fuel cap FORD FIESTA 1989 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 3 of 296

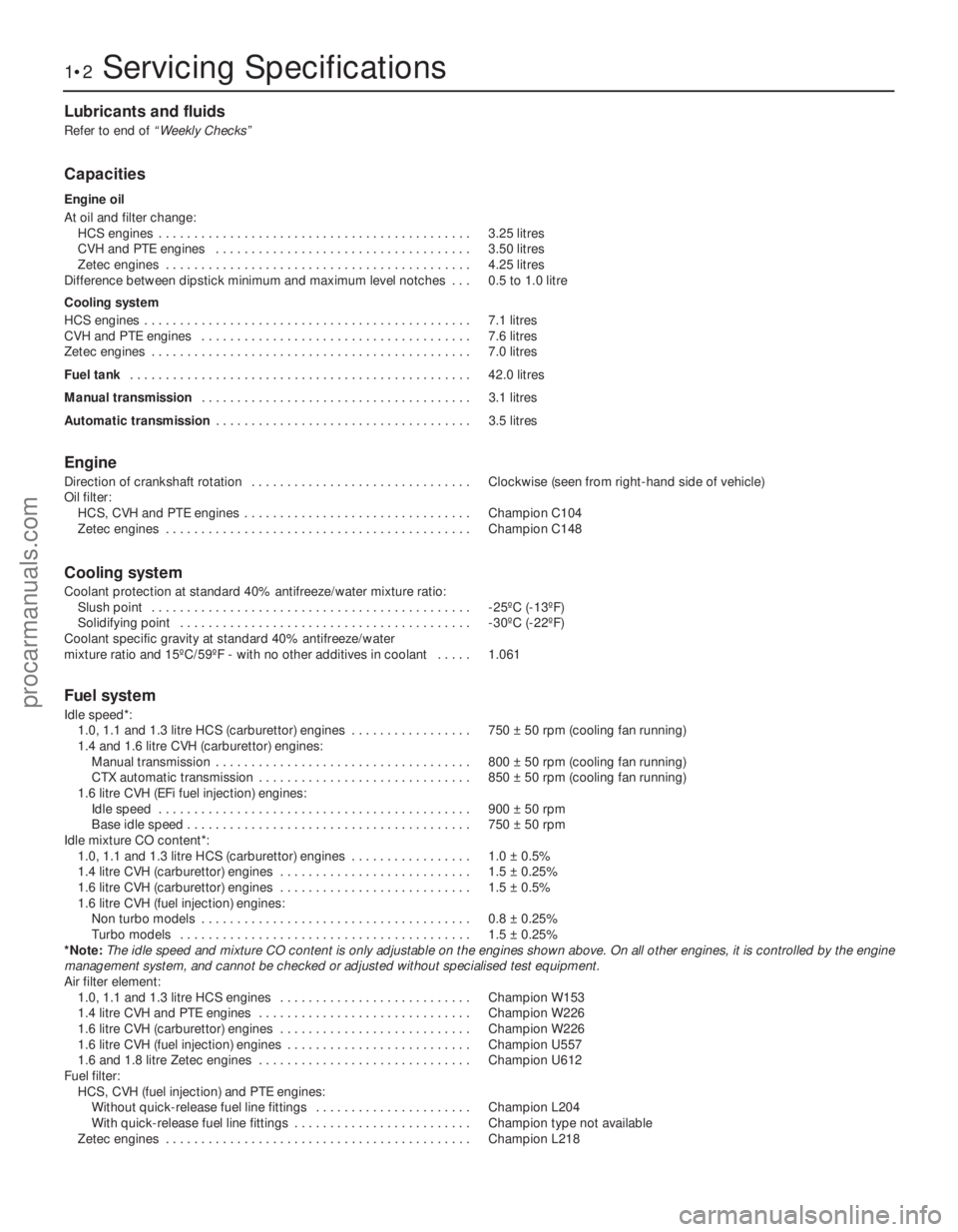

Lubricants and fluids

Refer to end of “Weekly Checks”

Capacities

Engine oil

At oil and filter change:HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 3.25 litres

CVH and PTE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

3.50 litresZetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . 4.25 litres

Difference between dipstick minimum and maximum level notches . . . 0.5 to 1.0 litre

Cooling system

HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . 7.1 litresCVH and PTE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 7.6 litresZetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . 7.0 litres

Fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . 42.0 litres

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 3.1 litres

Automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

3.5 litres

Engine

Direction of crankshaft rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clockwise (seen from right-hand side of vehicle)

Oil filter: HCS, CVH and PTE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion C104

Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . Champion C148

Cooling system

Coolant protection at standard 40% antifreeze/water mixture ratio:Slush point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . -25ºC (-13ºF)Solidifying point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . -30ºC (-22ºF)

Coolant specific gravity at standard 40% antifreeze/water

mixture ratio and 15ºC/59ºF - with no other additives in coolant . . . . . 1.061

Fuel system

Idle speed*: 1.0, 1.1 and 1.3 litre HCS (carburettor) engines . . . . . . . . . . . . . . . . . 750 ± 50 rpm (cooling fan running)

1.4 and 1.6 litre CVH (carburettor) engines:

Manual transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

800 ± 50 rpm (cooling fan running)CTX automatic transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 850 ± 50 rpm (cooling fan running)

1.6 litre CVH (EFi fuel injection) engines: Idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . 900 ± 50 rpmBase idle speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . 750 ± 50 rpm

Idle mixture CO content*: 1.0, 1.1 and 1.3 litre HCS (carburettor) engines . . . . . . . . . . . . . . . . . 1.0 ± 0.5%

1.4 litre CVH (carburettor) engines . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 ± 0.25%

1.6 litre CVH (carburettor) engines . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 ± 0.5%

1.6 litre CVH (fuel injection) engines:Non turbo models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . 0.8 ± 0.25%

Turbo models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . 1.5 ± 0.25%

*Note: The idle speed and mixture CO content is only adjustable on the engines \

shown above. On all other engines, it is controlled by the engine

management system, and cannot be checked or adjusted without specialised\

test equipment.

Air filter element: 1.0, 1.1 and 1.3 litre HCS engines . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W153

1.4 litre CVH and PTE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W226

1.6 litre CVH (carburettor) engines . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion W226

1.6 litre CVH (fuel injection) engines . . . . . . . . . . . . . . . . . . . . . . . . . . Champion U557

1.6 and 1.8 litre Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion U612

Fuel filter:

HCS, CVH (fuel injection) and PTE engines:Without quick-release fuel line fittings . . . . . . . . . . . . . . . . . . . . . . Champion L204

With quick-release fuel line fittings . . . . . . . . . . . . . . . . . . . . . . . . . Champion type not available

