gas type FORD GRANADA 1985 Service Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 110 of 255

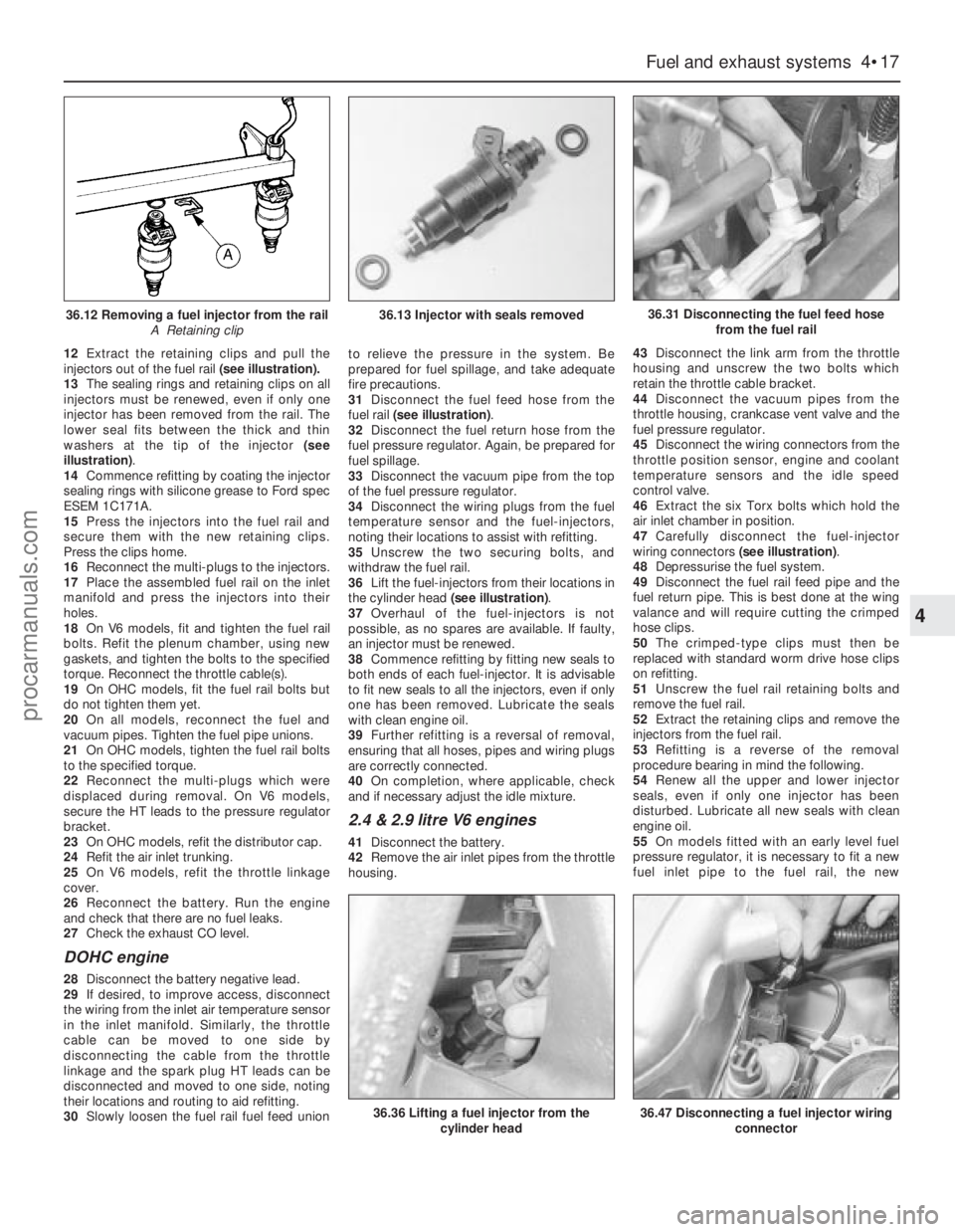

12Extract the retaining clips and pull the

injectors out of the fuel rail(see illustration).

13The sealing rings and retaining clips on all

injectors must be renewed, even if only one

injector has been removed from the rail. The

lower seal fits between the thick and thin

washers at the tip of the injector (see

illustration).

14Commence refitting by coating the injector

sealing rings with silicone grease to Ford spec

ESEM 1C171A.

15Press the injectors into the fuel rail and

secure them with the new retaining clips.

Press the clips home.

16Reconnect the multi-plugs to the injectors.

17Place the assembled fuel rail on the inlet

manifold and press the injectors into their

holes.

18On V6 models, fit and tighten the fuel rail

bolts. Refit the plenum chamber, using new

gaskets, and tighten the bolts to the specified

torque. Reconnect the throttle cable(s).

19On OHCmodels, fit the fuel rail bolts but

do not tighten them yet.

20On all models, reconnect the fuel and

vacuum pipes. Tighten the fuel pipe unions.

21On OHCmodels, tighten the fuel rail bolts

to the specified torque.

22Reconnect the multi-plugs which were

displaced during removal. On V6 models,

secure the HT leads to the pressure regulator

bracket.

23On OHCmodels, refit the distributor cap.

24Refit the air inlet trunking.

25On V6 models, refit the throttle linkage

cover.

26Reconnect the battery. Run the engine

and check that there are no fuel leaks.

27Check the exhaust CO level.

DOHC engine

28Disconnect the battery negative lead.

29If desired, to improve access, disconnect

the wiring from the inlet air temperature sensor

in the inlet manifold. Similarly, the throttle

cable can be moved to one side by

disconnecting the cable from the throttle

linkage and the spark plug HT leads can be

disconnected and moved to one side, noting

their locations and routing to aid refitting.

30Slowly loosen the fuel rail fuel feed unionto relieve the pressure in the system. Be

prepared for fuel spillage, and take adequate

fire precautions.

31Disconnect the fuel feed hose from the

fuel rail (see illustration).

32Disconnect the fuel return hose from the

fuel pressure regulator. Again, be prepared for

fuel spillage.

33Disconnect the vacuum pipe from the top

of the fuel pressure regulator.

34Disconnect the wiring plugs from the fuel

temperature sensor and the fuel-injectors,

noting their locations to assist with refitting.

35Unscrew the two securing bolts, and

withdraw the fuel rail.

36Lift the fuel-injectors from their locations in

the cylinder head (see illustration).

37Overhaul of the fuel-injectors is not

possible, as no spares are available. If faulty,

an injector must be renewed.

38Commence refitting by fitting new seals to

both ends of each fuel-injector. It is advisable

to fit new seals to all the injectors, even if only

one has been removed. Lubricate the seals

with clean engine oil.

39Further refitting is a reversal of removal,

ensuring that all hoses, pipes and wiring plugs

are correctly connected.

40On completion, where applicable, check

and if necessary adjust the idle mixture.

2.4 & 2.9 litre V6 engines

41Disconnect the battery.

42Remove the air inlet pipes from the throttle

housing.43Disconnect the link arm from the throttle

housing and unscrew the two bolts which

retain the throttle cable bracket.

44Disconnect the vacuum pipes from the

throttle housing, crankcase vent valve and the

fuel pressure regulator.

45Disconnect the wiring connectors from the

throttle position sensor, engine and coolant

temperature sensors and the idle speed

control valve.

46Extract the six Torx bolts which hold the

air inlet chamber in position.

47Carefully disconnect the fuel-injector

wiring connectors (see illustration).

48Depressurise the fuel system.

