belt FORD GRANADA 1985 Service Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 93 of 255

towards the engine and remove the old

drivebelt.

5Fit the new drivebelt, position the

compressor to achieve the correct belt tension

and tighten the strap and pivot bolts.

6Refit and secure the fan, when applicable,

and reconnect the battery.

7Recheck the belt tension after it has run for

at least 10 minutes under load.

Condenser fan and motor

8Disconnect the battery earth lead and

remove the radiator grille.

9Disconnect the fan wiring connector at the

right-hand side of the condenser.

10Remove the three securing bolts andremove the fan and motor(see illustration).

Turn the frame to position the fan wiring on the

dehydrator side to avoid damaging the wiring.

Take care also not to damage the condenser

fins or tube.

11Unclip the fan guard from the top of the

frame.

12To remove the fan blades from the motor,

remove the retaining nut and circlip. The nut

has a left-hand threadie it is undone

clockwise.

13With the blades removed, the motor can

be unscrewed from the frame.

14Reassemble and refit in the reverse order

of dismantling and removal.

De-ice thermostat

15Disconnect the battery negative lead.

16Disconnect the vacuum hoses from the

plenum chamber cover. Pull off the rubber seal

and remove the plenum chamber cover; it is

secured by four screws and one nut.

17Disconnect the thermostat from the

evaporator casing and remove it. Also remove

the thermostat probe.

18Refit by reversing the removal operations.

Heater water valve

19The heater water valve used with air

conditioning is vacuum-operated. It is located

on the right-hand side of the engine bay, near

the bulkhead. 20Drain the cooling system.

21Slacken the hose clips and detach the

coolant hoses from the valve, noting how they

are connected.

22Disconnect the vacuum hose from the top

of the valve.

23Unclip the valve from its bracket and

remove it.

24Refit by reversing the removal operations.

Refill the cooling system.

3•10Cooling, heating and ventilation systems

22.4 Air conditioning compressor adjuster

strap bolts (arrowed)22.10 Condenser fan securing bolts

(arrowed)

procarmanuals.com

Page 121 of 255

1Disconnect the battery negative (earth) lead.

2Disconnect the battery positive leads. These

may be protected by a plastic cover. Do not

allow the spanner to bridge the positive and

negative terminals.

3Release the battery hold-down clamp. Lift

out the battery. Keep it upright and be careful

not to drop it - it is heavy.

4Commence by placing the battery in its tray,

making sure it is the right way round. Secure it

with the hold-down clamp.

5Clean the battery terminals if necessary

then reconnect them. Connect the positive

lead first, then the negative lead.

1Should it appear that the alternator is not

charging the battery, check first that the

drivebelt is intact and in good condition and

that its tension is correct. Also check the

condition and security of the alternator

electrical connections and the battery leads.

2Accurate assessment of alternator output

requires special equipment and a degree of

skill. A rough idea of whether output is

adequate can be gained by using a voltmeter

(range 0 to 15 or 0 to 20 volts) as follows.

3Connect the voltmeter across the battery

terminals. Switch on the headlights and note

the voltage reading: it should be between 12

and 13 volts.

4Start the engine and run it at a fast idle

(approx 1500 rpm). Read the voltmeter: it

should indicate 13 to 14 volts.

5With the engine still running at a fast idle,

switch on as many electrical consumers as

possible (heated rear window, heater blower

etc). The voltage at the battery should be

maintained at 13 to 14 volts. Increase the

engine speed slightly if necessary to keep the

voltage up.

6If alternator output is low or zero, check the

brushes. If the brushes are OK, seek expert

advice.7Occasionally the condition may arise where

the alternator output is excessive. Clues to this

condition are constantly blowing bulbs;

brightness of lights vary considerably with

engine speed; overheating of alternator and

battery, possible with steam or fumes coming

from the battery. This condition is almost

certainly due to a defective voltage regulator,

but expert advice should be sought.

8Note that the alternator voltage regulator

can be renewed without removing the

alternator from the vehicle. The procedure is

part of brush renewal.

1Disconnect the battery negative lead.

2Disconnect the multi-plug from the rear of

the alternator. It may be secured by a wire clip.

3Slacken the alternator adjusting and pivot

nut(s), bolt(s)and washer(s)(see illustration).

Swing the alternator towards the engine and

slip the drivebelt(s) off the pulley.

4Support the alternator. Remove the

adjusting and pivot nuts, bolts and washers,

noting the fitted positions of the washers. Lift

out the alternator. Do not drop it, it is fragile.

5Refit by reversing the removal operations.

Tension the drivebelt(s) then tighten the

adjustment strap bolt followed by the pivot nut

and bolt. If there are two pivot bolts, tighten

the front one first.

6Refit the multi-plug and reconnect the

battery.

1The alternator brushes can be inspected or

renewed without removing the alternator from

the vehicle, but disconnect the battery

negative lead first.

