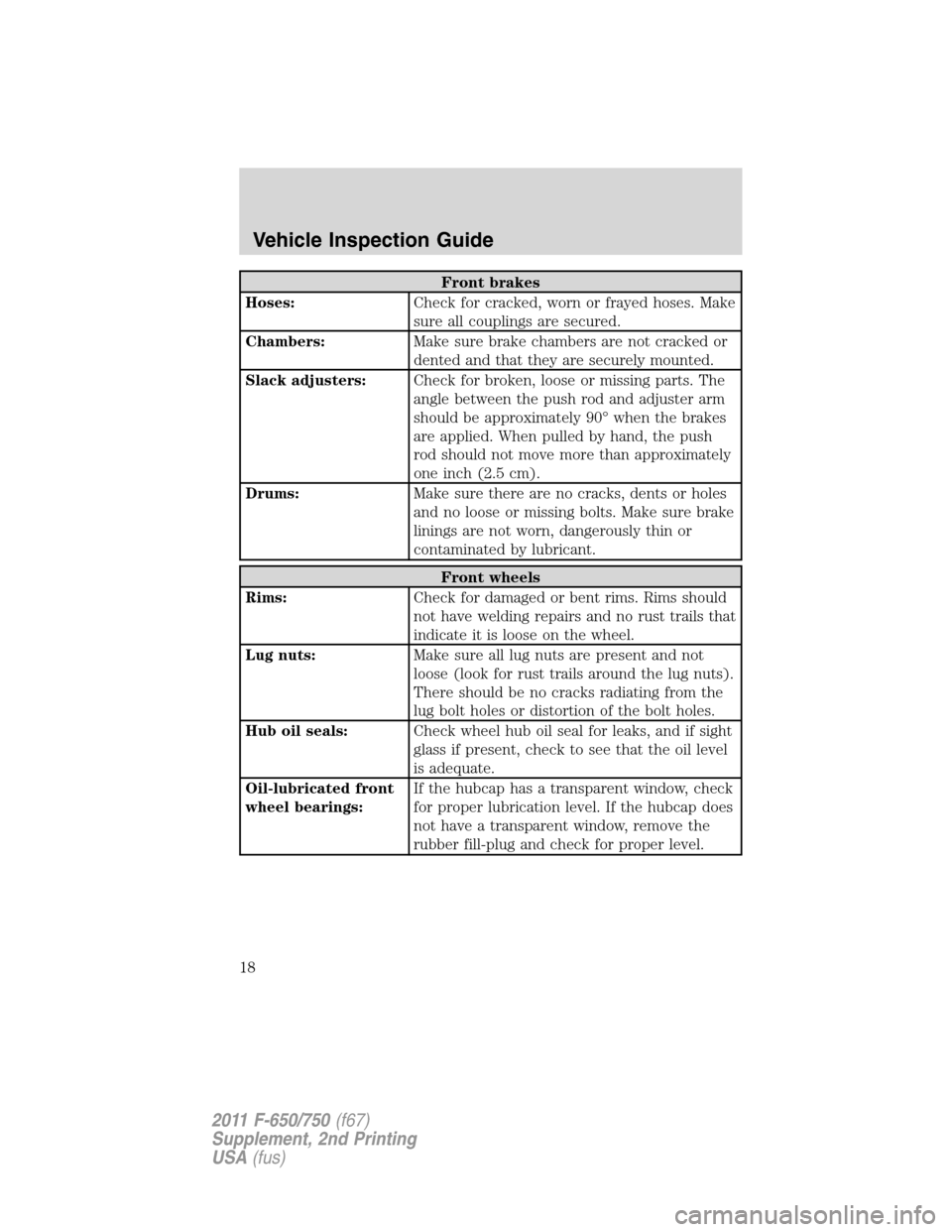

Front brakes

Hoses:Check for cracked, worn or frayed hoses. Make

sure all couplings are secured.

Chambers:Make sure brake chambers are not cracked or

dented and that they are securely mounted.

Slack adjusters:Check for broken, loose or missing parts. The

angle between the push rod and adjuster arm

should be approximately 90° when the brakes

are applied. When pulled by hand, the push

rod should not move more than approximately

one inch (2.5 cm).

Drums:Make sure there are no cracks, dents or holes

and no loose or missing bolts. Make sure brake

linings are not worn, dangerously thin or

contaminated by lubricant.

Front wheels

Rims:Check for damaged or bent rims. Rims should

not have welding repairs and no rust trails that

indicate it is loose on the wheel.

Lug nuts:Make sure all lug nuts are present and not

loose (look for rust trails around the lug nuts).

There should be no cracks radiating from the

lug bolt holes or distortion of the bolt holes.

Hub oil seals:Check wheel hub oil seal for leaks, and if sight

glass if present, check to see that the oil level

is adequate.

Oil-lubricated front

wheel bearings:If the hubcap has a transparent window, check

for proper lubrication level. If the hubcap does

not have a transparent window, remove the

rubber fill-plug and check for proper level.

Vehicle Inspection Guide

18

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 31 of 290

GAUGES

Base cluster with automatic transmission shown. Metric similar.

1.Tachometer:Indicates the engine speed in revolutions per minute.

Driving with your tachometer pointer continuously at the top of the scale

may damage the engine.

2.Engine oil pressure gauge:Indicates engine oil pressure. The

needle should stay in the normal operating range (between L and H). If

the needle falls below the normal range, stop the vehicle, turn off the

engine and check the engine oil level. Add oil if needed. If the oil level is

correct, have your vehicle checked at your authorized dealer.

3.Engine coolant temperature gauge:Indicates engine coolant

temperature. At normal operating temperature, the needle will be in the

normal range (between H and C).If it enters the red section, the

engine is overheating. Stop the vehicle as soon as safely possible,

switch off the engine and let the engine cool.

