body system FORD FIESTA 2007 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 332 of 1226

211 -00-12 Steering System - General Information 211-00-12

DIAGNOSIS AND TESTING

Symptom Possible Sources Action

Power steering lines.

Steering gear bushings worn

or perished.

2006.0 Fiesta 12/2006 Gl49906en

CHECK the power steering lin

clamps are secure. REFER to:

(21 1-02 Power Steering)

Power Steering Pump to

Steering Gear Pressure Line

- 1.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V

(Sigma), Vehicles With: Air

Conditioning

(Removal and

Installation),

Power Steering Pump to

Steering Gear Pressure Line

- 1.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V

(Sigma), Vehicles Without:

Air Conditioning

(Removal

and Installation),

Power Steering Pump to

Steering Gear Pressure Line

- I .3L Duratec-8V (Rocam)

(Removal and Installation),

Power Steering Pump to

Steering Gear Pressure Line

- I .4L Duratorq-TDCi (DV)

Diesel (Removal and Installa-

tion),

Power Steering Pump to

Steering Gear Pressure Line

- 2.OL Duratec-HE (M14) RHD

(Removal and Installation),

Steering Gear to Power

Steering

Fluid Reservoir

Return Line

- 2.OL Duratec-

HE

(M14) RHD (Removal and

Installation),

Steering Gear to Fluid Cooler

Return Hose (Removal and

Installation).

CHECK the power steering

lines for clearance from the

vehicle body, front axle cross-

member and steering gear.

CHECK the steering gear

transfer

lines for clearance from

the steering gear.

CHECK and INSTALL new

components as necessary.

I REFER to: Steering Gear

Bushing (21 1-02 Power

Steering,

Removal and

Installation).

procarmanuals.com

Page 335 of 1226

21 1-00-1 5 Steering System - General Information 21 I -00-1 5

DIAGNOSIS AND TESTING

2. With the road wheels in the straight ahead

position, gently turn the steering wheel to the

1 left and the right to check free play in the

steering linkage.

3. There should be no excessive free play at the

steering wheel rim. If there is excessive free

play, CHECK the tie-rod inner and outer ball

joints, REFER to Tie-Rod Component Test in

this procedure. CHECK the steering column

universal joint, REFER to Steering Column

Universal Joint Component Test in this

procedure. If there is no free play in the tie-rod

and the steering column, install a new steering

gear.

REFER to: Steering Gear (211-02 Power

Steering, Removal and installation).

Tie-Rod

A CAUTI0N:The steering gear boots must be

handled carefully to avoid damage. Use

new steering gear boot clamps when

installing the steering gear boots.

N0TE:Noises such as knocks, which may appear

to originate from the steering linkage, may also be

( , generated by front suspension components.

1. Raise and support the vehicle. REFER to:

(1 00-02 Jacking and Lifting)

Jacking (Description and Operation),

Lifting (Description and Operation).

3m ACAUTION:T~ prevent damage to the

steering linkage, turn the steering wheel to move the steering linkage to the steering

lock stop.

Turn the steering wheel to position the steering

linkage against the right-hand steering lock stop.

