brake sensor FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 32 of 454

lock nut. Discard axle lock nut. Separate tie rod end from knuckle.

2. Disconnect brake hose from strut (if necessary). Remove brake caliper assembly from knuckle and wire out of way. Remove nuts and

bolts holding ball joint and strut to knuckle assembly.

3. Remove knuckle assembly from ball joint and drive shaft. If binding occurs, use a dual-jawed puller to force knuckle/hub/rotor assembly

off drive axle shaft.

4. Using a puller, separate knuckle from wheel hub. Retain original outer bearing preload spacer to maintain bearing preload setting. If

replacing bearing, change spacer to maintain proper bearing preload (if necessary). See FRONT WHEEL BEARINGS under REMOVAL

& INSTALLATION. Scribe match marks between hub and rotor assembly. Remove rotor-to-hub bolts. Separate hub from rotor.

Installation

Align marks and install rotor on hub. Press knuckle and preload spacer into wheel hub assembly. To complete installation, reverse removal

procedure. Tighten axle shaft lock nut to 117-175 ft. lbs. (159-237 N.m).

REAR BRAKE CALIPER & PADS

Removal (Capri)

1. Raise and support vehicle. Remove tire and wheel assembly. Using needle-nose pliers, remove parking brake return spring. Loosen

parking brake cable housing adjusting nut. Remove cable housing from bracket on lower control arm. Loosen parking brake cable

bracket-to-caliper attaching bolt. Remove parking brake cable from caliper.

2. Remove lower caliper retaining bolt. Pivot caliper upward on upper caliper guide pin. Remove brake pad retaining spring, pads and

shims. If replacing rear brake pads only, reverse removal procedure to install. If removing caliper, proceed to next step.

3. Remove attaching clip from brake flex hose. Remove flex hose banjo bolt from caliper and discard copper washers. Remove lower

caliper retaining bolt. Using a cold chisel, remove upper caliper guide pin dust cap. Using an Allen wrench, remove upper caliper guide

pin. Lift caliper off rotor.

Installation

1. To install, fit brake pads and shims into caliper anchor plate. Remove upper guide pin and lower guide pin bushing from caliper.

Remove guide pin and guide pin bushing dust boots. Lubricate upper guide pin and lower guide pin bushing with Disc Brake Caliper

Slide Grease (D7AZ-19590-A).

2. To complete installation, reverse removal procedure. To fit caliper over new brake pads, it may be necessary to rotate caliper piston into

caliper bore. Use NEW copper washers on flex hose. Bleed brakes, and then pump brake pedal several times to seat pads.

REAR BRAKE ROTOR

Removal & Installation (Capri)

See REAR WHEEL BEARINGS under REMOVAL & INSTALLATION.

REAR BRAKE SHOES

Removal & Installation (Festiva)

Remove brake drum. Remove hold-down springs. Remove return springs. Remove self adjuster. See Fig. 8 . To install, reverse removal

procedure. Apply brake grease to all shoe contact points. See REAR BRAKE SHOES under ADJUSTMENTS.

REAR WHEEL CYLINDER

Removal & Installation (Festiva)

Remove rear brake shoes. Disconnect brake line from wheel cylinder. Remove wheel cylinder. To install, reverse removal procedure. Bleed

brake system.

MASTER BRAKE CYLINDER

Removal

Disconnect low fluid level sensor wiring (if equipped). Drain some brake fluid from reservoir. Disconnect brake lines from master cylinder.

Cap lines and master cylinder ports. Remove attaching nuts and master cylinder.

Installation

To install, reverse removal procedure. Fill master cylinder to proper level and bleed hydraulic system (if necessary).

POWER BRAKE UNIT

Removal & Installation

Remove master cylinder. Disconnect vacuum line. Remove clevis pin at brake pedal. Remove power brake unit. To install, reverse removal

procedure.

FRONT WHEEL BEARINGS NOTE:Hub and rotor are a m atched and balanced assem bly. Before rem oving rotor, locate paint or etch

m ark indicating proper hub-to-rotor alignm ent. If m arks are not present, m ark hub and rotor for

assem bly alignm ent. Failure to properly align hub and rotor can result in an im balance condition.

