FORD F750 2012 12.G User Guide

Manufacturer: FORD, Model Year: 2012, Model line: F750, Model: FORD F750 2012 12.GPages: 306, PDF Size: 1.74 MB

Page 11 of 306

WARNING:Exercise great caution when working on vehicle

equipped with an automatic fan clutch. The fan starts in motion

only after the engine coolant reaches a predetermined temperature or

the refrigerant pressure (if equipped with air conditioning) reaches a

predetermined setting. The fan starts at this point with no advance

warning. Never reach near, or permit objects to protrude into, the fan

blade radius while the engine is running as this could result in vehicle

damage, personal injury or death.

Engine starting (parking brake applied)

Safety/Emergency

equipmentBefore entering the cab, verify that the vehicle is

equipped with spare electrical fuses (if used),

three red reflective triangles, a properly charged

and rated fire extinguisher and wheel chocks.

Walk around the vehicle and verify all steps and

grab handles, inside and out as well as behind,

are tight and clean. Use extreme caution and a

three-point stance at all times. Inspect door

latches for positive closing, latching and locking.

Starting the

engineSet the parking brake, press the clutch (if

equipped with a manual transmission) and verify

the transmission is in neutral. Vehicles equipped

with an automatic transmission should be in N

(Neutral) or P (Park) (if equipped with a park

position).

Diesel engine:Turn the key to the on position;

when the

light in the instrument cluster

turns off, turn the key to start.

Gas engine:Turn the key to start, then release

it as soon as the engine starts.

Oil pressureVerify engine oil pressure builds to normal

operating range.

Vehicle Inspection Guide

11

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 12 of 306

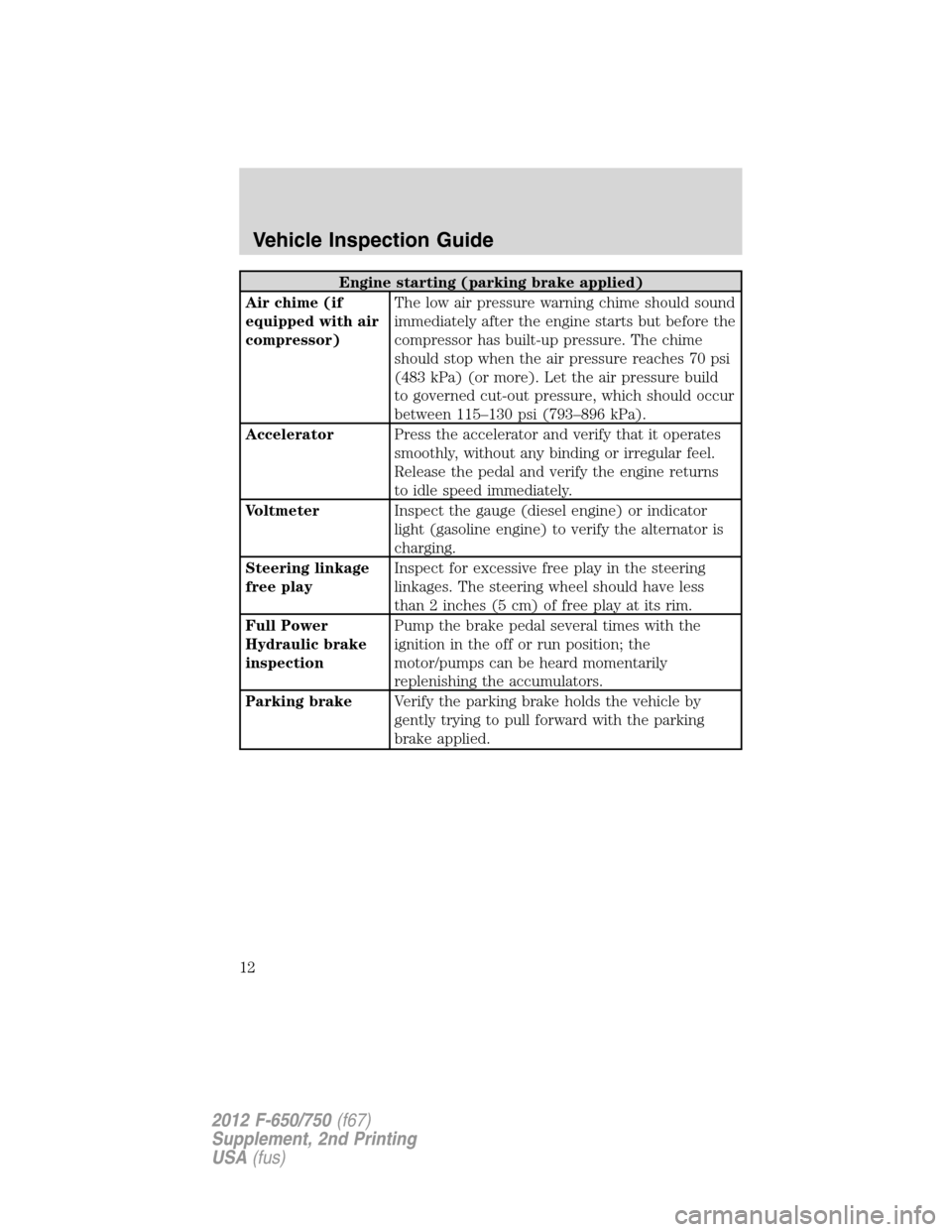

Engine starting (parking brake applied)

Air chime (if

equipped with air

compressor)The low air pressure warning chime should sound

immediately after the engine starts but before the

compressor has built-up pressure. The chime

should stop when the air pressure reaches 70 psi

(483 kPa) (or more). Let the air pressure build

to governed cut-out pressure, which should occur

between 115–130 psi (793–896 kPa).