Zetec engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . Champion L218

1•2Servicing Specifications

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 6 of 296

Maintenance – component location1•5

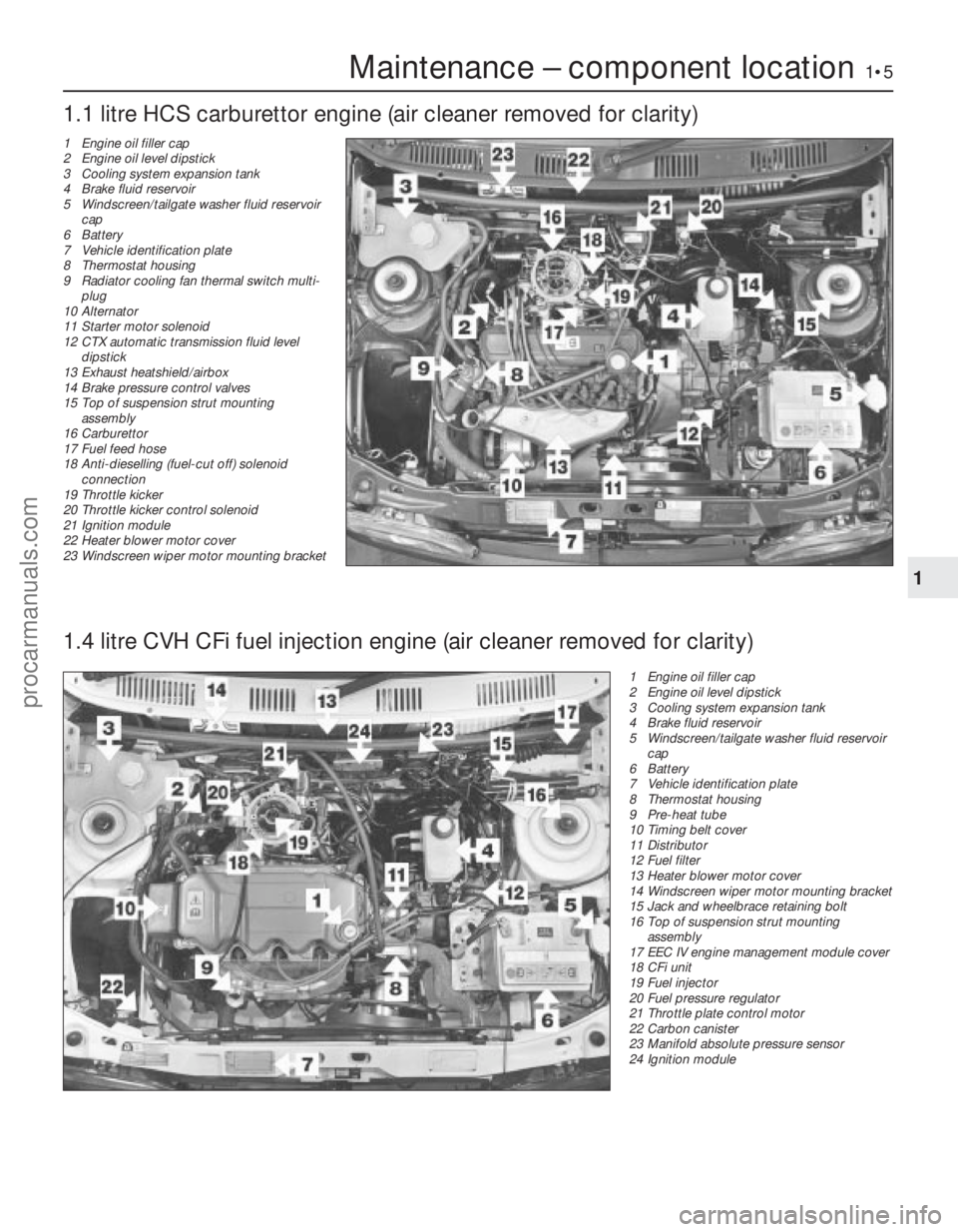

1 Engine oil filler cap

2 Engine oil level dipstick

3 Cooling system expansion tank

4 Brake fluid reservoir

5 Windscreen/tailgate washer fluid reservoircap

6 Battery

7 Vehicle identification plate

8 Thermostat housing

9 Pre-heat tube

10 Timing belt cover

11 Distributor

12 Fuel filter

13 Heater blower motor cover

14 Windscreen wiper motor mounting bracket

15 Jack and wheelbrace retaining bolt

16 Top of suspension strut mounting

assembly

17 EEC IV engine management module cover

18 CFi unit

19 Fuel injector

20 Fuel pressure regulator

21 Throttle plate control motor

22 Carbon canister

23 Manifold absolute pressure sensor

24 Ignition module

1.1 litre HCS carburettor engine (air cleaner removed for clarity)

1

1595Ford Fiesta Remake

1.4 litre CVH CFi fuel injection engine (air cleaner removed for clarity)

