run flat FORD F750 2012 12.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2012, Model line: F750, Model: FORD F750 2012 12.GPages: 306, PDF Size: 1.74 MB

Page 17 of 306

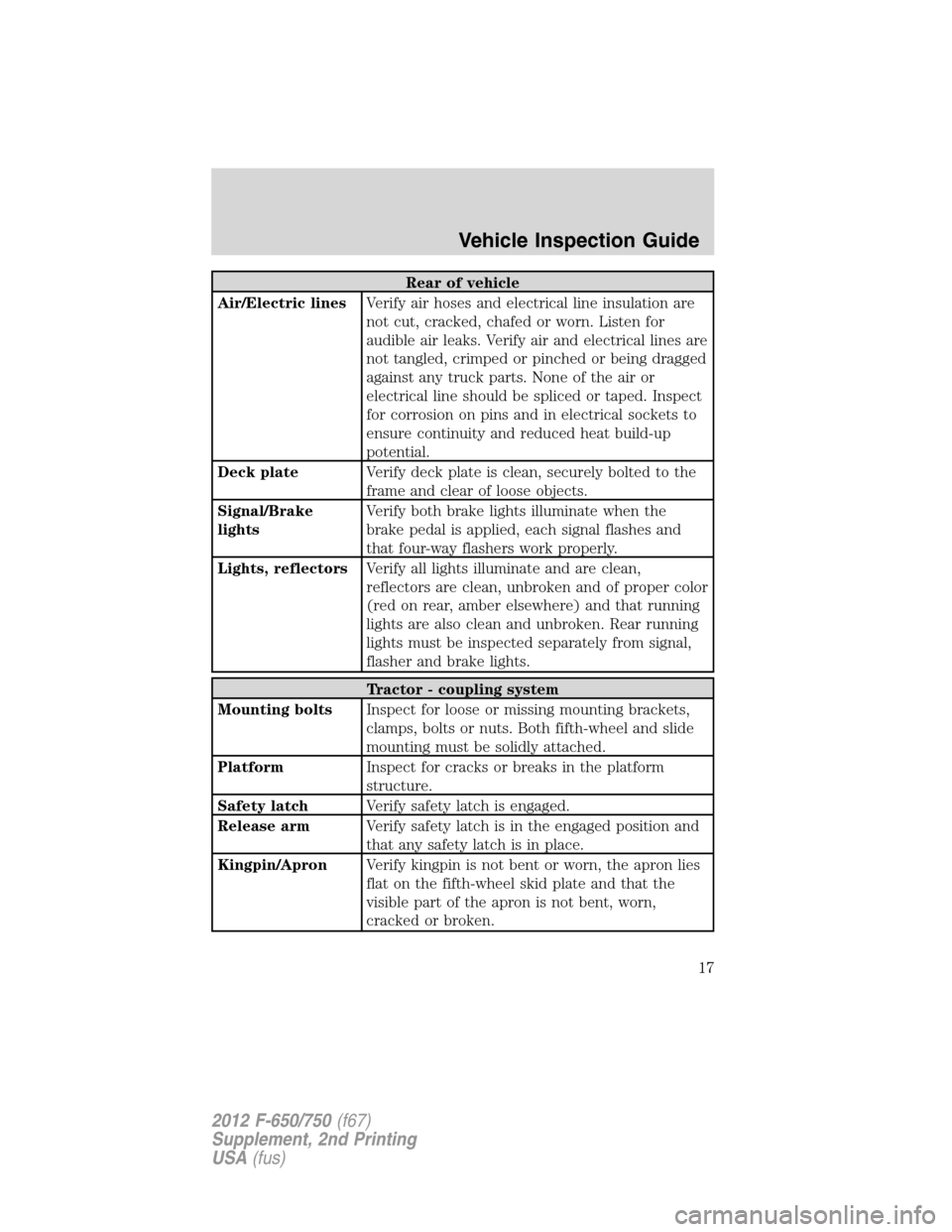

Rear of vehicle

Air/Electric linesVerify air hoses and electrical line insulation are

not cut, cracked, chafed or worn. Listen for

audible air leaks. Verify air and electrical lines are

not tangled, crimped or pinched or being dragged

against any truck parts. None of the air or

electrical line should be spliced or taped. Inspect

for corrosion on pins and in electrical sockets to

ensure continuity and reduced heat build-up

potential.

Deck plateVerify deck plate is clean, securely bolted to the

frame and clear of loose objects.

Signal/Brake

lightsVerify both brake lights illuminate when the

brake pedal is applied, each signal flashes and

that four-way flashers work properly.

Lights, reflectorsVerify all lights illuminate and are clean,

reflectors are clean, unbroken and of proper color

(red on rear, amber elsewhere) and that running

lights are also clean and unbroken. Rear running

lights must be inspected separately from signal,

flasher and brake lights.

Tractor - coupling system

Mounting boltsInspect for loose or missing mounting brackets,

clamps, bolts or nuts. Both fifth-wheel and slide

mounting must be solidly attached.

PlatformInspect for cracks or breaks in the platform

structure.

Safety latchVerify safety latch is engaged.

Release armVerify safety latch is in the engaged position and

that any safety latch is in place.

Kingpin/ApronVerify kingpin is not bent or worn, the apron lies

flat on the fifth-wheel skid plate and that the

visible part of the apron is not bent, worn,

cracked or broken.

Vehicle Inspection Guide

17

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 239 of 306

All tires with Steel Carcass Plies (if equipped):

This type of tire utilizes steel cords in the sidewalls. As such, they

cannot be treated like normal light truck tires. Tire service, including

adjusting the air pressure, must be performed by personnel trained,

supervised and equipped according to Federal Occupational Safety and

Health Administration (OSHA) regulations. For example, during any

procedure involving tire inflation, the technician or individual must

utilize a remote inflation device, and ensure that all persons are clear of

the trajectory area.