AcceleratorPress the accelerator and verify that it operates

smoothly, without any binding or irregular feel.

Release the pedal and verify the engine returns

to idle speed immediately.

VoltmeterInspect the gauge (diesel engine) or indicator

light (gasoline engine) to verify the alternator is

charging.

Steering linkage

free playInspect for excessive free play in the steering

linkages. The steering wheel should have less

than 2 inches (5 cm) of free play at its rim.

Full Power

Hydraulic brake

inspectionPump the brake pedal several times with the

ignition in the off or run position; the

motor/pumps can be heard momentarily

replenishing the accumulators.

Parking brakeVerify the parking brake holds the vehicle by

gently trying to pull forward with the parking

brake applied.

Vehicle Inspection Guide

12

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 13 of 306

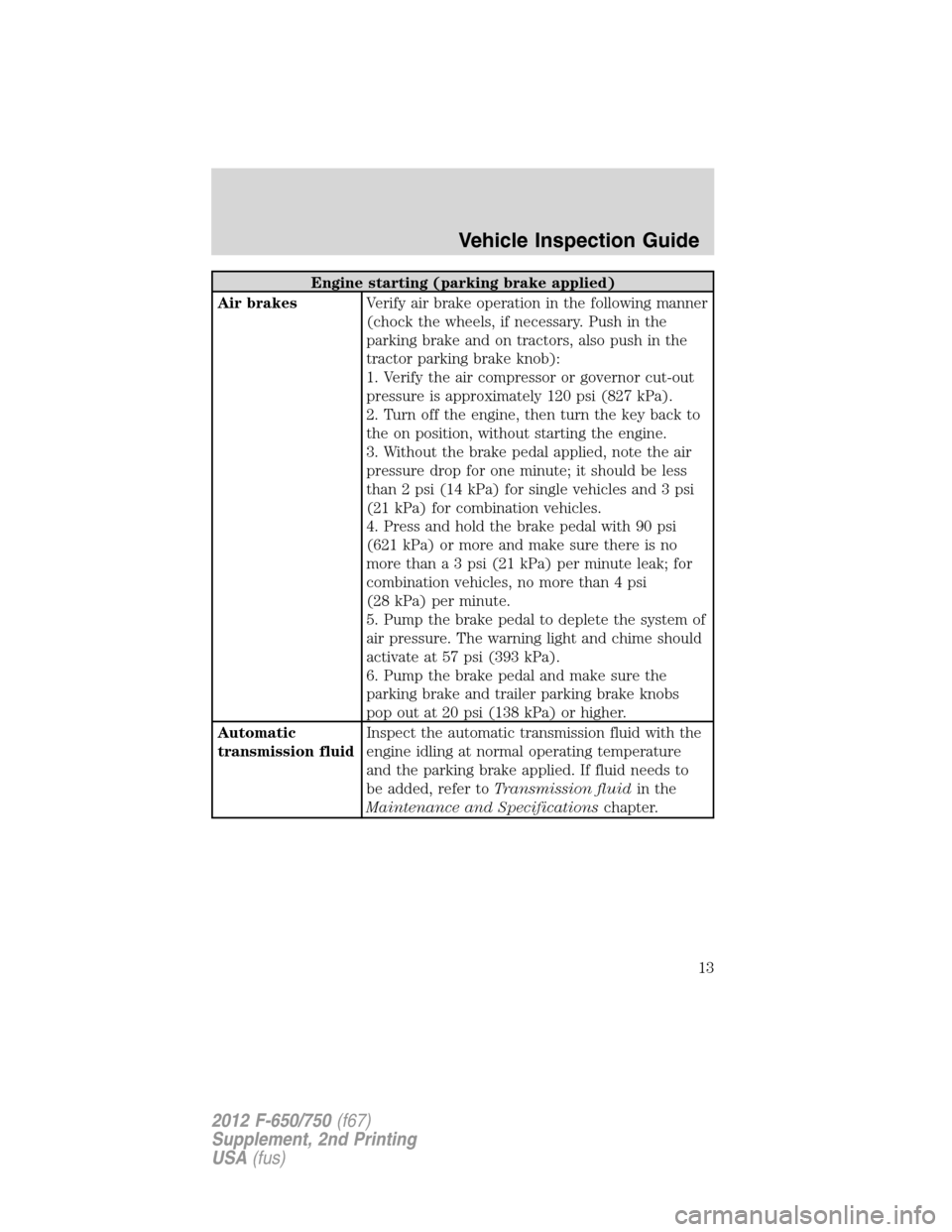

Engine starting (parking brake applied)

Air brakesVerify air brake operation in the following manner

(chock the wheels, if necessary. Push in the

parking brake and on tractors, also push in the

tractor parking brake knob):

1. Verify the air compressor or governor cut-out

pressure is approximately 120 psi (827 kPa).

