wipers FORD FIESTA 1989 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 240 of 296

50Undo the two screws securing the contact

switch and withdraw it from its tailgate

location.

51 Unclip and disconnect the switch multi-

plug, and disconnect the earth wiring.

Remove the switch.

52 Refit in the reverse order of removal.

Make sure that the pins and their contacts are

clean. On completion, check the operation of

the rear wipers, courtesy light, heated rear

window and the tailgate release/central

locking system.

Electric window switches

(1992 models onward)

53 On later models the electric window

switches are located in the upper surfaces of

the door stowage pockets. Removal and

refitting is the same as for the earlier centre

console mounted switches described

previously in this Section.

5 Bulbs (exterior lights) -

renewal

1

Note: Ensure that all exterior lights are

switched off before disconnecting the wiring

connectors to any exterior light bulbs. Note

that if a bulb fails, and has just been in use, it

will still be extremely hot, particularly in the

case of a headlight bulb.

Headlight

1 From within the engine compartment,

disconnect the multi-plug from the back of the

headlight.

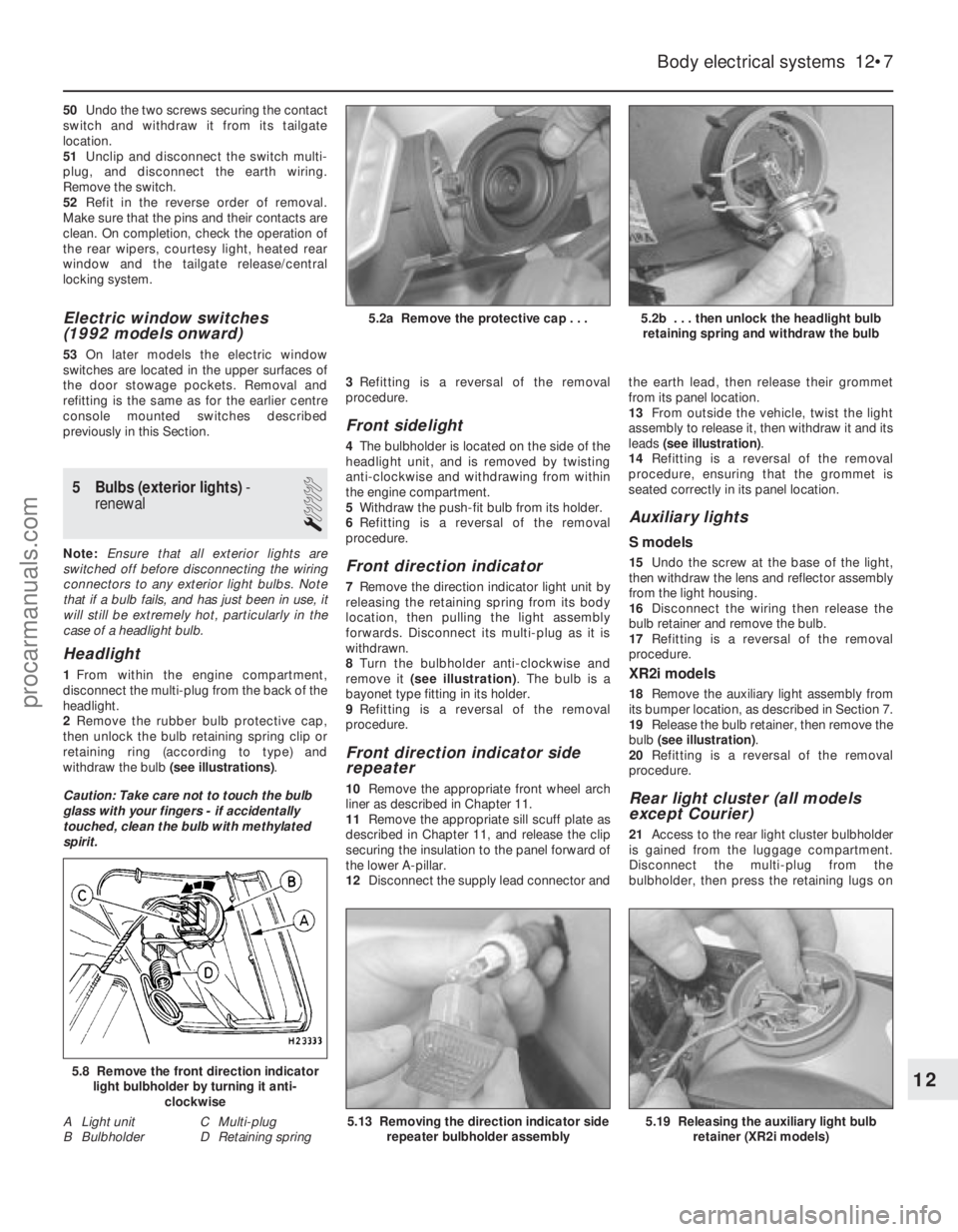

2 Remove the rubber bulb protective cap,

then unlock the bulb retaining spring clip or

retaining ring (according to type) and

withdraw the bulb (see illustrations).

Caution: Take care not to touch the bulb

glass with your fingers - if accidentally

touched, clean the bulb with methylated

spirit. 3

Refitting is a reversal of the removal

procedure.

Front sidelight

4 The bulbholder is located on the side of the

headlight unit, and is removed by twisting

anti-clockwise and withdrawing from within

the engine compartment.

5 Withdraw the push-fit bulb from its holder.

6 Refitting is a reversal of the removal

procedure.

Front direction indicator

7 Remove the direction indicator light unit by

releasing the retaining spring from its body

location, then pulling the light assembly

forwards. Disconnect its multi-plug as it is

withdrawn.

8 Turn the bulbholder anti-clockwise and

remove it (see illustration) . The bulb is a

bayonet type fitting in its holder.

9 Refitting is a reversal of the removal

procedure.

Front direction indicator side

repeater

10 Remove the appropriate front wheel arch

liner as described in Chapter 11.