49Disconnect the fuel rail feed pipe and the

fuel return pipe. This is best done at the wing

valance and will require cutting the crimped

hose clips.

50The crimped-type clips must then be

replaced with standard worm drive hose clips

on refitting.

51Unscrew the fuel rail retaining bolts and

remove the fuel rail.

52Extract the retaining clips and remove the

injectors from the fuel rail.

53Refitting is a reverse of the removal

procedure bearing in mind the following.

54Renew all the upper and lower injector

seals, even if only one injector has been

disturbed. Lubricate all new seals with clean

engine oil.

55On models fitted with an early level fuel

pressure regulator, it is necessary to fit a new

fuel inlet pipe to the fuel rail, the new

Fuel and exhaust systems 4•17

4

36.12 Removing a fuel injector from the rail

A Retaining clip36.13 Injector with seals removed36.31 Disconnecting the fuel feed hose

from the fuel rail

36.36 Lifting a fuel injector from the

cylinder head36.47 Disconnecting a fuel injector wiring

connector

procarmanuals.com

Page 112 of 255

24Unbolt and remove the regulator from the

fuel rail. Remove the sealing O-ring and

discard it; a new one must be used on

refitting.

25Refitting is a reverse of the removal

procedure applying a smear of clean engine oil

to the new regulator O-ring. On models

equipped with a late level regulator, ensure

that the return pipe is securely held in position

by the retaining collar.

26On completion, switch the ignition on and

off five times without cranking the engine to

pressurise the fuel system.

27With the system pressurised check all

disturbed fuel unions for signs of leakage.

1The potentiometer is located on the right-

hand side of the engine compartment, behind

the MAP sensor.

2Disconnect the battery negative lead.

3Remove the securing screw, then withdraw

the potentiometer and disconnect the wiring

plug.

4Refitting is a reversal of removal. On

completion adjust the idle mixture.1On 2.4 & 2.9 litre V6 engines, disconnect the

battery.

2Disconnect the switch wiring connector.

3Slacken and remove the switch from the

fuel rail (see illustration).

4Refitting is a reverse of removal, tightening

the switch to the specified torque setting.

Carburettor models

All engines except DOHC

1Remove the carburettor or, if preferred, the

final removal of the carburettor from the

manifold can be left until the manifold has

been removed).

2Drain the cooling system.

3Disconnect the coolant and vacuum pipes

from the manifold, noting their positions if

there is any possibility of confusion.

4Disconnect the wires from the manifold

heater and the coolant temperature sender

unit.

5Disconnect the crankcase ventilation hose

from the manifold.

6Unscrew the six nuts and bolts which

secure the manifold and withdraw it. Recover

the gasket.

7Before refitting the manifold, make sure that

the mating surfaces are perfectly clean.

8Apply a bead of sealant at least 5 mm (0.2 in)

wide around the central coolant aperture on

both sides of a new gasket.

9Place the gasket over the studs, then fit the

manifold and secure it with the six nuts and

bolts. Tighten the nuts and bolts evenly to the

specified torque.

10The remainder of refitting is a reversal of

the removal procedure. Refill the cooling

system on completion.

DOHC engine

11Disconnect the battery negative lead.

12Drain the cooling system.13Remove the air cleaner.

14Disconnect the coolant hoses from the

thermostat housing and the inlet manifold,

noting the locations to assist with refitting.

15Disconnect the fuel supply and return

hoses from the carburettor. Plug their ends to

minimise petrol spillage.

16Release the coolant hose from the bracket

under the automatic choke housing.

17Disconnect the HT leads from the spark

plugs, and move them to one side.

18Disconnect all relevant wiring and vacuum

pipes from the carburettor, thermostat

housing and inlet manifold, noting the

locations as an aid to refitting.

19Disconnect the crankcase breather hose

from the inlet manifold.

20Disconnect the throttle cable from the

throttle linkage.

21Make a final check to ensure that all

relevant wires, pipes and hoses have been

disconnected to facilitate removal of the

manifold.

22Unscrew the ten bolts and two nuts

securing the manifold to the cylinder head.

23Lift the manifold clear of the cylinder head

and recover the gasket.

24Recover the two plastic spark plug spacers

from the recesses in the cylinder head.

25If desired, the carburettor can be removed

from the manifold by unscrewing the securing

screws.

26Refitting is a reversal of removal, bearing

in mind the following points.

a)Ensure that all mating faces are clean and

renew all gaskets.

b)Ensure that the spark plug spacers are in

position in the cylinder head recesses

before refitting the manifold.

c)Tighten all manifold securing nuts and

bolts progressively to the specified torque.

d)Make sure that all hoses, pipes and wires

are securely reconnected in their original

positions. Replace all crimp-type hose

clips (where fitted) with standard worm

drive hose clips.

e)On completion, refill the cooling system,

check the adjustment of the throttle cable,

then check, and if necessary adjust the

idle speed and mixture.

Fuel-injection models

SOHC engine

27Disconnect the battery negative lead.

28Drain the cooling system.

29Disconnect the vacuum pipe(s) from the

manifold. The number of pipes varies

according to equipment. Label the pipes if

necessary (see illustration).

30Disconnect the fuel-injection harness

multi-plugs at the bulkhead end of the

manifold (see illustration).

31Disconnect the oil pressure warning light

sender wire from below the manifold.

32Release the hose clips and move the

airflow meter-to-manifold trunking clear of the

manifold.

