transmission FORD GRANADA 1985 Service User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 24 of 255

Chapter 2 Part A:

1.8 & 2.0 litre SOHC engines

Ancillary components - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Ancillary components - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Auxiliary shaft - examination and renovation . . . . . . . . . . . . . . . . . .31

Auxiliary shaft - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Auxiliary shaft - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Camshaft and cam followers - examination and renovation . . . . . .30

Camshaft - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Camshaft - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Compression test - description and interpretation . . . . . . . . . . . . .52

Crankcase ventilation system - general information . . . . . . . . . . . .24

Crankshaft and bearings - examination and renovation . . . . . . . . .27

Crankshaft and main bearings - refitting . . . . . . . . . . . . . . . . . . . . .36

Crankshaft and main bearings - removal . . . . . . . . . . . . . . . . . . . . .22

Crankshaft front oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . .17

Crankshaft rear oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Cylinder block and bores - examination and renovation . . . . . . . . .28

Cylinder head - decarbonising, valve grinding and renovation . . . .34

Cylinder head - dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Cylinder head - reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Cylinder head - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Cylinder head - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Engine and gearbox - reconnection . . . . . . . . . . . . . . . . . . . . . . . . .47

Engine dismantling - general information . . . . . . . . . . . . . . . . . . . . . .8

Engine mountings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Engine reassembly - general information . . . . . . . . . . . . . . . . . . . . .35

Engine - refitting without gearbox/transmission . . . . . . . . . . . . . . .49Engine - refitting with manual gearbox . . . . . . . . . . . . . . . . . . . . . . .48

Engine - removal leaving gearbox/transmission in vehicle . . . . . . . .5

Engine - removal with manual gearbox . . . . . . . . . . . . . . . . . . . . . . .6

Engine - separation from manual gearbox . . . . . . . . . . . . . . . . . . . . .7

Examination and renovation - general information . . . . . . . . . . . . .25

Flywheel/driveplate and adapter plate - refitting . . . . . . . . . . . . . . .40

Flywheel/driveplate and adapter plate - removal . . . . . . . . . . . . . . .15

Flywheel ring gear - examination and renovation . . . . . . . . . . . . . .33

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Initial start-up after overhaul or major repair . . . . . . . . . . . . . . . . . .51

Major operations possible with the engine in the vehicle . . . . . . . . .2

Major operations requiring engine removal . . . . . . . . . . . . . . . . . . . .3

Methods of engine removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Oil filter - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Oil pump - examination and renovation . . . . . . . . . . . . . . . . . . . . . .26

Oil pump - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Oil pump - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Pistons and connecting rods - examination and renovation . . . . . .29

Pistons and connecting rods - refitting . . . . . . . . . . . . . . . . . . . . . .37

Pistons and connecting rods - removal . . . . . . . . . . . . . . . . . . . . . .21

Sump - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Sump - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Timing belt - examination and renovation . . . . . . . . . . . . . . . . . . . .32

Timing belt and sprockets - refitting . . . . . . . . . . . . . . . . . . . . . . . . 45

Timing belt and sprockets - removal . . . . . . . . . . . . . . . . . . . . . . . .13

Valve clearances - checking and adjustment . . . . . . . . . . . . . . . . . .50

General1.8 HC E 2.0 HC 2.0 HC EFi

Manufacturer’s code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . REC NEL NRA

Bore - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.20 (3.39) 90.82 (3.58) 90.82 (3.58)

Stroke - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76.95 (3.03) 76.95 (3.03) 76.95 (3.03)

Cubic capacity - cc (cu in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1796 (109.6) 1993 (121.6) 1993 (121.6)

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.5:1 9.2:1 9.2:1

Compression pressure at cranking speed (all models) . . . . . . . . . . . . . . 11 to 13 bar (160 to 189 lbf/in

2)

Maximum power (DIN, kW @ rpm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 @ 5400 77 @ 5200 85 @ 5500

Maximum torque (DIN, Nm @ rpm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140 @ 3500 157 @ 4000 160 @ 4000

Lubrication system

Oil type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See“Lubricants and fluids”

Oil capacity (drain and refill, including filter) . . . . . . . . . . . . . . . . . . . . . . 3.75 litres (6.6 pints) approx

Oil pressure (SAE 10W/30 oil at 80°C/176°F):

At 750 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1 bar

At 2000 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 bar

Oil pressure relief valve opening pressure . . . . . . . . . . . . . . . . . . . . . . . 4.0 to 4.7 bar

Oil pressure warning light switch setting . . . . . . . . . . . . . . . . . . . . . . . . 0.3 to 0.5 bar

2A•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

2A

procarmanuals.com

Page 28 of 255

The cylinder head is of crossflow design

with the inlet manifold mounted on the left-

hand side and the exhaust manifold mounted

on the right-hand side.

Lubrication is by means of a bi-rotor pump

which draws oil through a strainer located

inside the sump, and forces it through a full-

flow filter into the engine oil galleries where it

is distributed to the crankshaft, camshaft and

auxiliary shaft. The big-end bearings are

supplied with oil via internal drillings in the

crankshaft.The undersides of the pistons are

supplied with oil from drillings in the big-ends.

The distributor shaft is intermittently supplied

with oil from the drilled auxiliary shaft. The

camshaft and cam followers are supplied with

oil via a drilled spray tube from the centre

camshaft bearing.

A semi-closed crankcase ventilation system

is employed whereby piston blow-by gases

are drawn into the inlet manifold via an oil

separator and on carburettor models a control

valve.

The following operations can be carried out

without removing the engine, although the

work may be easier and quicker with the

engine removed:

a)Removal and refitting of the cylinder head

b)Removal and refitting of the camshaft

(after removing the cylinder head)

c)Removal and refitting of the timing belt

and sprockets

d)Removal and refitting of the sump and oil

pump

e)Removal and refitting of the pistons,

connecting rods and big-end bearings

f)Renewal of the engine mountings

g)Renewal of the crankshaft oil seals

h)Removal and refitting of the auxiliary shaft

j)Removal and refitting of the flywheel

The engine must be removed from the

vehicle for the following operations:

a)Renewal of the crankshaft main bearings

b)Removal and refitting of the crankshaft

The engine may be lifted out either on its

own or together with the gearbox. Unless work

is also necessary on the gearbox it is

recommended that the engine is removed on

its own. Where automatic transmission is

fitted, the engine should be removed on its

own owing to the additional weight. If the

engine and gearbox are removed together,

they will have to be tilted at a very steep angle;

make sure that the range of the lifting tackle is

adequate.1Disconnect the battery negative lead.

2Remove the bonnet.

3On carburettor models, remove the air

cleaner. On fuel-injection models, remove the

air cleaner cover, vane airflow meter and air

inlet trunking.

4If a splash guard is fitted, remove it.

5Release the securing clips and bolts and

remove the upper half of the fan shroud. On

carburettor models remove the lower half of

the shroud too.

6Drain the cooling system.

7Disconnect the radiator top and bottom

hoses from the thermostat housing and water

pump. Disconnect the top hose spur from the

expansion tank and unclip it.

8Disconnect the heater hoses from the water

pump and from the inlet manifold or automatic

choke housing. Unclip the hoses.

9On models with power steering, remove the

steering pump.

10Disconnect the vacuum pipe(s) from the

inlet manifold, labelling them if there is any

possibility of confusion.

11Disconnect the following wiring, as

applicable:

a)Alternator

b)Temperature gauge sender

c)Engine management temperature sensor

d)Distributor

e)Oil pressure switch

f)Automatic choke and thermo-switch

g)Carburettor stepper motor

h)Fuel-injection system sub-harness

j)Inlet manifold heater

12Disconnect the HT lead from the coil.

