ground clearance FORD FESTIVA 1991 Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 101 of 454

Back To Article

ENGINE OVERHAUL

1991-92 FORD MOT OR CO. ENGINES 1.3L & 1.6L 4-Cylinder

ENGINE IDENTIFICATION

Engine can be identified by Vehicle Identification Number (VIN) on metal tab attached to instrument panel. Tab is close to windshield on

driver's side and is visible through windshield. VIN has 17 characters. The 8th character identifies engine.

ENGINE IDENTIFICATION CODES

ADJUSTMENTS

VALVE ARRANGEMENT

Firewall Side

In t ake val ves.

Radiator Side

Exhaust valves.

VALVE CLEARANCE ADJUSTMENT

Hydraulic lifters are used. Adjustment is NOT possible nor necessary.

REMOVAL & INSTALLATION

FUEL PRESSURE RELEASE

Remove rear seat. Remove fuel pump access panel. Disconnect fuel pump electrical connector. Start engine and allow to idle until engine dies.

ENGINE

Removal (1.3L)

1. Remove battery and battery tray. Index hood-to-hinge and remove hood. Drain coolant. Drain engine oil and transaxle fluid. Disconnect

vane airflow meter connector, vane airflow meter and hose.

2. Remove oil dipstick, cooling fan and radiator assembly. Disconnect accelerator cable from mounting bracket and throttle lever.

Disconnect speedometer cable at transaxle. Mark and disconnect fuel lines at fuel pump. Plug fuel lines. Remove heater hoses. Remove

brake booster vacuum hose. Disconnect transaxle vacuum hose.

3. Remove charcoal canister hoses from engine. Disconnect engine wiring harness. Remove alternator and brackets. Remove engine ground

strap. Raise vehicle and remove catalytic converter.

4. Disconnect A/C compressor without removing hoses, and set compressor aside. Disconnect distributor wiring at coil. On automatic

transaxle models, remove shift lever-to-manual shaft assembly nut. Remove shift cable from transaxle. Loosen front wheel bolts. Raise

vehicle and remove wheel assemblies.

5. Remove stabilizer mounting nuts and brackets. Remove lower arm clamp bolts and nuts. Pull lower arms downward, separating lower

arms from knuckles. Separate halfshafts and install Differential Plugs (T87C-7025-C) between differential side gears. See FWD AXLE

SHAFTS article in DRIVE AXLES Section.

6. On manual transaxle vehicles, disconnect clutch control cable and shift control cable rod. Remove stabilizer bar from transaxle. Remove

catalytic converter inlet pipe. Support engine assembly with hoist. Remove rear crossmember mount bolts. Remove front and rear engine

mount nuts.

7. Remove crossmember. Lower vehicle and attach engine lift hooks. Remove right engine mount bolt. Remove engine/transaxle assembly.

Remove gusset plates. Remove starter and flywheel cover. Remove torque converter bolts on automatic transaxle. Remove engine-to-

transaxle bolts. Separate transaxle from engine.

Installation (1.3L)

1. Install transaxle to engine in reverse order of removal. Attach hoist to engine/transaxle assembly and position in vehicle. Support engine

in chassis and install engine mount bolts. Raise vehicle and install front engine mount nut. Tighten nuts to specification. See TORQUE

SPECIFICATIONS table at end of article.

2. Position crossmember onto mounts and chassis. Tighten rear nut. Install mount-to-crossmember nuts and tighten. Remove differential

plugs and install halfshafts. To complete installation, reverse removal procedure. Tighten all bolts/nuts to specifications. Fill all fluid NOTE:For engine repair procedures not covered in this article, see ENGINE OVERHAUL PROCEDURES

-

GENERAL INFORMATION

article in the GENERAL INFORMAT ION section.

ApplicationVIN Code

Festiva

1.3L SOHC PFIH

Capri

1.6L DOHC PFIZ

1.6L DOHC PFI TURBO6

NOTE:When rem oving engine m ounts, m ark and note location and position to ensure proper installation.

Engine and transaxle are rem oved as an assem bly.

Page 1 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 108 of 454

front oil seal. Carefully slide camshaft out front of cylinder head. DO NOT d a ma ge b e a r in g b o r e s.

Inspection (1.3L)

1. Check cylinder head for warpage. See INSPECTION under CYLINDER HEAD under REMOVAL & INSTALLATION. Measure

camshaft lobes across their maximum dimensions. Inspect for scoring and wear. Replace camshaft if not within specification. See, in this

article, CAMSHAFT LOBE SPECIFICATIONS

table.

2. Measure camshaft bearing journals and cylinder head bores. See Fig. 6

and Fig. 7 . Subtract camshaft bearing journal O.D. from

cylinder head bore I.D. to obtain oil clearance. If clearance is not within specification, replace head and/or camshaft. See, in this article,

CAMSHAFT SPECIFICATIONS

table under ENGINE SPECIFICATIONS tables.

Installation (1.3L)

1. Oil camshaft and insert carefully. Install thrust plate. Install camshaft front oil seal. Install rocker arm shaft assemblies to original

location. Ensure oil holes in rocker arm shaft face downward.