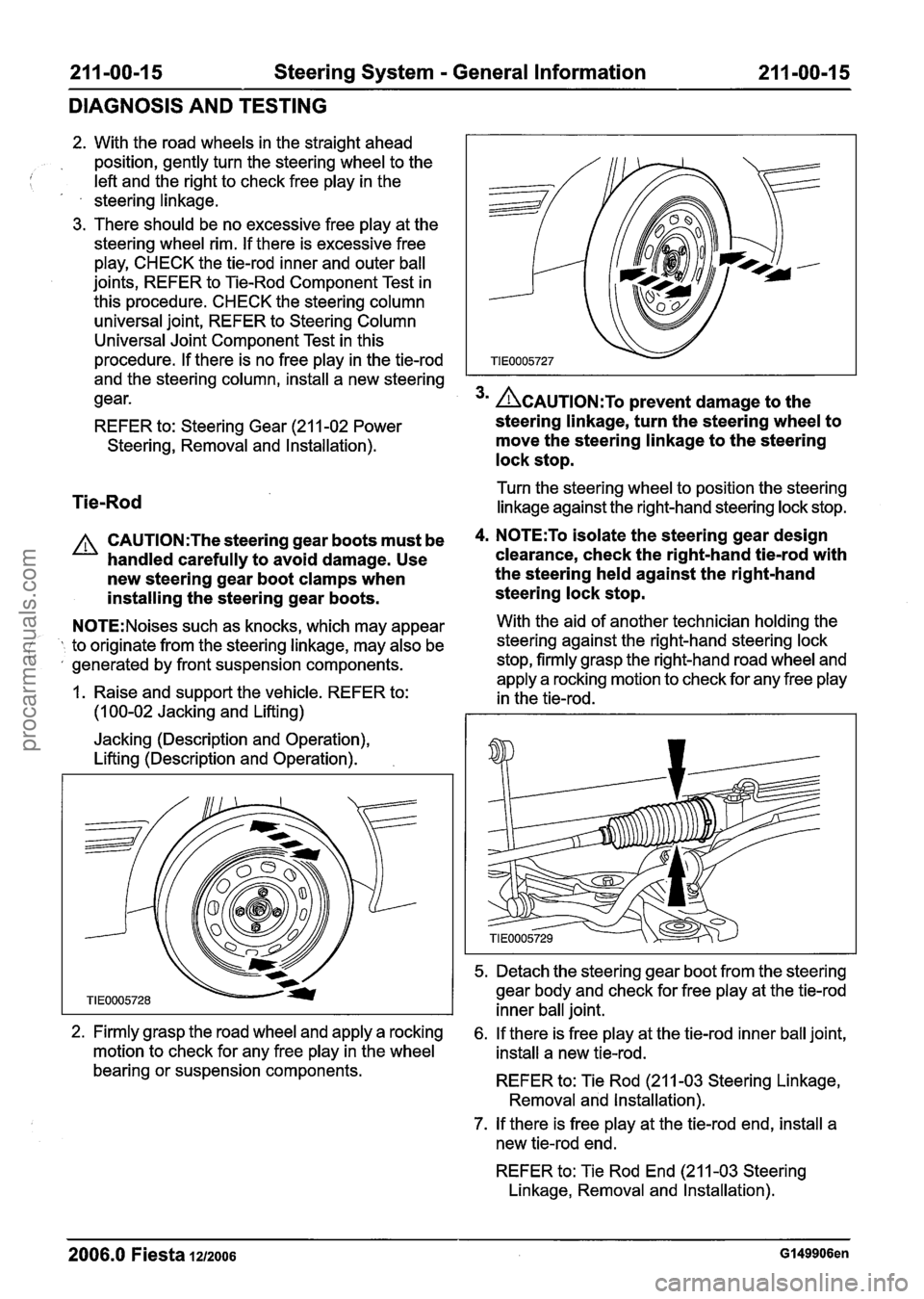

4. N0TE:To isolate the steering gear design

clearance, check the right-hand tie-rod with

the steering held against the right-hand

steering lock stop.

With the aid of another technician holding the

steering against the right-hand steering lock

stop, firmly grasp the right-hand road wheel and

apply a rocking motion to check for any free play

in the tie-rod.

5. Detach the steering gear boot from the steering

gear body and check for free play at the tie-rod

inner ball joint.

2. Firmly grasp the road wheel and apply a rocking 6. If there is free play at the tie-rod inner ball joint,

motion to check for any free play in the wheel

install a new tie-rod.

bearing or suspension components.

REFER to: Tie Rod (211-03 Steering Linkage,

Removal and installation).

7. If there is free play at the tie-rod end, install a

new tie-rod end.

REFER to: Tie Rod End (21 1-03 Steering

Linkage, Removal and Installation).

2006.0 Fiesta 1212006 GI 49906en

procarmanuals.com

Page 336 of 1226

21 1-00-1 6 Steering System - General Information 21 I -00-1 6

DIAGNOSIS AND TESTING

8m ACAUTION:T~ prevent damage to the

steering linkage, turn the steering wheel to

move the steering linkage to the steering

lock stop.

Turn the steering wheel to position the steering

linkage against the left-hand steering lock stop.

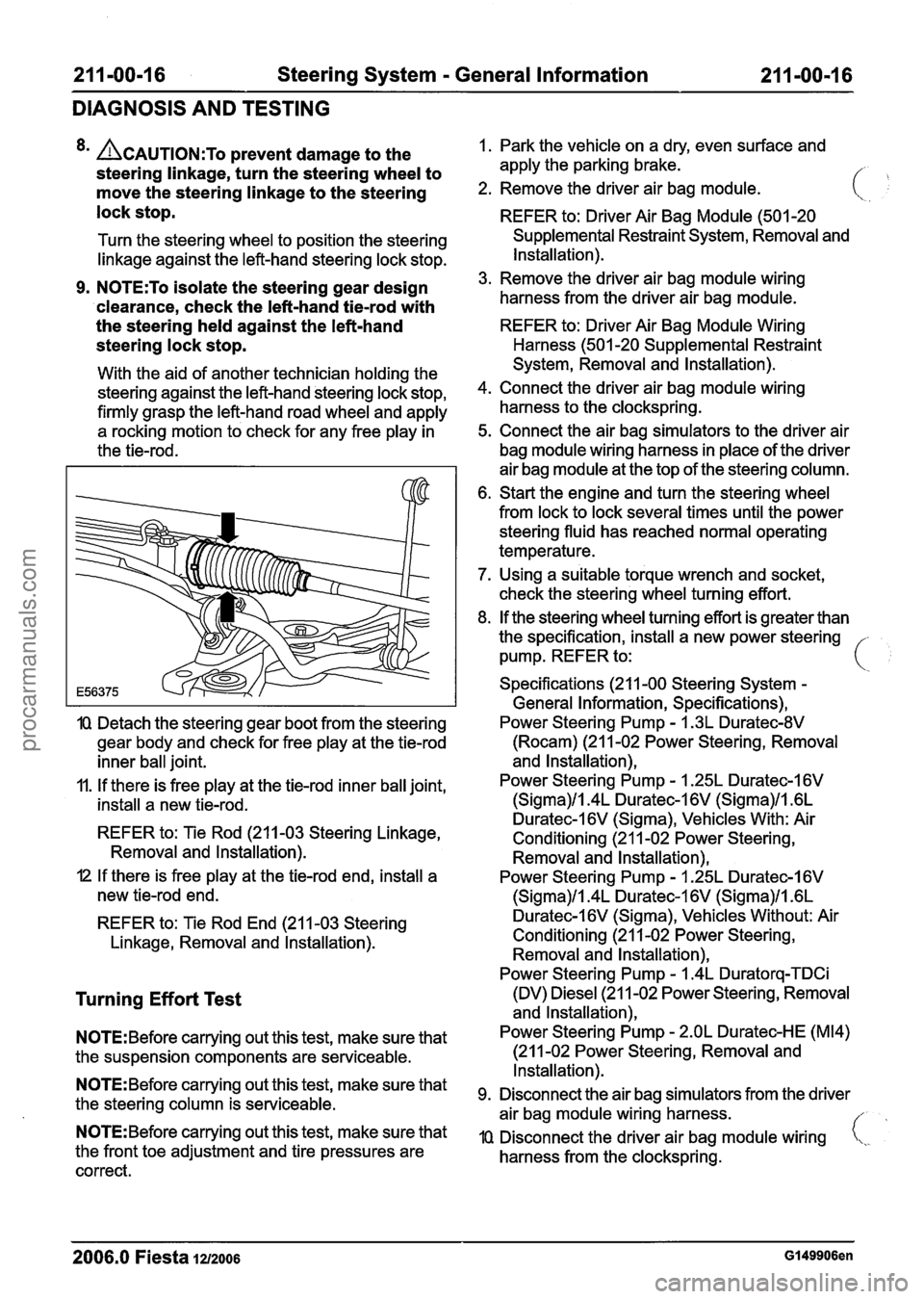

9. N0TE:To isolate the steering gear design

'clearance, check the left-hand

tiemrod with

the steering held against the left-hand

steering lock stop.

