automatic transmission FORD FIESTA 2007 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 165 of 1226

205-04-1 3 Front Drive Halfshafts 205-04-1 3

REMOVAL AND INSTALLATION

Intermediate Shaft

I

Materials

Name Specification

Removal

Manual transmission

1 fluid

A WARN1NG:Refer to the Material Safety Data

Sheets for the Automatic Transmission

Fluid E-AW. Failure to follow this

instruction may result in personal injury.

Certain Transmission and Power Steering

fluids supplied to Ford contain additives

which may cause skin irritation or other

skin reactions after contact.

WSD-M2C200-C

For additional information, refer to: Health

and Safety Precautions

(1 00-00 General

Information, Description and Operation).

See

- Transmission Fluids.

I. Remove the right-hand halfshaft.

, For additional information, refer to: Front

i, Halfshaft RH (205-04 Front Drive Halfshafts,

Removal and Installation).

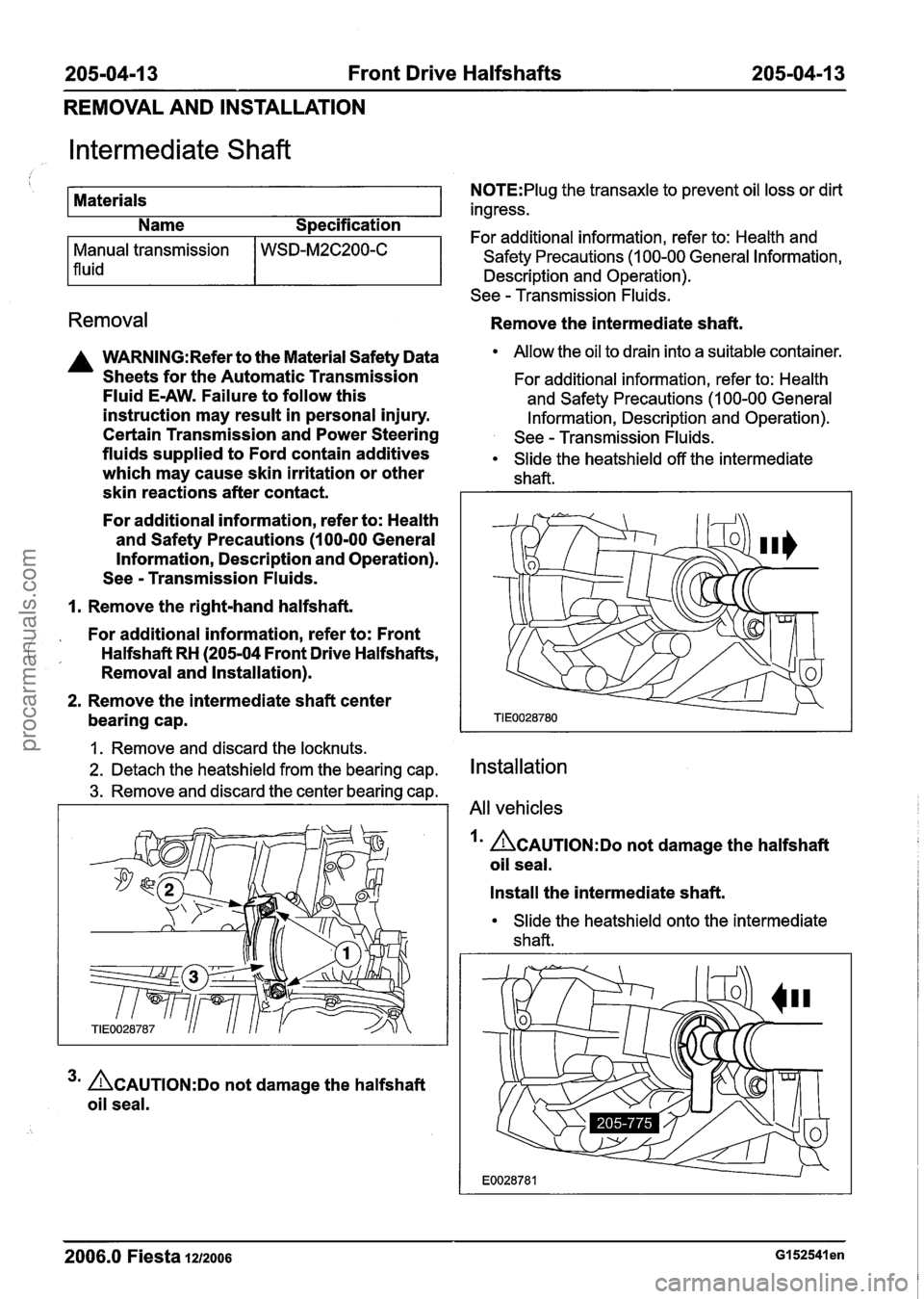

2. Remove the intermediate shaft center

bearing cap.

1. Remove and discard the locknuts.

2. Detach the heatshield from the bearing cap.

3. Remove and discard the center bearing cap.

3m ACAUTION:D~ not damage the halfshaft

oil seal.

N0TE:Plug the transaxle to prevent oil loss or dirt

ingress.

For additional information, refer to: Health and

Safety Precautions

(1 00-00 General Information,

Description and Operation).

See

- Transmission Fluids.

Remove the intermediate shaft.

Allow the oil to drain into a suitable container.

For additional information, refer to: Health

and Safety Precautions

(I 00-00 General

Information, Description and Operation).

See

- Transmission Fluids.

