heater FORD FESTIVA 1991 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 104 of 454

1. Position new gasket on exhaust manifold, and install turbocharger onto studs. Install 4 retaining nuts and tighten to specification. See

TORQUE SPECIFICATIONS

table at end of article.

2. Remove oil supply line from turbocharger. Position new (2-piece) exhaust gasket on cylinder head with heavy gasket installed first .

Carefully position turbocharger assembly in engine compartment and slide exhaust manifold on studs. Position heater tube bracket onto

exhaust stud. Install 11 retaining nuts onto exhaust manifold and tighten to specification. See TORQUE SPECIFICATIONS

table at

end of article. Tighten heater tube clamp bolt securely.

3. Raise vehicle. Position new gasket and install 2 retaining bolts on heater tube outlet. Install 2 retaining bolts into turbocharger support

bracket and tighten bolts to specification.

4. Connect coolant return hose. Connect oil return hose and secure with clamp. Position exhaust pipe onto turbocharger, and start nuts

and washers. Install 2 retaining bolts on exhaust hanger at engine. Slide on 2 rubber exhaust hangers at catalytic converter. Tighten

exhaust pipe retaining nuts to specification. Lower vehicle.

5. Install retaining bolt and brass washers on oil supply line, carefully position oil line into vehicle and hand-start bolt into engine block.

Connect and finger tighten oil line to turbocharger. Tighten oil line bolt and oil supply line on turbocharger to specification.

6. Connect coolant supply hose. Position air cleaner duct tube on turbocharger and tighten clamp. Install 2 screws retaining air cleaner

duct tube. Position power steering pump bracket on engine, and install 2 retaining bolts and one retaining nut. Tighten to specification.

Position power steering pump on mounting bracket, and install though bolt and adjuster. Connect lower radiator hose. Install power

steering belt. Position upper heat shield and install 2 retaining bolts finger tight.

7. Position lower heat shield and install three retaining bolts finger tight. Tighten all heat shield bolts to specification. Connect O2 sensor

and install connector into its retaining clip. See TORQUE SPECIFICATIONS

table at end of article. Position intercooler hose on

turbocharger and secure with clamp. Install throttle body air intake tube. Connect negative battery cable. Refill cooling system.

CYLINDER HEAD

Removal (1.3L)

1. Disconnect battery ground cable. Mark and disconnect fuel lines at fuel pump. Remove accessory belts, water pump pulley, crankshaft

pulley, timing belt covers, timing belt tensioner, timing belt, valve cover and exhaust and intake manifolds. Drain cooling system.

2. Mark and remove electrical connectors and vacuum hoses. Remove spark plug wires from spark plugs, and remove spark plugs. Remove

distributor cap. Disconnect vacuum hoses and distributor wiring.

3. Index distributor-to-mount position and remove hold-down bolt. Remove distributor assembly. Remove engine ground strap. Remove

front and rear engine lifting hooks. Remove upper radiator hose, by-pass hose and bracket.

4. Remove bolts retaining rocker arm shaft. Remove rocker arm assemblies. Remove cylinder head bolts. Remove head and gasket.

Inspection (1.3L)

1. Thoroughly clean and check gasket mating surface of cylinder head and block. Check cylinder for cracks, nicks, burrs or damage. Using

a straightedge and feeler gauge, check warpage over entire gasket area. Ensure cylinder head and/or block warpage does not

exceed .006" (.15 mm).

2. If warpage exceeds .006" (.15 mm), machine cylinder head and/or block gasket surface. Maximum machining allowed is .008" (.20 mm).

If more machining is required, replace block and/or cylinder head.

Installation (1.3L)

1. Place new head gasket properly on block. Carefully place cylinder head in position on block. Install head bolts. Tighten bolts in

sequence and in 2 steps. See Fig. 1

.

2. While tightening rocker arm shaft, slide shaft springs away from retaining bolt to prevent pinching springs. Tighten rocker arm shaft bolts

in sequence and to specification. See Fig. 5

. To complete installation, reverse removal procedure. Tighten all bolts/nuts to

specification. Fill all fluids to proper levels. NOTE:T urbocharger-to-exhaust m anifold m ounting nuts are of special quality. Ensure correct nuts are

used.

NOTE:Ensure one brass washer is positioned on each side of oil line fitting.

NOTE:Feed O2 sensor wire through upper heat shield. Install wire retainer under LH bolt.

NOTE:If turbocharger was replaced: Disconnect ignition coil, crank engine for 20 seconds, connect ignition

coil, start engine and run at idle for 30 seconds and check for leaks.

NOTE:If original tim ing belt is being reused, m ark direction of rotation for installation reference.

Page 4 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 111 of 454

bearing oil seal. To complete installation, reverse removal procedure.

WATER PUMP

Removal & Installation (1.3L)

Remove timing belt. Drain cooling system. Remove lower radiator hose and heater return hose from water pump. Remove water pump

retaining bolts and water pump. Clean gasket mounting surface and replace gasket. To install, reverse removal procedure.

Removal (1.6L)

1. Remove timing belt. See TIMING BELT . Drain cooling system. Remove timing belt tensioner and idler pulleys. Remove oil dipstick

bracket retaining bolt.

2. Remove power steering pump from retaining bracket, leaving hoses attached. Remove power steering bracket and position power

steering pump to one side. Remove water pump outlet. Remove water pump retaining bolts and water pump.

Installation (1.6L)

1. Clean all gasket surfaces. Transfer rubber belt cover seal to new water pump (if required). Position water pump with new gasket and

install retaining bolts. Install pump outlet with new gasket and "O" ring. See TORQUE SPECIFICATIONS

table at end of article.

2. Install oil dipstick retaining bolt. Install timing belt tensioner and idler pulleys. Install power steering pump bracket. Install power

steering pump. Tighten all bolts and nuts to specification. See TORQUE SPECIFICATIONS

table at end of article.

3. Install timing belt. Fill cooling system. Start engine and check for leaks and proper system function.

OIL PAN

Removal (1.3L)

Disconnect battery ground cable. Raise vehicle and drain engine oil. Remove flywheel housing dust cover. Remove oil pan retaining bolts,

nuts and stiffeners. Rotate crankshaft while removing oil pan. Remove baffle plate from oil pan. Clean gasket mating surfaces thoroughly.