With the aid of another technician holding the

steering against the left-hand steering lock stop,

firmly grasp the left-hand road wheel and apply

a rocking motion to check for any free play in

the tie-rod.

IQ Detach the steering gear boot from the steering

gear body and check for free play at the tie-rod

inner ball joint.

11. If there is free play at the tie-rod inner ball joint,

install a new tie-rod.

REFER to: Tie Rod (211-03 Steering Linkage,

Removal and lnstallation).

I2 If there is free play at the tie-rod end, install a

new tie-rod end.

REFER to: Tie Rod End (21 1-03 Steering

Linkage, Removal and lnstallation).

Turning Effort Test

N0TE:Before carrying out this test, make sure that

the suspension components are serviceable.

N0TE:Before carrying out this test, make sure that

the steering column is serviceable.

N0TE:Before carrying out this test, make sure that

the front toe adjustment and tire pressures are

correct. 1.

Park the vehicle on a dry, even surface and

apply the parking brake.

/- ,

2. Remove the driver air bag module.

REFER to: Driver Air Bag Module (501 -20

Supplemental Restraint System, Removal and

Installation).

3. Remove the driver air bag module wiring

harness from the driver air bag module.

REFER to: Driver Air Bag Module Wiring

Harness (501 -20 Supplemental Restraint

System, Removal and Installation).

4. Connect the driver air bag module wiring

harness to the clockspring.

5. Connect the air bag simulators to the driver air

bag module wiring harness in place of the driver

air bag module at the top of the steering column.

6. Start the engine and turn the steering wheel

from lock to lock several times until the power

steering fluid has reached normal operating

temperature.

7. Using a suitable torque wrench and socket,

check the steering wheel turning effort.

8. If the steering wheel turning effort is greater than

the specification, install a new power steering -

pump. REFER to: i

Specifications (21 1-00 Steering System -

General Information, Specifications),

Power Steering Pump

- I .3L Duratec-8V

(Rocam) (21 1-02 Power Steering, Removal

and lnstallation),

Power Steering Pump

- 1.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V (Sigma)/l .6L

Duratec-l6V (Sigma), Vehicles With: Air

Conditioning (21 1-02 Power Steering,

Removal and lnstallation),

Power Steering Pump

- I .25L Duratec-I 6V

(Sigma)/l.4L Duratec-1 6V (Sigma)/l .6L

Duratec-I 6V (Sigma), Vehicles Without: Air

Conditioning (21 1-02 Power Steering, Removal and lnstallation),

Power Steering Pump

- 1.4L Duratorq-TDCi

(DV) Diesel (21 1-02 Power Steering, Removal

and lnstallation),

Power Steering Pump

- 2.OL Duratec-HE (M14)

(21 1-02 Power Steering, Removal and

Installation).

Disconnect the air bag simulators from the driver

air bag module wiring harness.

//

IQ Disconnect the driver air bag module wiring i,,.

harness from the clockspring.

2006.0 Fiesta 1212006 GI 49906en

procarmanuals.com

Page 342 of 1226

21 1-00-22 Steering System - General Information 21 1-00-22

GENERAL PROCEDURES

Start the engine and slowly turn the steering

wheel from lock to lock and add power

steering fluid until the power steering fluid

in the power steering fluid reservoir does

not drop.

8. Switch OFF the engine and examine the

power steering hose connections, steering

gear boots, power steering valve body and

power steering pump for external leaks.

9. Check the power steering fluid level. Fill the

power steering fluid reservoir to the MAX

mark with the appropriate power steering

fluid.

For additional information, refer to:

Specifications (211

-00 Steering System -

General Information, Specifications).

10.