2. Turn off the engine, then turn the key back to

the on position, without starting the engine.

3. Without the brake pedal applied, note the air

pressure drop for one minute; it should be less

than 2 psi (14 kPa) for single vehicles and 3 psi

(21 kPa) for combination vehicles.

4. Press and hold the brake pedal with 90 psi

(621 kPa) or more and make sure there is no

more than a 3 psi (21 kPa) per minute leak; for

combination vehicles, no more than 4 psi

(28 kPa) per minute.

5. Pump the brake pedal to deplete the system of

air pressure. The warning light and chime should

activate at 57 psi (393 kPa).

6. Pump the brake pedal and make sure the

parking brake and trailer parking brake knobs

pop out at 20 psi (138 kPa) or higher.

Automatic

transmission fluidInspect the automatic transmission fluid with the

engine idling at normal operating temperature

and the parking brake applied. If fluid needs to

be added, refer toTransmission fluidin the

Maintenance and Specificationschapter.

Vehicle Inspection Guide

13

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 14 of 306

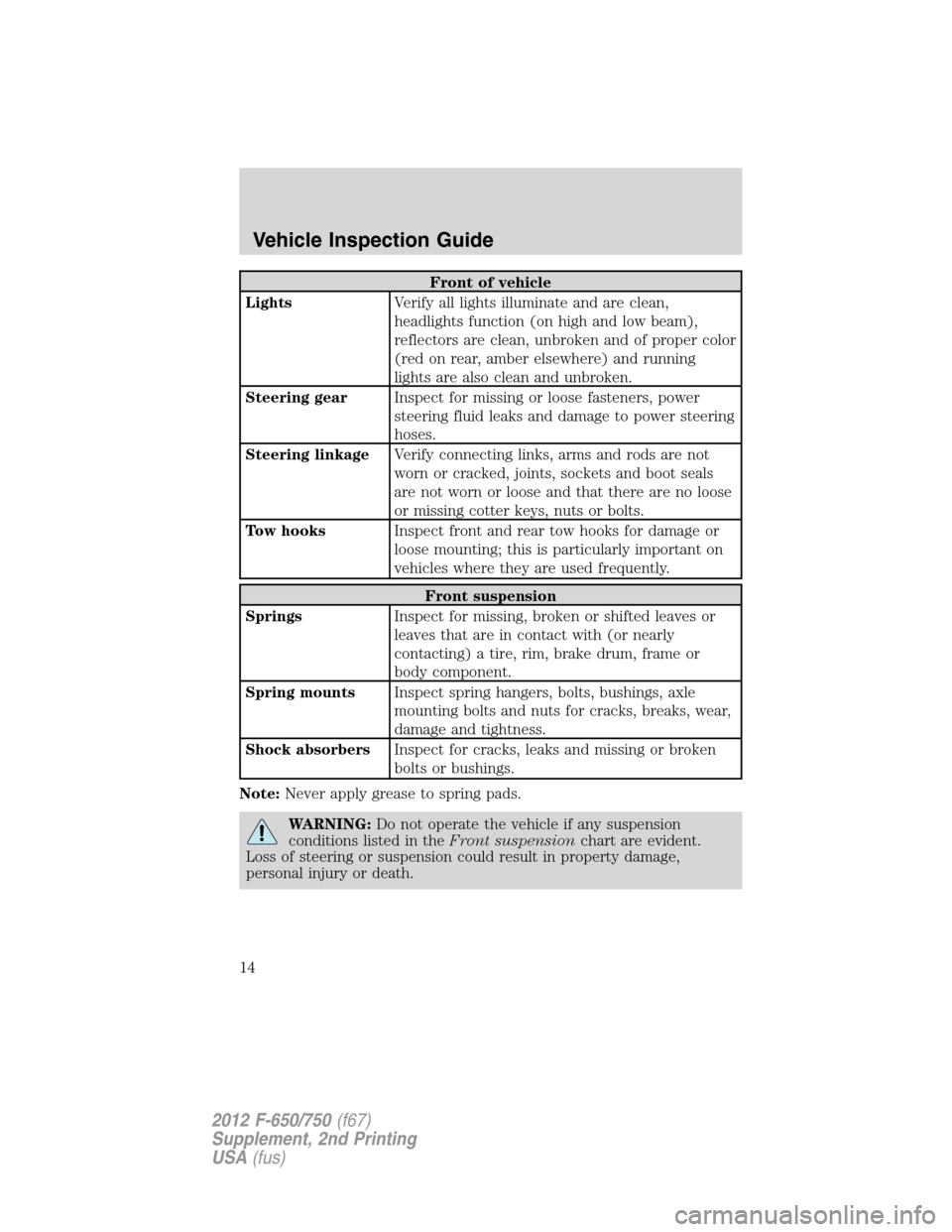

Front of vehicle

LightsVerify all lights illuminate and are clean,

headlights function (on high and low beam),

reflectors are clean, unbroken and of proper color

(red on rear, amber elsewhere) and running

lights are also clean and unbroken.

Steering gearInspect for missing or loose fasteners, power

steering fluid leaks and damage to power steering

hoses.

Steering linkageVerify connecting links, arms and rods are not

worn or cracked, joints, sockets and boot seals

are not worn or loose and that there are no loose

or missing cotter keys, nuts or bolts.