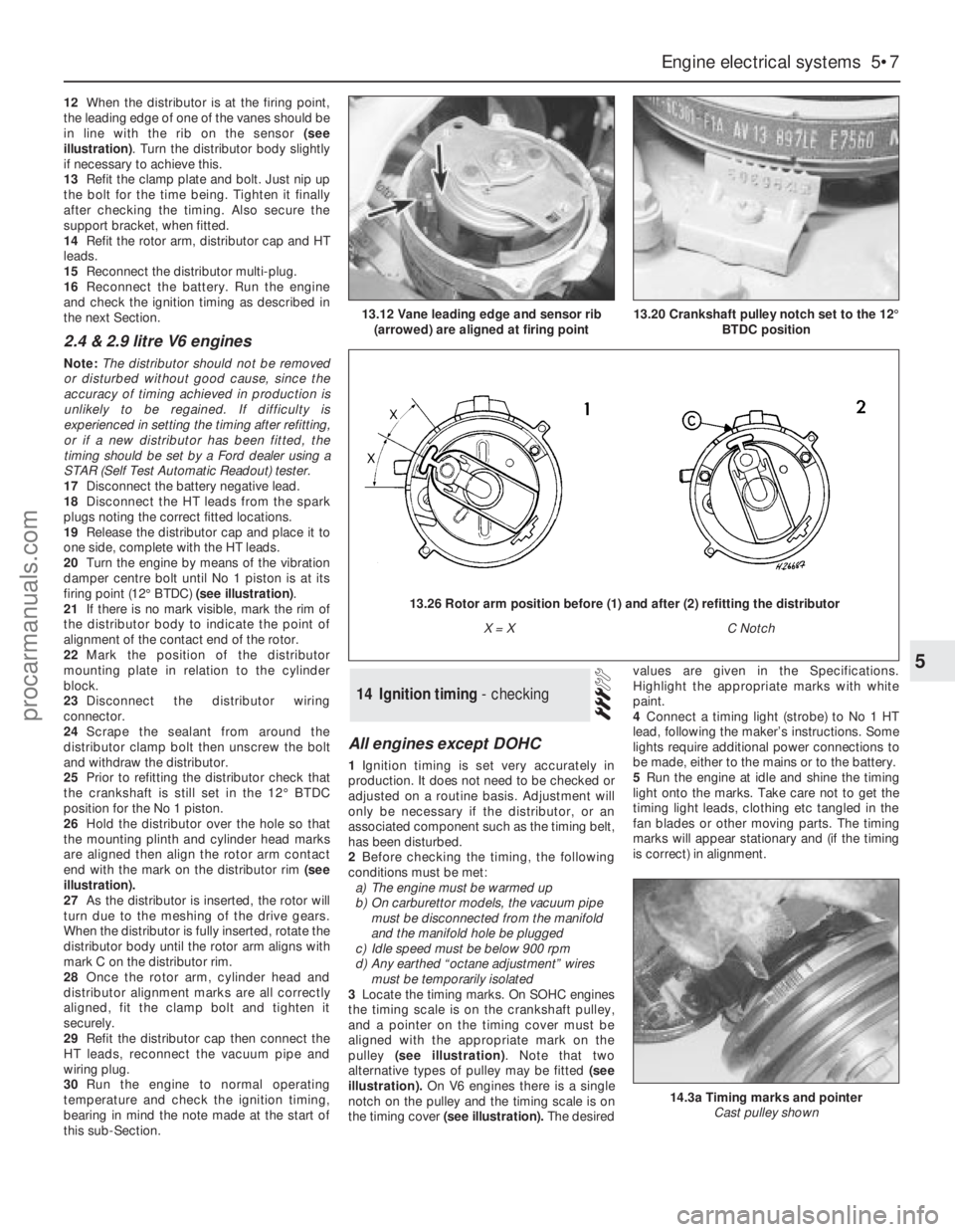

2From the rear of the alternator remove the

two screws which secure the voltage

regulator/brush carrier assembly. Withdraw

the assembly (see illustration).

3Measure the length of each brush

protruding from the carrier (see illustration). If

they are worn down to, or below, the minimumspecified, the old brushes will have to be

unsoldered and new ones soldered into place.

Some skill with a soldering iron will be

required; excess heat from the soldering iron

could damage the voltage regulator. When

fitted, the new brushes must move freely in

their holders.

4Clean the slip rings with a cloth moistened

with methylated spirit (see illustration). If they

are badly burnt or damaged, seek expert

advice.

5Refit the assembled brush carrier/voltage

regulator and secure it with the two screws. If

the alternator is on the vehicle, reconnect the

battery negative lead.

1If the starter motor fails to operate, first

check that the battery is charged by switching

on the headlights. If the headlights do not

come on, or rapidly become dim, the battery

or its connections are at fault.

2Check the security and condition of the

battery and starter solenoid connections.

Remember that the heavy lead to the solenoid

is always “live” - disconnect the battery

negative lead before using tools on the

solenoid connections.

8Starter motor - testing on the

vehicle7Alternator - brush renewal

6Alternator - removal and

refitting

5Alternator - testing on the

vehicle

4Battery - removal and refitting

5•4Engine electrical systems

7.3 Measuring brush protrusion7.4 Clean the slip rings (arrowed)

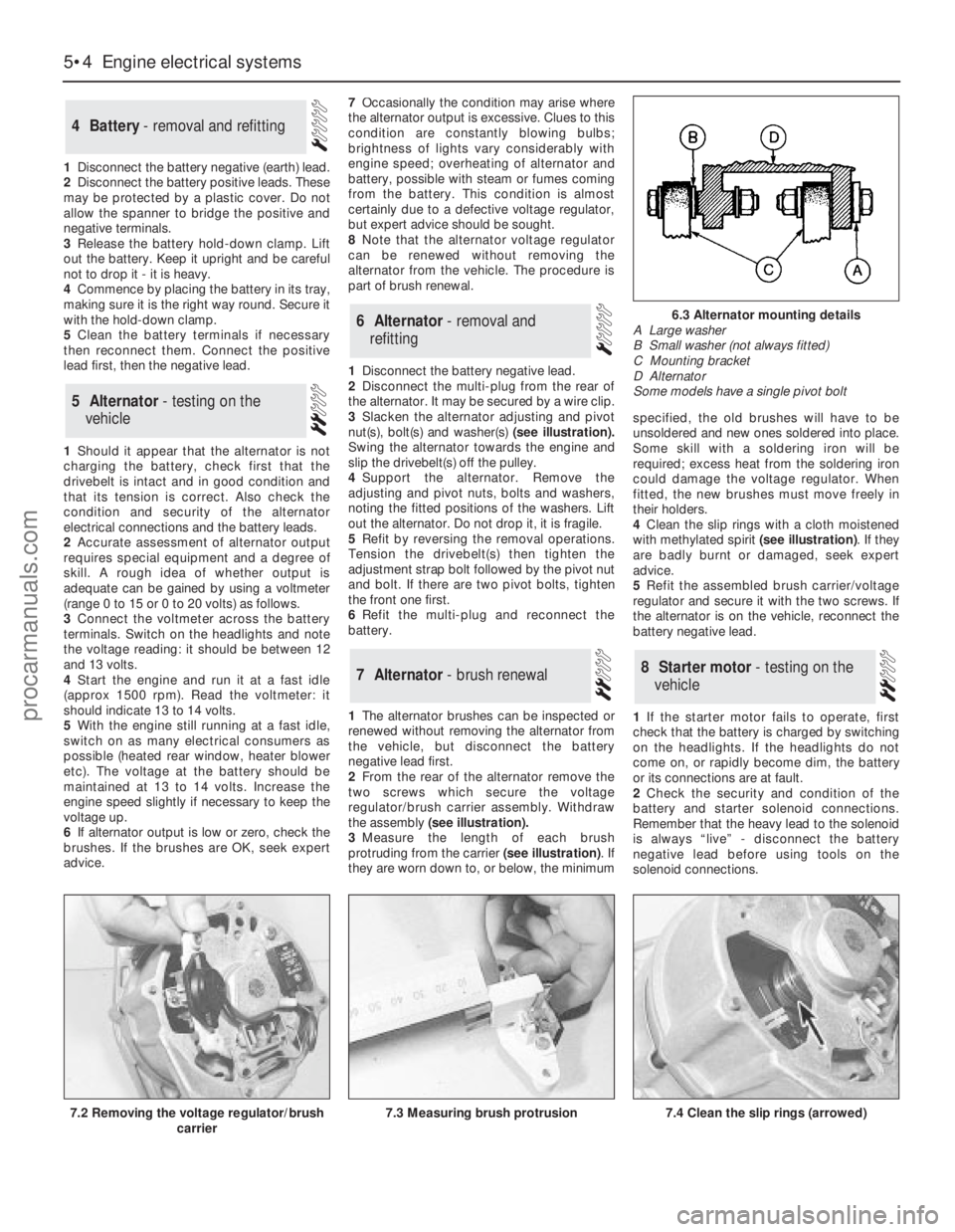

6.3 Alternator mounting details

A Large washer

B Small washer (not always fitted)