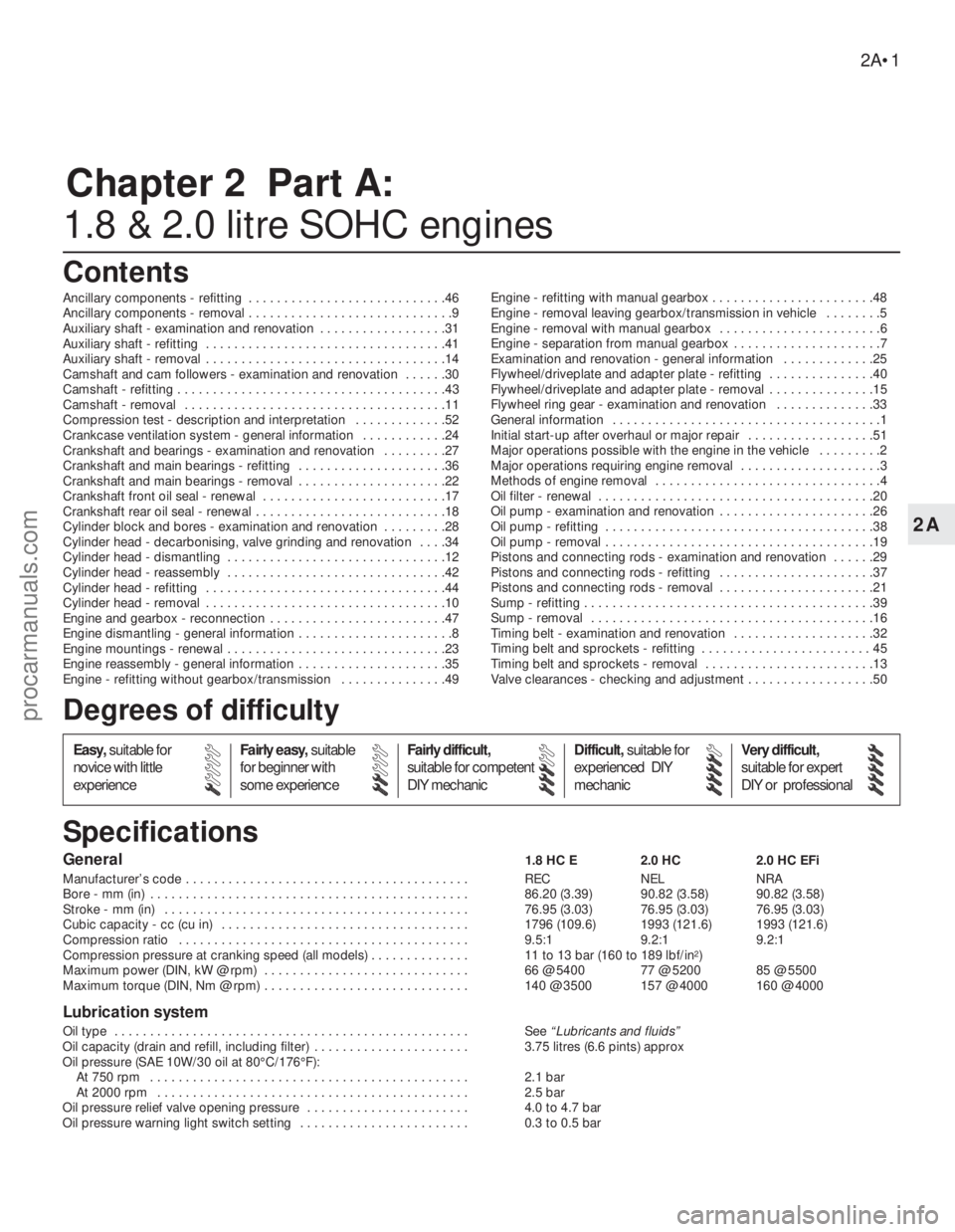

13If an oil level sensor is fitted, remove it

(see illustration).

14Unbolt the throttle cable bracket,

disconnect the inner cable and move the cable

and bracket aside. Also disconnect the

downshift cable on automatic transmission

models.

15On carburettor models, disconnect the

fuel lines from the fuel pump (mechanised

type) and from the carburettor. Be prepared

for fuel spillage.

16On fuel-injection models, disconnect the

fuel supply union from the injector rail, and the

fuel return pipe from the fuel pressureregulator. Be prepared for fuel spillage, and

for some spray if the supply side is still

under pressure.

17Unbolt the exhaust downpipe from the

manifold.

18On models with air conditioning, unbolt

the compressor and move it aside without

straining the flexible hoses.

19Remove the starter motor.

20Although not specified by the

manufacturers, the author advises that either

the radiator or the cooling fan be removed, to

reduce the risk of damage.

21Attach the lifting tackle to the two lifting

eyes on the engine, so that when suspended

the engine will be roughly horizontal. Take the

weight of the engine.

22Remove the single nut on each side which

secures each engine bearer to its mounting.

23Working under the vehicle, remove the

bracing strap which connects the engine and

transmission. Unbolt the adapter plate from

the bottom of the transmission bellhousing.

24On automatic transmission models, unbolt

the torque converter from the driveplate.

25Remove the engine-to-bellhousing bolts.

Note the location of the battery earth strap.

26Support the transmission, preferably with

a trolley jack.

27Check that nothing has been overlooked,

then raise the engine and draw it forwards

clear of the transmission input shaft. Do not

allow the weight of the engine to hang on the

shaft, and do not lift the transmission by it.

28On automatic transmission models, make

sure that the torque converter stays engaged

with the oil pump in the transmission as the

engine is withdrawn,

29Lift the engine out of the engine bay and

take it to the bench.

1Engine removal with automatic transmission

is not recommended.

2Proceed as in the previous Section,

paragraphs 1 to 18.

3Disconnect the wiring from the starter

motor, and release the battery earth cable

from its bellhousing bolt.

4Remove the radiator.

5Remove the propeller shaft.

6Disconnect and unclip the reversing light

switch and speedometer sender unit wiring.

7Disconnect the clutch cable.

8Unbolt the anti-roll bar mounting brackets

and lower the anti-roll bar as far as possible.

9From inside the vehicle remove the gear

lever.

10Drain the engine oil.

11Unhook the exhaust system from its

mounting on the gearbox crossmember. Either

support the system or remove it completely.

12Support the gearbox, preferably with a

trolley jack, then unbolt and remove the

gearbox crossmember. Note the earth strap (if

fitted) under one of the crossmember bolts.

13Attach lifting tackle to the two lifting eyes

on the engine so that when suspended it will

be at an angle of approximately 45°.

6Engine - removal with manual

gearbox

5Engine - removal leaving

gearbox/transmission in vehicle

4Methods of engine removal

3Major operations requiring

engine removal

2Major operations possible with

the engine in the vehicle

SOHCengines 2A•5

2A

5.13 Oil level sensor

procarmanuals.com

Page 29 of 255

14Take the weight of the engine and remove

the two engine bearer-to-mounting nuts.

15Lift the engine/transmission, at the same

time lowering the trolley jack. Draw the unit

forwards and lift it out of the engine bay.

16Temporarily refit the anti-roll bar if the

vehicle is to be moved.

1With the engine and gearbox on the bench,

remove the starter motor.

2Remove the bolt from the engine adapter plate.

3Remove the bracing strap and the

remaining engine-to-bellhousing bolts.

4With the aid of an assistant draw the

gearbox off the engine. Do not allow the weight

of the gearbox to hang on the input shaft.

1It is best to mount the engine on a

dismantling stand, but if this is not available,

stand the engine on a strong bench at a

comfortable working height. Failing this, it will

have to be stripped down on the floor.

2Cleanliness is most important, and if the

engine is dirty, it should be cleaned with

paraffin while keeping it in an upright position.

3Avoid working with the engine on a concrete

floor, as grit can be a real source of trouble.

4As parts are removed, clean them in paraffin.

However, do not immerse parts with internal

oilways in paraffin as it is difficult to remove,

usually requiring a high pressure hose.

5It is advisable to have suitable containers to

hold small items according to their use, as this

will help when reassembling the engine and

also prevent possible losses.

6Always obtain complete sets of gaskets

when the engine is being dismantled, but

retain the old gaskets with a view of using

them as a pattern to make a replacement if a

new one is not available.7When possible, refit nuts, bolts and washers

in their location after being removed, as this

helps protect the threads and will also be

helpful when reassembling the engine.

8Retain unserviceable components in order

to compare them with the new parts supplied.

9A Torx key, size T55, will be needed for

dealing with the cylinder head bolts. A 12-

spline key (to fit bolt size M8) will be needed

for the oil pump bolts. Other Torx and 12-

spline bolts may be encountered; sets of the

keys required to deal with them are available

from most motor accessory shops and tool

factors.

