lock FORD FLEX 2017 1.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2017, Model line: FLEX, Model: FORD FLEX 2017 1.GPages: 496, PDF Size: 5.92 MB

Page 263 of 496

6.

There is a distinct change from light to

dark in the left-hand portion of the

headlamp beam pattern. Position the

top edge of this cut-off 3 in (7.5 cm)

below the horizontal reference line. 7. To adjust the vertical aim, use a

suitable tool to rotate the adjuster

clockwise or counterclockwise.

Note: To see a clearer light pattern while

adjusting one headlamp, block the light

from the other headlamp.

8. Close the hood and switch the low beam headlamps off. Horizontal Aim Adjustment

Horizontal aim is not adjustable on your

vehicle.

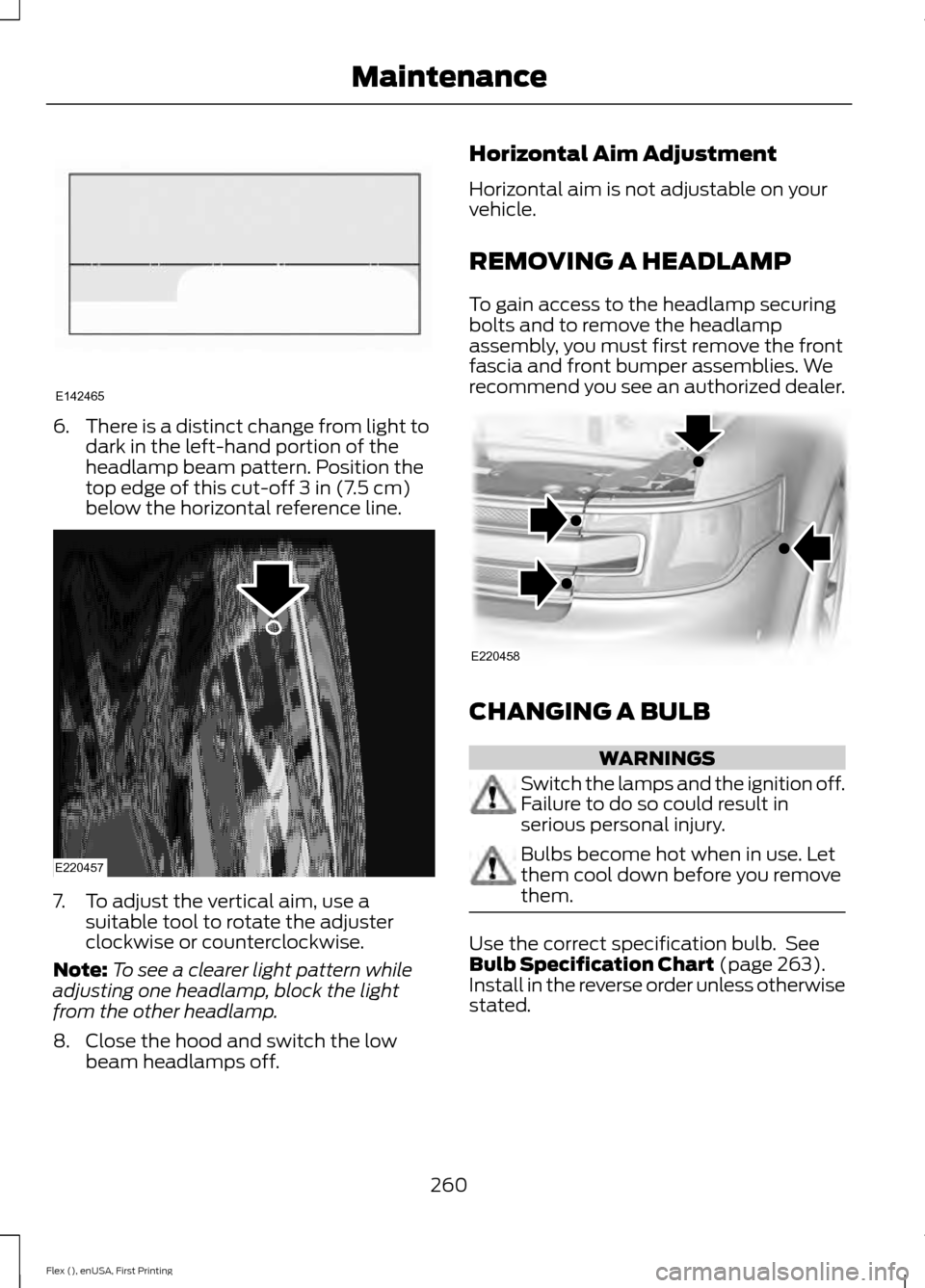

REMOVING A HEADLAMP

To gain access to the headlamp securing

bolts and to remove the headlamp

assembly, you must first remove the front

fascia and front bumper assemblies. We

recommend you see an authorized dealer.

CHANGING A BULB

WARNINGS

Switch the lamps and the ignition off.

Failure to do so could result in

serious personal injury.

Bulbs become hot when in use. Let

them cool down before you remove

them.

Use the correct specification bulb. See

Bulb Specification Chart

(page 263).

Install in the reverse order unless otherwise

stated.