Page 5 of 12 MITCHELL 1 ARTICLE - BRAKE SYSTEM 1991-92 BRAKES Disc & Drum

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 65 of 454

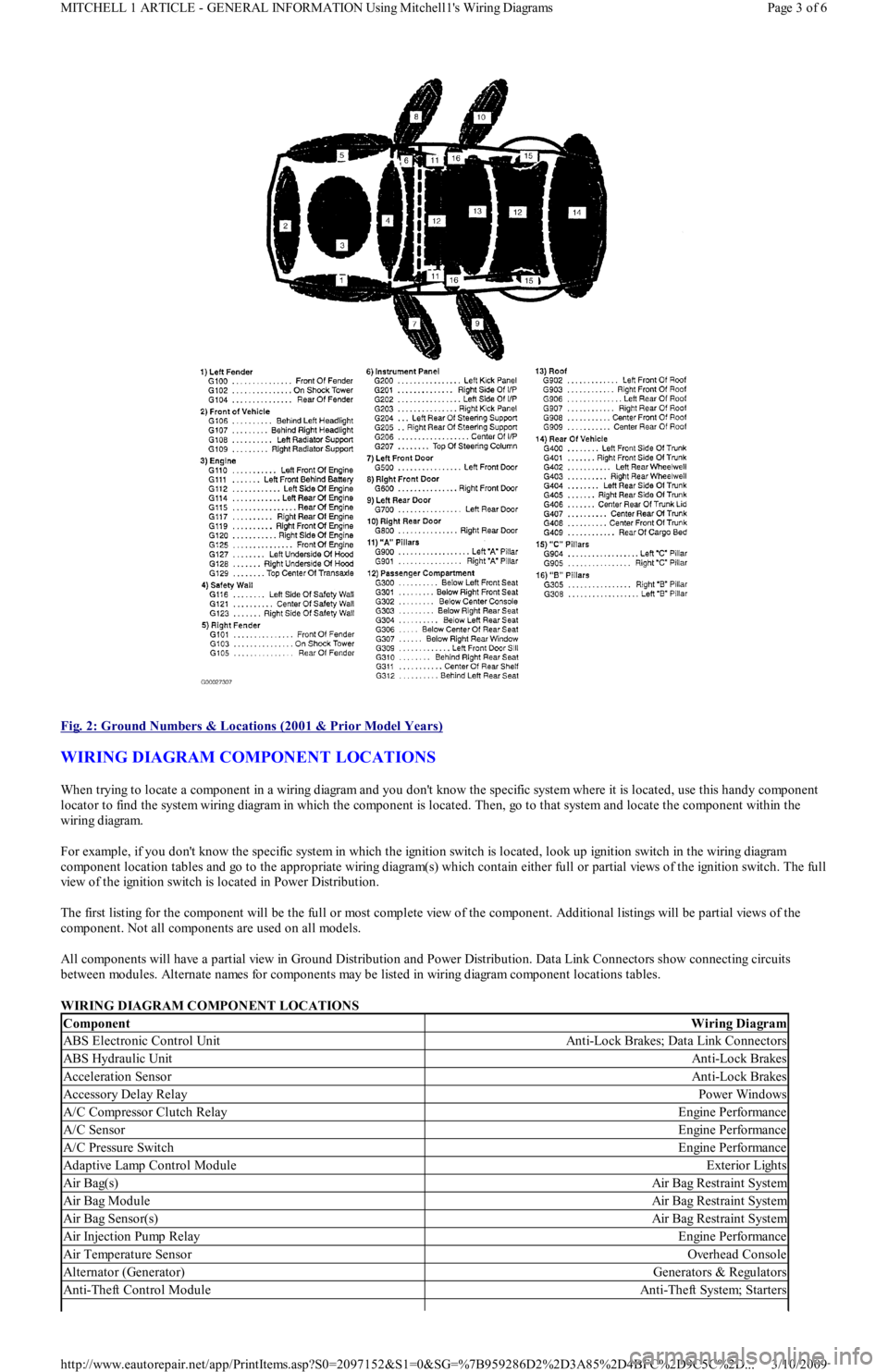

Fig. 2: Ground Numbers & Locations (2001 & Prior Model Years)

WIRING DIAGRAM COMPONENT LOCATIONS

When trying to locate a component in a wiring diagram and you don't know the specific system where it is located, use this handy component

locator to find the system wiring diagram in which the component is located. Then, go to that system and locate the component within the

wiring diagram.

For example, if you don't know the specific system in which the ignition switch is located, look up ignition switch in the wiring diagram

component location tables and go to the appropriate wiring diagram(s) which contain either full or partial views of the ignition switch. The full

view of the ignition switch is located in Power Distribution.

The first listing for the component will be the full or most complete view of the component. Additional listings will be partial views of the

component. Not all components are used on all models.

All components will have a partial view in Ground Distribution and Power Distribution. Data Link Connectors show connecting circuits

between modules. Alternate names for components may be listed in wiring diagram component locations tables.

WIRING DIAGRAM COMPONENT LOCATIONS

ComponentWiring Diagram

ABS Electronic Control UnitAnti-Lock Brakes; Data Link Connectors

ABS Hydraulic UnitAnti-Lock Brakes

Acceleration SensorAnti-Lock Brakes

Accessory Delay RelayPower Windows

A/C Compressor Clutch RelayEngine Performance

A/C SensorEngine Performance

A/C Pressure SwitchEngine Performance

Adaptive Lamp Control ModuleExterior Lights

Air Bag(s)Air Bag Restraint System

Air Bag ModuleAir Bag Restraint System

Air Bag Sensor(s)Air Bag Restraint System

Air Injection Pump RelayEngine Performance

Air Temperature SensorOverhead Console

Alternator (Generator)Generators & Regulators

Anti-Theft Control ModuleAnti-Theft System; Starters

Page 3 of 6 MITCHELL 1 ARTICLE - GENERAL INFORMATION Using Mitchell1's Wiring Diagrams

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 66 of 454

Autolamp Control RelayHeadlight Systems; Daytime Running Lights

Automatic Shutdown (ASD) RelayEngine Performance; Generators & Regulators

Autostick SwitchEngine Performance

Auxiliary Battery RelayGenerators & Regulators

Back-Up LightsBack-Up Lights; Exterior Lights

Barometric (BARO) Pressure SensorEngine Performance

BatteryPower Distribution

Battery Temperature SensorEngine Performance

Body Control ModuleBody Control Computer; Anti-Theft System; Daytime Running

Lights; Engine Performance; Headlight Systems; Warning Systems

Boost Control SolenoidEngine Performance

Boost SensorEngine Performance

Brake Fluid Level SwitchAnalog Instrument Panels

Brake On/Off (BOO) SwitchCruise Control Systems; Engine Performance; Shift Interlock

Systems

Buzzer ModuleWarning Systems

Camshaft Position (CMP) SensorEngine Performance

Central Control ModuleAnti-Theft System

ClockspringAir Bag Restraint System; Cruise Control Systems; Steering

Column Switches

Clutch Pedal Position SwitchStarters

Clutch Start SwitchStarters

Combination MeterAnalog Instrument Panels

Constant Control Relay Module (CCRM)Engine Performance; Electric Cooling Fans

Convenience CenterPower Distribution; Illumination/Interior Lights

Convertible Top MotorPower Convertible Top

Convertible Top SwitchPower Convertible Top

Crankshaft Position (CKP) SensorEngine Performance

Cruise Control ModuleCruise Control Systems

Cruise Control SwitchCruise Control Systems

Condenser Fan Relay(s)Electric Cooling Fans

Data Link Connector (DLC)Engine Performance

Da yt ime R u n n in g Ligh t s M o d u l eDaytime Running Lights; Exterior Lights

