ESP FORD GRANADA 1985 Service Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 159 of 255

important also to keep watch on those parts of

the vehicle not immediately visible, for

instance the underside, inside all the wheel

arches, and the lower part of the engine

compartment.

The basic maintenance routine for the

bodywork is washing - preferably with a lot of

water, from a hose. This will remove all the

loose solids which may have stuck to the

vehicle. It is important to flush these off in

such a way as to prevent grit from scratching

the finish. The wheel arches and underframe

need washing in the same way, to remove any

accumulated mud, which will retain moisture

and tend to encourage rust. Paradoxically

enough, the best time to clean the underframe

and wheel arches is in wet weather, when the

mud is thoroughly wet and soft. In very wet

weather, the underframe is usually cleaned of

large accumulations automatically, and this is

a good time for inspection.

Periodically, except on vehicles with a wax-

based underbody protective coating, it is a

good idea to have the whole of the underframe

of the vehicle steam-cleaned, engine

compartment included, so that a thorough

inspection can be carried out to see what

minor repairs and renovations are necessary.

Steam-cleaning is available at many garages,

and is necessary for the removal of the

accumulation of oily grime, which sometimes

is allowed to become thick in certain areas. If

steam-cleaning facilities are not available,

there are some excellent grease solvents

available which can be brush-applied; the dirt

can then be simply hosed off. Note that these

methods should not be used on vehicles with

wax-based underbody protective coating, or

the coating will be removed. Such vehicles

should be inspected annually, preferably just

prior to Winter, when the underbody should be

washed down, and any damage to the wax

coating repaired. Ideally, a completely fresh

coat should be applied. It would also be worth

considering the use of such wax-based

protection for injection into door panels, sills,

box sections, etc, as an additional safeguard

against rust damage, where such protection is

not provided by the vehicle manufacturer.

After washing paintwork, wipe off with a

chamois leather to give an unspotted clear

finish. A coat of clear protective wax polish will

give added protection against chemical

pollutants in the air. If the paintwork sheen has

dulled or oxidised, use a cleaner/polisher

combination to restore the brilliance of the

shine. This requires a little effort, but such

dulling is usually caused because regular

washing has been neglected. Care needs to

be taken with metallic paintwork, as special

non-abrasive cleaner/polisher is required to

avoid damage to the finish. Always check that

the door and ventilator opening drain holes

and pipes are completely clear, so that water

can be drained out. Brightwork should be

treated in the same way as paintwork.

Windscreens and windows can be kept clear

of the smeary film which often appears, by theuse of proprietary glass cleaner. Never use

any form of wax or other body or chromium

polish on glass.

Mats and carpets should be brushed or

vacuum-cleaned regularly, to keep them free

of grit. If they are badly stained, remove them

from the vehicle for scrubbing or sponging,

and make quite sure they are dry before

refitting. Seats and interior trim panels can be

kept clean by wiping with a damp cloth. If they

do become stained (which can be more

apparent on light-coloured upholstery), use a

little liquid detergent and a soft nail brush to

scour the grime out of the grain of the material.

Do not forget to keep the headlining clean in

the same way as the upholstery. When using

liquid cleaners inside the vehicle, do not over-

wet the surfaces being cleaned. Excessive

damp could get into the seams and padded

interior, causing stains, offensive odours or

even rot. If the inside of the vehicle gets wet

accidentally, it is worthwhile taking some

trouble to dry it out properly, particularly

where carpets are involved. Do not leave oil or

electric heaters inside the vehicle for this

purpose.

Repairs of minor scratches in

bodywork

If the scratch is very superficial, and does

not penetrate to the metal of the bodywork,

repair is very simple. Lightly rub the area of the

scratch with a paintwork renovator, or a very

fine cutting paste, to remove loose paint from

the scratch, and to clear the surrounding

bodywork of wax polish. Rinse the area with

clean water.

Apply touch-up paint to the scratch using a

fine paint brush; continue to apply fine layers

of paint until the surface of the paint in the

scratch is level with the surrounding

paintwork. Allow the new paint at least two

weeks to harden, then blend it into the

surrounding paintwork by rubbing the scratch

area with a paintwork renovator or a very fine

cutting paste. Finally, apply wax polish.

Where the scratch has penetrated right

through to the metal of the bodywork, causing

the metal to rust, a different repair technique is

required. Remove any loose rust from the

bottom of the scratch with a penknife, then

apply rust-inhibiting paint to prevent the

formation of rust in the future. Using a rubber

or nylon applicator, fill the scratch with

bodystopper paste. If required, this paste can

be mixed with cellulose thinners to provide a

very thin paste which is ideal for filling narrow

scratches. Before the stopper-paste in the

scratch hardens, wrap a piece of smoothcotton rag around the top of a finger. Dip the

finger in cellulose thinners, and quickly sweep

it across the surface of the stopper-paste in

the scratch; this will ensure that the surface of

the stopper-paste is slightly hollowed. The

scratch can now be painted over as described

earlier in this Section.

Repairs of dents in bodywork

When deep denting of the vehicle’s

bodywork has taken place, the first task is to

pull the dent out, until the affected bodywork

almost attains its original shape. There is little

point in trying to restore the original shape

completely, as the metal in the damaged area

will have stretched on impact, and cannot be

reshaped fully to its original contour. It is

better to bring the level of the dent up to a

point which is about 3 mm below the level of

the surrounding bodywork. In cases where the

dent is very shallow anyway, it is not worth

trying to pull it out at all. If the underside of the

dent is accessible, it can be hammered out

gently from behind, using a mallet with a

wooden or plastic head. Whilst doing this,

hold a suitable block of wood firmly against

the outside of the panel, to absorb the impact

from the hammer blows and thus prevent a

large area of the bodywork from being “belled-

out”.

Should the dent be in a section of the

bodywork which has a double skin, or some

other factor making it inaccessible from

behind, a different technique is called for. Drill

several small holes through the metal inside

the area - particularly in the deeper section.

Then screw long self-tapping screws into the

holes, just sufficiently for them to gain a good

purchase in the metal. Now the dent can be

pulled out by pulling on the protruding heads

of the screws with a pair of pliers.

The next stage of the repair is the removal

of the paint from the damaged area, and from

an inch or so of the surrounding “sound”

bodywork. This is accomplished most easily

by using a wire brush or abrasive pad on a

power drill, although it can be done just as

effectively by hand, using sheets of abrasive

paper. To complete the preparation for filling,

score the surface of the bare metal with a

screwdriver or the tang of a file, or

alternatively, drill small holes in the affected

area. This will provide a really good “key” for

the filler paste.

To complete the repair, see the Section on

filling and respraying.

Repairs of rust holes or gashes in

bodywork

Remove all paint from the affected area, and

from an inch or so of the surrounding “sound”

bodywork, using an abrasive pad or a wire

brush on a power drill. If these are not

available, a few sheets of abrasive paper will

do the job most effectively. With the paint

removed, you will be able to judge the severity

of the corrosion, and therefore decide whether

to renew the whole panel (if this is possible) or

4Minor body damage - repair

3Maintenance - upholstery and

carpets

12•2Bodywork and fittings

procarmanuals.com

Page 160 of 255

to repair the affected area. New body panels

are not as expensive as most people think,

and it is often quicker and more satisfactory to

fit a new panel than to attempt to repair large

areas of corrosion.

Remove all fittings from the affected area,

except those which will act as a guide to the

original shape of the damaged bodywork (eg

headlight shells etc). Then, using tin snips or a

hacksaw blade, remove all loose metal and

any other metal badly affected by corrosion.

Hammer the edges of the hole inwards, in

order to create a slight depression for the filler

paste.

Wire-brush the affected area to remove the

powdery rust from the

surface of the remaining metal. Paint the

affected area with rust-inhibiting paint, if the

back of the rusted area is accessible, treat this

also.