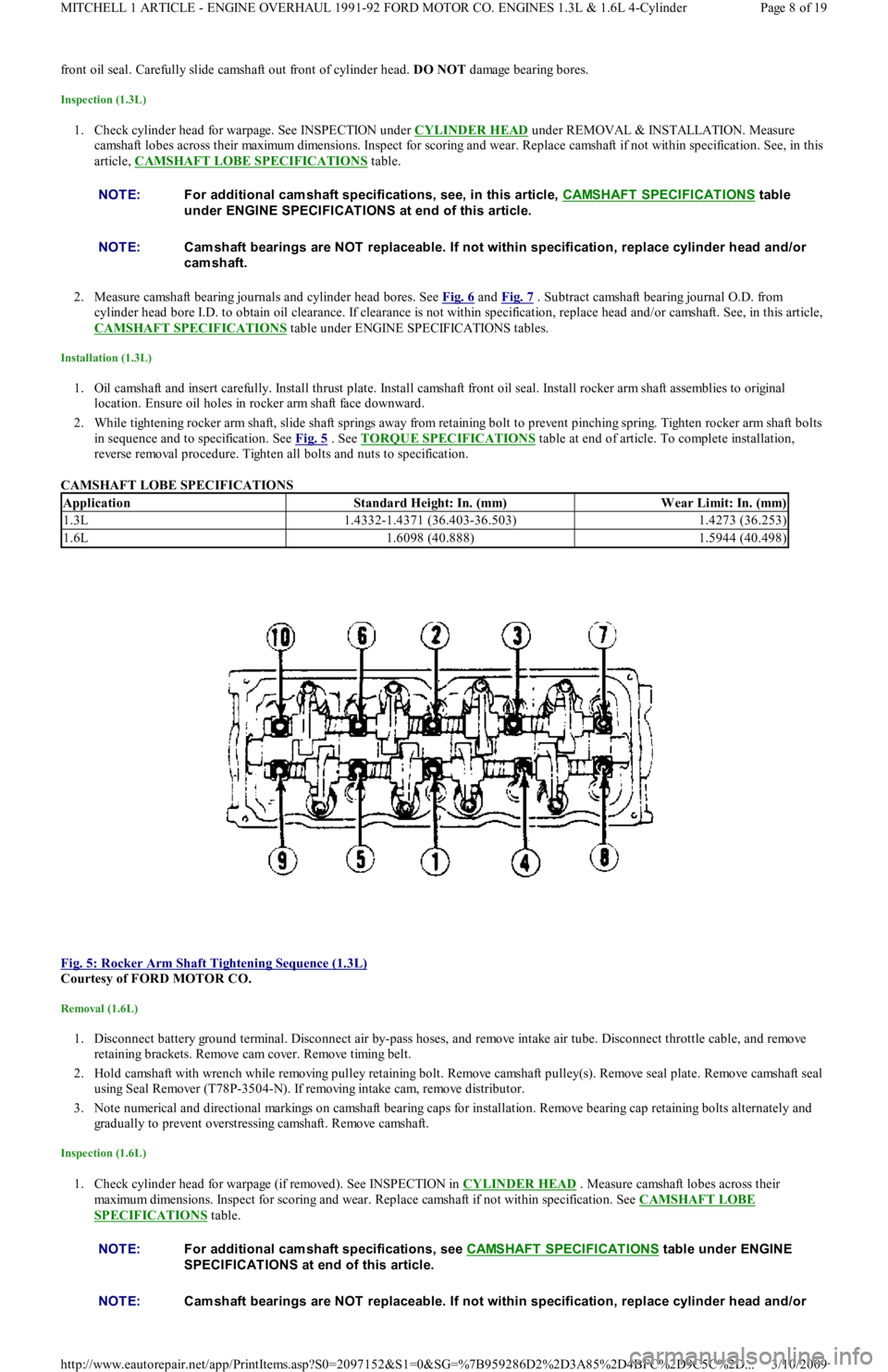

2. While tightening rocker arm shaft, slide shaft springs away from retaining bolt to prevent pinching spring. Tighten rocker arm shaft bolts

in sequence and to specification. See Fig. 5

. See TORQUE SPECIFICATIONS table at end of article. To complete installation,

reverse removal procedure. Tighten all bolts and nuts to specification.

CAMSHAFT LOBE SPECIFICATIONS

Fig. 5: Rocker Arm Shaft Tightening Sequence (1.3L)

Courtesy of FORD MOTOR CO.

Removal (1.6L)

1. Disconnect battery ground terminal. Disconnect air by-pass hoses, and remove intake air tube. Disconnect throttle cable, and remove

ret ain in g b racket s. Remo ve cam co ver. Remo ve t imin g b el t .

2. Hold camshaft with wrench while removing pulley retaining bolt. Remove camshaft pulley(s). Remove seal plate. Remove camshaft seal

using Seal Remover (T78P-3504-N). If removing intake cam, remove distributor.

3. Note numerical and directional markings on camshaft bearing caps for installation. Remove bearing cap retaining bolts alternately and

gradually to prevent overstressing camshaft. Remove camshaft.

Inspection (1.6L)

1. Check cylinder head for warpage (if removed). See INSPECTION in CYLINDER HEAD . Measure camshaft lobes across their

maximum dimensions. Inspect for scoring and wear. Replace camshaft if not within specification. See CAMSHAFT LOBE

SPECIFICATIONS table. NOTE:For additional cam shaft specifications, see, in this article, CAMSHAFT SPECIFICAT IONS

table

under ENGINE SPECIFICATIONS at end of this article.

NOTE:Cam shaft bearings are NOT replaceable. If not within specification, replace cylinder head and/or

cam shaft.

ApplicationStandard Height: In. (mm)W ear Limit: In. (mm)

1.3L1.4332-1.4371 (36.403-36.503)1.4273 (36.253)

1.6L1.6098 (40.888)1.5944 (40.498)

NOTE:For additional cam shaft specifications, see CAMSHAFT SPECIFICAT IONS table under ENGINE

SPECIFICAT IONS at end of this article.

NOTE:Cam shaft bearings are NOT replaceable. If not within specification, replace cylinder head and/or

Page 8 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 109 of 454

2. Measure camshaft bearing journals and cylinder head bores (with bearing caps in place and torqued to specification). See Fig. 7 .