Defogger RelayRear Window Defogger

Diagnostic Energy Reserve Module (DERM)Air Bag Restraint System

Discriminating Sensor (Air Bag)Air Bag Restraint System

DistributorEngine Performance

Door Lock ActuatorsPower Door Locks; Remote Keyless Entry

Door Lock Relay(s)Power Door Locks

Electrochromic MirrorPower Mirrors

Electronic Level Control (ELC) Height SensorElectronic Suspension

Electronic Level Control (ELC) ModuleElectronic Suspension

Engine Coolant Temperature (ECT) Sending UnitAnalog Instrument Panels

Engine Coolant Temperature (ECT) SensorEngine Performance

Engine Control ModuleEngine Performance; Generators & Regulators; Starters

ETACS ECUWarning Systems; Power Windows; Remote Keyless Entry

Evaporative (EVAP) Emissions CanisterEngine Performance

EVAP Canister Purge SolenoidEngine Performance

EVAP Canister Vent SolenoidEngine Performance

Exhaust Gas Recirculation (EGR) ValveEngine Performance

Fuel Tank Vacuum SensorEngine Performance

F o g Ligh t sHeadlight Systems; Daytime Running Lights

F o g Ligh t R e l a yHeadlight Systems; Daytime Running Lights

Fuel Door Release SolenoidPower Fuel Door Release

Fuel Gauge Sending UnitAnalog Instrument Panels

Fuel InjectorsEngine Performance

Fuel PumpEngine Performance

Fuel Pump RelayEngine Performance; Power Distribution

Fuse/Relay BlockPower Distribution

Fusible LinksPower Distribution; Generators & Regulators; Starters

GeneratorGenerators & Regulators; Engine Performance; Power Distribution

Generic Electronic Module (GEM)Body Control Modules; Electronic Suspension

Glow Plug RelayEngine Performance

Glow PlugsEngine Performance

GroundsGround Distribution

Headlight Door ModuleHeadlight Doors

Headlight RelayHeadlight Systems; Daytime Running Lights

HeadlightsHeadlight Systems; Daytime Running Lights

Heated Oxygen Sensor(s) (HO2S)Engine Performance

Heated Windshield Control ModuleHeated Windshields

Page 4 of 6 MITCHELL 1 ARTICLE - GENERAL INFORMATION Using Mitchell1's Wiring Diagrams

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 67 of 454

Height SensorElectronic Suspension

HornsSteering Column Switches

Horn RelaySteering Column Switches

Idle Air Control (IAC) Motor/ValveEngine Performance

Ignition Coil(s)Engine Performance

Ignition Key Lock CylinderAnti-Theft System

Ignition ModuleEngine Performance

Ignition SwitchPower Distribution; Engine Performance; Generators &

Regulators; Starters

Illuminated Entry ModuleIllumination/Interior Lights

Illumination LightsIllumination/Interior Lights

Impact SensorAir Bag Restraint System

Inertia Fuel Shutoff SwitchEngine Performance

In h ib it Rel ayStarters

Instrument ClusterAnalog Instrument Panels

Intake Air Temperature (IAT) SensorEngine Performance

Interior LightsIllumination/Interior Lights

In t erl o ck Swit chStarters

Junction BlockPower Distribution

Keyless Entry ReceiverRemote Keyless Entry

Key Reminder SwitchStarters

Knock SensorEngine Performance

Lamp Control ModuleExterior Lights

License Plate LampExterior Lights

Lighting Control ModuleLighting Control Modules; Anti-Theft System; Daytime Running

Lights; Headlight Systems

Lower RelayPower Convertible Top

Malfunction Indicator Light (MIL)Engine Performance; Instrument Panels

Manifold Absolute Pressure (MAP) SensorEngine Performance

Mass Airflow (MAF) SensorEngine Performance

Mega FuseGenerators & Regulators

Memory Seat/Mirror ModuleMemory Systems

M ir r o r De fo gge rRear Window Defogger

Moon Roof MotorPower Moon Roof

Moon Roof RelayPower Moon Roof

Multi-Function Control ModuleWarning Systems

Neutral Safety SwitchStarters

Oil Level SwitchEngine Performance

Oil Pressure Switch/Sending UnitAnalog Instrument Panels; Engine Performance

Overhead ConsoleOverhead Console

Oxygen Sensor(s) (O2S)Engine Performance

Parking Brake SwitchAnalog Instrument Panels

Park LightsExterior Lights

Park/Neutral Position SwitchStarters; Engine Performance; Anti-Theft System; Body Control

Module

Perimeter Lighting Control RelayExterior Lights

Power AmplifierPower Antennas

Power Antenna ModulePower Antennas

Power Antenna MotorPower Antennas

Power Distribution CenterPower Distribution; Generators & Regulators; Starters

Power Door Lock MotorsPower Door Locks

Power Mirror MotorsPower Mirrors; Memory Systems

Power Sliding Door ControllerPower Sliding Side Door

Power Seat MotorsPower Seats; Memory Systems

Power Steering Pressure SwitchEngine Performance

Power Top MotorPower Convertible Top

Power Top Relay(s)Power Convertible Top

Powertrain Control ModuleEngine Performance; Analog Instrument Panels; Cruise Control

Systems; Data Link Connectors; Generators & Regulators; Starters

Power Window MotorsPower Windows

Power Window Relay(s)Power Windows

Radiator Fan Motor(s)Electric Cooling Fans

Radiator Fan Relay(s)Engine Performance; Electric Cooling Fans;

Rainsense ModuleWiper/Washer Systems

Raise RelayPower Convertible Top

Remote Anti-Theft Personality (RAP) ModuleAnti-Theft System; Starters; Warning Systems

Seat Belt PretensionersAir Bag Restraint System

Seat Belt Retractor SolenoidPassive Restraints

Seat Belt SwitchAir Bag Restraint System; Passive Restraints

Shift Interlock SolenoidShift Interlock Systems

Page 5 of 6 MITCHELL 1 ARTICLE - GENERAL INFORMATION Using Mitchell1's Wiring Diagrams

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 68 of 454

Shift Lock ActuatorShift Interlock Systems

Side Marker LightsExterior Lights

SIR Coil Assembly (Clockspring)Air Bag Restraint System

Slip Ring (Clockspring)Air Bag Restraint System; Steering Column Switches

SRS Control ModuleAir Bag Restraint System

Starter MotorStarters

Starter Interrupt RelayStarters

Starter SolenoidStarters

Starter RelayStarters

Steering Wheel Position SensorAnti-Lock Brakes

StoplightsExterior Lights

Stoplight SwitchEngine Performance; Cruise Control Systems; Anti-Lock Brakes

Sun Roof ECUPower Sun Roof

Sun Roof MotorPower Sun Roof

Sun Roof Position SensorPower Sun Roof

TaillightsExterior Lights

Throttle Position (TP) SensorEngine Performance

Torque Converter Clutch Solenoid/SwitchEngine Performance

Traction Control SwitchAnti-Lock Brakes

Trailer Tow ConnectorExterior Lights

Trailer Tow RelayExterior Lights

Transmission/TransaxleEngine Performance

Transmission Control Module (TCM)Engine Performance; Starters

Transmission Range SensorStarters; Back-Up Lights; Engine Performance

Transmission Range SwitchBack-Up Lights; Engine Performance; Anti-Theft System

Turn Signal FlasherExterior Lights

Tu r n S ign a l Ligh t sExterior Lights

Twilight Sentinel SwitchHeadlight Systems; Daytime Running Lights

Vapor Canister Leak Detection PumpEngine Performance

Vehicle Control Module (VCM)Engine Performance

Vehicle Dynamic ModuleElectronic Suspension

Vehicle Speed Control ServoCruise Control Systems

Vehicle Speed SensorData Link Connectors; Analog Instrument Panels; Cruise Control