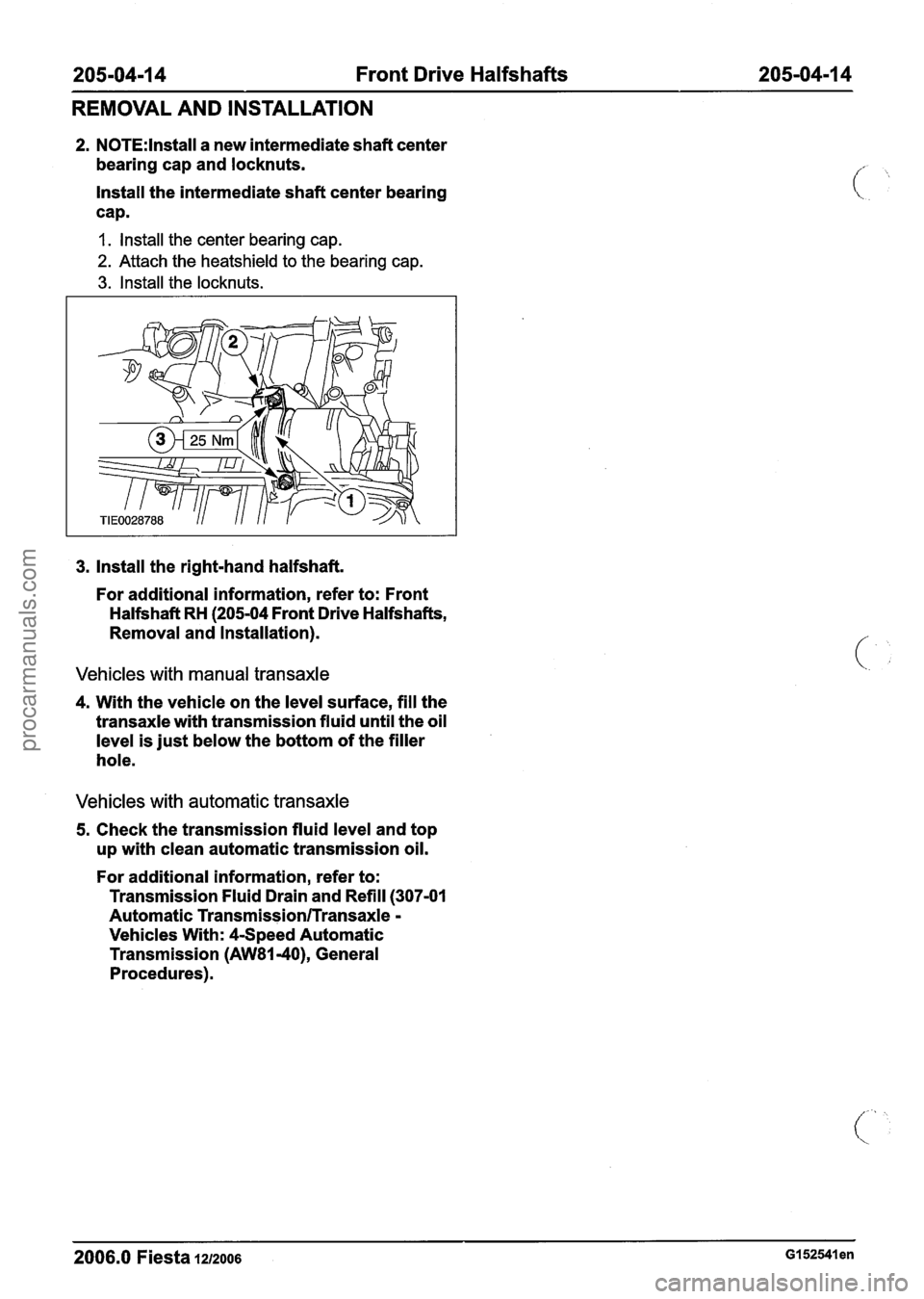

Slide the heatshield off the intermediate

shaft.

Installation

All vehicles

I' ACAUTION:D~ not damage the halfshaft

oil seal.

Install the intermediate shaft.

Slide the heatshield onto the intermediate

shaft.

2006.0 Fiesta 1212006 GI 52541 en

procarmanuals.com

Page 166 of 1226

205-04-1 4 Front Drive Halfshafts 205-04-1 4

REMOVAL AND INSTALLATION

2. N0TE:lnstall a new intermediate shaft center

bearing cap and locknuts.

Install the intermediate shaft center bearing

cap.

I. Install the center bearing cap.

2. Attach the heatshield to the bearing cap.

3. Install the locknuts.

3. Install the right-hand halfshaft.

For additional information, refer to: Front

Halfshaft RH (205-04 Front Drive Halfshafts,

Removal and Installation).

Vehicles with manual transaxle

4. With the vehicle on the level surface, fill the

transaxle with transmission fluid until the oil

level is just below the bottom of the filler

hole.

Vehicles with automatic transaxle

5. Check the transmission fluid level and top

up with clean automatic transmission oil.

For additional information, refer to:

Transmission Fluid Drain and Refill

(307-01

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

Transmission

(AW81-40), General

Procedures).

2006.0 Fiesta 1212006 GI 52541 en

procarmanuals.com

Page 198 of 1226

206-00-26 Brake System - General Information 206-00-26

DIAGNOSIS AND TESTING

TEST CONDITIONS DETAILSIRESU LTSIACTIONS

I J6: CHECK BRAKE PEDAL LINKAGE If

rn Disconnect the actuator rod from the pedal pin

and apply the brake pedal fully.

Did the pedal move freely?

-+ Yes

GO to J7.

+ No

REPAIR or INSTALL new brake pedal bush-

ings. REFER to: (206-06 Hydraulic Brake

Actuation)

Brake Pedal

- LHD, Vehicles With: Manual

Transaxle (Removal and Installation),

Brake Pedal

- LHD, Vehicles With: 4-Speed

Automatic Transmission

(AW81-40), Vehicles

With: Automated Gearshift (Removal and

Installation),

Brake Pedal

- RHD (Removal and Installation).

TEST the system for normal operation.

157: CHECK BRAKE PRESSURE CONTROL VALVE I

rn Check the brake pressure control valve for

contamination.

Is the brake fluid contaminated?

+ Yes

INSTALL a new brake pressure control valve.

FILL the brake master cylinder reservoir.

BLEED the brake system. REFER to: (206-00

Brake System

- General Information)

1 Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General

Procedures). TEST the system for normal operation.

1 * Ehicle OK.

2006.0 Fiesta 1212006 G28494en

procarmanuals.com

Page 200 of 1226

206-00-28 Brake System - General Information 206-00-28

DIAGNOSIS AND TESTING

PINPOINT TEST L : SLOW OR INCOMPLETE BRAKE PEDAL RETURN

TEST CONDITIONS

DETAILSIRESU LTSIACTIONS /"'

I L1: CHECK FOR BRAKE PEDAL RETURN I[<.

Run the engine at fast idle while making several

brake applications. Pull the brake pedal rear-

ward with approximately 44.5 N

(1 0 lbs) force.

Release the brake pedal and measure the

distance to the floor pan. Make a hard brake

application. Release the brake pedal and

measure the brake pedal to floor pan distance.

The brake pedal should return to its original

position.

Did the brake pedal return to its original posi-

tion?

+ Yes

Vehicle OK.

+ No

GO to L2.

