battery FORD FREESTAR 2004 1.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2004, Model line: FREESTAR, Model: FORD FREESTAR 2004 1.GPages: 280, PDF Size: 5.08 MB

Page 172 of 280

3. Start the vehicle.

If it is necessary to use the above procedure to move the gearshift lever,

it is possible that a fuse has blown or the vehicle’s brakelamps are not

operating properly. Refer toFuses and relaysin theRoadside

emergencies chapter.

Do not drive your vehicle until you verify that the brakelamps

are working.

Always set the parking brake fully and make sure the gearshift is

latched in P (Park). Turn the ignition to the LOCK position and

remove the key whenever you leave your vehicle.

If the parking brake is fully released, but the brake warning lamp

remains illuminated, the brakes may not be working properly.

See your dealer or a qualified service technician.

Driving with an automatic overdrive transaxle with column gearshift

Your transaxle is equipped with an adaptive learning strategy found in

the vehicle computer. This feature is designed to increase durability and

provide consistent shift feel over the life of the vehicle. A new vehicle or

transaxle may have firm and/or soft shifts. This operation is considered

normal and will not affect function or durability of the transaxle. Over

time, the adaptive learning process will fully update transaxle operation.

Additionally, whenever the battery is disconnected or a new battery

installed, the strategy must be relearned.

Your automatic overdrive transaxle provides fully automatic operation in

either D (Drive) or 3. Driving with the gearshift lever in D (Drive) gives

the best fuel economy for normal driving conditions. For manual control

start in 1 (First) and then shift manually.

To put your vehicle in gear, start the engine, depress the brake pedal,

then move gearshift lever out of P (Park). Once you place the gearshift

lever securely into position, gradually release the brake pedal and use

the accelerator as necessary.

Understanding the gearshift positions of the 4–speed automatic

transaxle

2004 Windstar (win)

Owners Guide (post-2002-fmt)

USA English (fus)

Driving

172

Page 180 of 280

If your vehicle has the optional trailer tow package it comes with heavy

duty cooling fans, auxiliary transmission fluid cooler, an auxiliary engine

oil cooler (4.2L engine only), heavy duty battery, trailer tow wiring

(including fuses and relays to isolate the vehicle lighting circuitry from

the trailer lighting) and a kit (in a cardboard box) that includes an

adapter wiring harness that contains the standard 4-pin trailer plug.

Trailer towing puts additional loads on your vehicle’s engine,

transmission, axle, brakes, tires, and suspension. For your safety and to

maximize vehicle performance, be sure to use the proper equipment

while towing.

Follow these guidelines to ensure safe towing procedure:

•Stay within your vehicle’s load limits. If exceeded, cargo should be

removed from the trailer and/or the vehicle until all weights are within

specified limits.

•Thoroughly prepare your vehicle for towing. Refer toPreparing to

towin this chapter.

•Use extra caution when driving while trailer towing. Refer toDriving

while you towin this chapter.

•Service your vehicle more frequently if you tow a trailer. Refer to

Special Operating Conditionsin the scheduled maintenance guide.

•Do not tow a trailer until your vehicle has been driven at least 800 km

(500 miles).

•Refer to the instructions included with towing accessories for the

proper installation and adjustment specifications.