Before filling can take place, it will be

necessary to block the hole in some way. This

can be achieved by the use of aluminium or

plastic mesh, or aluminium tape.

Aluminium or plastic mesh, or glass-fibre

matting, is probably the best material to use

for a large hole. Cut a piece to the

approximate size and shape of the hole to be

filled, then position it in the hole so that its

edges are below the level of the surrounding

bodywork. It can be retained in position by

several blobs of filler paste around its

periphery.

Aluminium tape should be used for small or

very narrow holes. Pull a piece off the roll, trim

it to the approximate size and shape required,

then pull off the backing paper (if used) and

stick the tape over the hole; it can be

overlapped if the thickness of one piece is

insufficient. Burnish down the edges of the

tape with the handle of a screwdriver or

similar, to ensure that the tape is securely

attached to the metal underneath.

Bodywork repairs - filling and

respraying

Before using this Section, see the Sections

on dent, deep scratch, rust holes and gash

repairs.

Many types of bodyfiller are available, but

generally speaking, those proprietary kits

which contain a tin of filler paste and a tube of

resin hardener are best for this type of repair.

A wide, flexible plastic or nylon applicator will

be found invaluable for imparting a smooth

and well-contoured finish to the surface of the

filler.

Mix up a little filler on a clean piece of card

or board - measure the hardener carefully

(follow the maker’s instructions on the pack),

otherwise the filler will set too rapidly or too

slowly. Using the applicator, apply the filler

paste to the prepared area; draw the

applicator across the surface of the filler to

achieve the correct contour and to level the

surface. As soon as a contour that

approximates to the correct one is achieved,

stop working the paste - if you carry on too

long, the paste will become sticky and begin

to “pick-up” on the applicator. Continue to

add thin layers of filler paste at 20-minuteintervals, until the level of the filler is just proud

of the surrounding bodywork.

Once the filler has hardened, the excess can

be removed using a metal plane or file. From

then on, progressively-finer grades of abrasive

paper should be used, starting with a 40-

grade production paper, and finishing with a

400-grade wet-and-dry paper. Always wrap

the abrasive paper around a flat rubber, cork,

or wooden block - otherwise the surface of the

filler will not be completely flat. During the

smoothing of the filler surface, the wet-and-

dry paper should be periodically rinsed in

water. This will ensure that a very smooth

finish is imparted to the filler at the final stage.

At this stage, the “dent” should be

surrounded by a ring of bare metal, which in

turn should be encircled by the finely

“feathered” edge of the good paintwork. Rinse

the repair area with clean water, until all of the

dust produced by the rubbing-down operation

has gone.

Spray the whole area with a light coat of

primer - this will show up any imperfections in

the surface of the filler. Repair these

imperfections with fresh filler paste or

bodystopper, and once more smooth the

surface with abrasive paper. Repeat this

spray-and-repair procedure until you are

satisfied that the surface of the filler, and the

feathered edge of the paintwork, are perfect.

Clean the repair area with clean water, and

allow to dry fully.

The repair area is now ready for final

spraying. Paint spraying must be carried out in

a warm, dry, windless and dust-free

atmosphere. This condition can be created

artificially if you have access to a large indoor

working area, but if you are forced to work in

the open, you will have to pick your day very

carefully. If you are working indoors, dousing

the floor in the work area with water will help

to settle the dust which would otherwise be in

the atmosphere. If the repair area is confined

to one body panel, mask off the surrounding

panels; this will help to minimise the effects of

a slight mis-match in paint colours. Bodywork

fittings (eg chrome strips, door handles etc)

will also need to be masked off. Use genuine

masking tape, and several thicknesses of

newspaper, for the masking operations.

Before commencing to spray, agitate the

aerosol can thoroughly, then spray a test area

(an old tin, or similar) until the technique is

mastered. Cover the repair area with a thick

coat of primer; the thickness should be built

up using several thin layers of paint, rather

than one thick one. Using 400-grade wet-and-

dry paper, rub down the surface of the primer

until it is really smooth. While doing this, the

work area should be thoroughly doused with

water, and the wet-and-dry paper periodically

rinsed in water. Allow to dry before spraying

on more paint.

Spray on the top coat, again building up thethickness by using several thin layers of paint.

Start spraying at one edge of the repair area,

and then, using a side-to-side motion, work

until the whole repair area and about 2 inches

of the surrounding original paintwork is

covered. Remove all masking material 10 to 15

minutes after spraying on the final coat of

paint.

Allow the new paint at least two weeks to

harden, then, using a paintwork renovator, or a

very fine cutting paste, blend the edges of the

paint into the existing paintwork. Finally, apply

wax polish.

Plastic components

With the use of more and more plastic body

components by the vehicle manufacturers (eg

bumpers. spoilers, and in some cases major

body panels), rectification of more serious

damage to such items has become a matter of

either entrusting repair work to a specialist in

this field, or renewing complete components.

Repair of such damage by the DIY owner is

not really feasible, owing to the cost of the

equipment and materials required for effecting

such repairs. The basic technique involves

making a groove along the line of the crack in

the plastic, using a rotary burr in a power drill.

The damaged part is then welded back

together, using a hot-air gun to heat up and

fuse a plastic filler rod into the groove. Any

excess plastic is then removed, and the area

rubbed down to a smooth finish. It is important

that a filler rod of the correct plastic is used, as

body components can be made of a variety of

different types (eg polycarbonate, ABS,

polypropylene).

Damage of a less serious nature (abrasions,

minor cracks etc) can be repaired by the DIY

owner using a two-part epoxy filler repair

material. Once mixed in equal proportions, this

is used in similar fashion to the bodywork filler

used on metal panels. The filler is usually

cured in twenty to thirty minutes, ready for

sanding and painting.

If the owner is renewing a complete

component himself, or if he has repaired it with

epoxy filler, he will be left with the problem of

finding a suitable paint for finishing which is

compatible with the type of plastic used. At

one time, the use of a universal paint was not

possible, owing to the complex range of

plastics encountered in body component

applications. Standard paints, generally

speaking, will not bond to plastic or rubber

satisfactorily. However, it is now possible to

obtain a plastic body parts finishing kit which

consists of a pre-primer treatment, a primer

and coloured top coat. Full instructions are

normally supplied with a kit, but basically, the

method of use is to first apply the pre-primer

to the component concerned, and allow it to

dry for up to 30 minutes. Then the primer is

applied, and left to dry for about an hour

before finally applying the special-coloured

top coat. The result is a correctly-coloured

component, where the paint will flex with the

plastic or rubber, a property that standard

paint does not normally posses.

Bodywork and fittings 12•3

12

If bodystopper is used, it can be

mixed with cellulose thinners,

to form a thin paste which is

ideal for filling small holes.

