lock FORD F750 2017 13.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: F750, Model: FORD F750 2017 13.GPages: 382, PDF Size: 5.18 MB

Page 170 of 382

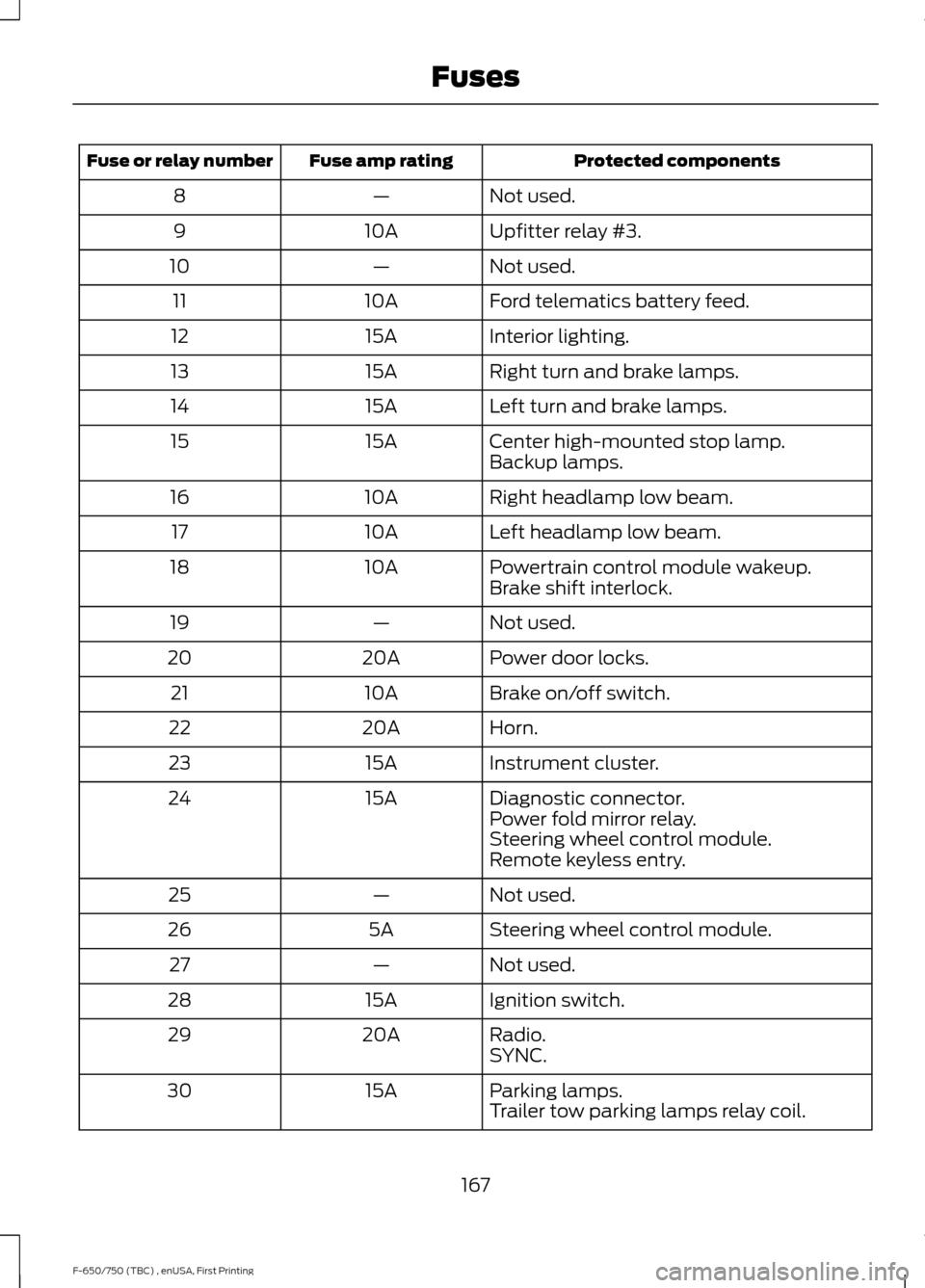

Protected components

Fuse amp rating

Fuse or relay number

Not used.

—

8

Upfitter relay #3.

10A

9

Not used.

—

10

Ford telematics battery feed.

10A

11

Interior lighting.

15A

12

Right turn and brake lamps.

15A

13

Left turn and brake lamps.

15A

14

Center high-mounted stop lamp.

15A

15

Backup lamps.

Right headlamp low beam.

10A

16

Left headlamp low beam.

10A

17

Powertrain control module wakeup.

10A

18

Brake shift interlock.

Not used.

—

19

Power door locks.

20A

20

Brake on/off switch.

10A

21

Horn.

20A

22

Instrument cluster.

15A

23

Diagnostic connector.

15A

24

Power fold mirror relay.

Steering wheel control module.

Remote keyless entry.

Not used.

—

25

Steering wheel control module.

5A

26

Not used.

—

27

Ignition switch.