Installation (1.3L)

Ensure gasket surfaces are clean. Apply oil resistant sealer to front and rear engine covers and across joint line of cylinder block.

Removal (1.6L)

1. Raise vehicle and drain engine oil. Remove frame brace retaining bolt. Loosen RH "A" arm front bolt, and pivot brace downward.

Disconnect front exhaust pipe from exhaust manifold (or turbocharger). Remove exhaust pipe bracket retaining bolts. Loosen rubber

exhaust hangers at catalytic converter.

2. Allow exhaust to hang supported by mechanic's wire. Disconnect turbocharger oil return hose (if equipped). Remove oil pan retaining

bolts. Carefully pry oil pan loose from cylinder block.

Installation (1.6L)

1. Clean pan and block gasket surfaces. Apply Gasket Sealant (E3AZ-19562-A) to new front and rear pan seals. Install seals to cylinder

block. Apply Gasket Sealant (E3AZ-19562-A) to oil pan gasket surface. See Fig. 8

. Install oil pan and tighten pan retaining bolts to

specification. See TORQUE SPECIFICATIONS

table at end of article.

2. Connect turbocharger oil return hose (if equipped). Install rubber exhaust hanger to brackets. Install new gasket and connect fro n t

exhaust pipe to exhaust manifold (or turbocharger). Install front exhaust pipe bracket. Tighten nuts and bolts to specification.

3. Pivot frame brace into position. Tighten retaining bolt to crossmember and RH "A" arm front retaining bolt to specification. Lower

vehicle, fill with oil and start engine. Check for oil leaks and system operation. NOTE:Raise engine slightly with floor jack, if required, to gain clearance for water pum p rem oval.

CAUT ION: DO NOT force a pry tool between cylinder block and oil pan.

Page 11 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 115 of 454

Installation

1. Install pressure regulator valve, spring, retainer and new cotter pin. Press a new seal in front cover housing. Install outer and inner gears

in housing. Install pump cover. Coat bolts with Loctite and tighten to specification. See TORQUE SPECIFICATIONS

table at end of

article.

2. Install new gasket and install front cover housing. Install new gasket and install pick-up tube and screen. Tighten all bolts/nuts to

specification. To complete installation, reverse removal procedure.

ENGINE COOLING

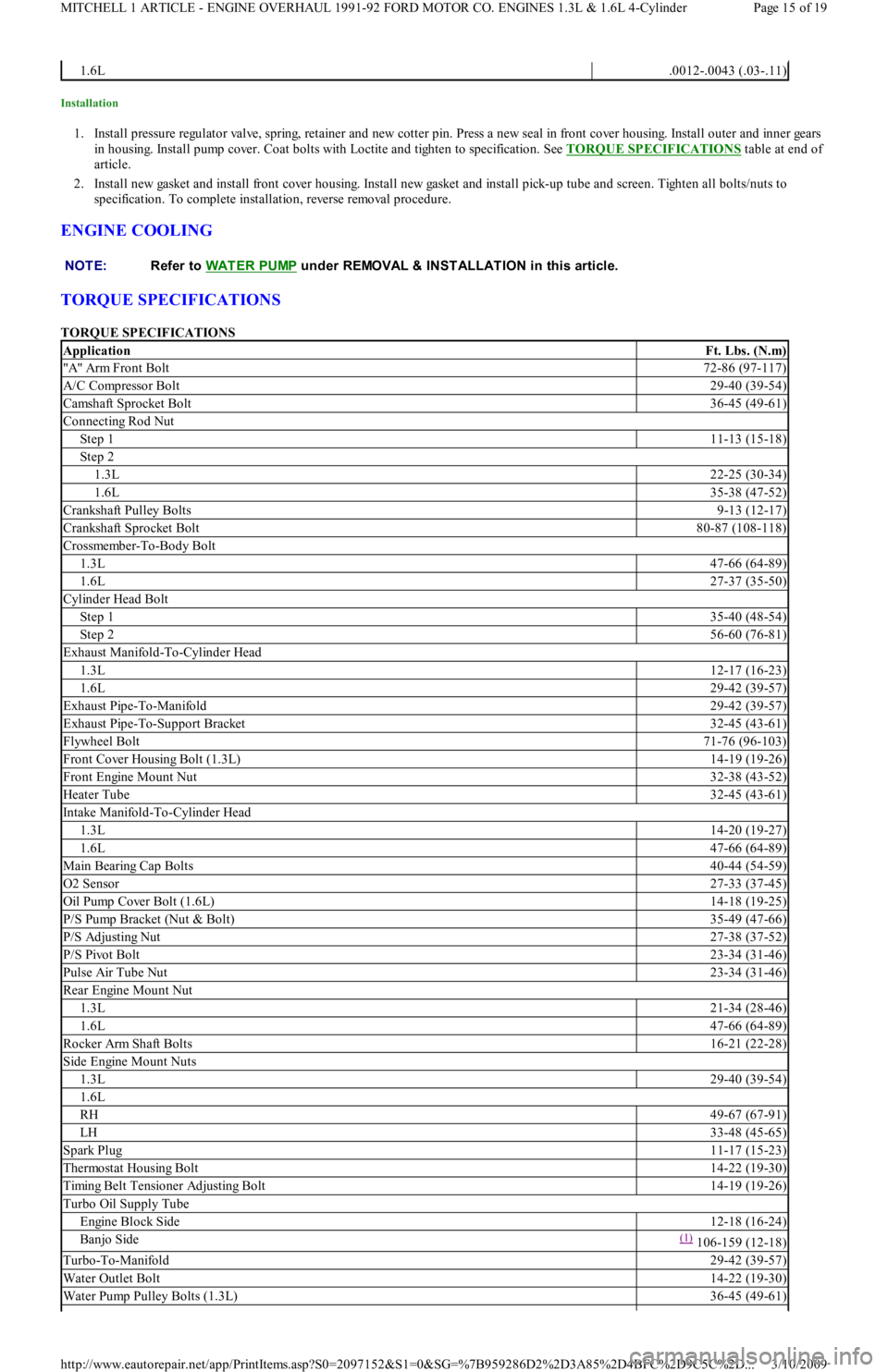

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

1.6L.0012-.0043 (.03-.11)

NOTE:Refer to WAT ER PUMP

under REMOVAL & INSTALLATION in this article.

