instrument cluster FORD FIESTA 1989 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 231 of 296

31Remove the seat belt upper anchor bolt

cover and undo the bolt.

32 Carefully prise up the seat belt guide from

its trim panel location, and remove it from the

seat belt. Allow the seat belt to retract through

the trim panel, clamping a clothes peg, or

similar item, onto its end to prevent it being

fully wound into the retractor.

33 Manoeuvre the trim panel out from under

the scuff plate, slackening or removing the

rearward scuff plate retaining screws if

necessary.

Refitting

34 Engage the trim panel under the scuff

plate, and refit and tighten the scuff plate

retaining screws as necessary.

35 Pull the seat belt through the trim panel,

refit the guide and press the panel onto the

body to re-engage the trim clips.

36 Refit the upper seat belt anchor,

tightening the bolt to the specified torque, and

refit its cover. Ensure that the anchor is free to

rotate.

37 Refit the plastic stud and the screw to the

lower and upper rear corners of the trim,

respectively.

38 Refit the seat belt to the slide bar, then

refit the slide bar by reversing the method of

removal. Ensure that the seat belt is not

twisted as it is located on the slide bar, and

that the bolt is tightened to the specified

torque.

39 Refit the rear seat cushion by reversing

the method of removal.

40 Press the door aperture weatherstrip back

into position.

Load compartment trim panels

(Courier models)

Removal

41 Using either a trim clip releasing tool or a

screwdriver with a broad flat blade, and

protecting the paintwork and trim with a layer

of rag, extract the clips securing the panel and

withdraw it.

Refitting

42 Refitting is the reverse of the removal

procedure.

43 Parcel shelf support/

loudspeaker housing -

removal and refitting

3

Removal

1 Remove the rear seat belt and retractor unit

from the appropriate side of the vehicle, as

described in Section 41.

2 Disconnect the luggage compartment

(courtesy) light, where fitted, by prising the

light assembly from its location using a thin

flat-bladed screwdriver, then twist the

bulbholder anti-clockwise to remove.

3 Detach the loudspeaker, where fitted, by

removing its retaining screws, disengaging its

locating tags and disconnecting its multi-plug. 4

Fold the seat backrest forward. Remove the

parcel shelf support/rear loudspeaker housing

retaining screws, then manoeuvre it out from

under the quarter panel trim as necessary, to

clear the seat backrest catch striker pin.

Refitting

5 Refitting is a reversal of the removal

procedure.

44 Passenger grab handle -

removal and refitting

1

Removal

1 Carefully prise up the trim flaps on either

end of the handle to expose the two mounting

screws.

2 Undo the mounting screws and remove the

grab handle.

Refitting

3 Refitting is the reverse procedure to

removal.

45 Centre console -

removal and refitting

1

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Carefully prise up the console switches, as

necessary, using a flat-bladed screwdriver,

then disconnect their multi-plugs.