Systems; Electronic Suspension

Voltage RegulatorGenerators & Regulators

Water-In-Fuel SensorEngine Performance; Analog Instrument Panels

Wheel Speed SensorsAnti-Lock Brakes

Window Timer ModulePower Convertible Top

Windshield Intermittent Wiper RelayWiper/Washer Systems

Windshield Washer MotorWiper/Washer Systems

Wiper MotorWiper/Washer Systems

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00130983

Page 6 of 6 MITCHELL 1 ARTICLE - GENERAL INFORMATION Using Mitchell1's Wiring Diagrams

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 102 of 454

levels to proper level.

Removal (1.6L & 1.6L Turbo)

1. Relieve fuel pressure and discharge air conditioning system (if equipped). See FUEL PRESSURE RELEASE under REMOVAL &

INSTALLATION. Disconnect and remove battery, battery tray and battery tray support bracket.

2. Release wiring harness retaining straps from battery support tray. Disconnect windshield washer supply hose between fluid reservoir and

hood. Mark hinge locations and remove hood.

3. Disconnect intake air tube and wiring to ignition coil and vane airflow meter. Remove air cleaner/vane airflow meter assembly. Remove

air cleaner assembly support brackets. Disconnect intercooler hoses from turbocharger (if equipped).

4. Drain engine coolant and remove radiator. Disconnect accelerator cable, and remove retaining bracket from cam cover. Position cable to

one side.

5. Disconnect and plug fuel lines at fuel filter and pressure regulator. Disconnect power brake booster manifold vacuum hose from

manifold. Disconnect heater hoses at heater core tubes. Label and remove vacuum hoses located at throttle body.

6. For manual transaxle turbocharged vehicles, disconnect clutch cable and remove support bracket and cable from transmission. On non-

turbo vehicles, disconnect clutch slave hydraulic line. For automatic transaxle, remove transaxle cooler lines.

7. Disconnect starter wiring at starter. Remove harness from locating strap on bracket. Disconnect alternator wiring. Disconnect wiring

from engine coolant sensors located on rear of engine block. Remove ground connection at bracket on thermostat cover. Disconnect O2

sensor wire, main wiring harness connector, TPS connector (turbocharged only), knock sensor connector, distributor wiring and

transaxle wiring. Disconnect ground wire and strap at front of engine, and reinstall lifting eye.

8. Remove engine oil dipstick and retaining clip. Remove power steering pump from mounting bracket. Remove power steering pump

mounting bracket. With hoses attached, position pump aside. Remove upper air conditioning compressor retaining bolts (if equipped).

9. Raise vehicle on hoist. Drain engine oil and cooling system. On vehicles with air conditioning, remove lower air conditioning

compressor mounting bolts, and position compressor out of way.

10. Remove front wheels and tires. Remove front ball joints-to-ste e r in g kn u c kl e s r e t a in in g b o l t s. R e mo ve sp l a sh gu a r d s. Dr a in t ransmission

oil and remove half shafts from differential. Remove front exhaust pipe bracket located on lower side of engine. Disconnect front

exhaust pipe from exhaust manifold, or turbocharger (if equipped).

11. Remove frame support bar-to-engine support bolt. Loosen right control arm bolt and, pivot support bar downward. Disengage rubber

exhaust hangers located directly behind catalytic converter. Allow exhaust system to hang down 6 inches, and support system with

mechanic's wire. Unbolt shift linkage and stabilizer bar at transaxle. Remove nuts from front and rear engine mounts, and lower vehicle.

12. Attach chains onto lift eyes at ends of cylinder head, and support engine with hoist. Remove RH engine mount through bolt. Raise

engine off mounts and slightly pivot engine/transaxle assembly. Disconnect oil pressure sensor and route starter/alternator wiring

harness from engine. Carefully lift engine/transaxle assembly, turn assembly while raising to clear brake master cylinder, shift linkage

universal joint, radiator support and air conditioning lines (if equipped).

13. Remove intake manifold support bracket. Remove gusset plate(s) (if equipped). Remove starter. Remove transaxle-to-engine retaining

bolts. Identify bolts to ensure correct installation. Separate transaxle from engine. On manual transaxle, remove pressure plate, clutch

disc and flywheel. On automatic transaxle, remove flexplate.

Installation (1.6L & 1.6L Turbo)

1. Install transaxle to engine in reverse order of removal. Attach hoist to engine/transaxle assembly and position assembly in vehicle.

Before engine contacts mounts, route starter, alternator and oil pressure sensor wiring, and connect oil pressure sensor. Lower engine

until front mount seats on crossmember. Install through bolt on RH engine mount. DO NOT tighten bolt.

2. Remove hoist. Raise vehicle and support with jackstands. Align rear engine mount to crossmember, and install retaining nuts to front

and rear engine mounts. Tighten nuts to specification. See TORQUE SPECIFICATIONS

table at end of article.

3. On manual transaxles, connect shift coupling and stabilizer. Tighten to specification. On automatic transaxles, connect shift linkage and

oil cooler lines. Tighten linkage retaining bolt, shift cable pivot and oil cooler hose clamps to specification. Connect front exhaust pipe

to manifold (or turbocharger). Install exhaust pipe to support bracket. Tighten bolts to specification. Tighten manifold (or turbocharger)

to specification. Attach rubber exhaust hangers. Position cross brace. Tighten retaining nut and bolt and right control arm front bolt.

4. Install drive axles. Install ball joint retaining bolts and tighten to specification. Mount A/C Compressor to engine (if equipped). Tighten

lower retaining bolts to specification. Install splash guards. Install tire and wheel assemblies. Tighten retaining nuts to specification.

5. Lower vehicle. Install upper A/C compressor retaining bolts (if equipped). Tighten bolts to specification. Tighten RH engine mo u n t

through bolt to specification. Connect alternator wiring.