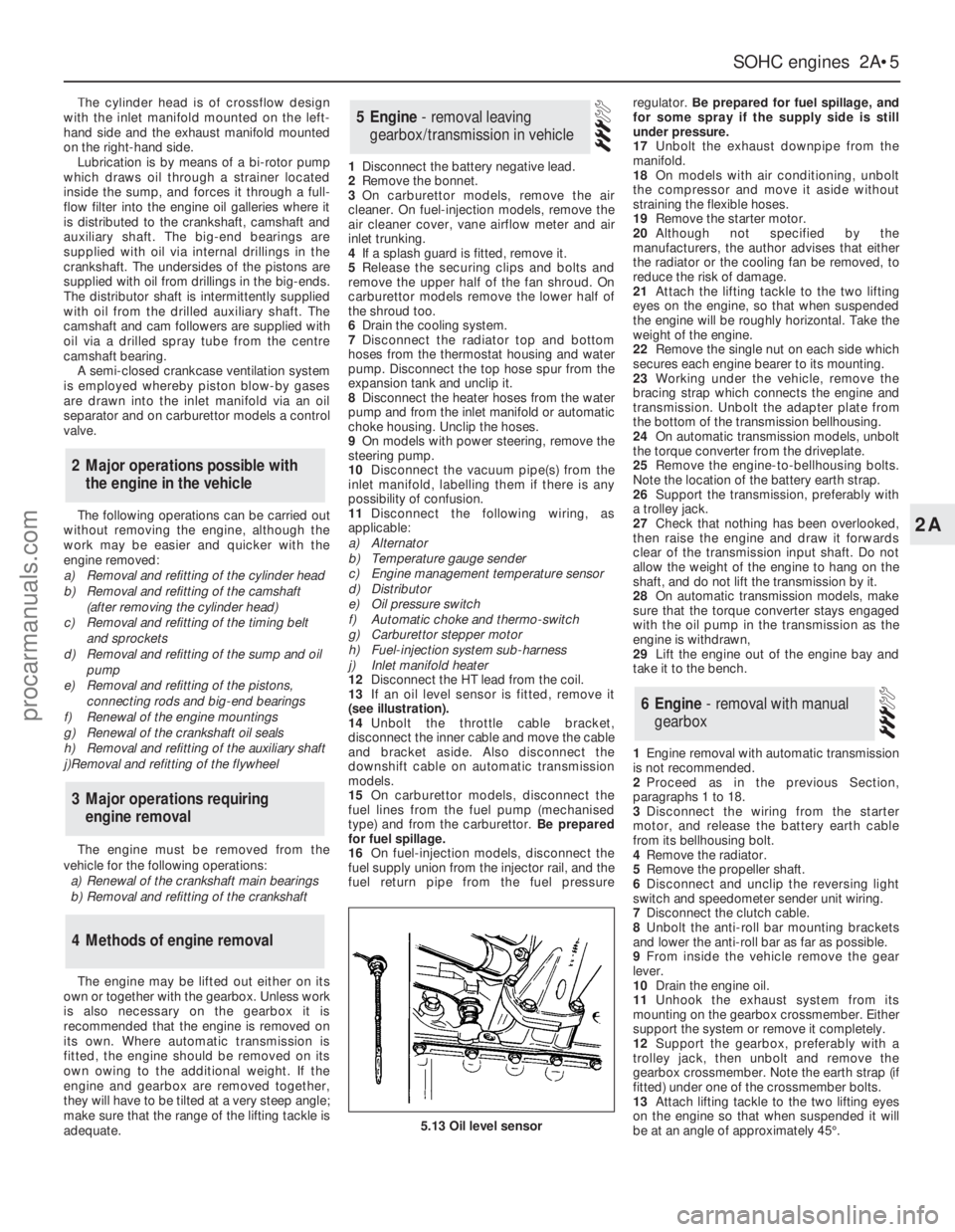

10Another tool which is useful, though by no

means essential, is a valve spring compressor

of the type which hooks under the camshaft

(see illustration). As a Ford tool this bears the

number 21-005-A; proprietary versions may

also be available.

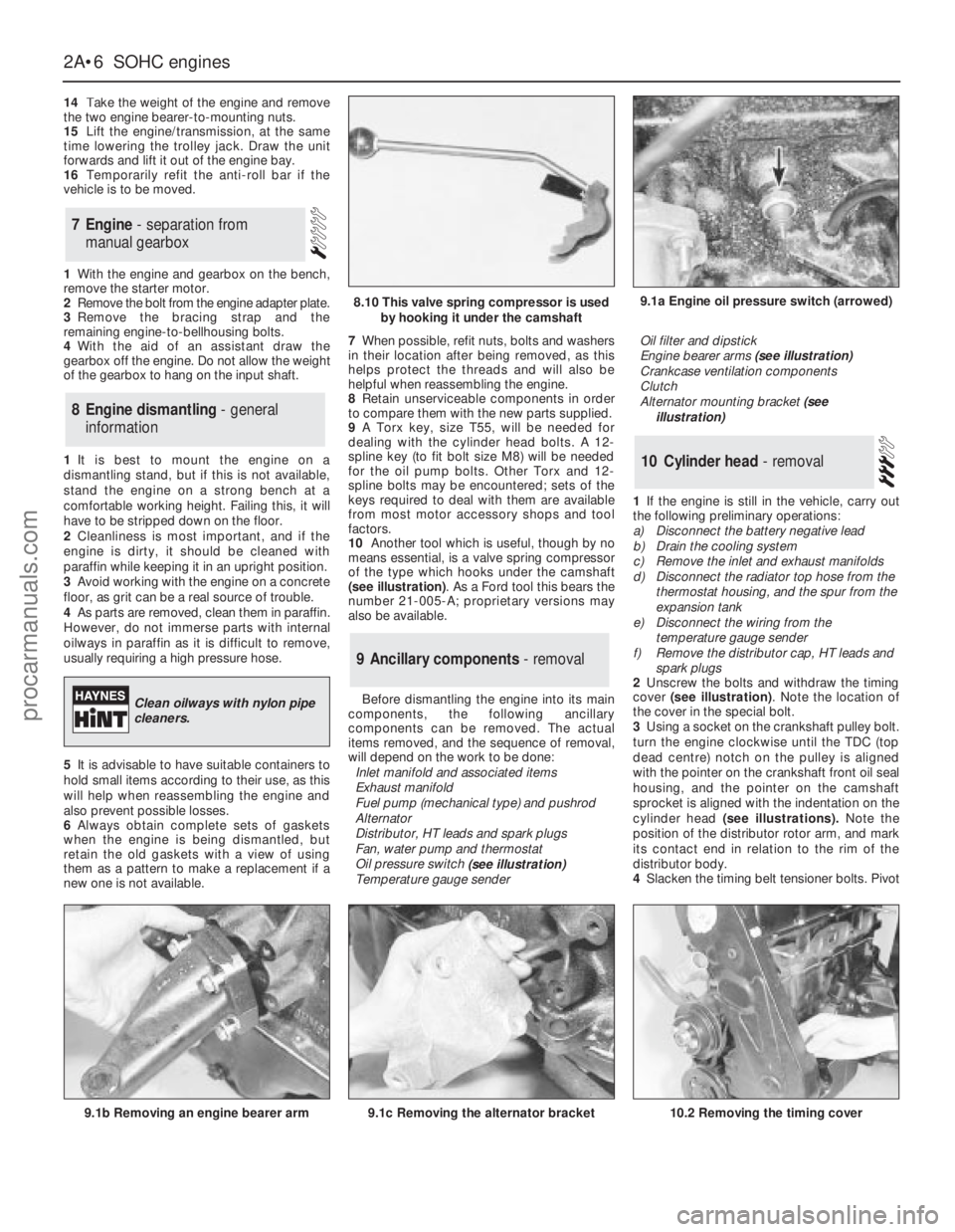

Before dismantling the engine into its main

components, the following ancillary

components can be removed. The actual

items removed, and the sequence of removal,

will depend on the work to be done:

Inlet manifold and associated items

Exhaust manifold

Fuel pump (mechanical type) and pushrod

Alternator

Distributor, HT leads and spark plugs

Fan, water pump and thermostat

Oil pressure switch

(see illustration)

Temperature gauge senderOil filter and dipstick

Engine bearer arms (see illustration)

Crankcase ventilation components

Clutch

Alternator mounting bracket (see

illustration)

1If the engine is still in the vehicle, carry out

the following preliminary operations:

a)Disconnect the battery negative lead

b)Drain the cooling system

c)Remove the inlet and exhaust manifolds

d)Disconnect the radiator top hose from the

thermostat housing, and the spur from the

expansion tank

e)Disconnect the wiring from the

temperature gauge sender

f)Remove the distributor cap, HT leads and

spark plugs

2Unscrew the bolts and withdraw the timing

cover (see illustration). Note the location of

the cover in the special bolt.

3Using a socket on the crankshaft pulley bolt.

turn the engine clockwise until the TDC (top

dead centre) notch on the pulley is aligned

with the pointer on the crankshaft front oil seal

housing, and the pointer on the camshaft

sprocket is aligned with the indentation on the

cylinder head (see illustrations).Note the

position of the distributor rotor arm, and mark

its contact end in relation to the rim of the

distributor body.