C Mounting bracket

D Alternator

Some models have a single pivot bolt

7.2 Removing the voltage regulator/brush

carrier

procarmanuals.com

Page 124 of 255

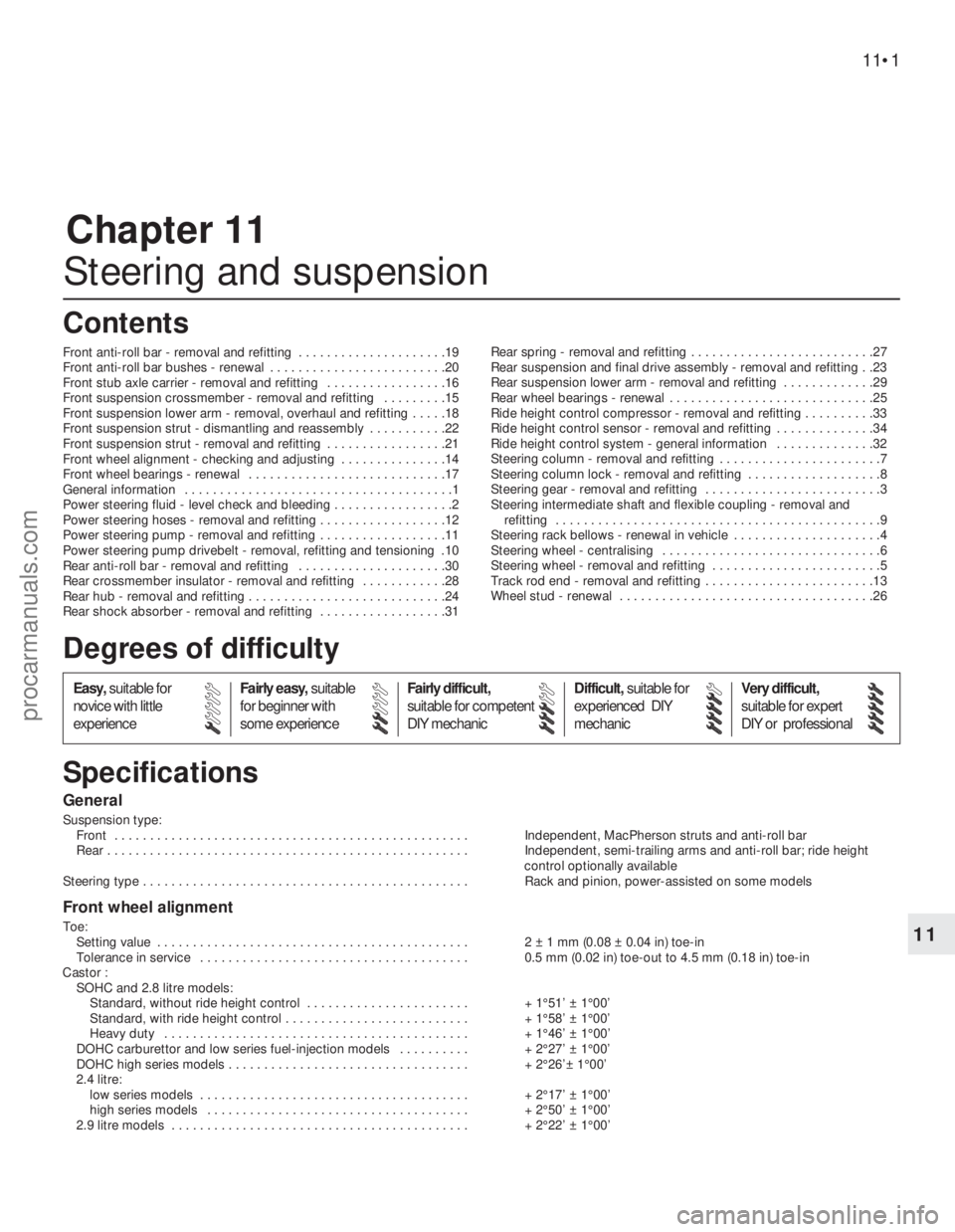

12When the distributor is at the firing point,

the leading edge of one of the vanes should be

in line with the rib on the sensor (see

illustration). Turn the distributor body slightly

if necessary to achieve this.

13Refit the clamp plate and bolt. Just nip up

the bolt for the time being. Tighten it finally

after checking the timing. Also secure the

support bracket, when fitted.

14Refit the rotor arm, distributor cap and HT

leads.

15Reconnect the distributor multi-plug.

16Reconnect the battery. Run the engine

and check the ignition timing as described in

the next Section.

2.4 & 2.9 litre V6 engines

Note: The distributor should not be removed

or disturbed without good cause, since the

accuracy of timing achieved in production is

unlikely to be regained. If difficulty is

experienced in setting the timing after refitting,

or if a new distributor has been fitted, the

timing should be set by a Ford dealer using a

STAR (Self Test Automatic Readout) tester.

17Disconnect the battery negative lead.

18Disconnect the HT leads from the spark

plugs noting the correct fitted locations.

19Release the distributor cap and place it to

one side, complete with the HT leads.

20Turn the engine by means of the vibration

damper centre bolt until No 1 piston is at its

firing point (12°BTDC) (see illustration).

21If there is no mark visible, mark the rim of

the distributor body to indicate the point of

alignment of the contact end of the rotor.

22Mark the position of the distributor

mounting plate in relation to the cylinder

block.

23Disconnect the distributor wiring

connector.

24Scrape the sealant from around the

distributor clamp bolt then unscrew the bolt

and withdraw the distributor.

25Prior to refitting the distributor check that

the crankshaft is still set in the 12°BTDC

position for the No 1 piston.

26Hold the distributor over the hole so that

the mounting plinth and cylinder head marks

are aligned then align the rotor arm contact

end with the mark on the distributor rim (see

illustration).

27As the distributor is inserted, the rotor will

turn due to the meshing of the drive gears.

When the distributor is fully inserted, rotate the

distributor body until the rotor arm aligns with

mark C on the distributor rim.

28Once the rotor arm, cylinder head and

distributor alignment marks are all correctly

aligned, fit the clamp bolt and tighten it

securely.

29Refit the distributor cap then connect the

HT leads, reconnect the vacuum pipe and

wiring plug.

30Run the engine to normal operating

temperature and check the ignition timing,

bearing in mind the note made at the start of

this sub-Section.

All engines except DOHC

1Ignition timing is set very accurately in

production. It does not need to be checked or

adjusted on a routine basis. Adjustment will

only be necessary if the distributor, or an

associated component such as the timing belt,

has been disturbed.

2Before checking the timing, the following

conditions must be met:

a)The engine must be warmed up

b)On carburettor models, the vacuum pipe

must be disconnected from the manifold

and the manifold hole be plugged

c)Idle speed must be below 900 rpm

d)Any earthed “octane adjustment” wires

must be temporarily isolated

3Locate the timing marks. On SOHC engines

the timing scale is on the crankshaft pulley,

and a pointer on the timing cover must be

aligned with the appropriate mark on the

pulley (see illustration). Note that two

alternative types of pulley may be fitted (see

illustration).On V6 engines there is a single

notch on the pulley and the timing scale is on

the timing cover (see illustration).The desiredvalues are given in the Specifications.