40Inlet manifold - removal and

refitting

39Fuel rail temperature switch -

removal and refitting

38Mixture adjustment

potentiometer - removal and

refitting

Fuel and exhaust systems 4•19

4

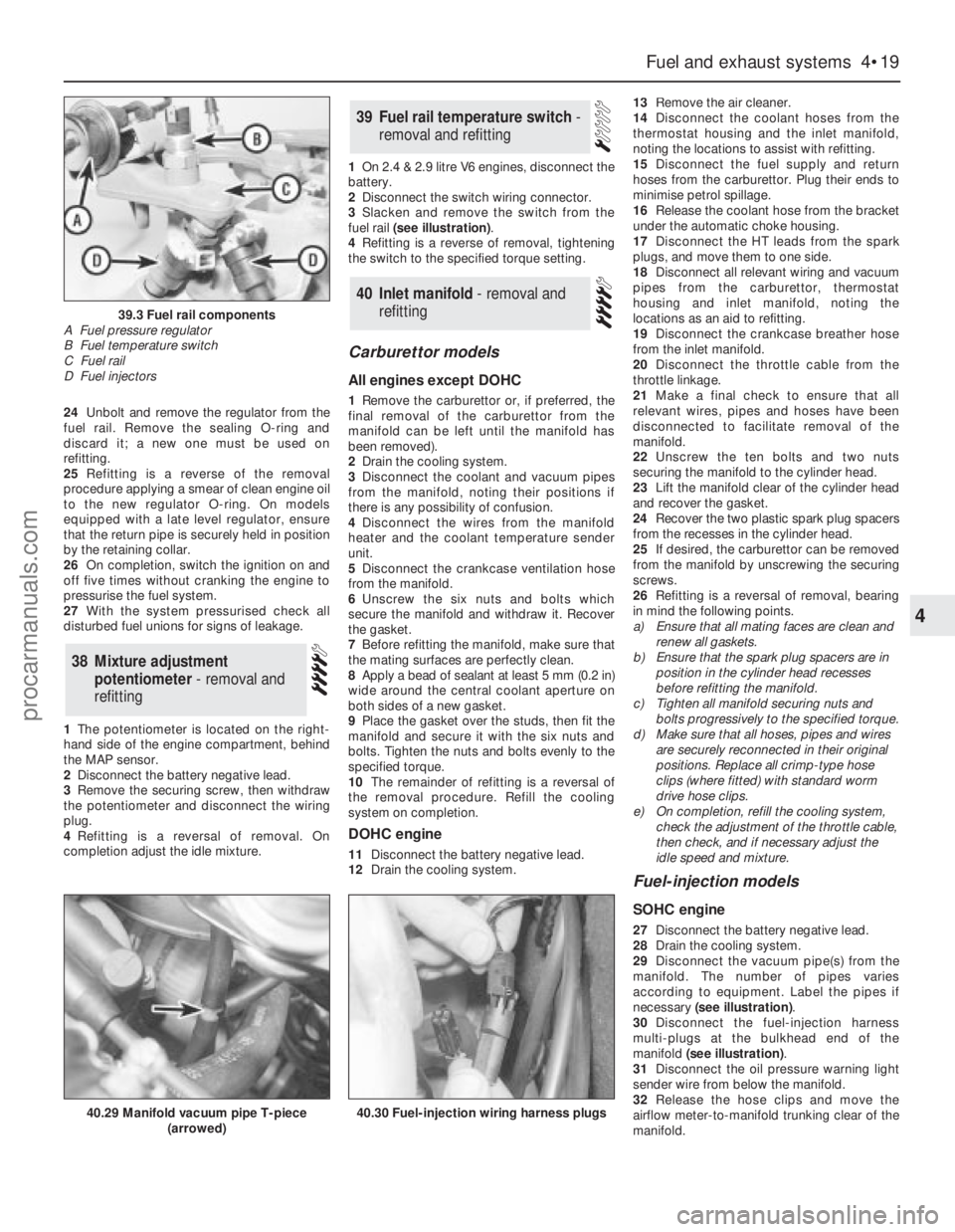

39.3 Fuel rail components

A Fuel pressure regulator

B Fuel temperature switch

C Fuel rail

D Fuel injectors

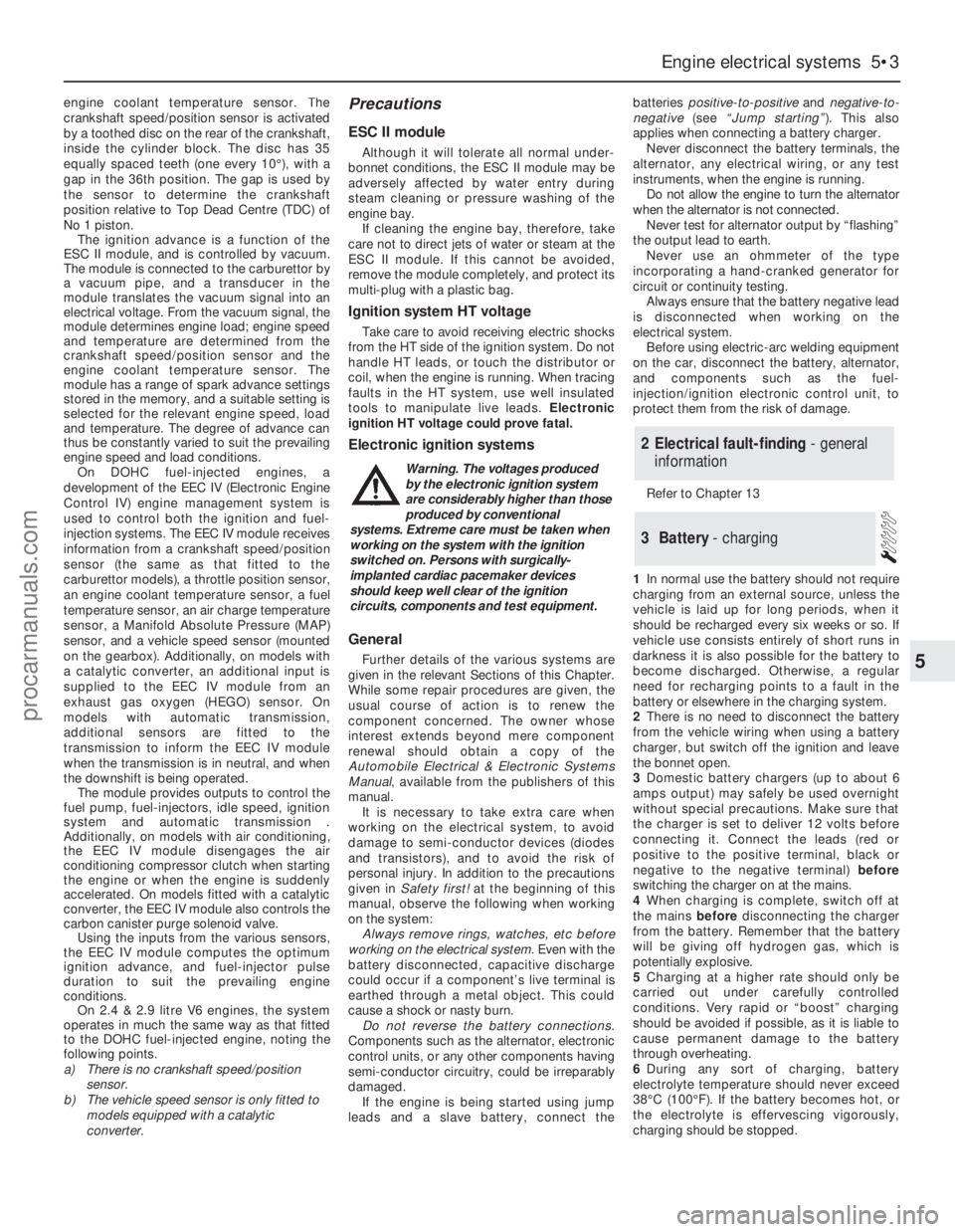

40.29 Manifold vacuum pipe T-piece

(arrowed)40.30 Fuel-injection wiring harness plugs

procarmanuals.com

Page 120 of 255

engine coolant temperature sensor. The

crankshaft speed/position sensor is activated

by a toothed disc on the rear of the crankshaft,

inside the cylinder block. The disc has 35

equally spaced teeth (one every 10°), with a

gap in the 36th position. The gap is used by

the sensor to determine the crankshaft

position relative to Top Dead Centre (TDC) of

No 1 piston.

The ignition advance is a function of the

ESC II module, and is controlled by vacuum.

The module is connected to the carburettor by

a vacuum pipe, and a transducer in the

module translates the vacuum signal into an

electrical voltage. From the vacuum signal, the

module determines engine load; engine speed

and temperature are determined from the

crankshaft speed/position sensor and the

engine coolant temperature sensor. The

module has a range of spark advance settings

stored in the memory, and a suitable setting is

selected for the relevant engine speed, load

and temperature. The degree of advance can

thus be constantly varied to suit the prevailing

engine speed and load conditions.

On DOHC fuel-injected engines, a

development of the EEC IV (Electronic Engine

Control IV) engine management system is

used to control both the ignition and fuel-

injection systems. The EEC IV module receives

information from a crankshaft speed/position

sensor (the same as that fitted to the

carburettor models), a throttle position sensor,

an engine coolant temperature sensor, a fuel

temperature sensor, an air charge temperature

sensor, a Manifold Absolute Pressure (MAP)

sensor, and a vehicle speed sensor (mounted

on the gearbox). Additionally, on models with

a catalytic converter, an additional input is

supplied to the EEC IV module from an

exhaust gas oxygen (HEGO) sensor. On

models with automatic transmission,

additional sensors are fitted to the

transmission to inform the EEC IV module

when the transmission is in neutral, and when

the downshift is being operated.