260

Flex (), enUSA, First Printing MaintenanceE142465 E220457 E220458

Page 264 of 496

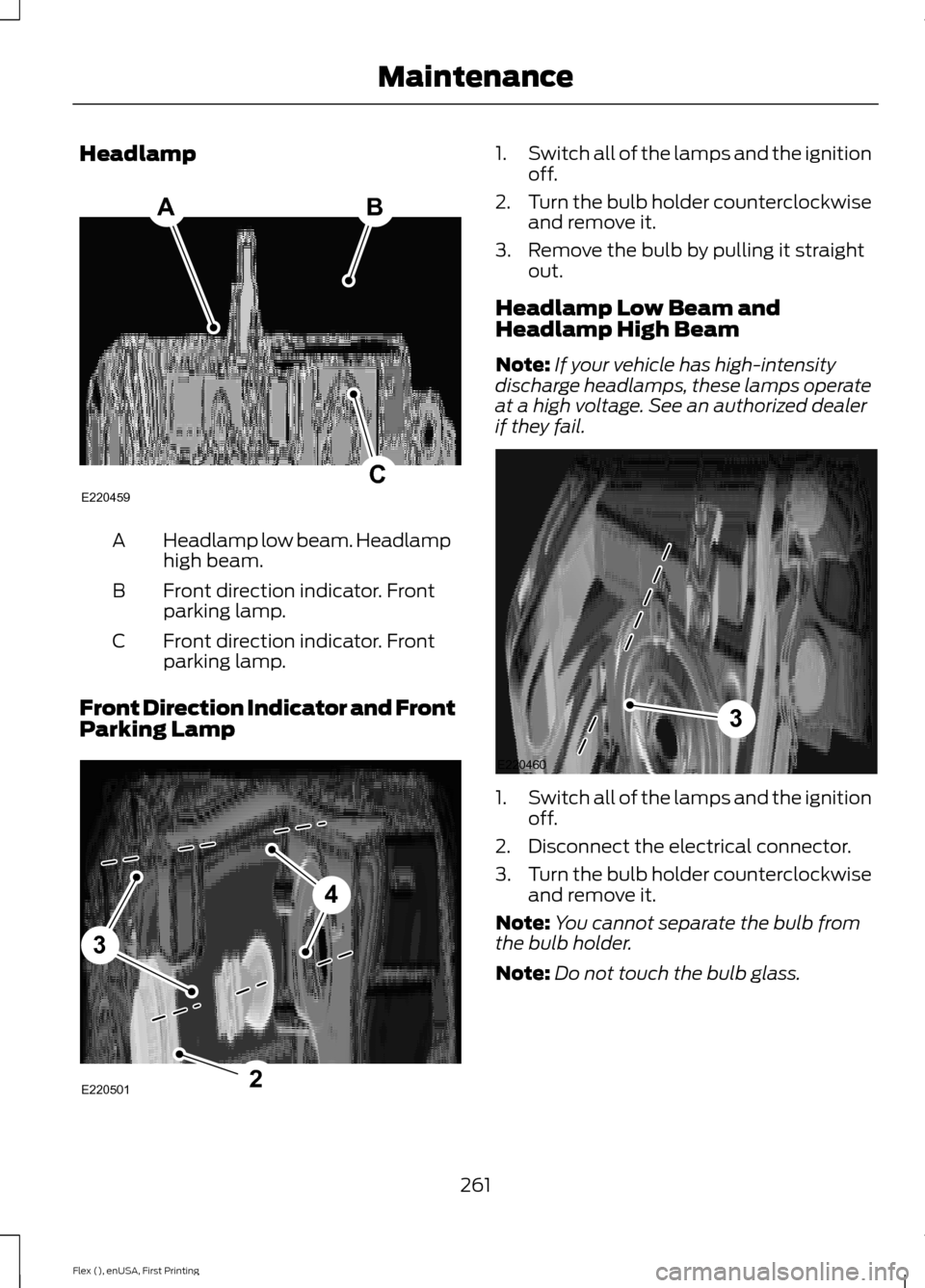

Headlamp

Headlamp low beam. Headlamp

high beam.

A

Front direction indicator. Front

parking lamp.

B

Front direction indicator. Front

parking lamp.

C

Front Direction Indicator and Front

Parking Lamp 1.

Switch all of the lamps and the ignition

off.

2. Turn the bulb holder counterclockwise

and remove it.

3. Remove the bulb by pulling it straight out.

Headlamp Low Beam and

Headlamp High Beam

Note: If your vehicle has high-intensity

discharge headlamps, these lamps operate

at a high voltage. See an authorized dealer

if they fail. 1.

Switch all of the lamps and the ignition

off.

2. Disconnect the electrical connector.

3. Turn the bulb holder counterclockwise

and remove it.

Note: You cannot separate the bulb from

the bulb holder.

Note: Do not touch the bulb glass.