Highlight the appropriate marks with white

paint.

4Connect a timing light (strobe) to No 1 HT

lead, following the maker’s instructions. Some

lights require additional power connections to

be made, either to the mains or to the battery.

5Run the engine at idle and shine the timing

light onto the marks. Take care not to get the

timing light leads, clothing etc tangled in the

fan blades or other moving parts. The timing

marks will appear stationary and (if the timing

is correct) in alignment.

14Ignition timing - checking

Engine electrical systems 5•7

5

13.12 Vane leading edge and sensor rib

(arrowed) are aligned at firing point13.20 Crankshaft pulley notch set to the 12°

BTDC position

14.3a Timing marks and pointer

Cast pulley shown

13.26 Rotor arm position before (1) and after (2) refitting the distributor

X = XC Notch

procarmanuals.com

Page 144 of 255

Chapter 11

Steering and suspension

Front anti-roll bar - removal and refitting . . . . . . . . . . . . . . . . . . . . .19

Front anti-roll bar bushes - renewal . . . . . . . . . . . . . . . . . . . . . . . . .20

Front stub axle carrier - removal and refitting . . . . . . . . . . . . . . . . .16

Front suspension crossmember - removal and refitting . . . . . . . . .15

Front suspension lower arm - removal, overhaul and refitting . . . . .18

Front suspension strut - dismantling and reassembly . . . . . . . . . . .22

Front suspension strut - removal and refitting . . . . . . . . . . . . . . . . .21

Front wheel alignment - checking and adjusting . . . . . . . . . . . . . . .14

Front wheel bearings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Power steering fluid - level check and bleeding . . . . . . . . . . . . . . . . .2

Power steering hoses - removal and refitting . . . . . . . . . . . . . . . . . .12

Power steering pump - removal and refitting . . . . . . . . . . . . . . . . . .11

Power steering pump drivebelt - removal, refitting and tensioning .10

Rear anti-roll bar - removal and refitting . . . . . . . . . . . . . . . . . . . . .30

Rear crossmember insulator - removal and refitting . . . . . . . . . . . .28

Rear hub - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Rear shock absorber - removal and refitting . . . . . . . . . . . . . . . . . .31Rear spring - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . .27

Rear suspension and final drive assembly - removal and refitting . .23

Rear suspension lower arm - removal and refitting . . . . . . . . . . . . .29

Rear wheel bearings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Ride height control compressor - removal and refitting . . . . . . . . . .33

Ride height control sensor - removal and refitting . . . . . . . . . . . . . .34

Ride height control system - general information . . . . . . . . . . . . . .32

Steering column - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .7

Steering column lock - removal and refitting . . . . . . . . . . . . . . . . . . .8

Steering gear - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .3

Steering intermediate shaft and flexible coupling - removal and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Steering rack bellows - renewal in vehicle . . . . . . . . . . . . . . . . . . . . .4

Steering wheel - centralising . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Steering wheel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .5

Track rod end - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .13

Wheel stud - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

General

Suspension type:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Independent, MacPherson struts and anti-roll bar

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Independent, semi-trailing arms and anti-roll bar; ride height

control optionally available

Steering type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rack and pinion, power-assisted on some models

Front wheel alignment

Toe:

Setting value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 ± 1 mm (0.08 ± 0.04 in) toe-in

Tolerance in service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 mm (0.02 in) toe-out to 4.5 mm (0.18 in) toe-in

Castor :

SOHC and 2.8 litre models:

Standard, without ride height control . . . . . . . . . . . . . . . . . . . . . . . + 1°51’ ± 1°00’

Standard, with ride height control . . . . . . . . . . . . . . . . . . . . . . . . . . + 1°58’ ± 1°00’

Heavy duty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + 1°46’ ± 1°00’

DOHC carburettor and low series fuel-injection models . . . . . . . . . . + 2°27’ ± 1°00’

DOHC high series models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + 2°26’± 1°00’

2.4 litre:

low series models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + 2°17’ ± 1°00’

high series models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + 2°50’ ± 1°00’

2.9 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + 2°22’ ± 1°00’

11•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

11

procarmanuals.com

Page 149 of 255

3Depress the locking button with a small

screwdriver. Draw the lock barrel out of its

housing using the key (see illustration).

4Refit by reversing the removal operations.

1The intermediate shaft and flexible coupling

are not available separately, and so must be

renewed as a unit.

2Disconnect the battery negative lead.

3Position the steering straight-ahead.

4Remove the pinch-bolts which secure the

upper and lower ends of the intermediate

shaft. Free the universal joint from the column

shaft, then pull the flexible coupling off the

pinion shaft.

5When refitting, engage the master spline on

the pinion shaft with the groove in the flexible

coupling.

6Tighten the pinch-bolts to the specified

torque.

7Reconnect the battery.

Refer to Chapter 1, Section 21.

All engines except DOHC

1Disconnect the battery negative lead.

2Wipe clean around the unions, then

disconnect the high pressure and return pipes

from the pump and the reservoir. Be prepared

for fluid spillage; take steps to keep fluid out of

the alternator.

3Remove the pump drivebelt(s).

4Remove the pump mounting, pivot and

adjustment bolts (as applicable) and lift the

pump from the engine (see illustration).

5If a new pump is to be fitted, recover the

pulley and mounting plate from the old pump.6Refit by reversing the removal operations.

Adjust the drivebelt tension on completion and

bleed the steering hydraulic system.

DOHC engines

7The pump is mounted on a bracket on the

front right-hand side of the cylinder block. To

improve access to the pump, firmly apply the

handbrake then jack up the front of the car

and support it securely on axle stands (see

“Jacking”).

8Place a suitable container under the pump,

unscrew the fluid pipe unions, and drain the

fluid.

9Remove the drivebelt with reference to

Chapter 1.

10Prevent the pulley from rotating using a

strap wrench (which can be improvised using

an old drivebelt and a large socket and

wrench), and unscrew the three pulley

securing bolts (see illustration). Withdraw the

pulley.

11Unscrew the three pump securing bolts

from the front of the pump bracket, and the

single bolt from the rear of the bracket, and

withdraw the pump (see illustration).

12Refitting is a reversal of removal, bearing

in mind the following points:

a)Reconnect the fluid unions using new O-

rings.

b)On completion, top-up and bleed the

power steering fluid circuit.1Disconnect the battery negative lead.

2Clean around the hose unions on the

steering gear. Remove the single securing

bolt, withdraw the hoses and catch the fluid

which will drain from the reservoir.

3Clean around the hose unions on the pump.

Disconnect the unions and remove the hoses.

4Refit in the reverse order to removal, using

new O-rings.

5Top-up the steering fluid and bleed the

system.

1Slacken the front wheel nuts, raise and

support the vehicle and remove the front

wheel on the side concerned.

2Slacken the track rod end locknut by half a

turn.

