bonnet FORD GRANADA 1985 Service Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 171 of 255

12•14Bodywork and fittings

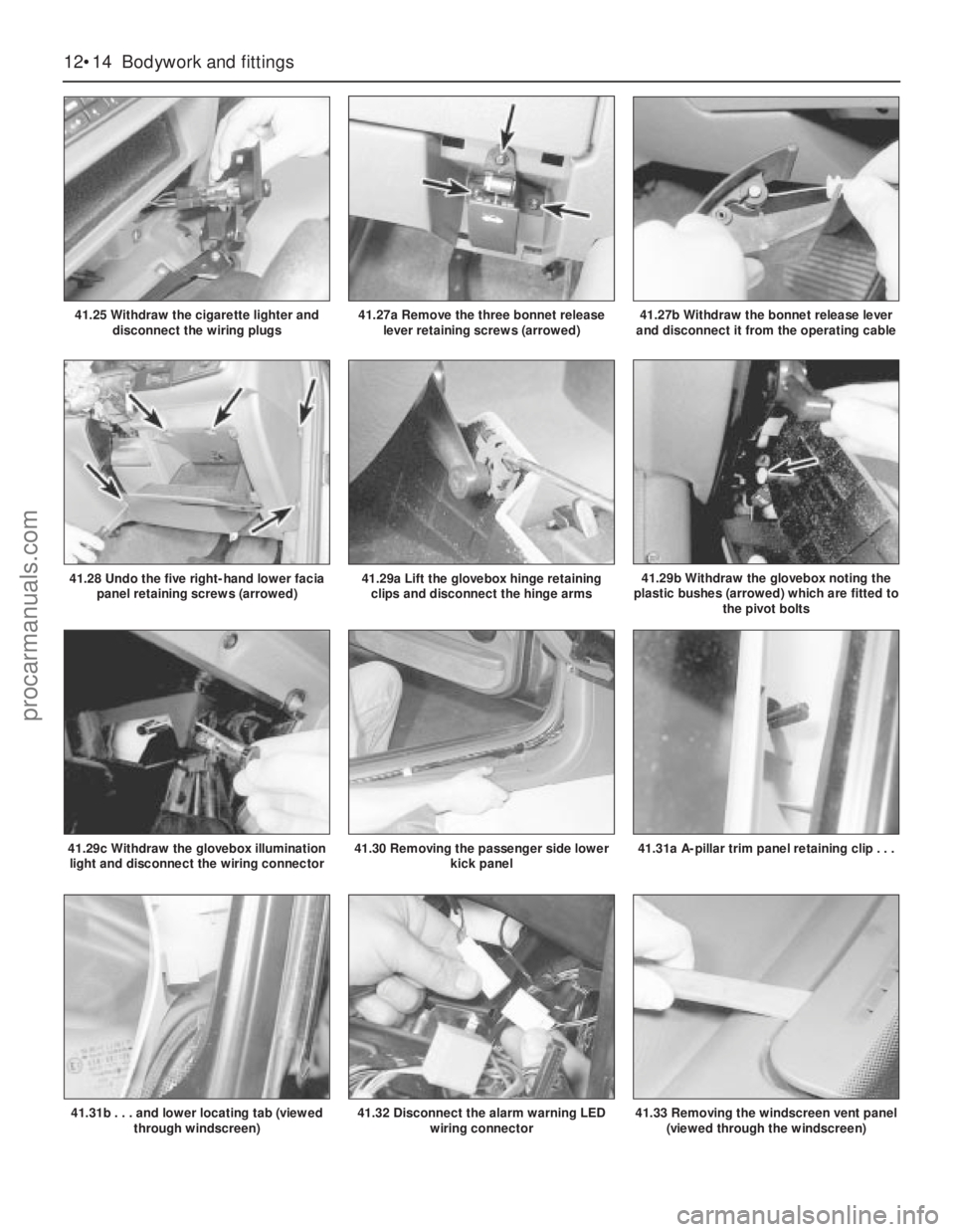

41.25 Withdraw the cigarette lighter and

disconnect the wiring plugs

41.30 Removing the passenger side lower

kick panel

41.29a Lift the glovebox hinge retaining

clips and disconnect the hinge arms41.29b Withdraw the glovebox noting the

plastic bushes (arrowed) which are fitted to

the pivot bolts

41.29c Withdraw the glovebox illumination

light and disconnect the wiring connector

41.28 Undo the five right-hand lower facia

panel retaining screws (arrowed)

41.31a A-pillar trim panel retaining clip . . .

41.31b . . . and lower locating tab (viewed

through windscreen)

41.27a Remove the three bonnet release

lever retaining screws (arrowed)41.27b Withdraw the bonnet release lever

and disconnect it from the operating cable

41.32 Disconnect the alarm warning LED

wiring connector41.33 Removing the windscreen vent panel

(viewed through the windscreen)

procarmanuals.com

Page 181 of 255

the circuit between the relevant connector and

the battery is problem-free.

13Continue to check the remainder of the

circuit in the same fashion.

14When a point is reached at which no

voltage is present, the problem must lie

between that point and the previous test point

with voltage. Most problems can be traced to

a broken, corroded or loose connection.

Finding a short-circuit

15To check for a short-circuit, first disconnect

the load(s) from the circuit (loads are the

components which draw current from a circuit,

such as bulbs, motors, heating elements, etc).

16Remove the relevant fuse from the circuit,

and connect a circuit tester or voltmeter to the

fuse connections.

17Switch on the circuit, bearing in mind that

some circuits are live only when the ignition

switch is moved to a particular position.

18If voltage is present (indicated either by

the tester bulb lighting or a voltmeter reading),

this means that there is a short-circuit.

19If no voltage is present, but the fuse still

blows with the load(s) connected, this

indicates an internal fault in the load(s).

Finding an earth fault

20The battery negative terminal is connected

to “earth” - the metal of the engine/transmission

and the car body - and most systems are wired

so that they only receive a positive feed, the

current returning via the metal of the car body.

This means that the component mounting andthe body form part of that circuit. Loose or

corroded mountings can therefore cause a range

of electrical faults, ranging from total failure of a

circuit, to a puzzling partial fault. In particular,

lights may shine dimly (especially when another

circuit sharing the same earth is in operation),

motors (eg wiper motors or the radiator cooling

fan motor) may run slowly, and the operation of

one circuit may have an apparently-unrelated

effect on another. Note that on many vehicles,

earth straps are used between certain

components, such as the engine/transmission

and the body, usually where there is no metal-to-

metal contact between components, due to

flexible rubber mountings, etc.

21To check whether a component is properly

earthed, disconnect the battery, and connect

one lead of an ohmmeter to a known good

earth point. Connect the other lead to the wire

or earth connection being tested. The

resistance reading should be zero; if not,

check the connection as follows.

22If an earth connection is thought to be

faulty, dismantle the connection, and clean

back to bare metal both the bodyshell and the

wire terminal, or the component’s earth

connection mating surface. Be careful to

remove all traces of dirt and corrosion, then

use a knife to trim away any paint, so that a

clean metal-to-metal joint is made. On

reassembly, tighten the joint fasteners

securely; if a wire terminal is being refitted, use

serrated washers between the terminal and

the bodyshell, to ensure a clean and secure

connection. When the connection is remade,

prevent the onset of corrosion in the future byapplying a coat of petroleum jelly or silicone-

based grease, or by spraying on (at regular

intervals) a proprietary ignition sealer, or a

water-dispersant lubricant.