Subtract camshaft bearing journal O.D. from cylinder head bore I.D. to obtain oil clearance. If clearance is not within specification,

replace head and/or camshaft. See CAMSHAFT SPECIFICATIONS

table under ENGINE SPECIFICATIONS at end of article.

Installation (1.6L)

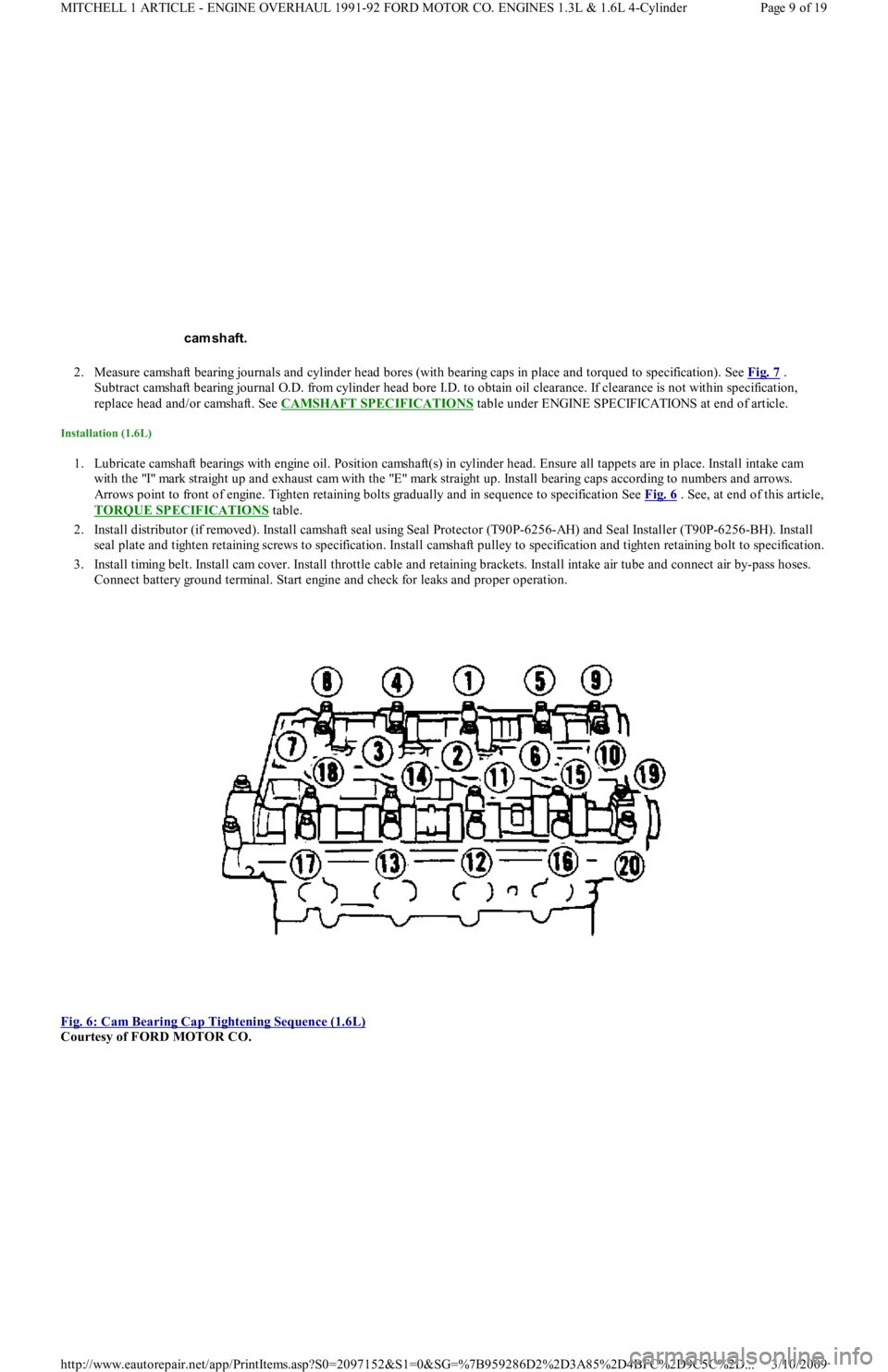

1. Lubricate camshaft bearings with engine oil. Position camshaft(s) in cylinder head. Ensure all tappets are in place. Install intake cam

with the "I" mark straight up and exhaust cam with the "E" mark straight up. Install bearing caps according to numbers and arrows.

Arrows point to front of engine. Tighten retaining bolts gradually and in sequence to specification See Fig. 6

. See, at end of this article,

TORQUE SPECIFICATIONS

table.

2. Install distributor (if removed). Install camshaft seal using Seal Protector (T90P-6256-AH) and Seal Installer (T90P-6256-BH). Install

seal plate and tighten retaining screws to specification. Install camshaft pulley to specification and tighten retaining bolt to specification.

3. Install timing belt. Install cam cover. Install throttle cable and retaining brackets. Install intake air tube and connect air by-pass hoses.

Connect battery ground terminal. Start engine and check for leaks and proper operation.

Fig. 6: Cam Bearing Cap Tightening Sequence (1.6L)

Courtesy of FORD MOTOR CO. cam shaft.

Page 9 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 111 of 454

bearing oil seal. To complete installation, reverse removal procedure.

WATER PUMP

Removal & Installation (1.3L)

Remove timing belt. Drain cooling system. Remove lower radiator hose and heater return hose from water pump. Remove water pump

retaining bolts and water pump. Clean gasket mounting surface and replace gasket. To install, reverse removal procedure.