procarmanuals.com

Page 175 of 255

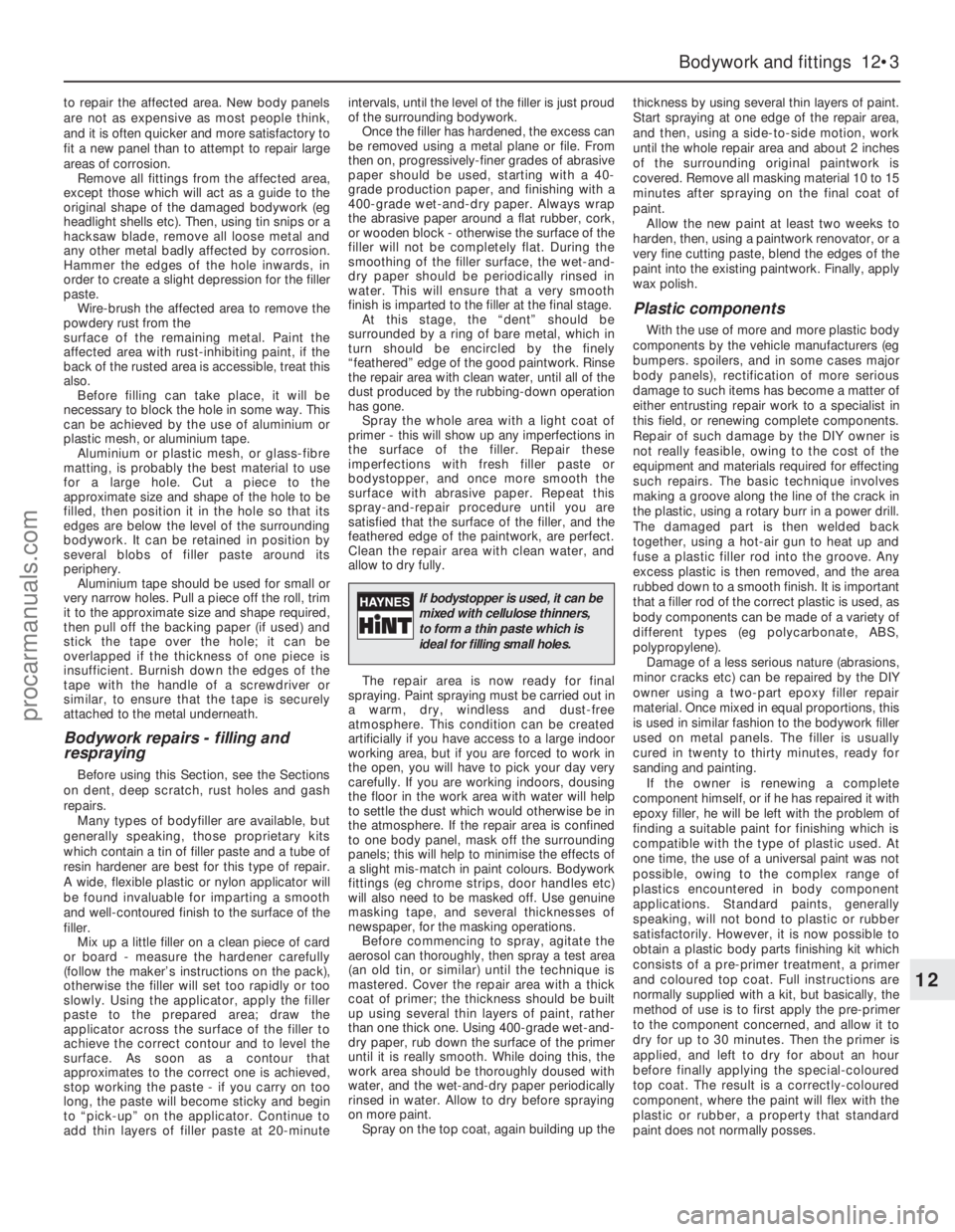

weatherstrips and remove the trim. Also

remove the webbing guide, which is secured

by two screws.

5Unbolt the lower anchor and the retractor,

again noting the position of any washers or

spacers. Remove the retractor and webbing

(see illustration).

6The seat belt buckle is secured to the seat

frame by two Torx screws(see illustration).

There is no need to renew the buckle just

because the retractor and webbing are being

renewed. If it is wished to remove the buckle,

first remove the seat.

7Refit by reversing the removal operations.

Tighten all anchorages to the specified torque,

and make sure that the belt is not twisted.1This Section describes the removal and

refitting of factory or dealer-installed rear seat

belts. A rear belt kit can be purchased from a

Ford dealer and should be found to

correspond with the items shown here. If a

proprietary kit is purchased, make sure it is

suitable for the vehicle in question and follow

the manufacturer’s instructions.

2Fold the rear seat cushion forwards.

3Feed the buckle webbing through the slits in

the carpet. Remove the buckle securing bolt,

remove the pins from the buckle elastic straps

and remove the buckles.

4Remove the lower anchor bolts, then fold

the seat backrests forwards. Fold back the

luggage area carpet and remove the backrest

hinges.

5Remove the seat back striker pins (low

series) or adjuster mechanism cover (high

series) (see illustration).

6Prise the webbing guides from each side

cushion.

7Remove the side cushions. Each one is

retained by a single nut and washer located

near the loudspeaker (see illustration). With

the nut and washer removed, the cushion is

then released by prising open the metal tags

which secure its bottom wire. Pull the bottom

of the cushion forwards and upwards to free it

from the retractor.

8The retractor can now be unbolted and thewebbing withdrawn through the side cushions.

9Commence refitting by fitting the retractor.

First fit the rear bolt and tighten it by a few

turns only, so that the retractor is still free to

move. Push the retractor rearwards and then

downwards so that it takes up its fitted

positions, then fit the front bolt. Tighten both

bolts to the specified torque.

10The remainder of refitting is a reversal of

the removal procedure. Tighten the belt and

buckle anchor bolts to the specified torque.

Cushion

1Fold the seat cushion forwards and remove

the hinge retaining screws (see illustration).

To remove the hinges as well, unbolt the

hinges from the body instead.

2When refitting, just nip up the hinge screws

or bolts and check the fit of the cushions.

Tighten the screws or bolts fully when

satisfied.

Backrests

3Fold the backrests forward and peel back

the carpet to expose the hinges (see

illustration).

4Remove the hinge screws, free the seat belt

webbing clips (when applicable) and remove

the backrests.

5Refit by reversing the removal operations.

49Rear seat components -

removal and refitting

48Rear seats belts - removal

and refitting

12•18Bodywork and fittings

47.1 Front seat belt adjustable top anchor

47.6 Front seat belt buckle secured by two

Torx screws (arrowed)

48.5 Removing a seat back striker pin49.1 Rear seat hinge-to-cushion screws48.7 Removing a side cushion nut

47.3 Removing the weatherstrip from the

B-pillar47.5 Seat belt retractor mechanism -

securing the bolt arrowed

procarmanuals.com

Page 181 of 255

the circuit between the relevant connector and

the battery is problem-free.

13Continue to check the remainder of the

circuit in the same fashion.

14When a point is reached at which no

voltage is present, the problem must lie

between that point and the previous test point

with voltage. Most problems can be traced to

a broken, corroded or loose connection.

Finding a short-circuit

15To check for a short-circuit, first disconnect

the load(s) from the circuit (loads are the

components which draw current from a circuit,

such as bulbs, motors, heating elements, etc).

16Remove the relevant fuse from the circuit,

and connect a circuit tester or voltmeter to the

fuse connections.

17Switch on the circuit, bearing in mind that

some circuits are live only when the ignition

switch is moved to a particular position.

18If voltage is present (indicated either by

the tester bulb lighting or a voltmeter reading),

this means that there is a short-circuit.

19If no voltage is present, but the fuse still

blows with the load(s) connected, this

indicates an internal fault in the load(s).

Finding an earth fault

20The battery negative terminal is connected

to “earth” - the metal of the engine/transmission

and the car body - and most systems are wired

so that they only receive a positive feed, the

current returning via the metal of the car body.

This means that the component mounting andthe body form part of that circuit. Loose or

corroded mountings can therefore cause a range

of electrical faults, ranging from total failure of a

circuit, to a puzzling partial fault. In particular,

lights may shine dimly (especially when another

circuit sharing the same earth is in operation),

motors (eg wiper motors or the radiator cooling

fan motor) may run slowly, and the operation of

one circuit may have an apparently-unrelated

effect on another. Note that on many vehicles,

earth straps are used between certain

components, such as the engine/transmission

and the body, usually where there is no metal-to-

metal contact between components, due to

flexible rubber mountings, etc.

21To check whether a component is properly

earthed, disconnect the battery, and connect

one lead of an ohmmeter to a known good

earth point. Connect the other lead to the wire

or earth connection being tested. The

resistance reading should be zero; if not,

check the connection as follows.