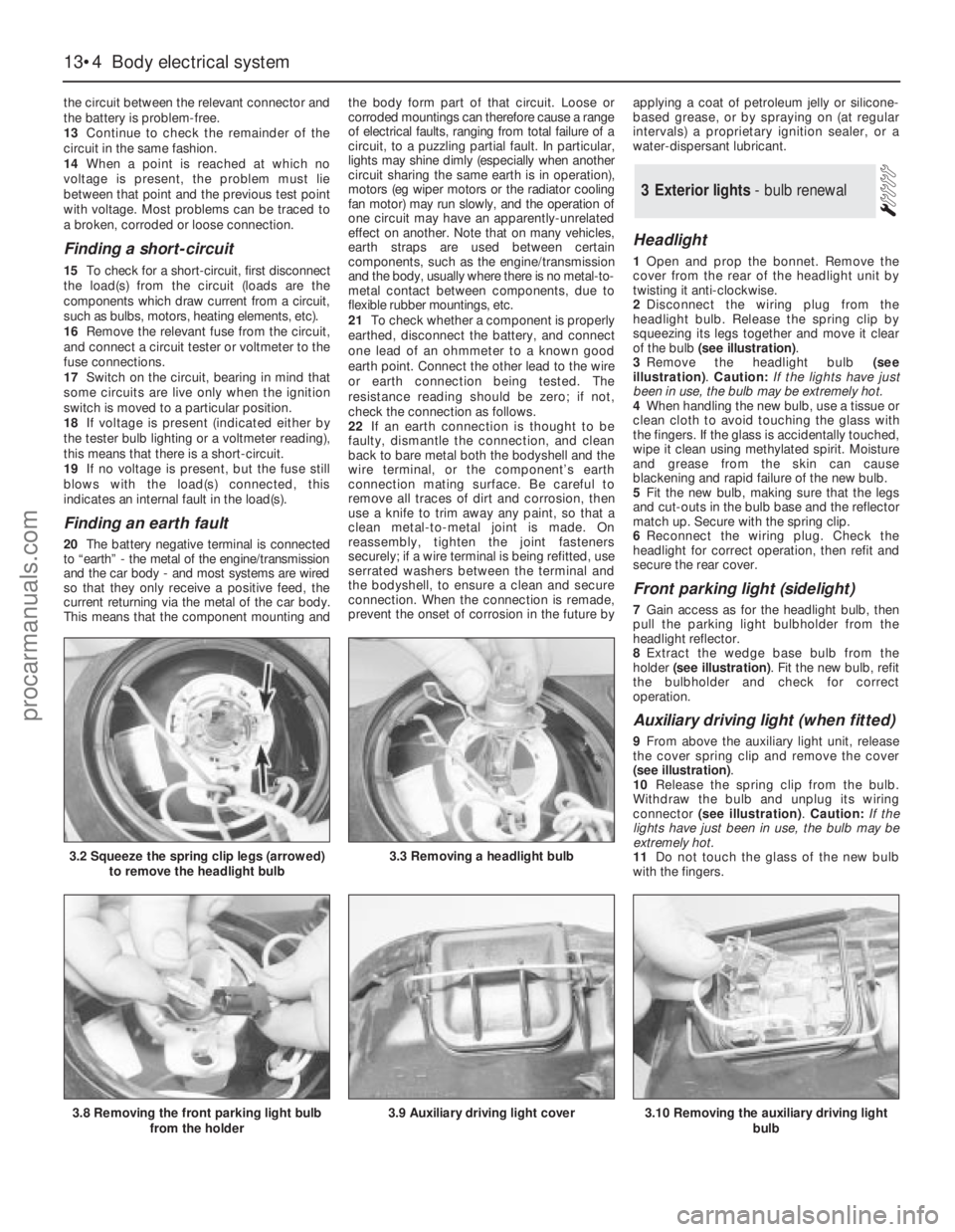

Headlight

1Open and prop the bonnet. Remove the

cover from the rear of the headlight unit by

twisting it anti-clockwise.

2Disconnect the wiring plug from the

headlight bulb. Release the spring clip by

squeezing its legs together and move it clear

of the bulb (see illustration).

3Remove the headlight bulb (see

illustration). Caution: If the lights have just

been in use, the bulb may be extremely hot.

4When handling the new bulb, use a tissue or

clean cloth to avoid touching the glass with

the fingers. If the glass is accidentally touched,

wipe it clean using methylated spirit. Moisture

and grease from the skin can cause

blackening and rapid failure of the new bulb.

5Fit the new bulb, making sure that the legs

and cut-outs in the bulb base and the reflector

match up. Secure with the spring clip.

6Reconnect the wiring plug. Check the

headlight for correct operation, then refit and

secure the rear cover.

Front parking light (sidelight)

7Gain access as for the headlight bulb, then

pull the parking light bulbholder from the

headlight reflector.

8Extract the wedge base bulb from the

holder (see illustration). Fit the new bulb, refit

the bulbholder and check for correct

operation.

Auxiliary driving light (when fitted)

9From above the auxiliary light unit, release

the cover spring clip and remove the cover

(see illustration).

10Release the spring clip from the bulb.

Withdraw the bulb and unplug its wiring

connector (see illustration). Caution: If the

lights have just been in use, the bulb may be

extremely hot.

11Do not touch the glass of the new bulb

with the fingers.

3Exterior lights - bulb renewal

13•4Body electrical system

3.2 Squeeze the spring clip legs (arrowed)

to remove the headlight bulb3.3 Removing a headlight bulb

3.8 Removing the front parking light bulb

from the holder3.9 Auxiliary driving light cover3.10 Removing the auxiliary driving light

bulb

procarmanuals.com

Page 182 of 255

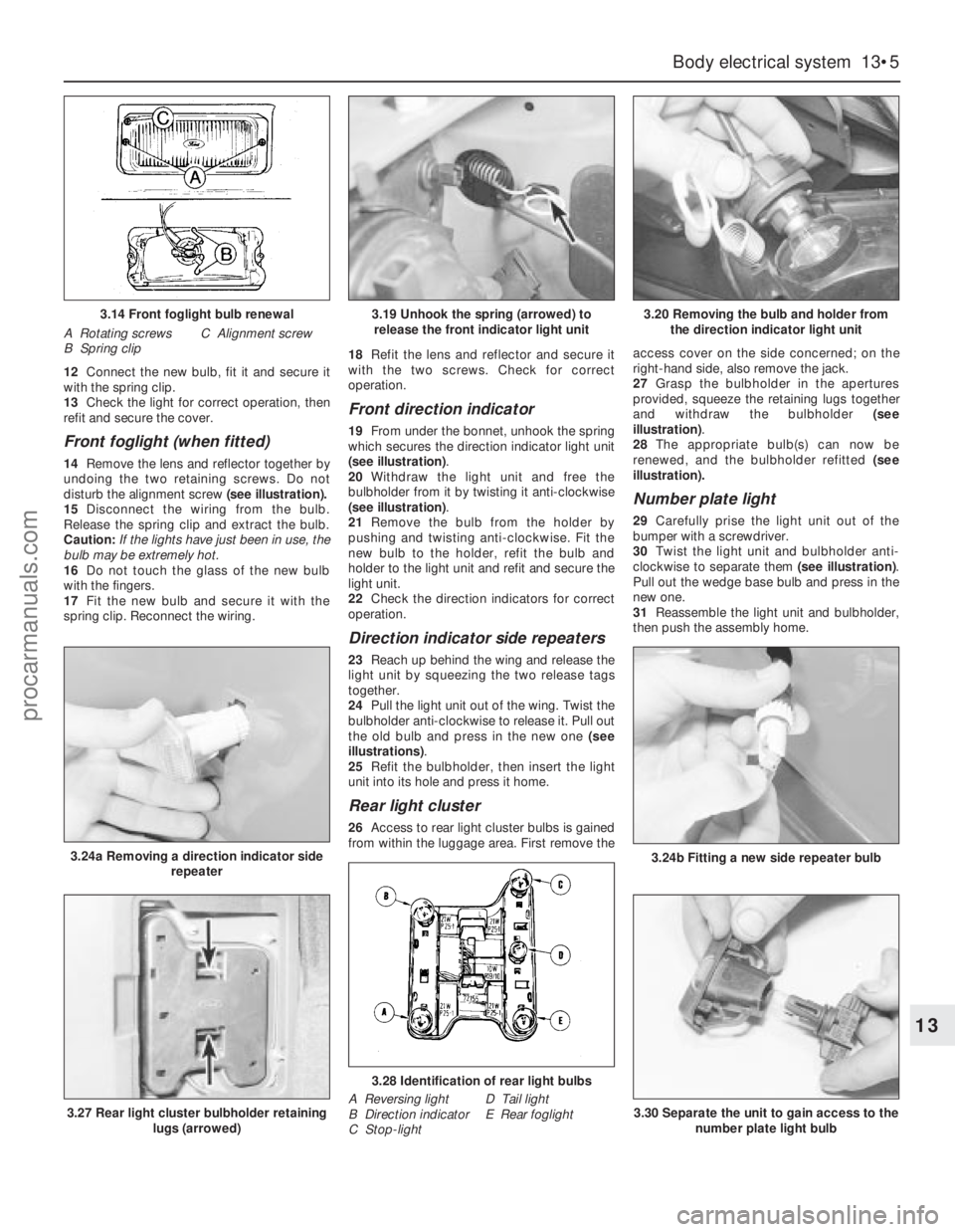

12Connect the new bulb, fit it and secure it

with the spring clip.

13Check the light for correct operation, then

refit and secure the cover.

Front foglight (when fitted)

14Remove the lens and reflector together by

undoing the two retaining screws. Do not

disturb the alignment screw (see illustration).

15Disconnect the wiring from the bulb.

Release the spring clip and extract the bulb.

Caution: If the lights have just been in use, the

bulb may be extremely hot.

16Do not touch the glass of the new bulb

with the fingers.

17Fit the new bulb and secure it with the

spring clip. Reconnect the wiring.18Refit the lens and reflector and secure it

with the two screws. Check for correct

operation.