4Slacken the timing belt tensioner bolts. Pivot

10Cylinder head - removal

9Ancillary components - removal

8Engine dismantling - general

information

7Engine - separation from

manual gearbox

2A•6SOHCengines

9.1a Engine oil pressure switch (arrowed)

9.1b Removing an engine bearer arm9.1c Removing the alternator bracket

8.10 This valve spring compressor is used

by hooking it under the camshaft

Clean oilways with nylon pipe

cleaners.

10.2 Removing the timing cover

procarmanuals.com

Page 32 of 255

10Unscrew the auxiliary shaft sprocket bolt

while holding the sprocket stationary with a

screwdriver inserted through one of the holes.

11Remove the auxiliary shaft sprocket using

a puller if necessary (see illustration).

12Unscrew the camshaft sprocket bolt while

holding the sprocket stationary with a

screwdriver engaged in one of the grooves.

Alternatively remove the rocker cover and use

a spanner on the camshaft lug.

13Remove the camshaft sprocket using a

puller if necessary, then remove the backplate.

Note that the oil seal can be removed using a

special removal tool or by using self-tapping

screws and a pair of grips.

1Remove the timing belt and the auxiliary

shaft sprocket (only) (Section 13).

2Remove the distributor.

3Remove the fuel pump and pushrod (not

applicable to models with an electric pump).

4Unscrew the bolts and remove the auxiliary

shaft front cover (see illustration).

5Unscrew the cross-head screws, using an

impact screwdriver if necessary, remove the

thrust plate and withdraw the auxiliary shaft

from the block (see illustrations).

6Cut the front cover gasket along the top of

the crankshaft front oil seal housing and

scrape off the gasket.

1If the engine is still in the vehicle, remove

the clutch or automatic transmission.

2Prevent the flywheel or driveplate rotating

by jamming the ring gear teeth, or by bolting a

strap to it.

3Remove the securing bolts and withdraw

the flywheel or driveplate. Do not drop it, it is

heavy.

4The engine adapter plate (backplate) may

now be withdrawn from the dowels if required

(see illustration).1If the engine is out of the vehicle, start at

paragraph 11. If possible, remove the sump

without inverting the engine, so that any

sludge in the bottom of the sump stays there.

2Disconnect the battery negative lead.

3Raise and support the front of the vehicle.

4Remove the splash guard, if fitted, and drain

the engine oil.

5Remove the starter motor.

6Remove the two nuts which secure the

engine bearers to the engine mountings.

7Release the steering shaft universal joint

strap bolt to allow for subsequent movement.

8Free the brake hydraulic pipes from the

clips on the front crossmember.9Support the engine, either with conventional

lifting tackle or with a bar positioned across

the engine bay and resting on two wooden

blocks drilled to fit securely on the suspension

turrets. Make sure the support arrangements

are satisfactory, as you will be working

underneath the suspended engine.

10Take the weight of the engine. Place a jack

under the front crossmember, remove the

crossmember mounting bolts and carefully

lower the jack. Only lower the crossmember

far enough to permit removal of the sump.

11Remove the 23 bolts retaining the sump.

12Remove the sump from the cylinder block

(see illustration). If it is stuck, hit it with a soft-

faced mallet, or prise it sideways (notbetween

the mating faces) with a large screwdriver or

bar.

13Recover the gaskets and sealing strips.

16Sump - removal

15Flywheel/driveplate and

adapter plate - removal

14Auxiliary shaft - removal

SOHCengines 2A•9

2A

13.9 Removing the crankshaft sprocket13.11 Removing the auxiliary shaft

sprocket14.4 Removing the auxiliary shaft front

cover

14.5b Removing the auxiliary shaft14.5a Removing the auxiliary shaft thrust

plate

15.4 Removing the engine adaptor plate

(backplate)16.12 Removing the sump

procarmanuals.com

Page 39 of 255

1Insert the oil pump driveshaft into the block

in its previously noted position.

2Prime the pump by injecting oil into it and

turning it by hand (see illustration).

3Fit the pump. insert the bolts and tighten

them to the specified torque with the splined

key.

4Insert the pick-up tube securing bolt and

tighten it.

5Where applicable refit the crankshaft front

oil seal housing together with a new gasket

and tighten the bolts. Make sure that the

bottom face of the housing is aligned with the

bottom face of the block.

6Refit the sump.

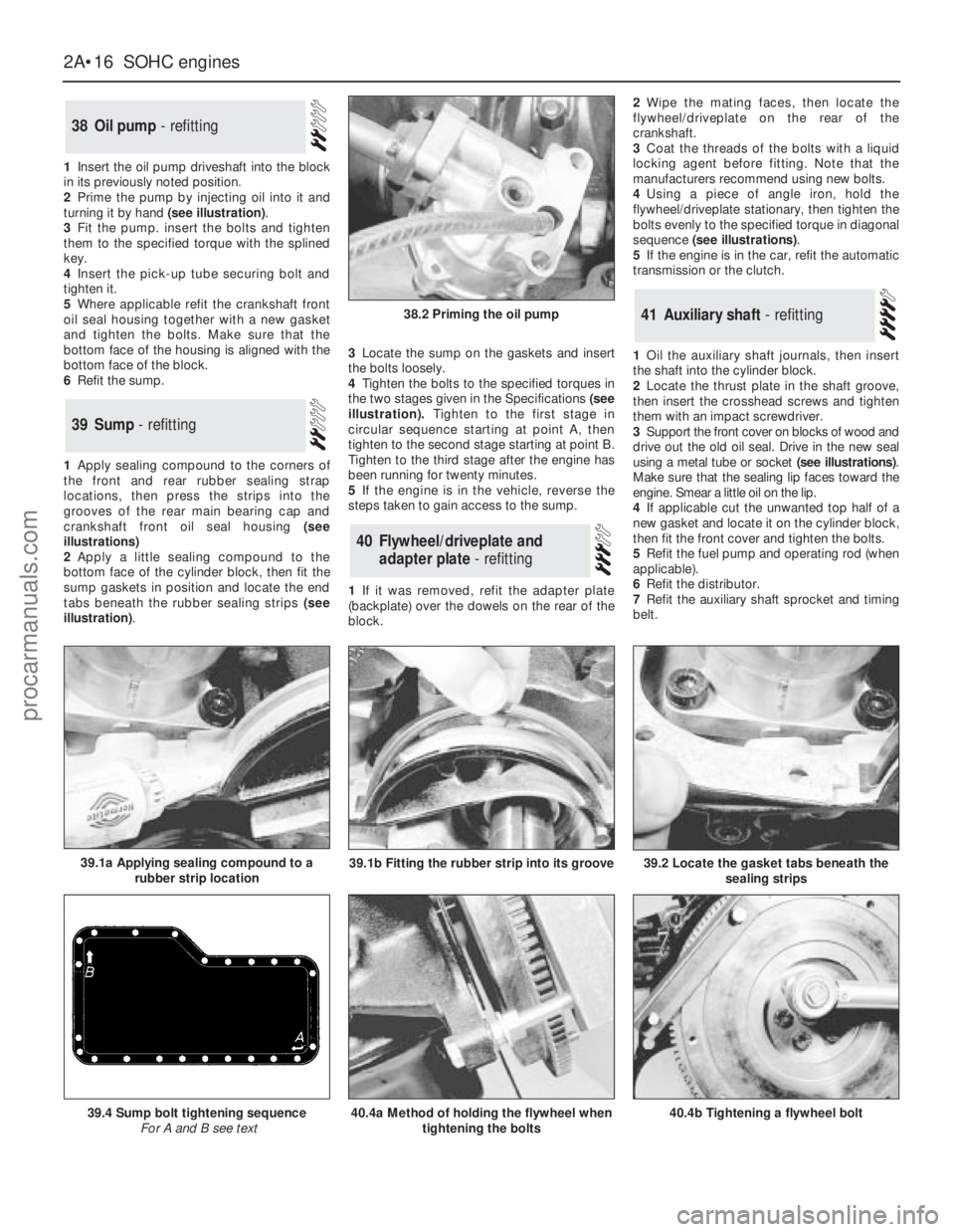

1Apply sealing compound to the corners of

the front and rear rubber sealing strap

locations, then press the strips into the

grooves of the rear main bearing cap and

crankshaft front oil seal housing (see

illustrations)

2Apply a little sealing compound to the

bottom face of the cylinder block, then fit the

sump gaskets in position and locate the end

tabs beneath the rubber sealing strips (see

illustration).3Locate the sump on the gaskets and insert

the bolts loosely.