3Remove the split pin from the track rod end

balljoint nut. Unscrew the nut a few turns (see

illustration).

4Break the balljoint taper with a proprietary

balljoint separator (see illustration). Remove

the separator and the nut and disengage the

track rod end from the steering arm.

5Unscrew the track rod end from the track

rod, being careful not to disturb the locknut.

13Track rod end - removal and

refitting

12Power steering hoses -

removal and refitting

11Power steering pump -

removal and refitting

10Power steering pump

drivebelt - removal, refitting

and tensioning

9Steering intermediate shaft

and flexible coupling - removal

and refitting

11•6Steering and suspension

8.3 Depress the column lock locking button

11.11 . . . for access to the front pump

securing bolts (arrowed)13.3 Track rod end balljoint nut unscrewed

11.4 Steering pump pivot bolt (arrowed) -

V6 model shown11.10 Unbolt the power steering pump

pulley . . .

procarmanuals.com

Page 158 of 255

Chapter 12

Bodywork and fittings

Bonnet - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Bonnet insulation panel - removal and refitting . . . . . . . . . . . . . . . .26

Bonnet release cable - removal and refitting . . . . . . . . . . . . . . . . . .11

Boot lid lock barrel - removal and refitting . . . . . . . . . . . . . . . . . . . .18

Boot lid - removal, refitting and adjustment . . . . . . . . . . . . . . . . . . . .9

Bumper mouldings - removal and refitting . . . . . . . . . . . . . . . . . . . .36

Bumpers - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Centre console - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .42

Door - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Door exterior handle - removal and refitting . . . . . . . . . . . . . . . . . .13

Door interior trim panel - removal and refitting . . . . . . . . . . . . . . . .22

Door latch assembly - removal and refitting . . . . . . . . . . . . . . . . . .15

Door lock barrel - removal and refitting . . . . . . . . . . . . . . . . . . . . . .14

Door striker plate - adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Door weatherstrip - removal and refitting . . . . . . . . . . . . . . . . . . . .16

Door window frame mouldings - removal and refitting . . . . . . . . . .31

Door window glass - removal and refitting . . . . . . . . . . . . . . . . . . . .23

Door window regulator mechanism - removal and refitting . . . . . . .24

Exterior mirror - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .39

Facia panels and trim - removal and refitting . . . . . . . . . . . . . . . . . .41

Front bumper - height adjustment . . . . . . . . . . . . . . . . . . . . . . . . . .34

Front seat - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Front seat air cushion - removal and refitting . . . . . . . . . . . . . . . . .45

Front seat belts - removal and refitting . . . . . . . . . . . . . . . . . . . . . .47

Front spoiler - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .37Fuel filler lock barrel - removal and refitting . . . . . . . . . . . . . . . . . . .21

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Headlining - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . .38

Interior mirror - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .40

Maintenance - bodywork and underframe . . . . . . . . . . . . . . . . . . . . .2

Maintenance - upholstery and carpets . . . . . . . . . . . . . . . . . . . . . . . .3

Major body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Minor body damage - repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Motifs and emblems - removal and refitting . . . . . . . . . . . . . . . . . .33

Overhead console - removal and refitting . . . . . . . . . . . . . . . . . . . .43

Radiator grille - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .27

Rear parcel shelf - removal and refitting . . . . . . . . . . . . . . . . . . . . .50

Rear quarter window moulding - removal and refitting . . . . . . . . . .32

Rear seat belts - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .48

Rear seat components - removal and refitting . . . . . . . . . . . . . . . . .49

Seat belts - care and maintenance . . . . . . . . . . . . . . . . . . . . . . . . .46

Side mouldings - removal and refitting . . . . . . . . . . . . . . . . . . . . . .28

Sliding roof - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . .10

Tailgate - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Tailgate latch assembly - removal and refitting . . . . . . . . . . . . . . . .19

Tailgate lock barrel - removal and refitting . . . . . . . . . . . . . . . . . . . .17

Tailgate strut - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .20

Tailgate window mouldings - removal and refitting . . . . . . . . . . . . .30

Windscreen and fixed glass - removal and refitting . . . . . . . . . . . . .25

Windscreen mouldings - removal and refitting . . . . . . . . . . . . . . . .29

Torque wrench settingsNm lbf ft

Front seat belt buckle to seat frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51 to 64 38 to 47

Seat belt retractor bolts (front and rear) . . . . . . . . . . . . . . . . . . . . . . . . . 25 to 45 18 to 33

Other seat belt anchorages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 to 45 18 to 33

Rear seat back hinge to body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 to 25 16 to 18

Rear seat back latch striker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 to 60 30 to 44

Front seat retaining bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 to 32 18 to 24

Front seat frame-to-slide bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 to 32 18 to 24

Rear bumper mountings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 16

Front bumper adjuster lockbolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 16

12•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

12

The bodyshell and floorpan are of pressed

steel, and form an integral part of the vehicle’s

structure. Various reinforcing and mounting

components beneath the floorpan are made of

HSLA (High Strength Low Alloy) and REPHOS

(rephosphorised) steels, which have superiorstrength-to-weight characteristics when

compared with conventional steels.

Extensive use is made of plastic for

peripheral components such as the radiator

grille, bumpers and wheel trims, and for much

of the interior trim.

Interior fittings are to the high standard

expected in a vehicle of this class, with even

the basic level models well equipped. A wide

range of options is available, including air

conditioning and leather upholstery.The general condition of a vehicle’s

bodywork is the one thing that significantly

affects its value. Maintenance is easy, but

needs to be regular. Neglect, particularly after

minor damage, can lead quickly to further

deterioration and costly repair bills. It is

2 Maintenance - bodywork and

underframe1 General information

procarmanuals.com

Page 174 of 255

19Slacken and remove the two switch panel

retaining screws then carefully slide the panel

up over the handbrake lever until the switch

wiring connectors can be accessed (see

illustrations). Disconnect the wiring

connectors from all the switches, then release

the loom from any relevant retaining clips and

manoeuvre the switch panel off the handbrake

lever.

20Slacken and remove the seven centre

console retaining screws (two at the front, one

on each side and three at the rear) then lift up

the console and disconnect the wiring

connector from the rear cigarette lighter.

Remove the console assembly from the car

(see illustrations).

21Refitting is a reverse of the removal

procedure.

1Disconnect the battery negative lead.

2Remove the interior light by carefully prising

it out of the console and disconnecting it.

3Remove the sliding roof control handle or

switches (as applicable).

4Remove the two retaining screws from the

front of the console. Pull the front of the

console down and then slide the assembly

rearwards to release it from the two clips (see

illustrations). These clips may be quite tight.

Disconnect the clock.

5Refit by reversing the removal operations.1Move the seat rearwards as far as possible,

then remove the two front retaining bolts (see

illustration).

2Disconnect the assist spring from under the

driver’s seat. (Moving the seat forwards will

reduce the tension on this spring, but also

makes it harder to get at.)

3When applicable, disconnect the seat

heating and/or adjustment motor multi-plugs.