Front direction indicator

19From under the bonnet, unhook the spring

which secures the direction indicator light unit

(see illustration).

20Withdraw the light unit and free the

bulbholder from it by twisting it anti-clockwise

(see illustration).

21Remove the bulb from the holder by

pushing and twisting anti-clockwise. Fit the

new bulb to the holder, refit the bulb and

holder to the light unit and refit and secure the

light unit.

22Check the direction indicators for correct

operation.

Direction indicator side repeaters

23Reach up behind the wing and release the

light unit by squeezing the two release tags

together.

24Pull the light unit out of the wing. Twist the

bulbholder anti-clockwise to release it. Pull out

the old bulb and press in the new one (see

illustrations).

25Refit the bulbholder, then insert the light

unit into its hole and press it home.

Rear light cluster

26Access to rear light cluster bulbs is gained

from within the luggage area. First remove theaccess cover on the side concerned; on the

right-hand side, also remove the jack.

27Grasp the bulbholder in the apertures

provided, squeeze the retaining lugs together

and withdraw the bulbholder (see

illustration).

28The appropriate bulb(s) can now be

renewed, and the bulbholder refitted (see

illustration).

Number plate light

29Carefully prise the light unit out of the

bumper with a screwdriver.

30Twist the light unit and bulbholder anti-

clockwise to separate them (see illustration).

Pull out the wedge base bulb and press in the

newone.

31Reassemble the light unit and bulbholder,

then push the assembly home.

Body electrical system 13•5

13

3.14 Front foglight bulb renewal

A Rotating screws

B Spring clipC Alignment screw

3.24a Removing a direction indicator side

repeater

3.19 Unhook the spring (arrowed) to

release the front indicator light unit3.20 Removing the bulb and holder from

the direction indicator light unit

3.24b Fitting a new side repeater bulb

3.27 Rear light cluster bulbholder retaining

lugs (arrowed)

3.28 Identification of rear light bulbs

A Reversing light

B Direction indicator

C Stop-lightD Tail light

E Rear foglight3.30 Separate the unit to gain access to the

number plate light bulb

procarmanuals.com

Page 185 of 255

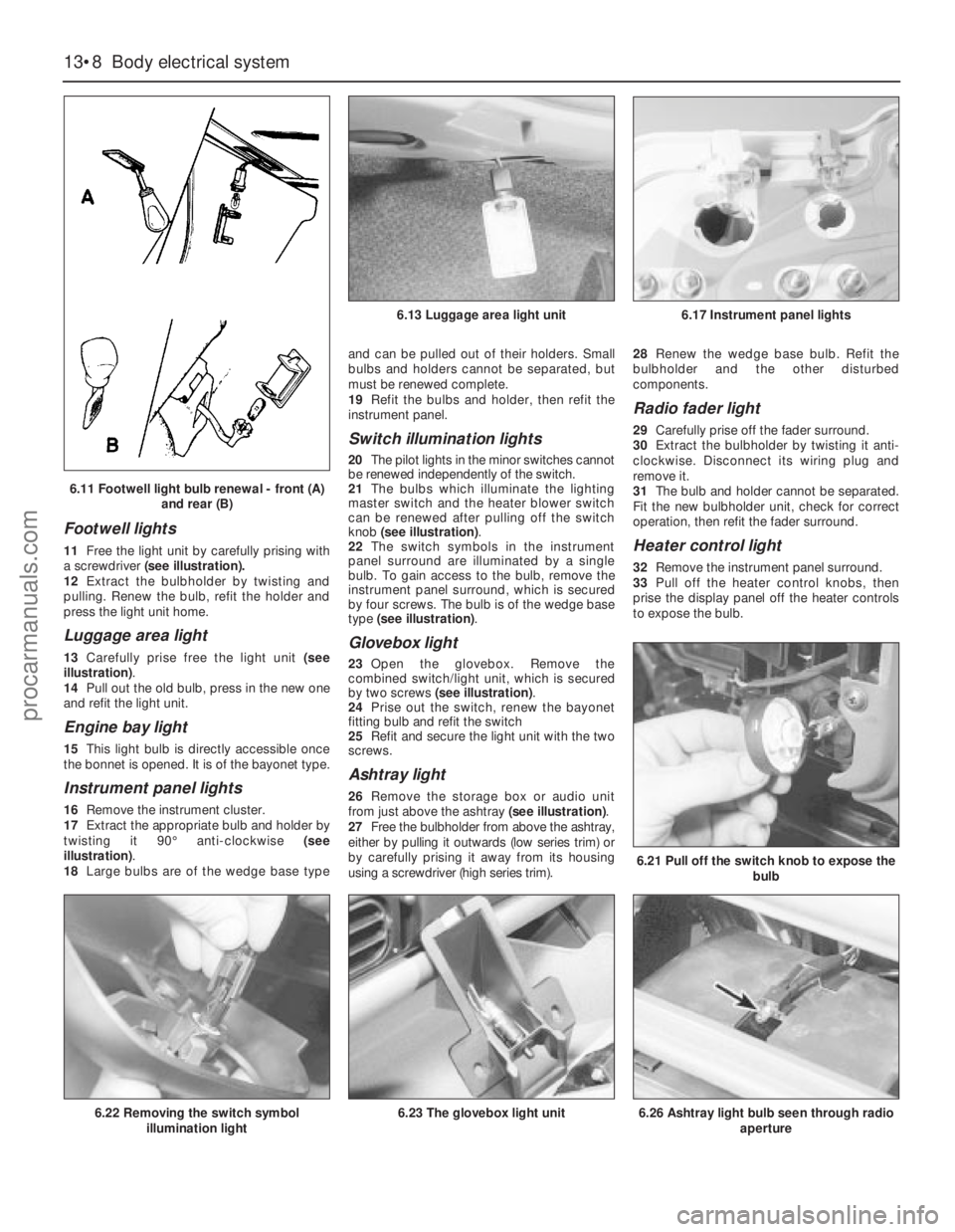

Footwell lights

11Free the light unit by carefully prising with

a screwdriver(see illustration).

12Extract the bulbholder by twisting and

pulling. Renew the bulb, refit the holder and

press the light unit home.

Luggage area light

13Carefully prise free the light unit (see

illustration).

14Pull out the old bulb, press in the new one

and refit the light unit.

Engine bay light

15This light bulb is directly accessible once

the bonnet is opened. It is of the bayonet type.

Instrument panel lights

16Remove the instrument cluster.

17Extract the appropriate bulb and holder by

twisting it 90°anti-clockwise (see

illustration).

18Large bulbs are of the wedge base typeand can be pulled out of their holders. Small

bulbs and holders cannot be separated, but

must be renewed complete.

19Refit the bulbs and holder, then refit the

instrument panel.

Switch illumination lights

20The pilot lights in the minor switches cannot

be renewed independently of the switch.

21The bulbs which illuminate the lighting

master switch and the heater blower switch

can be renewed after pulling off the switch

knob (see illustration).

22The switch symbols in the instrument

panel surround are illuminated by a single

bulb. To gain access to the bulb, remove the

instrument panel surround, which is secured

by four screws. The bulb is of the wedge base

type (see illustration).

Glovebox light

23Open the glovebox. Remove the

combined switch/light unit, which is secured

by two screws (see illustration).

24Prise out the switch, renew the bayonet

fitting bulb and refit the switch

25Refit and secure the light unit with the two

screws.

Ashtray light

26Remove the storage box or audio unit

from just above the ashtray (see illustration).

27Free the bulbholder from above the ashtray,

either by pulling it outwards (low series trim) or

by carefully prising it away from its housing

using a screwdriver (high series trim).28Renew the wedge base bulb. Refit the

bulbholder and the other disturbed

components.

Radio fader light

29Carefully prise off the fader surround.

30Extract the bulbholder by twisting it anti-

clockwise. Disconnect its wiring plug and

remove it.

31The bulb and holder cannot be separated.

Fit the new bulbholder unit, check for correct

operation, then refit the fader surround.

Heater control light

32Remove the instrument panel surround.

33Pull off the heater control knobs, then

prise the display panel off the heater controls

to expose the bulb.

13•8Body electrical system

6.21 Pull off the switch knob to expose the

bulb

6.26 Ashtray light bulb seen through radio

aperture6.22 Removing the switch symbol

illumination light6.23 The glovebox light unit

6.13 Luggage area light unit6.17 Instrument panel lights

6.11 Footwell light bulb renewal - front (A)

and rear (B)

procarmanuals.com

Page 187 of 255

1With the instrument cluster removed, a

particular gauge or other component can be

renewed by following the appropriate parts of

this Section.

2Remove all the light bulbs and holders from

the rear of the panel by twisting them anti-

clockwise.