The module provides outputs to control the

fuel pump, fuel-injectors, idle speed, ignition

system and automatic transmission .

Additionally, on models with air conditioning,

the EEC IV module disengages the air

conditioning compressor clutch when starting

the engine or when the engine is suddenly

accelerated. On models fitted with a catalytic

converter, the EEC IV module also controls the

carbon canister purge solenoid valve.

Using the inputs from the various sensors,

the EEC IV module computes the optimum

ignition advance, and fuel-injector pulse

duration to suit the prevailing engine

conditions.

On 2.4 & 2.9 litre V6 engines, the system

operates in much the same way as that fitted

to the DOHC fuel-injected engine, noting the

following points.

a)There is no crankshaft speed/position

sensor.

b)The vehicle speed sensor is only fitted to

models equipped with a catalytic

converter.Precautions

ESC II module

Although it will tolerate all normal under-

bonnet conditions, the ESC II module may be

adversely affected by water entry during

steam cleaning or pressure washing of the

engine bay.

If cleaning the engine bay, therefore, take

care not to direct jets of water or steam at the

ESC II module. If this cannot be avoided,

remove the module completely, and protect its

multi-plug with a plastic bag.

Ignition system HT voltage

Take care to avoid receiving electric shocks

from the HT side of the ignition system. Do not

handle HT leads, or touch the distributor or

coil, when the engine is running. When tracing

faults in the HT system, use well insulated

tools to manipulate live leads. Electronic

ignition HT voltage could prove fatal.

Electronic ignition systems

General

Further details of the various systems are

given in the relevant Sections of this Chapter.

While some repair procedures are given, the

usual course of action is to renew the

component concerned. The owner whose

interest extends beyond mere component

renewal should obtain a copy of the

Automobile Electrical & Electronic Systems

Manual, available from the publishers of this

manual.

It is necessary to take extra care when

working on the electrical system, to avoid

damage to semi-conductor devices (diodes

and transistors), and to avoid the risk of

personal injury. In addition to the precautions

given in Safety first!at the beginning of this

manual, observe the following when working

on the system:

Always remove rings, watches, etc before

working on the electrical system.Even with the

battery disconnected, capacitive discharge

could occur if a component’s live terminal is

earthed through a metal object. This could

cause a shock or nasty burn.

Do not reverse the battery connections.

Components such as the alternator, electronic

control units, or any other components having

semi-conductor circuitry, could be irreparably

damaged.

If the engine is being started using jump

leads and a slave battery, connect thebatteries positive-to-positiveand negative-to-

negative(see “Jump starting”). This also

applies when connecting a battery charger.

Never disconnect the battery terminals, the

alternator, any electrical wiring, or any test

instruments, when the engine is running.

Do not allow the engine to turn the alternator

when the alternator is not connected.

Never test for alternator output by “flashing”

the output lead to earth.

Never use an ohmmeter of the type

incorporating a hand-cranked generator for

circuit or continuity testing.

Always ensure that the battery negative lead

is disconnected when working on the

electrical system.

Before using electric-arc welding equipment

on the car, disconnect the battery, alternator,

and components such as the fuel-

injection/ignition electronic control unit, to

protect them from the risk of damage.

Refer to Chapter 13

1In normal use the battery should not require

charging from an external source, unless the

vehicle is laid up for long periods, when it

should be recharged every six weeks or so. If

vehicle use consists entirely of short runs in

darkness it is also possible for the battery to

become discharged. Otherwise, a regular

need for recharging points to a fault in the

battery or elsewhere in the charging system.

2There is no need to disconnect the battery

from the vehicle wiring when using a battery

charger, but switch off the ignition and leave

the bonnet open.

3Domestic battery chargers (up to about 6

amps output) may safely be used overnight

without special precautions. Make sure that

the charger is set to deliver 12 volts before

connecting it. Connect the leads (red or

positive to the positive terminal, black or

negative to the negative terminal) before

switching the charger on at the mains.

4When charging is complete, switch off at

the mains beforedisconnecting the charger

from the battery. Remember that the battery

will be giving off hydrogen gas, which is

potentially explosive.

5Charging at a higher rate should only be

carried out under carefully controlled

conditions. Very rapid or “boost” charging

should be avoided if possible, as it is liable to

cause permanent damage to the battery

through overheating.

6During any sort of charging, battery

electrolyte temperature should never exceed

38°C (100°F). If the battery becomes hot, or

the electrolyte is effervescing vigorously,

charging should be stopped.

3Battery - charging

2Electrical fault-finding - general

information

Engine electrical systems 5•3

5

Warning. The voltages produced

by the electronic ignition system

are considerably higher than those

produced by conventional

systems. Extreme care must be taken when

working on the system with the ignition

switched on. Persons with surgically-

implanted cardiac pacemaker devices

should keep well clear of the ignition

circuits, components and test equipment.

procarmanuals.com

Page 160 of 255

to repair the affected area. New body panels

are not as expensive as most people think,

and it is often quicker and more satisfactory to

fit a new panel than to attempt to repair large

areas of corrosion.

Remove all fittings from the affected area,

except those which will act as a guide to the

original shape of the damaged bodywork (eg

headlight shells etc). Then, using tin snips or a

hacksaw blade, remove all loose metal and

any other metal badly affected by corrosion.

Hammer the edges of the hole inwards, in

order to create a slight depression for the filler

paste.

Wire-brush the affected area to remove the

powdery rust from the

surface of the remaining metal. Paint the

affected area with rust-inhibiting paint, if the

back of the rusted area is accessible, treat this

also.

Before filling can take place, it will be

necessary to block the hole in some way. This

can be achieved by the use of aluminium or

plastic mesh, or aluminium tape.

Aluminium or plastic mesh, or glass-fibre

matting, is probably the best material to use

for a large hole. Cut a piece to the

approximate size and shape of the hole to be

filled, then position it in the hole so that its

edges are below the level of the surrounding

bodywork. It can be retained in position by

several blobs of filler paste around its

periphery.

Aluminium tape should be used for small or

very narrow holes. Pull a piece off the roll, trim

it to the approximate size and shape required,

then pull off the backing paper (if used) and

stick the tape over the hole; it can be

overlapped if the thickness of one piece is

insufficient. Burnish down the edges of the

tape with the handle of a screwdriver or

similar, to ensure that the tape is securely

attached to the metal underneath.

Bodywork repairs - filling and

respraying

Before using this Section, see the Sections

on dent, deep scratch, rust holes and gash

repairs.

Many types of bodyfiller are available, but

generally speaking, those proprietary kits

which contain a tin of filler paste and a tube of

resin hardener are best for this type of repair.

A wide, flexible plastic or nylon applicator will

be found invaluable for imparting a smooth

and well-contoured finish to the surface of the

filler.

Mix up a little filler on a clean piece of card

or board - measure the hardener carefully

(follow the maker’s instructions on the pack),

otherwise the filler will set too rapidly or too

slowly. Using the applicator, apply the filler

paste to the prepared area; draw the

applicator across the surface of the filler to

achieve the correct contour and to level the

surface. As soon as a contour that

approximates to the correct one is achieved,

stop working the paste - if you carry on too

long, the paste will become sticky and begin

to “pick-up” on the applicator. Continue to

add thin layers of filler paste at 20-minuteintervals, until the level of the filler is just proud

of the surrounding bodywork.