4Tighten the bolts to the specified torques in

the two stages given in the Specifications(see

illustration).Tighten to the first stage in

circular sequence starting at point A, then

tighten to the second stage starting at point B.

Tighten to the third stage after the engine has

been running for twenty minutes.

5If the engine is in the vehicle, reverse the

steps taken to gain access to the sump.

1If it was removed, refit the adapter plate

(backplate) over the dowels on the rear of the

block.2Wipe the mating faces, then locate the

flywheel/driveplate on the rear of the

crankshaft.

3Coat the threads of the bolts with a liquid

locking agent before fitting. Note that the

manufacturers recommend using new bolts.

4Using a piece of angle iron, hold the

flywheel/driveplate stationary, then tighten the

bolts evenly to the specified torque in diagonal

sequence (see illustrations).

5If the engine is in the car, refit the automatic

transmission or the clutch.

1Oil the auxiliary shaft journals, then insert

the shaft into the cylinder block.

2Locate the thrust plate in the shaft groove,

then insert the crosshead screws and tighten

them with an impact screwdriver.

3Support the front cover on blocks of wood and

drive out the old oil seal. Drive in the new seal

using a metal tube or socket (see illustrations).

Make sure that the sealing lip faces toward the

engine. Smear a little oil on the lip.

4If applicable cut the unwanted top half of a

new gasket and locate it on the cylinder block,

then fit the front cover and tighten the bolts.

5Refit the fuel pump and operating rod (when

applicable).

6Refit the distributor.

7Refit the auxiliary shaft sprocket and timing

belt.

41Auxiliary shaft - refitting

40Flywheel/driveplate and

adapter plate - refitting

39Sump - refitting

38Oil pump - refitting

2A•16SOHCengines

38.2 Priming the oil pump

40.4a Method of holding the flywheel when

tightening the bolts39.4 Sump bolt tightening sequence

For A and B see text40.4b Tightening a flywheel bolt

39.2 Locate the gasket tabs beneath the

sealing strips39.1a Applying sealing compound to a

rubber strip location39.1b Fitting the rubber strip into its groove

procarmanuals.com

Page 42 of 255

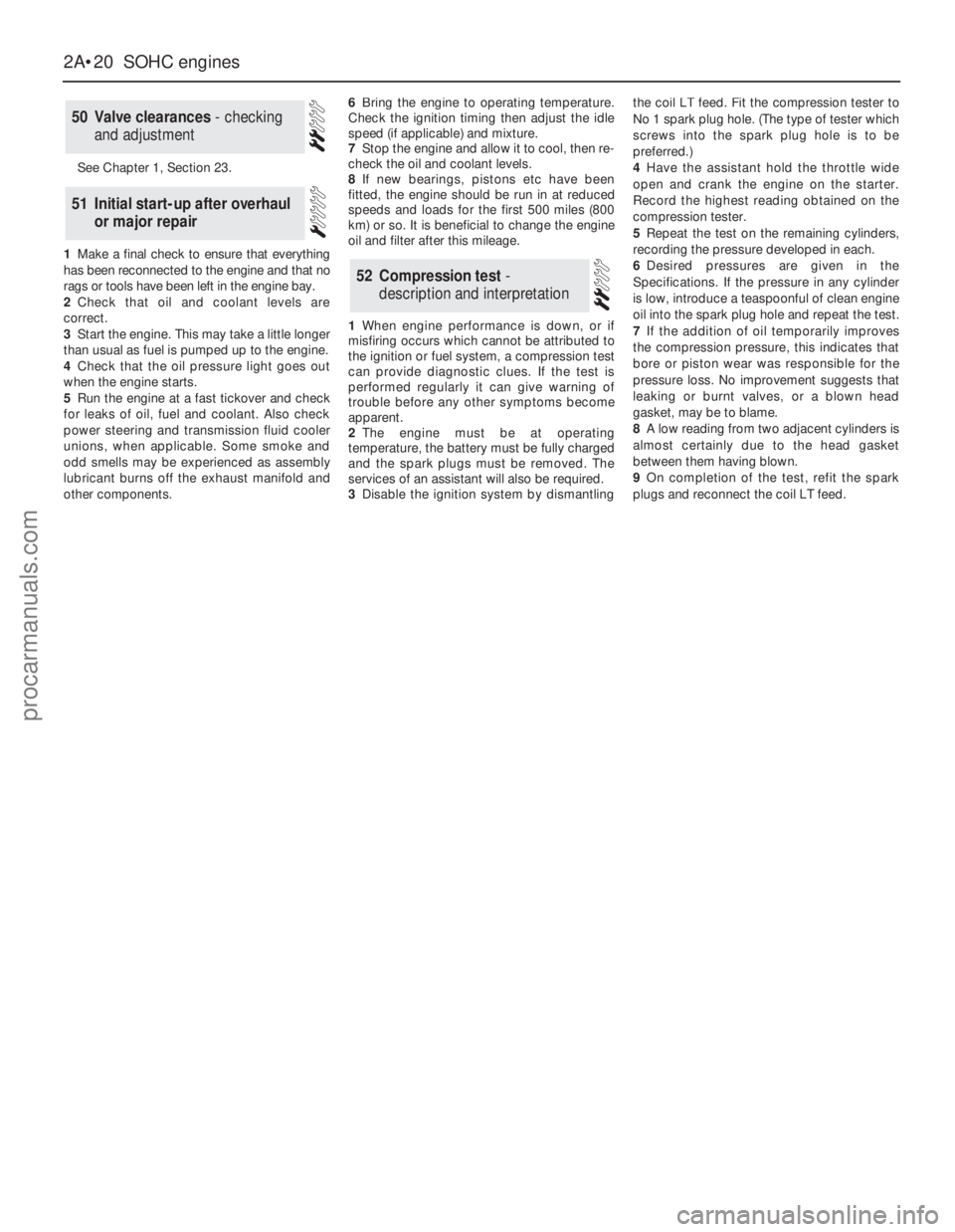

If the crankcase ventilation oil separator was

removed, apply a liquid locking agent to its

tube before pressing it into the cylinder block.

1Make sure that the clutch is centred.

2Apply a smear of grease or anti-seize

compound to the gearbox input shaft splines.

3With the aid of an assistant, offer the

gearbox to the engine. If the input shaft is

reluctant to enter the clutch, rock the gearbox

slightly or turn the crankshaft back and forth.

Support the gearbox until it is engaged with

the dowels on the engine - do not leave it

hanging on the input shaft.4Refit the engine-to-bellhousing bolts, the

bracing strap and the starter motor.

1Sling the engine/gearbox unit so that it

hangs at an angle of approximately 45°.

2Lower the unit into the engine bay, at the

same time moving it towards the rear of the

vehicle. Have an assistant watch as the unit is

lowered to check that no pipes, wires etc are

fouled or trapped.

3Raise the gearbox as the engine is lowered

until the unit takes up its correct position.

Secure the engine bearers to the mountings

and refit the gearbox crossmember.

4The remainder of refitting is a reversal of the

removal procedure. Refer to Section 6. Also

refer to Section 49, paragraph 9.

5Before starting the engine, refer to Section 51.

1On manual gearbox models, check that the

clutch is centred correctly. Apply a smear of

grease or anti-seize compound to the gearbox

input shaft.

2On automatic transmission models, check

that the torque converter is fully engaged with

the transmission oil pump.

3Sling the engine so that it is roughly horizontal.Lift it and position it over the engine bay.

4Lower the engine into place. Have an

assistant watch as the unit is lowered to check

that no pipes, wires etc are fouled or trapped.

5Guide the engine onto the transmission,

raising or lowering the transmission slightly if

necessary. Do not place any weight on the

transmission input shaft. With manual gearbox

models, rock the engine gently from side to

side to encourage the input shaft to enter the

clutch.

6When the engine and transmission are fully

engaged, refit the engine-to-bellhousing bolts.

Do not overlook the earth strap.

7Lower the engine so that the engine bearers

engage with the mountings. Fit the mounting

nuts and remove the lifting tackle.

8On automatic transmission models, bolt the

torque converter to the driveplate.