1 Engine oil filler cap

2 Engine oil level dipstick

3 Cooling system expansion tank

4 Brake fluid reservoir

5 Windscreen/tailgate washer fluid reservoir

cap

6 Battery

7 Vehicle identification plate

8 Thermostat housing

9 Radiator cooling fan thermal switch multi- plug

10 Alternator

11 Starter motor solenoid

12 CTX automatic transmission fluid level

dipstick

13 Exhaust heatshield/airbox

14 Brake pressure control valves

15 Top of suspension strut mounting

assembly

16 Carburettor

17 Fuel feed hose

18 Anti-dieselling (fuel-cut off) solenoid

connection

19 Throttle kicker

20 Throttle kicker control solenoid

21 Ignition module

22 Heater blower motor cover

23 Windscreen wiper motor mounting bracket

procarmanuals.com

http://vnx.su

Page 7 of 296

1•6Maintenance – component location

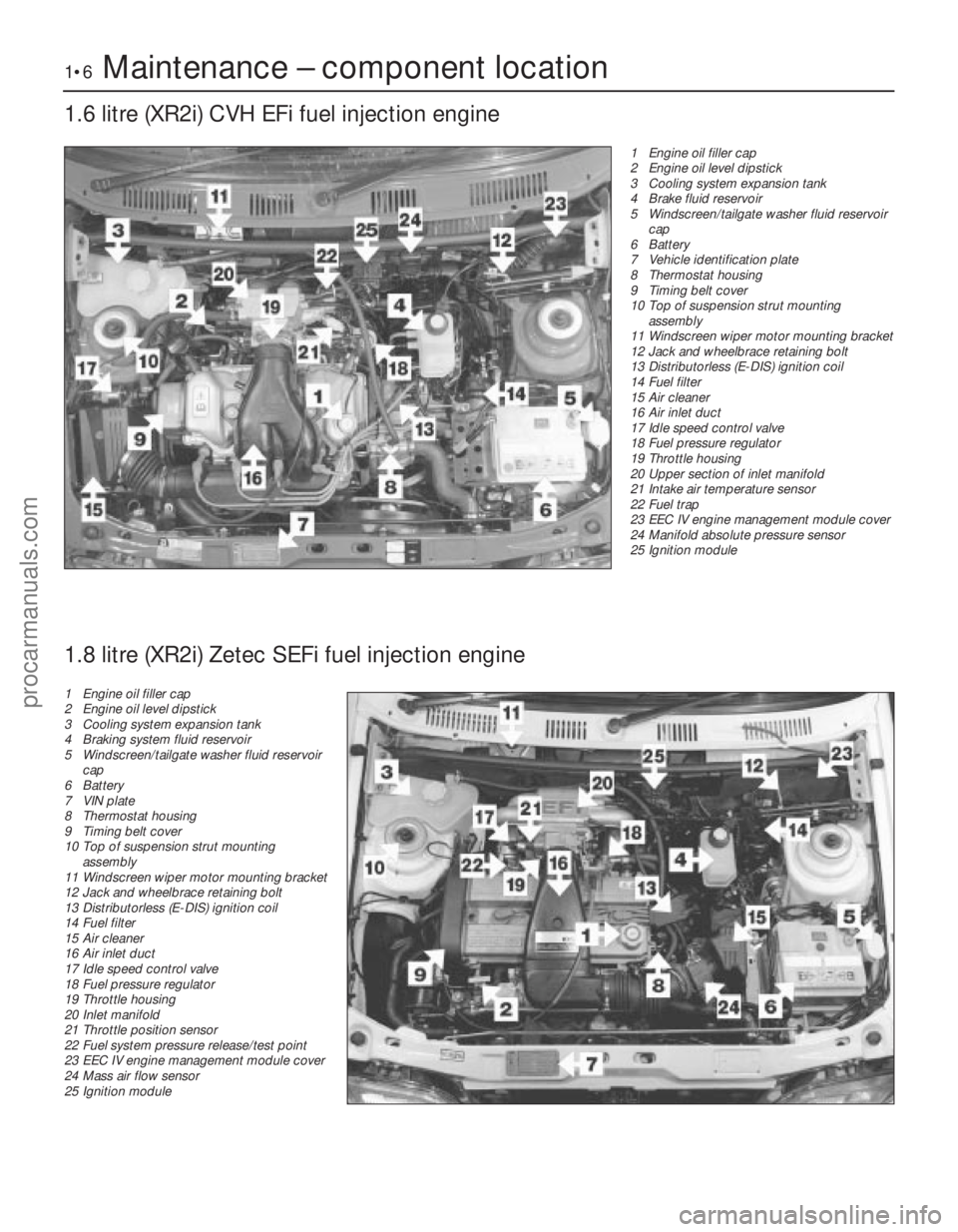

1.6 litre (XR2i) CVH EFi fuel injection engine

1595Ford Fiesta Remake1 Engine oil filler cap

2 Engine oil level dipstick

3 Cooling system expansion tank

4 Brake fluid reservoir

5 Windscreen/tailgate washer fluid reservoir

cap

6 Battery

7 Vehicle identification plate

8 Thermostat housing

9 Timing belt cover

10 Top of suspension strut mounting

assembly

11 Windscreen wiper motor mounting bracket

12 Jack and wheelbrace retaining bolt

13 Distributorless (E-DIS) ignition coil

14 Fuel filter

15 Air cleaner

16 Air inlet duct

17 Idle speed control valve

18 Fuel pressure regulator

19 Throttle housing

20 Upper section of inlet manifold

21 Intake air temperature sensor

22 Fuel trap

23 EEC IV engine management module cover

24 Manifold absolute pressure sensor

25 Ignition module

1.8 litre (XR2i) Zetec SEFi fuel injection engine

1 Engine oil filler cap

2 Engine oil level dipstick

3 Cooling system expansion tank

4 Braking system fluid reservoir

5 Windscreen/tailgate washer fluid reservoir

cap

6 Battery

7 VIN plate

8 Thermostat housing

9 Timing belt cover

10 Top of suspension strut mounting

assembly

11 Windscreen wiper motor mounting bracket

12 Jack and wheelbrace retaining bolt

13 Distributorless (E-DIS) ignition coil

14 Fuel filter

15 Air cleaner

16 Air inlet duct

17 Idle speed control valve

18 Fuel pressure regulator

19 Throttle housing

20 Inlet manifold

21 Throttle position sensor

22 Fuel system pressure release/test point

23 EEC IV engine management module cover

24 Mass air flow sensor

25 Ignition module

procarmanuals.com

http://vnx.su

Page 10 of 296

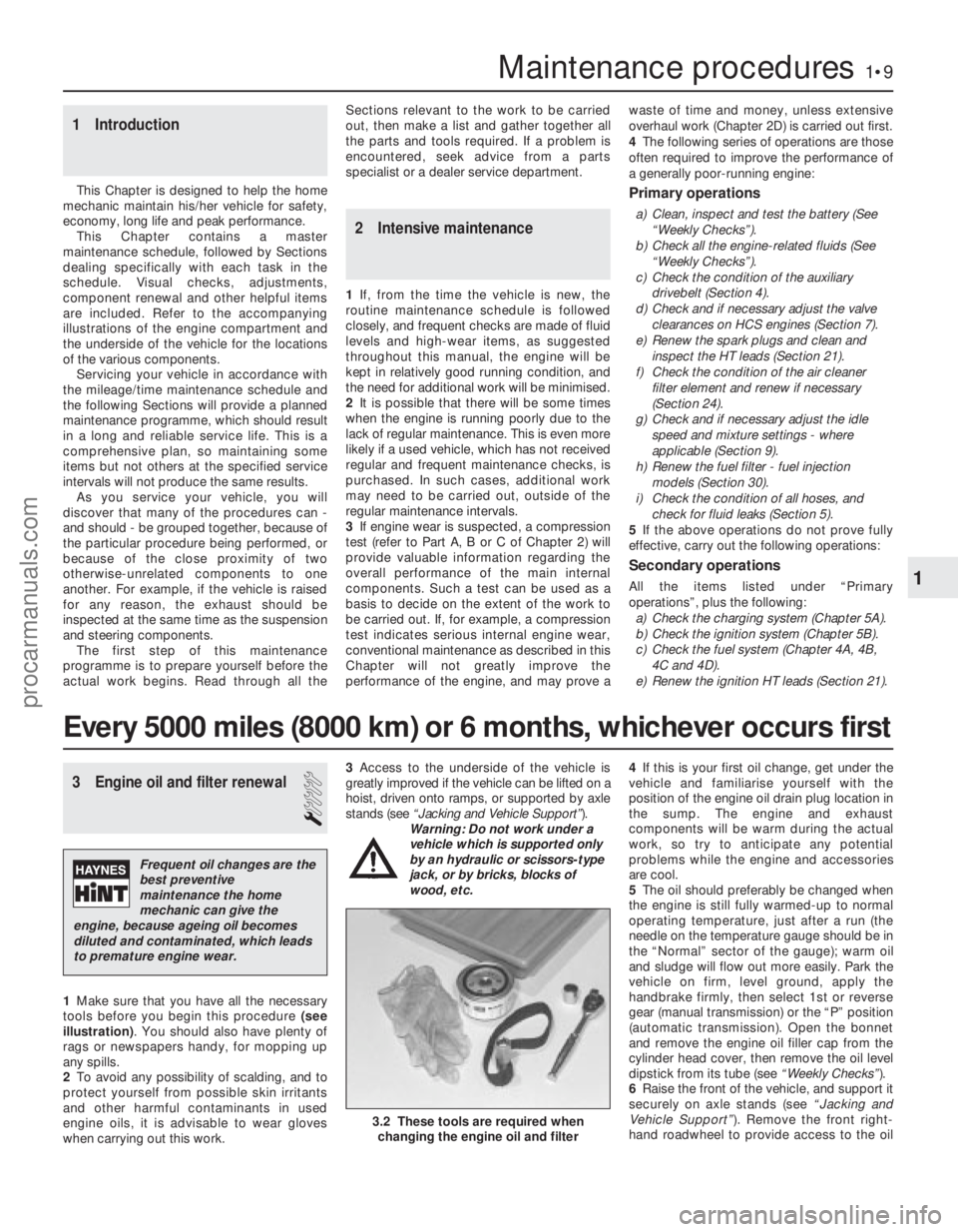

3 Engine oil and filter renewal

1

1Make sure that you have all the necessary

tools before you begin this procedure (see

illustration) . You should also have plenty of

rags or newspapers handy, for mopping up

any spills.

2 To avoid any possibility of scalding, and to

protect yourself from possible skin irritants

and other harmful contaminants in used

engine oils, it is advisable to wear gloves

when carrying out this work. 3

Access to the underside of the vehicle is

greatly improved if the vehicle can be lifted on a

hoist, driven onto ramps, or supported by axle

stands (see “Jacking and Vehicle Support” ).

Warning: Do not work under a

vehicle which is supported only

by an hydraulic or scissors-type

jack, or by bricks, blocks of

wood, etc. 4

If this is your first oil change, get under the

vehicle and familiarise yourself with the

position of the engine oil drain plug location in

the sump. The engine and exhaust

components will be warm during the actual

work, so try to anticipate any potential

problems while the engine and accessories

are cool.

5 The oil should preferably be changed when

the engine is still fully warmed-up to normal

operating temperature, just after a run (the

needle on the temperature gauge should be in

the “Normal” sector of the gauge); warm oil

and sludge will flow out more easily. Park the

vehicle on firm, level ground, apply the

handbrake firmly, then select 1st or reverse

gear (manual transmission) or the “P” position

(automatic transmission). Open the bonnet

and remove the engine oil filler cap from the

cylinder head cover, then remove the oil level

dipstick from its tube (see “Weekly Checks”).

6 Raise the front of the vehicle, and support it

securely on axle stands (see “Jacking and

Vehicle Support” ). Remove the front right-

hand roadwheel to provide access to the oil

1 Introduction

This Chapter is designed to help the home

mechanic maintain his/her vehicle for safety,

economy, long life and peak performance.

This Chapter contains a master

maintenance schedule, followed by Sections

dealing specifically with each task in the

schedule. Visual checks, adjustments,

component renewal and other helpful items

are included. Refer to the accompanying

illustrations of the engine compartment and

the underside of the vehicle for the locations

of the various components.