Once the filler has hardened, the excess can

be removed using a metal plane or file. From

then on, progressively-finer grades of abrasive

paper should be used, starting with a 40-

grade production paper, and finishing with a

400-grade wet-and-dry paper. Always wrap

the abrasive paper around a flat rubber, cork,

or wooden block - otherwise the surface of the

filler will not be completely flat. During the

smoothing of the filler surface, the wet-and-

dry paper should be periodically rinsed in

water. This will ensure that a very smooth

finish is imparted to the filler at the final stage.

At this stage, the “dent” should be

surrounded by a ring of bare metal, which in

turn should be encircled by the finely

“feathered” edge of the good paintwork. Rinse

the repair area with clean water, until all of the

dust produced by the rubbing-down operation

has gone.

Spray the whole area with a light coat of

primer - this will show up any imperfections in

the surface of the filler. Repair these

imperfections with fresh filler paste or

bodystopper, and once more smooth the

surface with abrasive paper. Repeat this

spray-and-repair procedure until you are

satisfied that the surface of the filler, and the

feathered edge of the paintwork, are perfect.

Clean the repair area with clean water, and

allow to dry fully.

The repair area is now ready for final

spraying. Paint spraying must be carried out in

a warm, dry, windless and dust-free

atmosphere. This condition can be created

artificially if you have access to a large indoor

working area, but if you are forced to work in

the open, you will have to pick your day very

carefully. If you are working indoors, dousing

the floor in the work area with water will help

to settle the dust which would otherwise be in

the atmosphere. If the repair area is confined

to one body panel, mask off the surrounding

panels; this will help to minimise the effects of

a slight mis-match in paint colours. Bodywork

fittings (eg chrome strips, door handles etc)

will also need to be masked off. Use genuine

masking tape, and several thicknesses of

newspaper, for the masking operations.

Before commencing to spray, agitate the

aerosol can thoroughly, then spray a test area

(an old tin, or similar) until the technique is

mastered. Cover the repair area with a thick

coat of primer; the thickness should be built

up using several thin layers of paint, rather

than one thick one. Using 400-grade wet-and-

dry paper, rub down the surface of the primer

until it is really smooth. While doing this, the

work area should be thoroughly doused with

water, and the wet-and-dry paper periodically

rinsed in water. Allow to dry before spraying

on more paint.

Spray on the top coat, again building up thethickness by using several thin layers of paint.

Start spraying at one edge of the repair area,

and then, using a side-to-side motion, work

until the whole repair area and about 2 inches

of the surrounding original paintwork is

covered. Remove all masking material 10 to 15

minutes after spraying on the final coat of

paint.

Allow the new paint at least two weeks to

harden, then, using a paintwork renovator, or a

very fine cutting paste, blend the edges of the

paint into the existing paintwork. Finally, apply

wax polish.

Plastic components

With the use of more and more plastic body

components by the vehicle manufacturers (eg

bumpers. spoilers, and in some cases major

body panels), rectification of more serious

damage to such items has become a matter of

either entrusting repair work to a specialist in

this field, or renewing complete components.

Repair of such damage by the DIY owner is

not really feasible, owing to the cost of the

equipment and materials required for effecting

such repairs. The basic technique involves

making a groove along the line of the crack in

the plastic, using a rotary burr in a power drill.

The damaged part is then welded back

together, using a hot-air gun to heat up and

fuse a plastic filler rod into the groove. Any

excess plastic is then removed, and the area

rubbed down to a smooth finish. It is important

that a filler rod of the correct plastic is used, as

body components can be made of a variety of

different types (eg polycarbonate, ABS,

polypropylene).

Damage of a less serious nature (abrasions,

minor cracks etc) can be repaired by the DIY

owner using a two-part epoxy filler repair

material. Once mixed in equal proportions, this

is used in similar fashion to the bodywork filler

used on metal panels. The filler is usually

cured in twenty to thirty minutes, ready for

sanding and painting.

If the owner is renewing a complete

component himself, or if he has repaired it with

epoxy filler, he will be left with the problem of

finding a suitable paint for finishing which is

compatible with the type of plastic used. At

one time, the use of a universal paint was not

possible, owing to the complex range of

plastics encountered in body component

applications. Standard paints, generally

speaking, will not bond to plastic or rubber

satisfactorily. However, it is now possible to

obtain a plastic body parts finishing kit which

consists of a pre-primer treatment, a primer

and coloured top coat. Full instructions are

normally supplied with a kit, but basically, the

method of use is to first apply the pre-primer

to the component concerned, and allow it to

dry for up to 30 minutes. Then the primer is

applied, and left to dry for about an hour

before finally applying the special-coloured

top coat. The result is a correctly-coloured

component, where the paint will flex with the

plastic or rubber, a property that standard

paint does not normally posses.

Bodywork and fittings 12•3

12

If bodystopper is used, it can be

mixed with cellulose thinners,

to form a thin paste which is

ideal for filling small holes.

procarmanuals.com

Page 242 of 255

Engine misfires throughout the driving speed range

m mFuel filter choked (Chapter 1).

m mFuel pump faulty, or delivery pressure low (Chapter 4).

m mFuel tank vent blocked, or fuel pipes restricted (Chapter 4).

m mVacuum leak at the throttle body, inlet manifold or associated hoses

(Chapter 4).

m mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m mFaulty spark plug HT leads (Chapter 5).

m mDistributor cap cracked or tracking internally (Chapter 5).

m mFaulty ignition coil (Chapter 5).

m mUneven or low cylinder compressions (Chapter 2).

m mFuel injection system fault (Chapter 4).

Engine hesitates on acceleration

m

mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m mVacuum leak at the throttle body, inlet manifold or associated hoses

(Chapter 4).

m mFuel injection system fault (Chapter 4).

Engine stalls

m

mVacuum leak at the throttle body, inlet manifold or associated hoses

(Chapter 4).

m mFuel filter choked (Chapter 1).

m mFuel pump faulty, or delivery pressure low (Chapter 4).

m mFuel tank vent blocked, or fuel pipes restricted (Chapter 4).

m mFuel injection system fault (Chapter 4).

Engine lacks power

m

mFuel filter choked (Chapter 1).

m mFuel pump faulty, or delivery pressure low (Chapter 4).

m mUneven or low cylinder compressions (Chapter 2).

m mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m mVacuum leak at the throttle body, inlet manifold or associated hoses

(Chapter 4).

m mFuel injection system fault (Chapter 4).

m mBrakes binding (Chapters 1 and 10).

m mClutch slipping (Chapter 6).

Engine backfires

m

mVacuum leak at the throttle body, inlet manifold or associated hoses

(Chapter 4).

m mFuel injection system fault (Chapter 4).

Oil pressure warning light illuminated with engine

running

m mLow oil level, or incorrect oil grade (Chapter 1).

m mFaulty oil pressure sensor (Chapter 2).

m mWorn engine bearings and/or oil pump (Chapter 2).

m mExcessively high engine operating temperature (Chapter 3).

m mOil pressure relief valve defective (Chapter 2).

m mOil pick-up strainer clogged (Chapter 2).

Note:Low oil pressure in a high-mileage engine at tickover is not

necessarily a cause for concern. Sudden pressure loss at speed is far

more significant. In any event, check the gauge or warning light sender

before condemning the engine.

Engine runs-on after switching off

m mExcessive carbon build-up in engine (Chapter 2).

m mExcessively high engine operating temperature (Chapter 3).