I L2: CHECK FOR BRAKE PEDAL BINDING

1 171 Check the brake pedal for free operation.

I Is the brake pedal operating freely?

+ Yes

I INSTALL a new brake booster. REFER to:

(206-07 Power Brake Actuation)

Brake Booster

- LHD (Removal and lnstallation),

Brake Booster

- RHD (Removal and lnstallation).

TEST the system for normal operation.

+ No

REPAIR or INSTALL new brake pedal bush-

ings. REFER to: (206-06 Hydraulic Brake

Actuation)

Brake Pedal

- LHD, Vehicles With: Manual

Transaxle (Removal and lnstallation),

Brake Pedal

- LHD, Vehicles With: 4-Speed

Automatic Transmission

(AW81-40), Vehicles

With: Automated Gearshift (Removal and

Installation),

Brake Pedal

- RHD (Removal and lnstallation).

TEST the system for normal operation.

Component Tests It is possible that all evidence of fluid leakage may

have washed off if the vehicle has been operated

in rain or snow, as brake fluid is water-soluble.

Hydraulic Leak Check Refill the system, bleed then apply the brakes

several times. Examine the system to verify that

NOTE:Thet-e is a common clutch and brake fluid

the reservoir fluid level is actually dropping. Locate

reservoir, therefore it is possible that a clutch leak

can lead to reduction in the reservoir level.

-- --

2006.0 Fiesta 1212006 G28494en

procarmanuals.com

Page 558 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-0 I Am82 Duratec-1 6V (Sigma)ll .6L Duratec-1 6V (Sigma)

303-01 Am82

REMOVAL

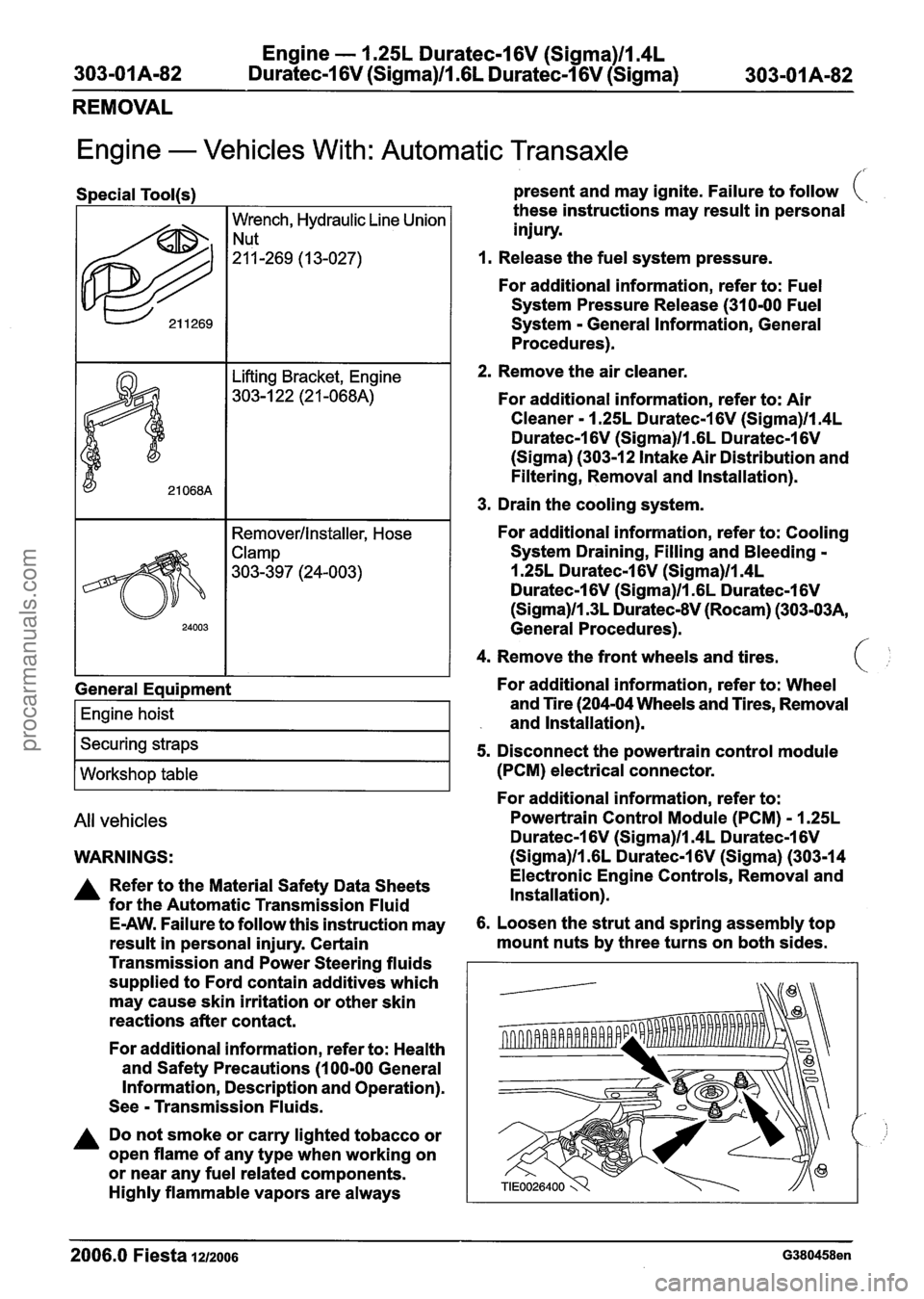

Lifting Bracket, Engine

303-1 22 (21 -068A)

Engine - Vehicles With: Automatic Transaxle

Special Tool(s) present and may ignite. Failure to follow (.

2. Remove the air cleaner.

622

For additional information, refer to: Air

Cleaner - 1.25L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)/l .6L Duratec-1 6V

(Sigma) (303-12 Intake Air Distribution and

Filtering, Removal and Installation).

I I 1 3. Drain the cooling system.

Wrench, Hydraulic Line Union

"-269 (13-027)

I I Remover/lnstaller, Hose I

these instructions may result in personal

injury.

1. Release the fuel system pressure.

For

additional information, refer to: Fuel

System Pressure Release (31 0-00 Fuel

System - General Information, General

Procedures).

General Eaui~ment

I Engine hoist I

I Securing straps I

I Workshop table I

All vehicles

WARNINGS:

A Refer to the Material Safety Data Sheets

for the Automatic Transmission

Fluid

E-AW. Failure to follow this instruction may

result in personal injury. Certain

Transmission and Power Steering fluids

supplied to Ford contain additives which

may cause skin irritation or other skin

reactions after contact.