261

Flex (), enUSA, First Printing MaintenanceE220459

AB

C 2

4

3

E220501 3

E220460

Page 265 of 496

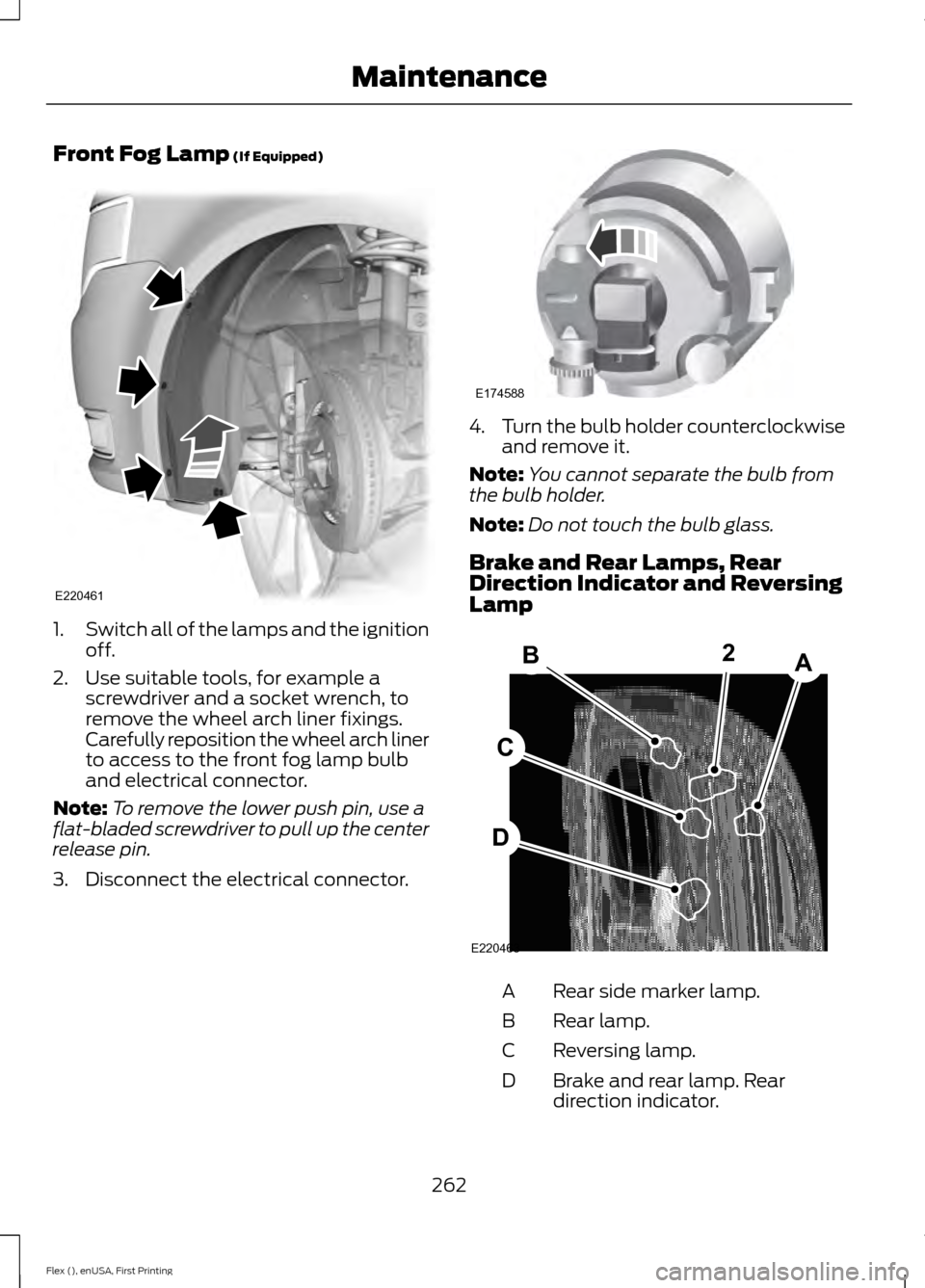

Front Fog Lamp (If Equipped)

1.

Switch all of the lamps and the ignition

off.

2. Use suitable tools, for example a screwdriver and a socket wrench, to

remove the wheel arch liner fixings.

Carefully reposition the wheel arch liner

to access to the front fog lamp bulb

and electrical connector.

Note: To remove the lower push pin, use a

flat-bladed screwdriver to pull up the center

release pin.

3. Disconnect the electrical connector. 4.

Turn the bulb holder counterclockwise

and remove it.

Note: You cannot separate the bulb from

the bulb holder.

Note: Do not touch the bulb glass.

Brake and Rear Lamps, Rear

Direction Indicator and Reversing

Lamp Rear side marker lamp.

A

Rear lamp.

B

Reversing lamp.

C

Brake and rear lamp. Rear

direction indicator.

D

262

Flex (), enUSA, First Printing MaintenanceE220461 E174588 E220463

C

BA

D

2

Page 266 of 496

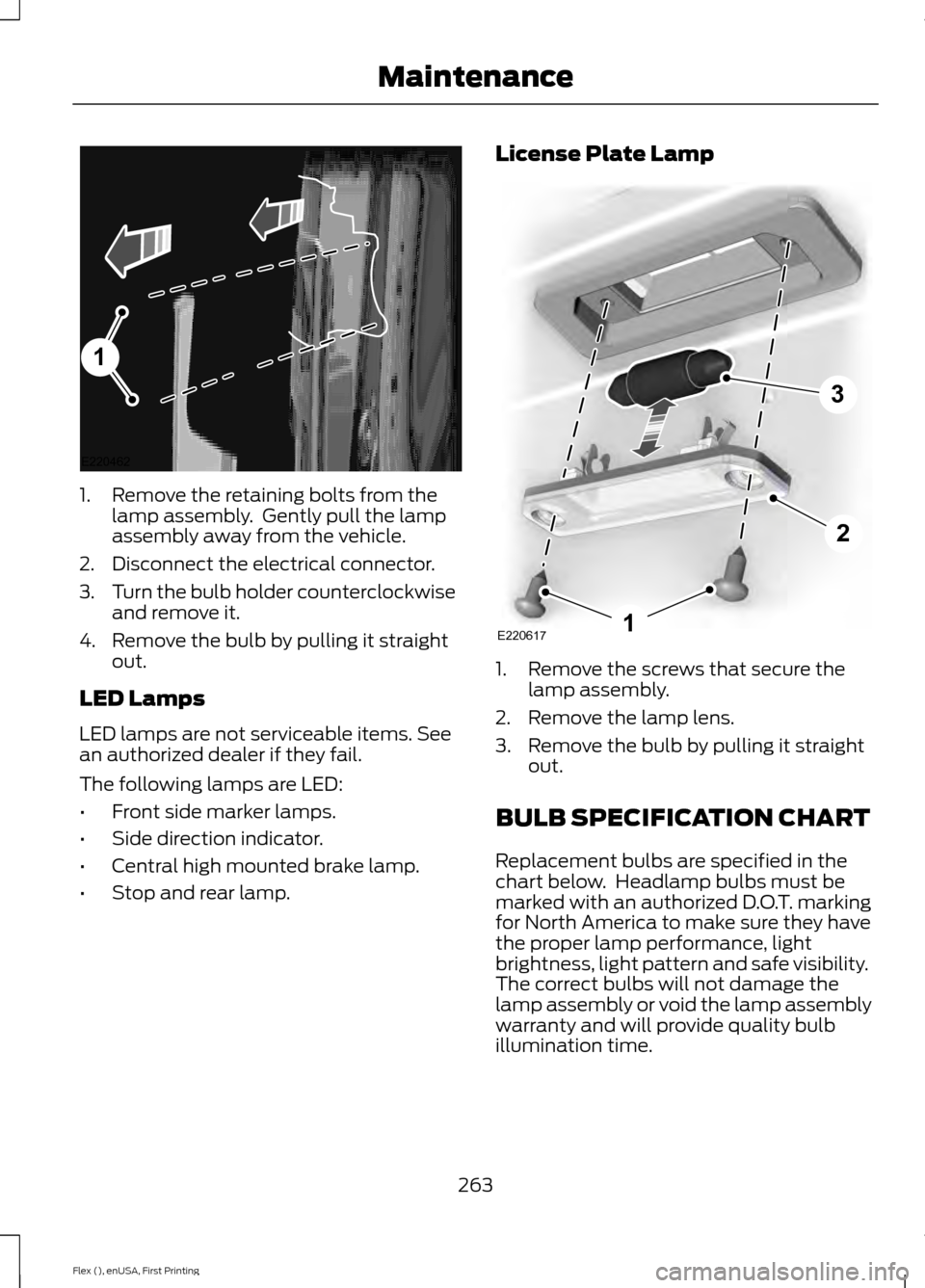

1. Remove the retaining bolts from the

lamp assembly. Gently pull the lamp

assembly away from the vehicle.