ApplicationFt. Lbs. (N.m)

"A" Arm Front Bolt72-86 (97-117)

A/C Compressor Bolt29-40 (39-54)

Camshaft Sprocket Bolt36-45 (49-61)

Connecting Rod Nut

Step 111-13 (15-18)

Step 2

1.3L22-25 (30-34)

1.6L35-38 (47-52)

Crankshaft Pulley Bolts9-13 (12-17)

Crankshaft Sprocket Bolt80-87 (108-118)

Crossmember-To-Body Bolt

1.3L47-66 (64-89)

1.6L27-37 (35-50)

Cylinder Head Bolt

Step 135-40 (48-54)

Step 256-60 (76-81)

Exhaust Manifold-To-Cylinder Head

1.3L12-17 (16-23)

1.6L29-42 (39-57)

Exhaust Pipe-To-Manifold29-42 (39-57)

Exhaust Pipe-To-Support Bracket32-45 (43-61)

Flywheel Bolt71-76 (96-103)

Front Cover Housing Bolt (1.3L)14-19 (19-26)

Front Engine Mount Nut32-38 (43-52)

Heater Tube32-45 (43-61)

Intake Manifold-To-Cylinder Head

1.3L14-20 (19-27)

1.6L47-66 (64-89)

Main Bearing Cap Bolts40-44 (54-59)

O2 Sensor27-33 (37-45)

Oil Pump Cover Bolt (1.6L)14-18 (19-25)

P/S Pump Bracket (Nut & Bolt)35-49 (47-66)

P/S Adjusting Nut27-38 (37-52)

P/S Pivot Bolt23-34 (31-46)

Pulse Air Tube Nut23-34 (31-46)

Rear Engine Mount Nut

1.3L21-34 (28-46)

1.6L47-66 (64-89)

Rocker Arm Shaft Bolts16-21 (22-28)

Side Engine Mount Nuts

1.3L29-40 (39-54)

1.6L

RH49-67 (67-91)

LH33-48 (45-65)

Spark Plug11-17 (15-23)

Thermostat Housing Bolt14-22 (19-30)

Timing Belt Tensioner Adjusting Bolt14-19 (19-26)

Turbo Oil Supply Tube

Engine Block Side12-18 (16-24)

Banjo Side(1) 106-159 (12-18)

Turbo-To-Manifold29-42 (39-57)

Water Outlet Bolt14-22 (19-30)

Water Pump Pulley Bolts (1.3L)36-45 (49-61)

Page 15 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 147 of 454

ELECTRONIC CONTROL ASSEMBLY (ECA)

REMOVAL & INSTALLATION

Disconnect negative battery cable. On Festiva, from under instrument panel, remove heater duct. On Capri, disengage push-pin retainers by

pulling back on front edges of both center carpet panels. Remove carpet panel retaining screws and panels. Disconnect ECA wire harness

connector. Remove ECA bolts and ECA. To install, reverse removal procedure. On Festiva, ensure mounting clip is inserted into bulkhead

recess.

FUEL SYSTEM

FUEL SYSTEM PRESSURE RELEASE

Remove rear seat assembly. With engine running, disconnect fuel pump connector. Run engine until it stalls to relieve fuel line pressure.