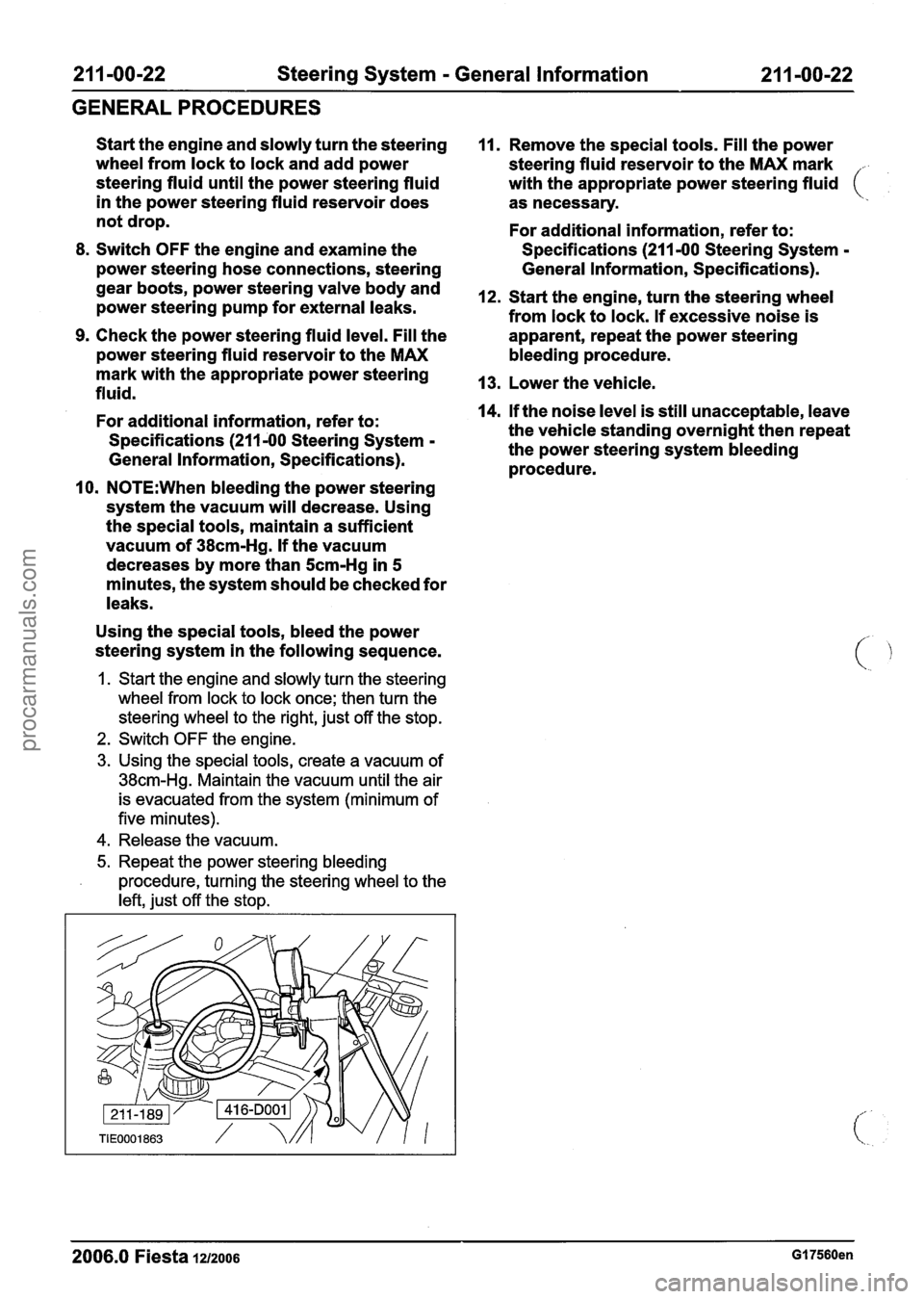

N0TE:When bleeding the power steering

system the vacuum will decrease. Using

the special tools, maintain a sufficient

vacuum of

38cm-Hg. If the vacuum

decreases by more than

5cm-Hg in 5

minutes, the system should be checked for

leaks.

Using the special tools, bleed the power

steering system in the following sequence.

1. Start the engine and slowly turn the steering

wheel from lock to lock once; then turn the

steering wheel to the right, just off the stop.

2. Switch OFF the engine.

3. Using the special tools, create a vacuum of

38cm-Hg. Maintain the vacuum until the air

is evacuated from the system (minimum of

five minutes).

4. Release the vacuum.

5. Repeat the power steering bleeding

procedure, turning the steering wheel to the

left, just off the stop.

11. Remove the special tools. Fill the power

steering fluid reservoir to the MAX mark

.

with the appropriate power steering fluid (

as necessary.

For additional information, refer to:

Specifications (211

-00 Steering System -

General Information, Specifications).

12. Start the engine, turn the steering wheel

from lock to lock. If excessive noise is

apparent, repeat the power steering

bleeding procedure.

13. Lower the vehicle.

14.

If the noise level is still unacceptable, leave

the vehicle standing overnight then repeat

the power steering system bleeding

procedure.

- -

2006.0 Fiesta 121zo06 GI 7560en

procarmanuals.com

Page 395 of 1226

21 1 -02-47 Power Steering 21 1-02-47

REMOVAL AND INSTALLATION

6. Detach the steering gear to power steering All vehicles

fluid cooler return hose from the power

-

/ I steering line.

Right-hand drive vehicles

7. Remove the steering gear heat shield.

9. Disconnect the power steering lines from the

steering gear valve body.

I. Remove the retaining bolt.

2. Rotate the clamp plate.

Allow the fluid to drain into a suitable

container.

Discard the O-ring seals.

10. Remove the steering gear to power steering

fluid cooler return hose.

Installation

1. N0TE:Make sure that the collar on the hose

is fully inserted into the quick release

coupling.

N0TE:Check the power steering lines to steering

gear valve body O-ring seals for damage or fatigue.

8.

N0TE:Note the position of the steering gear Install new O-rin~ seals as necessary. - to power steering fluid cooler return hose to

aid installation. To

install, reverse the removal procedure.

Detach the steering gear to power steering

2. Fill and bleed the power steering system. For

fluid cooler return hose bracket from the additional information, refer

to: (211 -00

steering gear. Steering System

- General

Information)

Power Steering System Filling (General

Procedures),

Power Steering System Bleeding (General

Procedures).