22If an earth connection is thought to be

faulty, dismantle the connection, and clean

back to bare metal both the bodyshell and the

wire terminal, or the component’s earth

connection mating surface. Be careful to

remove all traces of dirt and corrosion, then

use a knife to trim away any paint, so that a

clean metal-to-metal joint is made. On

reassembly, tighten the joint fasteners

securely; if a wire terminal is being refitted, use

serrated washers between the terminal and

the bodyshell, to ensure a clean and secure

connection. When the connection is remade,

prevent the onset of corrosion in the future byapplying a coat of petroleum jelly or silicone-

based grease, or by spraying on (at regular

intervals) a proprietary ignition sealer, or a

water-dispersant lubricant.

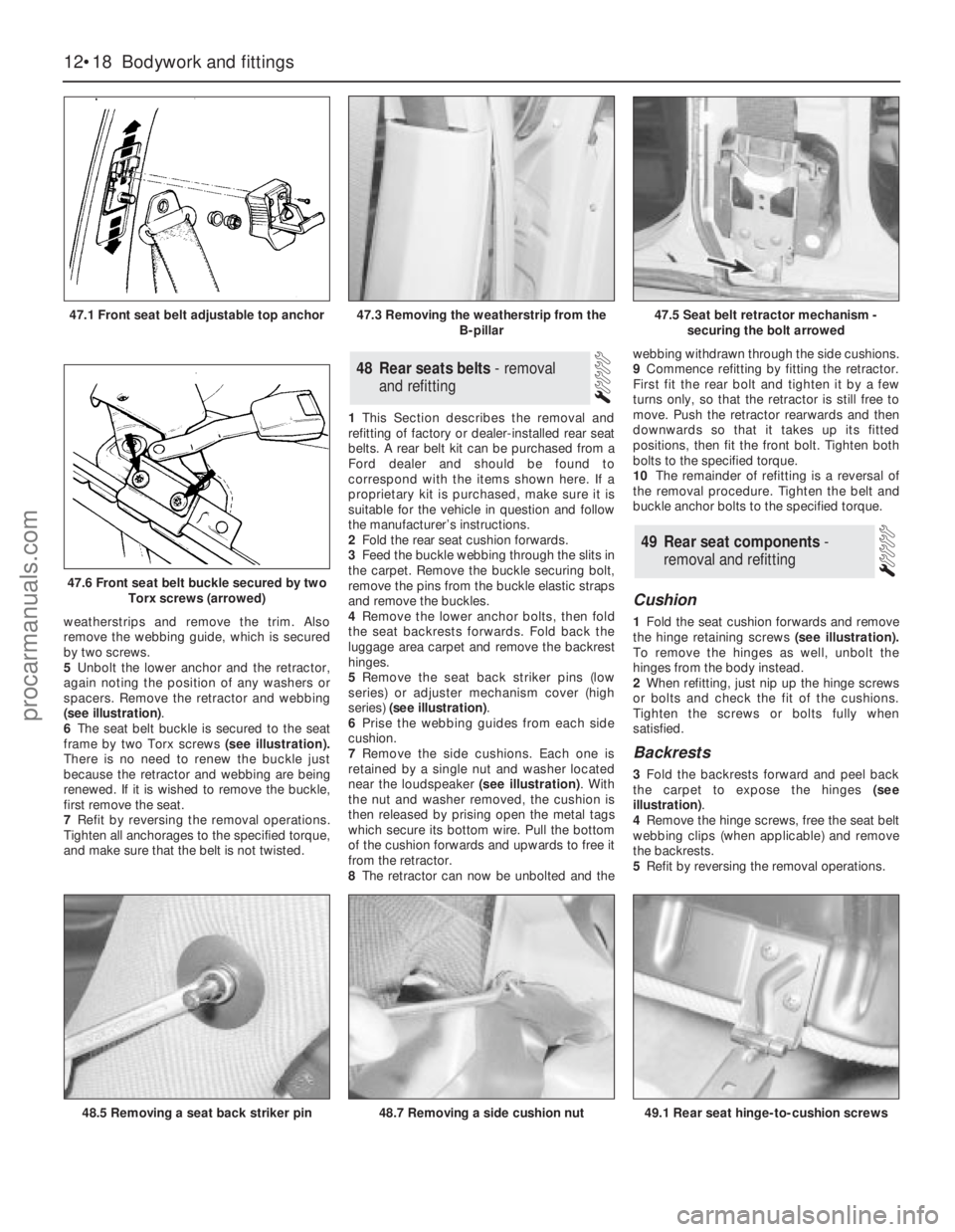

Headlight

1Open and prop the bonnet. Remove the

cover from the rear of the headlight unit by

twisting it anti-clockwise.

2Disconnect the wiring plug from the

headlight bulb. Release the spring clip by

squeezing its legs together and move it clear

of the bulb (see illustration).

3Remove the headlight bulb (see

illustration). Caution: If the lights have just

been in use, the bulb may be extremely hot.

4When handling the new bulb, use a tissue or

clean cloth to avoid touching the glass with

the fingers. If the glass is accidentally touched,

wipe it clean using methylated spirit. Moisture

and grease from the skin can cause

blackening and rapid failure of the new bulb.

5Fit the new bulb, making sure that the legs

and cut-outs in the bulb base and the reflector

match up. Secure with the spring clip.

6Reconnect the wiring plug. Check the

headlight for correct operation, then refit and

secure the rear cover.

Front parking light (sidelight)

7Gain access as for the headlight bulb, then

pull the parking light bulbholder from the

headlight reflector.

8Extract the wedge base bulb from the

holder (see illustration). Fit the new bulb, refit

the bulbholder and check for correct

operation.

Auxiliary driving light (when fitted)

9From above the auxiliary light unit, release

the cover spring clip and remove the cover

(see illustration).

10Release the spring clip from the bulb.

Withdraw the bulb and unplug its wiring

connector (see illustration). Caution: If the

lights have just been in use, the bulb may be

extremely hot.

11Do not touch the glass of the new bulb

with the fingers.

3Exterior lights - bulb renewal

13•4Body electrical system

3.2 Squeeze the spring clip legs (arrowed)

to remove the headlight bulb3.3 Removing a headlight bulb

3.8 Removing the front parking light bulb

from the holder3.9 Auxiliary driving light cover3.10 Removing the auxiliary driving light

bulb

procarmanuals.com

Page 184 of 255

Estate

19This procedure is the same as described

above for the Saloon models noting that it is

necessary to remove the luggage

compartment side trim panel to gain access to

the light cluster retaining nuts.

1It is recommended that beam adjustment be

carried out by a Ford garage using optical

alignment equipment. In an emergency,

however, the following procedure will produce

acceptable results.

2The vehicle should be normally laden and the

tyre pressures must be correct. Park the vehicle

on level ground, approximately 10 metres (33

feet) in front of a flat wall or garage door.

3Draw a vertical line on the wall or door

corresponding to the centre-line of the vehicle.

(The position of this line can be determined by

marking the centres of the windscreen and

rear window with crayon, then viewing the wall

or door from the rear of the vehicle.)