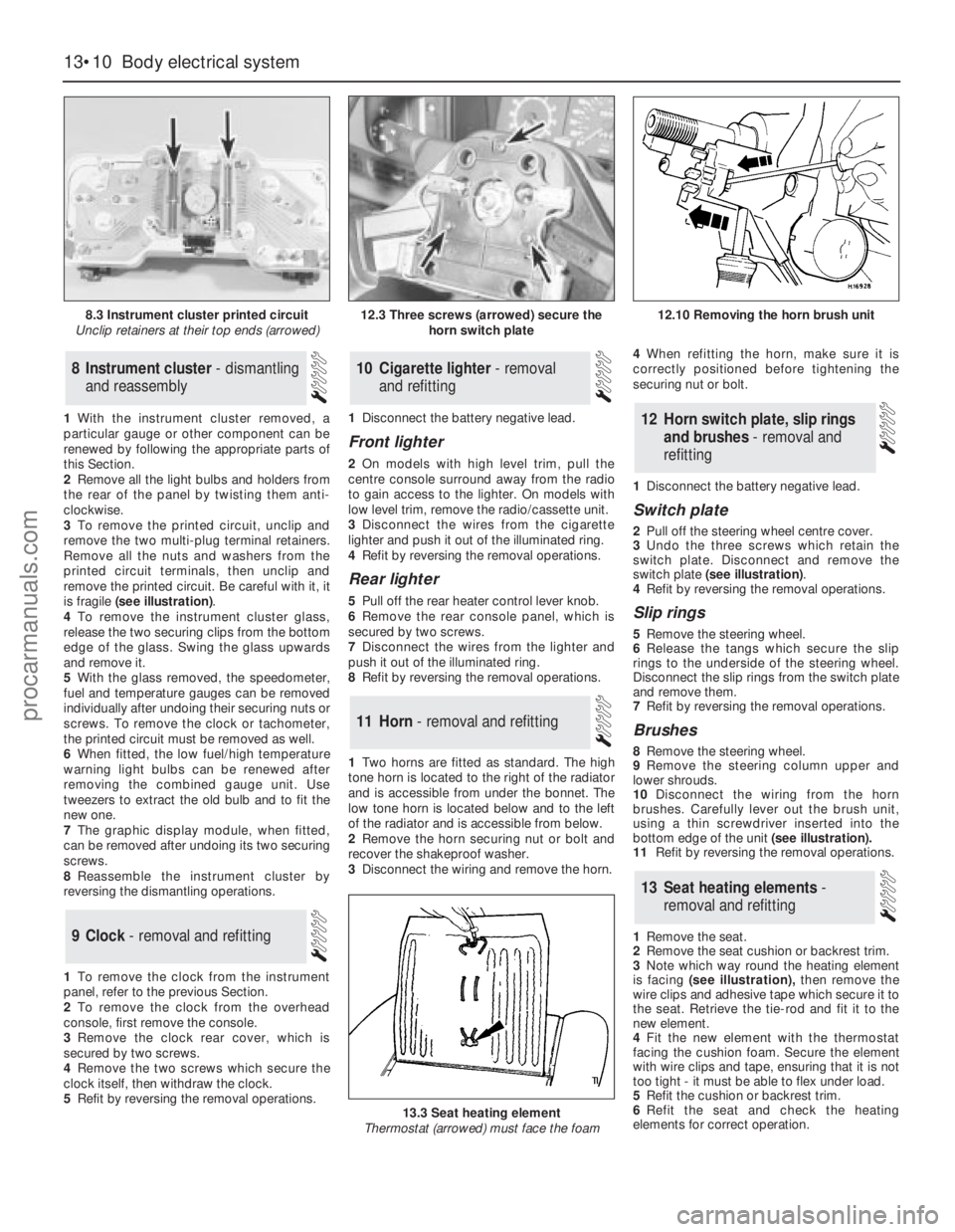

3To remove the printed circuit, unclip and

remove the two multi-plug terminal retainers.

Remove all the nuts and washers from the

printed circuit terminals, then unclip and

remove the printed circuit. Be careful with it, it

is fragile (see illustration).

4To remove the instrument cluster glass,

release the two securing clips from thebottom

edge of the glass. Swing the glass upwards

and remove it.

5With the glass removed, the speedometer,

fuel and temperature gauges can be removed

individually after undoing their securing nuts or

screws. To remove the clock or tachometer,

the printed circuit must be removed as well.

6When fitted, the low fuel/high temperature

warning light bulbs can be renewed after

removing the combined gauge unit. Use

tweezers to extract the old bulb and to fit the

new one.

7The graphic display module, when fitted,

can be removed after undoing its two securing

screws.

8Reassemble the instrument cluster by

reversing the dismantling operations.

1To remove the clock from the instrument

panel, refer to the previous Section.

2To remove the clock from the overhead

console, first remove the console.

3Remove the clock rear cover, which is

secured by two screws.

4Remove the two screws which secure the

clock itself, then withdraw the clock.

5Refit by reversing the removal operations.1Disconnect the battery negative lead.

Front lighter

2On models with high level trim, pull the

centre console surround away from the radio

to gain access to the lighter. On models with

low level trim, remove the radio/cassette unit.

3Disconnect the wires from the cigarette

lighter and push it out of the illuminated ring.

4Refit by reversing the removal operations.

Rear lighter

5Pull off the rear heater control lever knob.

6Remove the rear console panel, which is

secured by two screws.

7Disconnect the wires from the lighter and

push it out of the illuminated ring.

8Refit by reversing the removal operations.

1Two horns are fitted as standard. The high

tone horn is located to the right of the radiator

and is accessible from under the bonnet. The

low tone horn is located below and to the left

of the radiator and is accessible from below.

2Remove the horn securing nut or bolt and

recover the shakeproof washer.

3Disconnect the wiring and remove the horn.4When refitting the horn, make sure it is

correctly positioned before tightening the

securing nut or bolt.

1Disconnect the battery negative lead.

Switch plate

2Pull off the steering wheel centre cover.

3Undo the three screws which retain the

switch plate. Disconnect and remove the

switch plate (see illustration).

4Refit by reversing the removal operations.

Slip rings

5Remove the steering wheel.

6Release the tangs which secure the slip

rings to the underside of the steering wheel.

Disconnect the slip rings from the switch plate

and remove them.

7Refit by reversing the removal operations.

Brushes

8Remove the steering wheel.

9Remove the steering column upper and

lower shrouds.

10Disconnect the wiring from the horn

brushes. Carefully lever out the brush unit,

using a thin screwdriver inserted into the

bottom edge of the unit(see illustration).

11Refit by reversing the removal operations.

1Remove the seat.

2Remove the seat cushion or backrest trim.

3Note which way round the heating element

is facing (see illustration),then remove the

wire clips and adhesive tape which secure it to

the seat. Retrieve the tie-rod and fit it to the

new element.

4Fit the new element with the thermostat

facing the cushion foam. Secure the element

with wire clips and tape, ensuring that it is not

too tight - it must be able to flex under load.

5Refit the cushion or backrest trim.

6Refit the seat and check the heating

elements for correct operation.

13Seat heating elements -

removal and refitting

12Horn switch plate, slip rings

and brushes - removal and

refitting

11Horn - removal and refitting

10Cigarette lighter - removal

and refitting

9Clock - removal and refitting

8Instrument cluster - dismantling

and reassembly

13•10Body electrical system

8.3 Instrument cluster printed circuit

Unclip retainers at their top ends (arrowed)

13.3 Seat heating element

Thermostat (arrowed) must face the foam

12.3 Three screws (arrowed) secure the

horn switch plate12.10 Removing the horn brush unit

procarmanuals.com

Page 190 of 255

Heated rear window switch

Models before April 1992

50Remove the instrument panel surround,

which is secured by four screws.

51Carefully prise the switch from its location,

disconnect the multi-plug and remove it.

Models from April 1992

52Using a small flat-bladed screwdriver,

carefully prise the switch out of the centre

facia vent panel and disconnect the wiring

connector.

53On refitting, reconnect the wiring

connector and push the switch in until it clicks

into position.