Servicing your vehicle in accordance with

the mileage/time maintenance schedule and

the following Sections will provide a planned

maintenance programme, which should result

in a long and reliable service life. This is a

comprehensive plan, so maintaining some

items but not others at the specified service

intervals will not produce the same results. As you service your vehicle, you will

discover that many of the procedures can -

and should - be grouped together, because of

the particular procedure being performed, or

because of the close proximity of two

otherwise-unrelated components to one

another. For example, if the vehicle is raised

for any reason, the exhaust should be

inspected at the same time as the suspension

and steering components.

The first step of this maintenance

programme is to prepare yourself before the

actual work begins. Read through all the Sections relevant to the work to be carried

out, then make a list and gather together all

the parts and tools required. If a problem is

encountered, seek advice from a parts

specialist or a dealer service department.

2 Intensive maintenance

1

If, from the time the vehicle is new, the

routine maintenance schedule is followed

closely, and frequent checks are made of fluid

levels and high-wear items, as suggested

throughout this manual, the engine will be

kept in relatively good running condition, and

the need for additional work will be minimised.

2 It is possible that there will be some times

when the engine is running poorly due to the

lack of regular maintenance. This is even more

likely if a used vehicle, which has not received

regular and frequent maintenance checks, is

purchased. In such cases, additional work

may need to be carried out, outside of the

regular maintenance intervals.

3 If engine wear is suspected, a compression

test (refer to Part A, B or C of Chapter 2) will

provide valuable information regarding the

overall performance of the main internal

components. Such a test can be used as a

basis to decide on the extent of the work to

be carried out. If, for example, a compression

test indicates serious internal engine wear,

conventional maintenance as described in this

Chapter will not greatly improve the

performance of the engine, and may prove a waste of time and money, unless extensive

overhaul work (Chapter 2D) is carried out first.

4

The following series of operations are those

often required to improve the performance of

a generally poor-running engine:

Primary operations

a) Clean, inspect and test the battery (See

“Weekly Checks”).

b) Check all the engine-related fluids (See

“Weekly Checks”).

c) Check the condition of the auxiliary drivebelt (Section 4).

d) Check and if necessary adjust the valve

clearances on HCS engines (Section 7).

e) Renew the spark plugs and clean and inspect the HT leads (Section 21).

f) Check the condition of the air cleaner filter element and renew if necessary

(Section 24).

g) Check and if necessary adjust the idle speed and mixture settings - where

applicable (Section 9).

h) Renew the fuel filter - fuel injection models (Section 30).

i) Check the condition of all hoses, and check for fluid leaks (Section 5).

5 If the above operations do not prove fully

effective, carry out the following operations:

Secondary operations

All the items listed under “Primary

operations”, plus the following: a) Check the charging system (Chapter 5A).

b) Check the ignition system (Chapter 5B).

c) Check the fuel system (Chapter 4A, 4B,

4C and 4D).

e) Renew the ignition HT leads (Section 21).

Maintenance procedures1•9

3.2 These tools are required when changing the engine oil and filter

1

1595Ford Fiesta Remake

Every 5000 miles (8000 km) or 6 months, whichever occurs first

Frequent oil changes are the

best preventive

maintenance the home

mechanic can give the

engine, because ageing oil becomes

diluted and contaminated, which leads

to premature engine wear.

procarmanuals.com

http://vnx.su

Page 14 of 296

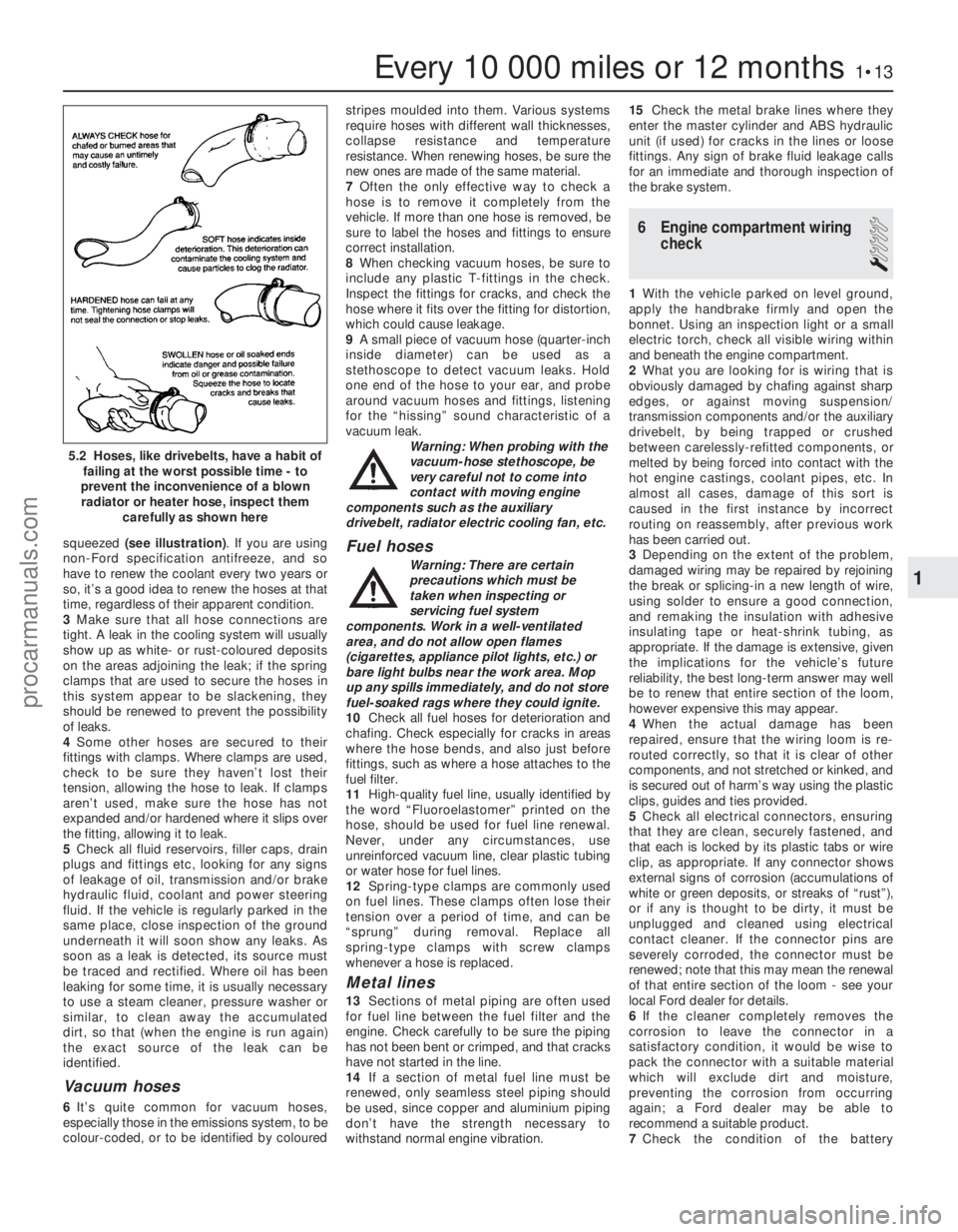

squeezed (see illustration) . If you are using

non-Ford specification antifreeze, and so

have to renew the coolant every two years or

so, it’s a good idea to renew the hoses at that

time, regardless of their apparent condition.

3 Make sure that all hose connections are

tight. A leak in the cooling system will usually

show up as white- or rust-coloured deposits

on the areas adjoining the leak; if the spring

clamps that are used to secure the hoses in

this system appear to be slackening, they

should be renewed to prevent the possibility

of leaks.

4 Some other hoses are secured to their

fittings with clamps. Where clamps are used,

check to be sure they haven’t lost their

tension, allowing the hose to leak. If clamps

aren’t used, make sure the hose has not

expanded and/or hardened where it slips over

the fitting, allowing it to leak.