For

additional information, refer to: Health

and Safety Precautions (1 00-00 General

Information, Description and Operation).

See

- Transmission Fluids.

A Do not smoke or carry lighted tobacco or

open flame of any type when working on

or near any

fuel related components.

Highly flammable vapors are always

For additional information, refer to: Cooling

System Draining, Filling and Bleeding -

1.25L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)ll .6L Duratec-1 6V

(Sigma)llm3L Duratec-8V (Rocam) (303-03A,

General Procedures). ,'

4. Remove the front wheels and tires. C'

For additional information, refer to: Wheel

and Tire (204-04 Wheels and Tires, Removal

and Installation).

5. Disconnect the powertrain control module

(PCM) electrical connector.

For

additional information, refer to:

Powertrain

Control Module (PCM) - 1.25L

Duratec-1 6V (Sigma)ll.4L Duratec-1 6V

(Sigma)ll .6L Duratec-1 6V (Sigma) (303-14

Electronic Engine Controls, Removal and

Installation).

6. Loosen the strut and spring assembly top

mount nuts by three turns on both sides.

--

2006.0 Fiesta 1212006 G380458en

procarmanuals.com

Page 616 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-01 A-1 40 Duratec-1 6V (Sigma)ll .6L

Duratec-1 6V (Sigma) 303-01 A-1 40

INSTALLATION

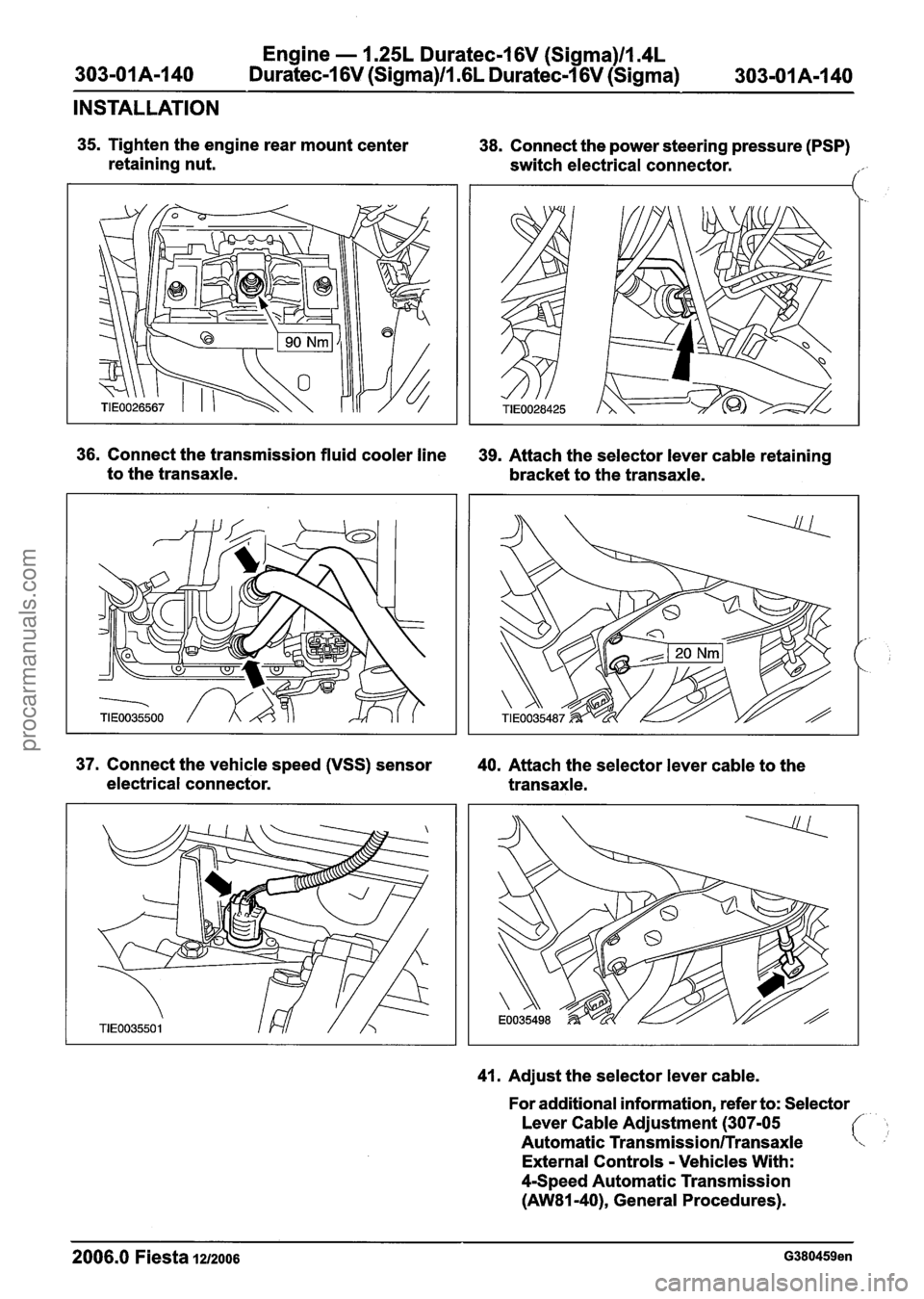

35. Tighten the engine rear mount center

retaining nut. 38. Connect the power steering pressure (PSP)

switch electrical connector.

,/'

36. Connect the transmission fluid cooler line 39. Attach the selector lever cable retaining

to the transaxle.

bracket to the transaxle.

37. Connect the vehicle speed (VSS) sensor

40. Attach the selector lever cable to the

electrical connector. transaxle.

41. Adjust the selector lever cable.

For additional information, refer to: Selector

Lever Cable Adjustment (307-05

Automatic

Transmission/Transaxle

External Controls - Vehicles With:

4-Speed Automatic Transmission

(AW81-40), General Procedures).