6. Position power steering pump bracket on stud. Lower pump into engine compartment. Install power steering pump bracket retaining

bolts and nut. Tighten to specification. Install power steering pump and belt. Tighten adjustment nut and pivot bolt to specification.

7. Install engine oil dipstick and retaining clip. Install ground strap and ground wire to cylinder head. Install clutch cable (if equipped).

Connect clutch hydraulic line if equipped with manual transaxle or naturally aspirated. Connect transmission electrical connectors.

Connect fuel lines to fuel filter and pressure regulator. Install intake air tube to throttle body.

8. Install intercooler hoses on turbocharged models. Install air cleaner assembly brackets. Install air cleaner assembly with airflow meter

attached. Install intake air tube. Install coil and airflow meter connectors. Connect coolant crankcase and air bypass hoses. Install

vacuum hoses as noted in disassembly.

9. Connect accelerator cable. Install retaining bracket. Install power brake booster hose. Remove speedometer cable from transaxle. Fill

transaxle to specification. See CAPACITIES in SERVICE & ADJUSTMENT SPECIFICATIONS article. Install speedometer cable.

Connect speedometer cable connector. Fill engine oil to capacity.

10. Install radiator/fan assembly. Tighten bracket retaining bolts to specification. Connect coolant hoses and fan electrical connector. Fill

coolant to specification.

11. Install hood and connect washer hose. Install battery tray support, battery tray, battery and battery hold-down. Connect battery

terminal. Evacuate and charge air conditioning system (if equipped). Road test vehicle and inspect for leaks.

INTAKE MANIFOLD

Removal (1.3L)

CAUT ION: DO NOT allow com pressor to hang by hoses. T ie up com pressor with m echanic's wire.

Page 2 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 130 of 454

IDLE SPEED & MIXTURE

IDLE MIXTURE

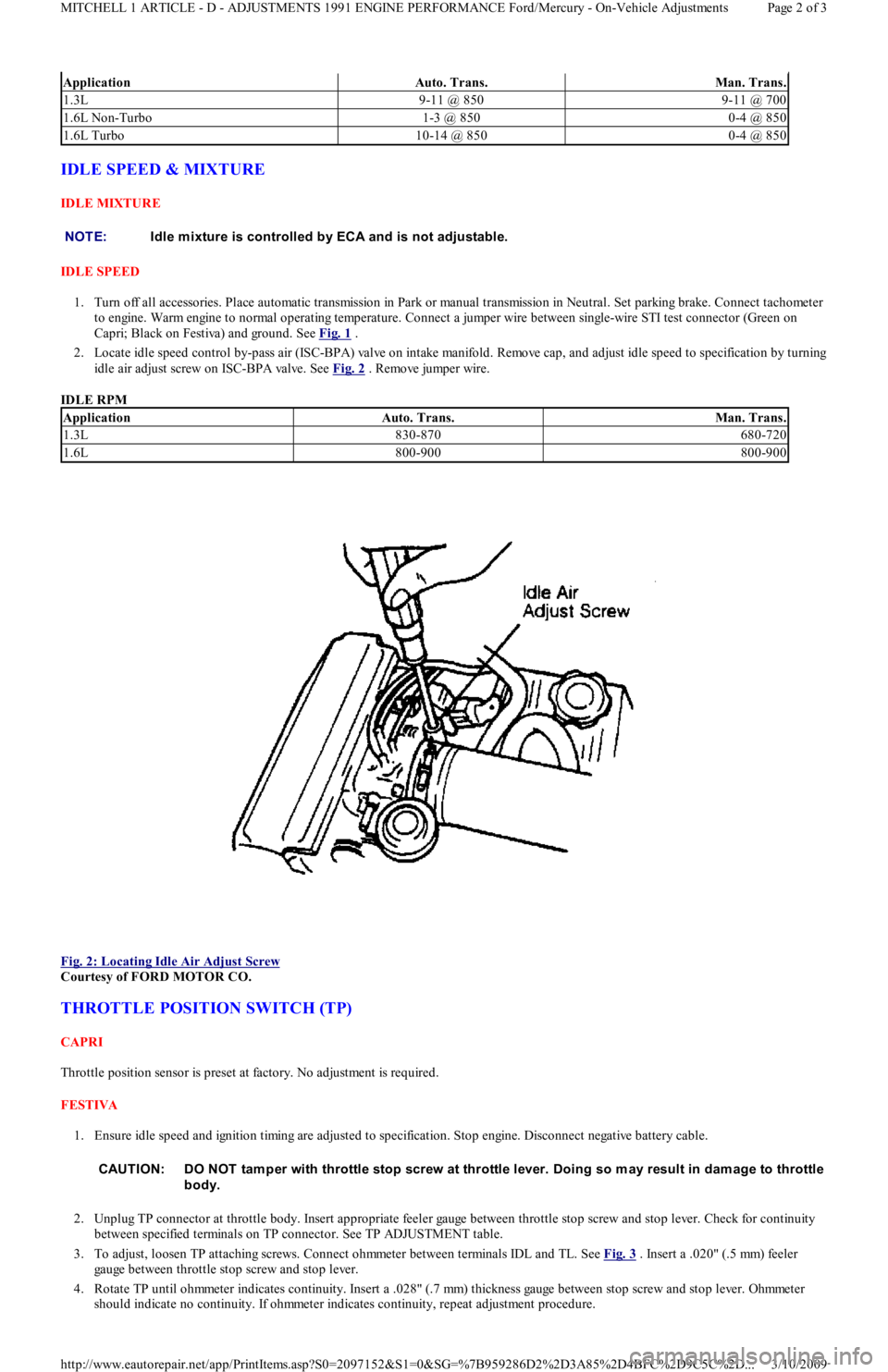

IDLE SPEED

1. Turn off all accessories. Place automatic transmission in Park or manual transmission in Neutral. Set parking brake. Connect tachometer

to engine. Warm engine to normal operating temperature. Connect a jumper wire between single-wire STI test connector (Green on

Capri; Black on Festiva) and ground. See Fig. 1

.

2. Locate idle speed control by-pass air (ISC-BPA) valve on intake manifold. Remove cap, and adjust idle speed to specification by turning

idle air adjust screw on ISC-BPA valve. See Fig. 2

. Remove jumper wire.