11 Remove the appropriate sill scuff plate as

described in Chapter 11, and release the clip

securing the insulation to the panel forward of

the lower A-pillar.

12 Disconnect the supply lead connector and the earth lead, then release their grommet

from its panel location.

13

From outside the vehicle, twist the light

assembly to release it, then withdraw it and its

leads (see illustration) .

14 Refitting is a reversal of the removal

procedure, ensuring that the grommet is

seated correctly in its panel location.

Auxiliary lights

S models

15 Undo the screw at the base of the light,

then withdraw the lens and reflector assembly

from the light housing.

16 Disconnect the wiring then release the

bulb retainer and remove the bulb.

17 Refitting is a reversal of the removal

procedure.

XR2i models

18 Remove the auxiliary light assembly from

its bumper location, as described in Section 7.

19 Release the bulb retainer, then remove the

bulb (see illustration) .

20 Refitting is a reversal of the removal

procedure.

Rear light cluster (all models

except Courier)

21 Access to the rear light cluster bulbholder

is gained from the luggage compartment.

Disconnect the multi-plug from the

bulbholder, then press the retaining lugs on

Body electrical systems 12•7

5.2b . . . then unlock the headlight bulb retaining spring and withdraw the bulb5.2a Remove the protective cap . . .

5.19 Releasing the auxiliary light bulb retainer (XR2i models)5.13 Removing the direction indicator siderepeater bulbholder assembly

5.8 Remove the front direction indicatorlight bulbholder by turning it anti-

clockwise

A Light unit C Multi-plug

B Bulbholder D Retaining spring12

1595Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 277 of 296

1595 Ford Fiesta Remake

MOT test checksREF•11

REF

Seat belts and seats

Note: The following checks are applicable to

all seat belts, front and rear.

M Examine the webbing of all the belts

(including rear belts if fitted) for cuts, serious

fraying or deterioration. Fasten and unfasten

each belt to check the buckles. If applicable,

check the retracting mechanism. Check the

security of all seat belt mountings accessible

fr om inside the vehicle.

M The front seats themselves must be

secur ely attached and the backrests must

lock in the upright position.

Doors

M Both front doors must be able to be opened

and closed from outside and inside, and must

latch securely when closed.