2006.0 Fiesta 1212006 G91967en

procarmanuals.com

Page 812 of 1226

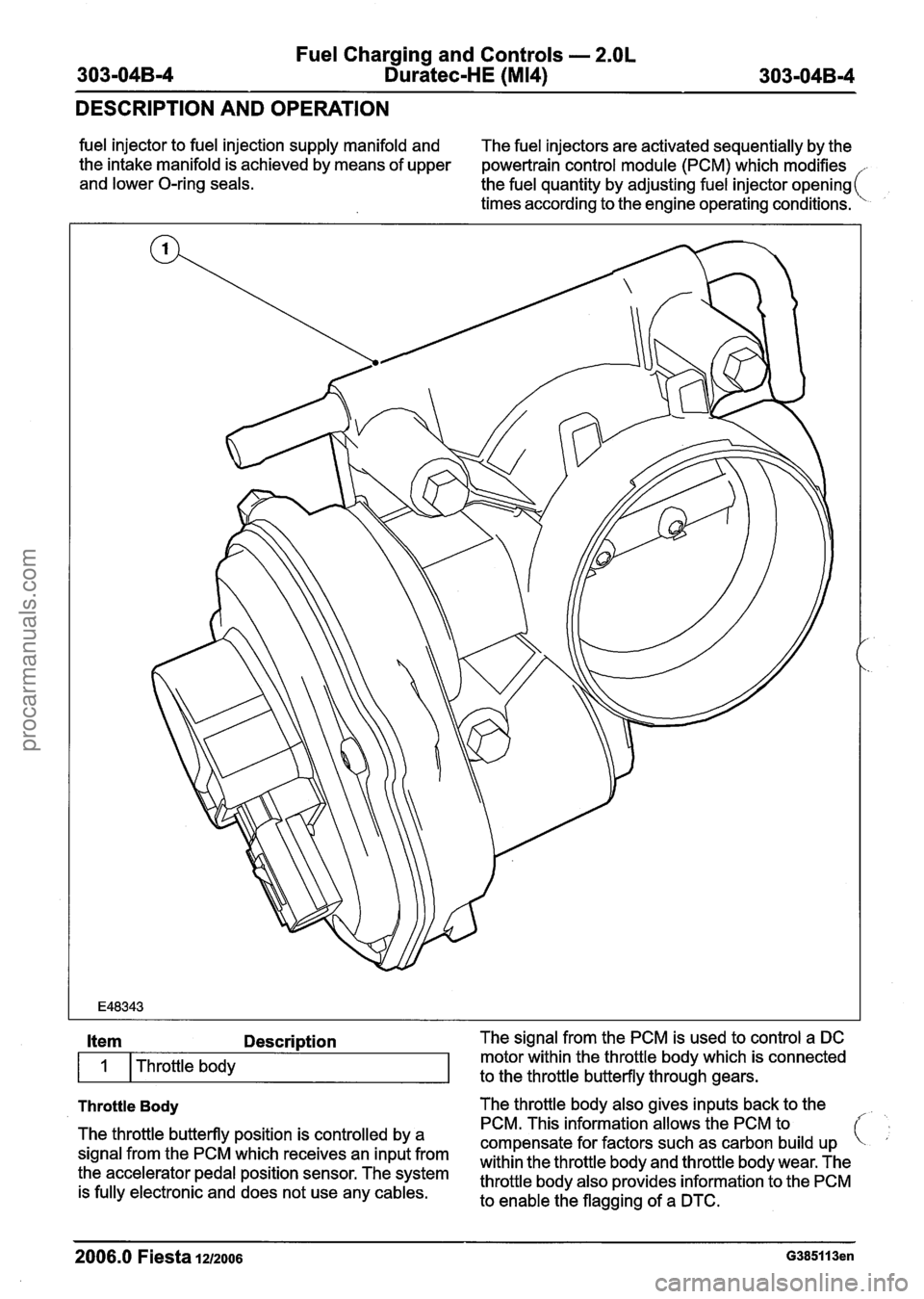

Fuel Charging and Controls - 2.OL

303-04B-4 Duratec-HE (M14) 303-04B-4

DESCRIPTION AND OPERATION

fuel injector to fuel injection supply manifold and

The fuel injectors are activated sequentially by the

the intake manifold is achieved by means of upper

powertrain control module (PCM) which modifies

and lower O-ring seals.

the fuel quantity by adjusting fuel injector opening

times according to the engine operating conditions.

Throttle Body The throttle body also gives inputs back to the

Item Description The signal from the PCM is used to control a DC

The throttle butterfly position is controlled by a

signal from the PCM which receives an input from

the accelerator pedal position sensor. The system

is fully electronic and does not use any cables.

I

PCM. This information allows the PCM to

compensate for factors such as carbon build up

within the throttle body and throttle body wear. The

throttle body also provides information to the PCM

to enable the flagging of a DTC.

Throttle

body

2006.0 Fiesta 1212006 G385113en

motor within the throttle body which is connected

to the throttle butterfly through gears.

procarmanuals.com

Page 814 of 1226

Fuel Charging and Controls - 2.OL

303-04B-6 Duratec-HE (M14) 303-04B-6

DIAGNOSIS AND TESTING

1 6 1 Heated Oxygen sensor (H02s) I

Item Description Fuel supply

1 7 1 Intake manifold I

5

Fuel injectors

Throttle body

The fuel supply for all petrol fueled variants is

equipped with a return-less fuel system. This

means that the fuel delivery pressure at the fuel

injectors, is monitored and controlled by the fuel

tank module. This control is achived by switching

the fuel pump on and off.

The fuel pump module for both the Ethanol E85

TO maintain the same or similar power output to variant vehicle and the unleaded fueled vehicle are

that of the unleaded fuel vehicle, the fuel injectors

very similar, visual^ the only difference is the fuel

have been replaced with high flow fuel injectors. pump electrical connections which on the Ethanol

E85 variant is sealed. This is not the only

differance, both fuel pump modules have different

(

Fuel composition monitoring fuel level sensor resistor card values.

The quantity of Ethanol E85 in relation to the

quantity of unleaded fuel contained in the fuel tank

at any one time is not monitored at the fuel tank.

The Ethanol percentage volume can only decrease

from its maximum 85% (pure Ethanol

E85), to zero

(1 00% unleaded fuel).

The fuel charging system compensates for the

changes in fuel composition using the signal

received by the power train control module (PCM)

from the

H02s. The PCM adapts the fueling and

ignition calibrations to suit the current fuel tank

content composition.

Cold start

To overcome the problems relating to cold start

inherent with Ethanol E85 vehicles (temperatures

down to -29 degrees centigrade), a block heater

has been installed into the engine coolant system.

The block heater is located to the rear of the engine

under the exhaust manifold. The block heater is

fitted with a dedicated harness which terminates at an external plug connector fitted into the radiator

grill.