15A

28

Radio.

20A

29

SYNC.

Parking lamps.

15A

30

Trailer tow parking lamps relay coil.

167

F-650/750 (TBC) , enUSA, First Printing Fuses

Page 171 of 382

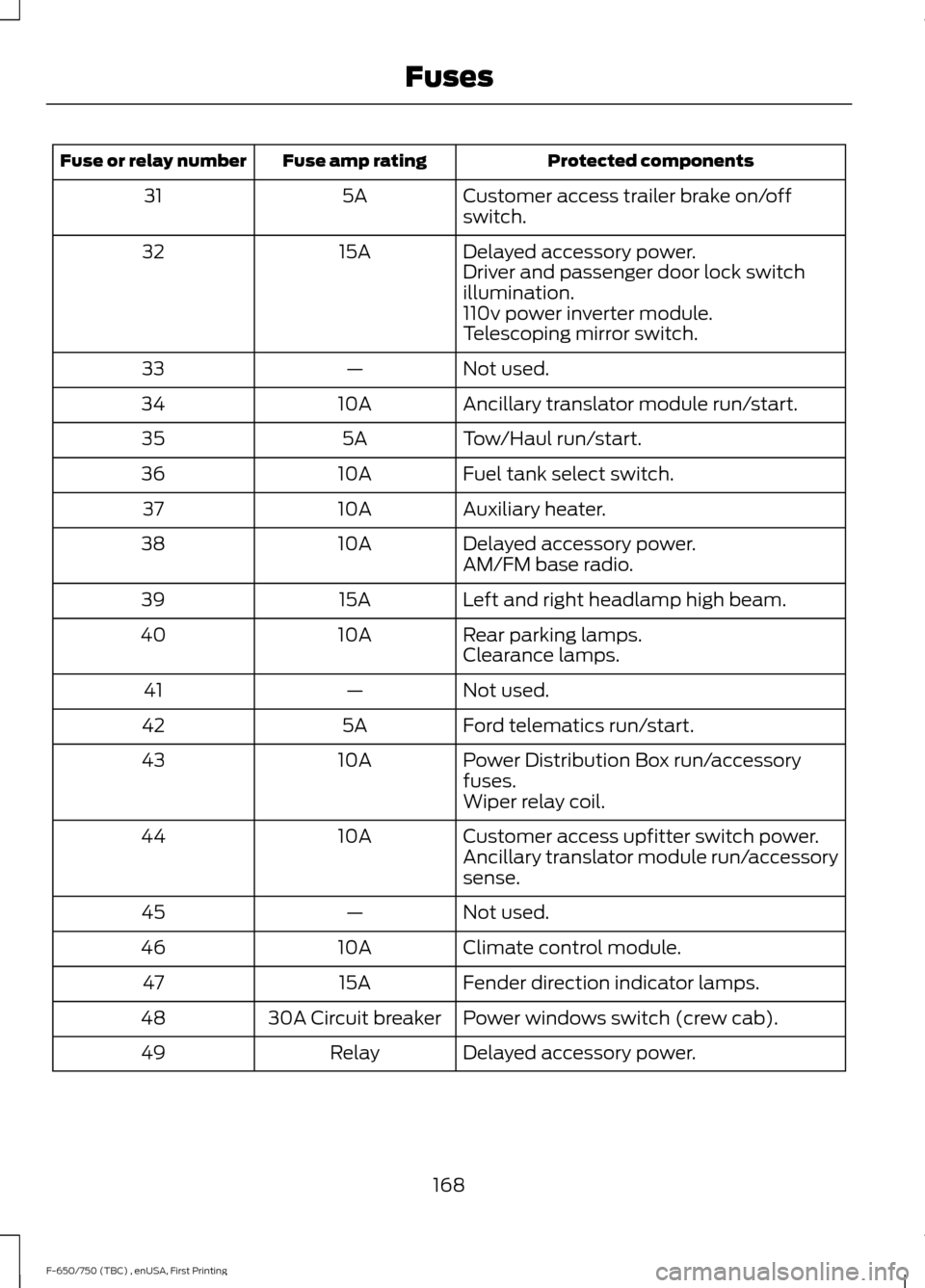

Protected components

Fuse amp rating

Fuse or relay number

Customer access trailer brake on/off

switch.

5A

31

Delayed accessory power.

15A

32

Driver and passenger door lock switch

illumination.

110v power inverter module.

Telescoping mirror switch.

Not used.

—

33

Ancillary translator module run/start.

10A

34

Tow/Haul run/start.

5A

35

Fuel tank select switch.

10A

36

Auxiliary heater.

10A

37

Delayed accessory power.

10A

38

AM/FM base radio.

Left and right headlamp high beam.

15A

39

Rear parking lamps.

10A

40

Clearance lamps.

Not used.

—

41

Ford telematics run/start.

5A

42

Power Distribution Box run/accessory

fuses.

10A

43

Wiper relay coil.

Customer access upfitter switch power.

10A

44

Ancillary translator module run/accessory

sense.