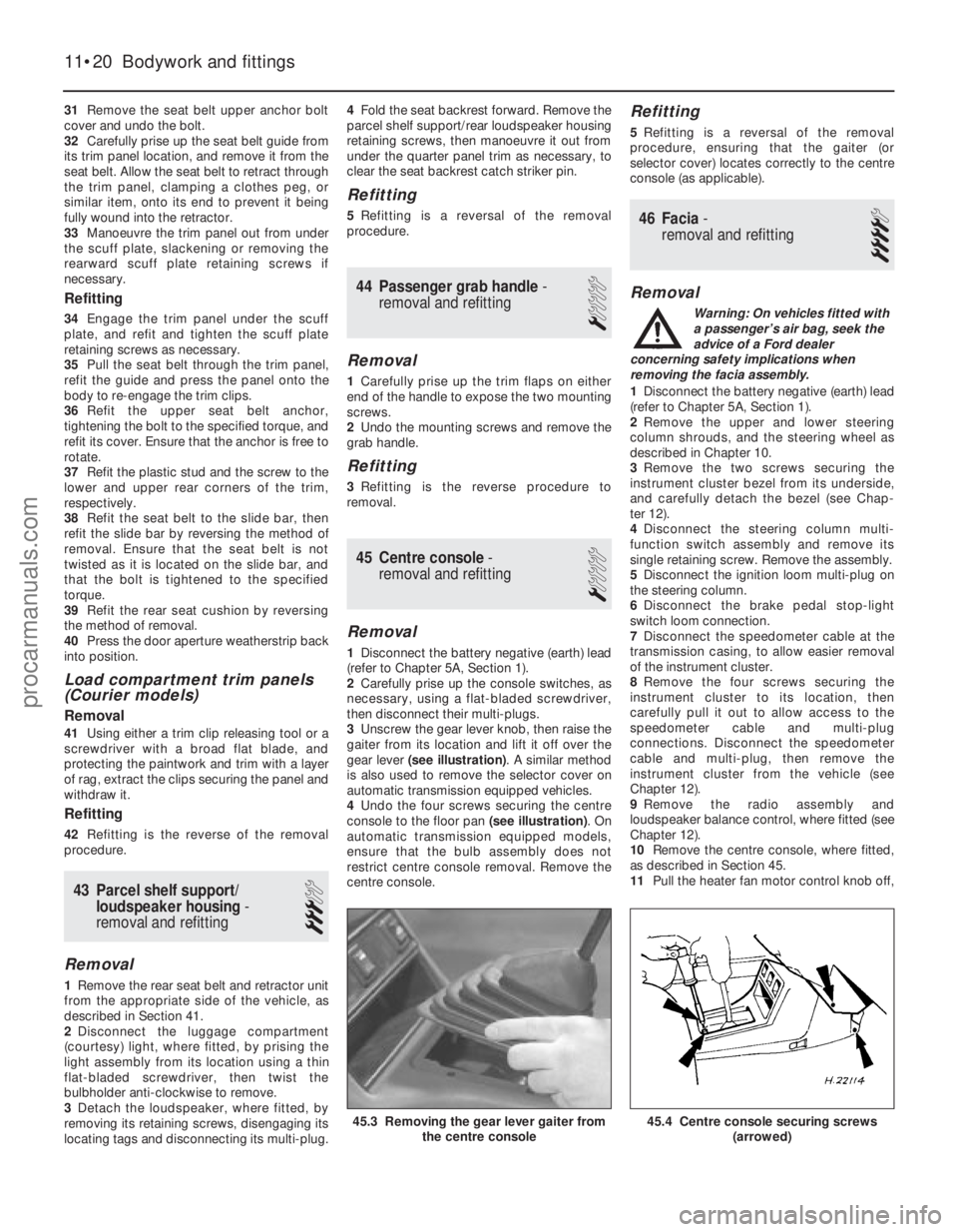

3 Unscrew the gear lever knob, then raise the

gaiter from its location and lift it off over the

gear lever (see illustration) . A similar method

is also used to remove the selector cover on

automatic transmission equipped vehicles.

4 Undo the four screws securing the centre

console to the floor pan (see illustration). On

automatic transmission equipped models,

ensure that the bulb assembly does not

restrict centre console removal. Remove the

centre console.

Refitting

5 Refitting is a reversal of the removal

procedure, ensuring that the gaiter (or

selector cover) locates correctly to the centre

console (as applicable).

46 Facia - removal and refitting

4

Removal

Warning: On vehicles fitted with

a passenger’s air bag, seek the

advice of a Ford dealer

concerning safety implications when

removing the facia assembly.

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the upper and lower steering

column shrouds, and the steering wheel as

described in Chapter 10.

3 Remove the two screws securing the

instrument cluster bezel from its underside,

and carefully detach the bezel (see Chap-

ter 12).

4 Disconnect the steering column multi-

function switch assembly and remove its

single retaining screw. Remove the assembly.

5 Disconnect the ignition loom multi-plug on

the steering column.

6 Disconnect the brake pedal stop-light

switch loom connection.

7 Disconnect the speedometer cable at the

transmission casing, to allow easier removal

of the instrument cluster.

8 Remove the four screws securing the

instrument cluster to its location, then

carefully pull it out to allow access to the

speedometer cable and multi-plug

connections. Disconnect the speedometer

cable and multi-plug, then remove the

instrument cluster from the vehicle (see

Chapter 12).

9 Remove the radio assembly and

loudspeaker balance control, where fitted (see

Chapter 12).

10 Remove the centre console, where fitted,

as described in Section 45.

11 Pull the heater fan motor control knob off,

11•20 Bodywork and fittings

45.4 Centre console securing screws

(arrowed)45.3 Removing the gear lever gaiter fromthe centre console

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 232 of 296

then move the air distribution and

temperature controls fully to the right. Unclip

and remove the heater slide facia towards the

left-hand side of the vehicle, removing the

slide control knobs only as necessary, and

disconnecting its bulbholder (bayonet type) as

it is withdrawn.