Engine noises

Pre-ignition (pinking) or knocking during acceleration or

under load

m mIgnition timing incorrect/ignition system fault (Chapters 1 and 5).

m mIncorrect grade of spark plug (Chapter 1).

m mIncorrect grade of fuel (Chapter 1).

m mVacuum leak at throttle body, inlet manifold or associated hoses

(Chapter 4).

m mExcessive carbon build-up in engine (Chapter 2).

m mFuel injection system fault (Chapter 4).

Whistling or wheezing noises

m

mLeaking inlet manifold or throttle body gasket (Chapter 4).

m mLeaking exhaust manifold gasket (Chapter 4).

m mLeaking vacuum hose (Chapters 4 and 10).

m mBlowing cylinder head gasket (Chapter 2).

Tapping or rattling noises

m

mWorn valve gear, timing chain, camshaft or hydraulic tappets

(Chapter 2).

m mAncillary component fault (water pump, alternator, etc) (Chapters 3,

5, etc).

Knocking or thumping noises

m mWorn big-end bearings (regular heavy knocking, perhaps less under

load) (Chapter 2).

m mWorn main bearings (rumbling and knocking, perhaps worsening

under load) (Chapter 2).

m mPiston slap (most noticeable when cold) (Chapter 2).

m mAncillary component fault (water pump, alternator, etc) (Chapters 3,

5, etc).

REF•7Fault Finding

2Cooling system

Overheating

m

mAuxiliary drivebelt broken or incorrectly adjusted (Chapter 1).

m mInsufficient coolant in system (Chapter 1).

m mThermostat faulty (Chapter 3).

m mRadiator core blocked, or grille restricted (Chapter 3).

m mElectric cooling fan or thermostatic switch faulty (Chapter 3).

m mViscous-coupled fan faulty (Chapter 3).

m mIgnition timing incorrect, or ignition system fault (Chapters 1 and 5).

m mInaccurate temperature gauge sender unit (Chapter 3).

m mAirlock in cooling system (Chapter 3).

Overcooling

m

mThermostat faulty (Chapter 3).

m mInaccurate temperature gauge sender unit (Chapter 3).

External coolant leakage

m

mDeteriorated or damaged hoses or hose clips (Chapter 1).

m mRadiator core or heater matrix leaking (Chapter 3).

m mPressure cap faulty (Chapter 3).

m mWater pump internal seal leaking (Chapter 3).

m mWater pump-to-block seal leaking (Chapter 3).

m mBoiling due to overheating (Chapter 3).

m mCore plug leaking (Chapter 2).

Internal coolant leakage

m

mLeaking cylinder head gasket (Chapter 2).

m mCracked cylinder head or cylinder block (Chapter 2).

Corrosion

m

mInfrequent draining and flushing (Chapter 1).

m mIncorrect coolant mixture or inappropriate coolant type (Chapter 1).

procarmanuals.com

Page 248 of 255

REF•13Glossary of Technical Terms

Catalytic converterA silencer-like device in

the exhaust system which converts certain

pollutants in the exhaust gases into less

harmful substances.

CirclipA ring-shaped clip used to prevent

endwise movement of cylindrical parts and

shafts. An internal circlip is installed in a

groove in a housing; an external circlip fits into

a groove on the outside of a cylindrical piece

such as a shaft.

ClearanceThe amount of space between

two parts. For example, between a piston and

a cylinder, between a bearing and a journal,

etc.

Coil springA spiral of elastic steel found in

various sizes throughout a vehicle, for

example as a springing medium in the

suspension and in the valve train.

CompressionReduction in volume, and

increase in pressure and temperature, of a

gas, caused by squeezing it into a smaller

space.

Compression ratioThe relationship between

cylinder volume when the piston is at top

dead centre and cylinder volume when the

piston is at bottom dead centre.

Constant velocity (CV) jointA type of

universal joint that cancels out vibrations

caused by driving power being transmitted

through an angle.

Core plugA disc or cup-shaped metal device

inserted in a hole in a casting through which

core was removed when the casting was

formed. Also known as a freeze plug or

expansion plug.

CrankcaseThe lower part of the engine

block in which the crankshaft rotates.

CrankshaftThe main rotating member, or

shaft, running the length of the crankcase,

with offset “throws” to which the connecting

rods are attached.

Crocodile clipSee Alligator clipDDiagnostic codeCode numbers obtained by

accessing the diagnostic mode of an engine

management computer. This code can be

used to determine the area in the system

where a malfunction may be located.

Disc brakeA brake design incorporating a

rotating disc onto which brake pads are

squeezed. The resulting friction converts the

energy of a moving vehicle into heat.

Double-overhead cam (DOHC)An engine

that uses two overhead camshafts, usually

one for the intake valves and one for the

exhaust valves.

Drivebelt(s)The belt(s) used to drive

accessories such as the alternator, water

pump, power steering pump, air conditioning

compressor, etc. off the crankshaft pulley.

DriveshaftAny shaft used to transmit

motion. Commonly used when referring to the

axleshafts on a front wheel drive vehicle.

Drum brakeA type of brake using a drum-

shaped metal cylinder attached to the inner

surface of the wheel. When the brake pedal is

pressed, curved brake shoes with friction

linings press against the inside of the drum to

slow or stop the vehicle.

EEGR valveA valve used to introduce exhaust

gases into the intake air stream.

Electronic control unit (ECU)A computer

which controls (for instance) ignition and fuel

injection systems, or an anti-lock braking

system. For more information refer to the

Haynes Automotive Electrical and Electronic

Systems Manual.

Electronic Fuel Injection (EFI)A computer

controlled fuel system that distributes fuel

through an injector located in each intake port

of the engine.

Emergency brakeA braking system,

independent of the main hydraulic system,

that can be used to slow or stop the vehicle if

the primary brakes fail, or to hold the vehicle

stationary even though the brake pedal isn’t

depressed. It usually consists of a hand lever

that actuates either front or rear brakes

mechanically through a series of cables and

linkages. Also known as a handbrake or

parking brake.EndfloatThe amount of lengthwise

movement between two parts. As applied to a

crankshaft, the distance that the crankshaft

can move forward and back in the cylinder

block.

Engine management system (EMS)A

computer controlled system which manages

the fuel injection and the ignition systems in

an integrated fashion.

Exhaust manifoldA part with several

passages through which exhaust gases leave

the engine combustion chambers and enter

the exhaust pipe.

F

Fan clutchA viscous (fluid) drive coupling

device which permits variable engine fan

speeds in relation to engine speeds.