FUEL INJECTORS

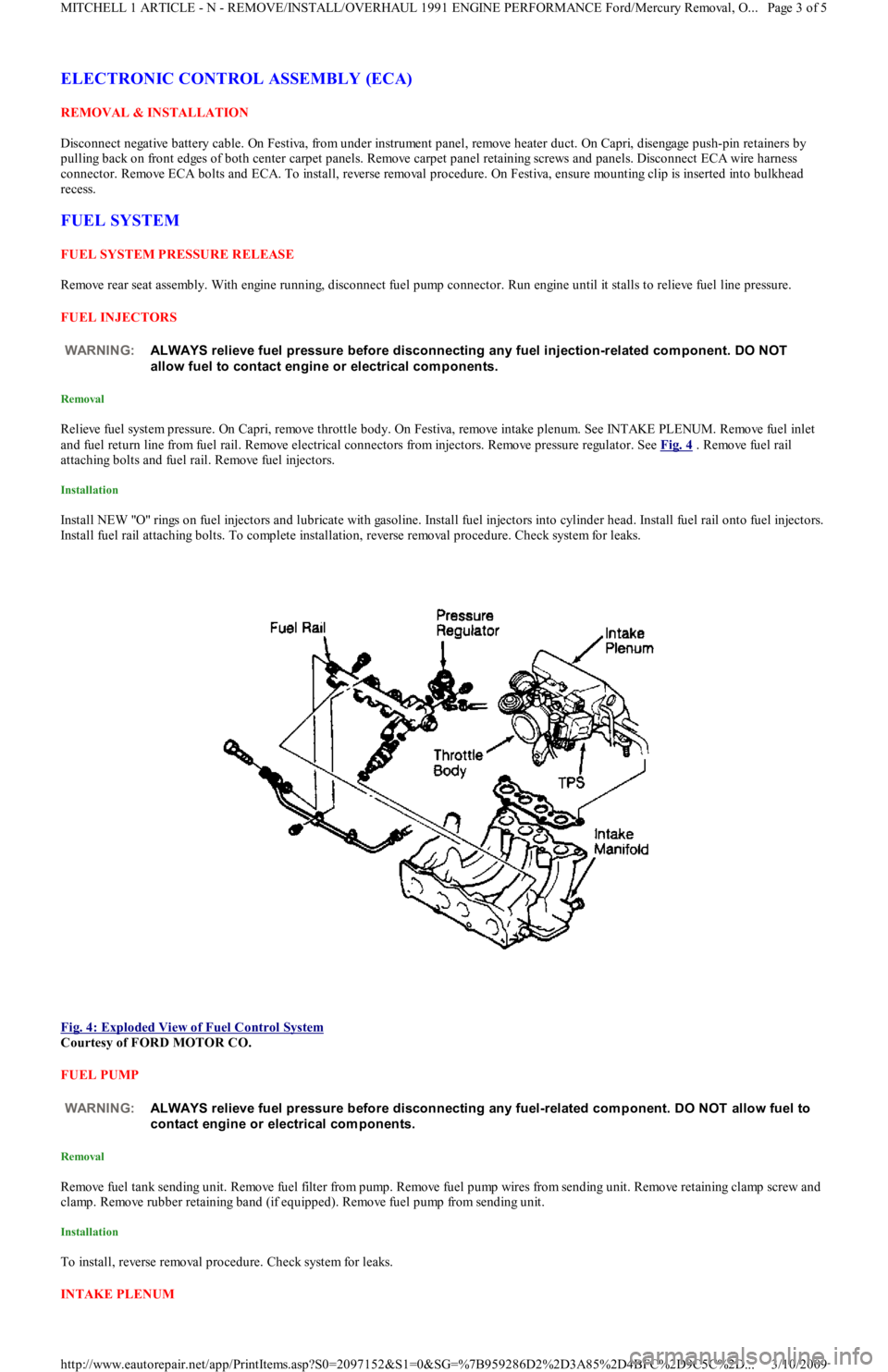

Removal

Relieve fuel system pressure. On Capri, remove throttle body. On Festiva, remove intake plenum. See INTAKE PLENUM. Remove fuel inlet

and fuel return line from fuel rail. Remove electrical connectors from injectors. Remove pressure regulator. See Fig. 4

. Remove fuel rail

attaching bolts and fuel rail. Remove fuel injectors.

Installation

Install NEW "O" rings on fuel injectors and lubricate with gasoline. Install fuel injectors into cylinder head. Install fuel rail onto fuel injectors.

Install fuel rail attaching bolts. To complete installation, reverse removal procedure. Check system for leaks.

Fig. 4: Exploded View of Fuel Control System

Courtesy of FORD MOTOR CO.

FUEL PUMP

Removal

Remove fuel tank sending unit. Remove fuel filter from pump. Remove fuel pump wires from sending unit. Remove retaining clamp screw and

clamp. Remove rubber retaining band (if equipped). Remove fuel pump from sending unit.

Installation

To install, reverse removal procedure. Check system for leaks.

INTAKE PLENUM WARNING:ALWAYS relieve fuel pressure before disconnecting any fuel injection-related com ponent. DO NOT

allow fuel to contact engine or electrical com ponents.

WARNING:ALWAYS relieve fuel pressure before disconnecting any fuel-related com ponent. DO NOT allow fuel to

contact engine or electrical com ponents.

Page 3 of 5 MITCHELL 1 ARTICLE - N - REMOVE/INSTALL/OVERHAUL 1991 ENGINE PERFORMANCE Ford/Mercury Removal, O

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 148 of 454

Removal

Drain radiator and remove negative battery cable. Disconnect throttle cable. Remove air duct from throttle body. Disconnect throttle position

sensor/switch connector. Mark all coolant and vacuum hoses for reassembly reference and remove from throttle body. See Fig. 4

. Remove

intake plenum bolts and remove intake plenum and gasket.

Installation

To install, reverse removal procedure. Use NEW intake plenum-to-intake manifold gasket. Tighten bolts to specification, see TORQUE

SPECIFICATIONS at end of article.

OXYGEN (O2) SENSOR

Removal & Installation

Disconnect negative battery cable. Disconnect wire harness connector, and remove oxygen sensor. If exhaust sensor is difficult to remove, use

rust penetrant to avoid possible damage to exhaust threads. If new sensor is not pre-coated with anti-seize, apply anti-seize compound to

sensor threads. DO NOT remove anti-seize from sensor. To install, tighten sensor and attach wire harness connector.

THROTTLE BODY

Removal & Installation

Drain radiator and remove negative battery cable. Remove resonance chamber. Disconnect throttle cable. Remove air duct. Mark all coolant

and vacuum hoses for reassembly reference and remove from throttle body. Disconnect throttle position sensor/switch connector. Remove

throttle body nuts and bolts. Remove throttle body and gasket. To install, reverse removal procedure using NEW throttle body-to-intake

plenum gasket.

THROTTLE POSITION SENSOR/SWITCH

Removal & Installation

Disconnect negative battery cable. Disconnect throttle position sensor/switch connector. Remove attaching bolts. Remove sensor/switch from

throttle body. To install, reverse removal procedure.

TURBOCHARGER

Removal

1. Drain radiator and remove negative battery cable. Remove throttle body air intake tube. Disconnect intercooler hose from turbocharger

assembly. Disconnect O2 sensor. Remove lower heat shield retaining bolts and lower heat shield from turbocharger. Remove upper heat

shield retaining bolts and upper heat shield from exhaust manifold.

2. Slide O2 sensor wire and guide through upper heat shield. Remove side heat shield retaining bolts from turbocharger, and remove sid e

heat shield. Remove power steering belt. Remove power steering pump through bolt and adjuster nuts and bolts. Disconnect lower

radiator hose from water pump.

3. Pull pump from bracket, and position pump to access mounting bracket retaining nut and bolts. Remove mounting bracket-to-engine nut

and bolts and remove bracket. Remove air cleaner duct retaining screws. Loosen clamp at turbocharger and move duct tube out of way.

Disconnect coolant supply hose at turbocharger.

4. Remove bolt and sealing washers attaching oil supply line at engine block. Raise vehicle on hoist. Remove nuts and washers from

exhaust pipe flange. Remove bolts attaching exhaust hanger to engine block. Slide rubber exhaust hangers from catalytic converter. Pull

exhaust pipe downward and to left side of vehicle. Disconnect oil return hose from turbocharger. Disconnect coolant return hose fro m

turbocharger.

5. Remove turbocharger support bracket retaining bolts. Remove coolant by-pass tube outlet-to-water pump bolts. Lower vehicle. Loosen

retaining clamp bolt on coolant by-pass tube at rear of cylinder head. Remove 11 retaining nuts from exhaust manifold. Position coolant

by-pass tube out of way after pulling bracket from exhaust stud.

6. Remove exhaust manifold by pulling off studs and moving assembly towards right side of engine compartment, clearing cooling fan.

With assembly removed from vehicle, remove turbocharger-to-exhaust manifold nuts. Separate assembly and discard gasket.

Installation

1. Install NEW gasket on exhaust manifold and install turbocharger onto studs. Install turbocharger-to-exhaust manifold nuts. Remo ve o il

supply line from turbocharger. Install NEW exhaust gasket on cylinder head. Install turbocharger and exhaust manifold assembly onto

studs. Install coolant by-pass tube bracket onto exhaust stud. Install 11 retaining nuts onto exhaust manifold.