2006.0 Fiesta 1212006 G380459en

procarmanuals.com

Page 621 of 1226

Engine - 1.25L Duratec-1 6V (Sigma)ll.4L

303-01 A-1 45 Duratec-1 6V (Sigma)ll .6L

Duratec-1 6V (Sigma) 303-01 A-1 45

INSTALLATION

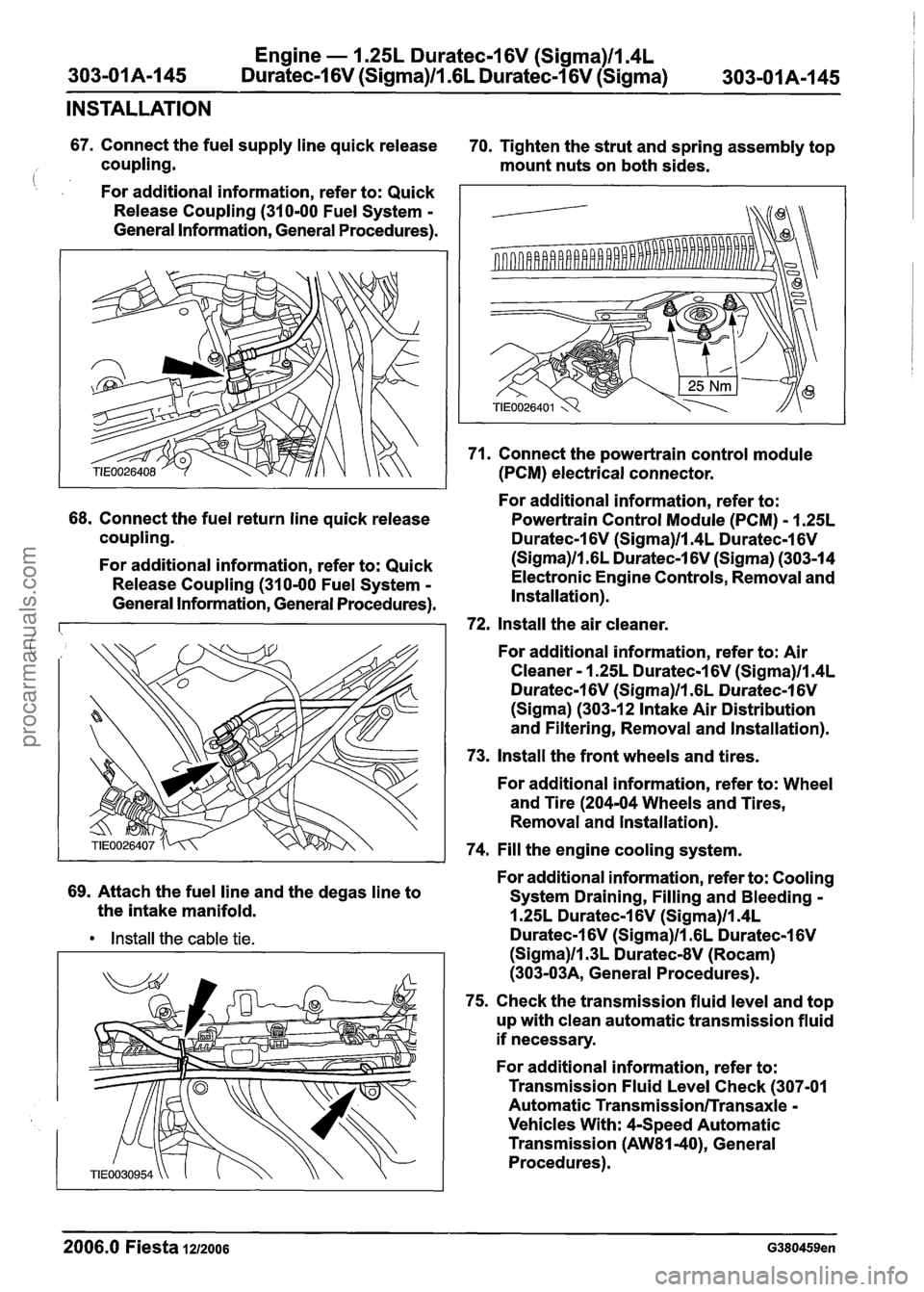

67. Connect the fuel supply line quick release

70. Tighten the strut and spring assembly top

coupling. mount nuts on both sides.

(: , For additional information, refer to: Quick

Release Coupling (310-00 Fuel System

-

General Information, General Procedures).

68. Connect the fuel return line quick release

coupling.

For additional information, refer to: Quick

Release Coupling (310-00 Fuel System

-

General Information, General Procedures).

69. Attach the fuel line and the degas line to

the intake manifold.

Install the cable tie.

71. Connect the powertrain control module

(PCM) electrical connector.

For additional information, refer to:

Powertrain Control Module (PCM)

- 1.25L

Duratec-1 6V (Sigma)llm4L Duratec-1 6V

(Sigma)ll.GL Duratec-1 6V (Sigma) (303-14

Electronic Engine Controls, Removal and

Installation).

72, Install the air cleaner.

For additional information, refer to: Air

Cleaner

- 1.25L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)ll.GL Duratec-1 6V

(Sigma) (303-1 2 Intake Air Distribution

and Filtering, Removal and Installation).

73. Install the front wheels and tires.

For additional information, refer to: Wheel

and Tire (204-04 Wheels and Tires,

Removal and lnstallation).

74. Fill the engine cooling system.

For additional information, refer to: Cooling

System Draining, Filling and Bleeding

-

1.25L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)ll .6L Duratec-1 6V

(Sigma)ll.3L DuratecdV (Rocam)

(303-03A, General Procedures).

75. Check the transmission fluid level and top

up with clean automatic transmission fluid

if necessary.

For additional information, refer to:

Transmission Fluid Level Check (307-01

Automatic

Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

Transmission

(AW81-40), General

Procedures).