Not used.

—

45

Climate control module.

10A

46

Fender direction indicator lamps.

15A

47

Power windows switch (crew cab).

30A Circuit breaker

48

Delayed accessory power.

Relay

49

168

F-650/750 (TBC) , enUSA, First Printing Fuses

Page 175 of 382

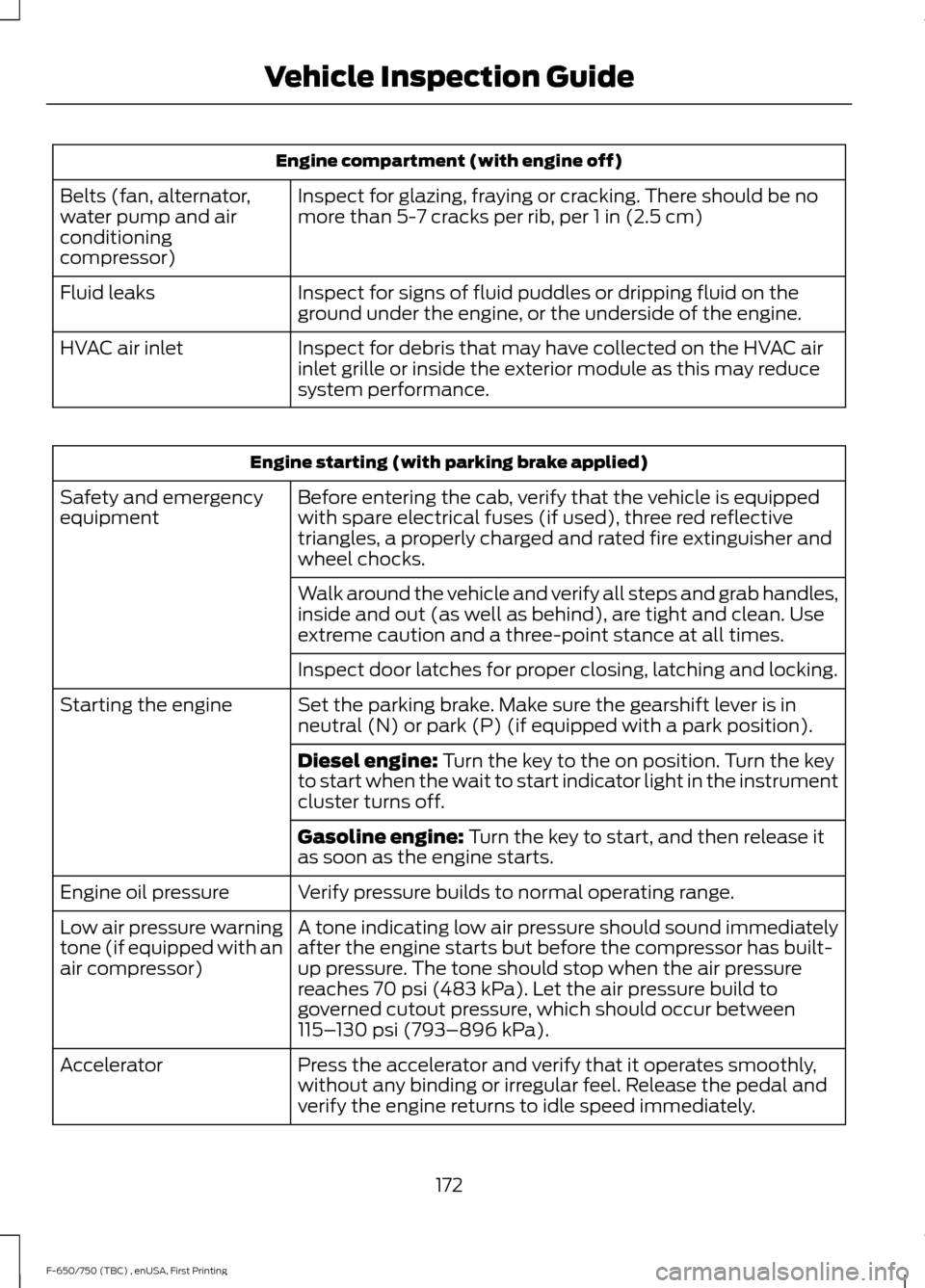

Engine compartment (with engine off)

Inspect for glazing, fraying or cracking. There should be no

more than 5-7 cracks per rib, per 1 in (2.5 cm)

Belts (fan, alternator,

water pump and air

conditioning

compressor)

Inspect for signs of fluid puddles or dripping fluid on the

ground under the engine, or the underside of the engine.

Fluid leaks

Inspect for debris that may have collected on the HVAC air

inlet grille or inside the exterior module as this may reduce

system performance.

HVAC air inlet Engine starting (with parking brake applied)

Before entering the cab, verify that the vehicle is equipped

with spare electrical fuses (if used), three red reflective

triangles, a properly charged and rated fire extinguisher and

wheel chocks.