2. Securely tighten heater tube clamp bolt. Raise vehicle. Install coolant by-pass tube outlet-to-water pump bolts. Install turbocharger

support bracket retaining bolts. Connect coolant return hose to turbocharger. Connect oil return hose to turbocharger. Install exhaust

pipe onto turbocharger, and hand tighten nuts and washers. Install bolts attaching exhaust hanger to engine block.

3. Slide rubber exhaust hangers onto catalytic converter. Tighten exhaust pipe nuts and washers. Lower vehicle. Install bolt and sealing

washers attaching oil supply line at engine block. Install oil supply line onto turbocharger. To complete installation, reverse removal

procedure. Tighten bolts and nuts to specification, see TORQUE SPECIFICATIONS

at end of article. NOTE:T o prevent dust and dirt from entering intake m anifold ports, cover ports with clean cloth after

rem oving intake plenum .

WARNING:DO NOT rem ove oxygen sensor when engine is hot.

NOTE:Clean throttle body exterior before rem oval.

CAUT ION: Before installing turbocharger, put .8 oz. (25 m l) engine oil into turbocharger oil inlet.

Page 4 of 5 MITCHELL 1 ARTICLE - N - REMOVE/INSTALL/OVERHAUL 1991 ENGINE PERFORMANCE Ford/Mercury Removal, O

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 153 of 454

Back To Article

C - SPECIFICATIONS

1991 ENGINE PERFORMANCE Ford/Mercury - Service & Adjustm ent Specifications

INTRODUCTION

Use this article to quickly find specifications related to servicing and on-vehicle adjustments. This is a quick-reference article to use when you

are familiar with an adjustment procedure and only need a specification.

CAPACITIES

BATTERY SPECIFICATIONS

FLUID CAPACITIES

FLUID CAPACITIES

QUICK-SERVICE

SERVICE INTERVALS & SPECIFICATIONS

REPLACEMENT INTERVALS

BELT ADJUSTMENTS

(1)

BELT ADJUSTMENTS

(1)

MECHANICAL CHECKS

ENGINE COMPRESSION

Check engine compression at specified cranking speed with engine at normal operating temperature, all spark plugs removed and throttle wide

open.

COMPRESSION SPECIFICATIONS

ApplicationAmp Hr. Rating

1.3L & 1.6L50

ApplicationQts. (L)

Crankcase (Includes Filter)3.6 (3.4)

Cooling System (Includes Heater)5.3 (5.0)

Manual Transaxle (Mercon)2.6 (2.5)

Automatic Transaxle (Mercon)6.0 (5.7)

ApplicationQts. (L)

Crankcase (Includes Filter)

Non-Turbo3.5 (3.3)

Turbo3.7 (3.5)

Cooling System (Includes Heater)

Non-Turbo5.3 (5.0)

Turbo6.3 (6.0)

Manual Transaxle (Mercon)3.4 (3.2)

Automatic Transaxle (Mercon)6.0 (5.7)

ComponentInterval (Miles)

Air Filter30,000

Camsh aft Timin g Bel t60,000

Coolant30,000

Oil & Filter3000

Spark Plugs30,000

ApplicationNew BeltUsed Belt

A/C Belt110-125 (50-57)92-110 (42-50)

Alternator Belt110-132 (50-60)95-110 (43-50)

(1)Tension in Lbs. (Kg) Using Strand Tension Gauge

ApplicationNew BeltUsed Belt

A/C Belt110-132 (50-60)110-132 (50-60)

Alternator Belt110-132 (50-60)110-132 (50-60)

(1)Tension in Lbs. (Kg) Using Strand Tension Gauge.

ApplicationSpecification

Compression Ratio

1.3L9.7:1

1.6L(1)

Compression Pressure(2)

Page 1 of 3 MITCHELL 1 ARTICLE - C - SPECIFICATIONS 1991 ENGINE PERFORMANCE Ford/Mercury - Service & Adjustment Spe