4Move the seat fully forwards and remove the

three rear retaining bolts. These bolts are

under plastic covers (see illustrations).

5Lift out the seat, complete with adjustment

mechanism and seat belt buckle.

6If a new seat is being fitted, transfer the

adjustment mechanism and other components

to it.

7Refit by reversing the removal operations.

Tighten the seat retaining bolts to the

specified torque.

1Remove the front seat as described in the

previous Section.

2Remove the side trim pieces from the seat.

Free the air tube by removing Its two securing

screws.

3Separate the backrest from the base of theseat by removing the four retaining bolts.

4Remove the backrest cover by unbending

its retaining tags and sliding it off.

5Expose the air cushion by lifting up the foam

padding. Cut the hog rings (wire loops) which

secure the corners of the cushion and remove

it with the air hoses.

6When refitting, use new hog rings. Position

the cut-out in the cushion level with the

second spring in the backrest.

7The remainder of refitting is a reversal of the

removal procedure.

1All models are fitted with inertia reel front

seat belts as standard. Rear seat belts are

available as an extra.

2Maintenance is limited to periodic

inspection of the belts for fraying or other

damage. Also check the operation of the

buckles and retractor mechanisms. In case of

damage or malfunction the belt must be

renewed.

3If it is wished to clean the belts, use only an

approved upholstery cleaner or a weak

solution of detergent, followed by rinsing with

water. Do not use solvents, strong detergents,

dyes or bleaches. Keep the belt extended until

it is dry.

4Belts which have been subjected to impact

loads must be renewed.

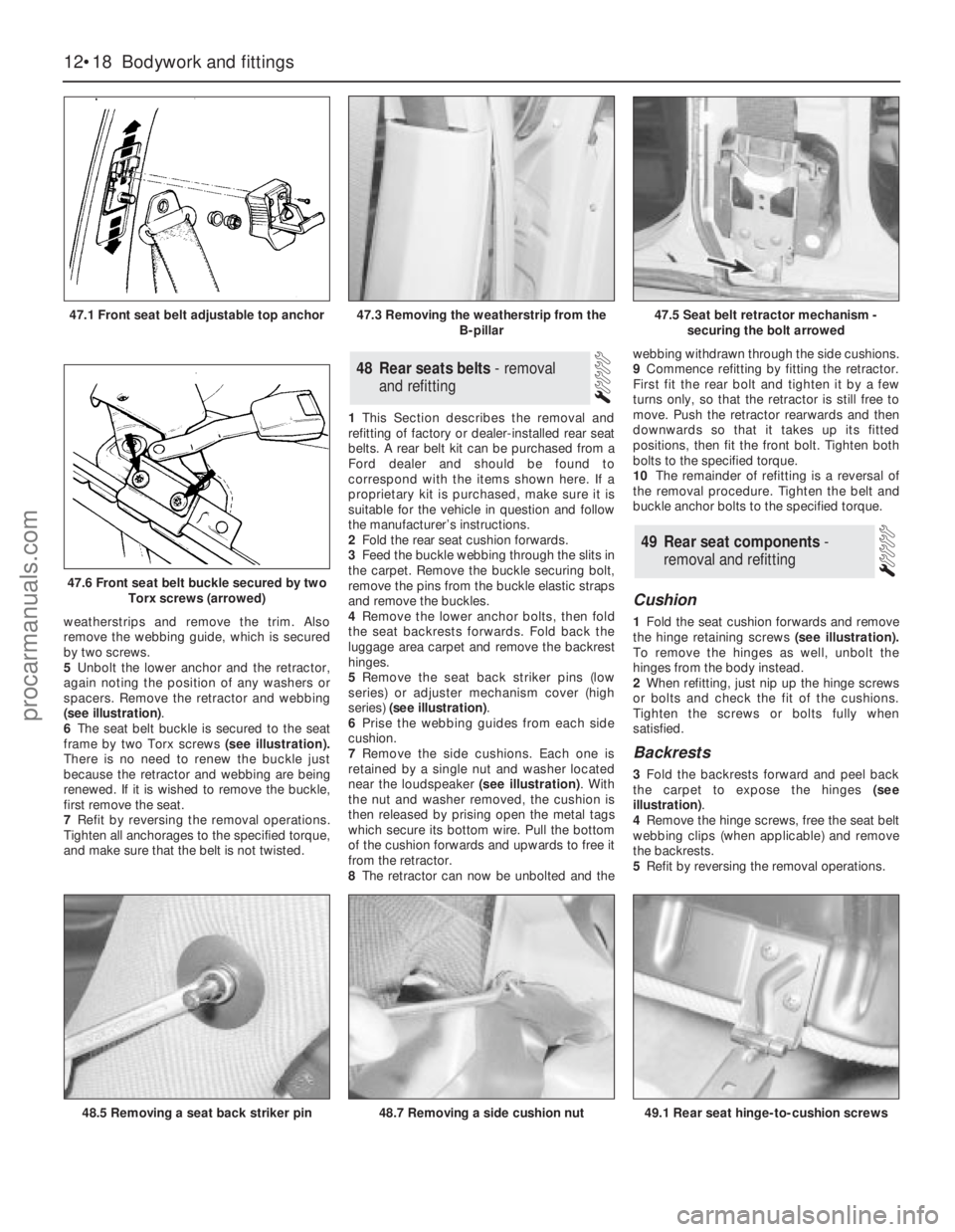

1Remove the cover from the belt top anchor.

With the adjustable type of anchor(see

illustration)the cover is removed by levering

out the adjuster button and removing two

screws.

2Remove the anchor bolt or nut and detach

the seat belt runner from it. Note the position

of any washers or spacers.

3Carefully pull out the door aperture

weatherstrips (front and rear) from the B-pillar

(see illustration). Unclip the pillar trim.

4Remove the screws which secure the

retractor cover trim, pull away more of the

47Front seats belts - removal

and refitting

46Seat belts - care and

maintenance

45Front seat air cushion -

removal and refitting

44Front seat - removal and

refitting

43Overhead console - removal

and refitting

Bodywork and fittings 12•17

12

43.4a One of the overhead console

retaining screws43.4b Slide the console rearwards to

release the clips (arrowed)44.1 Removing a front seat retaining bolt

44.4a Front seat outboard rear retaining

bolt44.4b The other two rear retaining bolts are

under the cover

procarmanuals.com

Page 175 of 255

weatherstrips and remove the trim. Also

remove the webbing guide, which is secured

by two screws.

5Unbolt the lower anchor and the retractor,

again noting the position of any washers or

spacers. Remove the retractor and webbing

(see illustration).

6The seat belt buckle is secured to the seat

frame by two Torx screws(see illustration).

There is no need to renew the buckle just

because the retractor and webbing are being

renewed. If it is wished to remove the buckle,

first remove the seat.

7Refit by reversing the removal operations.