IDLE RPM

Fig. 2: Locating Idle Air Adjust Screw

Courtesy of FORD MOTOR CO.

THROTTLE POSITION SWITCH (TP)

CAPRI

Throttle position sensor is preset at factory. No adjustment is required.

FESTIVA

1. Ensure idle speed and ignition timing are adjusted to specification. Stop engine. Disconnect negative battery cable.

2. Unplug TP connector at throttle body. Insert appropriate feeler gauge between throttle stop screw and stop lever. Check for continuity

between specified terminals on TP connector. See TP ADJUSTMENT table.

3. To adjust, loosen TP attaching screws. Connect ohmmeter between terminals IDL and TL. See Fig. 3

. Insert a .020" (.5 mm) feeler

gauge between throttle stop screw and stop lever.

4. Rotate TP until ohmmeter indicates continuity. Insert a .028" (.7 mm) thickness gauge between stop screw and stop lever. Ohmmeter

should indicate no continuity. If ohmmeter indicates continuity, repeat adjustment procedure.

ApplicationAuto. Trans.Man. Trans.

1.3L9-11 @ 8509-11 @ 700

1.6L Non-Turbo1-3 @ 8500-4 @ 850

1.6L Turbo10-14 @ 8500-4 @ 850

NOTE:Idle m ixture is controlled by ECA and is not adjustable.

ApplicationAuto. Trans.Man. Trans.

1.3L830-870680-720

1.6L800-900800-900

CAUT ION: DO NOT tam per with throttle stop screw at throttle lever. Doing so m ay result in dam age to throttle

body.

Page 2 of 3 MITCHELL 1 ARTICLE - D - ADJUSTMENTS 1991 ENGINE PERFORMANCE Ford/Mercury - On-Vehicle Adjustments

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 162 of 454

Connect BOB. Remove dust cover from BP sensor, located on passenger side cowl. Turn ignition on. Connect vacuum pump to BP sensor.

Measure voltage between pins BP and SIGRTN on BOB while applying vacuum to BP sensor. See BAROMETRIC PRESSURE SENSOR

OUTPUT VOLTAGE . Replace BP sensor if voltage is not as specified.

BAROMETRIC PRESSURE SENSOR OUTPUT VOLTAGE

BRAKE ON-OFF (BOO) SWITCH

Unplug connector from BOO switch at brake pedal. Connect ohmmeter to switch terminals. With pedal released, ohmmeter should indicate no

continuity. Ohmmeter should indicate continuity with pedal depressed.

CLUTCH ENGAGE SWITCH (CES)

Unplug connector from CES switch at clutch pedal. Connect ohmmeter to switch terminals. With pedal released, ohmmeter should indicate

continuity. Ohmmeter should indicate no continuity with pedal depressed.

CRANKSHAFT POSITION SENSOR (CPS) (1.3L)

Unplug 3-wire connector from distributor. Measure resistance between CPS terminal on distributor (Yellow/Blue wire) and ground. Replace

CPS if resistance is not 210-250 ohms.

CYLINDER IDENTIFICATION (CID) SENSOR (1.6L)

Turn ignition off. Connect BOB, leaving ECA connected. Turn ignition on, but DO NOT start engine. Measure voltage at BOB pin No. 34

(Yellow wire). Volt- meter should indicate less than one volt or more than 10 volts. Start engine and run at idle. Voltmeter should indicate 3-

5 volts. Replace CID sensor if voltage is not as specified.

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

1. Remove ECT sensor. ECT sensor is threaded into top of lower intake manifold on 1.3L, and on underside of intake manifold on 1.6L.

Place ECT sensor and thermometer into container of coolant.

2. Connect ohmmeter to coolant temperature sensor terminals. Cool or heat container. Note resistance at specified temperatures. See

ENGINE COOLANT TEMPERATURE SENSOR RESISTANCE

. Replace ECT sensor if resistance is not within specification.

ENGINE COOLANT TEMPERATURE SENSOR RESISTANCE

EXHAUST GAS OXYGEN (EGO) SENSOR

With engine at normal operating temperature, unplug connector from EGO in exhaust manifold. Measure voltage between EGO sensor

terminal and ground. Voltage should increase with increasing engine speed and decrease with decreasing engine speed. Voltage at idle should

fluctuate within a range of .2-.8 volt.

IDLE SW ITCH (1.6L)

Unplug connector from throttle position sensor on throttle body. Connect ohmmeter to switch terminals IDL and ground (Green/Orange and

Blue/Yellow wires on mating connector). Resistance must be less than 5 ohms with throttle in idle position, and more than 10,000 ohms with

throttle pedal depressed.

KNOCK SENSOR (1.6L TURBO)

Disconnect vacuum hose at distributor. Connect timing light. Start engine and record ignition timing. Tap intake plenum with a plastic mallet.

Knock sensor is okay if timing retards. If timing does not retard, check associated circuitry and components. See TIMING CONTROL

SYSTEMS under IGNITION SYSTEM.

NEUTRAL GEAR SWITCH (M/T)

1. Unplug connector near transmission. Place transmission in Neutral. Resistance across switch should be infinite.

2. Place transmission in any other gear. Resistance across switch should be zero ohms. If necessary, replace switch.

Vacuum In. Hg.(1) Voltage

03.84

53.36

102.66

151.93

201.26

25.58

(1)Voltage may vary by plus or minus 15 percent.

Temperature °F (°C)Ohms

-4 (-20)14,600-17,800

68 (20)2200-2700

104 (40)1000-1300

140 (60)500-650

176 (80)290-350

NOTE:A steady voltage higher than .55 volt indicates a continuously rich condition. A steady voltage lower

than .55 volt indicates a continuously lean condition.

Page 2 of 7 MITCHELL 1 ARTICLE - I - SYSTEM/COMPONENT TESTS 1991 ENGINE PERFORMANCE Ford Motor Co. - Ford/Merc

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 169 of 454

memory. Intermittent failures may be caused by a sensor, connector, or wiring. See INTERMITTENTS in TESTS W/O CODES article in the

ENGINE PERFORMANCE Section.

VISUAL CHECK & VEHICLE PREPARATION

Before connecting any equipment to diagnose EEC system, perform following preparatory procedures:

Verify condition of air cleaner and air ducts.

Check all vacuum hoses for leaks, restrictions, or improper routing.

Check EEC system wiring harness electrical connections for corrosion, bent or broken pins, loose wires or terminals, or improper

routing.