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 158 of 454

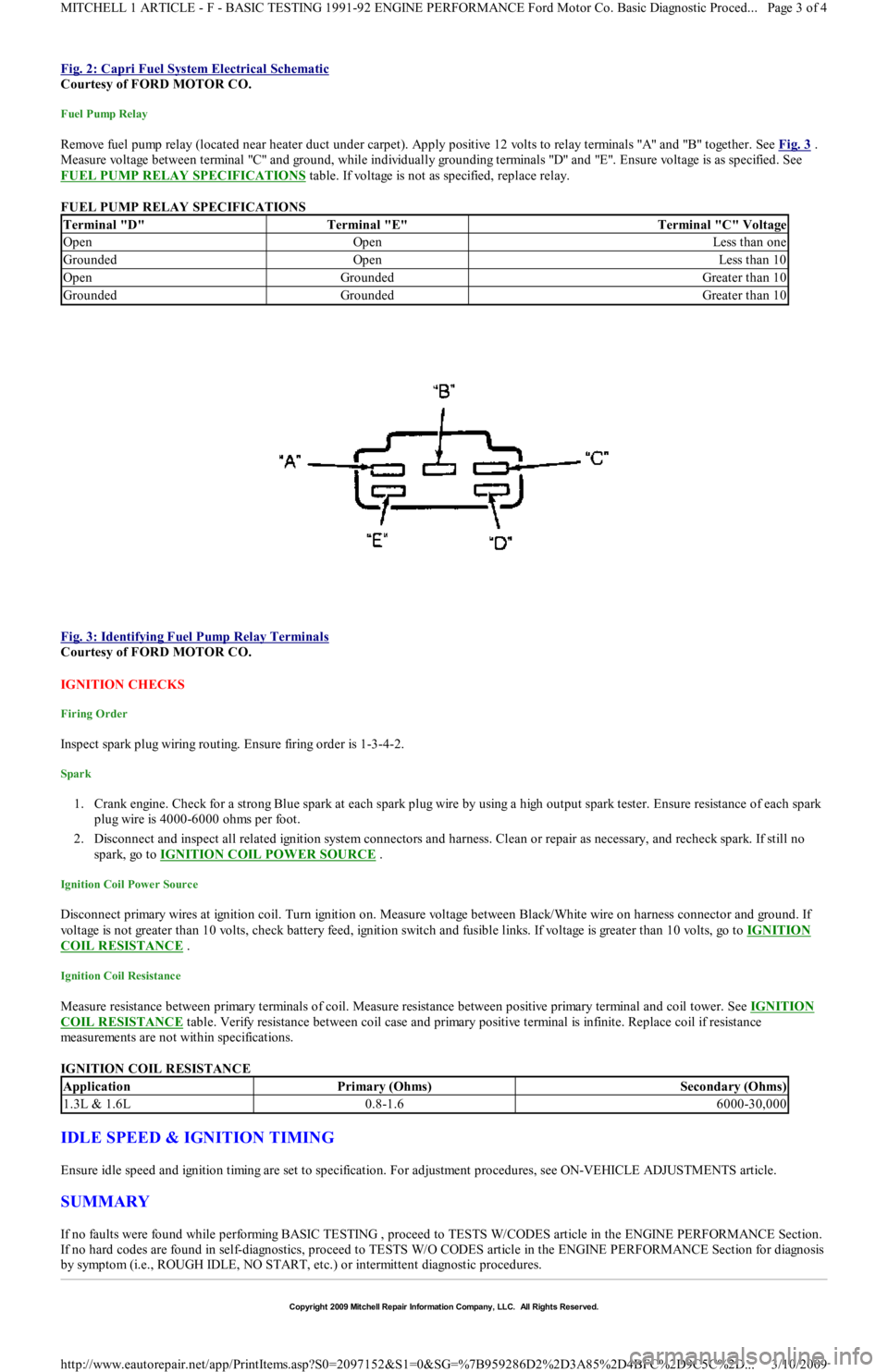

Fig. 2: Capri Fuel System Electrical Schematic

Courtesy of FORD MOTOR CO.

Fuel Pump Relay

Remove fuel pump relay (located near heater duct under carpet). Apply positive 12 volts to relay terminals "A" and "B" together. See Fig. 3 .

Measure voltage between terminal "C" and ground, while individually grounding terminals "D" and "E". Ensure voltage is as specified. See

FUEL PUMP RELAY SPECIFICATIONS

table. If voltage is not as specified, replace relay.

FUEL PUMP RELAY SPECIFICATIONS

Fig. 3: Identifying Fuel Pump Relay Terminals

Courtesy of FORD MOTOR CO.

IGNITION CHECKS

Firing Order

Inspect spark plug wiring routing. Ensure firing order is 1-3-4-2.

Spark

1. Crank engine. Check for a strong Blue spark at each spark plug wire by using a high output spark tester. Ensure resistance of each spark

plug wire is 4000-6000 ohms per foot.

2. Disconnect and inspect all related ignition system connectors and harness. Clean or repair as necessary, and recheck spark. If st il l n o

spark, go to IGNITION COIL POWER SOURCE

.

Ignition Coil Power Source

Disconnect primary wires at ignition coil. Turn ignition on. Measure voltage between Black/White wire on harness connector and ground. If

voltage is not greater than 10 volts, check battery feed, ignition switch and fusible links. If voltage is greater than 10 volts, go to IGNITION

COIL RESISTANCE .

Ignition Coil Resistance

Measure resistance between primary terminals of coil. Measure resistance between positive primary terminal and coil tower. See IGNITION

COIL RESISTANCE table. Verify resistance between coil case and primary positive terminal is infinite. Replace coil if resistance

measurements are not within specifications.

IGNITION COIL RESISTANCE

IDLE SPEED & IGNITION TIMING

Ensure idle speed and ignition timing are set to specification. For adjustment procedures, see ON-VEHICLE ADJUSTMENTS article.

SUMMARY

If no faults were found while performing BASIC TESTING , proceed to TESTS W/CODES article in the ENGINE PERFORMANCE Section.

If no hard codes are found in self-diagnostics, proceed to TESTS W/O CODES article in the ENGINE PERFORMANCE Section for diagnosis

by symptom (i.e., ROUGH IDLE, NO START, etc.) or intermittent diagnostic procedures.

Terminal "D"Terminal "E"Terminal "C" Voltage

OpenOpenLess than one

GroundedOpenLess than 10

OpenGroundedGreater than 10

GroundedGroundedGreater than 10

ApplicationPrimary (Ohms)Secondary (Ohms)

1.3L & 1.6L0.8-1.66000-30,000

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Page 3 of 4 MITCHELL 1 ARTICLE - F - BASIC TESTING 1991-92 ENGINE PERFORMANCE Ford Motor Co. Basic Diagnostic Proced

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 206 of 454

High Performance

HSC

High Swirl Combustion

HSO

High Specific Output

HTR

Heater

Hz

Hertz (Cycles Per Second)

"I"

IAC

Idle Air Control

IACV

Idle Air Control Valve

IAT

Intake Air Temperature

IC

Integrated Circuit

ID

Identification

I.D.

Inside Diameter

Ign.

Ignition

IMRC

Intake Manifold Runner Control

In.

In ch es

INCH Lbs.

Inch Pounds

in. Hg

Inches of Mercury

Inj.

Injector

IP

Instrument Panel

ISC

Idle Speed Control

IVSV

Idle Vacuum Switching Valve

Page 8 of 15 MITCHELL 1 ARTICLE - GENERAL INFORMATION Commonly Used Abbreviations