2006.0 Fiesta 1212006

procarmanuals.com

Page 874 of 1226

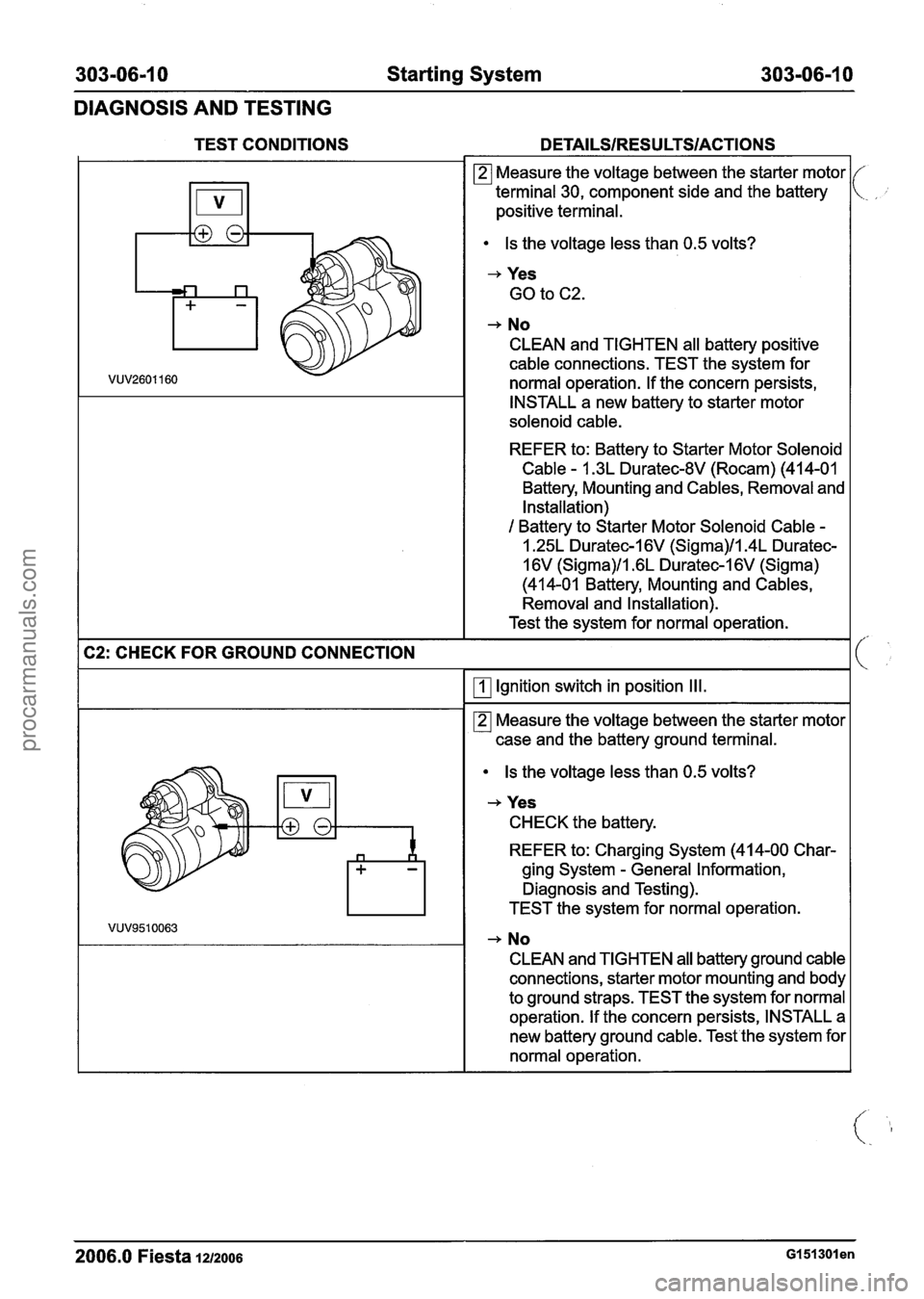

303-06-1 0 Starting System 303-06-1 0

DIAGNOSIS AND TESTING

TEST CONDITIONS DETAILSIRESULTSIACTIONS

Measure the voltage between the starter motor

terminal 30, component side and the battery

positive

terminal.

Is the voltage less than 0.5 volts?

+ Yes

GO to C2.

+ No

CLEAN and TIGHTEN all battery positive

cable connections. TEST the system for

normal operation. If the concern persists,

INSTALL a new battery to starter motor

solenoid cable.

REFER to: Battery to Starter Motor Solenoid

Cable - 1.3L Duratec-8V (Rocam) (41 4-01

Battery, Mounting and

Cables, Removal and

Installation)

1 Battery to Starter Motor Solenoid Cable -

1.25L Duratec-1 6V (Sigma)/l.4L Duratec-

16V (Sigma)/l.6L Duratec-1 6V (Sigma)

(414-01 Battery, Mounting and

Cables,

Removal and Installation).

Test the system for normal operation. - - ---

I C2: CHECK FOR GROUND CONNECTION

-

I f

Ignition switch in position Ill.

Is the voltage less than 0.5 volts?

-, Yes

CHECK the battery.

REFER to: Charging System (414-00 Char-

ging System

- General Information,

Diagnosis and Testing).

TEST the system for

normal operation.

+ No

CLEAN and TIGHTEN all battery ground cable

connections, starter motor mounting and body

to ground straps. TEST the system for

normal

operation. If the concern persists, INSTALL a

new battery ground

cable. Testlhe system for

normal operation.