Check ECA, sensors, and actuators for physical damage.

Check engine oil and coolant level.

Perform all necessary safety precautions to prevent personal injury or vehicle damage.

Set parking brake. Place shift lever in Park for automatic transmissions, or Neutral for manual transmissions. DO NOT move shift lever

during test unless specifically directed.

Turn off all lights and accessories. Ensure vehicle doors are closed when measuring voltage or resistance.

Start engine. Run at idle until upper radiator hose is hot and pressurized and engine is off fast idle. Check for leaks around exhaust

manifold, exhaust gas oxygen sensor, and vacuum hose connections.

Turn ignition off. Service items as required. Go to EQUIPMENT HOOK-UP .

EQUIPMENT HOOK-UP

VOM

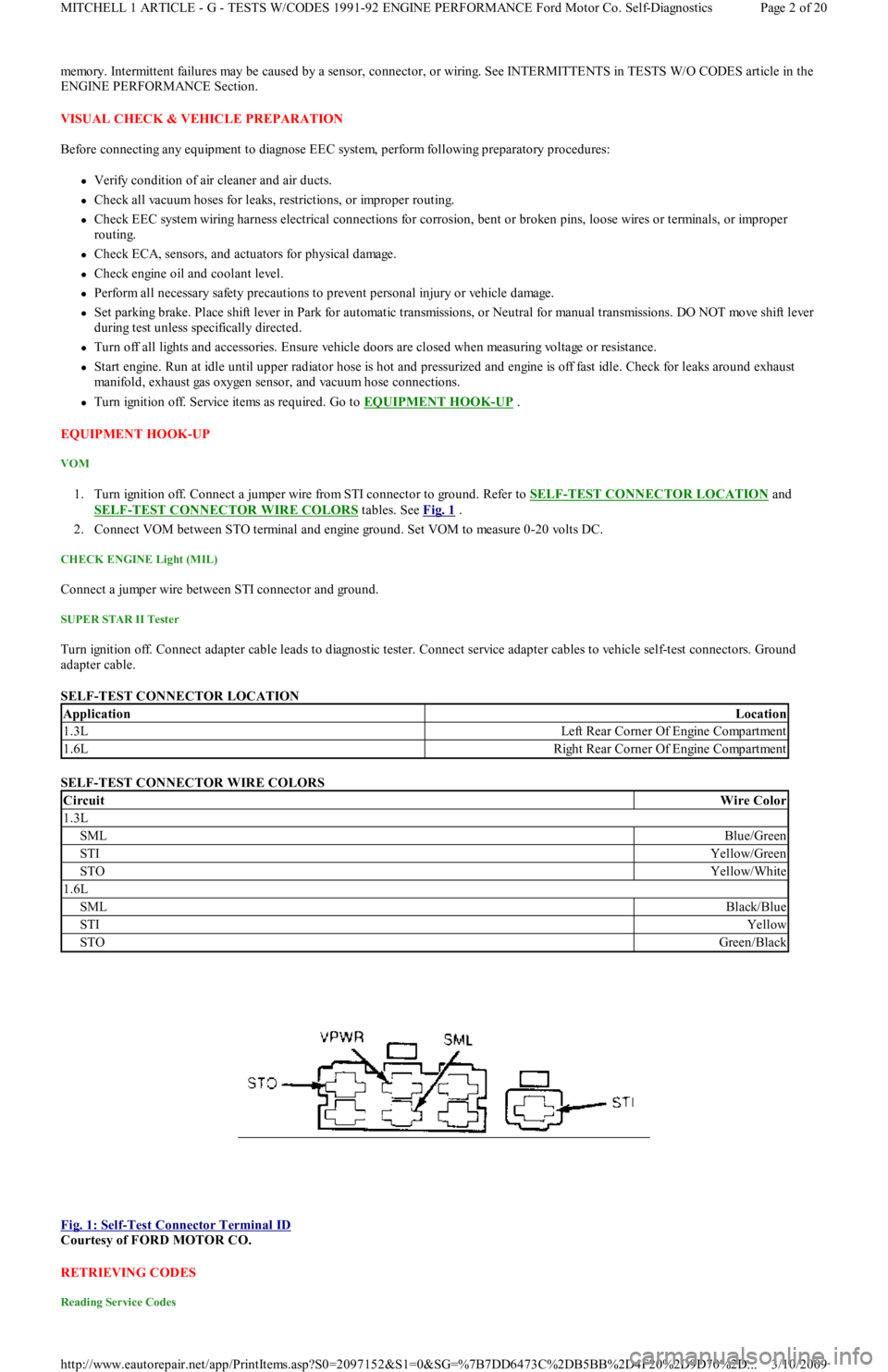

1. Turn ignition off. Connect a jumper wire from STI connector to ground. Refer to SELF-TEST CONNECTOR LOCATION and

SELF

-TEST CONNECTOR WIRE COLORS tables. See Fig. 1 .

2. Connect VOM between STO terminal and engine ground. Set VOM to measure 0-20 volts DC.

CHECK ENGINE Light (MIL)

Connect a jumper wire between STI connector and ground.

SUPER STAR II Tester

Turn ignition off. Connect adapter cable leads to diagnostic tester. Connect service adapter cables to vehicle self-test connectors. Ground

adapter cable.

SELF-TEST CONNECTOR LOCATION

SELF-TEST CONNECTOR WIRE COLORS

Fig. 1: Self

-Test Connector Terminal ID

Courtesy of FORD MOTOR CO.