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 219 of 454

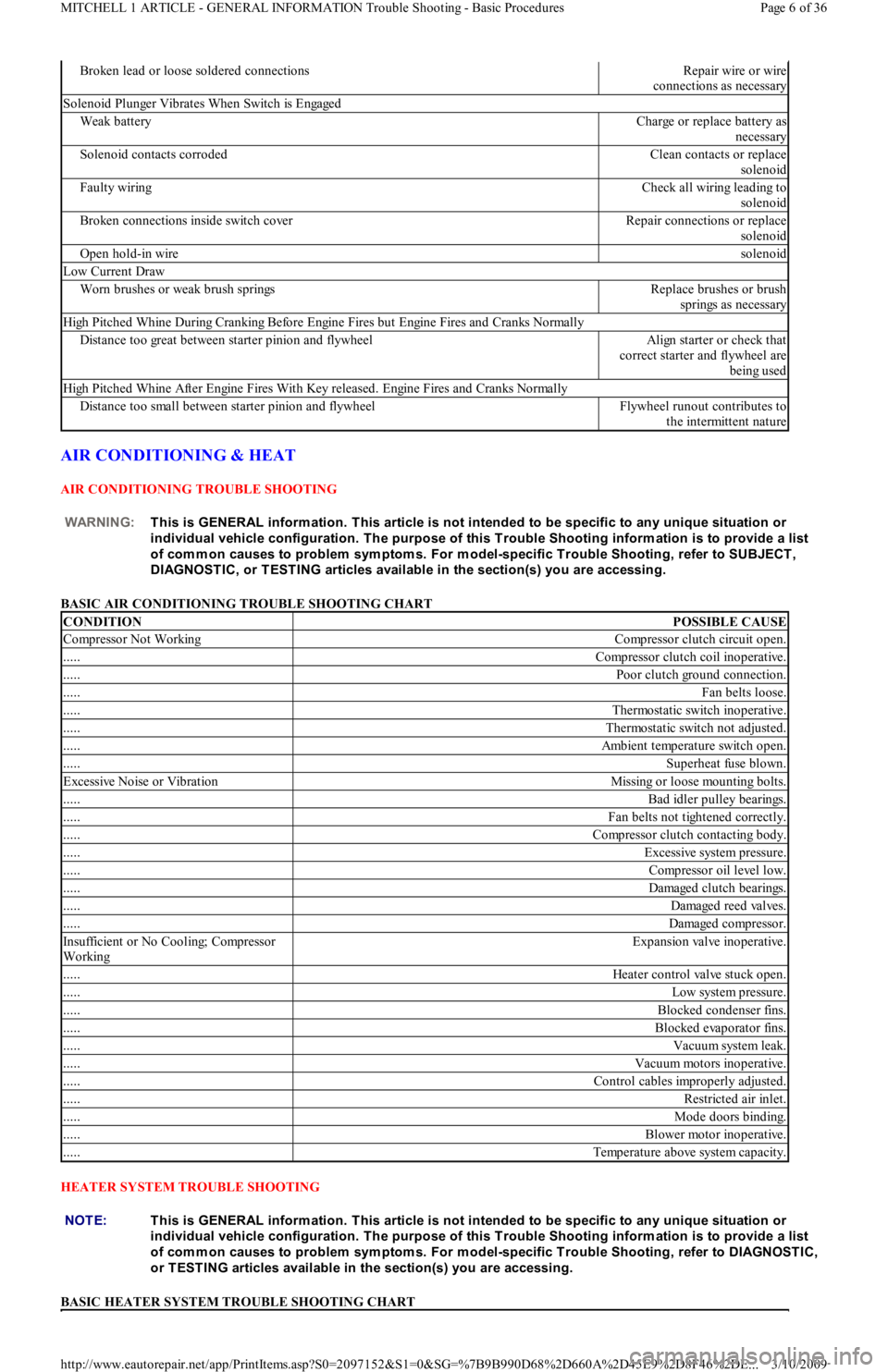

AIR CONDITIONING & HEAT

AIR CONDITIONING TROUBLE SHOOTING

BASIC AIR CONDITIONING TROUBLE SHOOTING CHART

HEATER SYSTEM TROUBLE SHOOTING

BASIC HEATER SYSTEM TROUBLE SHOOTING CHART

Broken lead or loose soldered connectionsRepair wire or wire

connections as necessary

Solenoid Plunger Vibrates When Switch is Engaged

Weak batteryCharge or replace battery as

necessary

Solenoid contacts corrodedClean contacts or replace

solenoid

Faulty wiringCheck all wiring leading to

solenoid

Broken connections inside switch coverRepair connections or replace

solenoid

Open hold-in wiresolenoid

Low Current Draw

Worn brushes or weak brush springsReplace brushes or brush

springs as necessary

High Pitched Whine During Cranking Before Engine Fires but Engine Fires and Cranks Normally

Distance too great between starter pinion and flywheelAlign starter or check that

correct starter and flywheel are

being used

High Pitched Whine After Engine Fires With Key released. Engine Fires and Cranks Normally

Distance too small between starter pinion and flywheelFlywheel runout contributes to

the intermittent nature

WARNING:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITIONPOSSIBLE CAUSE

Compressor Not WorkingCompressor clutch circuit open.

.....Compressor clutch coil inoperative.

.....Poor clutch ground connection.

.....Fan belts loose.

.....Thermostatic switch inoperative.

.....Thermostatic switch not adjusted.

.....Ambient temperature switch open.

.....Superheat fuse blown.

Excessive Noise or VibrationMissing or loose mounting bolts.

.....Bad idler pulley bearings.

.....Fan belts not tightened correctly.

.....Compressor clutch contacting body.

.....Excessive system pressure.

.....Compressor oil level low.

.....Damaged clutch bearings.

.....Damaged reed valves.

.....Damaged compressor.

In su fficien t o r No Co o l in g; Co mp resso r

WorkingExpansion valve inoperative.

.....Heater control valve stuck open.

.....Low system pressure.

.....Blocked condenser fins.

.....Blocked evaporator fins.

.....Vacuum system leak.

.....Vacuum motors inoperative.

.....Control cables improperly adjusted.

.....Restricted air inlet.

.....Mode doors binding.

.....Blower motor inoperative.

.....Temperature above system capacity.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to DIAGNOST IC,

or T EST ING articles available in the section(s) you are accessing.