Safety and emergency

equipment

Walk around the vehicle and verify all steps and grab handles,

inside and out (as well as behind), are tight and clean. Use

extreme caution and a three-point stance at all times.

Inspect door latches for proper closing, latching and locking.

Set the parking brake. Make sure the gearshift lever is in

neutral (N) or park (P) (if equipped with a park position).

Starting the engine

Diesel engine:

Turn the key to the on position. Turn the key

to start when the wait to start indicator light in the instrument

cluster turns off.

Gasoline engine:

Turn the key to start, and then release it

as soon as the engine starts.

Verify pressure builds to normal operating range.

Engine oil pressure

A tone indicating low air pressure should sound immediately

after the engine starts but before the compressor has built-

up pressure. The tone should stop when the air pressure

reaches

70 psi (483 kPa). Let the air pressure build to

governed cutout pressure, which should occur between

115– 130 psi (793–896 kPa)

.

Low air pressure warning

tone (if equipped with an

air compressor)

Press the accelerator and verify that it operates smoothly,

without any binding or irregular feel. Release the pedal and

verify the engine returns to idle speed immediately.

Accelerator

172

F-650/750 (TBC) , enUSA, First Printing Vehicle Inspection Guide

Page 184 of 382

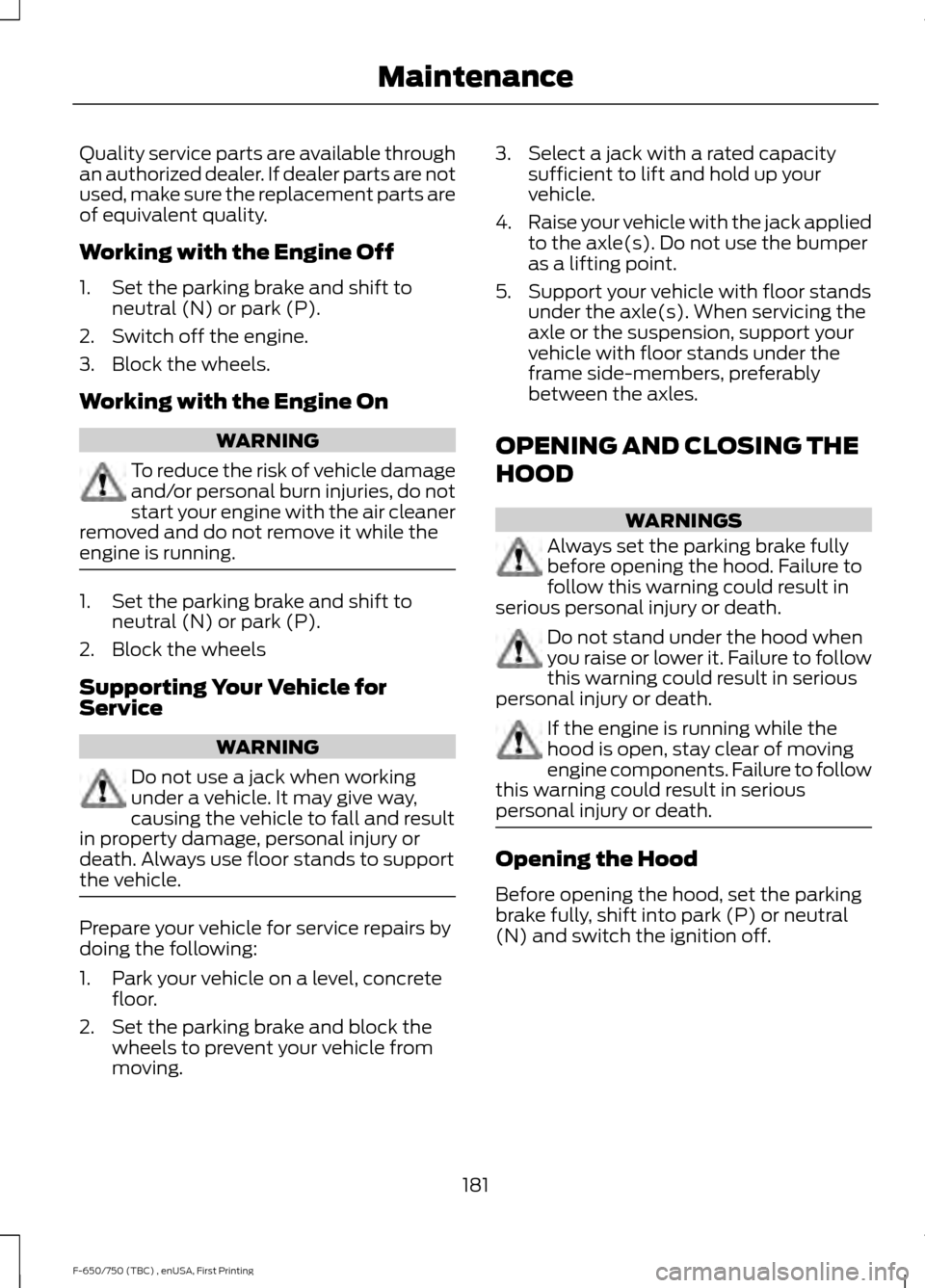

Quality service parts are available through

an authorized dealer. If dealer parts are not

used, make sure the replacement parts are

of equivalent quality.