Tow hooksInspect front and rear tow hooks for damage or

loose mounting; this is particularly important on

vehicles where they are used frequently.

Front suspension

SpringsInspect for missing, broken or shifted leaves or

leaves that are in contact with (or nearly

contacting) a tire, rim, brake drum, frame or

body component.

Spring mountsInspect spring hangers, bolts, bushings, axle

mounting bolts and nuts for cracks, breaks, wear,

damage and tightness.

Shock absorbersInspect for cracks, leaks and missing or broken

bolts or bushings.

Note:Never apply grease to spring pads.

WARNING:Do not operate the vehicle if any suspension

conditions listed in theFront suspensionchart are evident.

Loss of steering or suspension could result in property damage,

personal injury or death.

Vehicle Inspection Guide

14

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 15 of 306

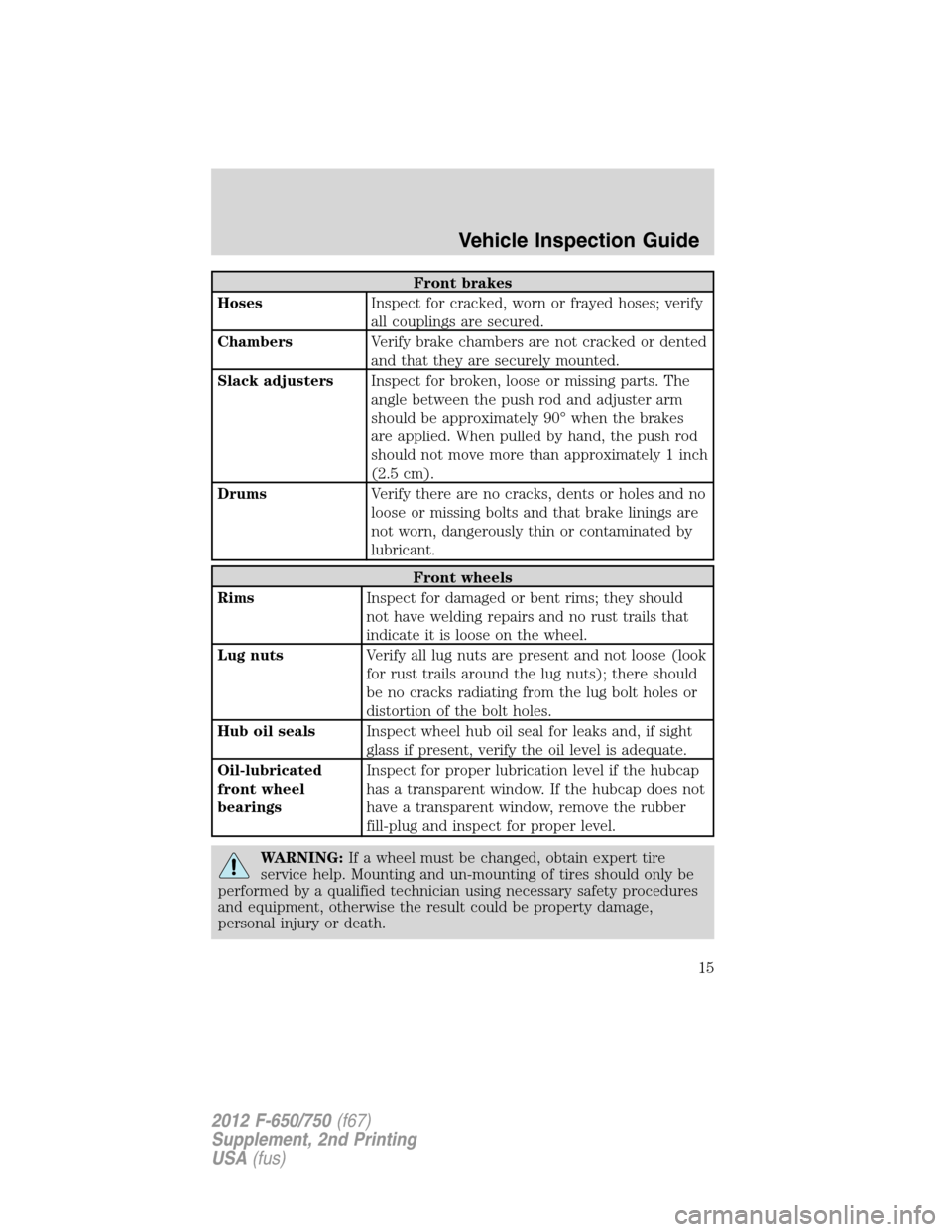

Front brakes

HosesInspect for cracked, worn or frayed hoses; verify

all couplings are secured.

ChambersVerify brake chambers are not cracked or dented

and that they are securely mounted.

Slack adjustersInspect for broken, loose or missing parts. The

angle between the push rod and adjuster arm

should be approximately 90° when the brakes

are applied. When pulled by hand, the push rod

should not move more than approximately 1 inch

(2.5 cm).

DrumsVerify there are no cracks, dents or holes and no

loose or missing bolts and that brake linings are

not worn, dangerously thin or contaminated by

lubricant.

Front wheels

RimsInspect for damaged or bent rims; they should

not have welding repairs and no rust trails that

indicate it is loose on the wheel.