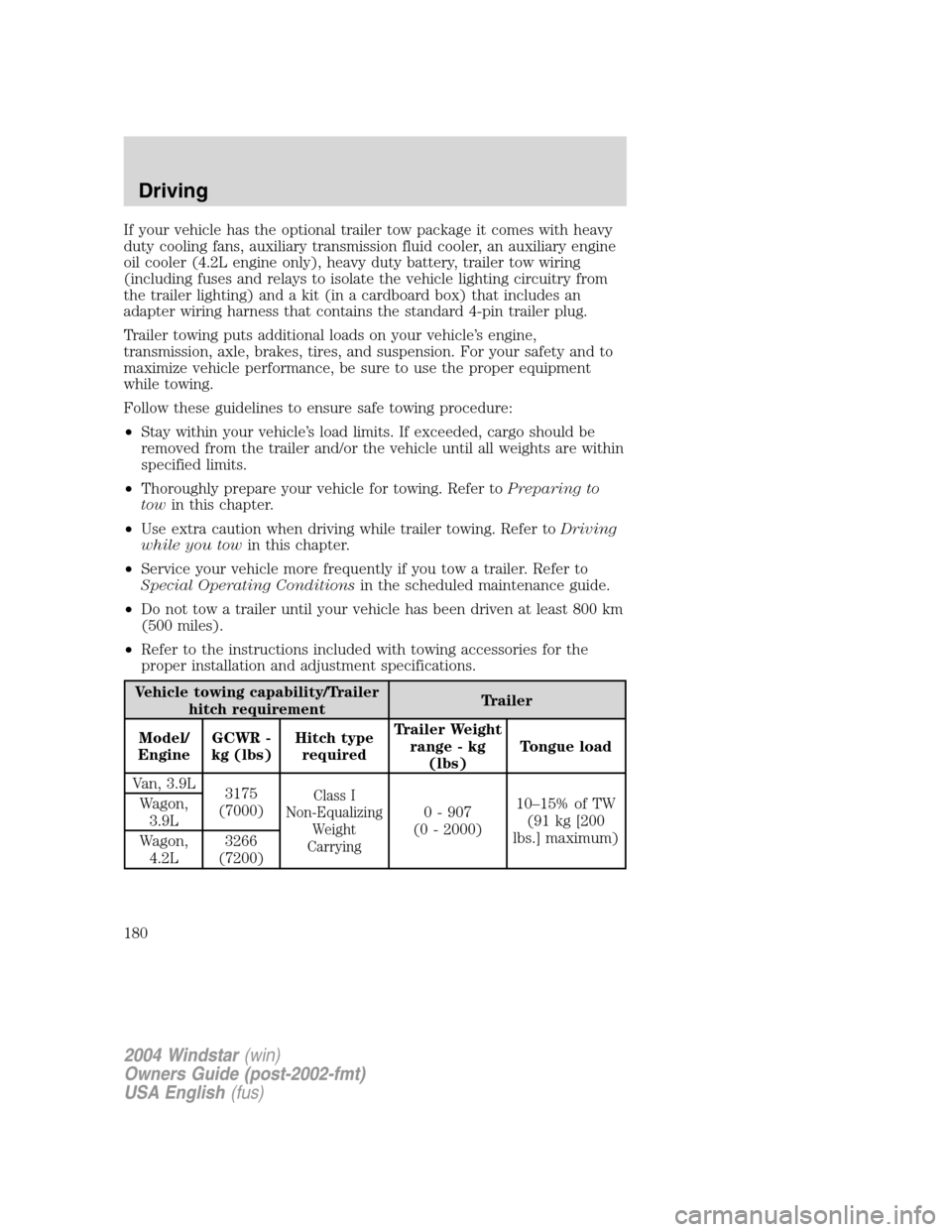

Vehicle towing capability/Trailer

hitch requirementTrailer

Model/

EngineGCWR -

kg (lbs)Hitch type

requiredTrailer Weight

range - kg

(lbs)Tongue load

Van, 3.9L

3175

(7000)

Class I

Non-Equalizing

Weight

Carrying

0 - 907

(0 - 2000)10–15% of TW

(91 kg [200

lbs.] maximum) Wagon,

3.9L

Wagon,

4.2L3266

(7200)

2004 Windstar(win)

Owners Guide (post-2002-fmt)

USA English(fus)

Driving

180

Page 185 of 280

Canadian customers who require roadside assistance, call

1–800–665–2006.

If you need to arrange roadside assistance for yourself, Ford Motor

Company will reimburse a reasonable amount. To obtain reimbursement

information, U.S. Ford or Mercury vehicles customers call

1-800-241-3673; Lincoln vehicle customers call 1–800–521–4140.

Canadian customers who need to obtain reimbursement information, call

1–800–665–2006.

ROADSIDE COVERAGE BEYOND BASIC WARRANTY

In the United States, you may purchase additional roadside assistance

coverage beyond this period through the Ford Auto Club by contacting

your Ford or Lincoln Mercury dealer.