2. Disconnect the electrical connector.

3. Turn the bulb holder counterclockwise

and remove it.

4. Remove the bulb by pulling it straight out.

LED Lamps

LED lamps are not serviceable items. See

an authorized dealer if they fail.

The following lamps are LED:

• Front side marker lamps.

• Side direction indicator.

• Central high mounted brake lamp.

• Stop and rear lamp. License Plate Lamp

1. Remove the screws that secure the

lamp assembly.

2. Remove the lamp lens.

3. Remove the bulb by pulling it straight out.

BULB SPECIFICATION CHART

Replacement bulbs are specified in the

chart below. Headlamp bulbs must be

marked with an authorized D.O.T. marking

for North America to make sure they have

the proper lamp performance, light

brightness, light pattern and safe visibility.

The correct bulbs will not damage the

lamp assembly or void the lamp assembly

warranty and will provide quality bulb

illumination time.

263

Flex (), enUSA, First Printing Maintenance1

E220462 E2206171

2

3

Page 271 of 496

•

Use a quality wax that does not contain

abrasives.

• Follow the manufacturer ’s instructions

to apply and remove the wax.

• Apply a small amount of wax in a

back-and-forth motion, not in circles.

• Do not allow wax to come in contact

with any non-body (low-gloss black)

colored trim. The wax will discolor or

stain the parts over time.

•Roof racks.

• Bumpers.

• Grained door handles.

• Side moldings.

• Mirror housings.

• Windshield cowl area.

• Do not apply wax to glass areas.

• After waxing, your car's paint should

feel smooth, and be free of streaks and

smudges.

CLEANING THE ENGINE

Engines are more efficient when they are

clean because grease and dirt buildup keep

the engine warmer than normal.

When washing:

• Take care when using a power washer

to clean the engine. The high-pressure

fluid could penetrate the sealed parts

and cause damage.

• Do not spray a hot engine with cold

water to avoid cracking the engine

block or other engine components.

• Spray Motorcraft Engine Shampoo and

Degreaser on all parts that require

cleaning and pressure rinse clean. In

Canada, use Motorcraft Engine

Shampoo.

• Never wash or rinse the engine while it

is hot or running; water in the running

engine may cause internal damage. •

Never wash or rinse any ignition coil,

spark plug wire or spark plug well, or

the area in and around these locations.

• Cover the battery, power distribution

box, and air filter assembly to prevent

water damage when cleaning the

engine.

CLEANING THE WINDOWS AND

WIPER BLADES

Car wash chemicals and environmental

fallout can result in windshield and wiper

blade contamination. Dirty windshield and

wipers will result in poor windshield wiper

operation. Keep the windshield and wiper

blades clean to maintain windshield wiper

performance.

To clean the windshield and wiper blades:

• Clean the windshield with a

non-abrasive glass cleaner. When

cleaning the interior of the windshield,

avoid getting any glass cleaner on the

instrument panel or door panels. Wipe

any glass cleaner off these surfaces

immediately.

• For windshields contaminated with

tree sap, chemicals, wax or bugs, clean

the entire windshield using steel wool

(no greater than 0000 grade) in a

circular motion and rinse with water.

• Clean the wiper blades with isopropyl

rubbing alcohol or windshield washer

concentrate.

Note: Do not use razor blades or other

sharp objects to clean or remove decals

from the inside of the heated rear window.

The vehicle warranty does not cover

damage caused to the heated rear window

grid lines.

268

Flex (), enUSA, First Printing Vehicle Care

Page 297 of 496

1.

T-type mini-spare: This spare tire

begins with the letter T for tire size and

may have Temporary Use Only molded in

the sidewall.

2. Full-size dissimilar spare with label

on wheel:

This spare tire has a label on

the wheel that states: THIS WHEEL AND

TIRE ASSEMBLY FOR TEMPORARY USE

ONLY.

When driving with one of the dissimilar

spare tires listed above, do not:

• Exceed

50 mph (80 km/h).

• Load the vehicle beyond maximum

vehicle load rating listed on the Safety

Compliance Label.

• Tow a trailer.

• Use snow chains on the end of the

vehicle with the dissimilar spare tire.

• Use more than one dissimilar spare tire

at a time.

• Use commercial car washing

equipment.

• Try to repair the dissimilar spare tire.

Use of one of the dissimilar spare tires

listed above at any one wheel location can

lead to impairment of the following:

• Handling, stability and braking

performance.

• Comfort and noise.

• Ground clearance and parking at curbs.

• Winter weather driving capability.

• Wet weather driving capability.

• All-wheel driving capability.

3. Full-size dissimilar spare without

label on wheel

When driving with the full-size dissimilar

spare wheel and tire assembly, do not:

• Exceed

70 mph (113 km/h).

• Use more than one dissimilar spare

wheel and tire assembly at a time. •

Use commercial car washing

equipment.

• Use snow chains on the end of the

vehicle with the dissimilar spare wheel

and tire assembly.

The usage of a full-size dissimilar spare

wheel and tire assembly can lead to

impairment of the following:

• Handling, stability and braking

performance.

• Comfort and noise.

• Ground clearance and parking at curbs.

• Winter weather driving capability.

• Wet weather driving capability.

• All-wheel driving capability.

When driving with the full-size dissimilar

spare wheel and tire assembly additional

caution should be given to:

• Towing a trailer.

• Driving vehicles equipped with a

camper body.

• Driving vehicles with a load on the

cargo rack.

Drive cautiously when using a full-size

dissimilar spare wheel and tire assembly

and seek service as soon as possible.