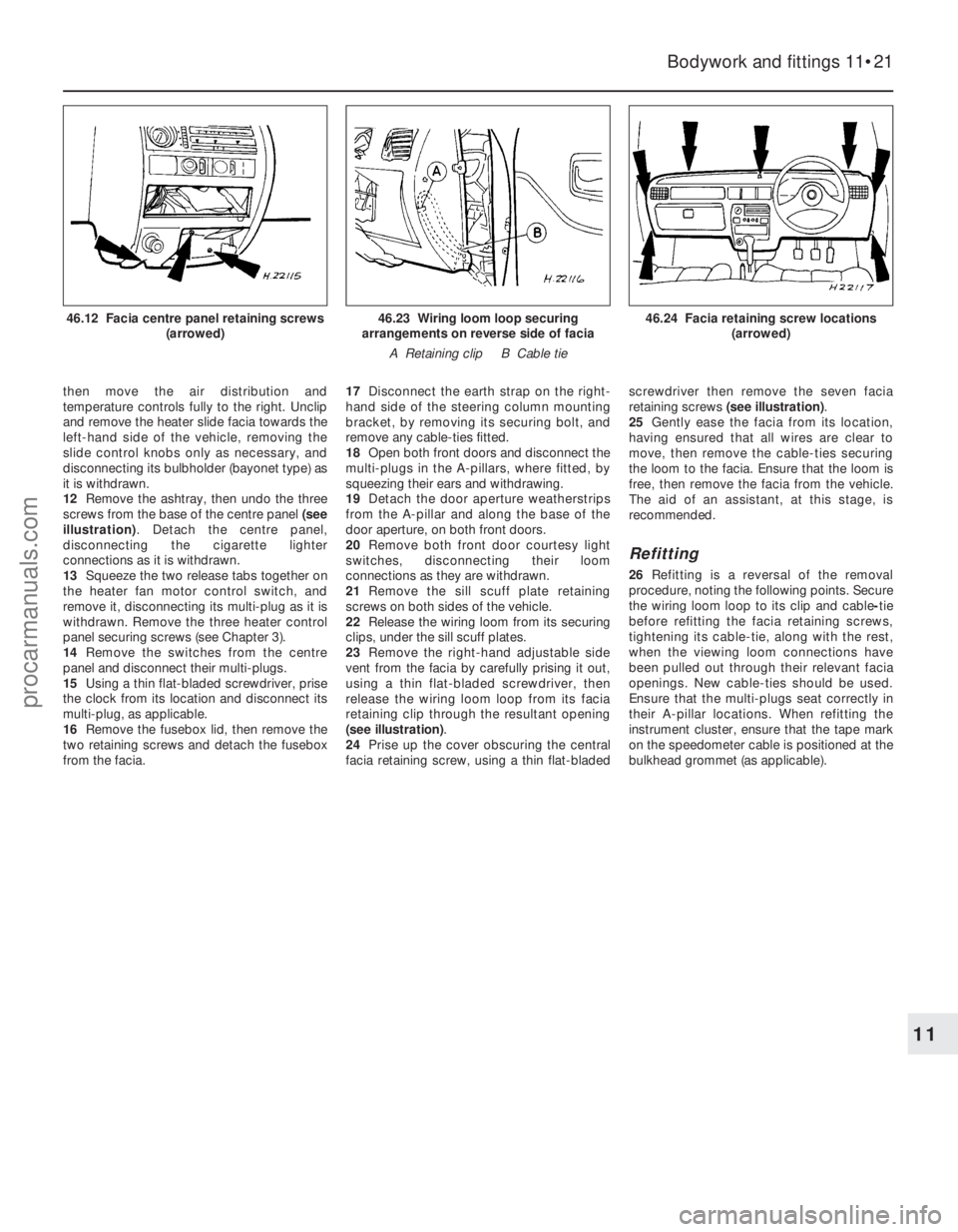

12Remove the ashtray, then undo the three

screws from the base of the centre panel (see

illustration) . Detach the centre panel,

disconnecting the cigarette lighter

connections as it is withdrawn.

13 Squeeze the two release tabs together on

the heater fan motor control switch, and

remove it, disconnecting its multi-plug as it is

withdrawn. Remove the three heater control

panel securing screws (see Chapter 3).

14 Remove the switches from the centre

panel and disconnect their multi-plugs.

15 Using a thin flat-bladed screwdriver, prise

the clock from its location and disconnect its

multi-plug, as applicable.

16 Remove the fusebox lid, then remove the

two retaining screws and detach the fusebox

from the facia. 17

Disconnect the earth strap on the right-

hand side of the steering column mounting

bracket, by removing its securing bolt, and

remove any cable-ties fitted.

18 Open both front doors and disconnect the

multi-plugs in the A-pillars, where fitted, by

squeezing their ears and withdrawing.

19 Detach the door aperture weatherstrips

from the A-pillar and along the base of the

door aperture, on both front doors.

20 Remove both front door courtesy light

switches, disconnecting their loom

connections as they are withdrawn.

21 Remove the sill scuff plate retaining

screws on both sides of the vehicle.

22 Release the wiring loom from its securing

clips, under the sill scuff plates.

23 Remove the right-hand adjustable side

vent from the facia by carefully prising it out,

using a thin flat-bladed screwdriver, then

release the wiring loom loop from its facia

retaining clip through the resultant opening

(see illustration) .

24 Prise up the cover obscuring the central

facia retaining screw, using a thin flat-bladed screwdriver then remove the seven facia

retaining screws

(see illustration) .

25 Gently ease the facia from its location,

having ensured that all wires are clear to

move, then remove the cable-ties securing

the loom to the facia. Ensure that the loom is

free, then remove the facia from the vehicle.

The aid of an assistant, at this stage, is

recommended.

Refitting

26 Refitting is a reversal of the removal

procedure, noting the following points. Secure

the wiring loom loop to its clip and cable -tie

before refitting the facia retaining screws,

tightening its cable-tie, along with the rest,

when the viewing loom connections have

been pulled out through their relevant facia

openings. New cable-ties should be used.