Working with the Engine Off

1. Set the parking brake and shift to

neutral (N) or park (P).

2. Switch off the engine.

3. Block the wheels.

Working with the Engine On WARNING

To reduce the risk of vehicle damage

and/or personal burn injuries, do not

start your engine with the air cleaner

removed and do not remove it while the

engine is running. 1. Set the parking brake and shift to

neutral (N) or park (P).

2. Block the wheels

Supporting Your Vehicle for

Service WARNING

Do not use a jack when working

under a vehicle. It may give way,

causing the vehicle to fall and result

in property damage, personal injury or

death. Always use floor stands to support

the vehicle. Prepare your vehicle for service repairs by

doing the following:

1. Park your vehicle on a level, concrete

floor.

2. Set the parking brake and block the wheels to prevent your vehicle from

moving. 3. Select a jack with a rated capacity

sufficient to lift and hold up your

vehicle.

4. Raise your vehicle with the jack applied

to the axle(s). Do not use the bumper

as a lifting point.

5. Support your vehicle with floor stands under the axle(s). When servicing the

axle or the suspension, support your

vehicle with floor stands under the

frame side-members, preferably

between the axles.

OPENING AND CLOSING THE

HOOD WARNINGS

Always set the parking brake fully

before opening the hood. Failure to

follow this warning could result in

serious personal injury or death. Do not stand under the hood when

you raise or lower it. Failure to follow

this warning could result in serious

personal injury or death. If the engine is running while the

hood is open, stay clear of moving

engine components. Failure to follow

this warning could result in serious

personal injury or death. Opening the Hood

Before opening the hood, set the parking

brake fully, shift into park (P) or neutral

(N) and switch the ignition off.

181

F-650/750 (TBC) , enUSA, First Printing Maintenance

Page 189 of 382

Only use oils certified for gasoline engines

by the American Petroleum Institute (API).

An oil with this trademark symbol

conforms to the current engine and

emission system protection standards and

fuel economy requirements of the

International Lubricants Specification

Advisory Committee (ILSAC).

To top up the engine oil level do the

following:

1. Clean the area surrounding the engine

oil filler cap before you remove it.

2. Remove the engine oil filler cap. See Under Hood Overview (page 183).

Turn it counterclockwise and remove

it.

3. Add engine oil that meets Ford specifications. See

Capacities and

Specifications (page 258). You may

have to use a funnel to pour the engine

oil into the opening.

4. Recheck the oil level.

5. If the oil level is correct, replace the dipstick and make sure it is fully seated.

6. Replace the engine oil filler cap. Turn it clockwise until you feel a strong

resistance.

Note: Do not add oil further than the

maximum mark. Oil levels above the

maximum mark may cause engine damage. Note:

Make sure you install the oil filler cap

correctly.

Note: Soak up any spillage with an

absorbent cloth immediately.

ENGINE OIL CHECK - 6.7L

DIESEL

To check the engine oil level consistently

and accurately, do the following:

1. Make sure the parking brake is on. Make

sure the transmission is in park (P) or

neutral (N).

2. Run engine until it reaches normal operating temperature.

3. Make sure that your vehicle is on level ground.

4. Switch the engine off and wait 15 minutes for the oil to drain into the oil

pan. Checking the engine oil level too

soon after you switch the engine off

may result in an inaccurate reading.

5. Open the hood. See

Opening and

Closing the Hood (page 181).

6. Remove the dipstick and wipe it with a clean, lint-free cloth. See

Under

Hood Overview (page 184).

7. Replace the dipstick and remove it again to check the oil level. See

Engine Oil Dipstick

(page 185).

8. Make sure that the oil level is between

the maximum and minimum marks. If

the oil level is at the minimum mark,

add oil immediately. See

Capacities

and Specifications (page 263).

9. If the oil level is correct, replace the dipstick and make sure it is fully seated.

Note: Do not remove the dipstick when the

engine is running.

Note: If the oil level is between the

maximum and minimum marks, the oil level

is acceptable. Do not add oil.

186

F-650/750 (TBC) , enUSA, First Printing MaintenanceE142732

Page 190 of 382

Note:

The oil consumption of new engines

reaches its normal level after approximately

3,100 mi (5,000 km).

Adding Engine Oil WARNING

Do not remove the filler cap when

the engine is running.

Do not use supplemental engine oil

additives because they are unnecessary

and could lead to engine damage that may

not be covered by the vehicle Warranty.

The American Petroleum Institute (API)

service symbol is used to identify the

proper engine oil for your vehicle's engine.

The API service symbol will be displayed

on the oil container you purchase. The API

service symbol displays the oil

performance category in the top half of

symbol and the viscosity grade in the

center of the symbol.