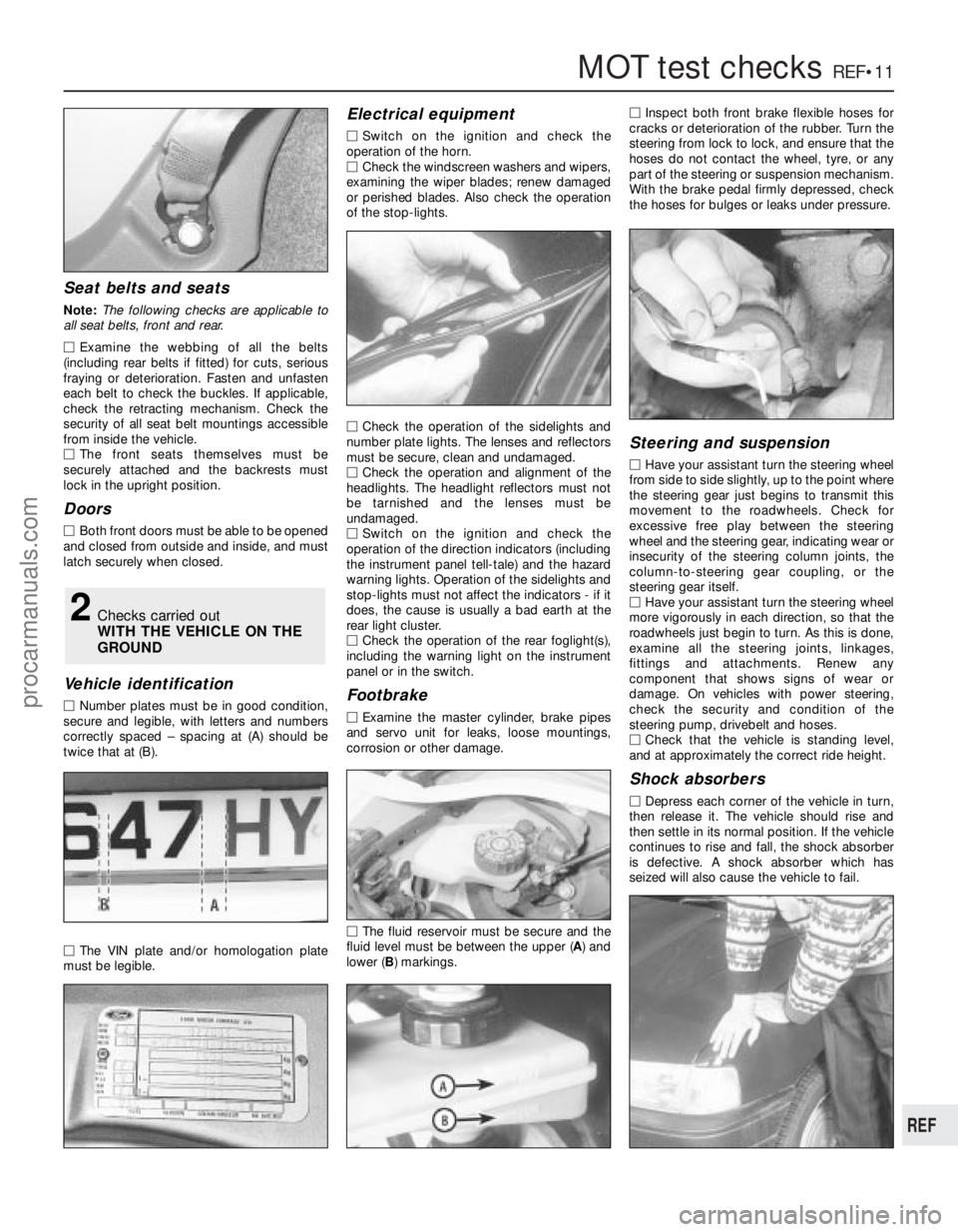

V ehicle identification

M Number plates must be in good condition,

secur e and legible, with letters and numbers

corr ectly spaced – spacing at (A) should be

twice that at (B).

M The VIN plate and/or homologation plate

must be legible.

Electrical equipment

M Switch on the ignition and check the

operation of the horn.

M Check the windscreen washers and wipers,

examining the wiper blades; renew damaged

or perished blades. Also check the operation

of the stop-lights.