Lug nutsVerify all lug nuts are present and not loose (look

for rust trails around the lug nuts); there should

be no cracks radiating from the lug bolt holes or

distortion of the bolt holes.

Hub oil sealsInspect wheel hub oil seal for leaks and, if sight

glass if present, verify the oil level is adequate.

Oil-lubricated

front wheel

bearingsInspect for proper lubrication level if the hubcap

has a transparent window. If the hubcap does not

have a transparent window, remove the rubber

fill-plug and inspect for proper level.

WARNING:If a wheel must be changed, obtain expert tire

service help. Mounting and un-mounting of tires should only be

performed by a qualified technician using necessary safety procedures

and equipment, otherwise the result could be property damage,

personal injury or death.

Vehicle Inspection Guide

15

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 16 of 306

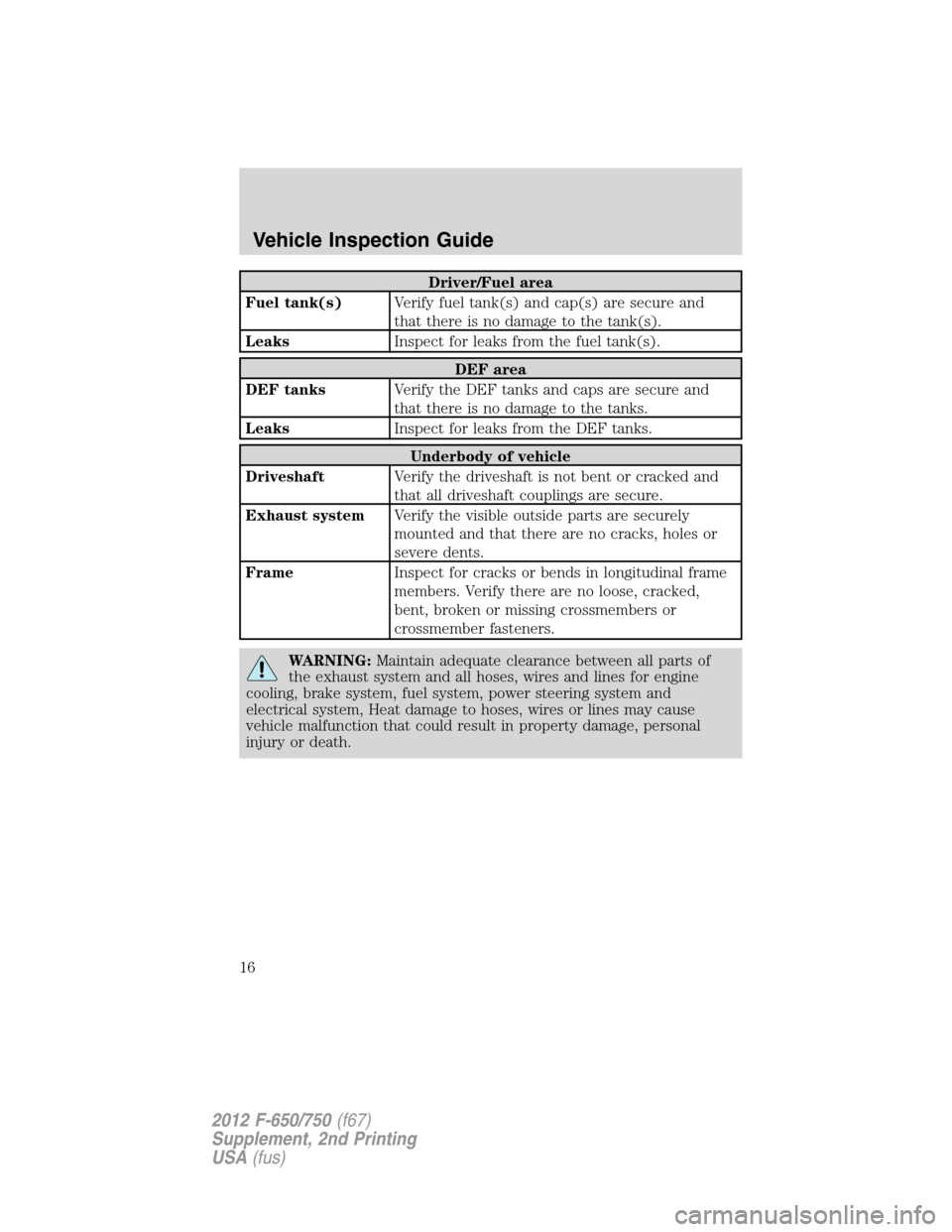

Driver/Fuel area

Fuel tank(s)Verify fuel tank(s) and cap(s) are secure and

that there is no damage to the tank(s).

LeaksInspect for leaks from the fuel tank(s).

DEF area

DEF tanksVerify the DEF tanks and caps are secure and

that there is no damage to the tanks.

LeaksInspect for leaks from the DEF tanks.

Underbody of vehicle

DriveshaftVerify the driveshaft is not bent or cracked and

that all driveshaft couplings are secure.

Exhaust systemVerify the visible outside parts are securely

mounted and that there are no cracks, holes or

severe dents.

FrameInspect for cracks or bends in longitudinal frame

members. Verify there are no loose, cracked,

bent, broken or missing crossmembers or

crossmember fasteners.