To top up the engine oil level do the

following:

1. Clean the area surrounding the engine

oil filler cap before you remove it.

2. Remove the engine oil filler cap. See Under Hood Overview

(page 184).

Turn it counterclockwise and remove

it. 3. Add engine oil that meets Ford

specifications. See

Capacities and

Specifications (page 263). You may

have to use a funnel to pour the engine

oil into the opening.

4. Recheck the oil level.

5. If the oil level is correct, replace the dipstick and make sure it is fully seated.

6. Replace the engine oil filler cap. Turn it clockwise until you feel a strong

resistance.

Note: Do not add oil further than the

maximum mark. Oil levels above the

maximum mark may cause engine damage.

Note: Make sure you install the oil filler cap

correctly.

Note: Soak up any spillage with an

absorbent cloth immediately.

CHANGING THE ENGINE OIL

AND OIL FILTER WARNINGS

Do not handle a hot oil filter with

bare hands.

Continuous contact with used motor

oil has caused cancer in laboratory

mice. Protect your skin by washing

with soap and water. If your vehicle is equipped with a diesel

engine, an Intelligent Oil Life Monitor™

calculates the proper oil change service

interval. When the information display

indicates: OIL CHANGE REQUIRED, change

the engine oil and oil filter. See

Information Displays

(page 62).

The engine oil filter protects your engine

by filtering harmful, abrasive or sludge

particles and particles significantly smaller

than most available will-fit filters. See

Motorcraft Parts

(page 254).

187

F-650/750 (TBC) , enUSA, First Printing MaintenanceE163371

Page 194 of 382

the coolant is visible and the radiator

is almost full. If coolant is added to

bring the level within the minimum and

maximum range when the engine is not

cold, the system may remain

underfilled.

4. Replace the coolant reservoir cap, turn

it clockwise until you feel a strong

resistance.

5. Check the coolant level in the coolant reservoir the next few times you drive

your vehicle. If necessary, add enough

prediluted engine coolant to bring the

coolant level to the proper level.

Note: If prediluted coolant is not available,

use the approved antifreeze concentrate

diluting it to 50/50 with distilled water. See

Capacities and Specifications (page 258).

Using water that has not been deionised

may contribute to deposit formation,

corrosion or plugging of the small cooling

system passageways.

If you have to add more than 1.1 qt (1 L) of

engine coolant per month, have your

vehicle checked as soon as possible.

Operating an engine with a low level of

coolant can result in engine overheating

and possible engine damage.

Note: During normal vehicle operation, the

coolant may change color from orange to

pink or light red. As long as the coolant is

clear and uncontaminated, this color change

does not indicate the coolant has degraded

nor does it require the coolant to be drained,

the system to be flushed, or the coolant to

be replaced. Note:

In case of emergency, you can add a

large amount of water without coolant in

order to reach a vehicle service location.

Water alone, without coolant, can cause

engine damage from corrosion, overheating

or freezing. When you reach a service

location, you must have the cooling system

drained, flushed and refilled using the

correct specification prediluted coolant or

antifreeze concentrate. See

Capacities and

Specifications (page 258).

Do not use the following as a coolant

substitute:

• Alcohol.

• Methanol.

• Brine.

• Any coolant mixed with alcohol or

methanol antifreeze.

Alcohol and other liquids can cause engine

damage from overheating or freezing.

Do not add extra inhibitors or additives to

the coolant. These can be harmful and

compromise the corrosion protection of

the coolant.

Recycled Coolant

We do not recommend the use of recycled

coolant as an approved recycling process

is not yet available.

Dispose of used engine coolant in an

appropriate manner. Follow your

community ’s regulations and standards

for recycling and disposing of automotive

fluids.

191

F-650/750 (TBC) , enUSA, First Printing Maintenance

Page 198 of 382

Adding Coolant

WARNING

Never remove the coolant reservoir

cap while the engine is running or hot.

Note:

Automotive fluids are not

interchangeable. Do not use coolant or

windshield washer fluid outside of its

specified function and vehicle location.

Note: Do not use stop leak pellets, cooling

system sealants, or non-specified additives

as they can cause damage to the engine

cooling or heating systems. Resulting

component damage may not be covered by

the vehicle Warranty.

It is very important to use prediluted

coolant approved to the correct

specification in order to avoid plugging the

small passageways in the engine cooling

system. See Capacities and

Specifications (page 258). Do not mix

different colors or types of coolant in your

vehicle. Mixing of engine coolants or using

an incorrect coolant may harm the engine

or cooling system components and may

not be covered by the vehicle Warranty.

Note: Coolants marketed for all makes and

models may not be approved to Ford

specifications and may cause damage to

the cooling system. Resulting component

damage may not be covered by the vehicle

Warranty.