5 Check all fluid reservoirs, filler caps, drain

plugs and fittings etc, looking for any signs

of leakage of oil, transmission and/or brake

hydraulic fluid, coolant and power steering

fluid. If the vehicle is regularly parked in the

same place, close inspection of the ground

underneath it will soon show any leaks. As

soon as a leak is detected, its source must

be traced and rectified. Where oil has been

leaking for some time, it is usually necessary

to use a steam cleaner, pressure washer or

similar, to clean away the accumulated

dirt, so that (when the engine is run again)

the exact source of the leak can be

identified.

Vacuum hoses

6 It’s quite common for vacuum hoses,

especially those in the emissions system, to be

colour-coded, or to be identified by coloured stripes moulded into them. Various systems

require hoses with different wall thicknesses,

collapse resistance and temperature

resistance. When renewing hoses, be sure the

new ones are made of the same material.

7

Often the only effective way to check a

hose is to remove it completely from the

vehicle. If more than one hose is removed, be

sure to label the hoses and fittings to ensure

correct installation.

8 When checking vacuum hoses, be sure to

include any plastic T-fittings in the check.

Inspect the fittings for cracks, and check the

hose where it fits over the fitting for distortion,

which could cause leakage.

9 A small piece of vacuum hose (quarter-inch

inside diameter) can be used as a

stethoscope to detect vacuum leaks. Hold

one end of the hose to your ear, and probe

around vacuum hoses and fittings, listening

for the “hissing” sound characteristic of a

vacuum leak. Warning: When probing with the

vacuum-hose stethoscope, be

very careful not to come into

contact with moving engine

components such as the auxiliary

drivebelt, radiator electric cooling fan, etc.

Fuel hoses

Warning: There are certain

precautions which must be

taken when inspecting or

servicing fuel system

components. Work in a well-ventilated

area, and do not allow open flames

(cigarettes, appliance pilot lights, etc.) or

bare light bulbs near the work area. Mop

up any spills immediately, and do not store

fuel-soaked rags where they could ignite.

10 Check all fuel hoses for deterioration and

chafing. Check especially for cracks in areas

where the hose bends, and also just before

fittings, such as where a hose attaches to the

fuel filter.

11 High-quality fuel line, usually identified by

the word “Fluoroelastomer” printed on the

hose, should be used for fuel line renewal.

Never, under any circumstances, use

unreinforced vacuum line, clear plastic tubing

or water hose for fuel lines.

12 Spring- type clamps are commonly used

on fuel lines. These clamps often lose their

tension over a period of time, and can be

“sprung” during removal. Replace all

spring- type clamps with screw clamps

whenever a hose is replaced.

Metal lines

13 Sections of metal piping are often used

for fuel line between the fuel filter and the

engine. Check carefully to be sure the piping

has not been bent or crimped, and that cracks

have not started in the line.

14 If a section of metal fuel line must be

renewed, only seamless steel piping should

be used, since copper and aluminium piping

don’t have the strength necessary to

withstand normal engine vibration. 15

Check the metal brake lines where they

enter the master cylinder and ABS hydraulic

unit (if used) for cracks in the lines or loose

fittings. Any sign of brake fluid leakage calls

for an immediate and thorough inspection of

the brake system.

6 Engine compartment wiring check

1

1With the vehicle parked on level ground,

apply the handbrake firmly and open the

bonnet. Using an inspection light or a small

electric torch, check all visible wiring within

and beneath the engine compartment.

2 What you are looking for is wiring that is

obviously damaged by chafing against sharp

edges, or against moving suspension/

transmission components and/or the auxiliary

drivebelt, by being trapped or crushed

between carelessly-refitted components, or

melted by being forced into contact with the

hot engine castings, coolant pipes, etc. In

almost all cases, damage of this sort is

caused in the first instance by incorrect

routing on reassembly, after previous work

has been carried out.

3 Depending on the extent of the problem,

damaged wiring may be repaired by rejoining

the break or splicing-in a new length of wire,

using solder to ensure a good connection,

and remaking the insulation with adhesive

insulating tape or heat-shrink tubing, as

appropriate. If the damage is extensive, given

the implications for the vehicle’s future

reliability, the best long-term answer may well

be to renew that entire section of the loom,

however expensive this may appear.

4 When the actual damage has been

repaired, ensure that the wiring loom is re-

routed correctly, so that it is clear of other

components, and not stretched or kinked, and

is secured out of harm’s way using the plastic

clips, guides and ties provided.

5 Check all electrical connectors, ensuring

that they are clean, securely fastened, and

that each is locked by its plastic tabs or wire

clip, as appropriate. If any connector shows

external signs of corrosion (accumulations of

white or green deposits, or streaks of “rust”),

or if any is thought to be dirty, it must be

unplugged and cleaned using electrical

contact cleaner. If the connector pins are

severely corroded, the connector must be

renewed; note that this may mean the renewal

of that entire section of the loom - see your

local Ford dealer for details.

6 If the cleaner completely removes the

corrosion to leave the connector in a

satisfactory condition, it would be wise to

pack the connector with a suitable material

which will exclude dirt and moisture,

preventing the corrosion from occurring

again; a Ford dealer may be able to

recommend a suitable product.

7 Check the condition of the battery

Every 10 000 miles or 12 months1•13

5.2 Hoses, like drivebelts, have a habit of

failing at the worst possible time - to

prevent the inconvenience of a blown radiator or heater hose, inspect them

carefully as shown here

1

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 15 of 296

connections - remake the connections or

renew the leads if a fault is found. Use the

same techniques to ensure that all earth

points in the engine compartment provide

good electrical contact through clean, metal-

to-metal joints, and that all are securely

fastened. (In addition to the earth connection

at the engine lifting eye, and that from the

transmission to the body/battery, there are

others in various places, so check carefully).

8Refer to Section 21 for details of spark plug

(HT) lead checks.

7 Valve clearance adjustment

2

Refer to Chapter 2, Part A.