Removal (1.6L)

1. Remove timing belt. See TIMING BELT . Drain cooling system. Remove timing belt tensioner and idler pulleys. Remove oil dipstick

bracket retaining bolt.

2. Remove power steering pump from retaining bracket, leaving hoses attached. Remove power steering bracket and position power

steering pump to one side. Remove water pump outlet. Remove water pump retaining bolts and water pump.

Installation (1.6L)

1. Clean all gasket surfaces. Transfer rubber belt cover seal to new water pump (if required). Position water pump with new gasket and

install retaining bolts. Install pump outlet with new gasket and "O" ring. See TORQUE SPECIFICATIONS

table at end of article.

2. Install oil dipstick retaining bolt. Install timing belt tensioner and idler pulleys. Install power steering pump bracket. Install power

steering pump. Tighten all bolts and nuts to specification. See TORQUE SPECIFICATIONS

table at end of article.

3. Install timing belt. Fill cooling system. Start engine and check for leaks and proper system function.

OIL PAN

Removal (1.3L)

Disconnect battery ground cable. Raise vehicle and drain engine oil. Remove flywheel housing dust cover. Remove oil pan retaining bolts,

nuts and stiffeners. Rotate crankshaft while removing oil pan. Remove baffle plate from oil pan. Clean gasket mating surfaces thoroughly.

Installation (1.3L)

Ensure gasket surfaces are clean. Apply oil resistant sealer to front and rear engine covers and across joint line of cylinder block.

Removal (1.6L)

1. Raise vehicle and drain engine oil. Remove frame brace retaining bolt. Loosen RH "A" arm front bolt, and pivot brace downward.

Disconnect front exhaust pipe from exhaust manifold (or turbocharger). Remove exhaust pipe bracket retaining bolts. Loosen rubber

exhaust hangers at catalytic converter.

2. Allow exhaust to hang supported by mechanic's wire. Disconnect turbocharger oil return hose (if equipped). Remove oil pan retaining

bolts. Carefully pry oil pan loose from cylinder block.

Installation (1.6L)

1. Clean pan and block gasket surfaces. Apply Gasket Sealant (E3AZ-19562-A) to new front and rear pan seals. Install seals to cylinder

block. Apply Gasket Sealant (E3AZ-19562-A) to oil pan gasket surface. See Fig. 8

. Install oil pan and tighten pan retaining bolts to

specification. See TORQUE SPECIFICATIONS

table at end of article.

2. Connect turbocharger oil return hose (if equipped). Install rubber exhaust hanger to brackets. Install new gasket and connect fro n t

exhaust pipe to exhaust manifold (or turbocharger). Install front exhaust pipe bracket. Tighten nuts and bolts to specification.

3. Pivot frame brace into position. Tighten retaining bolt to crossmember and RH "A" arm front retaining bolt to specification. Lower

vehicle, fill with oil and start engine. Check for oil leaks and system operation. NOTE:Raise engine slightly with floor jack, if required, to gain clearance for water pum p rem oval.

CAUT ION: DO NOT force a pry tool between cylinder block and oil pan.

Page 11 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 129 of 454

Back To Article

D - ADJUSTMENTS

1991 ENGINE PERFORMANCE Ford/Mercury - On-Vehicle Adjustm ents

ADJUSTMENTS

ENGINE MECHANICAL

Before beginning any on-vehicle adjustments to fuel or ignition systems, ensure engine mechanical condition is okay.

VALVE CLEARANCE

IGNITION TIMING

CAPRI

1. Place automatic transmission in Park or manual transmission in Neutral. Disconnect and plug hoses attached to vacuum diaphragm

assembly on distributor. Connect tachometer and timing light. Turn off all electrical loads.

2. Start engine, and warm it to operating temperature. Ensure idle speed is set to specification, adjusting if necessary. See IDLE SPEED &

MIXTURE . Determine initial timing. See IGNITION TIMING table. If base timing is not correct, loosen distributor mounting bolts

and rotate distributor until marks align. Tighten bolts to 14-18 ft. lbs. (19-25 N.m).

3. Increase engine RPM while observing timing light. Verify ignition timing advances. For Turbo models, go to step 5). For non-Turbo

models, continue with step 4).

4. On non-Turbo models, apply 16 in. Hg vacuum to chamber "A". Verify timing advances by 26-30 degrees. Remove vacuum source from

chamber "A". Apply 8 in. Hg vacuum to chamber "B" while observing timing. Verify timing advances by 3-7 degrees. Stop engine, and

remove test equipment.

5. On Turbo models, apply 20 in. Hg vacuum to advance diaphragm. Verify timing advances by 13-17 degrees. Disconnect vacuum source.

Apply 8 psi (.6 kg/cm

2 ) pressure to advance diaphragm. Verify timing retards by 3-7 degrees. Stop engine, and remove test equipment.