M Check the operation of the sidelights and

number plate lights. The lenses and reflectors

must be secure, clean and undamaged.

M Check the operation and alignment of the

headlights. The headlight reflectors must not

be tarnished and the lenses must be

undamaged.

M Switch on the ignition and check the

operation of the direction indicators (including

the instrument panel tell-tale) and the hazard

war ning lights. Operation of the sidelights and

stop-lights must not affect the indicators - if it

does, the cause is usually a bad earth at the

r ear light cluster.

M Check the operation of the rear foglight(s),

including the warning light on the instrument

panel or in the switch.

Footbrake

M Examine the master cylinder, brake pipes

and servo unit for leaks, loose mountings,

corr osion or other damage.

M The fluid reservoir must be secure and the

fluid level must be between the upper ( A) and

lower ( B) markings. M

Inspect both front brake flexible hoses for

cracks or deterioration of the rubber . Turn the

steering from lock to lock, and ensure that the

hoses do not contact the wheel, tyre, or any

part of the steering or suspension mechanism.

With the brake pedal firmly depressed, check

the hoses for bulges or leaks under pressure.

Steering and suspension

M Have your assistant turn the steering wheel

fr om side to side slightly, up to the point where

the steering gear just begins to transmit this

movement to the roadwheels. Check for

excessive free play between the steering

wheel and the steering gear, indicating wear or

insecurity of the steering column joints, the

column-to-steering gear coupling, or the

steering gear itself.

M Have your assistant turn the steering wheel

mor e vigorously in each direction, so that the

r oadwheels just begin to turn. As this is done,

examine all the steering joints, linkages,

fittings and attachments. Renew any

component that shows signs of wear or

damage. On vehicles with power steering,

check the security and condition of the

steering pump, drivebelt and hoses.

M Check that the vehicle is standing level,

and at approximately the correct ride height.

Shock absorbers

M Depr ess each corner of the vehicle in turn,

then release it. The vehicle should rise and

then settle in its normal position. If the vehicle

continues to rise and fall, the shock absorber

is defective. A shock absorber which has

seized will also cause the vehicle to fail.

2Checks carried out

WITH THE VEHICLE ON THE

GROUND

procarmanuals.com

http://vnx.su

Page 280 of 296

The vehicle owner who does his or her own

maintenance according to the recommended

service schedules should not have to use this

section of the manual very often. Modern

component reliability is such that, provided

those items subject to wear or deterioration

are inspected or renewed at the specified

intervals, sudden failure is comparatively rare.

Faults do not usually just happen as a result of

sudden failure, but develop over a period of

time. Major mechanical failures in particular are usually preceded by characteristic

symptoms over hundreds or even thousands

of miles. Those components which do

occasionally fail without warning are often

small and easily carried in the vehicle.

With any fault-finding, the first step is to

decide where to begin investigations.

Sometimes this is obvious, but on other

occasions, a little detective work will be

necessary. The owner who makes half a

dozen haphazard adjustments or replacements may be successful in curing a

fault (or its symptoms), but will be none the

wiser if the fault recurs, and ultimately may

have spent more time and money than was

necessary. A calm and logical approach will

be found to be more satisfactory in the long

run. Always take into account any warning

signs or abnormalities that may have been

noticed in the period preceding the fault -

power loss, high or low gauge readings,

unusual smells, etc - and remember that

Engine

m

m

Engine backfires

m

m Engine difficult to start when cold

m

m Engine difficult to start when hot

m

m Engine fails to rotate when attempting to start

m

m Engine hesitates on acceleration

m

m Engine idles erratically

m

m Engine lacks power

m

m Engine misfires at idle speed

m

m Engine misfires throughout the driving speed range

m

m Engine noises

m

m Engine rotates, but will not start

m

m Engine runs-on after switching off

m

m Engine stalls

m

m Engine starts, but stops immediately

m

m Oil pressure warning light illuminated with engine running

m

m Starter motor noisy or excessively-rough in engagement

Cooling system

m

mCorrosion

m

m External coolant leakage

m

m Internal coolant leakage

m

m Overcooling

m

m Overheating

Fuel and exhaust systems

m

mExcessive fuel consumption

m

m Excessive noise or fumes from exhaust system

m

m Fuel leakage and/or fuel odour

Clutch

m

mClutch fails to disengage (unable to select gears)