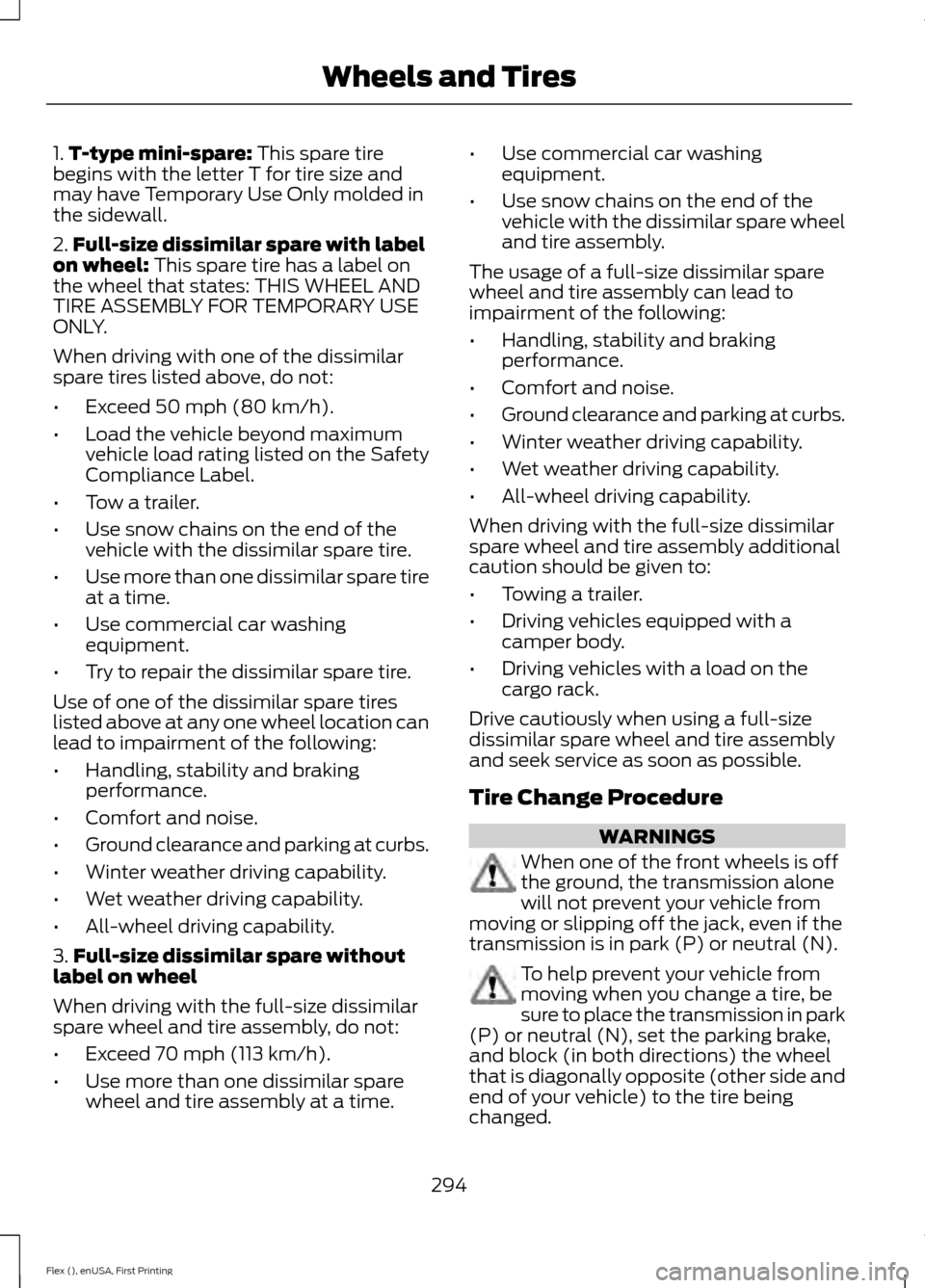

Tire Change Procedure WARNINGS

When one of the front wheels is off

the ground, the transmission alone

will not prevent your vehicle from

moving or slipping off the jack, even if the

transmission is in park (P) or neutral (N). To help prevent your vehicle from

moving when you change a tire, be

sure to place the transmission in park

(P) or neutral (N), set the parking brake,

and block (in both directions) the wheel

that is diagonally opposite (other side and

end of your vehicle) to the tire being

changed.

294

Flex (), enUSA, First Printing Wheels and Tires

Page 298 of 496

WARNINGS

Never get underneath a vehicle that

is supported only by a jack. If the

vehicle slips off the jack, you or

someone else could be seriously injured. Do not attempt to change a tire on

the side of the vehicle close to

moving traffic. Pull far enough off the

road to avoid the danger of being hit when

operating the jack or changing the wheel. Always use the jack provided as

original equipment with your vehicle.

If using a jack other than the one

provided as original equipment with your

vehicle, make sure the jack capacity is

adequate for the vehicle weight, including

any vehicle cargo or modifications. Note:

Passengers should not remain in your

vehicle when the vehicle is being jacked.

Note: Jack at the specified locations to

avoid damage to the vehicle.

Note: If the third row seat is stowed in the

floor, you will need to unstow it to access

the spare tire.

1. Park on a level surface, set the parking

brake and activate the hazard flashers.

2. Place the transmission in park (P) and

turn the engine off. 3. Block the diagonally opposite wheel. 4. Remove the carpeted floor panel

located in the rear of the vehicle, then

remove the wing nut that secures the

spare tire by turning it

counterclockwise.

5. Lift and remove the spare tire from the

trunk.

6. Remove the second wing nut that secures the jack retention bracket by

turning it counterclockwise. Then

remove the jack kit from the vehicle.

7. Remove the jack, L-shaped bolt, and the wrench from the felt bag. Fold

down the wrench socket to use to

loosen the lug nuts and to operate the

jack.