WARNING:Maintain adequate clearance between all parts of

the exhaust system and all hoses, wires and lines for engine

cooling, brake system, fuel system, power steering system and

electrical system, Heat damage to hoses, wires or lines may cause

vehicle malfunction that could result in property damage, personal

injury or death.

Vehicle Inspection Guide

16

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 17 of 306

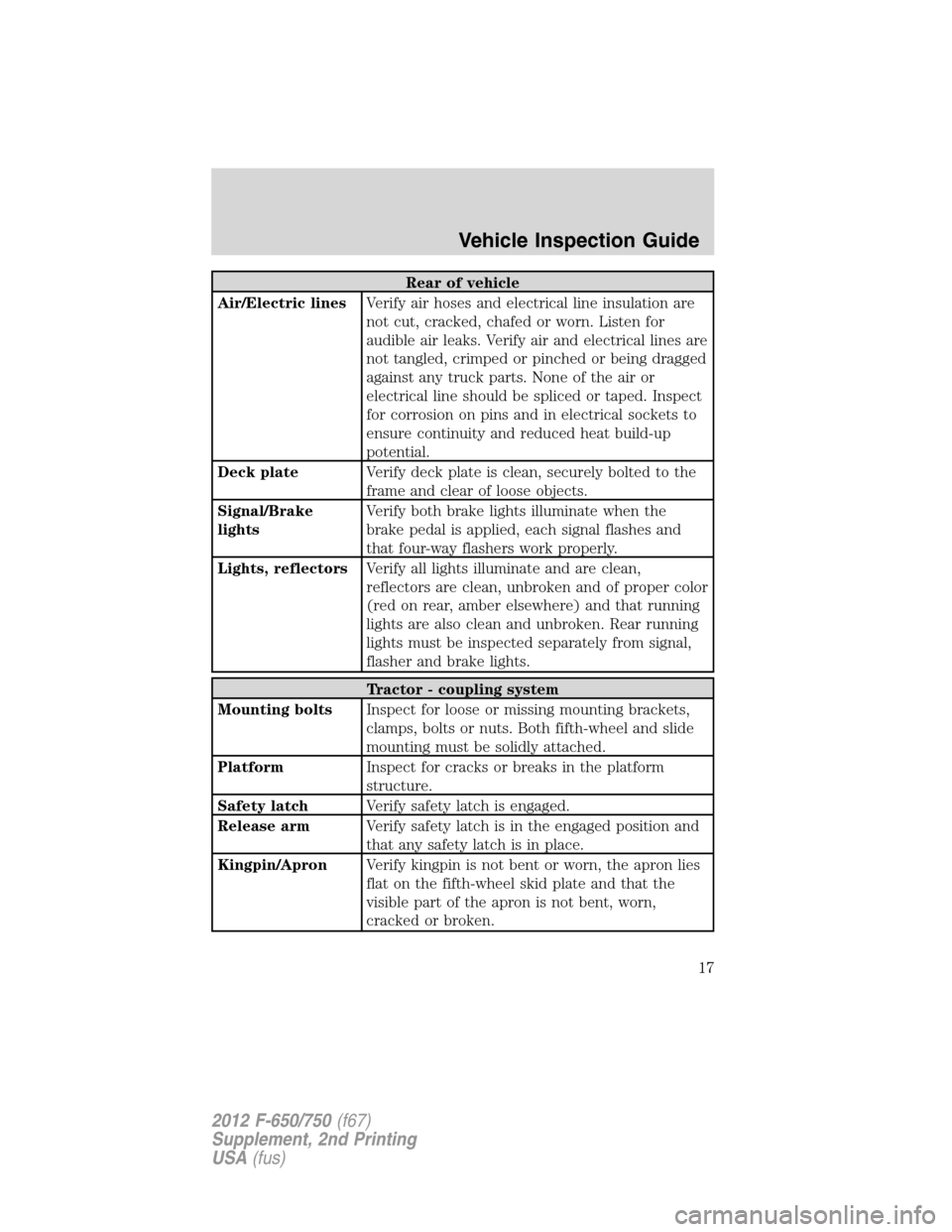

Rear of vehicle

Air/Electric linesVerify air hoses and electrical line insulation are

not cut, cracked, chafed or worn. Listen for

audible air leaks. Verify air and electrical lines are

not tangled, crimped or pinched or being dragged

against any truck parts. None of the air or

electrical line should be spliced or taped. Inspect

for corrosion on pins and in electrical sockets to

ensure continuity and reduced heat build-up

potential.

Deck plateVerify deck plate is clean, securely bolted to the

frame and clear of loose objects.

Signal/Brake

lightsVerify both brake lights illuminate when the

brake pedal is applied, each signal flashes and

that four-way flashers work properly.

Lights, reflectorsVerify all lights illuminate and are clean,

reflectors are clean, unbroken and of proper color

(red on rear, amber elsewhere) and that running

lights are also clean and unbroken. Rear running

lights must be inspected separately from signal,

flasher and brake lights.

Tractor - coupling system

Mounting boltsInspect for loose or missing mounting brackets,

clamps, bolts or nuts. Both fifth-wheel and slide

mounting must be solidly attached.

PlatformInspect for cracks or breaks in the platform

structure.

Safety latchVerify safety latch is engaged.