m

m Clutch slips (engine speed increases, with no increase in vehicle

speed)

m m Judder as clutch is engaged

m

m Noise when depressing or releasing clutch pedal

m

m Pedal travels to floor - no pressure or very little resistance

Manual transmission

m

mJumps out of gear

m

m Lubricant leaks

m

m Noisy in neutral with engine running

m

m Noisy in one particular gear

m

m Vibration

Automatic transmission

m

mEngine will not start in any gear, or starts in gears other than Park

or Neutral

m m Fluid leakage

m

m General gear selection problems

m

m Transmission fluid brown, or has burned smell

m

m Transmission slips, shifts roughly, is noisy, or has no drive in

forward or reverse gears

m m Transmission will not downshift (kickdown) with accelerator fully

depressed

Driveshafts

m mClicking or knocking noise on turns (at slow speed on full-lock)

m

m Vibration when accelerating or decelerating

Braking system

m

mBrake pedal feels spongy when depressed

m

m Brakes binding

m

m Excessive brake pedal effort required to stop vehicle

m

m Excessive brake pedal travel

m

m Judder felt through brake pedal or steering wheel when braking

m

m Noise (grinding or high-pitched squeal) when brakes applied

m

m Rear wheels locking under normal braking

m

m Vehicle pulls to one side under braking

Suspension and steering systems

m

mExcessive pitching and/or rolling around corners, or during

braking

m m Excessive play in steering

m

m Excessively-stiff steering

m

m Lack of power assistance

m

m Tyre wear excessive

m

m Vehicle pulls to one side

m

m Wandering or general instability

m

m Wheel wobble and vibration

Electrical system

m

mBattery will not hold a charge for more than a few days

m

m Electric windows inoperative, or unsatisfactory in operation

m

m Horn inoperative, or unsatisfactory in operation

m

m Ignition warning light fails to come on

m

m Ignition warning light remains illuminated with engine running

m

m Instrument readings inaccurate or erratic

m

m Lights inoperative

m

m Windscreen/tailgate washers inoperative, or unsatisfactory in

operation

m m Windscreen/tailgate wipers inoperative, or unsatisfactory in

operation

REF•14Fault finding

1595 Ford Fiesta Remake

Introduction

procarmanuals.com

http://vnx.su

Page 286 of 296

1595 Ford Fiesta Remake

REF•20Fault finding

Electrical system

Note:For problems associated with the starting system, refer to the

faults listed under “Engine” earlier in this Section.

Battery will not hold a charge for more than a few

days

m m Battery defective internally (Chapter 5A).

m

m Battery terminal connections loose or corroded (Chapter 5A).

m

m Auxiliary drivebelt worn or incorrectly-adjusted (Chapter 1).

m

m Alternator not charging at correct output (Chapter 5A).

m

m Alternator or voltage regulator faulty (Chapter 5A).

m

m Short-circuit causing continual battery drain (Chapters 5A and 12).

Ignition (no-charge) warning light remains

illuminated with engine running

m mAuxiliary drivebelt broken, worn, or incorrectly-adjusted (Chap-

ter 1).

m m Alternator brushes worn, sticking, or dirty (Chapter 5A).

m

m Alternator brush springs weak or broken (Chapter 5A).

m

m Internal fault in alternator or voltage regulator (Chapter 5A).

m

m Broken, disconnected, or loose wiring in charging circuit (Chap-

ter 5A).

Ignition (no-charge) warning light fails to come on

m mWarning light bulb blown (Chapter 12).

m

m Broken, disconnected, or loose wiring in warning light circuit

(Chapters 5A and 12).

m m Alternator faulty (Chapter 5A).

Lights inoperative

m

mBulb blown (Chapter 12).

m

m Corrosion of bulb or bulbholder contacts (Chapter 12).

m

m Blown fuse (Chapter 12).

m

m Faulty relay (Chapter 12).

m

m Broken, loose, or disconnected wiring (Chapter 12).

m

m Faulty switch (Chapter 12).

Instrument readings inaccurate or erratic

Instrument readings increase with engine speed

m

mFaulty voltage regulator (Chapter 12).