295

Flex (), enUSA, First Printing Wheels and TiresE142551 E211099

Page 299 of 496

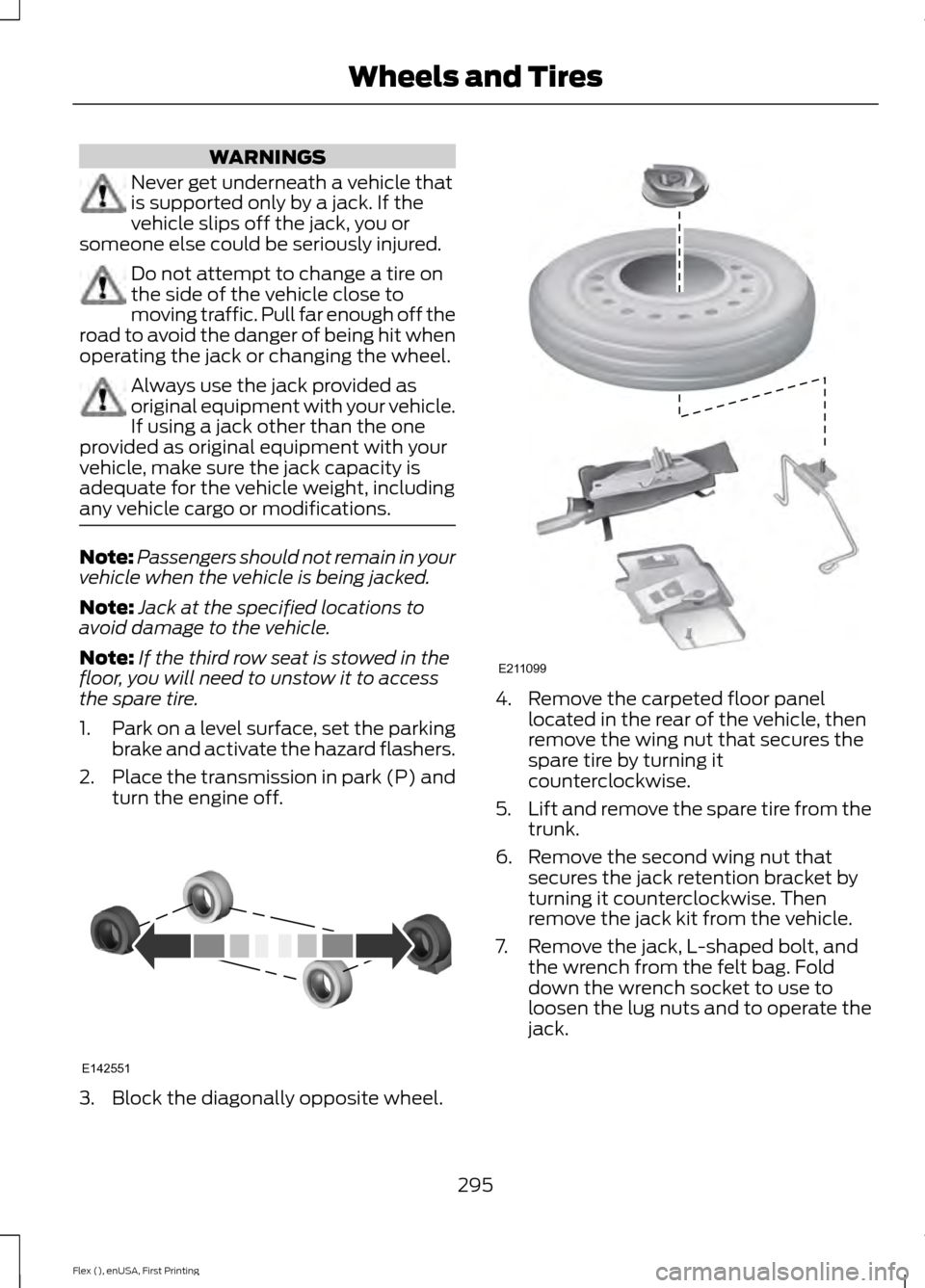

8. Remove the wheel cover with the lug

wrench tip and loosen each wheel lug

nut one-half turn counterclockwise,

but do not remove them until the wheel

is raised off the ground. 9. The vehicle jacking points are shown

above, and are depicted on the warning

label on the jack. 10. Put the jack in the jack notch next to

the tire you are changing. Turn the

jack handle clockwise until the wheel

is completely off the ground.

11. Remove the lug nuts with the lug wrench.

12. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward. Reinstall the lug nuts

until the wheel is snug against the

hub. Do not fully tighten the lug nuts

until the wheel has been lowered.

13. Lower the wheel by turning the jack handle counterclockwise. 14.

Remove the jack and fully tighten the

lug nuts in the order shown. See

Technical Specifications (page

298).