WARNING:An inflated tire and rim can be very dangerous if

improperly used, serviced or maintained. To avoid serious injury,

never attempt to re-inflate a tire which has been run flat or seriously

under-inflated without first removing the tire from the wheel assembly

for inspection. Do not attempt to add air to tires or replace tires or

wheels without first taking precautions to protect persons and

property.

Maintenance and Specifications

239

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)

Page 244 of 306

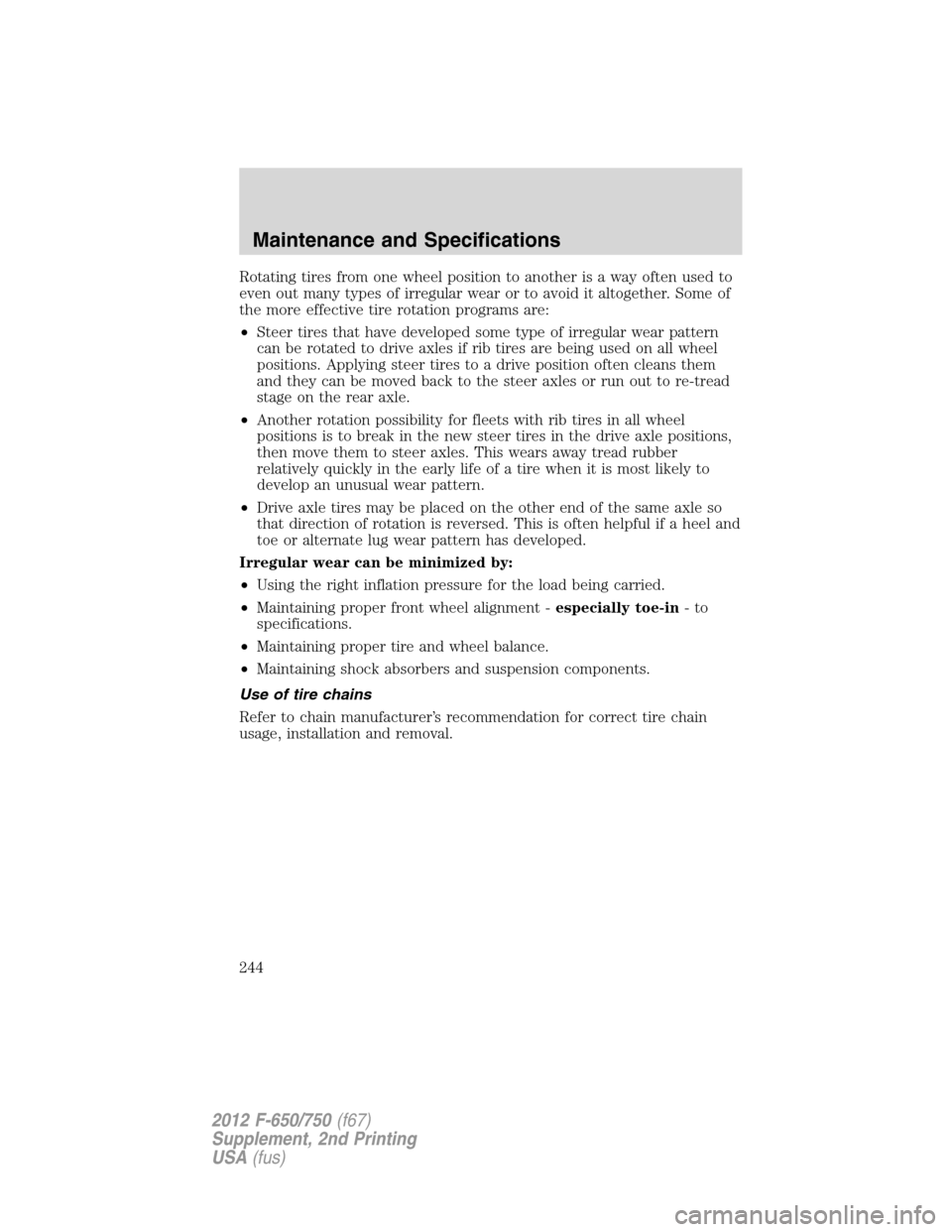

Rotating tires from one wheel position to another is a way often used to

even out many types of irregular wear or to avoid it altogether. Some of

the more effective tire rotation programs are:

•Steer tires that have developed some type of irregular wear pattern

can be rotated to drive axles if rib tires are being used on all wheel

positions. Applying steer tires to a drive position often cleans them

and they can be moved back to the steer axles or run out to re-tread

stage on the rear axle.

•Another rotation possibility for fleets with rib tires in all wheel

positions is to break in the new steer tires in the drive axle positions,

then move them to steer axles. This wears away tread rubber

relatively quickly in the early life of a tire when it is most likely to

develop an unusual wear pattern.

•Drive axle tires may be placed on the other end of the same axle so

that direction of rotation is reversed. This is often helpful if a heel and

toe or alternate lug wear pattern has developed.

Irregular wear can be minimized by:

•Using the right inflation pressure for the load being carried.

•Maintaining proper front wheel alignment -especially toe-in-to

specifications.

•Maintaining proper tire and wheel balance.

•Maintaining shock absorbers and suspension components.

Use of tire chains

Refer to chain manufacturer’s recommendation for correct tire chain

usage, installation and removal.

Maintenance and Specifications

244

2012 F-650/750(f67)

Supplement, 2nd Printing

USA(fus)