9The remainder of refitting is a reversal of the

removal procedure. Note the following

additional points:

a)Refill the engine with oil

b)Check the transmission oil level if

necessary

c)Adjust the tension of the accessory

drivebelts

d)Adjust the throttle cable

e)Adjust the downshift cable when

applicable

f)Refill the cooling system

10Before starting the engine, see Section 51

49Engine - refitting without

gearbox/transmission

48Engine - refitting with manual

gearbox

47Engine and gearbox -

reconnection

SOHCengines 2A•19

2A

45.16 Holding the crankshaft pulley with

two bolts and a lever while tightening the

central bolt

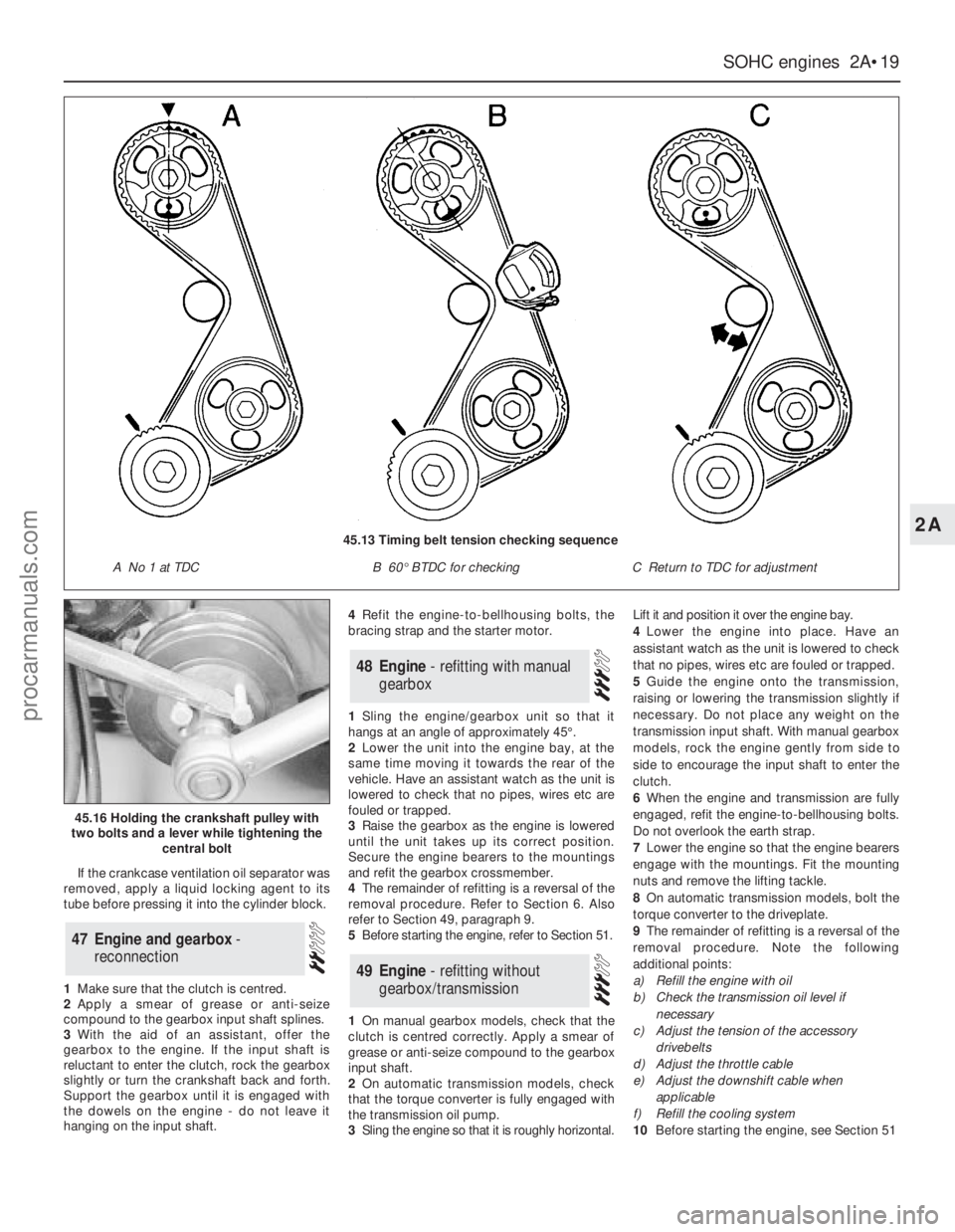

45.13 Timing belt tension checking sequence

A No 1 at TDCB 60°BTDC for checkingC Return to TDC for adjustment

procarmanuals.com

Page 43 of 255

See Chapter 1, Section 23.

1Make a final check to ensure that everything

has been reconnected to the engine and that no

rags or tools have been left in the engine bay.

2Check that oil and coolant levels are

correct.

3Start the engine. This may take a little longer

than usual as fuel is pumped up to the engine.

4Check that the oil pressure light goes out

when the engine starts.

5Run the engine at a fast tickover and check

for leaks of oil, fuel and coolant. Also check

power steering and transmission fluid cooler

unions, when applicable. Some smoke and

odd smells may be experienced as assembly

lubricant burns off the exhaust manifold and

other components.6Bring the engine to operating temperature.

Check the ignition timing then adjust the idle

speed (if applicable) and mixture.

7Stop the engine and allow it to cool, then re-

check the oil and coolant levels.

8If new bearings, pistons etc have been

fitted, the engine should be run in at reduced

speeds and loads for the first 500 miles (800

km) or so. It is beneficial to change the engine

oil and filter after this mileage.

1When engine performance is down, or if

misfiring occurs which cannot be attributed to

the ignition or fuel system, a compression test

can provide diagnostic clues. If the test is

performed regularly it can give warning of

trouble before any other symptoms become

apparent.

2The engine must be at operating

temperature, the battery must be fully charged

and the spark plugs must be removed. The

services of an assistant will also be required.

3Disable the ignition system by dismantlingthe coil LT feed. Fit the compression tester to

No 1 spark plug hole. (The type of tester which

screws into the spark plug hole is to be

preferred.)

4Have the assistant hold the throttle wide

open and crank the engine on the starter.

Record the highest reading obtained on the

compression tester.

5Repeat the test on the remaining cylinders,

recording the pressure developed in each.

6Desired pressures are given in the

Specifications. If the pressure in any cylinder

is low, introduce a teaspoonful of clean engine

oil into the spark plug hole and repeat the test.

7If the addition of oil temporarily improves

the compression pressure, this indicates that

bore or piston wear was responsible for the

pressure loss. No improvement suggests that

leaking or burnt valves, or a blown head

gasket, may be to blame.

8A low reading from two adjacent cylinders is

almost certainly due to the head gasket

between them having blown.

9On completion of the test, refit the spark

plugs and reconnect the coil LT feed.