If the coolant level is at or below the

minimum mark, add prediluted coolant

immediately. For vehicles with overflow coolant systems

with a non-pressurized cap on the coolant

recovery system, add coolant to the

coolant recovery reservoir when the engine

is cool. Add prediluted coolant to the

maximum level. For all vehicles which have

a coolant degas system with a pressurized

cap, or if it is necessary to remove the

coolant pressure relief cap on the radiator,

follow these steps to add engine coolant:

1. Turn the engine off and let it cool.

2. Unscrew the cap slowly. Any pressure

escapes as you unscrew the cap.

3. Fill the coolant reservoir slowly with prediluted engine coolant to within the

minimum and maximum range on the

engine coolant reservoir. If you

removed the radiator cap in an

overflow system, fill the radiator until

the coolant is visible and the radiator

is almost full. If coolant is added to

bring the level within the minimum and

maximum range when the engine is not

cold, the system may remain

underfilled.

4. Replace the coolant reservoir cap, turn

it clockwise until you feel a strong

resistance.

5. Check the coolant level in the coolant reservoir the next few times you drive

your vehicle. If necessary, add enough

prediluted engine coolant to bring the

coolant level to the proper level.

Note: If prediluted coolant is not available,

use the approved antifreeze concentrate

diluting it to 50/50 with distilled water. See

Capacities and Specifications (page 258).

Using water that has not been deionised

may contribute to deposit formation,

corrosion or plugging of the small cooling

system passageways.

195

F-650/750 (TBC) , enUSA, First Printing Maintenance

Page 199 of 382

If you have to add more than 1.1 qt (1 L) of

engine coolant per month, have your

vehicle checked as soon as possible.

Operating an engine with a low level of

coolant can result in engine overheating

and possible engine damage.

Note: During normal vehicle operation, the

coolant may change color from orange to

pink or light red. As long as the coolant is

clear and uncontaminated, this color change

does not indicate the coolant has degraded

nor does it require the coolant to be drained,

the system to be flushed, or the coolant to

be replaced.

Note: In case of emergency, you can add a

large amount of water without coolant in

order to reach a vehicle service location.

Water alone, without coolant, can cause

engine damage from corrosion, overheating

or freezing. When you reach a service

location, you must have the cooling system

drained, flushed and refilled using the

correct specification prediluted coolant or

antifreeze concentrate. See

Capacities and

Specifications (page 258).

Do not use the following as a coolant

substitute:

• Alcohol.

• Methanol.

• Brine.

• Any coolant mixed with alcohol or

methanol antifreeze.

Alcohol and other liquids can cause engine

damage from overheating or freezing.

Do not add extra inhibitors or non-specified

additives to the coolant. These can be

harmful and compromise the corrosion

protection of the coolant. Engine and Secondary Cooling

System Refill Procedure

The following procedure should be used

when refilling the engine or secondary

cooling systems after it has been drained

or become extremely low:

1. Before you remove the cap, turn the

engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the cap. Slowly turn cap

counterclockwise until pressure begins

to release.

3. Step back while the pressure releases.

4. When you are sure that all the pressure

has been released, use the cloth to turn

it counterclockwise and remove the

cap.

5. Slowly add prediluted engine coolant to the coolant reservoir until the

coolant level is within the minimum

and maximum range as listed on the

reservoir.

6. Reinstall the pressure relief cap.

7. Start and run the engine at 2000 rpm for 2 minutes.

8. Shut engine off, and remove the pressure relief cap as previously

outlined.

9. If required, add prediluted engine coolant to the coolant reservoir until

the coolant level is within the minimum

and maximum range as listed on the

reservoir.

10. Engine cooling system:

Repeat

Step 5 until the coolant level has

stabilized (is no longer dropping after

each step) and the upper radiator

hose at the radiator is warm to the

touch (indicating that the engine

thermostat is open and coolant is

flowing through the radiator).