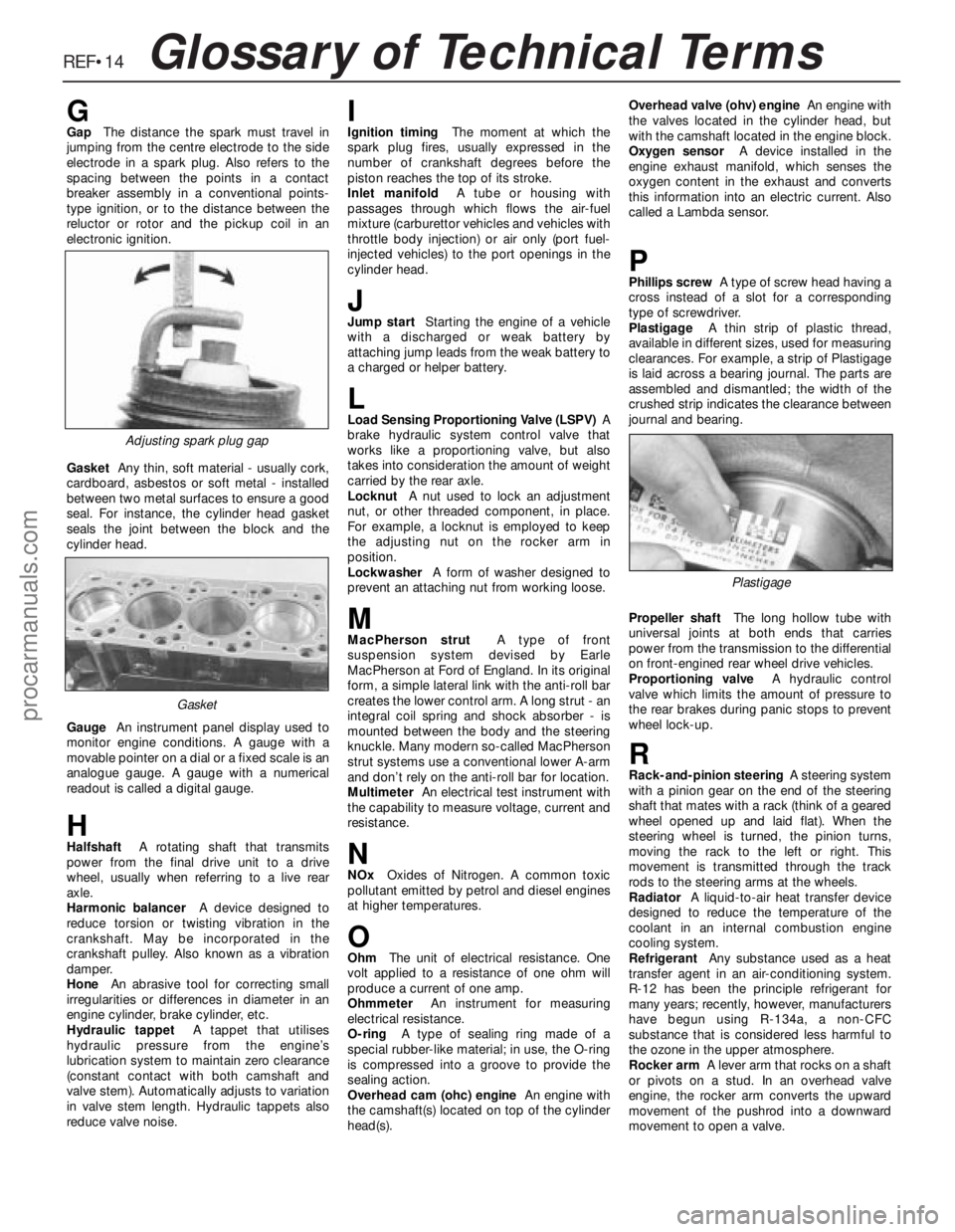

Feeler bladeA thin strip or blade of hardened

steel, ground to an exact thickness, used to

check or measure clearances between parts.

Firing orderThe order in which the engine

cylinders fire, or deliver their power strokes,

beginning with the number one cylinder.

Flywheel A heavy spinning wheel in which

energy is absorbed and stored by means of

momentum. On cars, the flywheel is attached

to the crankshaft to smooth out firing

impulses.

Free playThe amount of travel before any

action takes place. The “looseness” in a

linkage, or an assembly of parts, between the

initial application of force and actual

movement. For example, the distance the

brake pedal moves before the pistons in the

master cylinder are actuated.

FuseAn electrical device which protects a

circuit against accidental overload. The typical

fuse contains a soft piece of metal which is

calibrated to melt at a predetermined current

flow (expressed as amps) and break the

circuit.

Fusible linkA circuit protection device

consisting of a conductor surrounded by

heat-resistant insulation. The conductor is

smaller than the wire it protects, so it acts as

the weakest link in the circuit. Unlike a blown

fuse, a failed fusible link must frequently be

cut from the wire for replacement.Catalytic converter

Crankshaft assembly

Accessory drivebelts

Feeler blade

procarmanuals.com

Page 249 of 255

REF•14Glossary of Technical Terms

GGapThe distance the spark must travel in

jumping from the centre electrode to the side

electrode in a spark plug. Also refers to the

spacing between the points in a contact

breaker assembly in a conventional points-

type ignition, or to the distance between the

reluctor or rotor and the pickup coil in an

electronic ignition.

GasketAny thin, soft material - usually cork,

cardboard, asbestos or soft metal - installed

between two metal surfaces to ensure a good

seal. For instance, the cylinder head gasket

seals the joint between the block and the

cylinder head.

GaugeAn instrument panel display used to

monitor engine conditions. A gauge with a

movable pointer on a dial or a fixed scale is an

analogue gauge. A gauge with a numerical

readout is called a digital gauge.

HHalfshaftA rotating shaft that transmits

power from the final drive unit to a drive

wheel, usually when referring to a live rear

axle.

Harmonic balancerA device designed to

reduce torsion or twisting vibration in the

crankshaft. May be incorporated in the

crankshaft pulley. Also known as a vibration

damper.

HoneAn abrasive tool for correcting small

irregularities or differences in diameter in an

engine cylinder, brake cylinder, etc.

Hydraulic tappetA tappet that utilises

hydraulic pressure from the engine’s

lubrication system to maintain zero clearance

(constant contact with both camshaft and

valve stem). Automatically adjusts to variation

in valve stem length. Hydraulic tappets also

reduce valve noise.

IIgnition timingThe moment at which the

spark plug fires, usually expressed in the

number of crankshaft degrees before the

piston reaches the top of its stroke.

Inlet manifoldA tube or housing with

passages through which flows the air-fuel

mixture (carburettor vehicles and vehicles with

throttle body injection) or air only (port fuel-

injected vehicles) to the port openings in the

cylinder head.

JJump startStarting the engine of a vehicle

with a discharged or weak battery by

attaching jump leads from the weak battery to

a charged or helper battery.

LLoad Sensing Proportioning Valve (LSPV)A

brake hydraulic system control valve that

works like a proportioning valve, but also

takes into consideration the amount of weight

carried by the rear axle.

LocknutA nut used to lock an adjustment

nut, or other threaded component, in place.

For example, a locknut is employed to keep

the adjusting nut on the rocker arm in

position.

LockwasherA form of washer designed to

prevent an attaching nut from working loose.

MMacPherson strutA type of front

suspension system devised by Earle

MacPherson at Ford of England. In its original

form, a simple lateral link with the anti-roll bar

creates the lower control arm. A long strut - an

integral coil spring and shock absorber - is

mounted between the body and the steering

knuckle. Many modern so-called MacPherson

strut systems use a conventional lower A-arm

and don’t rely on the anti-roll bar for location.

MultimeterAn electrical test instrument with

the capability to measure voltage, current and

resistance.

NNOxOxides of Nitrogen. A common toxic

pollutant emitted by petrol and diesel engines

at higher temperatures.

OOhmThe unit of electrical resistance. One

volt applied to a resistance of one ohm will

produce a current of one amp.

OhmmeterAn instrument for measuring

electrical resistance.

O-ringA type of sealing ring made of a

special rubber-like material; in use, the O-ring

is compressed into a groove to provide the

sealing action.

Overhead cam (ohc) engineAn engine with

the camshaft(s) located on top of the cylinder

head(s).Overhead valve (ohv) engineAn engine with

the valves located in the cylinder head, but

with the camshaft located in the engine block.

Oxygen sensorA device installed in the

engine exhaust manifold, which senses the

oxygen content in the exhaust and converts

this information into an electric current. Also

called a Lambda sensor.