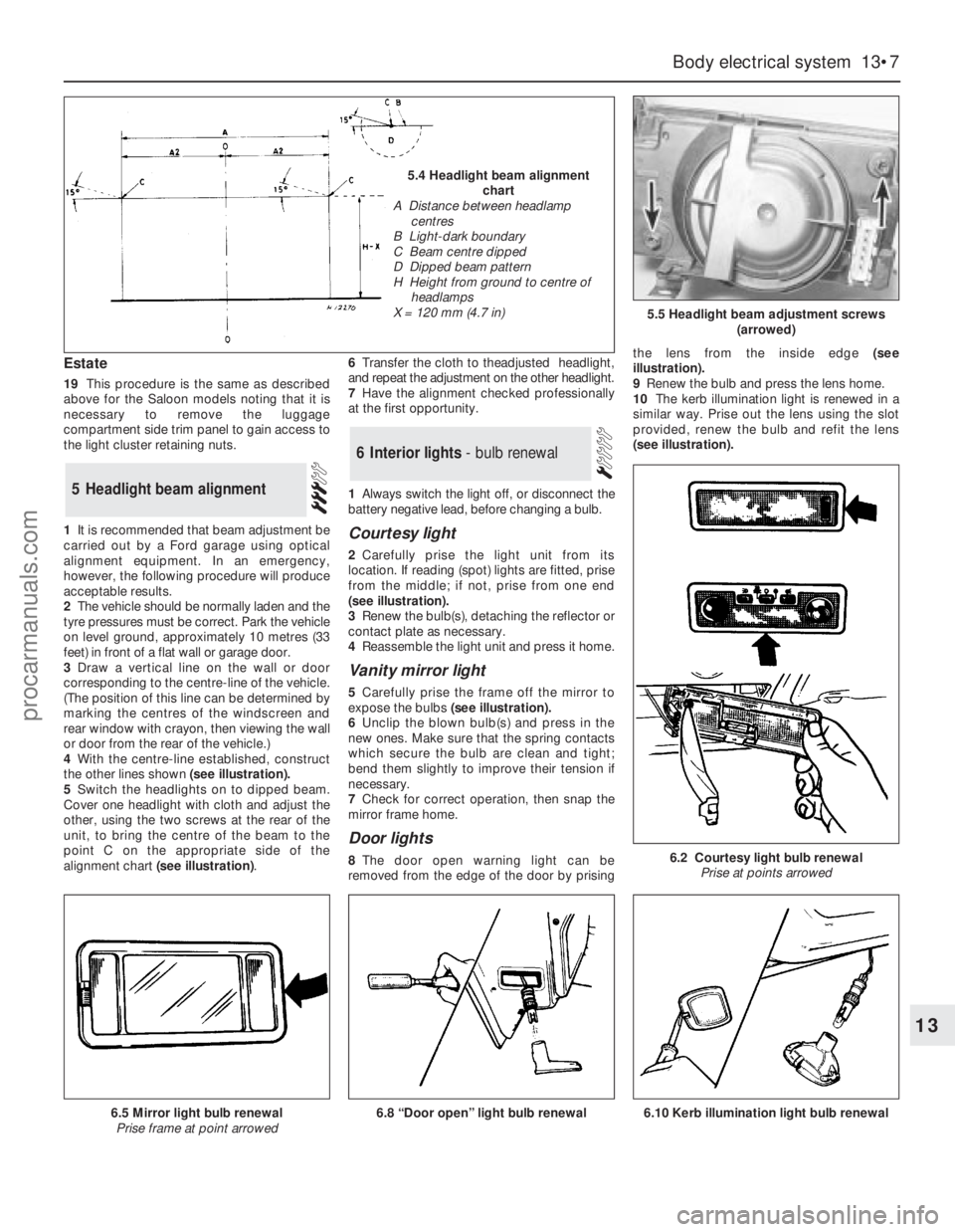

4With the centre-line established, construct

the other lines shown (see illustration).

5Switch the headlights on to dipped beam.

Cover one headlight with cloth and adjust the

other, using the two screws at the rear of the

unit, to bring the centre of the beam to the

point C on the appropriate side of the

alignment chart (see illustration).6Transfer the cloth to theadjusted headlight,

and repeat the adjustment on the other headlight.

7Have the alignment checked professionally

at the first opportunity.

1Always switch the light off, or disconnect the

battery negative lead, before changing a bulb.

Courtesy light

2Carefully prise the light unit from its

location. If reading (spot) lights are fitted, prise

from the middle; if not, prise from one end

(seeillustration).

3Renew the bulb(s), detaching the reflector or

contact plate as necessary.

4Reassemble the light unit and press it home.

Vanity mirror light

5Carefully prise the frame off the mirror to

expose the bulbs(see illustration).

6Unclip the blown bulb(s) and press in the

new ones. Make sure that the spring contacts

which secure the bulb are clean and tight;

bend them slightly to improve their tension if

necessary.

7Check for correct operation, then snap the

mirror frame home.

Door lights

8The door open warning light can be

removed from the edge of the door by prisingthe lens from the inside edge (see

illustration).

9Renew the bulb and press the lens home.

10The kerb illumination light is renewed in a

similar way. Prise out the lens using the slot

provided, renew the bulb and refit the lens

(seeillustration).

6Interior lights - bulb renewal

5Headlight beam alignment

Body electrical system 13•7

13

5.5 Headlight beam adjustment screws

(arrowed)

6.2 Courtesy light bulb renewal

Prise at points arrowed

6.8 “Door open” light bulb renewal6.5 Mirror light bulb renewal

Prise frame at point arrowed

5.4 Headlight beam alignment

chart

A Distance between headlamp

centres

B Light-dark boundary

C Beam centre dipped

D Dipped beam pattern

H Height from ground to centre of

headlamps

X = 120 mm (4.7 in)

6.10 Kerb illumination light bulb renewal

procarmanuals.com

Page 194 of 255

Estate

7Note that when removing the rear window

wiper arm, it will be necessary to detach the

washer hose from the spindle prior to

removing the wiper arm retaining nut (see

illustration).

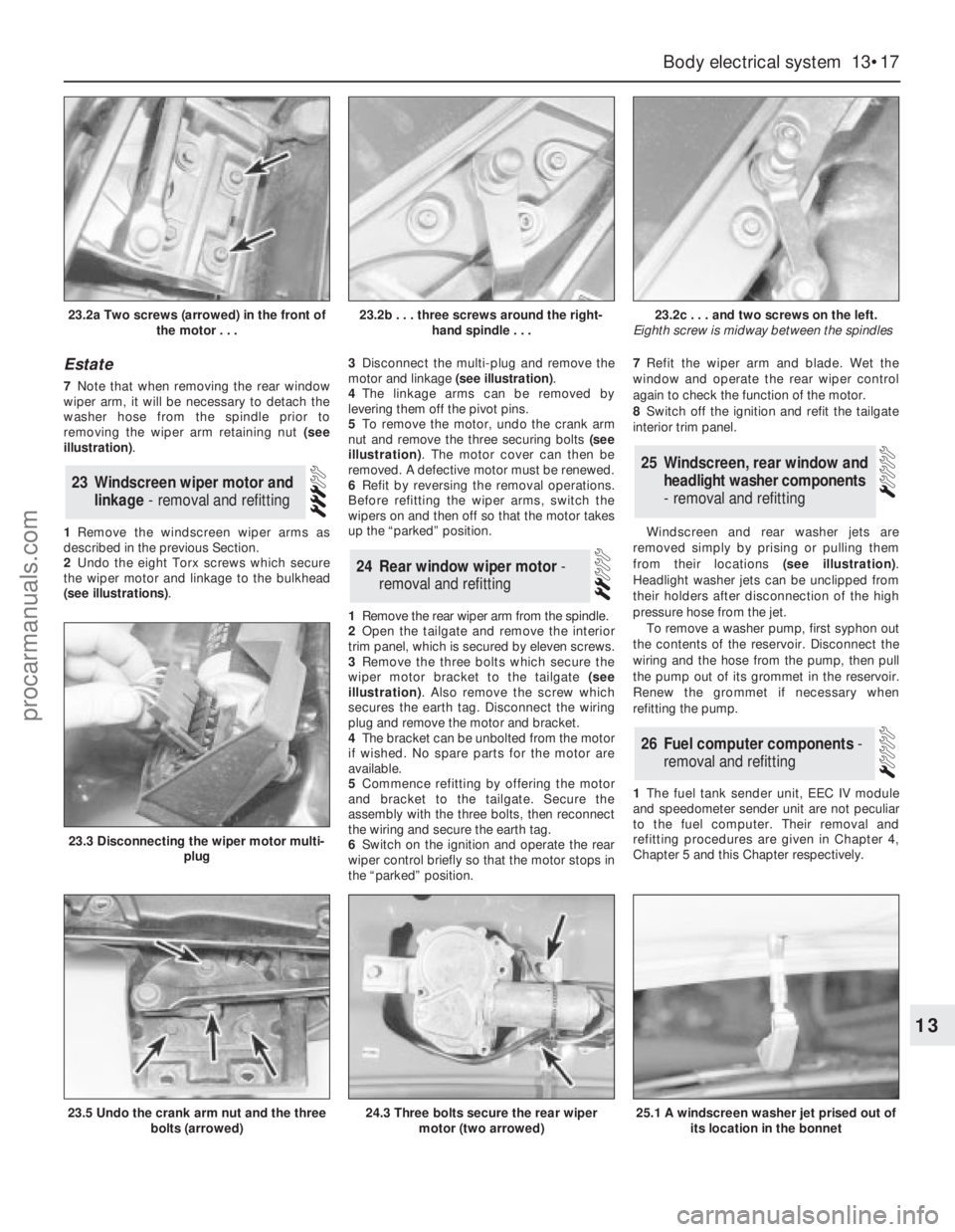

1Remove the windscreen wiper arms as

described in the previous Section.