Fuel or temperature gauges give no reading

m

mFaulty gauge sender unit (Chapters 3 or 4A, 4B, 4C, or 4D).

m

m Wiring open-circuit (Chapter 12).

m

m Faulty gauge (Chapter 12).

Fuel or temperature gauges give continuous maximum

reading

m mFaulty gauge sender unit (Chapters 3 or 4A, 4B, 4C, or 4D).

m

m Wiring short-circuit (Chapter 12).

m

m Faulty gauge (Chapter 12).

Horn inoperative, or unsatisfactory in operation

Horn fails to operate

m

mBlown fuse (Chapter 12).

m

m Cable or cable connections loose, broken or disconnected

(Chapter 12).

m m Faulty horn (Chapter 12).

Horn emits intermittent or unsatisfactory sound

m

mCable connections loose (Chapter 12).

m

m Horn mountings loose (Chapter 12).

m

m Faulty horn (Chapter 12).

Horn operates all the time

m

mHorn push either earthed or stuck down (Chapter 12).

m

m Horn cable to horn push earthed (Chapter 12).

Windscreen/tailgate wipers inoperative or

unsatisfactory in operation

Wipers fail to operate, or operate very slowly

m mWiper blades stuck to screen, or linkage seized or binding

(Chapter 12).

m m Blown fuse (Chapter 12).

m

m Cable or cable connections loose, broken or disconnected

(Chapter 12).

m m Faulty relay (Chapter 12).

m

m Faulty wiper motor (Chapter 12).

Wiper blades sweep over too large or too small an area of

the glass

m mWiper arms incorrectly-positioned on spindles (Chapter 1).

m

m Excessive wear of wiper linkage (Chapter 1).

m

m Wiper motor or linkage mountings loose or insecure (Chapter 12).

Wiper blades fail to clean the glass effectively

m

mWiper blade rubbers worn or perished ( “Weekly Checks”).

m

m Wiper arm tension springs broken, or arm pivots seized (Chap-

ter 1).

m m Insufficient windscreen washer additive to adequately remove

road film ( “Weekly Checks” ).

Windscreen/tailgate washers inoperative, or

unsatisfactory in operation

One or more washer jets inoperative

m mBlocked washer jet ( “Weekly Checks”or Chapter 1).

m

m Disconnected, kinked or restricted fluid hose (Chapter 1).

m

m Insufficient fluid in washer reservoir ( “Weekly Checks”).

Washer pump fails to operate

m

mBroken or disconnected wiring or connections (Chapter 12).

m

m Blown fuse (Chapter 12).

m

m Faulty washer switch (Chapter 12).

m

m Faulty washer pump (Chapter 12).

Washer pump runs for some time before fluid is emitted

from jets

m mFaulty one-way valve in fluid supply hose (Chapter 12).

Electric windows inoperative, or unsatisfactory in

operation

Window glass will only move in one direction

m mFaulty switch (Chapter 12).

Window glass slow to move

m

mIncorrectly-adjusted door glass guide channels (Chapter 11).

m

m Regulator seized or damaged, or in need of lubrication (Chapter

11).

m m Door internal components or trim fouling regulator (Chapter 11).

m

m Faulty motor (Chapter 12).

Window glass fails to move

m

mIncorrectly-adjusted door glass guide channels (Chapter 11).

m

m Blown fuse (Chapter 12).

m

m Faulty relay (Chapter 12).

m

m Broken or disconnected wiring or connections (Chapter 12).

m

m Faulty motor (Chapter 12).