PPhillips screwA type of screw head having a

cross instead of a slot for a corresponding

type of screwdriver.

PlastigageA thin strip of plastic thread,

available in different sizes, used for measuring

clearances. For example, a strip of Plastigage

is laid across a bearing journal. The parts are

assembled and dismantled; the width of the

crushed strip indicates the clearance between

journal and bearing.

Propeller shaftThe long hollow tube with

universal joints at both ends that carries

power from the transmission to the differential

on front-engined rear wheel drive vehicles.

Proportioning valveA hydraulic control

valve which limits the amount of pressure to

the rear brakes during panic stops to prevent

wheel lock-up.

RRack-and-pinion steeringA steering system

with a pinion gear on the end of the steering

shaft that mates with a rack (think of a geared

wheel opened up and laid flat). When the

steering wheel is turned, the pinion turns,

moving the rack to the left or right. This

movement is transmitted through the track

rods to the steering arms at the wheels.

RadiatorA liquid-to-air heat transfer device

designed to reduce the temperature of the

coolant in an internal combustion engine

cooling system.

RefrigerantAny substance used as a heat

transfer agent in an air-conditioning system.

R-12 has been the principle refrigerant for

many years; recently, however, manufacturers

have begun using R-134a, a non-CFC

substance that is considered less harmful to

the ozone in the upper atmosphere.

Rocker armA lever arm that rocks on a shaft

or pivots on a stud. In an overhead valve

engine, the rocker arm converts the upward

movement of the pushrod into a downward

movement to open a valve.

Adjusting spark plug gap

Plastigage

Gasket

procarmanuals.com

Page 254 of 255

Q

Quarter window moulding - 12•10

R

Radiator - 3•3, 12•9

Radio fader light - 13•8

Radio or radio/cassette player - 13•20, 13•21

Rear light cluster - 13•5, 13•6

Recline motor - 13•15

Regulator mechanism - 12•9

Relays - 13•13

Respraying - 12•3

Reversing light switch - 7B•3, 13•12, 13•13

Ride height control - 11•12, 11•13

Road test - 1•16

Rocker shaft - 2C•12

Rotor arm - 5•5

Routine maintenance and servicing- 1•1et

seq

Rust holes or gashes in bodywork - 12•2

S

Safety first! - 0•5

Scalding - 0•5

Scratches in bodywork - 12•2

Screw threads and fastenings - REF•4

Seals and hoses - 1•19

Seat air cushion - 12•17

Seat belts - 0•12, 1•10, 12•17, 12•18

Seats - 0•12, 12•17, 12•18, 13•10, 13•13,

13•15

Selector rod - 7B•4

Servo - 10•12, 10•13, 13•20

Shock absorbers - 0•12, 0•13, 11•12

Short-circuit - 13•4

Side mouldings - 12•10

Sidelight - 13•4

Sliding roof - 12•5, 13•12, 13•16

Spare parts - 0•8

Spark plugs - 1•12, 5•5

Speakers - 13•21, 13•22

Speed control system components - 13•19,

13•20

Speedometer sender unit - 13•16

Spoiler - 12•11

Springs - 0•13, 11•11

Starter inhibitor/reversing light switch -

7B•3, 13•13

Starter motor - 5•4, 5•5

Starter motor noisy or excessively-rough in

engagement - REF•6

Starter motor turns engine slowly - REF•6

Steering and suspension - 0•12, 0•13, 1•15,

1•16, 11•1et seq,REF•10

Steering column- 0•11, 11•5

Steering gear - 11•3

Steering intermediate shaft and flexible

coupling - 11•6Steering play - REF•10

Steering rack bellows - 11•4

Steering stiff - REF•10

Steering wheel - 0•11, 11•4, 11•5

Steering wheel and column -

Stop-light switch - 13•12

Strut - 11•9, 11•10

Stub axle carrier - 11•7

Sump - 2A•9, 2A•16, 2B•15, 2C•9, 2C•19

Switch illumination lights - 13•8

Switches - 13•9, 13•11, 13•12, 13•13,

13•18, 13•19

T

Tailgate - 12•4, 12•7, 13•12, 13•18

Tailgate wash/wipe inoperative, or

unsatisfactory in operation - REF•11

Tailgate window mouldings - 12•10

Tappets - 2C•13

Temperature gauge gives false reading -

REF•11

Temperature gauge sender - 3•7

Thermostat - 3•3

Throttle body - 4•15

Throttle cable - 4•7

Throttle kicker - 4•13

Throttle pedal - 4•6

Throttle position sensor - 4•15

Timing belt - 2A•8, 2A•14, 2A•18

Timing chain - 2B•8, 2B•10, 2C•9, 2C•17

Tools and working facilities- REF•1et seq

Towing - 0•7

Track rod end - 11•6

Transmission fluid brown, or has burned

smell - REF•9

Transmission slips, shifts roughly, is noisy,

or has no drive in forward or reverse

gears - REF•9

Transmission will not downshift (kickdown)

with accelerator pedal fully depressed -

REF•9

Tyre wear - REF•10

Tyres - 0•14, 1•7

U

Ultrasonic sensor - 13•23

Underbody inspection - 1•15

Unleaded fuel - 4•23

V

Vacuum dump valve/switch - 13•19

Vacuum hoses - 2C•7

Vacuum line modification - 7B•4

Vacuum pull-down adjustment - 4•13

Vacuum pump - 13•20

Vacuum servo - 10•12, 10•13, 13•20

Valve block and pump assembly - 10•13

Valve clearances - 1•13, 2A•20, 2C•21Valve grinding - 2A•14

Vane airflow meter(s) - 4•16

Vanity mirror light - 13•7

Vapour separator - 4•7

Vehicle identification - 0•9, 0•12

Vehicle pulls to one side - REF•9, REF•10

Vehicle speed sensor - 5•12

Vibration damper (MT75type gearbox) - 8•4

Viscous-coupled fan - 3•5

W

Wandering or general instability - REF•10

Warning light bulbs - 13•18

Wash/wipe inoperative, or unsatisfactory in

operation - REF•11

Wash/wipe switch - 13•12

Washer fluid - 1•7, 13•19

Washer jets inoperative - REF•11

Washer pump fails to operate - REF•11

Washer pump runs for some time before

fluid is emitted from jets - REF•11

Water pump - 3•5

Water pump/alternator drivebelt - 3•7

Weatherstrip - 12•7

Weber 2V carburettor - 4•9, 4•10

Weber 2V TLD carburettor - 4•11, 4•12,

4•13

Wheel alignment - 11•7

Wheel bearings - 0•13, 11•8, 11•11

Wheel changing - 0•7

Wheel sensors - 10•12

Wheel stud - 11•11

Wheel wobble and vibration - REF•10

Wheels - 0•14, 1•10

Wheels locking under normal braking -

REF•10

Window frame mouldings - 12•10

Window glass - 12•8

Window glass fails to move - REF•11

Window glass slow to move - REF•11

Window glass will only move in one

direction - REF•11

Window operating motor - 13•15

Window operating switch - 13•12

Windscreen - 0•11, 12•9

Windscreen mouldings - 12•10

Windscreen, rear window and headlight

washer components - 13•17

Wiper arms and blades - 13•16

Wiper blades - 1•9

Wiper blades fail to clean the glass

effectively - REF•11

Wiper blades sweep over too large or too

small an area of the glass - REF•11

Wiper motor - 13•17

Wipers fail to operate, or operate very

slowly - REF•11

Wiring diagrams- WD•0 et seq

Working facilities - REF•3

IND•3Index

procarmanuals.com