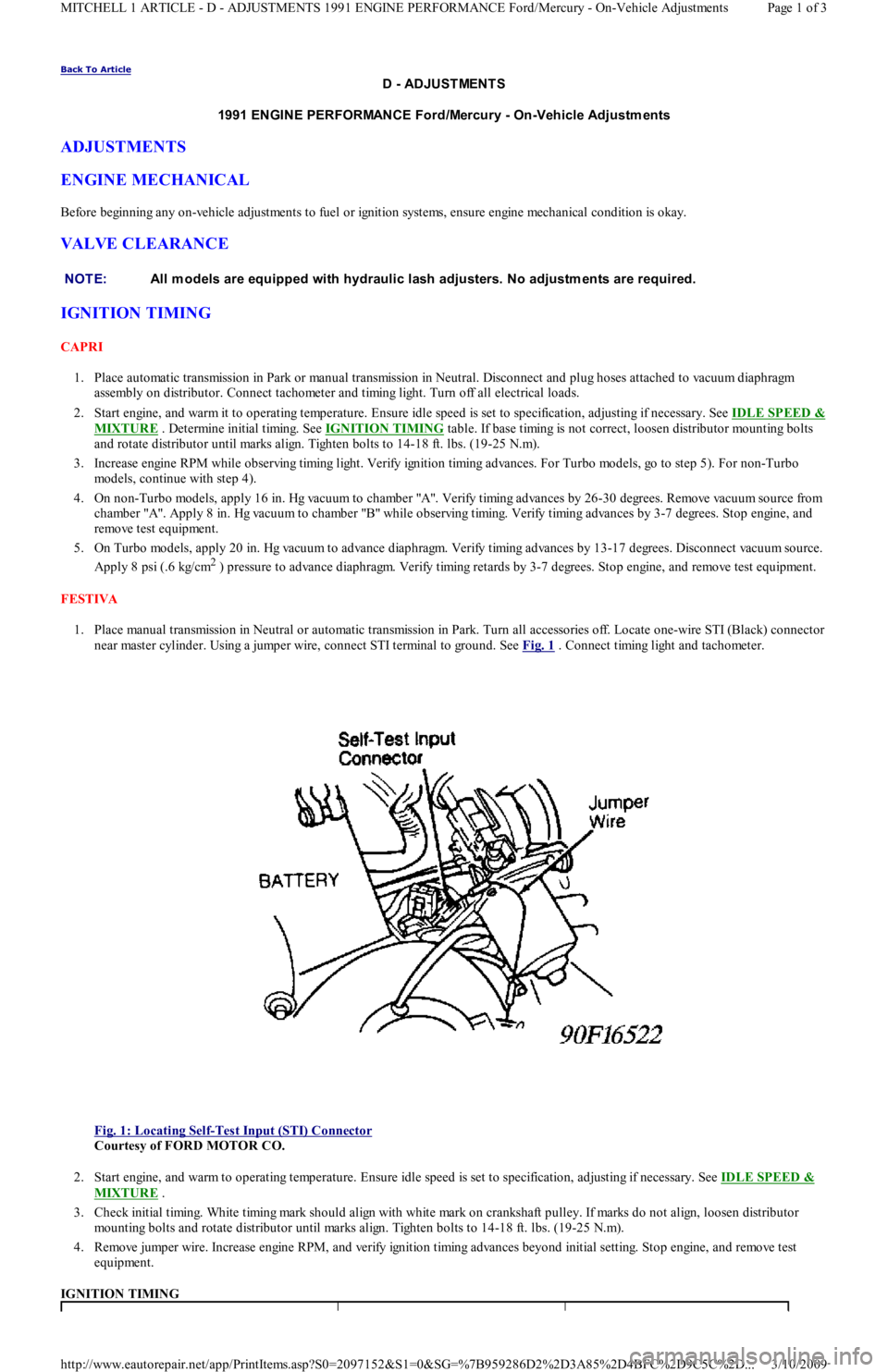

FESTIVA

1. Place manual transmission in Neutral or automatic transmission in Park. Turn all accessories off. Locate one-wire STI (Black) connector

near master cylinder. Using a jumper wire, connect STI terminal to ground. See Fig. 1

. Connect timing light and tachometer.

Fig. 1: Locating Self

-Test Input (STI) Connector

Courtesy of FORD MOTOR CO.

2. Start engine, and warm to operating temperature. Ensure idle speed is set to specification, adjusting if necessary. See IDLE SPEED &

MIXTURE .

3. Check initial timing. White timing mark should align with white mark on crankshaft pulley. If marks do not align, loosen distributor

mounting bolts and rotate distributor until marks align. Tighten bolts to 14-18 ft. lbs. (19-25 N.m).

4. Remove jumper wire. Increase engine RPM, and verify ignition timing advances beyond initial setting. Stop engine, and remove test

equipment.

IGNITION TIMING NOTE:All m odels are equipped with hydraulic lash adjusters. No adjustm ents are required.

Page 1 of 3 MITCHELL 1 ARTICLE - D - ADJUSTMENTS 1991 ENGINE PERFORMANCE Ford/Mercury - On-Vehicle Adjustments

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 218 of 454

Broken clutch housingSee STARTER article

Pinion shaft rusted or drySee STARTER article

Engine basic timing incorrectSee Ignition Timing in TUNE-

UP article

Broken teeth on engine flywheelReplace flywheel and check for

starter pinion gear damage

Starter Will Not Crank Engine

Faulty overrunning clutchSee STARTER article

Broken clutch housingSee STARTER article

Broken flywheel teethReplace flywheel and check for

starter pinion gear damage

Armature shaft sheared or reduction gear teeth strippedSee STARTER article

Weak batteryCharge or replace battery as

necessary

Faulty solenoidSee On-Vehicle Tests in

STARTER article

Poor groundsCheck all ground connections

for tight and clean connections

Ignition switch faulty or misadjustedAdjust or replace ignition

switch as necessary

Starter Cranks Engine Slowly

Battery weak or defectiveCharge or replace battery as

necessary

Engine overheatedSee ENGINE COOLING

SYSTEM article

Engine oil too heavyCheck that proper viscosity oil

is used

Poor battery-to-starter connectionsCheck that all between battery

and starter are clean and tight

Current draw too low or too highSee Bench Tests in STARTER

article

Bent armature, loose pole shoes screws or worn bearingSee STARTER article

Burned solenoid contactsReplace solenoid

Faulty starterReplace starter

S t a r t e r E n ga ge s E n gin e On l y M o me n t a r il y

Engine timing too far advancedSee Ignition Timing in TUNE-

UP article

Overrunning clutch not engaging properlyReplace overrunning clutch.