procarmanuals.com

http://vnx.su

Page 295 of 296

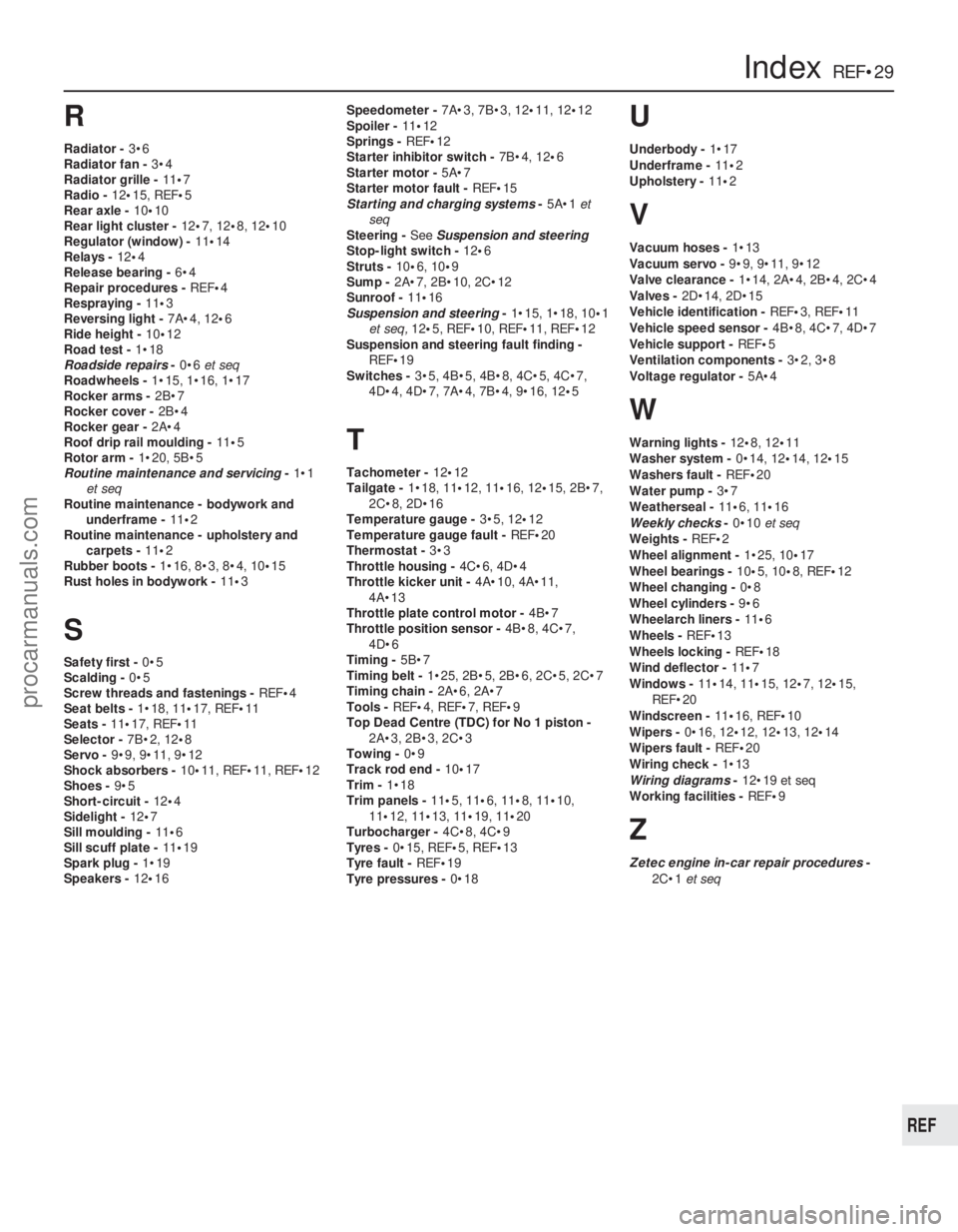

R

Radiator -3•6

Radiator fan - 3•4

Radiator grille - 11•7

Radio - 12•15, REF •5

Rear axle - 10•10

Rear light cluster - 12•7, 12•8, 12 •10

Regulator (window) - 11•14

Relays - 12•4

Release bearing - 6•4

Repair procedures - REF•4

Respraying - 11•3

Reversing light - 7A•4, 12•6

Ride height - 10•12

Road test - 1•18

Roadside repairs -0•6 et seq

Roadwheels - 1•15, 1•16, 1•17

Rocker arms - 2B•7

Rocker cover - 2B•4

Rocker gear - 2A•4

Roof drip rail moulding - 11•5

Rotor arm - 1•20, 5B•5

Routine maintenance and servicing -1•1

et seq

Routine maintenance - bodywork and

underframe - 11•2

Routine maintenance - upholstery and carpets - 11•2

Rubber boots - 1•16, 8•3, 8•4, 10 •15

Rust holes in bodywork - 11•3

S

Safety first - 0•5

Scalding - 0•5

Screw threads and fastenings - REF•4

Seat belts - 1•18, 11•17, REF•11

Seats - 11•17, REF •11

Selector - 7B•2, 12•8

Servo - 9•9, 9•11, 9•12

Shock absorbers - 10•11, REF •11, REF•12

Shoes - 9•5

Short-circuit - 12•4

Sidelight - 12•7

Sill moulding - 11•6

Sill scuff plate - 11•19

Spark plug - 1•19

Speakers - 12•16 Speedometer -

7A•3, 7B•3, 12•11, 12•12

Spoiler - 11•12

Springs - REF•12

Starter inhibitor switch - 7B•4, 12•6

Starter motor - 5A•7

Starter motor fault - REF•15

Starting and charging systems -5A•1 et

seq

Steering - See Suspension and steering

Stop-light switch - 12•6

Struts - 10•6, 10• 9

Sump - 2A•7, 2B•10, 2C•12

Sunroof - 11•16

Suspension and steering -1•15, 1•18, 10 •1

et seq, 12•5, REF •10, REF •11, REF• 12

Suspension and steering fault finding -

REF •19

Switches - 3•5, 4B•5, 4B•8, 4C•5, 4C•7,

4D•4, 4D•7, 7A•4, 7B•4, 9•16, 12 •5

T

Tachometer - 12•12