Similarly in Canada, for uninterrupted Roadside Assistance coverage, you

may purchase extended coverage prior to your Basic Warranty’s Roadside

Assistance expiring. For more information and enrollment, contact

1–877–294–2582 or visit our website at www.ford.ca.

HAZARD FLASHER CONTROL

The hazard flasher is located on the

instrument panel by the radio. The

hazard flashers will operate when

the ignition is off.

Push in the flasher control and all

front and rear direction signals will

flash. Press the flasher control again

to turn them off. Use it when your vehicle is disabled and is creating a

safety hazard for other motorists.

Note:With extended use, the flasher may run down your battery.

FUEL PUMP SHUT-OFF SWITCH

This device stops the electric fuel pump from sending fuel to the engine

when your vehicle has had a substantial jolt.

After an accident, if the engine cranks but does not start, this switch

may have been activated.

2004 Windstar(win)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

185

Page 190 of 280

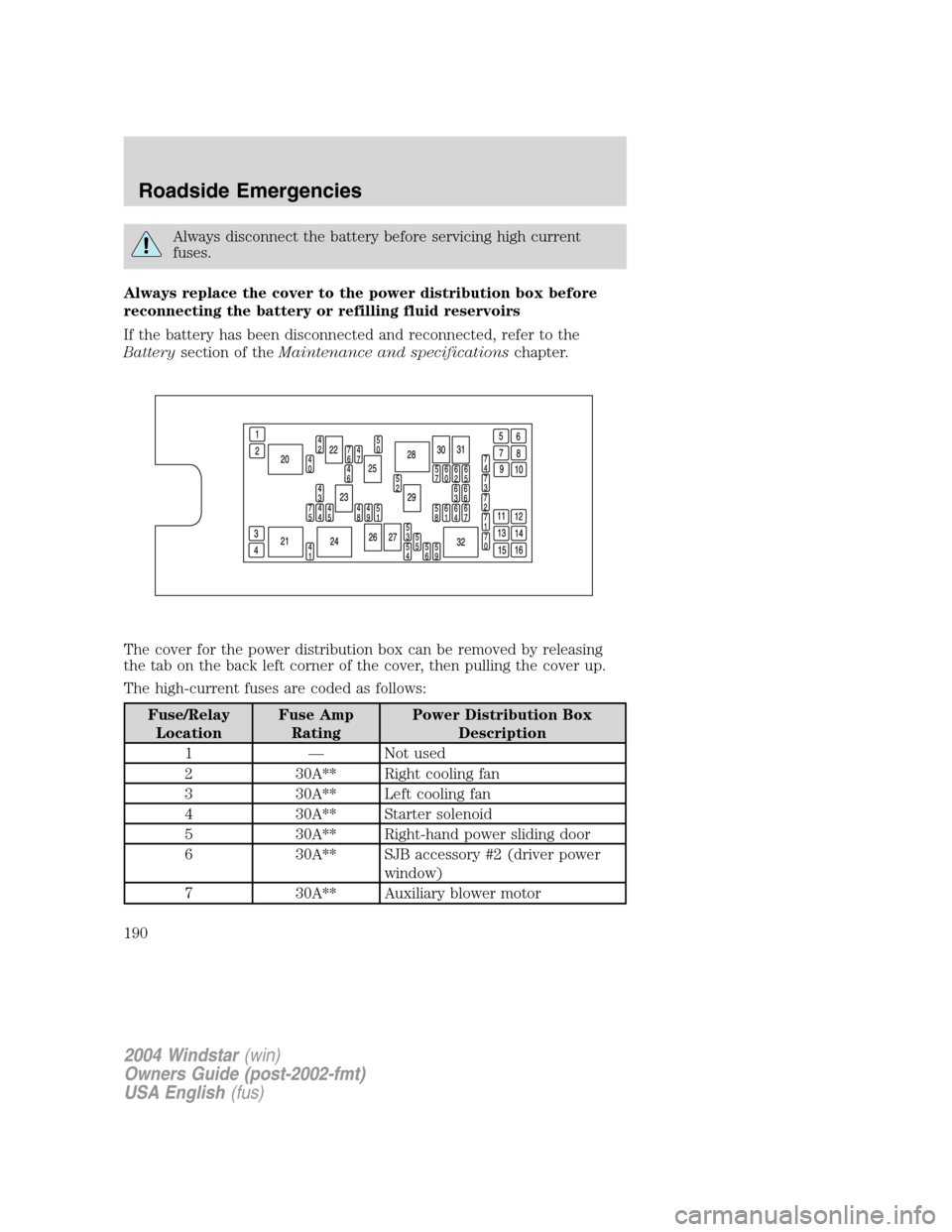

Always disconnect the battery before servicing high current

fuses.