8 Manual transmission oil level check

1

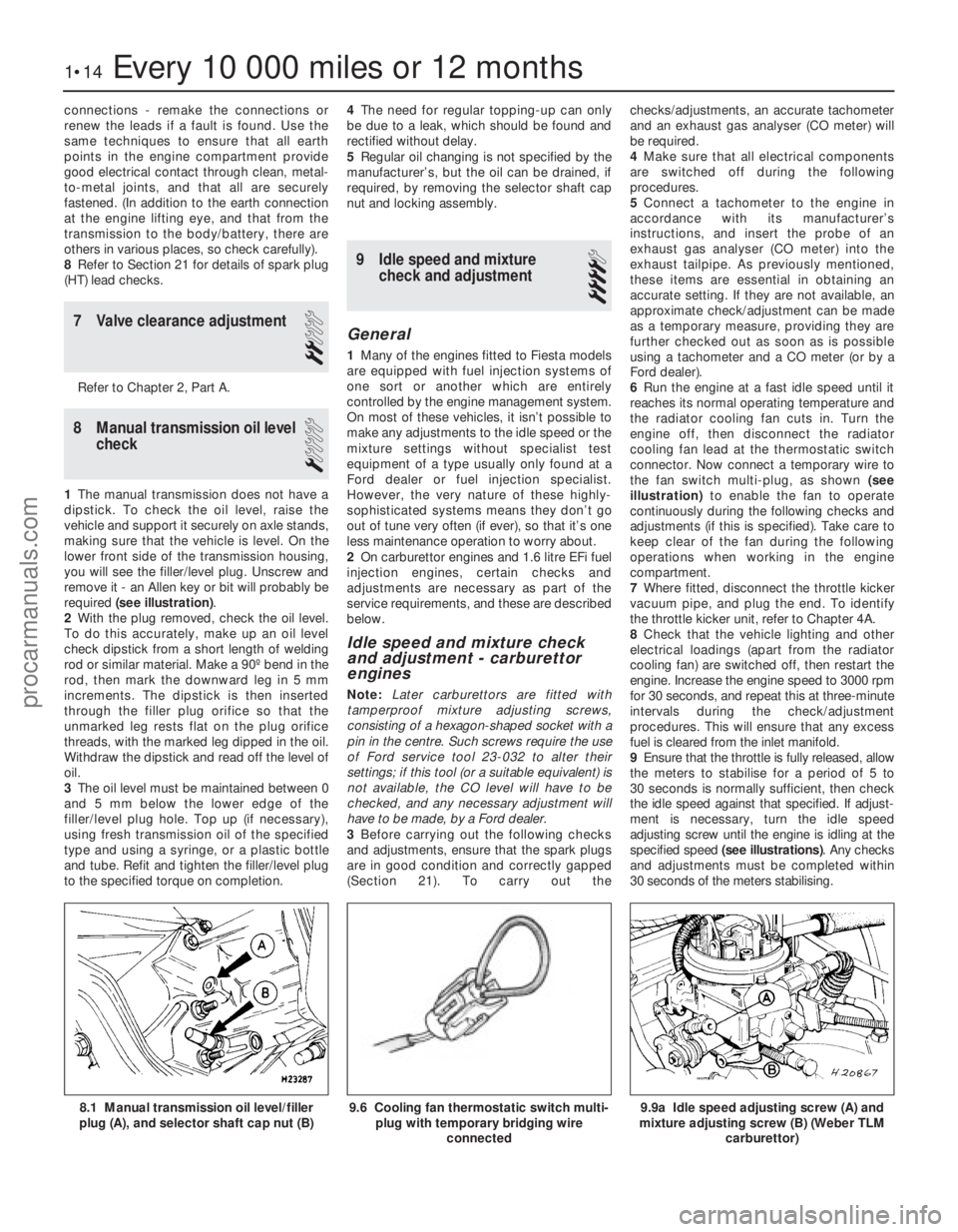

1The manual transmission does not have a

dipstick. To check the oil level, raise the

vehicle and support it securely on axle stands,

making sure that the vehicle is level. On the

lower front side of the transmission housing,

you will see the filler/level plug. Unscrew and

remove it - an Allen key or bit will probably be

required (see illustration) .

2 With the plug removed, check the oil level.

To do this accurately, make up an oil level

check dipstick from a short length of welding

rod or similar material. Make a 90º bend in the

rod, then mark the downward leg in 5 mm

increments. The dipstick is then inserted

through the filler plug orifice so that the

unmarked leg rests flat on the plug orifice

threads, with the marked leg dipped in the oil.

Withdraw the dipstick and read off the level of

oil.

3 The oil level must be maintained between 0

and 5 mm below the lower edge of the

filler/level plug hole. Top up (if necessary),

using fresh transmission oil of the specified

type and using a syringe, or a plastic bottle

and tube. Refit and tighten the filler/level plug

to the specified torque on completion. 4

The need for regular topping-up can only

be due to a leak, which should be found and

rectified without delay.

5 Regular oil changing is not specified by the

manufacturer’s, but the oil can be drained, if

required, by removing the selector shaft cap

nut and locking assembly.

9 Idle speed and mixture check and adjustment

4

General

1Many of the engines fitted to Fiesta models

are equipped with fuel injection systems of

one sort or another which are entirely

controlled by the engine management system.

On most of these vehicles, it isn’t possible to

make any adjustments to the idle speed or the

mixture settings without specialist test

equipment of a type usually only found at a

Ford dealer or fuel injection specialist.

However, the very nature of these highly-

sophisticated systems means they don’t go

out of tune very often (if ever), so that it’s one

less maintenance operation to worry about.

2 On carburettor engines and 1.6 litre EFi fuel

injection engines, certain checks and

adjustments are necessary as part of the

service requirements, and these are described

below.

Idle speed and mixture check

and adjustment - carburettor

engines

Note: Later carburettors are fitted with

tamperproof mixture adjusting screws,

consisting of a hexagon-shaped socket with a

pin in the centre. Such screws require the use

of Ford service tool 23-032 to alter their

settings; if this tool (or a suitable equivalent) is

not available, the CO level will have to be

checked, and any necessary adjustment will

have to be made, by a Ford dealer.

3 Before carrying out the following checks

and adjustments, ensure that the spark plugs

are in good condition and correctly gapped

(Section 21). To carry out the checks/adjustments, an accurate tachometer

and an exhaust gas analyser (CO meter) will

be required.

4

Make sure that all electrical components

are switched off during the following

procedures.

5 Connect a tachometer to the engine in

accordance with its manufacturer’s

instructions, and insert the probe of an

exhaust gas analyser (CO meter) into the

exhaust tailpipe. As previously mentioned,

these items are essential in obtaining an

accurate setting. If they are not available, an

approximate check/adjustment can be made

as a temporary measure, providing they are

further checked out as soon as is possible

using a tachometer and a CO meter (or by a

Ford dealer).

6 Run the engine at a fast idle speed until it

reaches its normal operating temperature and

the radiator cooling fan cuts in. Turn the

engine off, then disconnect the radiator

cooling fan lead at the thermostatic switch

connector. Now connect a temporary wire to

the fan switch multi-plug, as shown (see

illustration) to enable the fan to operate

continuously during the following checks and

adjustments (if this is specified). Take care to

keep clear of the fan during the following

operations when working in the engine

compartment.

7 Where fitted, disconnect the throttle kicker

vacuum pipe, and plug the end. To identify

the throttle kicker unit, refer to Chapter 4A.

8 Check that the vehicle lighting and other

electrical loadings (apart from the radiator

cooling fan) are switched off, then restart the

engine. Increase the engine speed to 3000 rpm

for 30 seconds, and repeat this at three-minute

intervals during the check/adjustment

procedures. This will ensure that any excess

fuel is cleared from the inlet manifold.

9 Ensure that the throttle is fully released, allow

the meters to stabilise for a period of 5 to

30 seconds is normally sufficient, then check

the idle speed against that specified. If adjust-

ment is necessary, turn the idle speed

adjusting screw until the engine is idling at the

specified speed (see illustrations) . Any checks

and adjustments must be completed within

30 seconds of the meters stabilising.

1•14Every 10 000 miles or 12 months

9.9a Idle speed adjusting screw (A) and

mixture adjusting screw (B) (Weber TLM

carburettor)9.6 Cooling fan thermostatic switch multi-plug with temporary bridging wire

connected8.1 Manual transmission oil level/filler

plug (A), and selector shaft cap nut (B)

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 16 of 296

10If adjustment to the mixture is required,

the tamperproof cap will need to be removed

from the carburettor to gain access to the

mixture screw. To do this, first unclip the fuel

trap from the side of the air cleaner unit, then

remove the air cleaner unit, ensuring that the

crankcase ventilation trap remains connected.

Prise free the tamperproof cap (with the aid of

a thin-bladed screwdriver), then with the

vacuum and emissions control pipes

connected to it, relocate the air cleaner unit

temporarily into position.

11 Turn the mixture adjustment screw

clockwise to weaken the mixture, or

anti-clockwise to richen it, until the CO

reading is as given in the Specifications. If a

CO meter is not being used, weaken the

mixture as described, then enrich the mixture until the maximum engine speed is obtained,

consistent with even running.

12

If necessary, re-adjust the idle speed then

check the CO reading again. Repeat as

necessary until both the idle speed and CO

reading are correct.

13 Where required by law (as in some

European countries), fit a new tamperproof

cap to the mixture adjustment screw.

14 Disconnect the tachometer and the CO

meter, refit the air cleaner unit, and reconnect

the fan switch lead to complete.

Base idle speed and mixture

check and adjustment - 1.6 litre

EFi engines

15 Proceed as described above in

paragraphs 3 to 6 inclusive, then continue as

follows.

16 Run the engine at a fast idle speed until it

reaches its normal operating temperature and

the cooling fan cuts in. Check the CO content

of the exhaust, and compare it against the

specified reading. If the CO content reading is

incorrect, it can be adjusted by prising free

the tamperproof cap for access to the mixture

CO adjustment screw (see illustration), and

turning the screw in the required direction to

suit.

17 The operational idle speed is controlled by

the EEC IV engine management module and is

not adjustable. However, if the base idle

speed is incorrect, the module will not have an

accurate datum point from which to establish the normal operational idle speed. If idle

problems have been experienced, the base

idle speed should be checked as follows.