Tighten all anchorages to the specified torque,

and make sure that the belt is not twisted.1This Section describes the removal and

refitting of factory or dealer-installed rear seat

belts. A rear belt kit can be purchased from a

Ford dealer and should be found to

correspond with the items shown here. If a

proprietary kit is purchased, make sure it is

suitable for the vehicle in question and follow

the manufacturer’s instructions.

2Fold the rear seat cushion forwards.

3Feed the buckle webbing through the slits in

the carpet. Remove the buckle securing bolt,

remove the pins from the buckle elastic straps

and remove the buckles.

4Remove the lower anchor bolts, then fold

the seat backrests forwards. Fold back the

luggage area carpet and remove the backrest

hinges.

5Remove the seat back striker pins (low

series) or adjuster mechanism cover (high

series) (see illustration).

6Prise the webbing guides from each side

cushion.

7Remove the side cushions. Each one is

retained by a single nut and washer located

near the loudspeaker (see illustration). With

the nut and washer removed, the cushion is

then released by prising open the metal tags

which secure its bottom wire. Pull the bottom

of the cushion forwards and upwards to free it

from the retractor.

8The retractor can now be unbolted and thewebbing withdrawn through the side cushions.

9Commence refitting by fitting the retractor.

First fit the rear bolt and tighten it by a few

turns only, so that the retractor is still free to

move. Push the retractor rearwards and then

downwards so that it takes up its fitted

positions, then fit the front bolt. Tighten both

bolts to the specified torque.

10The remainder of refitting is a reversal of

the removal procedure. Tighten the belt and

buckle anchor bolts to the specified torque.

Cushion

1Fold the seat cushion forwards and remove

the hinge retaining screws (see illustration).

To remove the hinges as well, unbolt the

hinges from the body instead.

2When refitting, just nip up the hinge screws

or bolts and check the fit of the cushions.

Tighten the screws or bolts fully when

satisfied.

Backrests

3Fold the backrests forward and peel back

the carpet to expose the hinges (see

illustration).

4Remove the hinge screws, free the seat belt

webbing clips (when applicable) and remove

the backrests.

5Refit by reversing the removal operations.

49Rear seat components -

removal and refitting

48Rear seats belts - removal

and refitting

12•18Bodywork and fittings

47.1 Front seat belt adjustable top anchor

47.6 Front seat belt buckle secured by two

Torx screws (arrowed)

48.5 Removing a seat back striker pin49.1 Rear seat hinge-to-cushion screws48.7 Removing a side cushion nut

47.3 Removing the weatherstrip from the

B-pillar47.5 Seat belt retractor mechanism -

securing the bolt arrowed

procarmanuals.com

Page 176 of 255

Backrest catch

6Fold the backrest forwards. Remove the

catch cover, which is secured by two screws

(see illustration).

7Remove the two Torx screws which secure

the catch. Unhook the operating rod from the

catch and remove it.

8The operating rod and button can now be

withdrawn if wished. When refitting, position

the rod with the hooked end facing inwards.

9Refit the catch, engage it with the operating

rod and secure it with the Torx screws.

10Refit and secure the catch cover. Check

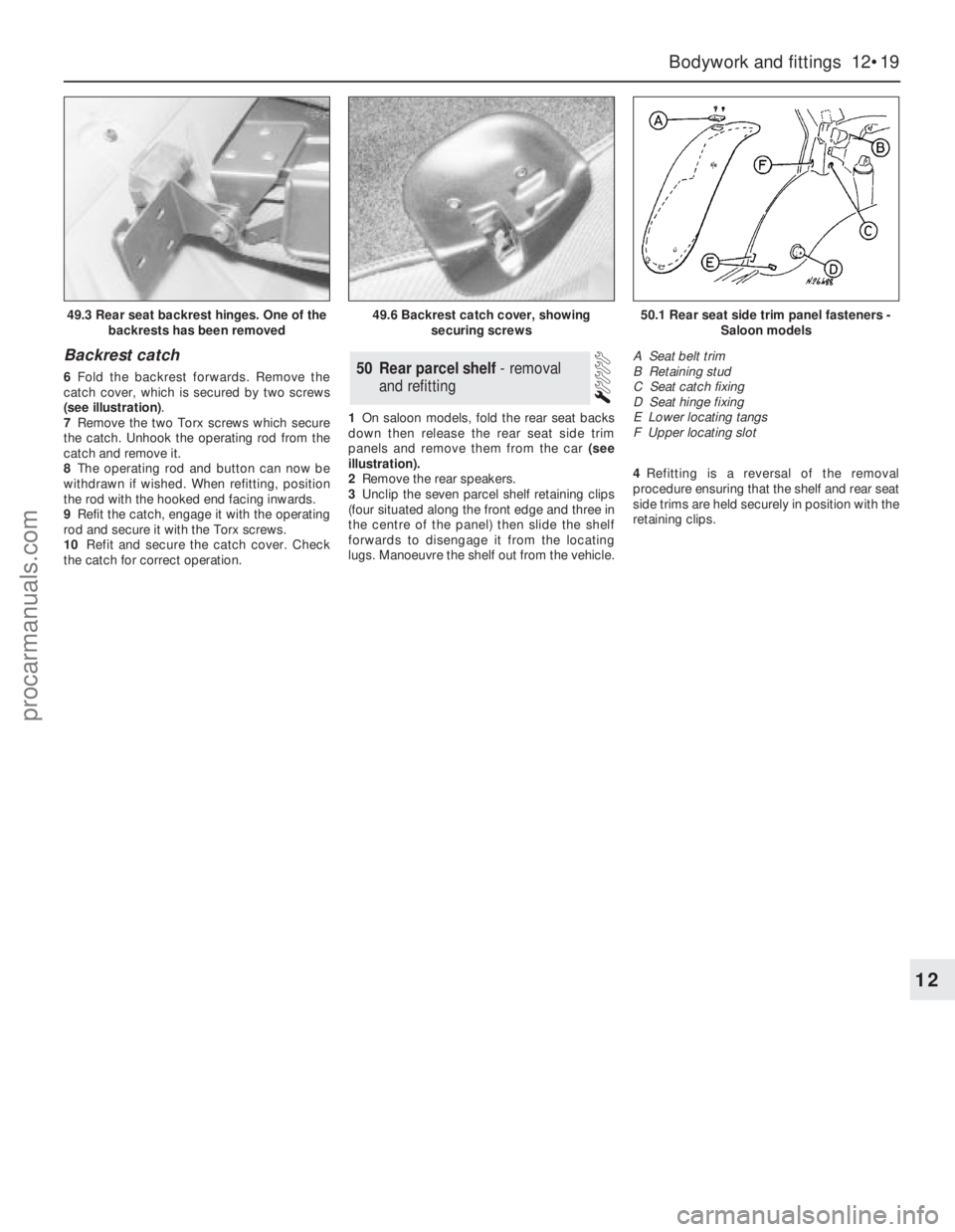

the catch for correct operation.1On saloon models, fold the rear seat backs

down then release the rear seat side trim

panels and remove them from the car (see

illustration).

2Remove the rear speakers.