RETRIEVING CODES

Reading Service Codes

ApplicationLocation

1.3LLeft Rear Corner Of Engine Compartment

1.6LRight Rear Corner Of Engine Compartment

CircuitWire Color

1.3L

SMLBlue/Green

STIYellow/Green

STOYellow/White

1.6L

SMLBlack/Blue

STIYellow

STOGreen/Black

Page 2 of 20 MITCHELL 1 ARTICLE - G - TESTS W/CODES 1991-92 ENGINE PERFORMANCE Ford Motor Co. Self-Diagnostics

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 170 of 454

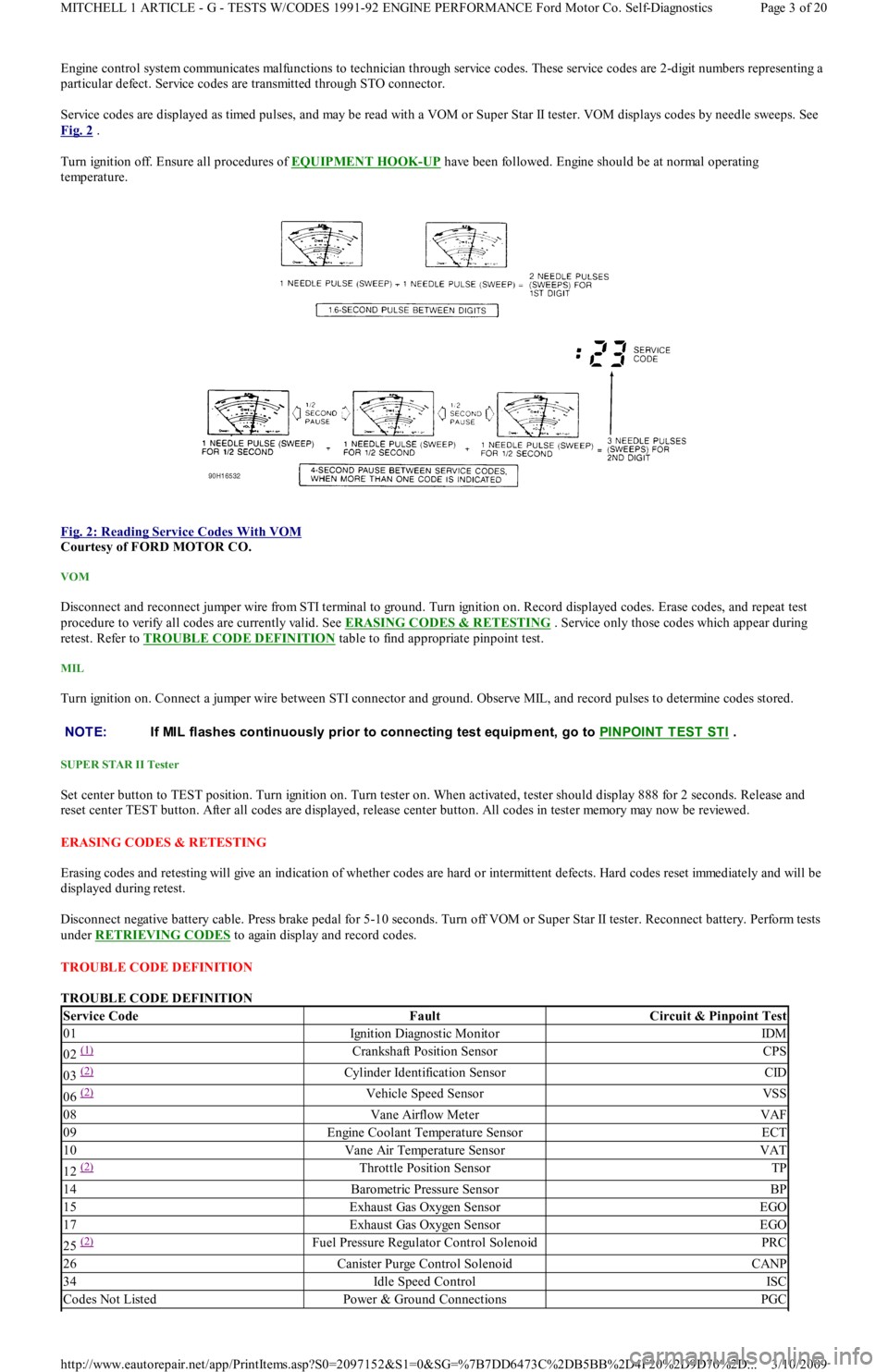

Engine control system communicates malfunctions to technician through service codes. These service codes are 2-digit numbers representing a

particular defect. Service codes are transmitted through STO connector.

Service codes are displayed as timed pulses, and may be read with a VOM or Super Star II tester. VOM displays codes by needle sweeps. See

Fig. 2

.

Turn ignition off. Ensure all procedures of EQUIPMENT HOOK

-UP have been followed. Engine should be at normal operating

temperature.

Fig. 2: Reading Service Codes With VOM

Courtesy of FORD MOTOR CO.

VOM

Disconnect and reconnect jumper wire from STI terminal to ground. Turn ignition on. Record displayed codes. Erase codes, and repeat test

procedure to verify all codes are currently valid. See ERASING CODES & RETESTING . Service only those codes which appear during

retest. Refer to TROUBLE CODE DEFINITION

table to find appropriate pinpoint test.

MIL

Turn ignition on. Connect a jumper wire between STI connector and ground. Observe MIL, and record pulses to determine codes stored.

SUPER STAR II Tester

Set center button to TEST position. Turn ignition on. Turn tester on. When activated, tester should display 888 for 2 seconds. Release and

reset center TEST button. After all codes are displayed, release center button. All codes in tester memory may now be reviewed.

ERASING CODES & RETESTING

Erasing codes and retesting will give an indication of whether codes are hard or intermittent defects. Hard codes reset immediately and will be

displayed during retest.

Disconnect negative battery cable. Press brake pedal for 5-10 seconds. Turn off VOM or Super Star II tester. Reconnect battery. Perform tests

under RETRIEVING CODES

to again display and record codes.

TROUBLE CODE DEFINITION

TROUBLE CODE DEFINITION

NOTE:If MIL flashes continuously prior to connecting test equipm ent, go to PINPOINT T EST ST I .

Service CodeFaultCircuit & Pinpoint Test

01Ignition Diagnostic MonitorIDM

02 (1) Crankshaft Position SensorCPS

03 (2) Cylinder Identification SensorCID

06 (2) Vehicle Speed SensorVSS

08Vane Airflow MeterVAF

09Engine Coolant Temperature SensorECT

10Vane Air Temperature SensorVAT

12 (2) Throttle Position SensorTP

14Barometric Pressure SensorBP

15Exhaust Gas Oxygen SensorEGO

17Exhaust Gas Oxygen SensorEGO

25 (2) Fuel Pressure Regulator Control SolenoidPRC

26Canister Purge Control SolenoidCANP

34Idle Speed ControlISC

Codes Not ListedPower & Ground ConnectionsPGC

Page 3 of 20 MITCHELL 1 ARTICLE - G - TESTS W/CODES 1991-92 ENGINE PERFORMANCE Ford Motor Co. Self-Diagnostics

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...