196

F-650/750 (TBC) , enUSA, First Printing Maintenance

Page 205 of 382

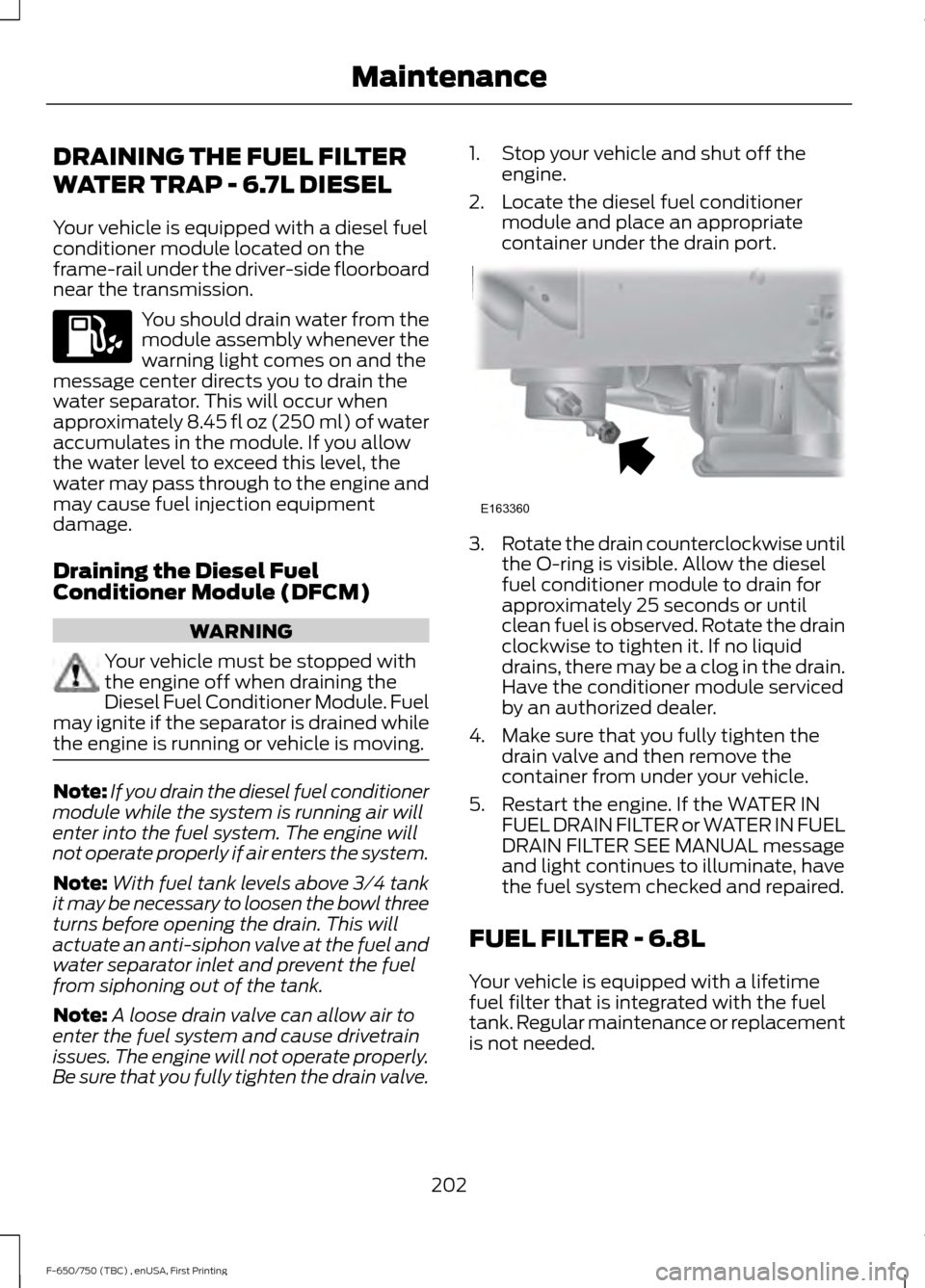

DRAINING THE FUEL FILTER

WATER TRAP - 6.7L DIESEL

Your vehicle is equipped with a diesel fuel

conditioner module located on the

frame-rail under the driver-side floorboard

near the transmission.

You should drain water from the

module assembly whenever the

warning light comes on and the

message center directs you to drain the

water separator. This will occur when

approximately 8.45 fl oz (250 ml) of water

accumulates in the module. If you allow

the water level to exceed this level, the

water may pass through to the engine and

may cause fuel injection equipment

damage.

Draining the Diesel Fuel

Conditioner Module (DFCM) WARNING

Your vehicle must be stopped with

the engine off when draining the

Diesel Fuel Conditioner Module. Fuel

may ignite if the separator is drained while

the engine is running or vehicle is moving. Note:

If you drain the diesel fuel conditioner

module while the system is running air will

enter into the fuel system. The engine will

not operate properly if air enters the system.

Note: With fuel tank levels above 3⁄4 tank

it may be necessary to loosen the bowl three

turns before opening the drain. This will

actuate an anti-siphon valve at the fuel and

water separator inlet and prevent the fuel

from siphoning out of the tank.

Note: A loose drain valve can allow air to

enter the fuel system and cause drivetrain

issues. The engine will not operate properly.

Be sure that you fully tighten the drain valve. 1. Stop your vehicle and shut off the

engine.

2. Locate the diesel fuel conditioner module and place an appropriate

container under the drain port. 3.

Rotate the drain counterclockwise until

the O-ring is visible. Allow the diesel

fuel conditioner module to drain for

approximately 25 seconds or until

clean fuel is observed. Rotate the drain

clockwise to tighten it. If no liquid

drains, there may be a clog in the drain.

Have the conditioner module serviced

by an authorized dealer.

4. Make sure that you fully tighten the drain valve and then remove the

container from under your vehicle.

5. Restart the engine. If the WATER IN FUEL DRAIN FILTER or WATER IN FUEL

DRAIN FILTER SEE MANUAL message

and light continues to illuminate, have

the fuel system checked and repaired.

FUEL FILTER - 6.8L

Your vehicle is equipped with a lifetime

fuel filter that is integrated with the fuel

tank. Regular maintenance or replacement

is not needed.

202

F-650/750 (TBC) , enUSA, First Printing Maintenance E163360