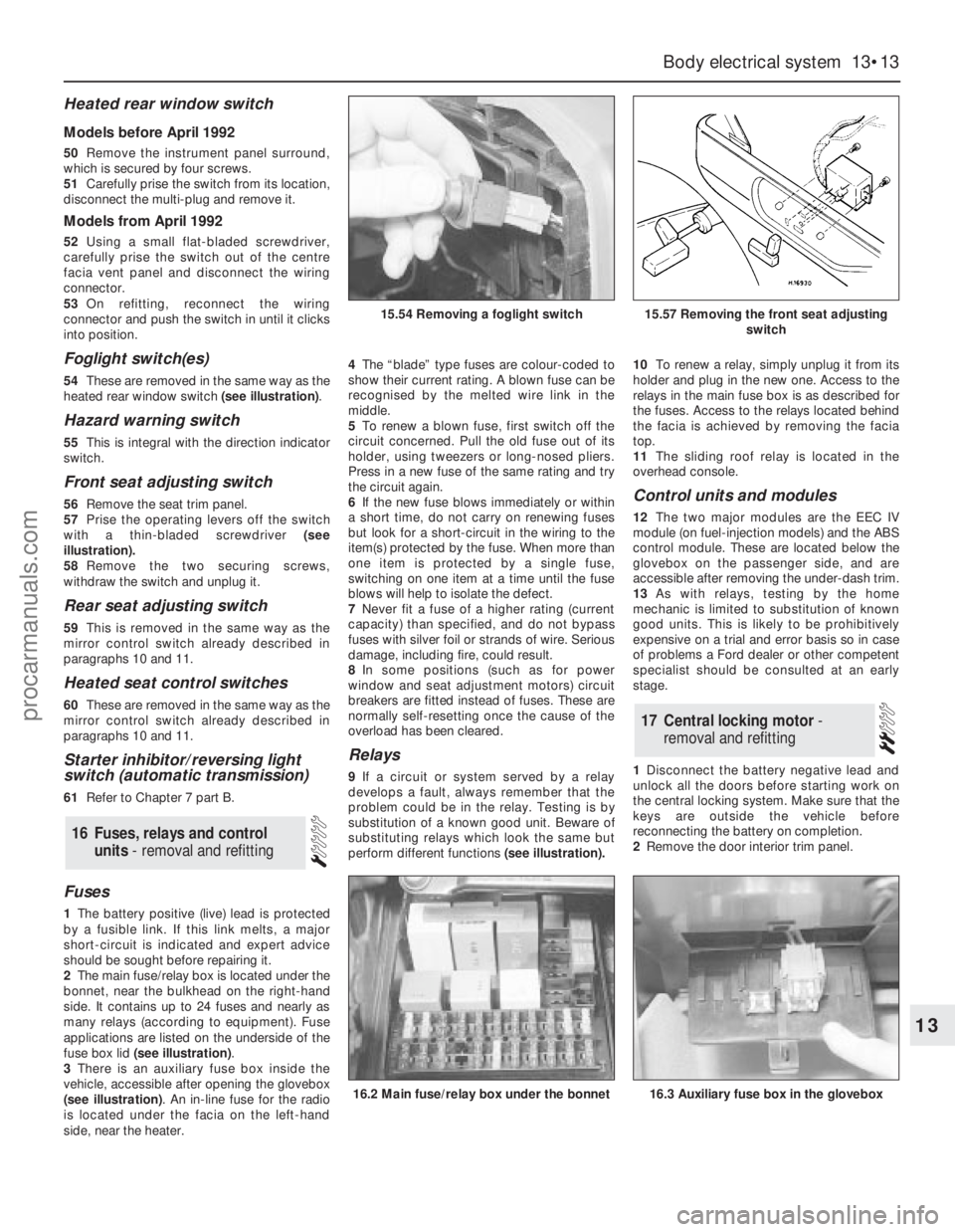

Foglight switch(es)

54These are removed in the same way as the

heated rear window switch (see illustration).

Hazard warning switch

55This is integral with the direction indicator

switch.

Front seat adjusting switch

56Remove the seat trim panel.

57Prise the operating levers off the switch

with a thin-bladed screwdriver (see

illustration).

58Remove the two securing screws,

withdraw the switch and unplug it.

Rear seat adjusting switch

59This is removed in the same way as the

mirror control switch already described in

paragraphs 10 and 11.

Heated seat control switches

60These are removed in the same way as the

mirror control switch already described in

paragraphs 10 and 11.

Starter inhibitor/reversing light

switch (automatic transmission)

61Refer to Chapter 7 part B.

Fuses

1The battery positive (live) lead is protected

by a fusible link. If this link melts, a major

short-circuit is indicated and expert advice

should be sought before repairing it.

2The main fuse/relay box is located under the

bonnet, near the bulkhead on the right-hand

side. It contains up to 24 fuses and nearly as

many relays (according to equipment). Fuse

applications are listed on the underside of the

fuse box lid (see illustration).

3There is an auxiliary fuse box inside the

vehicle, accessible after opening the glovebox

(see illustration). An in-line fuse for the radio

is located under the facia on the left-hand

side, near the heater.4The“blade” type fuses are colour-coded to

show their current rating. A blown fuse can be

recognised by the melted wire link in the

middle.

5To renew a blown fuse, first switch off the

circuit concerned. Pull the old fuse out of its

holder, using tweezers or long-nosed pliers.

Press in a new fuse of the same rating and try

the circuit again.

6If the new fuse blows immediately or within

a short time, do not carry on renewing fuses

but look for a short-circuit in the wiring to the

item(s) protected by the fuse. When more than

one item is protected by a single fuse,

switching on one item at a time until the fuse

blows will help to isolate the defect.

7Never fit a fuse of a higher rating (current

capacity) than specified, and do not bypass

fuses with silver foil or strands of wire. Serious

damage, including fire, could result.

8In some positions (such as for power

window and seat adjustment motors) circuit

breakers are fitted instead of fuses. These are

normally self-resetting once the cause of the

overload has been cleared.

Relays

9If a circuit or system served by a relay

develops a fault, always remember that the

problem could be in the relay. Testing is by

substitution of a known good unit. Beware of

substituting relays which look the same but

perform different functions(see illustration).10To renew a relay, simply unplug it from its

holder and plug in the new one. Access to the

relays in the main fuse box is as described for

the fuses. Access to the relays located behind

the facia is achieved by removing the facia

top.

11The sliding roof relay is located in the

overhead console.

Control units and modules

12The two major modules are the EEC IV

module (on fuel-injection models) and the ABS

control module. These are located below the

glovebox on the passenger side, and are

accessible after removing the under-dash trim.

13As with relays, testing by the home

mechanic is limited to substitution of known

good units. This is likely to be prohibitively

expensive on a trial and error basis so in case

of problems a Ford dealer or other competent

specialist should be consulted at an early

stage.

1Disconnect the battery negative lead and

unlock all the doors before starting work on

the central locking system. Make sure that the

keys are outside the vehicle before

reconnecting the battery on completion.

2Remove the door interior trim panel.

17Central locking motor -

removal and refitting

16Fuses, relays and control

units - removal and refitting

Body electrical system 13•13

13

15.54 Removing a foglight switch15.57 Removing the front seat adjusting

switch

16.2 Main fuse/relay box under the bonnet16.3 Auxiliary fuse box in the glovebox

procarmanuals.com

Page 193 of 255

1Remove the overhead console.

2Remove the three bolts which secure the

motor (see illustration).Lower the motor,

disconnect the multi-plug and remove it.

Recover the relay.

3When refitting, make sure that the motor

drivegear meshes with the roof operating

mechanism. Refit the relay, reconnect the

multi-plug and secure the motor with the three

bolts.