Ensure that the multi-plugs seat correctly in

their A-pillar locations. When refitting the

instrument cluster, ensure that the tape mark

on the speedometer cable is positioned at the

bulkhead grommet (as applicable).

Bodywork and fittings 11•21

46.24 Facia retaining screw locations (arrowed)46.23 Wiring loom loop securing

arrangements on reverse side of facia

A Retaining clip B Cable tie46.12 Facia centre panel retaining screws (arrowed)

11

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 241 of 296

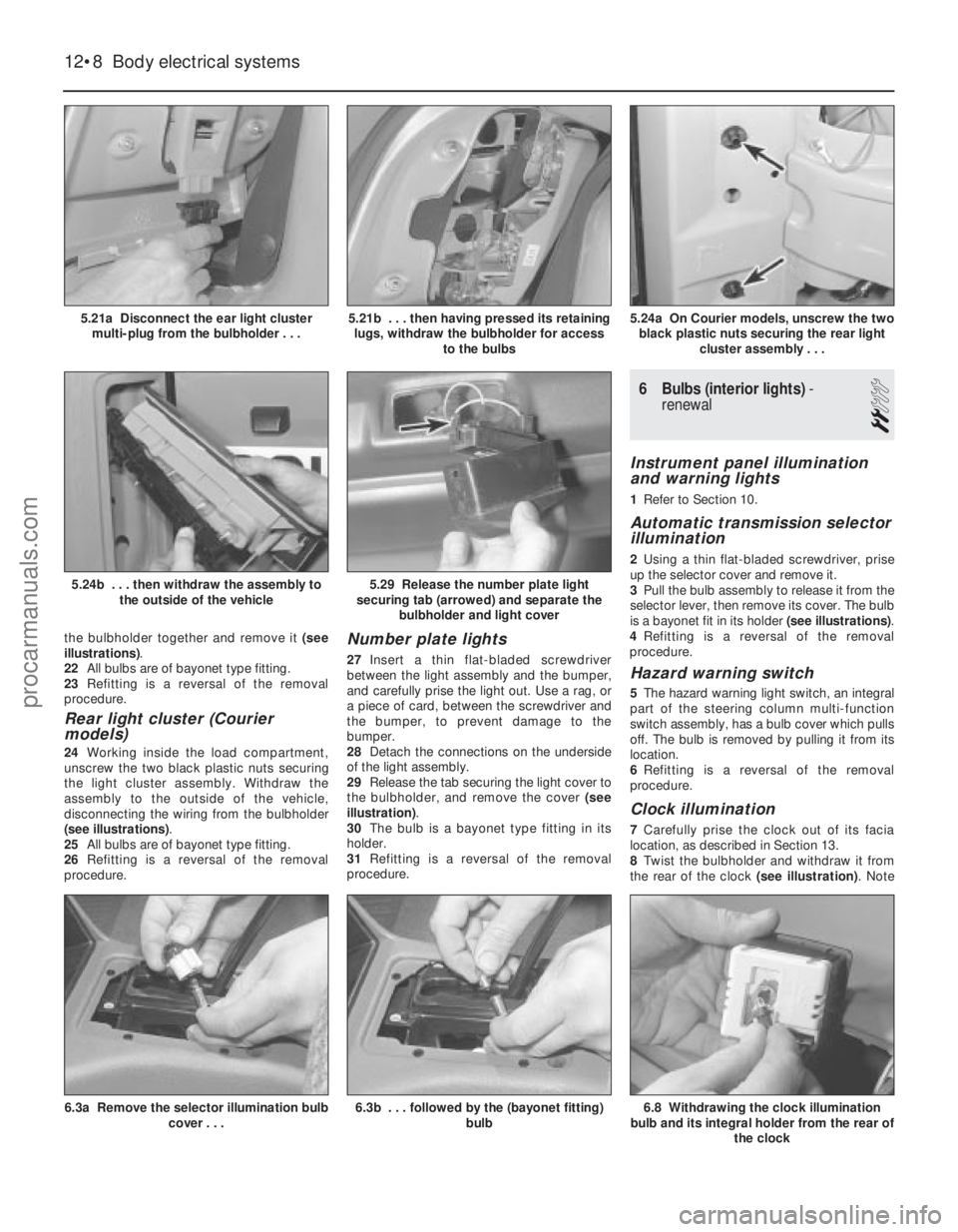

the bulbholder together and remove it (see

illustrations) .

22 All bulbs are of bayonet type fitting.

23 Refitting is a reversal of the removal

procedure.

Rear light cluster (Courier

models)

24 Working inside the load compartment,

unscrew the two black plastic nuts securing

the light cluster assembly. Withdraw the

assembly to the outside of the vehicle,

disconnecting the wiring from the bulbholder

(see illustrations) .

25 All bulbs are of bayonet type fitting.

26 Refitting is a reversal of the removal

procedure.

Number plate lights

27 Insert a thin flat-bladed screwdriver

between the light assembly and the bumper,

and carefully prise the light out. Use a rag, or

a piece of card, between the screwdriver and

the bumper, to prevent damage to the

bumper.