Always replace the cover to the power distribution box before

reconnecting the battery or refilling fluid reservoirs

If the battery has been disconnected and reconnected, refer to the

Batterysection of theMaintenance and specificationschapter.

The cover for the power distribution box can be removed by releasing

the tab on the back left corner of the cover, then pulling the cover up.

The high-current fuses are coded as follows:

Fuse/Relay

LocationFuse Amp

RatingPower Distribution Box

Description

1 — Not used

2 30A** Right cooling fan

3 30A** Left cooling fan

4 30A** Starter solenoid

5 30A** Right-hand power sliding door

6 30A** SJB accessory #2 (driver power

window)

7 30A** Auxiliary blower motor

2004 Windstar(win)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

190

Page 203 of 280

5. Repeat this tightness check procedure when servicing the spare tire

pressure (every six months, per scheduled maintenance guide), or at any

time that the spare tire is disturbed through service of other

components.

6. If removed, install the spare tire lock (if equipped) into the bumper

drive tube with the spare tire lock key (if equipped) and jack handle.

Wheel lug nut torque specifications

Retighten the lug nuts to the specified torque at 800 km (500 miles)

after any wheel disturbance (rotation, flat tire, wheel removal, etc.).

Bolt size Wheel lug nut torque*

Nm Lb-ft

1�2x 20 113-153 85-115

* Torque specifications are for nut and bolt threads free of dirt and

rust. Use only Ford recommended replacement fasteners.

When a wheel is installed, always remove any corrosion, dirt or

foreign materials present on the mounting surfaces of the wheel

or the surface of the front disc brake hub and rotor that contacts the

wheel. Installing wheels without correct metal-to-metal contact at the

wheel mounting surfaces can cause the wheel nuts to loosen and the

wheel to come off while the vehicle is in motion, resulting in loss of

control.

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Batteries contain sulfuric acid which can burn skin, eyes and

clothing, if contacted.

Do not attempt to push-start your vehicle. Automatic

transmissions do not have push-start capability; doing so may

damage the catalytic converter.

2004 Windstar(win)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

203

Page 204 of 280

Preparing your vehicle

When the battery is disconnected or a new battery is installed, the

transmission must relearn its shift strategy. As a result, the transmission

may have firm and/or soft shifts. This operation is considered normal and

will not affect function or durability of the transmission. Over time, the

adaptive learning process will fully update transmission operation.

1.Use only a 12–volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other moving

parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect any electrical

surges. Turn all other accessories off.

Connecting the jumper cables

1. Connect the positive (+) jumper cable to the positive (+) terminal of

the discharged battery.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

+–+–

2004 Windstar(win)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

204

Page 205 of 280

2. Connect the other end of the positive (+) cable to the positive (+)

terminal of the assisting battery.

3. Connect the negative (-) cable to the negative (-) terminal of the

assisting battery.

+–+–

+–+–

2004 Windstar(win)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

205

Page 206 of 280

4. Make the final connection of the negative (-) cable to an exposed

metal part of the stalled vehicle’s engine, away from the battery and the

carburetor/fuel injection system.Do notuse fuel lines, engine rocker

covers or the intake manifold asgroundingpoints.

Do not connect the end of the second cable to the negative (-)

terminal of the battery to be jumped. A spark may cause an

explosion of the gases that surround the battery.

5. Ensure that the cables are clear of fan blades, belts, moving parts of

both engines, or any fuel delivery system parts.

Jump starting

1. Start the engine of the booster vehicle and run the engine at

moderately increased speed.

2. Start the engine of the disabled vehicle.

3. Once the disabled vehicle has been started, run both engines for an

additional three minutes before disconnecting the jumper cables.