WARNING:Never remove the coolant reservoir cap while the

engine is running or hot.

4.Diesel exhaust fluid (DEF) gauge:Shows fluid level in DEF tank.

Instrument Cluster

31

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 102 of 290

If the booster seat slides on the vehicle seat, placing a rubberized mesh

sold as shelf or carpet liner under the booster seat may improve this

condition. Do not introduce any item thicker than this under the booster

seat. Check with the booster seat manufacturer’s instructions.

The importance of shoulder belts

Using a booster without a shoulder belt increases the risk of a child’s

head hitting a hard surface in a collision. For this reason, you should

never use a booster seat with a lap belt only. It is generally best to use a

booster seat with lap/shoulder belts in the back seat.

Move a child to a different seating location if the shoulder belt does not

stay positioned on the shoulder during use.

Follow all instructions provided by the manufacturer of the booster seat.

WARNING:Never place, or allow a child to place, the shoulder

belt under a child’s arm or behind the back because it reduces

the protection for the upper part of the body and may increase the risk

of injury or death in a collision.

Safety belt maintenance

Inspect the vehicle safety belts and child safety seat systems periodically

to make sure they work properly and are not damaged. Inspect the

vehicle and child seat safety belts to make sure there are no nicks, tears

or cuts. Replace if necessary. All vehicle safety belt assemblies, including

retractors, buckles, front safety belt buckle assemblies, buckle support

assemblies (slide bar-if equipped), shoulder belt height adjusters (if

equipped), shoulder belt guide on seatback (if equipped), child safety

seat LATCH and tether anchors, and attaching hardware, should be

inspected after a collision. Refer to the child restraint manufacturer’s

instructions for additional inspection and maintenance information

specific to the child restraint. Ford Motor Company recommends that all

safety belt assemblies in use in vehicles involved in a collision be

replaced. However, if the collision was minor and an authorized dealer

finds that the belts do not show damage and continue to operate

properly, they do not need to be replaced. Safety belt assemblies not in

use during a collision should also be inspected and replaced if either

damage or improper operation is noted.

For proper care of soiled safety belts, refer toInteriorin theCleaning

chapter.

Seating and Safety Restraints

102

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 105 of 290

Note:When starting the engine, do not press the accelerator as engine

damage may result.

1. Ensure headlamps and all accessories are turned off, the parking

brake is applied and the transmission is in the neutral position (or P

[Park] for Allison 2200 transmissions).

2. Turn the key to the on position, but do not start the engine.

In cooler weather, the air intake

heater may activate the WAIT TO

START light in the instrument

cluster. If the WAIT TO START light

illuminates,do notcrank the engine until the light goes off.

WARNING:If equipped with an air intake heater, DO NOT use

ether or any other starting fluids. The use of starting fluids

(ether) in an engine equipped with an air intake heater could cause an

explosion and result in property damage and/or personal injury.

3. When the WAIT TO START light turns off, turn the key to the start

position; when the engine starts, release the key.

If the engine does not start after 30 seconds of cranking, allow two

minutes for the starter to cool before trying again. Excessive cranking

may damage the starter.

After the engine starts:

•On some engines, the WAIT TO

START light should illuminate

after the engine starts. Allow the

engine to idle about three

minutes or until the engine coolant temperature gauge begins to rise.

Maintain idle speed until the WAIT TO START light cycles off to

indicate the air intake heater has shut off (approximately six

minutes). Operating the engine at higher speeds will reduce the

effectiveness of the air inlet heater.

•Do not increase engine speed until the oil pressure gauge indicates

normal pressure (as indicated by the arrows); this should be indicated

on the gauge within 15 seconds after starting.

•Idle the engine for three to five minutes before operating with a full

load.

•Try to limit engine idle to 10 minutes. Excessive idling reduces fuel

economy.

Driving

105

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 106 of 290

•When starting a cold engine, increase the engine RPM slowly to make

sure adequate lubrication is available to the bearings.

Cold weather operation

WARNING:Do not use volatile starting aids such as ether,

propane or gasoline in the engine air intake system. Glow plugs

may ignite vapors which can cause engine damage or personal injury.

In order to operate the engine in temperatures of 32°F (0°C) or lower,

read the following instructions:

•Make sure that the batteries are of sufficient size and are fully

charged. Check other electrical components to make sure they’re in

optimum condition.

•Use a permanent-type engine coolant solution to protect the engine

against damage from freezing.

•If your vehicle is equipped with a water-fuel separator, drain it daily.

Fill the fuel tank at the end of daily operation to prevent condensation

in the fuel system.

•Make sure you use proper cold weather engine oil and that it is at its

proper level.

•At temperatures of –4°F (–20°C) or below, it is recommended that you

use a crankcase-mounted coolant heater to improve cold engine

starting.

•If operating in arctic temperatures of –20°F (–29°C) or lower, consult

your truck dealer for information about special cold weather

equipment and precautions.

Note:Idling in cold weather will not heat the engine to its normal

operating temperature. Long periods of idling in cold weather can cause

a build-up of heavy deposits of carbon and rust on valve stems causing

them to stick which, in turn, can cause valvetrain damage.

Winter fronts

The use of winter fronts, or other air-restrictive devices mounted in front

of the radiator on vehicles with chassis-mounted charge air coolers, are

not recommended unless extremely cold weather conditions exist. Air

flow restriction can cause high exhaust temperatures, power loss,

excessive fan usage and a reduction in fuel economy. If you must use a

winter front, the device should have a permanent opening of at least 120

sq in. (774 sq. cm) directly in line with the fan hub.

Driving

106

2011 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)