4Check the operation of the motor, then refit

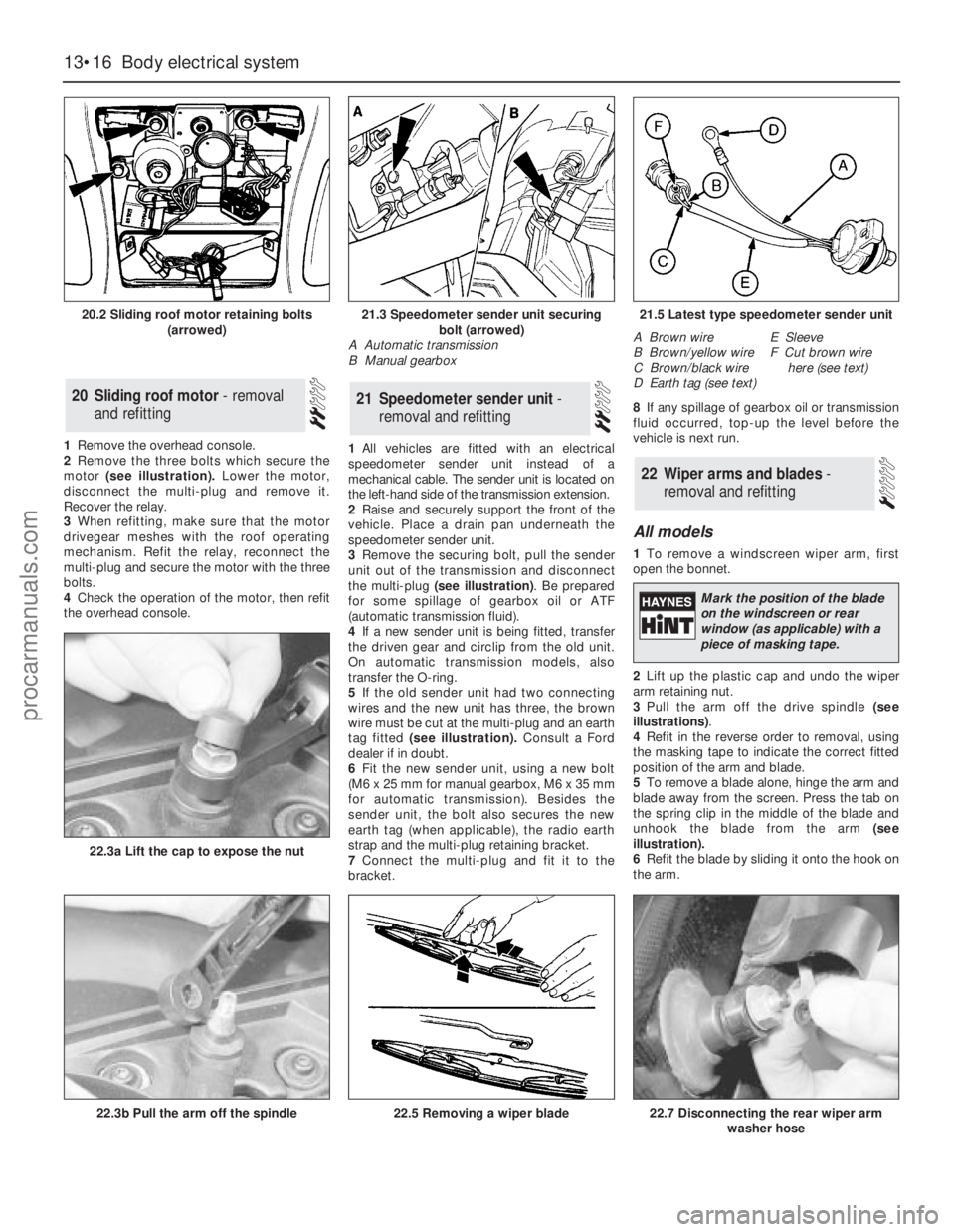

the overhead console.1All vehicles are fitted with an electrical

speedometer sender unit instead of a

mechanical cable. The sender unit is located on

the left-hand side of the transmission extension.

2Raise and securely support the front of the

vehicle. Place a drain pan underneath the

speedometer sender unit.

3Remove the securing bolt, pull the sender

unit out of the transmission and disconnect

the multi-plug (see illustration). Be prepared

for some spillage of gearbox oil or ATF

(automatic transmission fluid).

4If a new sender unit is being fitted, transfer

the driven gear and circlip from the old unit.

On automatic transmission models, also

transfer the O-ring.

5If the old sender unit had two connecting

wires and the new unit has three, the brown

wire must be cut at the multi-plug and an earth

tag fitted (see illustration).Consult a Ford

dealer if in doubt.

6Fit the new sender unit, using a new bolt

(M6 x 25 mm for manual gearbox, M6 x 35 mm

for automatic transmission). Besides the

sender unit, the bolt also secures the new

earth tag (when applicable), the radio earth

strap and the multi-plug retaining bracket.

7Connect the multi-plug and fit it to the

bracket.8If any spillage of gearbox oil or transmission

fluid occurred, top-up the level before the

vehicle is next run.

All models

1To remove a windscreen wiper arm, first

open the bonnet.

2Lift up the plastic cap and undo the wiper

arm retaining nut.

3Pull the arm off the drive spindle (see

illustrations).

4Refit in the reverse order to removal, using

the masking tape to indicate the correct fitted

position of the arm and blade.

5To remove a blade alone, hinge the arm and

blade away from the screen. Press the tab on

the spring clip in the middle of the blade and

unhook the blade from the arm (see

illustration).

6Refit the blade by sliding it onto the hook on

the arm.

22Wiper arms and blades -

removal and refitting

21Speedometer sender unit -

removal and refitting20Sliding roof motor - removal

and refitting

13•16Body electrical system

20.2 Sliding roof motor retaining bolts

(arrowed)

22.3b Pull the arm off the spindle

22.3a Lift the cap to expose the nut

22.5 Removing a wiper blade22.7 Disconnecting the rear wiper arm

washer hose

21.3 Speedometer sender unit securing

bolt (arrowed)

A Automatic transmission

B Manual gearbox21.5 Latest type speedometer sender unit

A Brown wire

B Brown/yellow wire

C Brown/black wire

D Earth tag (see text)E Sleeve

F Cut brown wire

here (see text)

Mark the position of the blade

on the windscreen or rear

window (as applicable) with a

piece of masking tape.

procarmanuals.com

Page 194 of 255

Estate

7Note that when removing the rear window

wiper arm, it will be necessary to detach the

washer hose from the spindle prior to

removing the wiper arm retaining nut (see

illustration).

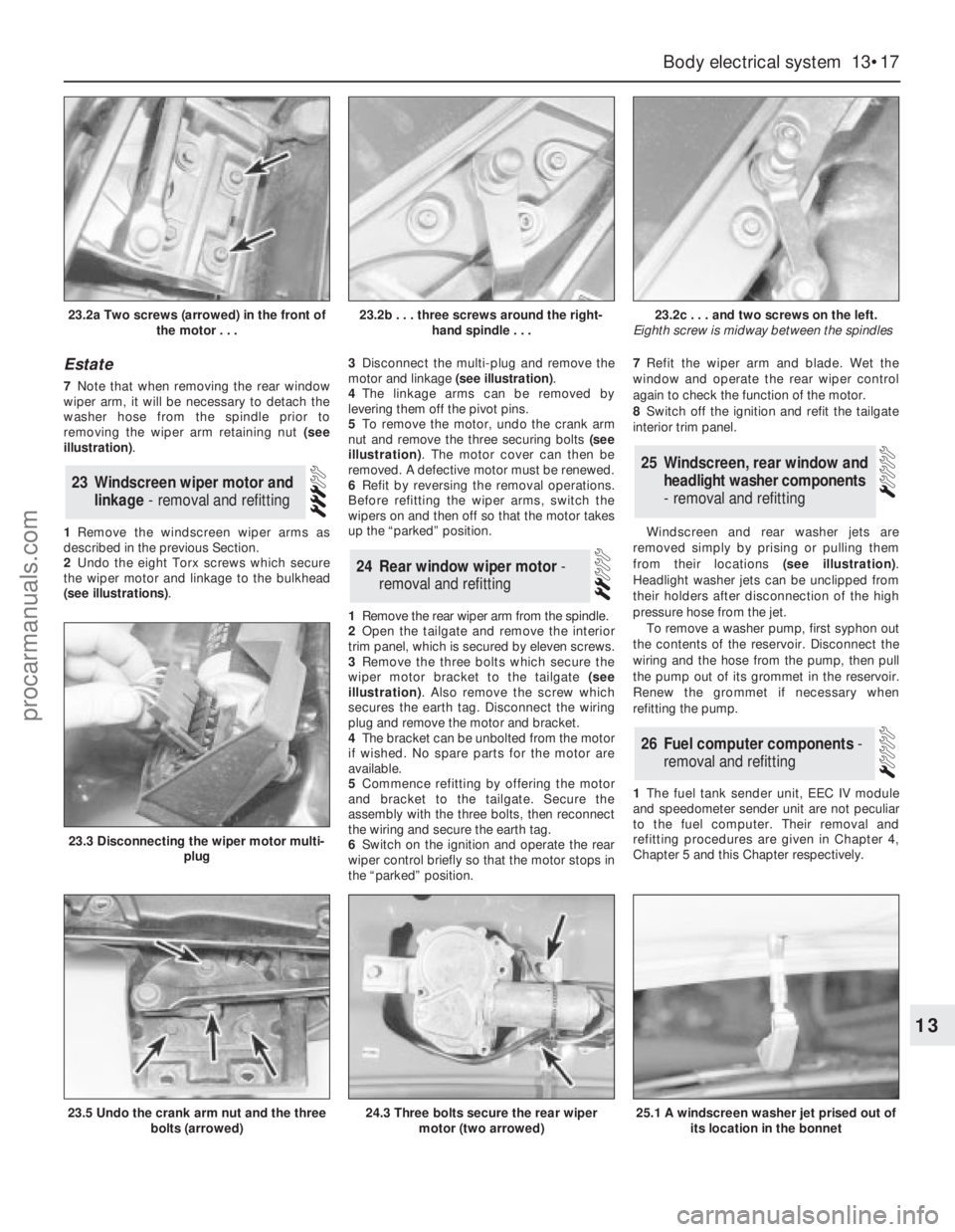

1Remove the windscreen wiper arms as

described in the previous Section.

2Undo the eight Torx screws which secure

the wiper motor and linkage to the bulkhead

(see illustrations).3Disconnect the multi-plug and remove the

motor and linkage (see illustration).