See STARTER article

Broken starter clutchSee STARTER article

Broken teeth on engine flywheelReplace flywheel and check

starter pinion gear for damage

Weak drive assembly thrust springSee STARTER article

Weak hold-in coilSee Bench Tests in STARTER

article

Starter Drive Will Not Engage

Defective point assemblySee Testing in STARTER

article

Poor point assembly groundSee Testing in STARTER

article

Defective pull-in coilReplace starter solenoid

Starter Relay Does Not Close

Dead batteryCharge or replace battery as

necessary

Faulty wiringCheck all wiring and

connections leading to relay

Neutral safety switch faultyReplace neutral safety switch

Starter relay faultyReplace starter relay

Starter Drive Will Not Disengage

Starter motor loose on mountingsTighten starter attach bolts

Worn drive end bushingSee STARTER article

Damaged engine flywheel teethReplace flywheel and starter

pinion gear for damage

Drive yolk return spring broken or missingReplace return spring

Faulty ignition switchReplace ignition switch

Insufficient clearance between winding leads to solenoid terminal and main contact in solenoidReplace starter solenoid

Starter clutch not disengagingReplace starter clutch

Ignition starter switchReplace ignition switch

contacts sticking

Starter Relay Operates but Solenoid Does Not

Faulty solenoid switch, switch connections or relayCheck all wiring between relay

and solenoid or replace relay

or solenoid as necessary

Page 5 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 233 of 454

Starter Turns but Engine Does Not Rotate

Starter clutch slippingSee STARTER article

Broken clutch housingSee STARTER article

Pinion shaft rusted or drySee STARTER article

Engine basic timing incorrectSee Ignition Timing in

TUNE-UP article

Broken teeth on engine flywheelReplace flywheel and check

for starter pinion gear damage

Starter Will Not Crank Engine

Faulty overrunning clutchSee STARTER article

Broken clutch housingSee STARTER article

Broken flywheel teethReplace flywheel and check

for starter pinion gear damage

Armature shaft sheared or reduction gear teeth strippedSee STARTER article

Weak batteryCharge or replace battery as

necessary

Faulty solenoidSee On-Vehicle Tests in

STARTER article

Poor groundsCheck all ground connections

for tight and clean

connections

Ignition switch faulty or misadjustedAdjust or replace ignition

switch as necessary

Starter Cranks Engine Slowly

Battery weak or defectiveCharge or replace battery as

necessary

Engine overheatedSee ENGINE COOLING

SYSTEM article

Engine oil too heavyCheck that proper viscosity

oil is used

Poor battery-to-starter connectionsCheck that all between

battery and starter are clean

and tight

Current draw too low or too highSee Bench Tests in

STARTER article

Bent armature, loose pole shoes screws or worn bearingsSee STARTER article

Burned solenoid contactsReplace solenoid

Faulty starterReplace starter

S t a r t e r E n ga ge s E n gin e On l y M o me n t a r il y

Engine timing too far advancedSee Ignition Timing in

TUNE-UP article

Overrunning clutch not engaging properlyReplace overrunning clutch.

See STARTER article

Broken starter clutchSee STARTER article

Broken teeth on engine flywheelReplace flywheel and check

starter pinion gear for damage

Weak drive assembly thrust springSee STARTER article

Weak hold-in coilSee Bench Tests in

STARTER article

Starter Drive Will Not Engage

Defective point assemblySee Testing in STARTER

article

Poor point assembly groundSee Testing in STARTER

article

Defective pull-in coilReplace starter solenoid

Starter Relay Does Not Close

Dead batteryCharge or replace battery as

necessary

Faulty wiringCheck all wiring and

connections leading to relay

Neutral safety switch faultyReplace neutral safety switch

Starter relay faultyReplace starter relay

Starter Drive Will Not Disengage

Starter motor loose on mountingsTighten starter attach bolts

Worn drive end bushingSee STARTER article

Damaged engine flywheel teethReplace flywheel and starter

pinion gear for damage

Drive yolk return spring broken or missingReplace return spring

Faulty ignition switchReplace ignition switch

Insufficient clearance between winding leads to solenoid terminal and main contact in solenoidReplace starter solenoid

Starter clutch not disengagingReplace starter clutch

Ignition starter switch contacts stickingReplace ignition switch

Starter Relay Operates but Solenoid Does Not

Page 20 of 36 MITCHELL 1 ARTICLE - GENERAL INFORMATION Trouble Shooting - Basic Procedures