52Compression test -

description and interpretation

51Initial start-up after overhaul

or major repair

50Valve clearances - checking

and adjustment

2A•20SOHCengines

procarmanuals.com

Page 44 of 255

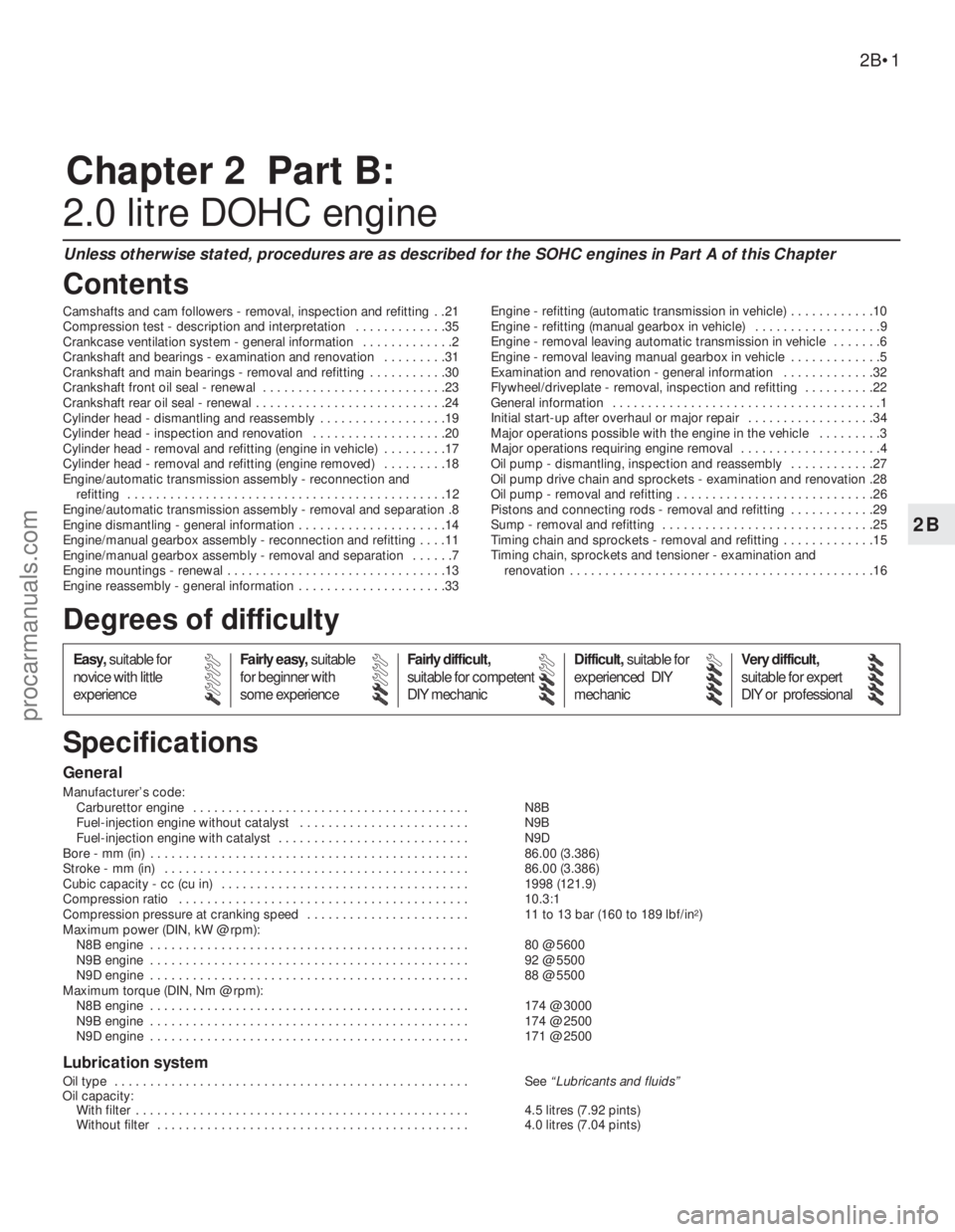

Chapter 2 Part B:

2.0 litre DOHC engine

Unless otherwise stated, procedures are as described for the SOHC engines in Part A of this Chapter

Camshafts and cam followers - removal, inspection and refitting . .21

Compression test - description and interpretation . . . . . . . . . . . . .35

Crankcase ventilation system - general information . . . . . . . . . . . . .2

Crankshaft and bearings - examination and renovation . . . . . . . . .31

Crankshaft and main bearings - removal and refitting . . . . . . . . . . .30

Crankshaft front oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . .23

Crankshaft rear oil seal - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Cylinder head - dismantling and reassembly . . . . . . . . . . . . . . . . . .19

Cylinder head - inspection and renovation . . . . . . . . . . . . . . . . . . .20

Cylinder head - removal and refitting (engine in vehicle) . . . . . . . . .17

Cylinder head - removal and refitting (engine removed) . . . . . . . . .18

Engine/automatic transmission assembly - reconnection and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Engine/automatic transmission assembly - removal and separation .8

Engine dismantling - general information . . . . . . . . . . . . . . . . . . . . .14

Engine/manual gearbox assembly - reconnection and refitting . . . .11

Engine/manual gearbox assembly - removal and separation . . . . . .7

Engine mountings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Engine reassembly - general information . . . . . . . . . . . . . . . . . . . . .33Engine - refitting (automatic transmission in vehicle) . . . . . . . . . . . .10

Engine - refitting (manual gearbox in vehicle) . . . . . . . . . . . . . . . . . .9

Engine - removal leaving automatic transmission in vehicle . . . . . . .6

Engine - removal leaving manual gearbox in vehicle . . . . . . . . . . . . .5

Examination and renovation - general information . . . . . . . . . . . . .32

Flywheel/driveplate - removal, inspection and refitting . . . . . . . . . .22

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Initial start-up after overhaul or major repair . . . . . . . . . . . . . . . . . .34

Major operations possible with the engine in the vehicle . . . . . . . . .3

Major operations requiring engine removal . . . . . . . . . . . . . . . . . . . .4

Oil pump - dismantling, inspection and reassembly . . . . . . . . . . . .27

Oil pump drive chain and sprockets - examination and renovation .28

Oil pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Pistons and connecting rods - removal and refitting . . . . . . . . . . . .29

Sump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Timing chain and sprockets - removal and refitting . . . . . . . . . . . . .15

Timing chain, sprockets and tensioner - examination and

renovation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

General

Manufacturer’s code:

Carburettor engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N8B

Fuel-injection engine without catalyst . . . . . . . . . . . . . . . . . . . . . . . . N9B

Fuel-injection engine with catalyst . . . . . . . . . . . . . . . . . . . . . . . . . . . N9D

Bore - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.00 (3.386)

Stroke - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86.00 (3.386)

Cubic capacity - cc (cu in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1998 (121.9)

Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.3:1

Compression pressure at cranking speed . . . . . . . . . . . . . . . . . . . . . . . 11 to 13 bar (160 to 189 lbf/in

2)

Maximum power (DIN, kW @ rpm):

N8B engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 @ 5600

N9B engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92 @ 5500

N9D engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88 @ 5500

Maximum torque (DIN, Nm @ rpm):

N8B engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174 @ 3000

N9B engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174 @ 2500

N9D engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171 @ 2500

Lubrication system

Oil type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See “Lubricants and fluids”

Oil capacity:

With filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.5 litres (7.92 pints)

Without filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.0 litres (7.04 pints)

2B•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

2B

procarmanuals.com

Page 46 of 255

DOHCengine 2B•3

2B

Torque wrench settingsNmlbf ft

Main bearing cap bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90 to 10466 to 77

Big-end bearing cap bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 to 84 to 6

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 to 1711 to 13

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tighten further 85°to 95°Tighten further 85°to 95°

Crankshaft pulley bolt:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45 to 5833 to 43

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tighten further 80°to 90°Tighten further 80°to 90°

Camshaft sprocket bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55 to 6341 to 46

Flywheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82 to 9261 to 68

Oil pump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 127 to 9

Oil pump sprocket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 to 1912 to 14

Oil pump chain tensioner bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 to 137 to 10

Sump bolts and nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 106 to 7

Sump studs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 to 84 to 6

Sump drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2815 to 21

Sump front mounting plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 to 2817 to 21

Oil baffle nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2113 to 15

Oil pick-up pipe-to-cylinder block bolts . . . . . . . . . . . . . . . . . . . . . . . . .9 to 137 to 10

Oil pressure warning lamp switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 to 2213 to 16

Cylinder head bolts:

M11 bolts:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2518

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5541

Stage 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tighten further 90°Tighten further 90°

Stage 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tighten further 90°Tighten further 90°

M8 bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36 to 3927 to 29

Camshaft cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 to 84 to 6

Camshaft bearing cap nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22 to 2616 to 19

Lower timing chain guide:

Upper bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 to 137 to 10

Lower bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24 to 2818 to 21

Upper and lower timing chain cover bolts . . . . . . . . . . . . . . . . . . . . . . .7 to 105 to 7

Crankshaft rear oil seal housing bolts . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Engine-to-gearbox/transmission bolts . . . . . . . . . . . . . . . . . . . . . . . . . .29 to 4121 to 30

The 2.0 litre DOHC (Double OverHead

Camshaft) engine was introduced in June

1989 to replace the 2.0 litre SOHC engine

used previously in the Granada range, at the

same time a 2.0 litre version of the Scorpio

model was also introduced. The engine is of

four-cylinder, in-line type.

The crankshaft incorporates five main

bearings. Thrustwashers are fitted to the

centre main bearing in order to control

crankshaft endfloat.

The camshafts are driven by a chain from

the crankshaft and operate the angled valves

via hydraulic cam followers. One camshaft

operates the inlet valves, and the other

operates the exhaust valves.

The distributor is driven directly from the

front of the inlet camshaft, and the oil pump is

driven by a chain from the crankshaft. An

electric fuel pump is mounted in the fuel tank.

Lubrication is by means of a bi-rotor pump

which draws oil through a strainer located

inside the sump, and forces it through a full-

flow filter into the engine oil galleries, from

where it is distributed to the crankshaft and

camshafts. The big-end bearings are supplied

with oil via internal drillings in the crankshaft.

The undersides of the pistons are suppliedwith oil from drillings in the connecting rods.

The hydraulic cam followers are supplied with

oil from passages in the cylinder head. The

camshafts are lubricated by oil from spray

tubes mounted above the camshaft bearing

caps.