4The linkage arms can be removed by

levering them off the pivot pins.

5To remove the motor, undo the crank arm

nut and remove the three securing bolts (see

illustration). The motor cover can then be

removed. A defective motor must be renewed.

6Refit by reversing the removal operations.

Before refitting the wiper arms, switch the

wipers on and then off so that the motor takes

up the “parked” position.

1Remove the rear wiper arm from the spindle.

2Open the tailgate and remove the interior

trim panel, which is secured by eleven screws.

3Remove the three bolts which secure the

wiper motor bracket to the tailgate (see

illustration). Also remove the screw which

secures the earth tag. Disconnect the wiring

plug and remove the motor and bracket.

4The bracket can be unbolted from the motor

if wished. No spare parts for the motor are

available.

5Commence refitting by offering the motor

and bracket to the tailgate. Secure the

assembly with the three bolts, then reconnect

the wiring and secure the earth tag.

6Switch on the ignition and operate the rear

wiper control briefly so that the motor stops in

the “parked” position.7Refit the wiper arm and blade. Wet the

window and operate the rear wiper control

again to check the function of the motor.

8Switch off the ignition and refit the tailgate

interior trim panel.

Windscreen and rear washer jets are

removed simply by prising or pulling them

from their locations (see illustration).

Headlight washer jets can be unclipped from

their holders after disconnection of the high

pressure hose from the jet.

To remove a washer pump, first syphon out

the contents of the reservoir. Disconnect the

wiring and the hose from the pump, then pull

the pump out of its grommet in the reservoir.

Renew the grommet if necessary when

refitting the pump.

1The fuel tank sender unit, EEC IV module

and speedometer sender unit are not peculiar

to the fuel computer. Their removal and

refitting procedures are given in Chapter 4,

Chapter 5 and this Chapter respectively.

26Fuel computer components -

removal and refitting

25Windscreen, rear window and

headlight washer components

- removal and refitting

24Rear window wiper motor -

removal and refitting

23Windscreen wiper motor and

linkage - removal and refitting

Body electrical system 13•17

13

23.2a Two screws (arrowed) in the front of

the motor . . .23.2b . . . three screws around the right-

hand spindle . . .23.2c . . . and two screws on the left.

Eighth screw is midway between the spindles

23.5 Undo the crank arm nut and the three

bolts (arrowed)

23.3 Disconnecting the wiper motor multi-

plug

24.3 Three bolts secure the rear wiper

motor (two arrowed)25.1 A windscreen washer jet prised out of

its location in the bonnet

procarmanuals.com

Page 195 of 255

Computer module and bulb

Models before April 1992

2Remove the instrument panel surround,

which is secured by four screws.

3Carefully pull the module from its location.

Release the multi-plug by pressing

downwards and disconnect it.

4The module illumination bulbholder may

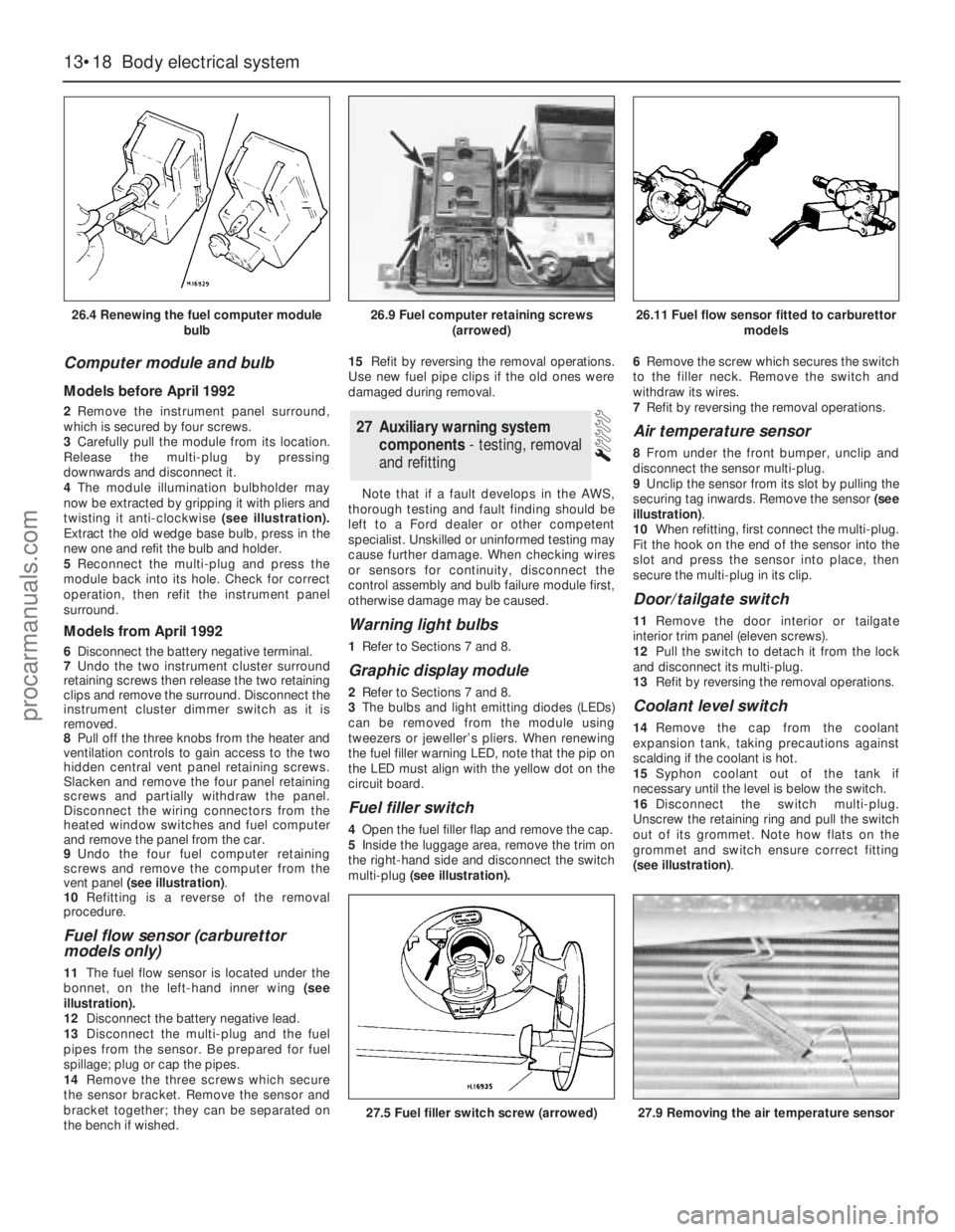

now be extracted by gripping it with pliers and

twisting it anti-clockwise (see illustration).

Extract the old wedge base bulb, press in the

new one and refit the bulb and holder.

5Reconnect the multi-plug and press the

module back into its hole. Check for correct

operation, then refit the instrument panel

surround.

Models from April 1992

6Disconnect the battery negative terminal.

7Undo the two instrument cluster surround

retaining screws then release the two retaining

clips and remove the surround. Disconnect the

instrument cluster dimmer switch as it is

removed.

8Pull off the three knobs from the heater and

ventilation controls to gain access to the two

hidden central vent panel retaining screws.

Slacken and remove the four panel retaining

screws and partially withdraw the panel.

Disconnect the wiring connectors from the

heated window switches and fuel computer

and remove the panel from the car.

9Undo the four fuel computer retaining

screws and remove the computer from the

vent panel (see illustration).

10Refitting is a reverse of the removal

procedure.

Fuel flow sensor (carburettor

models only)

11The fuel flow sensor is located under the

bonnet, on the left-hand inner wing (see

illustration).

12Disconnect the battery negative lead.

13Disconnect the multi-plug and the fuel

pipes from the sensor. Be prepared for fuel

spillage; plug or cap the pipes.

14Remove the three screws which secure

the sensor bracket. Remove the sensor and

bracket together; they can be separated on

the bench if wished.15Refit by reversing the removal operations.

Use new fuel pipe clips if the old ones were

damaged during removal.

Note that if a fault develops in the AWS,

thorough testing and fault finding should be

left to a Ford dealer or other competent

specialist. Unskilled or uninformed testing may

cause further damage. When checking wires

or sensors for continuity, disconnect the

control assembly and bulb failure module first,

otherwise damage may be caused.

Warning light bulbs

1Refer to Sections 7 and 8.

Graphic display module

2Refer to Sections 7 and 8.

3The bulbs and light emitting diodes (LEDs)

can be removed from the module using

tweezers or jeweller’s pliers. When renewing

the fuel filler warning LED, note that the pip on

the LED must align with the yellow dot on the

circuit board.

Fuel filler switch

4Open the fuel filler flap and remove the cap.