18

Disconnect the multi-plug from the idle

speed control valve and increase the engine

speed to 2000 rpm, hold it at that speed for

30 seconds, then fully release the throttle and

check if the base idle speed registered is as

specified.

19 If adjustment is necessary, prise free the

tamperproof plug using a suitable small

screwdriver to gain access to the base idle

speed adjustment screw in the throttle body.

Turn the screw in the required direction to

adjust the base idle speed to the specified

amount. Turning the screw anti-clockwise

increases the idle speed (see illustration).

20 Increase the engine speed to 2000 rpm

again, hold it at that speed for 30 seconds,

then fully release the throttle once more.

Check and further adjust the base idle speed

if required, then fit a new tamperproof plug

into position.

21 Reconnect the idle speed control valve

multi-plug and check that the engine speed

briefly rises to about 900 rpm, then drops

down to the specified normal idle speed.

22 On completion, disconnect the

tachometer and the CO meter, but continue

running the engine at idle speed for a period

of about five minutes, to enable the engine

management module to relearn its values

before switching it off.

10 Steering, suspension and roadwheel check

2

Front suspension and steering

check

1Chock the rear wheels then jack up the

front of the car and support it on axle stands

(see “Jacking and Vehicle Support” ).

2 Visually inspect the balljoint dust covers

and the steering gear gaiters for splits, chafing

or deterioration (see illustrations) . Any wear

of these components will cause loss of

Every 10 000 miles or 12 months1•15

9.9d Idle speed mixture adjusting

screw (A) and idle speed adjusting screw (B) (Weber TLD carburettor)9.9c Idle speed mixture adjusting

screw (A) and idle speed adjusting screw (B) (Weber DFTM carburettor)9.9b Idle speed adjusting screw (A) and

mixture adjusting screw (B) (Weber TLDM carburettor)

10.2a Check the condition of the track rodend balljoint dust cover (arrowed)9.19 Base idle speed adjustment screw(arrowed) on the 1.6 litre EFi engine

9.16 Adjusting the idle mixture CO content on the 1.6 litre EFi engine

1

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 23 of 296

the corrosion which would otherwise occur

as the corrosion inhibitors become progress-

ively less effective. Always use an ethylene

glycol-based antifreeze which is suitable for

use in mixed-metal cooling systems.

20If the antifreeze used is to Ford’s

specification, the levels of protection it affords

are indicated in the Specifications Section of

this Chapter. To give the recommended

standard mixture ratio for this antifreeze, 40%

(by volume) of antifreeze must be mixed with

60% of clean, soft water; if you are using any

other type of antifreeze, follow its

manufacturer’s instructions to achieve the

correct ratio. It is best to make up slightly

more than the system’s specified capacity, so

that a supply is available for subsequent

topping-up.

21 Before adding antifreeze, the cooling

system should be completely drained,

preferably flushed, and all hoses checked for

condition and security. As noted earlier, fresh

antifreeze will rapidly find any weaknesses in

the system.

22 After filling with antifreeze, a label should

be attached to the expansion tank, stating the

type and concentration of antifreeze used,

and the date installed. Any subsequent

topping-up should be made with the same

type and concentration of antifreeze. If

topping-up using antifreeze to Ford’s

specification, note that a 50/50 mixture is

permissible, purely for convenience.

23 Do not use engine antifreeze in the

windscreen/tailgate washer system, as it will

damage the vehicle’s paintwork. A

screenwash additive should be added to the

washer system in its maker’s recommended

quantities.

Antifreeze - notes on renewal

24 Ford state that, where antifreeze to Ford

specification ESD-M97B-49-A is used, it will

last the lifetime of the vehicle. This is subject

to it being used in the recommended

concentration, unmixed with any other type of

antifreeze or additive, and topped-up when

necessary using only that antifreeze mixed 50/50 with clean water. If any other type of

antifreeze is added, the lifetime guarantee no

longer applies; to restore the lifetime

protection, the system must be drained and

thoroughly reverse-flushed before fresh

coolant mixture is poured in.

25

If the vehicle’s history (and therefore the

quality of the antifreeze in it) is unknown,

owners who wish to follow Ford’s

recommendations are advised to drain and

thoroughly reverse-flush the system before

refilling with fresh coolant mixture. If the

appropriate quality of antifreeze is used, the

coolant can then be left for the life of the

vehicle.

26 If any antifreeze other than Ford’s is to be

used, the coolant must be renewed at regular

intervals to provide an equivalent degree of

protection; the conventional recommendation

is to renew the coolant every two or three

years.

27 The above assumes the use of a mixture

(in exactly the specified concentration) of

clean, soft water and of antifreeze to Ford’s

specification or equivalent. It is also assumed

that the cooling system is maintained in a

scrupulously-clean condition, by ensuring that

only clean coolant is added on topping-up,

and by thorough reverse-flushing whenever

the coolant is drained.

General cooling system checks

28 The engine should be cold for the cooling

system checks, so perform the following

procedure before driving the vehicle, or

after it has been shut off for at least three

hours.

29 Remove the expansion tank filler cap, and

clean it thoroughly inside and out with a rag.

Also clean the filler neck on the expansion

tank. The presence of rust or corrosion in the

filler neck indicates that the coolant should be

changed. The coolant inside the expansion

tank should be relatively clean and

transparent. If it is rust-coloured, drain and

flush the system, and refill with a fresh coolant

mixture.

30 Carefully check the radiator hoses and heater hoses along their entire length; renew

any hose which is cracked, swollen or

deteriorated (see Section 5).

31

Inspect all other cooling system

components (joint faces, etc.) for leaks. A leak

in the cooling system will usually show up as

white- or rust-coloured deposits on the area

adjoining the leak. Where any problems of this

nature are found on system components,

renew the component or gasket with

reference to Chapter 3.

32 Clean the front of the radiator with a soft

brush to remove all insects, leaves, etc,

embedded in the radiator fins. Be careful not

to damage the radiator fins, or cut your fingers

on them.

24 Air cleaner element renewal

1

1 The air cleaner filter element is located in

the air cleaner assembly mounted either on

top of the carburettor or CFi unit, or on the

left-hand or right-hand side of the engine

compartment at the front. Remove the air

cleaner lid as follows according to type.

Carburettor and CFi fuel

injection models

2 Undo the two or three retaining screws on

the top of the air cleaner lid (see illustration).

3 Release the clips, and lift off the air cleaner

cover (see illustration) .

EFi fuel injection models

4If the idle speed control valve is

mounted on the air cleaner, disconnect the

multi-plug and the air bypass hose from the

valve.

5 Disconnect the flexible hose between the

air cleaner lid and the air inlet duct or

turbocharger air intake.

6 Release the retaining clips and lift off the air

cleaner lid (see illustration) .

1•22Every 30 000 miles or three years

24.6 On EFi fuel injection engines, release

the retaining clips and lift off the air

cleaner lid24.3 . . . then spring back the clips and lift of the lid24.2 On carburettor and CFi fuel injectionengines, undo the air cleaner lid retaining

screws . . .

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 25 of 296

engine idling, the hot-air inlet is open to allow

warm air from the exhaust manifold area to

enter the air cleaner. If the flap operates as

described, it is functioning correctly (see

illustration) .

21 If the flap fails to operate as described,

check the condition of the vacuum pipe and

its connections, and check that the flap valve

has not seized. If these are in order, either the

temperature sensor or vacuum actuator is

faulty, and a new air cleaner assembly must

be obtained. Refit the main air duct on

completion.

25 Emission control system

check

1

General

1Of the emission control systems that may

be fitted, only the crankcase ventilation

system and the evaporative emission control

systems require regular checking, and even

then, the components of these systems

require minimal attention.

2 Should it be felt that the other systems are

not functioning correctly, the advice of a

dealer should be sought.

Crankcase ventilation system

3 The function of the crankcase ventilation

system is to reduce the emission of unburned

hydrocarbons from the crankcase, and to

minimise the formation of oil sludge. By

ensuring that a depression is created in the

crankcase under most operating conditions,

particularly at idle, and by positively inducing

fresh air into the system, the oil vapours and

“blow-by” gases collected in the crankcase

are drawn from the crankcase, through the air

cleaner or oil separator, into the inlet tract, to

be burned by the engine during normal

combustion.