--

2006.0 Fiesta 1212006 G380459en

procarmanuals.com

Page 759 of 1226

Engine Cooling - I .3L Duratec-8V

(Rocam)llm25L Duratec-1 6V (Sigma)ll.4L

303-03A-17 Duratec-1 6V (Sigma)/lm6L Duratec-1 6V (Sigma) 303-03A-17

DIAGNOSIS AND TESTING

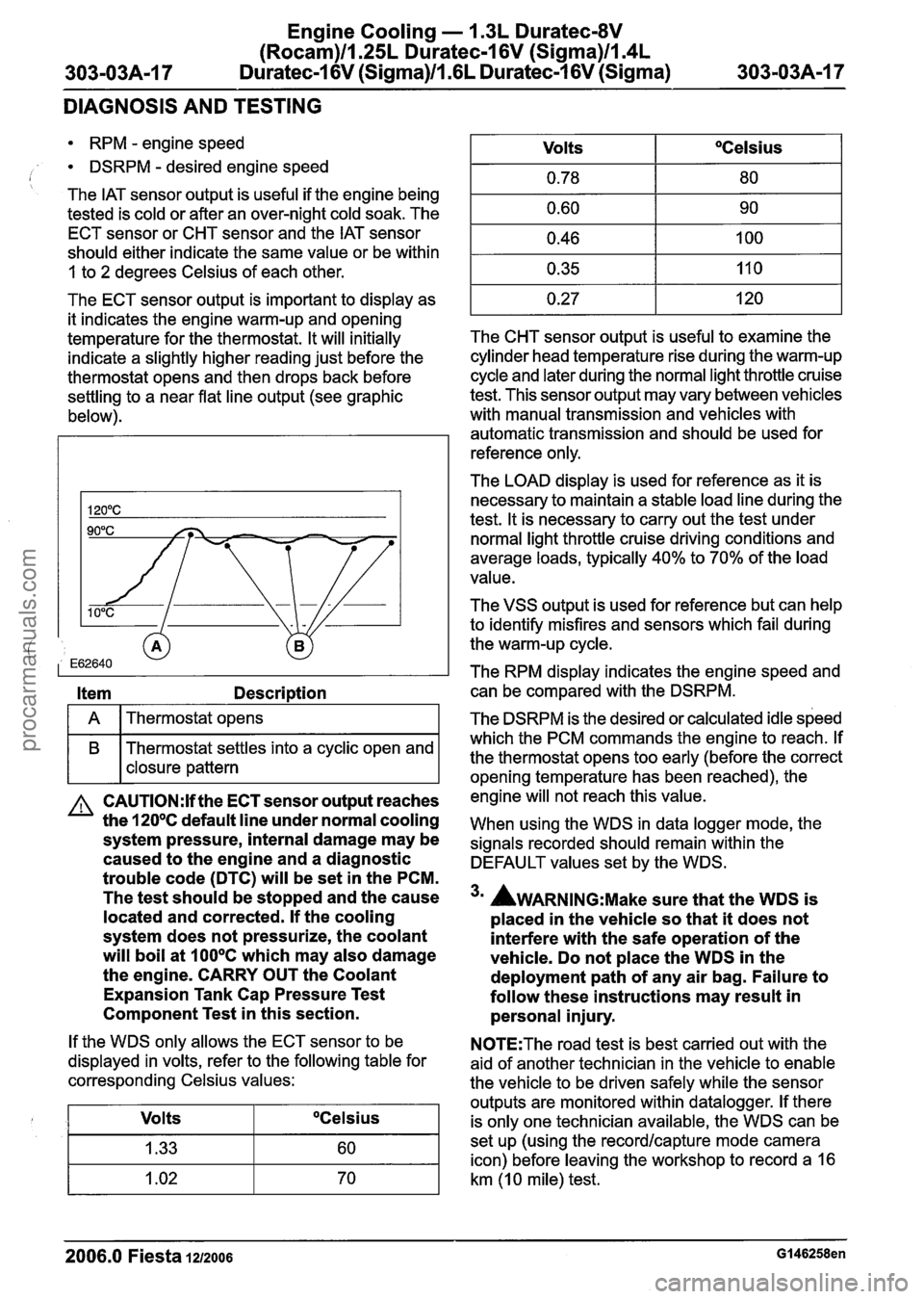

RPM - engine speed

i DSRPM - desired engine speed

The IAT sensor output is useful if the engine being

tested is cold or after an over-night cold soak. The

ECT sensor or CHT sensor and the IAT sensor

should either indicate the same value or be within

1 to 2 degrees Celsius of each other.

The ECT sensor output is important to display as

it indicates the engine warm-up and opening

temperature for the thermostat. It will initially

indicate a slightly higher reading just before the

thermostat opens and then drops back before

settling to a near flat line output (see graphic

below).

Item Description

I A I Thermostat opens I

B Thermostat settles into a cyclic open and

I I closure pattern

A CAUTI0N:lf the ECT sensor output reaches

the

120°C default line under normal cooling

system pressure, internal damage may be

caused to the engine and a diagnostic

trouble code (DTC) will be set in the PCM.

The test should be stopped and the cause

located and corrected. If the cooling

system does not pressurize, the coolant

will boil at

100°C which may also damage

the engine. CARRY OUT the Coolant

Expansion Tank Cap Pressure Test

Component Test in this section.

If the WDS only allows the ECT sensor to be

displayed in volts, refer to the following table for

corresponding Celsius values:

Volts

OCelsius

The CHT sensor output is useful to examine the

cylinder head temperature rise during the warm-up

cycle and later during the normal light throttle cruise

test. This sensor output may vary between vehicles

with manual transmission and vehicles with

automatic transmission and should be used for

reference only.

Volts

0.78

0.60

0.46

0.35

0.27

The

LOAD display is used for reference as it is

necessary to maintain a stable load line during the

test. It is necessary to carry out the test under

normal light throttle cruise driving conditions and

average loads, typically

40% to 70% of the load

value.

OCelsius

80

90

100

11 0

120

The VSS output is used for reference but can help

to identify misfires and sensors which fail during

the warm-up cycle.

The RPM display indicates the engine speed and can be compared with the DSRPM.

The DSRPM is the desired or calculated idle speed

which the PCM commands the engine to reach. If

the thermostat opens too early (before the correct

opening temperature has been reached), the

engine will not reach this value.

When using the WDS in data logger mode, the

signals recorded should remain within the

DEFAULT values set by the WDS.

3m AWARNING:M~~~ sure that the WDS is

placed in the vehicle so that it does not

interfere with the safe operation of the

vehicle. Do not place the WDS in the

deployment path of any air bag. Failure to

follow these instructions may result in personal injury.

N0TE:The road test is best carried out with the

aid of another technician in the vehicle to enable

the vehicle to be driven safely while the sensor

outputs are monitored within datalogger. If there

is only one technician available, the WDS can be

set up (using the

recordlcapture mode camera

icon) before leaving the workshop to record a

16

km (1 0 mile) test.

2006.0 Fiesta 1212006 GI 46258en

procarmanuals.com

Page 785 of 1226

303-03B-15 Engine Cooling - 2.OL Duratec-HE (M14) 303-03B-15

DIAGNOSIS AND TESTING

A CAUTI0N:lf the ECT sensor output reaches

the

120°C default line under normal cooling

system pressure, internal damage may be

caused to the engine and a diagnostic

trouble code (DTC) will be set in the PCM.