2006.0 Fiesta 1212006 GI 51 301 en

procarmanuals.com

Page 941 of 1226

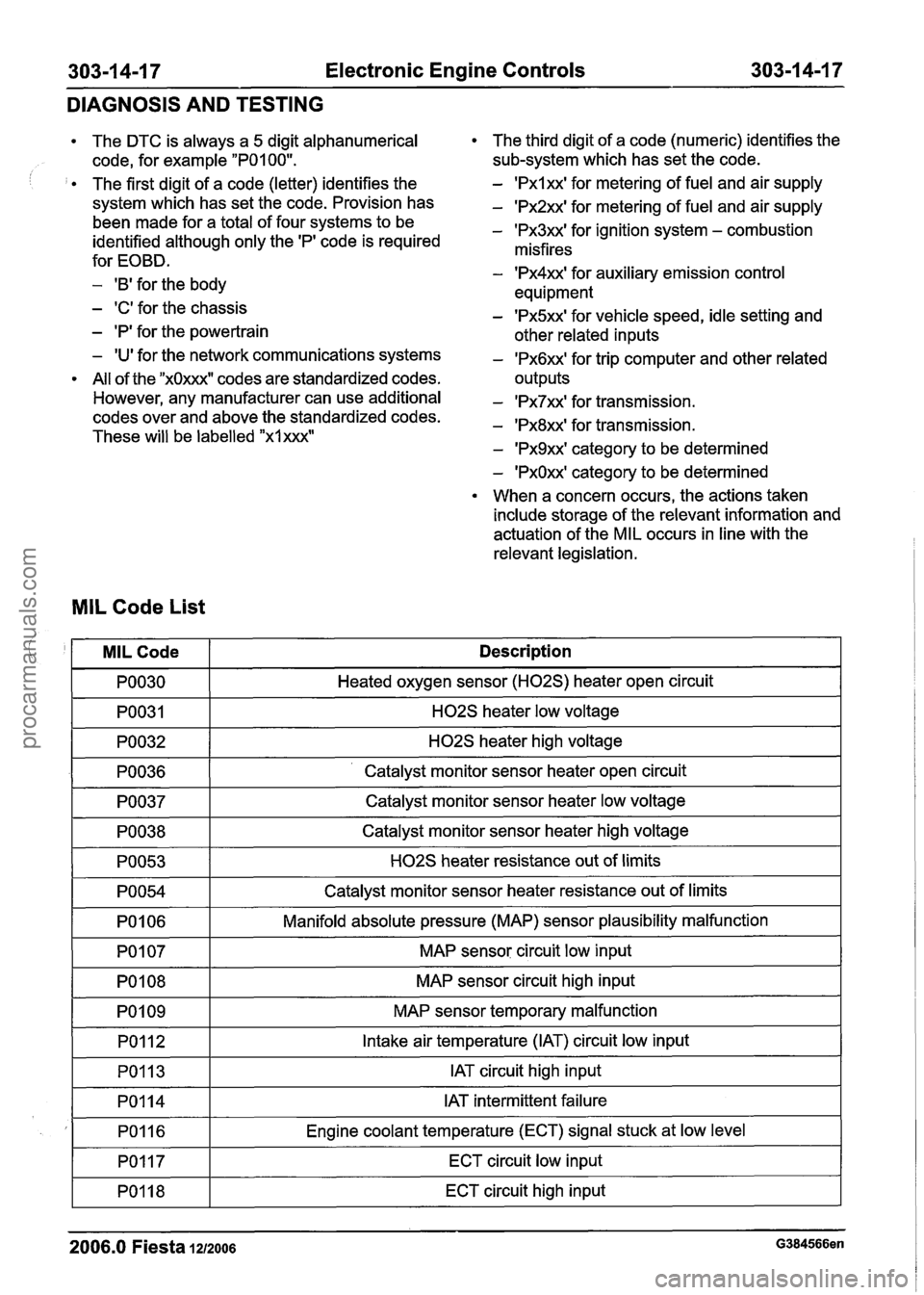

303-1 4-1 7 Electronic Engine Controls 303-1 4-1 7

DIAGNOSIS AND TESTING

The DTC is always a 5 digit alphanumerical

code, for example

"POI 00".

The first digit of a code (letter) identifies the

system which has set the code. Provision has

been made for a total of four systems to be

identified although only the

'PI code is required

for EOBD.

- 'B' for the body

- 'C' for the chassis

- 'P' for the powertrain

- 'U' for the network communications systems

All of the

"xOxxxW codes are standardized codes.

However, any manufacturer can use additional

codes over and above the standardized codes.

These will be labelled

"xlxxx"

The third digit of a code (numeric) identifies the

sub-system which has set the code.

- 'Pxlxx' for metering of fuel and air supply

- 'Px2xx' for metering of fuel and air supply

- 'Px3xx' for ignition system - combustion

misfires

- 'Px4xx' for auxiliary emission control

equipment

- 'Px5xx' for vehicle speed, idle setting and

other related inputs

- 'Px6xx' for trip computer and other related

outputs

- 'Px7xx' for transmission.

- 'Px8xx' for transmission.

- 'Px9xx' category to be determined

- 'PxOxx' category to be determined

When a concern occurs, the actions taken

include storage of the relevant information and

actuation of the MIL occurs in line with the

relevant legislation.

MIL Code List

I PO030 I Heated oxygen sensor (H02S) heater open circuit I

! '