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 319 of 454

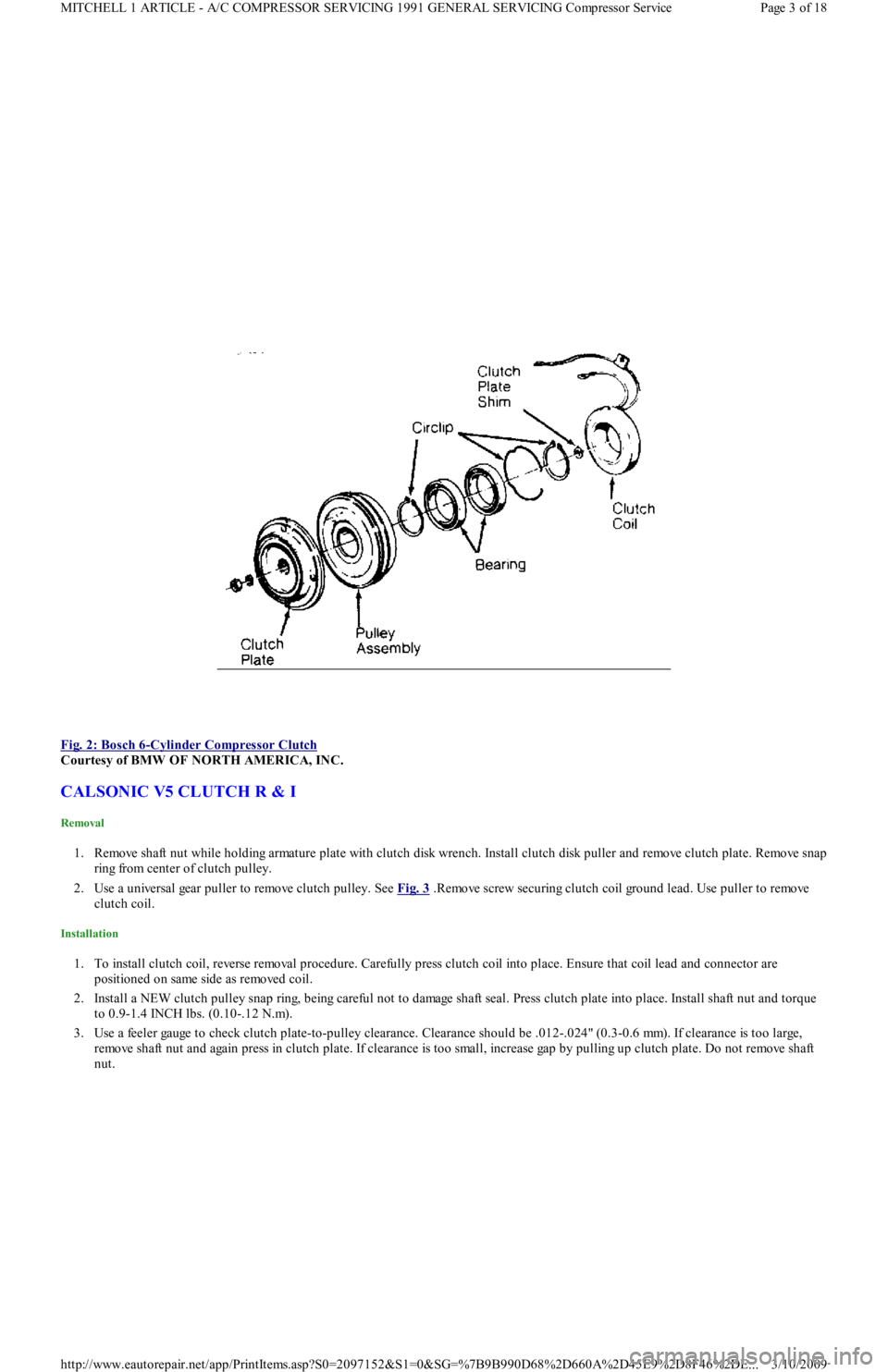

Fig. 2: Bosch 6

-Cylinder Compressor Clutch

Courtesy of BMW OF NORTH AMERICA, INC.

CALSONIC V5 CLUTCH R & I

Removal

1. Remove shaft nut while holding armature plate with clutch disk wrench. Install clutch disk puller and remove clutch plate. Remo ve sn ap

ring from center of clutch pulley.

2. Use a universal gear puller to remove clutch pulley. See Fig. 3

.Remove screw securing clutch coil ground lead. Use puller to remove

clutch coil.

Installation

1. To install clutch coil, reverse removal procedure. Carefully press clutch coil into place. Ensure that coil lead and connector are

positioned on same side as removed coil.

2. Install a NEW clutch pulley snap ring, being careful not to damage shaft seal. Press clutch plate into place. Install shaft nut and torque

to 0.9-1.4 INCH lbs. (0.10-.12 N.m).

3. Use a feeler gauge to check clutch plate-to-pulley clearance. Clearance should be .012-.024" (0.3-0.6 mm). If clearance is too large,

remove shaft nut and again press in clutch plate. If clearance is too small, increase gap by pulling up clutch plate. Do not remo ve sh aft

nut.

Page 3 of 18 MITCHELL 1 ARTICLE - A/C COMPRESSOR SERVICING 1991 GENERAL SERVICING Compressor Service

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...

Page 441 of 454

Fig. 2: Checking Release Lever Clearance

Courtesy of FORD MOTOR CO.

CLUTCH PEDAL SPECIFICATIONS

CLUTCH PEDAL HEIGHT

1. Disconnect clutch cable from release lever at transaxle. Measure distance from upper center of pedal to firewall. See Fig. 1

. If not

within specifications, check pedal mounting for wear or damage. See CLUTCH PEDAL SPECIFICATIONS

.

2. If adjustment is required, remove instrument panel bracket and air duct located under steering column. Loosen clutch pedal switch lock

nut and rotate switch until correct clutch pedal height is obtained.

3. Install clutch cable at transaxle. Recheck pedal height. If connecting clutch cable changes pedal height, check cable for improper

routing, binding or adjustment. If connecting push rod changes pedal height, check for proper push rod adjustment. Install carpet and

insulation to complete adjustment.

REMOVAL & INSTALLATION

CLUTCH ASSEMBLY

Removal

1. Disconnect negative battery cable. Loosen clutch cable adjuster nut and disengage cable from release lever.

2. Remove starter. Disconnect back-up light switch and neutral switch. Disconnect ground cable/strap and supporting brackets. Disconnect

speedometer cable from transaxle.