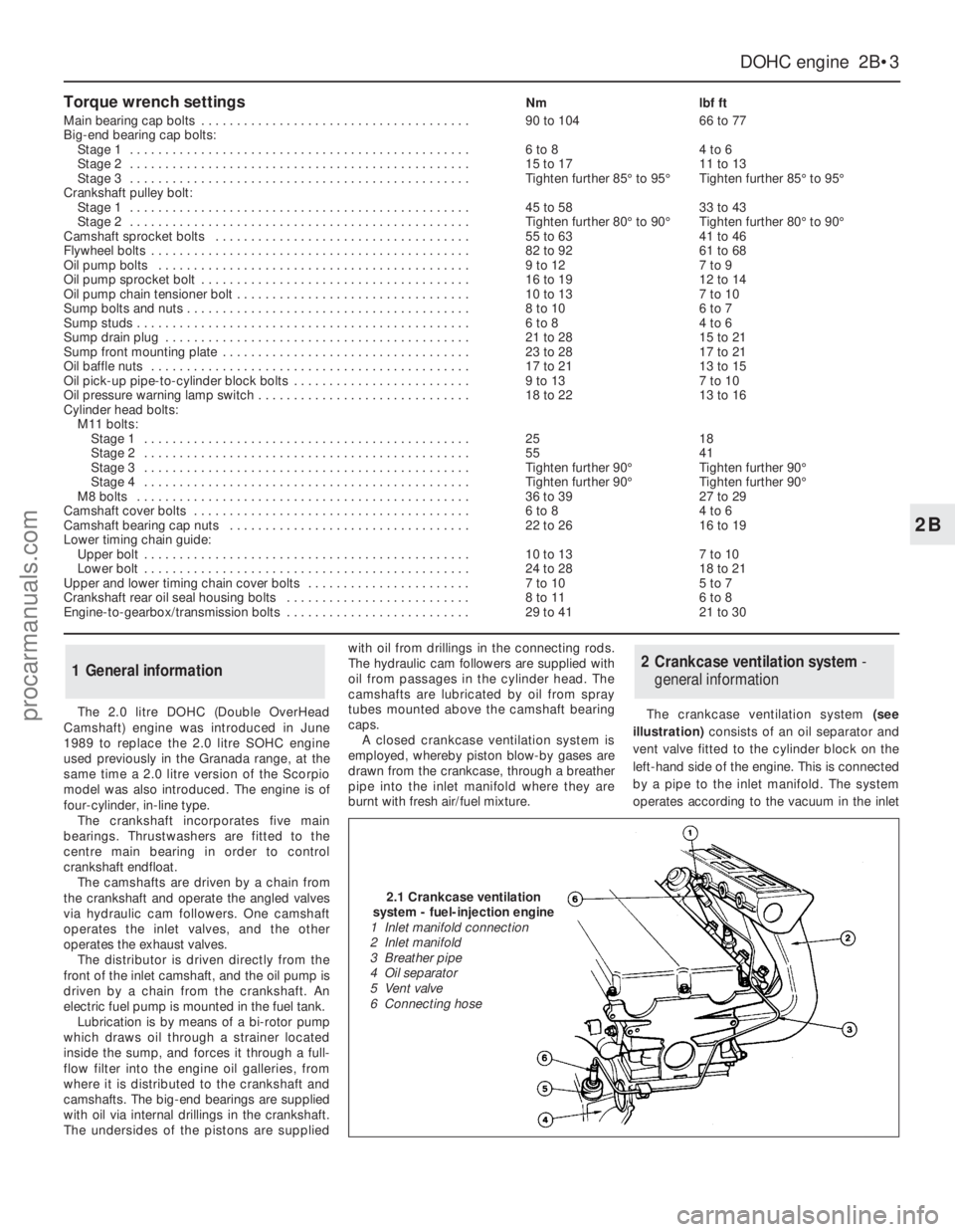

A closed crankcase ventilation system is

employed, whereby piston blow-by gases are

drawn from the crankcase, through a breather

pipe into the inlet manifold where they are

burnt with fresh air/fuel mixture.The crankcase ventilation system (see

illustration)consists of an oil separator and

vent valve fitted to the cylinder block on the

left-hand side of the engine. This is connected

by a pipe to the inlet manifold. The system

operates according to the vacuum in the inlet

2Crankcase ventilation system -

general information1General information

2.1 Crankcase ventilation

system - fuel-injection engine

1 Inlet manifold connection

2 Inlet manifold

3 Breather pipe

4 Oil separator

5 Vent valve

6 Connecting hose

procarmanuals.com

Page 48 of 255

27Remove the starter motor.

28Remove the exhaust downpipe.

29Ensure that the steering wheel is

positioned in the straight-ahead position then,

using a dab of paint or a suitable marker pen,

make alignment marks between the

intermediate shaft lower clamp and steering

gear pinion. Slacken and remove the lower

clamp bolt then disconnect the intermediate

shaft from the steering gear (see illustration).

30Working inside the vehicle, place a

wooden block under the clutch pedal to raise

it fully against the stop, so holding the

automatic adjuster pawl clear of the toothed

quadrant.

31Disconnect the clutch cable from the

clutch release arm, and pass the cable

through the bellhousing.

32Support the gearbox with a trolley jack,

using a block of wood between the jack and

the gearbox to spread the load.

33Unscrew and remove the remaining

engine-to-gearbox bolts, and remove the bolt

from the engine adapter plate (see

illustration). Recover any shims fitted

between the sump and the gearbox when

removing the lower engine-to-gearbox bolts.

34Make a final check to ensure that all

relevant wires, pipes and hoses have been

disconnected and positioned clear of the

engine to facilitate engine removal.

35Attach a suitable hoist to the engine lifting

brackets located at the front and rear of the

cylinder head, and carefully take the weight of

the engine.

36To improve clearance in the engine

compartment when lifting the engine, unbolt

the engine mounting brackets from the

cylinder block, and remove them (see

illustration).

37Detach the brake lines from the front

suspension crossmember (see illustration).

38Support the crossmember with a jack (do

not remove the jack from under the gearbox),

then loosen the bolts securing the

crossmember to the underbody. Remove the

bolts from one side, and carefully lower the

crossmember to allow sufficient room for the

sump to clear the steering rack and

crossmember when pulling the engine

forwards from the gearbox (see illustration).39Gently raise the engine, then pull it

forwards to disconnect it from the gearbox.

Ensure that the gearbox is adequately

supported, and take care not to strain the

gearbox input shaft.

40Once clear of the gearbox, lift the engine

from the vehicle, taking care not to damage

the components in the engine compartment.

Note:Refer to Part A, Section 4 of this

Chapter and to the warning that appears at the

start of Section 5 before proceeding. A

suitable hoist and lifting tackle will be required

for this operation.

1Proceed as described in paragraphs 1 to 21

of Section 5.

2Unscrew and remove the top engine-to-

transmission bolts which are accessible from

the engine compartment. Note the location of

the earth strap, vacuum pipe bracket, and

transmission dipstick tube bracket, as

applicable.

3Proceed as described in paragraphs 23 to 29

of Section 5.4Where applicable, remove the bolt securing

the transmission fluid dipstick tube to the left-

hand side of the cylinder block.

5Working through the starter motor aperture,

unscrew the four torque converter-to-

driveplate nuts. It will be necessary to turn the

crankshaft, using a suitable spanner on the

crankshaft pulley bolt, in order to gain access

to each bolt in turn through the aperture.

6Support the transmission with a trolley jack,

using a block of wood between the jack and

the transmission to spread the load.

7Unscrew and remove the remaining engine-

to-transmission bolts, and remove the bolt

from the engine adapter plate. Recover any

shims fitted between the sump and the

transmission when removing the lower engine-

to-transmission bolts. Where applicable, pull

the blanking plug from the adapter plate.

8Proceed as described in paragraphs 34 to 38

of Section 5.

9Gently raise the engine, then pull the engine

forwards to disconnect it from the

transmission. Ensure that the torque converter

is held firmly in place in the transmission

housing, otherwise it could fall out resulting in

fluid spillage and possible damage. It may be

necessary to rock the engine a little to release

it from the transmission.

10Once clear of the transmission, lift the

engine from the vehicle, taking care not to

damage the components in the engine

compartment.

6Engine - removal leaving

automatic transmission in vehicle

DOHCengine 2B•5

2B

5.29 Intermediate shaft lower clamp bolt

(arrowed)5.33 Engine adaptor plate bolt (arrowed)5.36 Remove the engine mounting brackets

to improve clearance

5.37 Removing a brake line securing clip

from the suspension crossmember5.38 Removing a suspension crossmember

securing bolt

It may be necessary to rock

the engine a little to release it

from the gearbox.

procarmanuals.com