Page 6 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 220 of 454

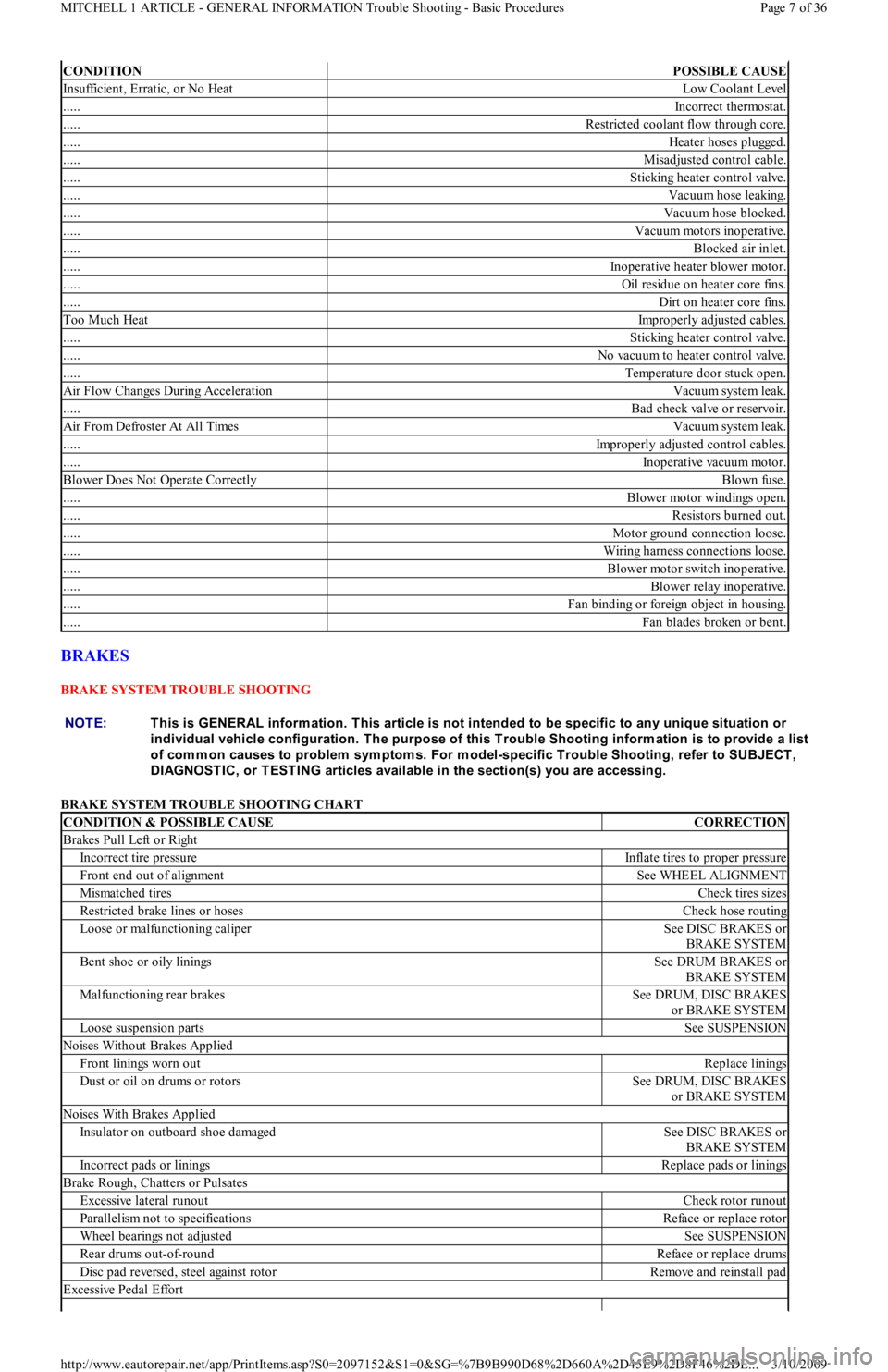

BRAKES

BRAKE SYSTEM TROUBLE SHOOTING

BRAKE SYSTEM TROUBLE SHOOTING CHART

CONDITIONPOSSIBLE CAUSE

Insufficient, Erratic, or No HeatLow Coolant Level

.....Incorrect thermostat.

.....Restricted coolant flow through core.

.....Heater hoses plugged.

.....Misadjusted control cable.

.....Sticking heater control valve.

.....Vacuum hose leaking.

.....Vacuum hose blocked.

.....Vacuum motors inoperative.

.....Blocked air inlet.

.....Inoperative heater blower motor.

.....Oil residue on heater core fins.

.....Dirt on heater core fins.

Too Much HeatImproperly adjusted cables.

.....Sticking heater control valve.

.....No vacuum to heater control valve.

.....Temperature door stuck open.

Air Flow Changes During AccelerationVacuum system leak.

.....Bad check valve or reservoir.

Air From Defroster At All TimesVacuum system leak.

.....Improperly adjusted control cables.

.....Inoperative vacuum motor.

Blower Does Not Operate CorrectlyBlown fuse.

.....Blower motor windings open.

.....Resistors burned out.

.....Motor ground connection loose.

.....Wiring harness connections loose.

.....Blower motor switch inoperative.

.....Blower relay inoperative.

.....Fan binding or foreign object in housing.

.....Fan blades broken or bent.

NOTE:This is GENERAL inform ation. This article is not intended to be specific to any unique situation or

individual vehicle configuration. T he purpose of this T rouble Shooting inform ation is to provide a list

of com m on causes to problem sym ptom s. For m odel-specific T rouble Shooting, refer to SUBJECT ,

DIAGNOST IC, or T EST ING articles available in the section(s) you are accessing.

CONDITION & POSSIBLE CAUSECORRECTION

Brakes Pull Left or Right

Incorrect tire pressureInflate tires to proper pressure

Front end out of alignmentSee WHEEL ALIGNMENT

Mismatched tiresCheck tires sizes

Restricted brake lines or hosesCheck hose routing

Loose or malfunctioning caliperSee DISC BRAKES or

BRAKE SYSTEM

Bent shoe or oily liningsSee DRUM BRAKES or

BRAKE SYSTEM

Malfunctioning rear brakesSee DRUM, DISC BRAKES

or BRAKE SYSTEM

Loose suspension partsSee SUSPENSION

Noises Without Brakes Applied

Front linings worn outReplace linings

Dust or oil on drums or rotorsSee DRUM, DISC BRAKES

or BRAKE SYSTEM

Noises With Brakes Applied

Insulator on outboard shoe damagedSee DISC BRAKES or

BRAKE SYSTEM

Incorrect pads or liningsReplace pads or linings

Brake Rough, Chatters or Pulsates

Excessive lateral runoutCheck rotor runout

Parallelism not to specificationsReface or replace rotor

Wheel bearings not adjustedSee SUSPENSION

Rear drums out-of-roundReface or replace drums

Disc pad reversed, steel against rotorRemove and reinstall pad

Excessive Pedal Effort

Page 7 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...