2Undo the eight Torx screws which secure

the wiper motor and linkage to the bulkhead

(see illustrations).3Disconnect the multi-plug and remove the

motor and linkage (see illustration).

4The linkage arms can be removed by

levering them off the pivot pins.

5To remove the motor, undo the crank arm

nut and remove the three securing bolts (see

illustration). The motor cover can then be

removed. A defective motor must be renewed.

6Refit by reversing the removal operations.

Before refitting the wiper arms, switch the

wipers on and then off so that the motor takes

up the “parked” position.

1Remove the rear wiper arm from the spindle.

2Open the tailgate and remove the interior

trim panel, which is secured by eleven screws.

3Remove the three bolts which secure the

wiper motor bracket to the tailgate (see

illustration). Also remove the screw which

secures the earth tag. Disconnect the wiring

plug and remove the motor and bracket.

4The bracket can be unbolted from the motor

if wished. No spare parts for the motor are

available.

5Commence refitting by offering the motor

and bracket to the tailgate. Secure the

assembly with the three bolts, then reconnect

the wiring and secure the earth tag.

6Switch on the ignition and operate the rear

wiper control briefly so that the motor stops in

the “parked” position.7Refit the wiper arm and blade. Wet the

window and operate the rear wiper control

again to check the function of the motor.

8Switch off the ignition and refit the tailgate

interior trim panel.

Windscreen and rear washer jets are

removed simply by prising or pulling them

from their locations (see illustration).

Headlight washer jets can be unclipped from

their holders after disconnection of the high

pressure hose from the jet.

To remove a washer pump, first syphon out

the contents of the reservoir. Disconnect the

wiring and the hose from the pump, then pull

the pump out of its grommet in the reservoir.

Renew the grommet if necessary when

refitting the pump.

1The fuel tank sender unit, EEC IV module

and speedometer sender unit are not peculiar

to the fuel computer. Their removal and

refitting procedures are given in Chapter 4,

Chapter 5 and this Chapter respectively.

26Fuel computer components -

removal and refitting

25Windscreen, rear window and

headlight washer components

- removal and refitting

24Rear window wiper motor -

removal and refitting

23Windscreen wiper motor and

linkage - removal and refitting

Body electrical system 13•17

13

23.2a Two screws (arrowed) in the front of

the motor . . .23.2b . . . three screws around the right-

hand spindle . . .23.2c . . . and two screws on the left.

Eighth screw is midway between the spindles

23.5 Undo the crank arm nut and the three

bolts (arrowed)

23.3 Disconnecting the wiper motor multi-

plug

24.3 Three bolts secure the rear wiper

motor (two arrowed)25.1 A windscreen washer jet prised out of

its location in the bonnet

procarmanuals.com

Page 241 of 255

REF•6

Engine fails to rotate when attempting to start

m mBattery terminal connections loose or corroded (Chapter 1).

m mBattery discharged or faulty (Chapter 5).

m mBroken, loose or disconnected wiring in the starting circuit

(Chapter 5).

m mDefective starter solenoid or switch (Chapter 5).

m mDefective starter motor (Chapter 5).

m mStarter pinion or flywheel/driveplate ring gear teeth loose or broken

(Chapters 2 or 5).

m mEngine earth strap broken or disconnected.

Starter motor turns engine slowly

m

mPartially-discharged battery (recharge, use jump leads, or push

start) (Chapter 5).

m mBattery terminals loose or corroded (Chapter 1).

m mBattery earth to body defective (Chapter 5).

m mEngine earth strap loose.

m mStarter motor (or solenoid) wiring loose (Chapter 5).

m mStarter motor internal fault (Chapter 5).

Engine rotates, but will not start

m

mFuel pump inertia switch tripped (electric pump) (Chapter 4).

m mFuel tank empty.

m mBattery discharged (engine rotates slowly) (Chapter 5).

m mBattery terminal connections loose or corroded (Chapter 1).

m mIgnition components damp or damaged (Chapters 1 and 5).

m mBroken, loose or disconnected wiring in the ignition circuit

(Chapters 1 and 5).

m mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m mFuel injection system fault (Chapter 4).

m mMajor mechanical failure (eg broken timing chain) (Chapter 2).

Engine difficult to start when cold

m

mBattery discharged (Chapter 5).

m mBattery terminal connections loose or corroded (Chapter 1).

m mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m mFuel injection system fault (Chapter 4).

m mOther ignition system fault (Chapters 1 and 5).

m mLow cylinder compressions (Chapter 2).

Engine difficult to start when hot

m

mAir filter element dirty or clogged (Chapter 1).

m mFuel injection system fault (Chapter 4).

m mLow cylinder compressions (Chapter 2).

Starter motor noisy or excessively-rough in

engagement

m mStarter pinion or flywheel/driveplate ring gear teeth loose or broken

(Chapters 2 or 5).

m mStarter motor mounting bolts loose or missing (Chapter 5).

m mStarter motor internal components worn or damaged (Chapter 5).

Engine starts, but stops immediately

m

mLoose or faulty electrical connections in the ignition circuit

(Chapters 1 and 5).

m mVacuum leak at the throttle body or inlet manifold (Chapter 4).

m mFuel injection system fault (Chapter 4).

Engine idles erratically

m

mCarburettor stepper motor plunger dirty (2.0 litre only) (Chapter 5)

m mIncorrectly-adjusted idle speed (Chapter 4).

m mAir filter element clogged (Chapter 1).

m mVacuum leak at the throttle body, inlet manifold or associated hoses

(Chapter 4).

m mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m mUneven or low cylinder compressions (Chapter 2).

m mCamshaft lobes worn (Chapter 2).

m mFuel injection system fault (Chapter 4).

Engine misfires at idle speed

m

mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m mFaulty spark plug HT leads (Chapter 5).

m mVacuum leak at the throttle body, inlet manifold or associated hoses

(Chapter 4).

m mFuel injection system fault (Chapter 4).

m mDistributor cap cracked or tracking internally, where applicable

(Chapter 5).

m mUneven or low cylinder compressions (Chapter 2).

m mDisconnected, leaking, or perished crankcase ventilation hoses

(Chapter 4).

Fault Finding

spark plugs may only be pointers to some underlying fault.

The pages which follow provide an easy-reference guide to the more

common problems which may occur during the operation of the

vehicle. These problems and their possible causes are grouped under

headings denoting various components or systems, such as Engine,

Cooling system, etc. The Chapter and/or Section which deals with the

problem is also shown in brackets. Whatever the fault, certain basic

principles apply. These are as follows:

Verify the fault. This is simply a matter of being sure that you know

what the symptoms are before starting work. This is particularly

important if you are investigating a fault for someone else, who may

not have described it very accurately.

Don’t overlook the obvious. For example, if the vehicle won’t start, is

there fuel in the tank? (Don’t take anyone else’s word on this particular

point, and don’t trust the fuel gauge either!) If an electrical fault isindicated, look for loose or broken wires before digging out the test

gear.