28 Detach the connections on the underside

of the light assembly.

29 Release the tab securing the light cover to

the bulbholder, and remove the cover (see

illustration) .

30 The bulb is a bayonet type fitting in its

holder.

31 Refitting is a reversal of the removal

procedure.

6 Bulbs (interior lights) -

renewal

2

Instrument panel illumination

and warning lights

1 Refer to Section 10.

Automatic transmission selector

illumination

2Using a thin flat-bladed screwdriver, prise

up the selector cover and remove it.

3 Pull the bulb assembly to release it from the

selector lever, then remove its cover. The bulb

is a bayonet fit in its holder (see illustrations).

4 Refitting is a reversal of the removal

procedure.

Hazard warning switch

5 The hazard warning light switch, an integral

part of the steering column multi-function

switch assembly, has a bulb cover which pulls

off. The bulb is removed by pulling it from its

location.

6 Refitting is a reversal of the removal

procedure.

Clock illumination

7 Carefully prise the clock out of its facia

location, as described in Section 13.

8 Twist the bulbholder and withdraw it from

the rear of the clock (see illustration). Note

12•8Body electrical systems

6.8 Withdrawing the clock illumination

bulb and its integral holder from the rear of

the clock6.3b . . . followed by the (bayonet fitting) bulb6.3a Remove the selector illumination bulbcover . . .

5.29 Release the number plate light

securing tab (arrowed) and separate the bulbholder and light cover5.24b . . . then withdraw the assembly to

the outside of the vehicle

5.24a On Courier models, unscrew the twoblack plastic nuts securing the rear light cluster assembly . . .5.21b . . . then having pressed its retaininglugs, withdraw the bulbholder for access to the bulbs5.21a Disconnect the ear light clustermulti-plug from the bulbholder . . .

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 244 of 296

work should therefore be carried out by a

Ford dealer or service station with the

necessary facilities.