Release armVerify safety latch is in the engaged position and

that any safety latch is in place.

Kingpin/ApronVerify kingpin is not bent or worn, the apron lies

flat on the fifth-wheel skid plate and that the

visible part of the apron is not bent, worn,

cracked or broken.

Vehicle Inspection Guide

17

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 18 of 306

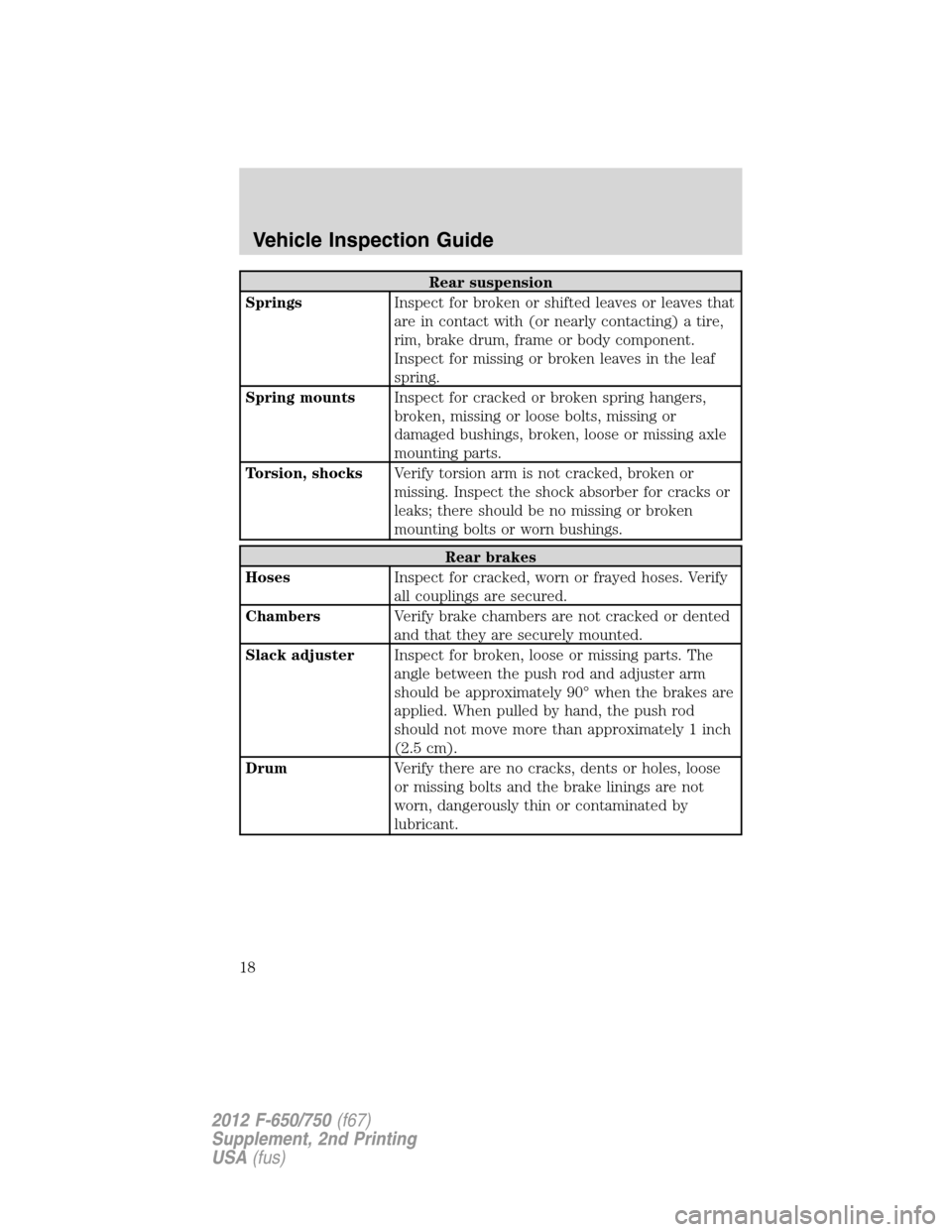

Rear suspension

SpringsInspect for broken or shifted leaves or leaves that

are in contact with (or nearly contacting) a tire,

rim, brake drum, frame or body component.

Inspect for missing or broken leaves in the leaf

spring.

Spring mountsInspect for cracked or broken spring hangers,

broken, missing or loose bolts, missing or

damaged bushings, broken, loose or missing axle

mounting parts.

Torsion, shocksVerify torsion arm is not cracked, broken or

missing. Inspect the shock absorber for cracks or

leaks; there should be no missing or broken

mounting bolts or worn bushings.

Rear brakes

HosesInspect for cracked, worn or frayed hoses. Verify

all couplings are secured.

ChambersVerify brake chambers are not cracked or dented

and that they are securely mounted.

Slack adjusterInspect for broken, loose or missing parts. The

angle between the push rod and adjuster arm

should be approximately 90° when the brakes are

applied. When pulled by hand, the push rod

should not move more than approximately 1 inch

(2.5 cm).

DrumVerify there are no cracks, dents or holes, loose

or missing bolts and the brake linings are not

worn, dangerously thin or contaminated by

lubricant.