Cure the disease, not the symptom. Substituting a flat battery with a

fully-charged one will get you off the hard shoulder, but if the

underlying cause is not attended to, the new battery will go the same

way. Similarly, changing oil-fouled spark plugs for a new set will get

you moving again, but remember that the reason for the fouling (if it

wasn’t simply an incorrect grade of plug) will have to be established

and corrected.

Don’t take anything for granted. Particularly, don’t forget that a

“new” component may itself be defective (especially if it’s been rattling

around in the boot for months), and don’t leave components out of a

fault diagnosis sequence just because they are new or recently-fitted.

When you do finally diagnose a difficult fault, you’ll probably realise

that all the evidence was there from the start.

1 Engine

procarmanuals.com

Page 249 of 255

REF•14Glossary of Technical Terms

GGapThe distance the spark must travel in

jumping from the centre electrode to the side

electrode in a spark plug. Also refers to the

spacing between the points in a contact

breaker assembly in a conventional points-

type ignition, or to the distance between the

reluctor or rotor and the pickup coil in an

electronic ignition.

GasketAny thin, soft material - usually cork,

cardboard, asbestos or soft metal - installed

between two metal surfaces to ensure a good

seal. For instance, the cylinder head gasket

seals the joint between the block and the

cylinder head.

GaugeAn instrument panel display used to

monitor engine conditions. A gauge with a

movable pointer on a dial or a fixed scale is an

analogue gauge. A gauge with a numerical

readout is called a digital gauge.

HHalfshaftA rotating shaft that transmits

power from the final drive unit to a drive

wheel, usually when referring to a live rear

axle.

Harmonic balancerA device designed to

reduce torsion or twisting vibration in the

crankshaft. May be incorporated in the

crankshaft pulley. Also known as a vibration

damper.

HoneAn abrasive tool for correcting small

irregularities or differences in diameter in an

engine cylinder, brake cylinder, etc.

Hydraulic tappetA tappet that utilises

hydraulic pressure from the engine’s

lubrication system to maintain zero clearance

(constant contact with both camshaft and

valve stem). Automatically adjusts to variation

in valve stem length. Hydraulic tappets also

reduce valve noise.

IIgnition timingThe moment at which the

spark plug fires, usually expressed in the

number of crankshaft degrees before the

piston reaches the top of its stroke.

Inlet manifoldA tube or housing with

passages through which flows the air-fuel

mixture (carburettor vehicles and vehicles with

throttle body injection) or air only (port fuel-

injected vehicles) to the port openings in the

cylinder head.

JJump startStarting the engine of a vehicle

with a discharged or weak battery by

attaching jump leads from the weak battery to

a charged or helper battery.

LLoad Sensing Proportioning Valve (LSPV)A

brake hydraulic system control valve that

works like a proportioning valve, but also

takes into consideration the amount of weight

carried by the rear axle.

LocknutA nut used to lock an adjustment

nut, or other threaded component, in place.

For example, a locknut is employed to keep

the adjusting nut on the rocker arm in

position.

LockwasherA form of washer designed to

prevent an attaching nut from working loose.

MMacPherson strutA type of front

suspension system devised by Earle

MacPherson at Ford of England. In its original

form, a simple lateral link with the anti-roll bar

creates the lower control arm. A long strut - an

integral coil spring and shock absorber - is

mounted between the body and the steering

knuckle. Many modern so-called MacPherson

strut systems use a conventional lower A-arm

and don’t rely on the anti-roll bar for location.

MultimeterAn electrical test instrument with

the capability to measure voltage, current and

resistance.

NNOxOxides of Nitrogen. A common toxic

pollutant emitted by petrol and diesel engines

at higher temperatures.

OOhmThe unit of electrical resistance. One

volt applied to a resistance of one ohm will

produce a current of one amp.

OhmmeterAn instrument for measuring

electrical resistance.

O-ringA type of sealing ring made of a

special rubber-like material; in use, the O-ring

is compressed into a groove to provide the

sealing action.

Overhead cam (ohc) engineAn engine with

the camshaft(s) located on top of the cylinder

head(s).Overhead valve (ohv) engineAn engine with

the valves located in the cylinder head, but

with the camshaft located in the engine block.

Oxygen sensorA device installed in the

engine exhaust manifold, which senses the

oxygen content in the exhaust and converts

this information into an electric current. Also

called a Lambda sensor.

PPhillips screwA type of screw head having a

cross instead of a slot for a corresponding

type of screwdriver.

PlastigageA thin strip of plastic thread,

available in different sizes, used for measuring

clearances. For example, a strip of Plastigage

is laid across a bearing journal. The parts are

assembled and dismantled; the width of the

crushed strip indicates the clearance between

journal and bearing.

Propeller shaftThe long hollow tube with

universal joints at both ends that carries

power from the transmission to the differential

on front-engined rear wheel drive vehicles.

Proportioning valveA hydraulic control

valve which limits the amount of pressure to

the rear brakes during panic stops to prevent

wheel lock-up.

RRack-and-pinion steeringA steering system

with a pinion gear on the end of the steering

shaft that mates with a rack (think of a geared

wheel opened up and laid flat). When the

steering wheel is turned, the pinion turns,

moving the rack to the left or right. This

movement is transmitted through the track

rods to the steering arms at the wheels.

RadiatorA liquid-to-air heat transfer device

designed to reduce the temperature of the

coolant in an internal combustion engine

cooling system.

RefrigerantAny substance used as a heat

transfer agent in an air-conditioning system.

R-12 has been the principle refrigerant for

many years; recently, however, manufacturers

have begun using R-134a, a non-CFC

substance that is considered less harmful to

the ozone in the upper atmosphere.

Rocker armA lever arm that rocks on a shaft

or pivots on a stud. In an overhead valve

engine, the rocker arm converts the upward

movement of the pushrod into a downward

movement to open a valve.