5Inside the luggage area, remove the trim on

the right-hand side and disconnect the switch

multi-plug(see illustration).6Remove the screw which secures the switch

to the filler neck. Remove the switch and

withdraw its wires.

7Refit by reversing the removal operations.

Air temperature sensor

8From under the front bumper, unclip and

disconnect the sensor multi-plug.

9Unclip the sensor from its slot by pulling the

securing tag inwards. Remove the sensor (see

illustration).

10When refitting, first connect the multi-plug.

Fit the hook on the end of the sensor into the

slot and press the sensor into place, then

secure the multi-plug in its clip.

Door/tailgate switch

11Remove the door interior ortailgate

interior trim panel (eleven screws).

12Pull the switch to detach it from the lock

and disconnect its multi-plug.

13Refit by reversing the removal operations.

Coolant level switch

14Remove the cap from the coolant

expansion tank, taking precautions against

scalding if the coolant is hot.

15Syphon coolant out of the tank if

necessary until the level is below the switch.

16Disconnect the switch multi-plug.

Unscrew the retaining ring and pull the switch

out of its grommet. Note how flats on the

grommet and switch ensure correct fitting

(see illustration).

27Auxiliary warning system

components - testing, removal

and refitting

13•18Body electrical system

26.4 Renewing the fuel computer module

bulb

27.5 Fuel filler switch screw (arrowed)27.9 Removing the air temperature sensor

26.9 Fuel computer retaining screws

(arrowed)26.11 Fuel flow sensor fitted to carburettor

models

procarmanuals.com

Page 196 of 255

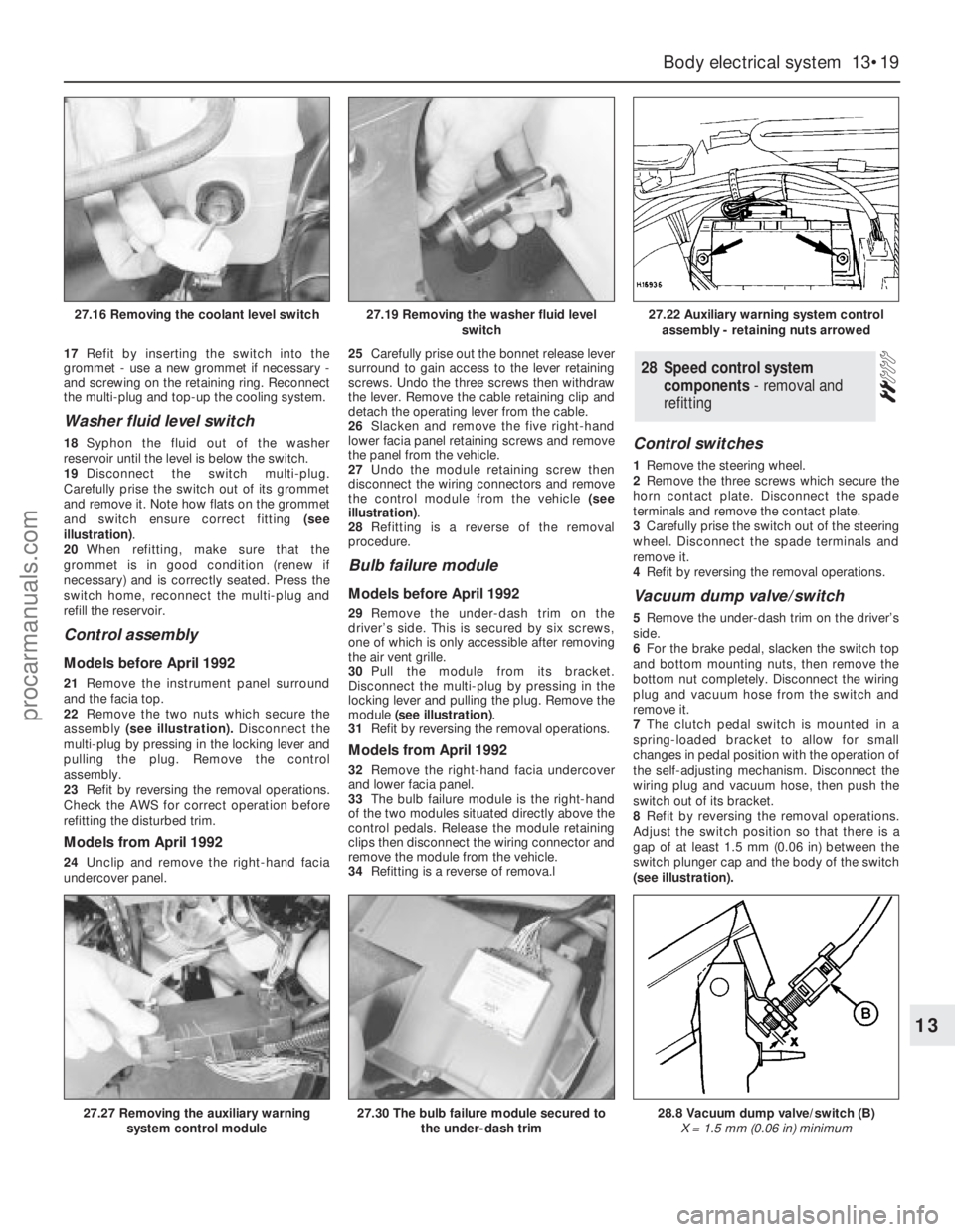

17Refit by inserting the switch into the

grommet - use a new grommet if necessary -

and screwing on the retaining ring. Reconnect

the multi-plug and top-up the cooling system.

Washer fluid level switch

18Syphon the fluid out of the washer

reservoir until the level is below the switch.

19Disconnect the switch multi-plug.

Carefully prise the switch out of its grommet

and remove it. Note how flats on the grommet

and switch ensure correct fitting (see

illustration).

20When refitting, make sure that the

grommet is in good condition (renew if

necessary) and is correctly seated. Press the

switch home, reconnect the multi-plug and

refill the reservoir.

Control assembly

Models before April 1992

21Remove the instrument panel surround

and the facia top.

22Remove the two nuts which secure the

assembly(see illustration).Disconnect the

multi-plug by pressing in the locking lever and

pulling the plug. Remove the control

assembly.

23Refit by reversing the removal operations.

Check the AWS for correct operation before

refitting the disturbed trim.

Models from April 1992

24Unclip and remove the right-hand facia

undercover panel.25Carefully prise out the bonnet release lever

surround to gain access to the lever retaining

screws. Undo the three screws then withdraw

the lever. Remove the cable retaining clip and

detach the operating lever from the cable.

26Slacken and remove the five right-hand

lower facia panel retaining screws and remove

the panel from the vehicle.

27Undo the module retaining screw then

disconnect the wiring connectors and remove

the control module from the vehicle (see

illustration).

28Refitting is a reverse of the removal

procedure.

Bulb failure module

Models before April 1992

29Remove the under-dash trim on the

driver’s side. This is secured by six screws,

one of which is only accessible after removing

the air vent grille.

30Pull the module from its bracket.

Disconnect the multi-plug by pressing in the

locking lever and pulling the plug. Remove the

module (see illustration).

31Refit by reversing the removal operations.

Models from April 1992

32Remove the right-hand facia undercover

and lower facia panel.

33The bulb failure module is the right-hand

of the two modules situated directly above the

control pedals. Release the module retaining

clips then disconnect the wiring connector and

remove the module from the vehicle.

34Refitting is a reverse of remova.l

Control switches

1Remove the steering wheel.

2Remove the three screws which secure the

horn contact plate. Disconnect the spade

terminals and remove the contact plate.

3Carefully prise the switch out of the steering

wheel. Disconnect the spade terminals and

remove it.

4Refit by reversing the removal operations.

Vacuum dump valve/switch

5Remove the under-dash trim on the driver’s

side.

6For the brake pedal, slacken the switch top

and bottom mounting nuts, then remove the

bottom nut completely. Disconnect the wiring

plug and vacuum hose from the switch and

remove it.

7The clutch pedal switch is mounted in a

spring-loaded bracket to allow for small

changes in pedal position with the operation of

the self-adjusting mechanism. Disconnect the

wiring plug and vacuum hose, then push the

switch out of its bracket.

8Refit by reversing the removal operations.

Adjust the switch position so that there is a

gap of at least 1.5 mm (0.06 in) between the

switch plunger cap and the body of the switch

(see illustration).

28Speed control system

components - removal and

refitting

Body electrical system 13•19

13

27.16 Removing the coolant level switch27.19 Removing the washer fluid level

switch27.22 Auxiliary warning system control

assembly - retaining nuts arrowed

27.27 Removing the auxiliary warning

system control module27.30 The bulb failure module secured to

the under-dash trim28.8 Vacuum dump valve/switch (B)

X = 1.5 mm (0.06 in) minimum

procarmanuals.com