The test should be stopped and the cause

located and corrected. If the cooling

system does not pressurize, the coolant

will boil at

1 OO°C which may also damage

the engine. CARRY

OUT the Coolant

Expansion Tank Cap Pressure Test

Component Test in this section.

If the WDS only allows the ECT sensor to be

displayed in volts, refer to the following table for

corresponding Celsius values:

The CHT sensor output is useful to examine the

cylinder head temperature rise during the warm-up

cycle and later during the normal light throttle cruise

test. This sensor output may vary between vehicles

with manual transmission and vehicles with automatic transmission and should be used for

reference only.

Volts

1.33

1.02

0.78

0.60

0.46

0.35 0.27

The LOAD display is used for reference as it is

necessary to maintain a stable load line during the

test. It is necessary to carry out the test under

normal light throttle cruise driving conditions and

average loads, typically 40% to 70% of the load

value.

OCelsius

60

70

80

90

100

110

120 '

The VSS output is used for reference but can help

to identify misfires and sensors which fail during

the warm-up cycle.

The RPM display indicates the engine speed and

can be compared with the DSRPM.

The DSRPM is the desired or calculated idle speed

which the PCM commands the engine to reach. If

the thermostat opens too early (before the correct

opening temperature has been reached), the

engine will not reach this value. When

using the WDS in data logger mode, the

signals recorded should remain within the

DEFAULT values set by the WDS.

3m AWARNING:M~~~ sure that the WDS is

placed in the vehicle so that it does not

interfere with the safe operation of the

vehicle. Do not place the WDS in the

deployment path of any air bag. Failure to

follow these instructions may result in personal injury.

N0TE:The road test is best carried out with the

aid of another technician in the vehicle to enable

the vehicle to be driven safely while the sensor

outputs are monitored within datalogger. If there

is only one technician available, the WDS can be

set up (using the

recordlcapture mode camera

icon) before leaving the workshop to record a 16

km (1 0 mile) test.

N0TE:The results from the test are more

conclusive if the engine is cold when the test is

started.

Carry out a road test.

REFER to:

RoadIRoller Testing (1 00-00 General

Information, Description and Operation).

4. Drive the vehicle at a constant throttle opening

and set speed until the ECT value settles into

a shallow rise and fall signal, close to a straight

line. This indicates that the thermostat is

functioning correctly.

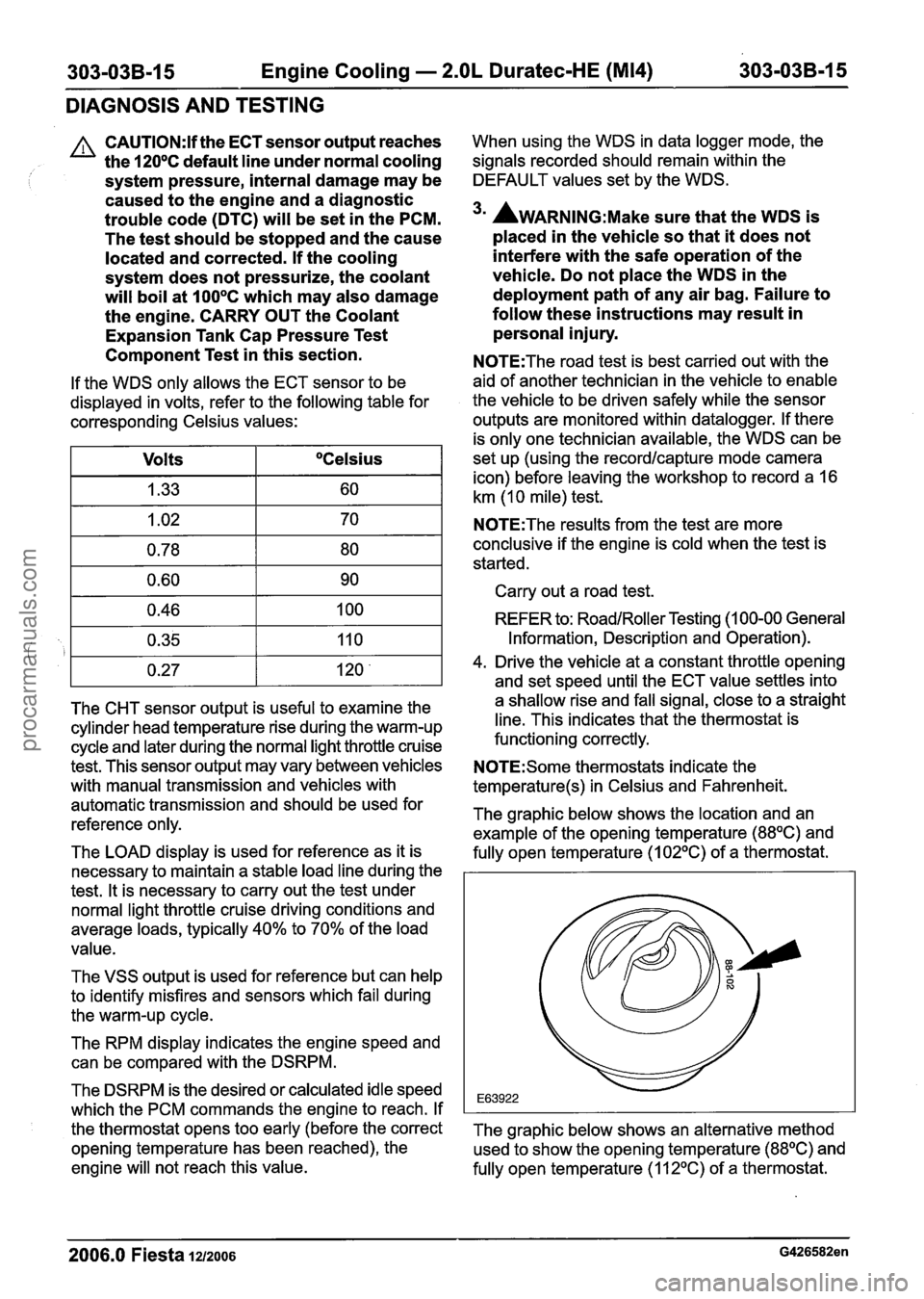

N0TE:Some thermostats indicate the

temperature(s) in Celsius and Fahrenheit.

The graphic below shows the location and an

example of the opening temperature

(88OC) and

fully open temperature (1

02OC) of a thermostat.