Adjusting spark plug gap

Plastigage

Gasket

procarmanuals.com

Page 254 of 255

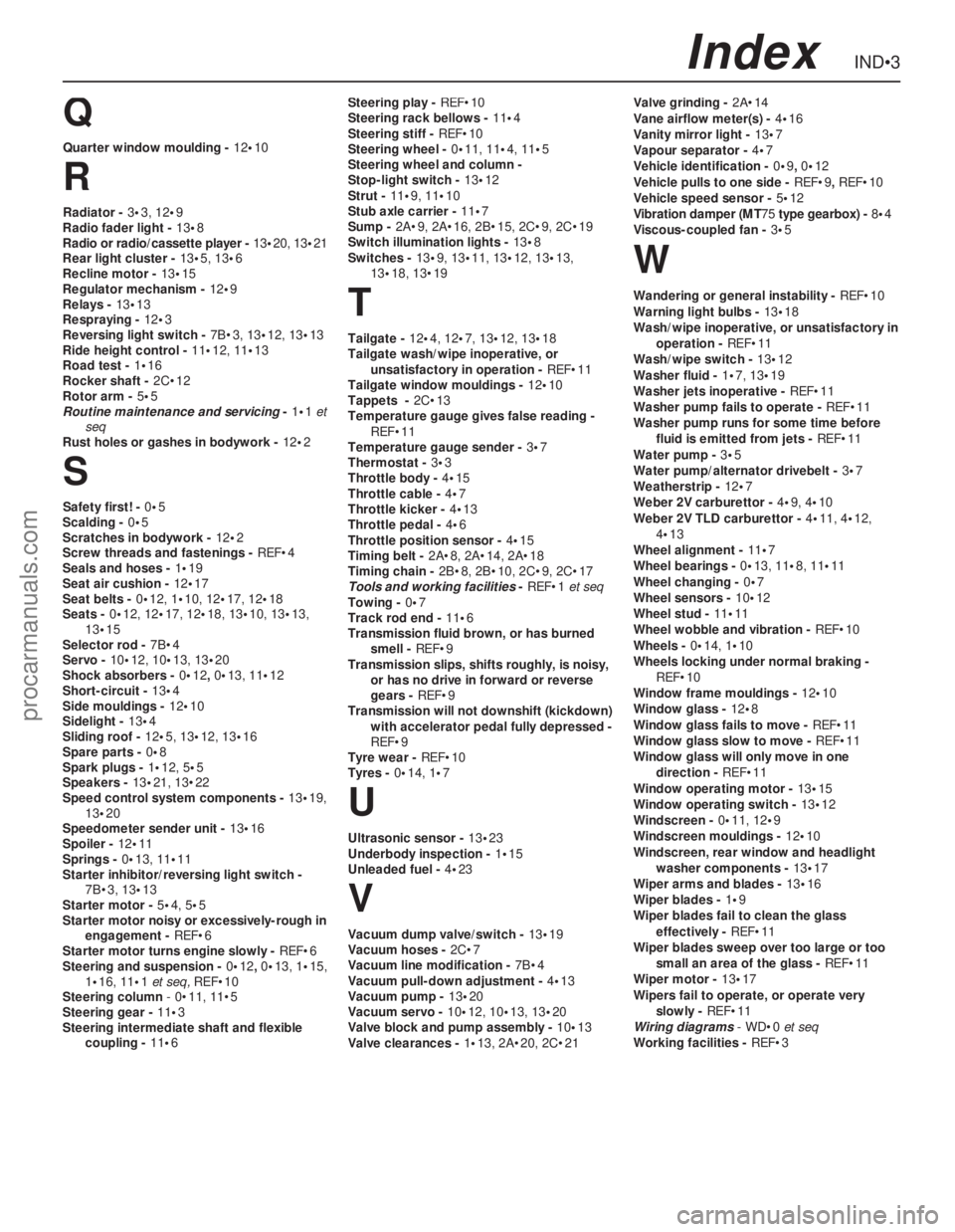

Q

Quarter window moulding - 12•10

R

Radiator - 3•3, 12•9

Radio fader light - 13•8

Radio or radio/cassette player - 13•20, 13•21

Rear light cluster - 13•5, 13•6

Recline motor - 13•15

Regulator mechanism - 12•9

Relays - 13•13

Respraying - 12•3

Reversing light switch - 7B•3, 13•12, 13•13

Ride height control - 11•12, 11•13

Road test - 1•16

Rocker shaft - 2C•12

Rotor arm - 5•5

Routine maintenance and servicing- 1•1et

seq

Rust holes or gashes in bodywork - 12•2

S

Safety first! - 0•5

Scalding - 0•5

Scratches in bodywork - 12•2

Screw threads and fastenings - REF•4

Seals and hoses - 1•19

Seat air cushion - 12•17

Seat belts - 0•12, 1•10, 12•17, 12•18

Seats - 0•12, 12•17, 12•18, 13•10, 13•13,

13•15

Selector rod - 7B•4

Servo - 10•12, 10•13, 13•20

Shock absorbers - 0•12, 0•13, 11•12

Short-circuit - 13•4

Side mouldings - 12•10

Sidelight - 13•4

Sliding roof - 12•5, 13•12, 13•16

Spare parts - 0•8

Spark plugs - 1•12, 5•5

Speakers - 13•21, 13•22

Speed control system components - 13•19,

13•20

Speedometer sender unit - 13•16

Spoiler - 12•11

Springs - 0•13, 11•11

Starter inhibitor/reversing light switch -

7B•3, 13•13

Starter motor - 5•4, 5•5

Starter motor noisy or excessively-rough in

engagement - REF•6

Starter motor turns engine slowly - REF•6

Steering and suspension - 0•12, 0•13, 1•15,

1•16, 11•1et seq,REF•10

Steering column- 0•11, 11•5

Steering gear - 11•3

Steering intermediate shaft and flexible

coupling - 11•6Steering play - REF•10

Steering rack bellows - 11•4

Steering stiff - REF•10

Steering wheel - 0•11, 11•4, 11•5

Steering wheel and column -

Stop-light switch - 13•12

Strut - 11•9, 11•10

Stub axle carrier - 11•7

Sump - 2A•9, 2A•16, 2B•15, 2C•9, 2C•19

Switch illumination lights - 13•8

Switches - 13•9, 13•11, 13•12, 13•13,

13•18, 13•19

T

Tailgate - 12•4, 12•7, 13•12, 13•18

Tailgate wash/wipe inoperative, or

unsatisfactory in operation - REF•11

Tailgate window mouldings - 12•10

Tappets - 2C•13

Temperature gauge gives false reading -

REF•11

Temperature gauge sender - 3•7

Thermostat - 3•3

Throttle body - 4•15

Throttle cable - 4•7

Throttle kicker - 4•13

Throttle pedal - 4•6

Throttle position sensor - 4•15

Timing belt - 2A•8, 2A•14, 2A•18

Timing chain - 2B•8, 2B•10, 2C•9, 2C•17

Tools and working facilities- REF•1et seq

Towing - 0•7

Track rod end - 11•6

Transmission fluid brown, or has burned

smell - REF•9

Transmission slips, shifts roughly, is noisy,

or has no drive in forward or reverse

gears - REF•9

Transmission will not downshift (kickdown)

with accelerator pedal fully depressed -

REF•9

Tyre wear - REF•10

Tyres - 0•14, 1•7

U

Ultrasonic sensor - 13•23

Underbody inspection - 1•15

Unleaded fuel - 4•23

V

Vacuum dump valve/switch - 13•19

Vacuum hoses - 2C•7

Vacuum line modification - 7B•4

Vacuum pull-down adjustment - 4•13

Vacuum pump - 13•20

Vacuum servo - 10•12, 10•13, 13•20

Valve block and pump assembly - 10•13

Valve clearances - 1•13, 2A•20, 2C•21Valve grinding - 2A•14

Vane airflow meter(s) - 4•16

Vanity mirror light - 13•7

Vapour separator - 4•7

Vehicle identification - 0•9, 0•12

Vehicle pulls to one side - REF•9, REF•10

Vehicle speed sensor - 5•12

Vibration damper (MT75type gearbox) - 8•4

Viscous-coupled fan - 3•5

W

Wandering or general instability - REF•10

Warning light bulbs - 13•18

Wash/wipe inoperative, or unsatisfactory in

operation - REF•11

Wash/wipe switch - 13•12

Washer fluid - 1•7, 13•19

Washer jets inoperative - REF•11

Washer pump fails to operate - REF•11

Washer pump runs for some time before

fluid is emitted from jets - REF•11

Water pump - 3•5

Water pump/alternator drivebelt - 3•7

Weatherstrip - 12•7

Weber 2V carburettor - 4•9, 4•10

Weber 2V TLD carburettor - 4•11, 4•12,

4•13

Wheel alignment - 11•7

Wheel bearings - 0•13, 11•8, 11•11

Wheel changing - 0•7

Wheel sensors - 10•12

Wheel stud - 11•11

Wheel wobble and vibration - REF•10

Wheels - 0•14, 1•10

Wheels locking under normal braking -

REF•10

Window frame mouldings - 12•10

Window glass - 12•8

Window glass fails to move - REF•11

Window glass slow to move - REF•11

Window glass will only move in one

direction - REF•11

Window operating motor - 13•15

Window operating switch - 13•12

Windscreen - 0•11, 12•9

Windscreen mouldings - 12•10

Windscreen, rear window and headlight

washer components - 13•17

Wiper arms and blades - 13•16

Wiper blades - 1•9

Wiper blades fail to clean the glass

effectively - REF•11

Wiper blades sweep over too large or too

small an area of the glass - REF•11

Wiper motor - 13•17

Wipers fail to operate, or operate very

slowly - REF•11

Wiring diagrams- WD•0 et seq

Working facilities - REF•3

IND•3Index

procarmanuals.com