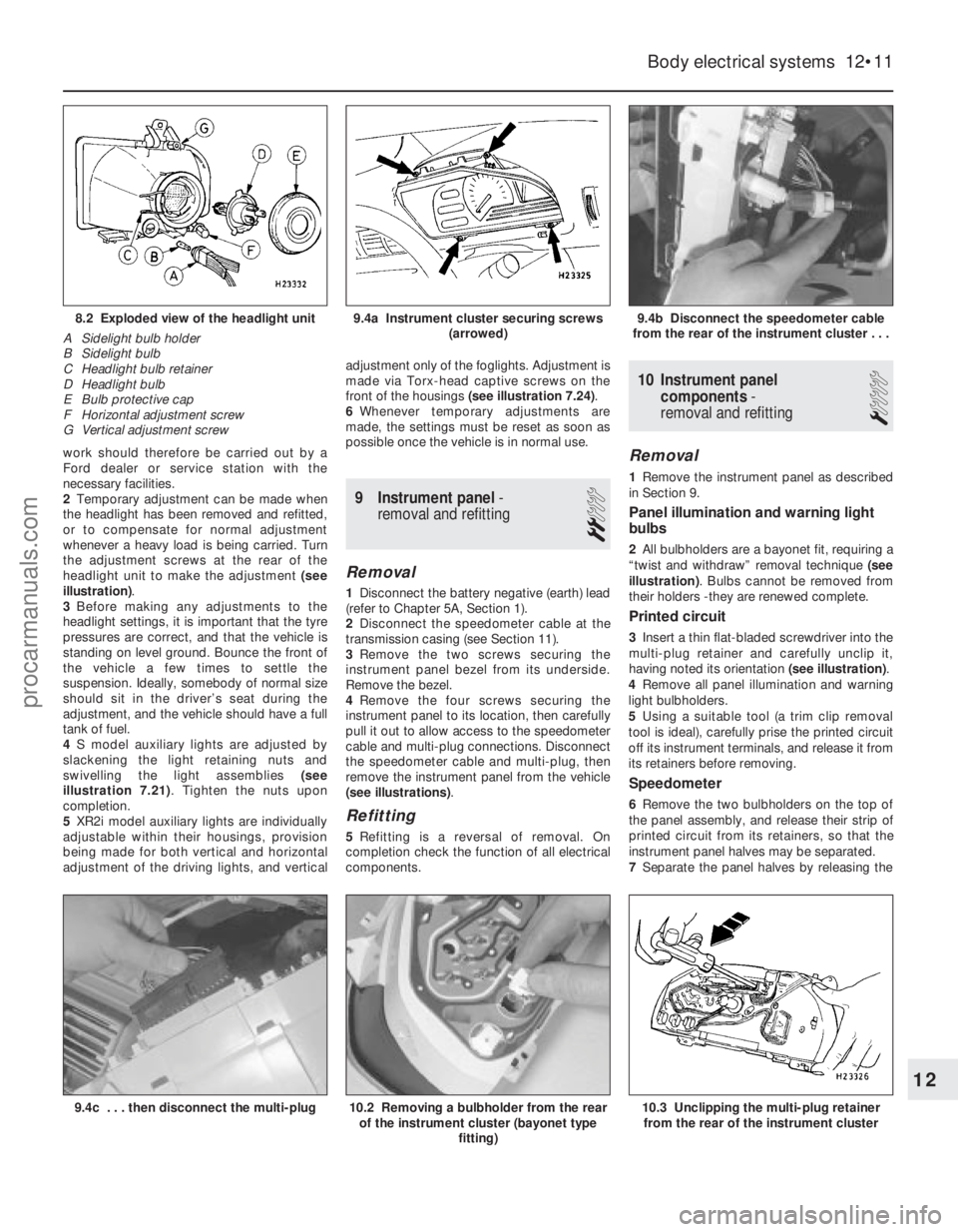

2Temporary adjustment can be made when

the headlight has been removed and refitted,

or to compensate for normal adjustment

whenever a heavy load is being carried. Turn

the adjustment screws at the rear of the

headlight unit to make the adjustment (see

illustration) .

3 Before making any adjustments to the

headlight settings, it is important that the tyre

pressures are correct, and that the vehicle is

standing on level ground. Bounce the front of

the vehicle a few times to settle the

suspension. Ideally, somebody of normal size

should sit in the driver’s seat during the

adjustment, and the vehicle should have a full

tank of fuel.

4 S model auxiliary lights are adjusted by

slackening the light retaining nuts and

swivelling the light assemblies (see

illustration 7.21) . Tighten the nuts upon

completion.

5 XR2i model auxiliary lights are individually

adjustable within their housings, provision

being made for both vertical and horizontal

adjustment of the driving lights, and vertical adjustment only of the foglights. Adjustment is

made via Torx-head captive screws on the

front of the housings

(see illustration 7.24) .

6 Whenever temporary adjustments are

made, the settings must be reset as soon as

possible once the vehicle is in normal use.

9 Instrument panel -

removal and refitting

2

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Disconnect the speedometer cable at the

transmission casing (see Section 11).

3 Remove the two screws securing the

instrument panel bezel from its underside.

Remove the bezel.

4 Remove the four screws securing the

instrument panel to its location, then carefully

pull it out to allow access to the speedometer

cable and multi-plug connections. Disconnect

the speedometer cable and multi-plug, then

remove the instrument panel from the vehicle

(see illustrations) .

Refitting

5Refitting is a reversal of removal. On

completion check the function of all electrical

components.

10 Instrument panel

components -

removal and refitting

1

Removal

1 Remove the instrument panel as described

in Section 9.

Panel illumination and warning light

bulbs

2 All bulbholders are a bayonet fit, requiring a

“twist and withdraw” removal technique (see

illustration) . Bulbs cannot be removed from

their holders -they are renewed complete.

Printed circuit

3 Insert a thin flat-bladed screwdriver into the

multi-plug retainer and carefully unclip it,

having noted its orientation (see illustration).

4 Remove all panel illumination and warning

light bulbholders.

5 Using a suitable tool (a trim clip removal

tool is ideal), carefully prise the printed circuit

off its instrument terminals, and release it from

its retainers before removing.

Speedometer

6 Remove the two bulbholders on the top of

the panel assembly, and release their strip of

printed circuit from its retainers, so that the

instrument panel halves may be separated.

7 Separate the panel halves by releasing the

Body electrical systems 12•11

9.4b Disconnect the speedometer cable

from the rear of the instrument cluster . . .9.4a Instrument cluster securing screws (arrowed)8.2 Exploded view of the headlight unit

A Sidelight bulb holder

B Sidelight bulb

C Headlight bulb retainer

D Headlight bulb

E Bulb protective cap

F Horizontal adjustment screw

G Vertical adjustment screw

10.3 Unclipping the multi-plug retainer from the rear of the instrument cluster10.2 Removing a bulbholder from the rear of the instrument cluster (bayonet type

fitting)9.4c . . . then disconnect the multi-plug

12

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 245 of 296

retaining tags, taking care to avoid damaging

or losing the warning light graphic strips (see

illustration) .

8 Remove its two Torx-head retaining

screws, then detach and withdraw the

speedometer from the front of the assembly.

Tachometer

9 Carry out the procedure given in

paragraphs 6 and 7.

10 Carefully prise the printed circuit from the

tachometer terminals, using a similar method

to that described in paragraph 5, releasing it

from its retainers as necessary.

11 Remove its two Torx-head retaining

screws, then unclip and withdraw the

tachometer from the front of the assembly.

Fuel and temperature gauge

assembly

12 Removal and refitting procedures are

similar in method to those for the tachometer,

but only one Torx-head screw retains the

assembly.

Refitting

13 Refitting is a reversal of removal.

11 Speedometer cable -

removal and refitting

2

Removal

1 Remove the instrument panel as described

in Section 9.

2 Unscrew the speedometer cable from the

pinion/speed sensor on the transmission (see

illustration) .