Vehicle Inspection Guide

18

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 19 of 306

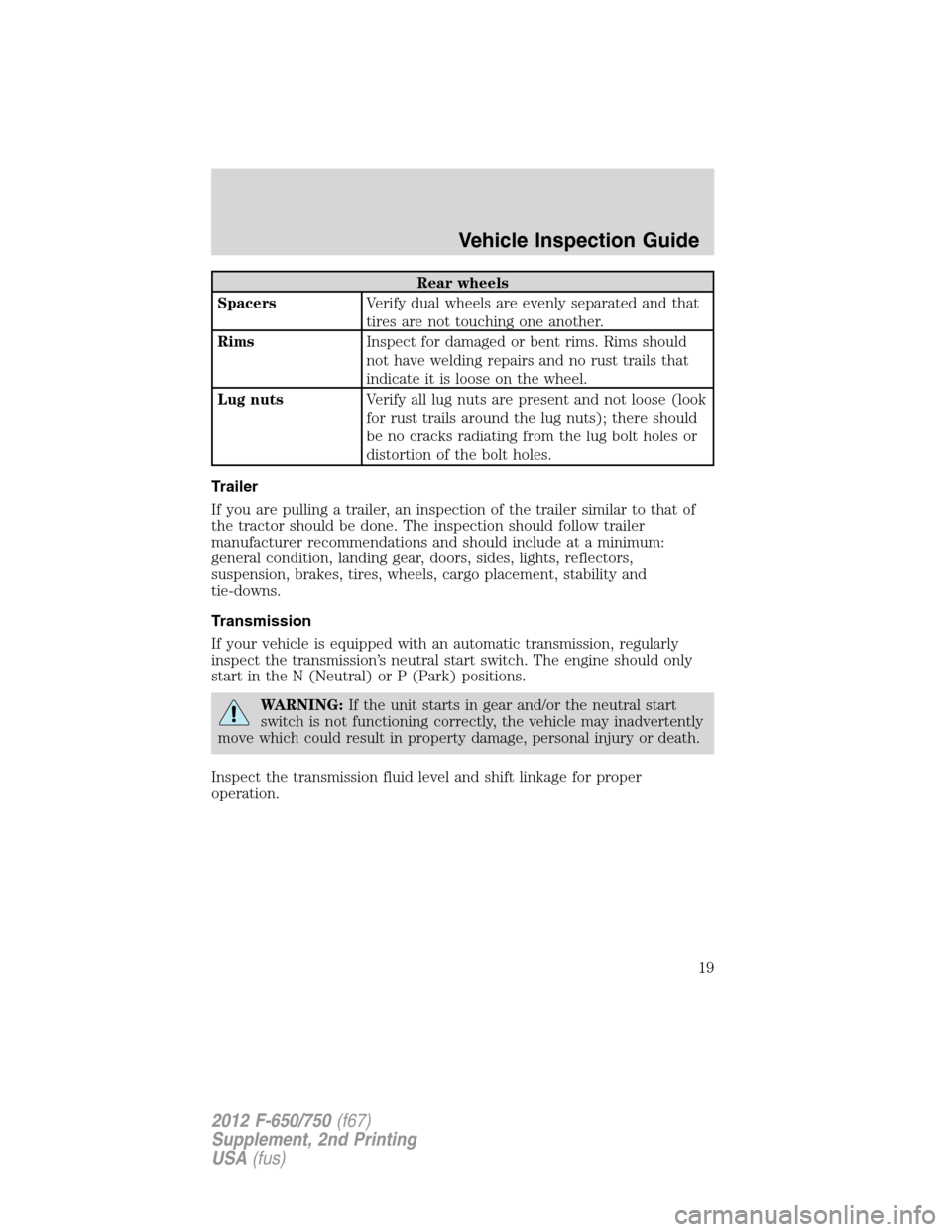

Rear wheels

SpacersVerify dual wheels are evenly separated and that

tires are not touching one another.

RimsInspect for damaged or bent rims. Rims should

not have welding repairs and no rust trails that

indicate it is loose on the wheel.

Lug nutsVerify all lug nuts are present and not loose (look

for rust trails around the lug nuts); there should

be no cracks radiating from the lug bolt holes or

distortion of the bolt holes.

Trailer

If you are pulling a trailer, an inspection of the trailer similar to that of

the tractor should be done. The inspection should follow trailer

manufacturer recommendations and should include at a minimum:

general condition, landing gear, doors, sides, lights, reflectors,

suspension, brakes, tires, wheels, cargo placement, stability and

tie-downs.

Transmission

If your vehicle is equipped with an automatic transmission, regularly

inspect the transmission’s neutral start switch. The engine should only

start in the N (Neutral) or P (Park) positions.

WARNING:If the unit starts in gear and/or the neutral start

switch is not functioning correctly, the vehicle may inadvertently

move which could result in property damage, personal injury or death.

Inspect the transmission fluid level and shift linkage for proper

operation.

Vehicle Inspection Guide

19

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 20 of 306

WARNING LIGHTS AND CHIMES

Base instrument cluster for diesel engine with standard measure

shown; metric similar

Base instrument cluster for gasoline engine with standard

measure shown; metric similar

Warning lights can alert you to a vehicle condition that may become

serious enough to cause expensive repairs by illuminating when a

problem exists with one of your vehicle’s systems. Many lights illuminate

Instrument Cluster

20

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)