-1 H02S heater low voltage I

I PO032 I H02S heater high voltage I

MILCode

PO036 1- ' Catalyst monitor sensor heater open circuit I

Description

PO037

I PO054 I Catalyst monitor sensor heater resistance out of limits I

Catalyst monitor sensor heater low voltage

PO038

PO053

I PO106 I Manifold absolute pressure (MAP) sensor plausibility malfunction I

-

Catalyst monitor sensor heater high voltage

H02S heater resistance out of limits

I PO107 I MAP sensor circuit low input I

PO108

PO1 09 MAP sensor

circuit high input

MAP sensor temporary malfunction

PO1 12

PO113

I PO117 I ECT circuit low input I

Intake air temperature (IAT) circuit low input

IAT circuit high input

I

2006.0 Fiesta 1212006 G384566en

PO114

PO1 16

PO118

IAT intermittent failure

Engine coolant temperature (ECT) signal stuck at low level

ECT circuit high input

procarmanuals.com

Page 944 of 1226

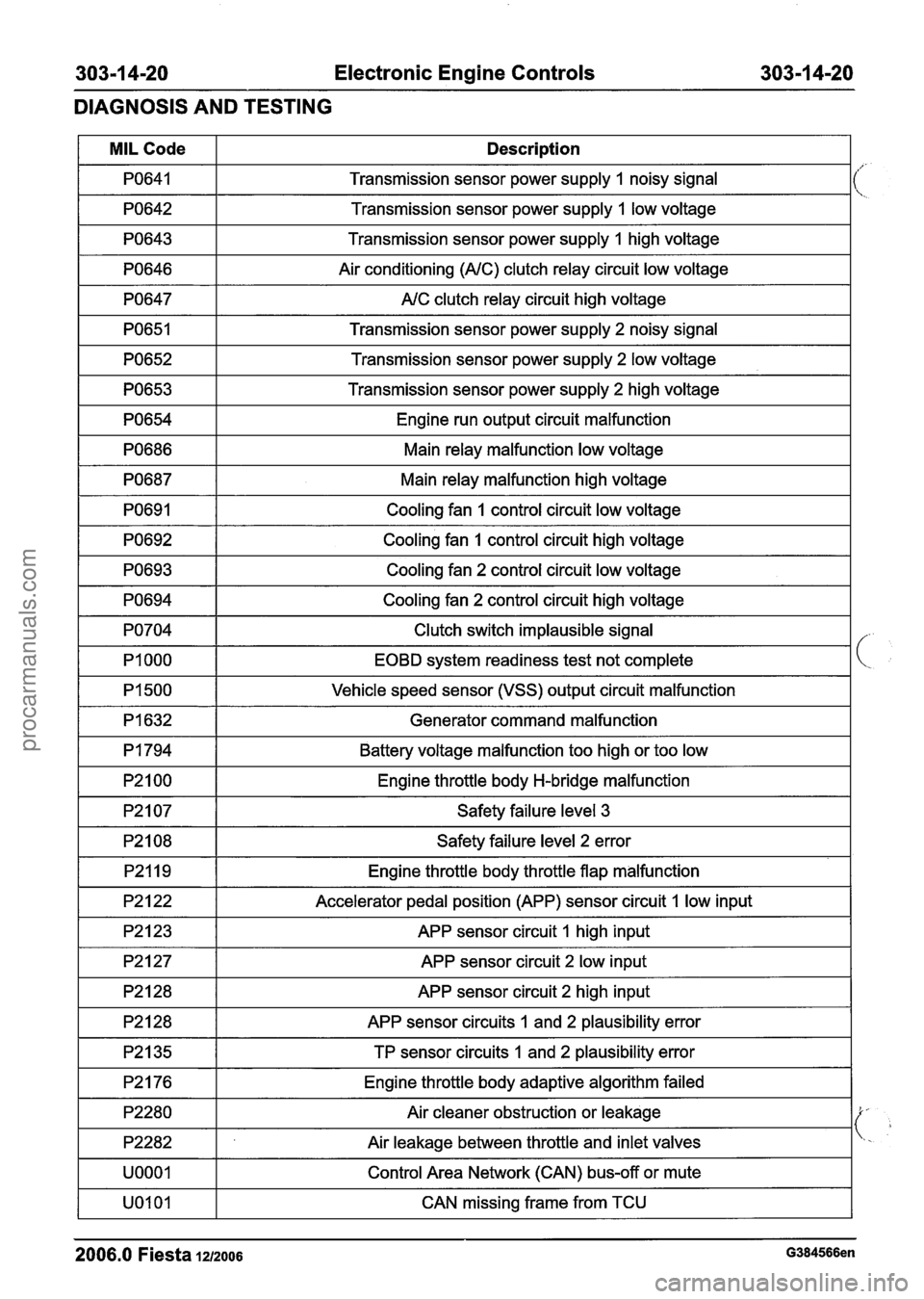

303-1 4-20 Electronic Engine Controls 303-1 4-20

DIAGNOSIS AND TESTING

1 PO643 1 Transmission sensor power supply 1 high voltage I

MIL Code

PO641

PO642

1 PO646 1 Air conditioning (NC) clutch relay circuit low voltage I

1 PO647 1 NC clutch relay circuit high voltage I

Description

Transmission sensor power supply 1 noisy signal

Transmission sensor power supply

I low voltage

I PO651 I Transmission sensor power supply 2 noisy signal I

i

PO652

PO653

Transmission sensor power supply 2 low voltage

Transmission sensor power supply

2 high voltage

PO654

PO686

1 PO692 1 Cooling fan 1 control circuit high voltage I

Engine run output circuit malfunction

Main relay malfunction low voltage

PO687

PO691

1 PO693 1 Cooling fan 2 control circuit low voltage I

Main relay malfunction high voltage

Cooling fan

1 control circuit low voltage

1 PO694 1 Cooling fan 2 control circuit high voltage I

I PI500 I Vehicle speed sensor (VSS) output circuit malfunction I

PO704

PI 000

Generator command malfunction I

Clutch switch implausible signal

EOBD system readiness test not complete

I P2107 I Safety failure level 3 I

PI 794

P2100

I P2108 I Safety failure level 2 error I

Battery voltage malfunction too high or too low

Engine throttle body H-bridge malfunction

APP sensor circuit 1 high input I

P2119

P2122

1 P2127 1 APP sensor circuit 2 low input I

Engine throttle body throttle flap malfunction

Accelerator pedal position (APP) sensor circuit

1 low input

1 P2128 1 APP sensor circuit 2 high input I

1 P2176 1 Engine throttle body adaptive algorithm failed 1

P2128

P2135

APP sensor circuits I and 2 plausibility error

TP sensor circuits 1 and 2 plausibility error

I UOOOl I Control Area Network (CAN) bus-off or mute I

P2280

P2282

I UOlOl I CAN missing frame from TCU I

Air cleaner obstruction or leakage

Air leakage between throttle and inlet valves

2006.0 Fiesta 1212006 G384566en

procarmanuals.com