3 Release the cable-ties and retaining clips in

the engine compartment, and withdraw the

cable grommet from the bulkhead. 4

Note the cable routing for use when

refitting. Pull the speedometer cable through

into the engine compartment, and remove it

from the car.

Refitting

5 Refitting is the reversal of removal. Ensure

that the cable is routed as noted before

removal, secured with the relevant clips and

cable-ties, and that the grommet is properly

located in the bulkhead.

12 Cigarette lighter -

removal and refitting

1

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Remove the cigarette lighter element

(heated section).

3 Carefully prise the element barrel out from

the illuminated surround, disconnecting its

multi-plug as it is withdrawn.

4 Hinge the illuminated surround out

carefully, removing its bulb feed connector as

it is withdrawn.

Refitting

5 Refitting is a reversal of the removal

procedure.

13 Clock -

removal and refitting

1

Removal

1 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

2 Using a thin flat-bladed screwdriver,

carefully prise the clock out of the facia (see

illustration) . Use a piece of card or similar to

prevent damage to the facia. Withdraw the

clock so that its multi-plug may be

disconnected, then remove it from the vehicle.

Refitting

3 Refitting is a reversal of removal. Reset the

clock on completion.

14 Horn -

removal and refitting

1

Removal

1 The horn is mounted forward on the left-

hand side of the engine compartment, near

the battery.

2 Disconnect the battery negative (earth) lead

(refer to Chapter 5A, Section 1).

3 Remove the wiring loom connection from

the horn(s).

4 Both single and dual horns are mounted to

a bracket which is secured to the bodywork

by a single bolt. Remove the bolt and

withdraw the horn(s) and bracket from the

vehicle. The horn(s) may be separated from

the bracket, as required, by removing the

retaining nut(s).

Refitting

5 Refitting is a reversal of removal.

15 Wiper arms -

removal and refitting

1

Removal

1 With the wiper(s) “parked” (ie in the normal

at-rest position), mark the positions of the

blade(s) on the screen, using a wax crayon or

strips of masking tape.

2 Lift up the plastic cap from the bottom of

the wiper arm, and loosen the nut one or two

turns.

3 Lift the wiper arm, and release it from the

taper on the spindle by moving it from side to

side.

4 Completely remove the nut and washer,

then withdraw the wiper arm from the

spindle.

Refitting

5 Refitting is a reversal of the removal

procedure. Make sure that the arm is fitted in

the previously-noted position.

12•12 Body electrical systems

13.2 Carefully prise the clock out of the facia11.2 Detaching the speedometer cable atthe transmission casing10.7 Rear view of instrument cluster

A Retaining tags

B Multi-plug retainer

C Speedometer cable connection

D Speedometer gauge retaining screws

E Tachometer terminals (obscured by protective pad)