15. Install the wheel cover.

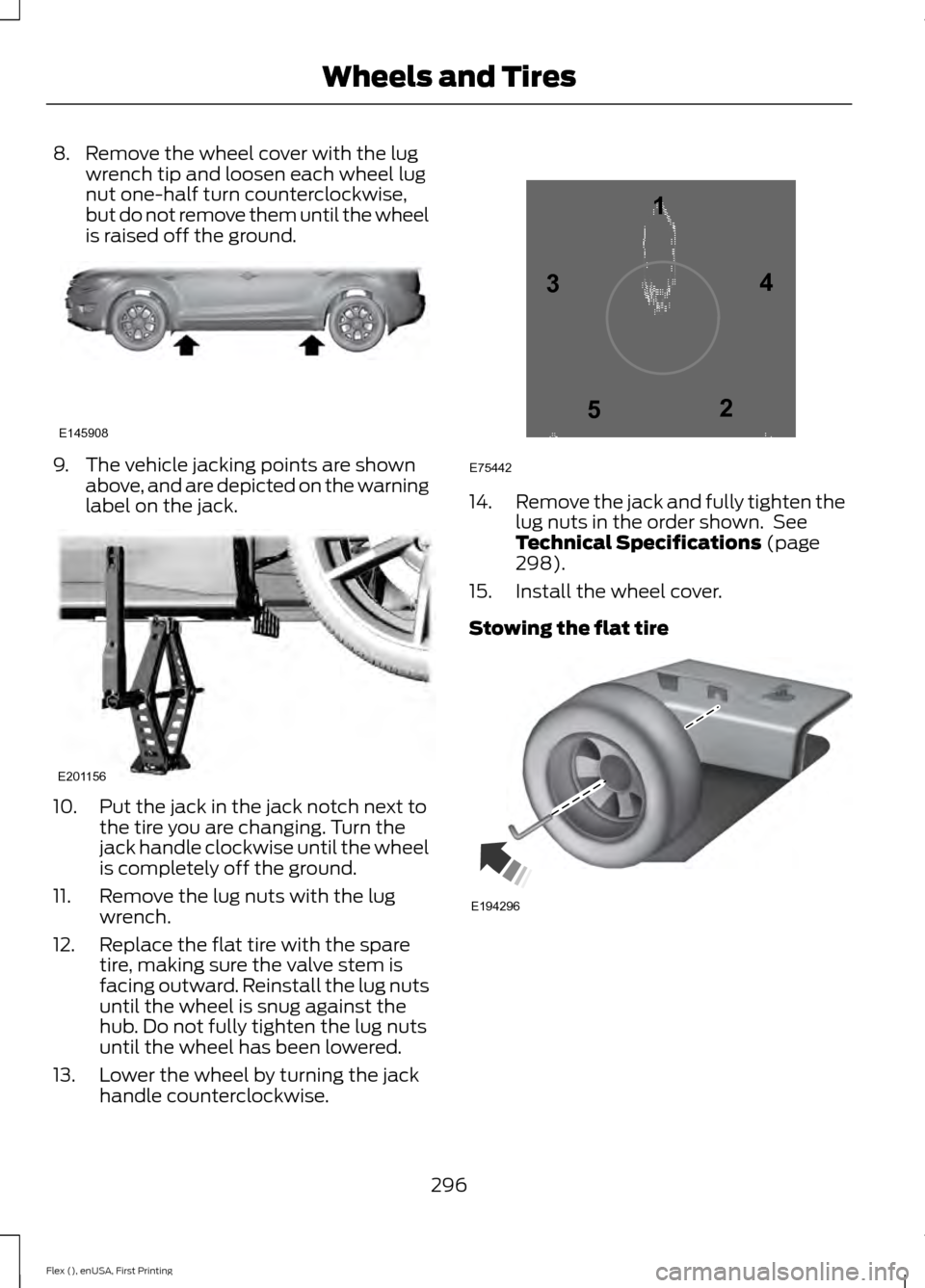

Stowing the flat tire 296

Flex (), enUSA, First Printing Wheels and TiresE145908 E201156 12

3

4

5

E75442 E194296

Page 300 of 496

If you are stowing the flat tire, remove the

L-shaped bolt from the external pocket of

the felt bag. With the third row seat in the

raised position, stand the flat tire in the

rear of the vehicle with the tire

’s valve stem

facing the rear of the vehicle. Fasten the

flat tire to the vehicle by inserting the

L-shaped bolt through one of the lug bolt

holes in the wheel. Turn it clockwise into

the threaded hole in the vehicle until the

tire is secured.

If you are stowing the temporary spare tire,

place the tire over the jack and secure it

with the large wing nut.

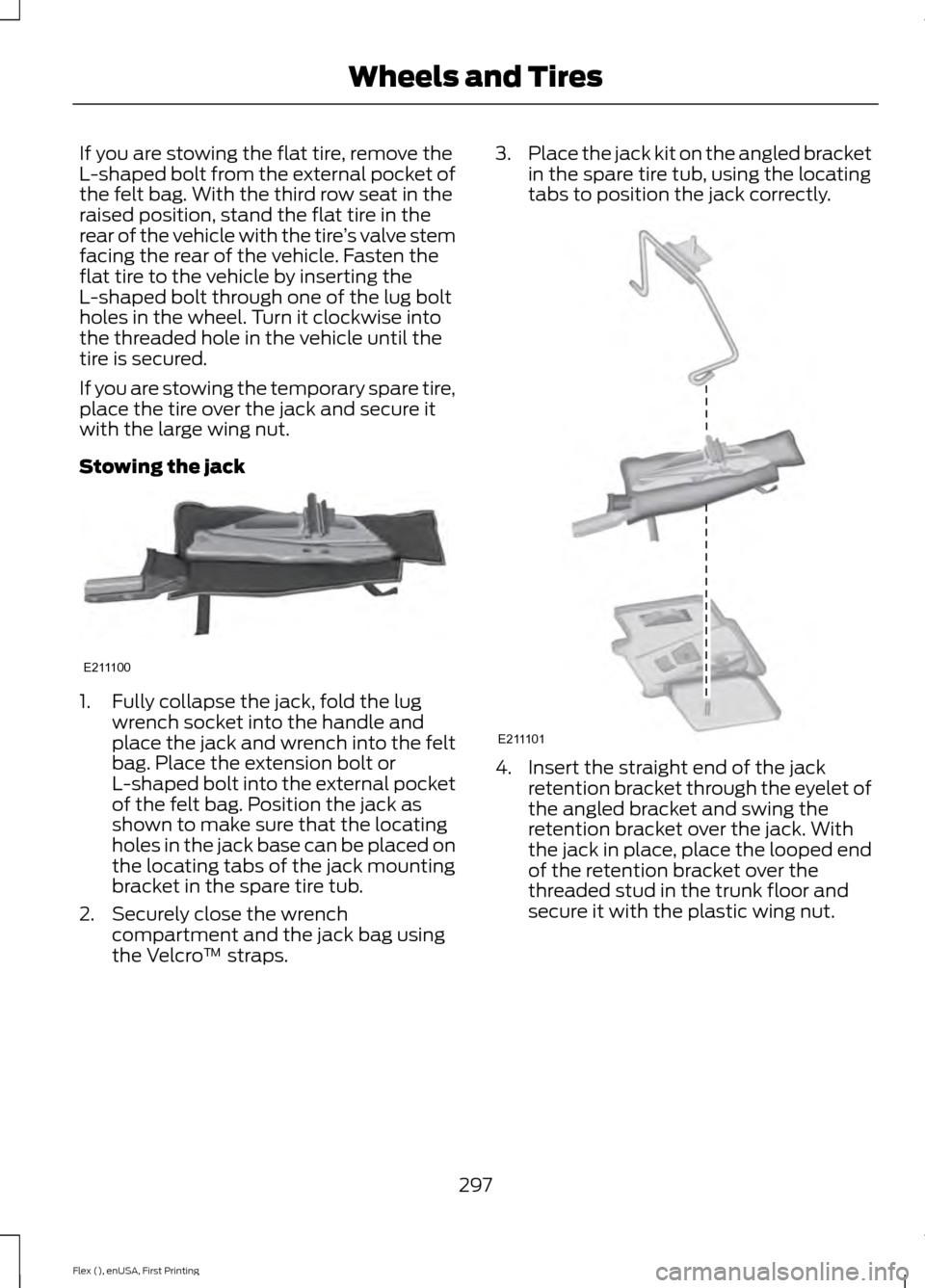

Stowing the jack 1. Fully collapse the jack, fold the lug

wrench socket into the handle and

place the jack and wrench into the felt

bag. Place the extension bolt or

L-shaped bolt into the external pocket

of the felt bag. Position the jack as

shown to make sure that the locating

holes in the jack base can be placed on

the locating tabs of the jack mounting

bracket in the spare tire tub.