+–+–

2004 Windstar(win)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

206

Page 207 of 280

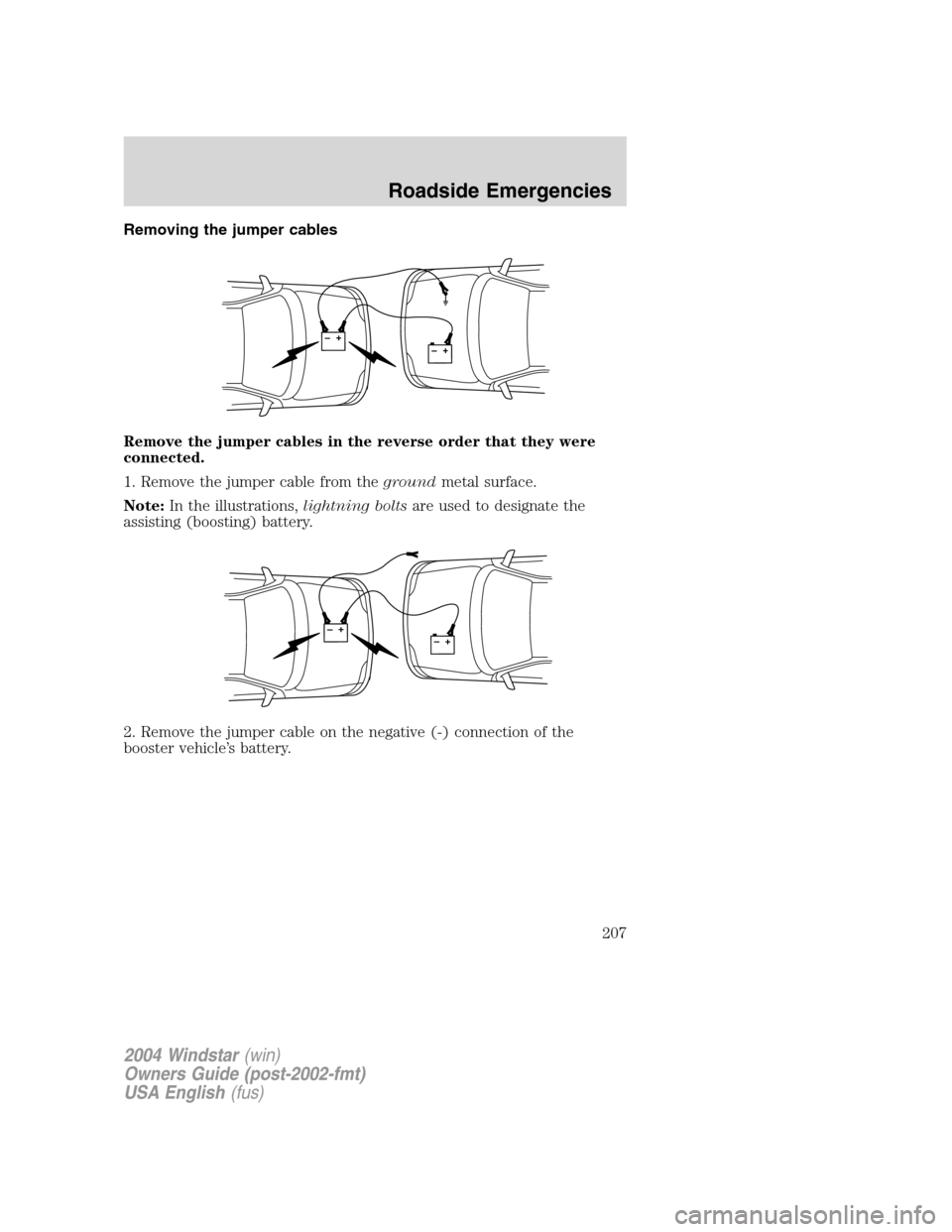

Removing the jumper cables

Remove the jumper cables in the reverse order that they were

connected.

1. Remove the jumper cable from thegroundmetal surface.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Remove the jumper cable on the negative (-) connection of the

booster vehicle’s battery.