F Tachometer gauge retaining screws

G Fuel and temperature gauge assembly

terminals

H Fuel and temperature gauge assembly retaining screw

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 277 of 296

1595 Ford Fiesta Remake

MOT test checksREF•11

REF

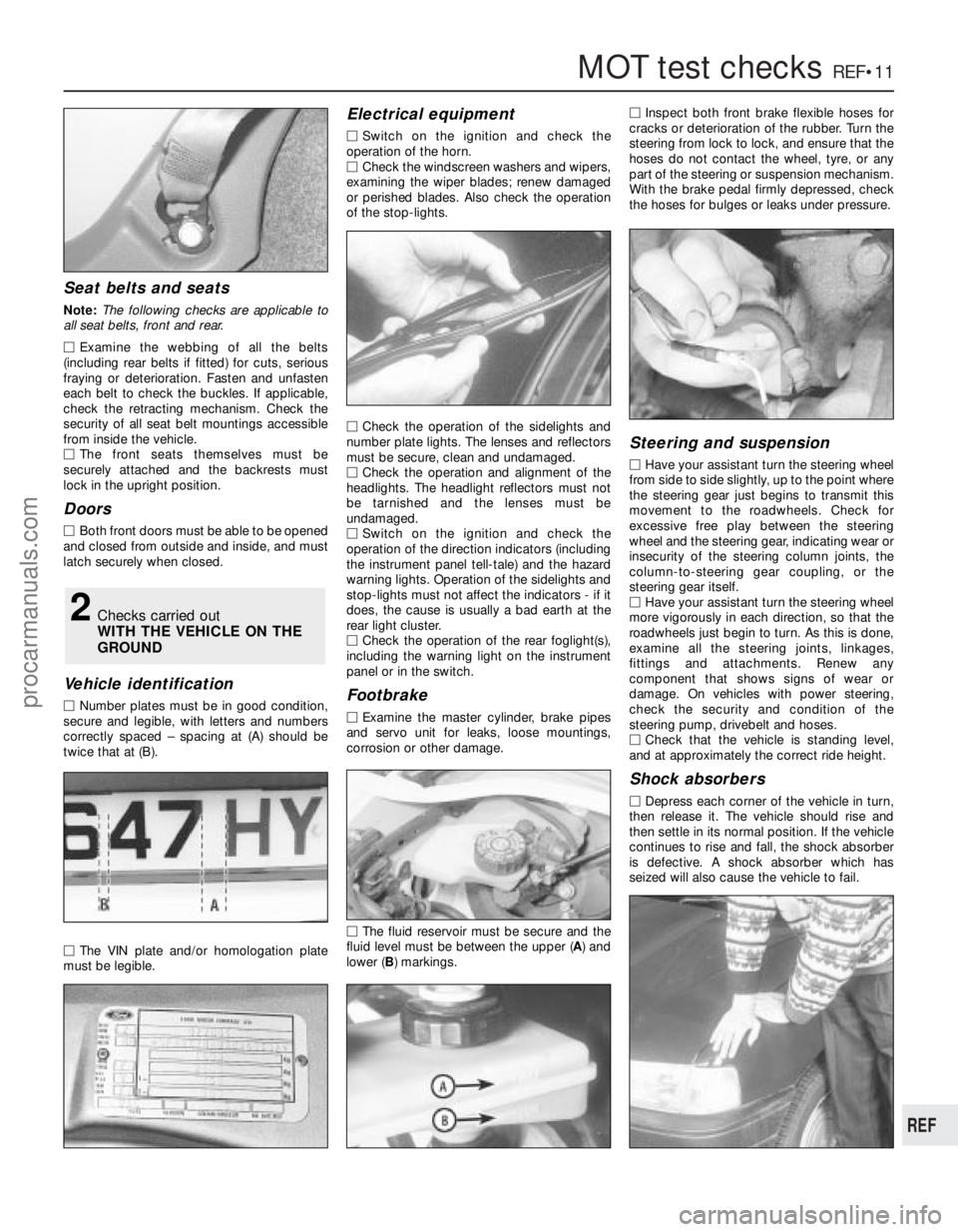

Seat belts and seats

Note: The following checks are applicable to

all seat belts, front and rear.

M Examine the webbing of all the belts

(including rear belts if fitted) for cuts, serious

fraying or deterioration. Fasten and unfasten

each belt to check the buckles. If applicable,

check the retracting mechanism. Check the

security of all seat belt mountings accessible

fr om inside the vehicle.

M The front seats themselves must be

secur ely attached and the backrests must

lock in the upright position.

Doors

M Both front doors must be able to be opened

and closed from outside and inside, and must

latch securely when closed.

V ehicle identification

M Number plates must be in good condition,

secur e and legible, with letters and numbers

corr ectly spaced – spacing at (A) should be

twice that at (B).

M The VIN plate and/or homologation plate

must be legible.

Electrical equipment

M Switch on the ignition and check the

operation of the horn.

M Check the windscreen washers and wipers,

examining the wiper blades; renew damaged

or perished blades. Also check the operation

of the stop-lights.

M Check the operation of the sidelights and

number plate lights. The lenses and reflectors

must be secure, clean and undamaged.

M Check the operation and alignment of the

headlights. The headlight reflectors must not

be tarnished and the lenses must be

undamaged.

M Switch on the ignition and check the

operation of the direction indicators (including

the instrument panel tell-tale) and the hazard

war ning lights. Operation of the sidelights and

stop-lights must not affect the indicators - if it

does, the cause is usually a bad earth at the

r ear light cluster.

M Check the operation of the rear foglight(s),

including the warning light on the instrument

panel or in the switch.

Footbrake

M Examine the master cylinder, brake pipes

and servo unit for leaks, loose mountings,

corr osion or other damage.

M The fluid reservoir must be secure and the

fluid level must be between the upper ( A) and

lower ( B) markings. M

Inspect both front brake flexible hoses for

cracks or deterioration of the rubber . Turn the

steering from lock to lock, and ensure that the

hoses do not contact the wheel, tyre, or any

part of the steering or suspension mechanism.

With the brake pedal firmly depressed, check

the hoses for bulges or leaks under pressure.

Steering and suspension

M Have your assistant turn the steering wheel

fr om side to side slightly, up to the point where

the steering gear just begins to transmit this

movement to the roadwheels. Check for

excessive free play between the steering

wheel and the steering gear, indicating wear or

insecurity of the steering column joints, the

column-to-steering gear coupling, or the

steering gear itself.

M Have your assistant turn the steering wheel

mor e vigorously in each direction, so that the

r oadwheels just begin to turn. As this is done,

examine all the steering joints, linkages,

fittings and attachments. Renew any

component that shows signs of wear or

damage. On vehicles with power steering,

check the security and condition of the

steering pump, drivebelt and hoses.

M Check that the vehicle is standing level,

and at approximately the correct ride height.

Shock absorbers

M Depr ess each corner of the vehicle in turn,

then release it. The vehicle should rise and

then settle in its normal position. If the vehicle

continues to rise and fall, the shock absorber

is defective. A shock absorber which has

seized will also cause the vehicle to fail.

2Checks carried out

WITH THE VEHICLE ON THE

GROUND

procarmanuals.com

http://vnx.su