2. Securely close the wrench compartment and the jack bag using

the Velcro ™ straps. 3.

Place the jack kit on the angled bracket

in the spare tire tub, using the locating

tabs to position the jack correctly. 4. Insert the straight end of the jack

retention bracket through the eyelet of

the angled bracket and swing the

retention bracket over the jack. With

the jack in place, place the looped end

of the retention bracket over the

threaded stud in the trunk floor and

secure it with the plastic wing nut.

297

Flex (), enUSA, First Printing Wheels and TiresE211100 E211101

Page 309 of 496

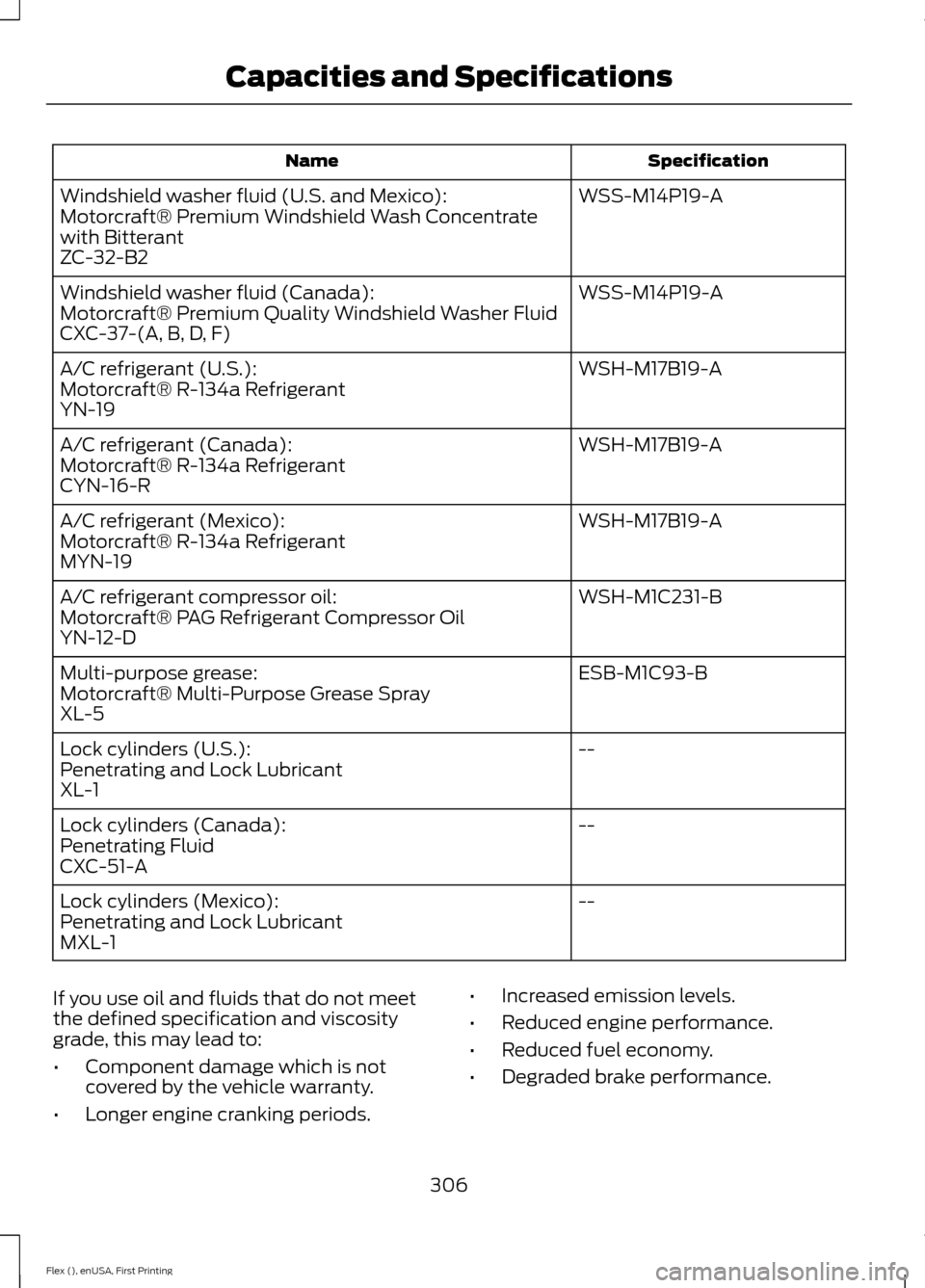

Specification

Name

WSS-M14P19-A

Windshield washer fluid (U.S. and Mexico):

Motorcraft® Premium Windshield Wash Concentrate

with Bitterant

ZC-32-B2

WSS-M14P19-A

Windshield washer fluid (Canada):

Motorcraft® Premium Quality Windshield Washer Fluid

CXC-37-(A, B, D, F)

WSH-M17B19-A

A/C refrigerant (U.S.):

Motorcraft® R-134a Refrigerant

YN-19

WSH-M17B19-A

A/C refrigerant (Canada):

Motorcraft® R-134a Refrigerant

CYN-16-R

WSH-M17B19-A

A/C refrigerant (Mexico):

Motorcraft® R-134a Refrigerant

MYN-19

WSH-M1C231-B

A/C refrigerant compressor oil:

Motorcraft® PAG Refrigerant Compressor Oil

YN-12-D

ESB-M1C93-B

Multi-purpose grease:

Motorcraft® Multi-Purpose Grease Spray

XL-5

--

Lock cylinders (U.S.):

Penetrating and Lock Lubricant

XL-1

--

Lock cylinders (Canada):

Penetrating Fluid

CXC-51-A

--

Lock cylinders (Mexico):

Penetrating and Lock Lubricant

MXL-1

If you use oil and fluids that do not meet

the defined specification and viscosity

grade, this may lead to:

• Component damage which is not

covered by the vehicle warranty.

• Longer engine cranking periods. •

Increased emission levels.

• Reduced engine performance.

• Reduced fuel economy.

• Degraded brake performance.

306

Flex (), enUSA, First Printing Capacities and Specifications