+–+–

+–+–

2004 Windstar(win)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

207

Page 208 of 280

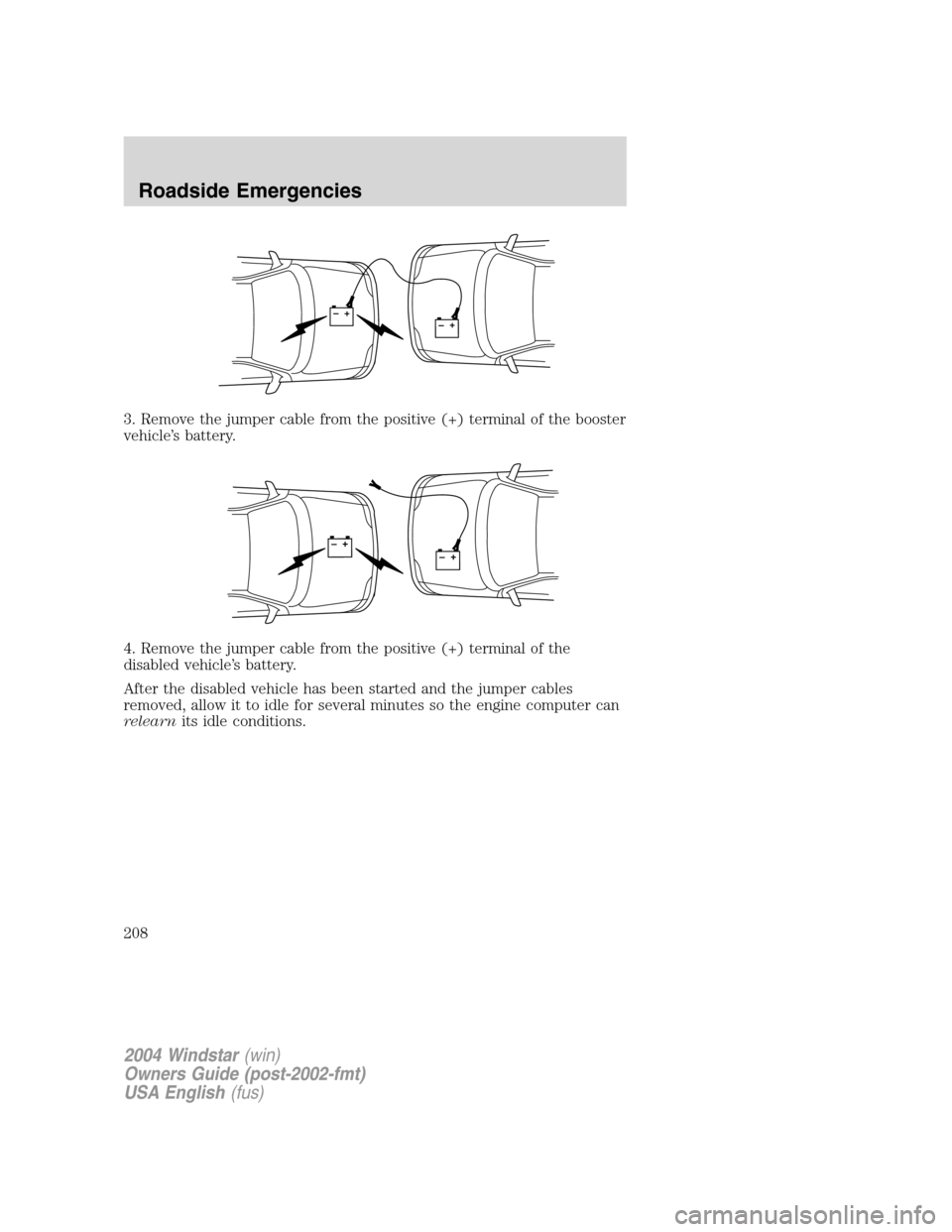

3. Remove the jumper cable from the positive (+) terminal of the booster

vehicle’s battery.

4. Remove the jumper cable from the positive (+) terminal of the

disabled vehicle’s battery.

After the disabled vehicle has been started and the jumper cables

removed, allow it to idle for several minutes so the engine computer can

relearnits idle conditions.

+–+–

+–+–

2004 Windstar(win)

Owners Guide (post-2002-fmt)

USA English(fus)

Roadside Emergencies

208