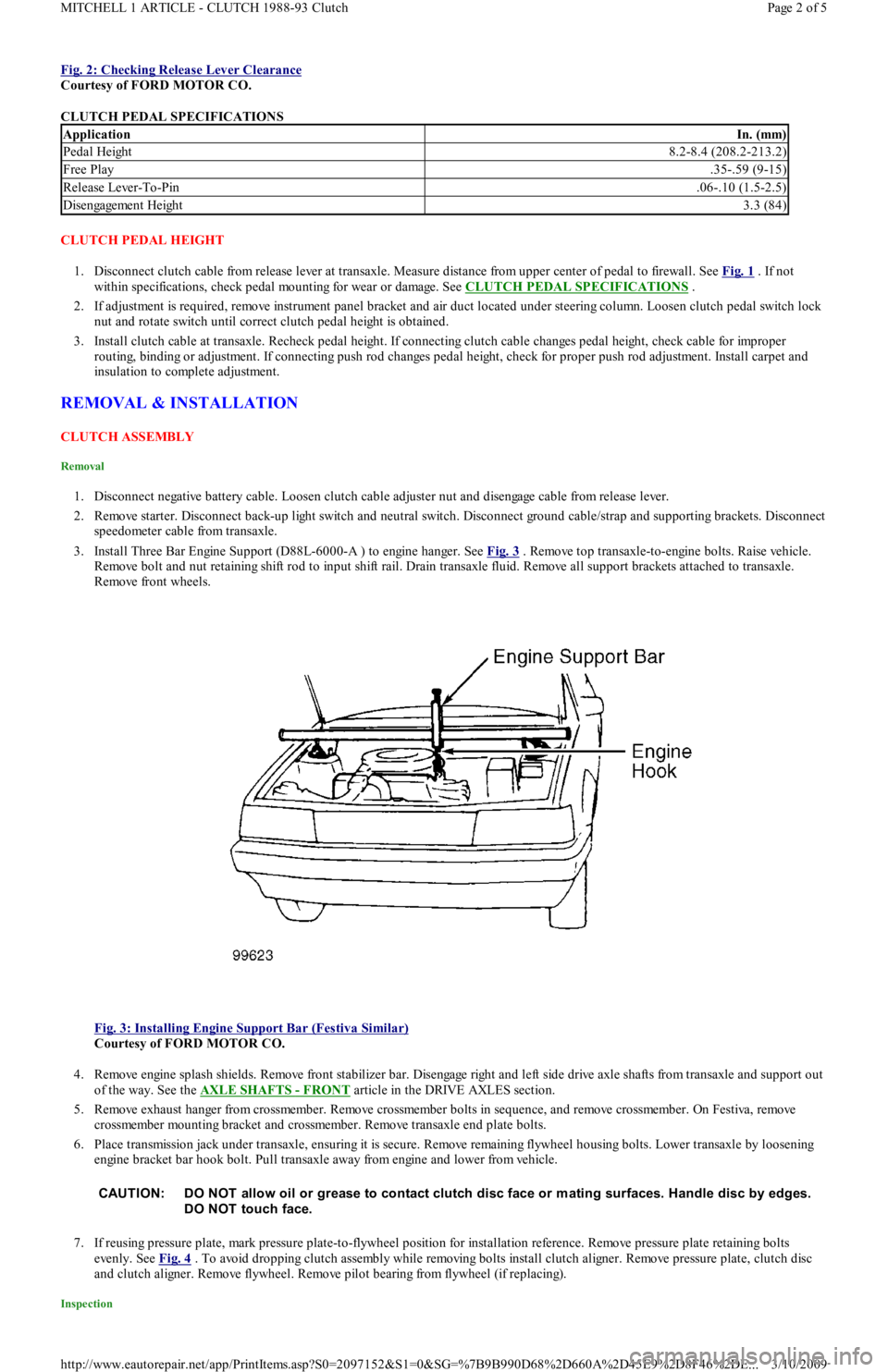

3. Install Three Bar Engine Support (D88L-6000-A ) to engine hanger. See Fig. 3

. Remove top transaxle-to-engine bolts. Raise vehicle.

Remove bolt and nut retaining shift rod to input shift rail. Drain transaxle fluid. Remove all support brackets attached to transaxle.

Remove front wheels.

Fig. 3: Installing Engine Support Bar (Festiva Similar)

Courtesy of FORD MOTOR CO.

4. Remove engine splash shields. Remove front stabilizer bar. Disengage right and left side drive axle shafts from transaxle and support out

of the way. See the AXLE SHAFTS

- FRONT article in the DRIVE AXLES section.

5. Remove exhaust hanger from crossmember. Remove crossmember bolts in sequence, and remove crossmember. On Festiva, remove

crossmember mounting bracket and crossmember. Remove transaxle end plate bolts.

6. Place transmission jack under transaxle, ensuring it is secure. Remove remaining flywheel housing bolts. Lower transaxle by loosening

engine bracket bar hook bolt. Pull transaxle away from engine and lower from vehicle.

7. If reusing pressure plate, mark pressure plate-to-flywheel position for installation reference. Remove pressure plate retaining bolts

evenly. See Fig. 4

. To avoid dropping clutch assembly while removing bolts install clutch aligner. Remove pressure plate, clutch disc

and clutch aligner. Remove flywheel. Remove pilot bearing from flywheel (if replacing).

Inspection

ApplicationIn. (mm)

Pedal Height8.2-8.4 (208.2-213.2)

Free Play.35-.59 (9-15)

Release Lever-To-Pin.06-.10 (1.5-2.5)

Disengagement Height3.3 (84)

CAUT ION: DO NOT allow oil or grease to contact clutch disc face or m ating surfaces. Handle disc by edges.

DO NOT touch face.

Page 2 of 5 MITCHELL 1 ARTICLE - CLUTCH 1988-93 Clutch

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B9B990D68%2D660A%2D45E9%2D8F46%2DE

...