The graphic below shows an alternative method used to show the opening temperature

(88OC) and

fully open temperature

(112OC) of a thermostat.

2006.0 Fiesta 1212006 G426582en

procarmanuals.com

Page 961 of 1226

Automatic Transmission/Transaxle .

Vehicles With: 4-Speed Automatic

Transmission

(AW81-40)

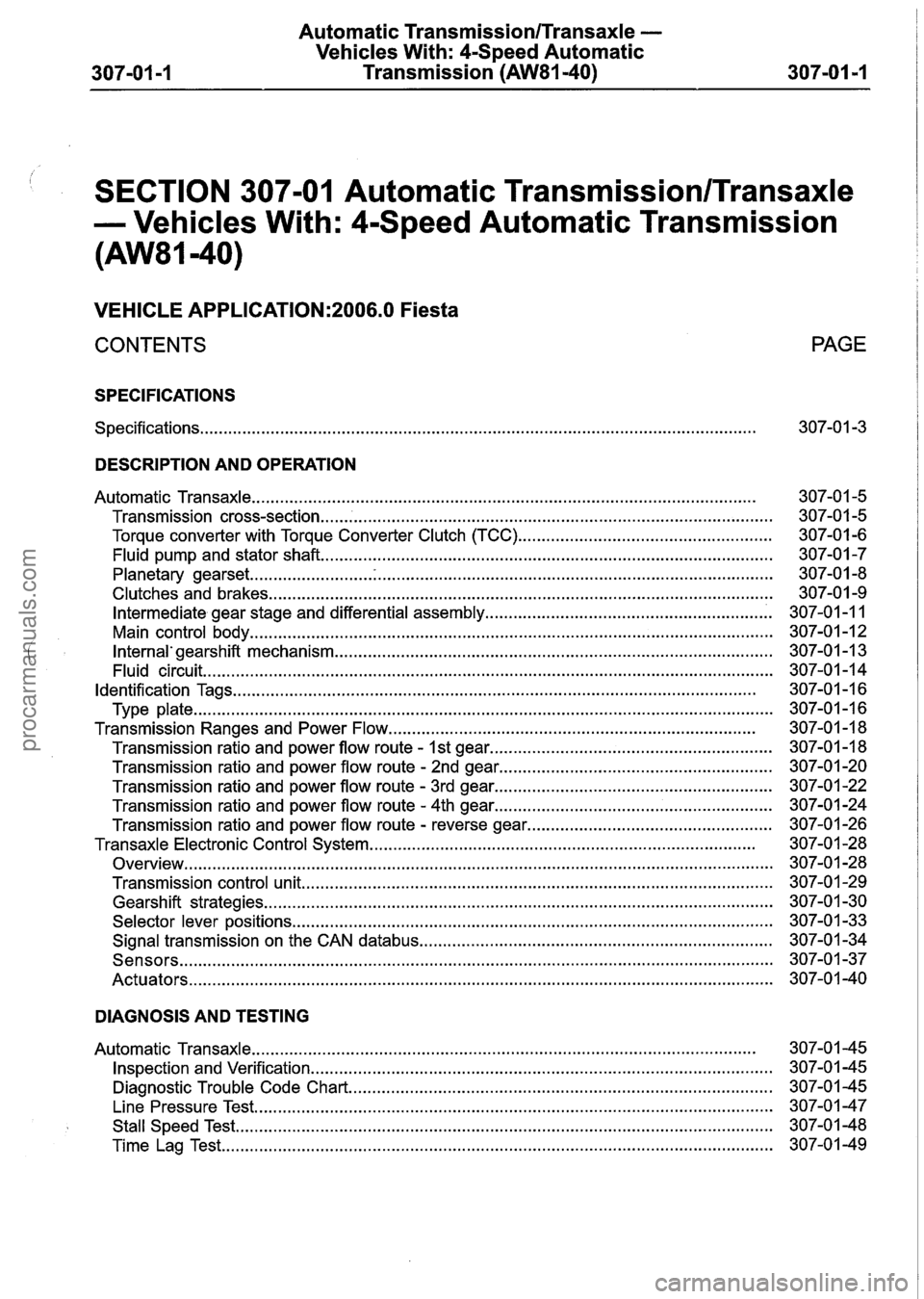

SECTION 307-01 Automatic Transmission/Transaxle

. Vehicles With: 4-Speed Automatic Transmission

(AW81-40)

VEHICLE APPLICATION:2006.0 Fiesta

CONTENTS PAGE

SPECIFICATIONS

Specifications

........................................................................\

.............................................. 307-0 1 -3

DESCRIPTION AND OPERATION

Automatic Transaxle

........................................................................\

...................................

Transmission cross-section ........................................................................\

........................

Torque converter with Torque Converter Clutch (TCC) ......................................................

Fluid pump and stator shaft ........................................................................\

........................

........................................................................\

......... Planetary gearset ......................... .:

Clutches and brakes ........................................................................\

...................................

Intermediate gear stage and differential assembly .............................................................

Main control body ........................................................................\

.......................................

Internal' gearshift mechanism ........................................................................\

.....................

Fluid circuit ........................................................................\

.................................................

........................................................................\

....................................... Identification Tags

Type plate

........................................................................\

...................................................

Transmission Ranges and Power Flow ........................................................................\

......

Transmission ratio and power flow route - 1st gear ............................................................

Transmission ratio and power flow route - 2nd gear ..........................................................

Transmission ratio and power flow route . 3rd gear ...........................................................

Transmission ratio and power flow route . 4th gear ...........................................................

Transmission ratio and power flow route . reverse gear ....................................................

Transaxle Electronic Control System ........................................................................\

..........

........................................................................\

..................................................... Overview

Transmission control unit

........................................................................\

............................

........................................................................\

.................................... Gearshift strategies

Selector lever positions

........................................................................\

..............................

Signal transmission on the CAN databus ........................................................................\

...

........................................................................\

...................................................... Sensors

........................................................................\

.................................................... Actuators

DIAGNOSIS AND TESTING

Automatic Transaxle

........................................................................\

................................... 307-01

Inspection and Verification ........................................................................\

.................... 307-01

Diagnostic Trouble Code Chart

........................................................................\

.................. 307-01

........................................................................\

...................................... Line Pressure Test 307-01

Stall Speed Test

........................................................................\

....................................... 307-01

Time Lag Test

........................................................................\

............................................. 307-01

procarmanuals.com