4 On HCS engines, the system consists of a

vented oil filler cap (with an integral mesh

filter) and a hose connecting it to the oil

separator/engine breather valve connector on

the underside of the air cleaner housing. A further hose leads from the adapter/filter to

the inlet manifold.

5

On CVH engines, a closed-circuit type

crankcase ventilation system is used, the

function of which is basically the same as that

described for the HCS engine types, but the

breather hose connects directly to the rocker

cover. A separate filter is fitted in the hose to

the rocker cover in certain applications (see

illustration) .

6 The system fitted to the PTE engines is

similar to that used on the earlier (CVH)

engines on which these engines are based,

but with revisions to the hose arrangement to

suit the remotely sited air cleaner and fuel

injection system layout.

7 On Zetec engines, the crankcase ventilation

system main components are the oil

separator mounted on the front (radiator) side

of the cylinder block/crankcase, and the

Positive Crankcase Ventilation (PCV) valve set

in a rubber grommet in the separator’s left-

hand upper end. The associated pipework

consists of a crankcase breather pipe and two

flexible hoses connecting the PCV valve to a

union on the left-hand end of the inlet

manifold, and a crankcase breather hose

connecting the cylinder head cover to the air

cleaner assembly. A small foam filter in the

air cleaner prevents dirt from being drawn

directly into the engine.

8 Check that all components of the system

are securely fastened, correctly routed (with

no kinks or sharp bends to restrict flow) and in

sound condition; renew any worn or damaged

components.

9 On HCS engines, remove and inspect the

oil filler cap to ensure that it is in good

condition, and not blocked up with sludge.

10 Disconnect the hoses at the cap, and

clean the cap if necessary by brushing the

inner mesh filter with petrol, and blowing

through with light pressure from an air line.

Renew the cap if it is badly congested.

11 If oil leakage is noted, disconnect the

various hoses and pipes, and check that all

are clear and unblocked. Remove the air

cleaner lid, and check that the hose from the

cylinder head cover to the air cleaner housing

is clear and undamaged. 12

Where fitted, the PCV valve is designed to

allow gases to flow out of the crankcase only,

so that a depression is created in the

crankcase under most operating conditions,

particularly at idle. Therefore, if either the oil

separator or the PCV valve are thought to be

blocked, they must be renewed (see Chap-

ter 4E). In such a case, however, there is

nothing to be lost by attempting to flush out

the blockage using a suitable solvent. The

PCV valve should rattle when shaken.

13 While the air filter element is removed (see

Section 24), wipe out the housing, and on

Zetec engines, withdraw the small foam filter

from its location in the rear right-hand corner

of the housing (see illustration) . If the foam is

badly clogged with dirt or oil, it must be

cleaned by soaking it in a suitable solvent,

and allowed to dry before being refitted.

Evaporative emission control

systems

14 Refer to the checks contained in Chap-

ter 4E.

26 Automatic transmission fluid renewal

1

1The automatic transmission fluid should

only be changed when the transmission is

cold.

2 Position the vehicle over an inspection pit,

on vehicle ramps, or jack it up and securely

support it on axle stands, but make sure that

it is level.

3 Place a suitable container beneath the drain

plug on the transmission sump pan. Remove

the transmission fluid dipstick to speed up the

draining operation.

4 Thoroughly clean the area around the drain

plug in the transmission sump pan, then

unscrew the plug and allow the fluid to drain

into the container.

5 When all the fluid has drained (this may take

quite some time) clean the drain plug, then

refit it together with a new seal and tighten it

securely.

6 Place a funnel with a fine mesh screen in

the dipstick tube, and fill the transmission with

1•24Every 30 000 miles or three years

25.13 The crankcase ventilation system foam filter is located in the air cleaner housing on Zetec engines25.5 Crankcase ventilation system filter on CVH engines

24.20 Air cleaner inlet and flap valve onthe CVH engine

A Flap open (cool air inlet closed)

B Warm air inlet

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 26 of 296

the specified type of fluid. It is essential that

no dirt is introduced into the transmission

during this operation.

7Depending on the extent to which the fluid

was allowed to drain, it is possible that the

amount of fluid required when filling the

transmission may be more than the specified

amount (see “Lubricants, fluids and tyre

pressures” ). However, due to fluid remaining in

the system, it is more likely that less than the

specified amount will be required. Add about

half the specified amount, then run the engine

up to its normal operating temperature and

check the level on the dipstick. When the level

approaches the maximum mark, proceed as

detailed in Section 20 to check the level and

complete the final topping-up as described.

27 Handbrake adjustment

3

1 Chock the front wheels then jack up the

rear of the car and support it on axle stands

(see “Jacking and Vehicle Support” ). Fully

release the handbrake.

2 Check that the handbrake cables are

correctly routed and secured by the retaining

clips at the appropriate points under the vehicle.

3 The handbrake is checked for adjustment

by measuring the amount of movement

possible in the handbrake adjuster plungers.

These are located on the inside face of each

rear brake backplate (see illustration) . Thetotal movement of the two plungers combined

should be between 0.5 and 2.0 mm. If the

movement measured is outside of this

tolerance, the handbrake is in need of

adjustment. Adjustment is made altering the

position of the in-line cable adjuster sleeve.

4

When adjustment to the handbrake is

necessary, a new adjustment sleeve locking

pin will be required, and this must therefore

be obtained before making the adjustment.

5 To adjust the handbrake, first ensure that it

is fully released, then firmly apply the

footbrake a few times to ensure that the rear

brake adjustment is taken up by the automatic

adjusters. Extract the locking pin from

the adjuster sleeve (see illustration), then

turn the sleeve to set the combined move-

ment of the plungers within the tolerance range specified (0.5 to 2.0 mm). Turn the

locking nut by hand as tight as is possible

(two clicks) against the adjustment sleeve.

Now grip the locknut with a suitable wrench,

and turn it a further two clicks (maximum).

6

Secure the adjustment by inserting the new

lock pin.

7 Check that the operation of the handbrake

is satisfactory, then lower the vehicle to the

ground, apply the handbrake and remove the

chocks from the front wheels.

28 Front wheel alignment check

4

Refer to Chapter 10, Section 29.

Every 30 000 miles or three years1•25

27.5 Handbrake cable adjuster locking

pin (A), locknut (B) and adjuster sleeve (C)27.3 Handbrake adjustment plunger

located on the inside face of each rear brake backplate

1

1595Ford Fiesta Remake

Every 40 000 miles

29 Timing belt renewal

4

Refer to Chapter 2, Part B or C as

applicable.

Every 60 000 miles

30 Fuel filter renewal

1

Warning: Petrol is extremely

flammable, so extra precautions

must be taken when working on

any part of the fuel system. Do

not smoke, or allow open flames or bare

light bulbs, near the work area. Also, do

not work in a garage if a natural gas-type appliance with a pilot light is present.

While performing any work on the fuel system, wear safety glasses, and have a

suitable (Class B) fire extinguisher on

hand. If you spill any fuel on your skin,

rinse it off immediately with soap and

water.

1

On fuel injection engines, an in-line fuel

filter is provided in the fuel pump outlet line.

The filter is located in the engine compartment

either below and behind the battery, or on the

left-hand side of the engine compartment

bulkhead. The renewal procedure is the same

for both locations. The filter performs a vital

role in keeping dirt and other foreign matter

out of the fuel system, and so must be renewed at regular intervals, or whenever you

have reason to suspect that it may be

clogged. It is always unpleasant working

under a vehicle - pressure-washing or hosing

clean the underbody in the filter’s vicinity will

make working conditions more tolerable, and

will reduce the risk of getting dirt into the fuel

system.

2

Depressurise the fuel system as described

in the relevant Part of Chapter 4.

3 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1), then position

a suitable container beneath the fuel filter to

catch escaping fuel. Have a rag handy to soak

procarmanuals.com

http://vnx.su