3Unclip the seven parcel shelf retaining clips

(four situated along the front edge and three in

the centre of the panel) then slide the shelf

forwards to disengage it from the locating

lugs. Manoeuvre the shelf out from the vehicle.4Refitting is a reversal of the removal

procedure ensuring that the shelf and rear seat

side trims are held securely in position with the

retaining clips.50Rear parcel shelf - removal

and refitting

Bodywork and fittings 12•19

12

49.3 Rear seat backrest hinges. One of the

backrests has been removed49.6 Backrest catch cover, showing

securing screws50.1 Rear seat side trim panel fasteners -

Saloon models

A Seat belt trim

B Retaining stud

C Seat catch fixing

D Seat hinge fixing

E Lower locating tangs

F Upper locating slot

procarmanuals.com

Page 179 of 255

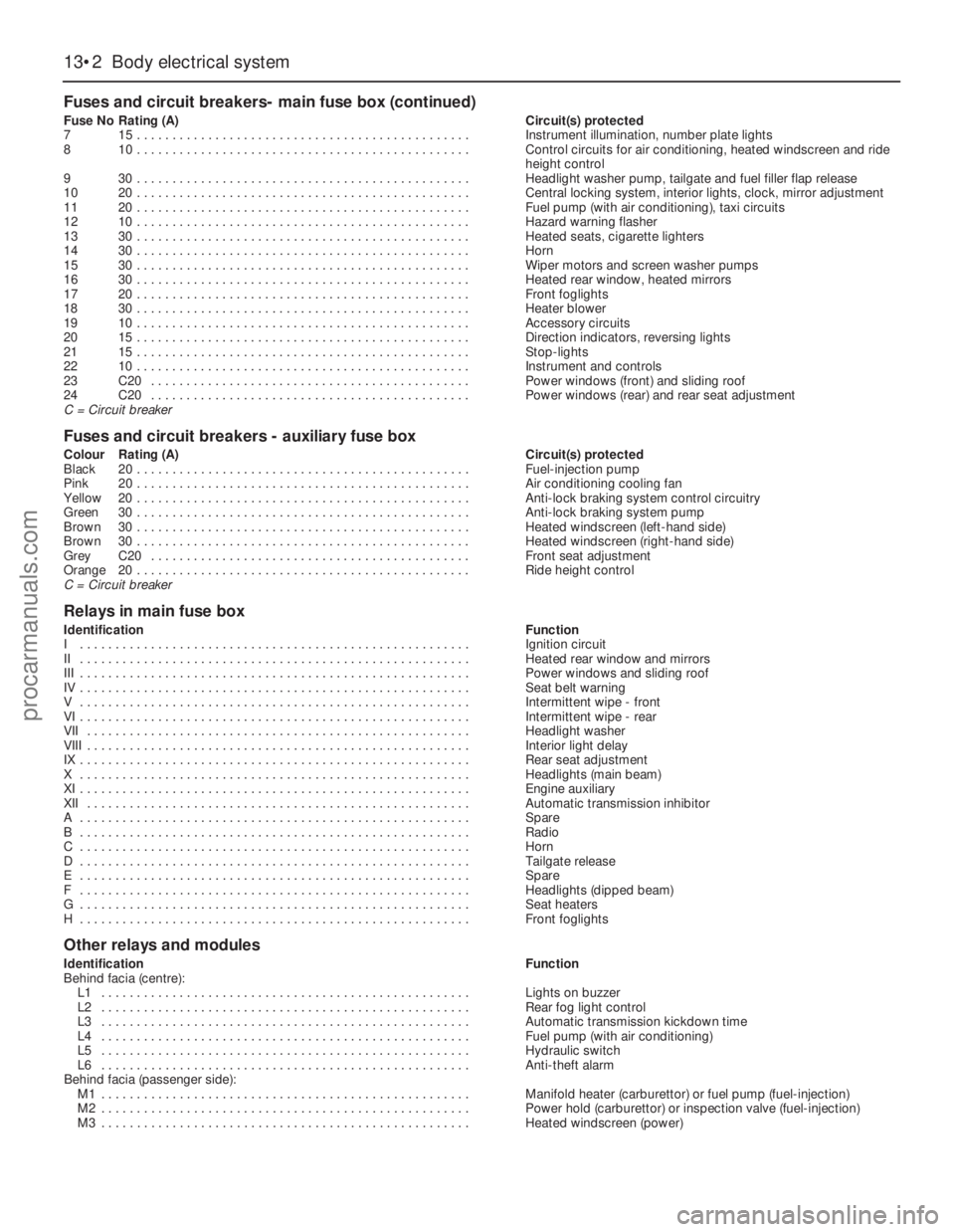

13•2Body electrical system

Fuses and circuit breakers- main fuse box (continued)

Fuse NoRating (A)Circuit(s) protected

715 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Instrument illumination, number plate lights

810 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Control circuits for air conditioning, heated windscreen and ride

height control

930 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Headlight washer pump, tailgate and fuel filler flap release

1020 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Central locking system, interior lights, clock, mirror adjustment

1120 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fuel pump (with air conditioning), taxi circuits

1210 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Hazard warning flasher

1330 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Heated seats, cigarette lighters

1430 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Horn

1530 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Wiper motors and screen washer pumps

1630 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Heated rear window, heated mirrors

1720 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Front foglights

1830 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Heater blower

1910 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Accessory circuits

2015 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Direction indicators, reversing lights

2115 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Stop-lights

2210 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Instrument and controls

23C20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Power windows (front) and sliding roof

24C20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Power windows (rear) and rear seat adjustment

C = Circuit breaker

Fuses and circuit breakers - auxiliary fuse box

Colour Rating (A)Circuit(s) protected

Black20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fuel-injection pump

Pink20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Air conditioning cooling fan

Yellow20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Anti-lock braking system control circuitry

Green30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Anti-lock braking system pump

Brown30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Heated windscreen (left-hand side)

Brown30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Heated windscreen (right-hand side)

GreyC20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Front seat adjustment

Orange20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Ride height control

C = Circuit breaker

Relays in main fuse box

IdentificationFunction

I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Ignition circuit

II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Heated rear window and mirrors

III . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Power windows and sliding roof

IV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Seat belt warning

V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Intermittent wipe - front

VI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Intermittent wipe - rear

VII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Headlight washer

VIII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Interior light delay

IX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Rear seat adjustment

X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Headlights (main beam)

XI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Engine auxiliary

XII . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Automatic transmission inhibitor

A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Spare

B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Radio

C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Horn

D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tailgate release

E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Spare

F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Headlights (dipped beam)

G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Seat heaters

H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Front foglights

Other relays and modules

IdentificationFunction

Behind facia (centre):

L1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Lights on buzzer

L2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Rear fog light control

L3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Automatic transmission kickdown time

L4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fuel pump (with air conditioning)

L5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Hydraulic switch

L6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Anti-theft alarm

Behind facia (passenger side):

M1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Manifold heater (carburettor) or fuel pump (fuel-injection)

M2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Power hold (carburettor) or inspection valve (fuel-injection)

M3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Heated windscreen (power)

procarmanuals.com