Tailgate - 1•18, 11•12, 11•16, 12•15, 2B•7,

2C•8, 2D•16

Temperature gauge - 3•5, 12•12

Temperature gauge fault - REF•20

Thermostat - 3•3

Throttle housing - 4C•6, 4D•4

Throttle kicker unit - 4A•10, 4A•11,

4A•13

Throttle plate control motor - 4B•7

Throttle position sensor - 4B•8, 4C•7,

4D•6

Timing - 5B•7

Timing belt - 1•25, 2B•5, 2B•6, 2C•5, 2C•7

Timing chain - 2A•6, 2A•7

Tools - REF•4, REF•7, REF•9

Top Dead Centre (TDC) for No 1 piston - 2A•3, 2B•3, 2C•3

Towing - 0•9

Track rod end - 10•17

Trim - 1•18

Trim panels - 11•5, 11 •6, 11•8, 11 •10,

11 •12, 11•13, 11•19, 11•20

Turbocharger - 4C•8, 4C•9

Tyres - 0•15, REF•5, REF •13

Tyre fault - REF•19

Tyre pressures - 0•18

U

Underbody -1•17

Underframe - 11•2

Upholstery - 11•2

V

Vacuum hoses - 1•13

Vacuum servo - 9•9, 9•11, 9•12

Valve clearance - 1•14, 2A•4, 2B•4, 2C•4

Valves - 2D•14, 2D•15

Vehicle identification - REF•3, REF •11

Vehicle speed sensor - 4B•8, 4C•7, 4D•7

Vehicle support - REF•5

Ventilation components - 3•2, 3•8

Voltage regulator - 5A•4

W

Warning lights - 12•8, 12•11

Washer system - 0•14, 12•14, 12•15

Washers fault - REF•20

Water pump - 3•7

Weatherseal - 11•6, 11•16

Weekly checks -0•10 et seq

Weights - REF•2

Wheel alignment - 1•25, 10•17

Wheel bearings - 10•5, 10 •8, REF •12

Wheel changing - 0•8

Wheel cylinders - 9•6

Wheelarch liners - 11•6

Wheels - REF•13

Wheels locking - REF•18

Wind deflector - 11•7

Windows - 11•14, 11•15, 12 •7, 12•15,

REF•20

Windscreen - 11•16, REF •10

Wipers - 0•16, 12• 12, 12•13, 12•14

Wipers fault - REF•20

Wiring check - 1•13

Wiring diagrams - 12•19 et seq

Working facilities - REF•9

Z

Zetec engine in-car repair procedures -

2C•1 et seq

IndexREF•29

REF

1595 Ford Fiesta Remakeprocarmanuals.com

http://vnx.su