auxiliary battery location FORD GRANADA 1985 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 7 of 255

1•6Maintenance Procedures

This Chapter is designed to help the home

mechanic maintain his/her vehicle for safety,

economy, long life and peak performance.

The Chapter contains a master maintenance

schedule, followed by Sections dealing

specifically with each task in the schedule.

Visual checks, adjustments, component

renewal and other helpful items are included.

Refer to the accompanying illustrations of the

engine compartment and the underside of the

vehicle for the locations of the various

components.

Servicing your vehicle in accordance with

the mileage/time maintenance schedule and

the following Sections will provide a planned

maintenance programme, which should result

in a long and reliable service life. This is a

comprehensive plan, so maintaining some

items but not others at the specified service

intervals, will not produce the same results.

As you service your vehicle, you will

discover that many of the procedures can -

and should - be grouped together, because of

the particular procedure being performed, or

because of the close proximity of two

otherwise-unrelated components to one

another. For example, if the vehicle is raised

for any reason, the exhaust can be inspected

at the same time as the suspension and

steering components.

The first step in this maintenanceprogramme is to prepare yourself before the

actual work begins. Read through all the

Sections relevant to the work to be carried out,

then make a list and gather together all the

parts and tools required. If a problem is

encountered, seek advice from a parts

specialist, or a dealer service department.

If, from the time the vehicle is new, the

routine maintenance schedule is followed

closely, and frequent checks are made of fluid

levels and high-wear items, as suggested

throughout this manual, the engine will be kept

in relatively good running condition, and the

need for additional work will be minimised.

It is possible that there will be times when

the engine is running poorly due to the lack of

regular maintenance. This is even more likely if

a used vehicle, which has not received regular

and frequent maintenance checks, is

purchased. In such cases, additional work

may need to be carried out, outside of the

regular maintenance intervals.

If engine wear is suspected, a compression

test will provide valuable information regarding

the overall performance of the main internal

components. Such a test can be used as a

basis to decide on the extent of the work to be

carried out. If, for example, a compression test

indicates serious internal engine wear,

conventional maintenance as described in this

Chapter will not greatly improve theperformance of the engine, and may prove a

waste of time and money, unless extensive

overhaul work is carried out first.

The following series of operations are those

most often required to improve the

performance of a generally poor-running

engine:

Primary operations

a)Clean, inspect and test the battery

(Section 6)

b)Check all the engine-related fluids

(Section 3).

c)Check the condition and tension of the

auxiliary drivebelt (Section 21).

d)Renew the spark plugs (Section 20).

e)Inspect the distributor cap, rotor arm and

HT leads - as applicable (Chapter 5).

f)Check the condition of the air cleaner filter

element, and renew if necessary (Section 38).

g)Renew the fuel filter (Section 41).

h)Check the condition of all hoses, and

check for fluid leaks (Section 10).

i)Check the idle speed and mixture settings

- as applicable (Chapter 4).

If the above operations do not prove fully

effective, carry out the following secondary

operations:

Secondary operations

a)Check the charging system (Chapter 5).

b)Check the ignition system (Chapter 5).

c)Check the fuel system (Chapter 4).

d)Renew the distributor cap and rotor arm -

as applicable (Chapter 5).

f)Renew the ignition HT leads - as

applicable (Chapter 5).

2Intensive maintenance

1Introduction

Engine oil

1Check the oil level as follows.

2With the vehicle parked on level ground,

and with the engine having been stopped for a

few minutes, open and prop the bonnet.

Withdraw the dipstick, wipe it on a clean ragand re-insert it fully. Withdraw it again and

read the oil level relative to the marks on the

end of the stick (see illustration).

3The oil level should be in between the MAX

and MIN marks on the dipstick. If it is at or

below the MIN mark, top-up (via the oil filler

cap) without delay. The quantity of oil required

to raise the lever from MIN to MAX on the

dipstick is approximately 1 litre. Do not overfill

(see illustration).

4The rate of oil consumption depends onleaks and on the quantity of oil burnt. External

leakage should be obvious. Oil which is burnt

may enter the combustion chambers through

the valve guides or past the piston rings;

excessive blow-by past the rings can also

force oil out via the crankcase ventilation

system. Driving conditions also affect oil

consumption.

5Always use the correct grade and type of oil

as shown in “Lubricants and fluids”.

Coolant

6Check the coolant level as follows.

7Open and prop the bonnet. Observe the

level of coolant through the translucent walls

of the expansion tank (on the right-hand side

of the engine bay). The level should be up to

the MAX mark when the engine is cold, and

may be somewhat above the mark when hot.

8If topping-up is necessary, wait for the

system to cool down if it is hot. Place a thick

rag over the expansion tank cap and slacken it

3Fluid level checks

3.2 Dipstick markings3.3 Topping up the engine oil

Warning: DO NOT remove the

expansion tank pressure cap

when the engine is hot, as there

is a great risk of scalding.

Weekly checks

procarmanuals.com

Page 28 of 255

The cylinder head is of crossflow design

with the inlet manifold mounted on the left-

hand side and the exhaust manifold mounted

on the right-hand side.

Lubrication is by means of a bi-rotor pump

which draws oil through a strainer located

inside the sump, and forces it through a full-

flow filter into the engine oil galleries where it

is distributed to the crankshaft, camshaft and

auxiliary shaft. The big-end bearings are

supplied with oil via internal drillings in the

crankshaft.The undersides of the pistons are

supplied with oil from drillings in the big-ends.

The distributor shaft is intermittently supplied

with oil from the drilled auxiliary shaft. The

camshaft and cam followers are supplied with

oil via a drilled spray tube from the centre

camshaft bearing.

A semi-closed crankcase ventilation system

is employed whereby piston blow-by gases

are drawn into the inlet manifold via an oil

separator and on carburettor models a control

valve.

The following operations can be carried out

without removing the engine, although the

work may be easier and quicker with the

engine removed:

a)Removal and refitting of the cylinder head

b)Removal and refitting of the camshaft

(after removing the cylinder head)

c)Removal and refitting of the timing belt

and sprockets

d)Removal and refitting of the sump and oil

pump

e)Removal and refitting of the pistons,

connecting rods and big-end bearings

f)Renewal of the engine mountings

g)Renewal of the crankshaft oil seals

h)Removal and refitting of the auxiliary shaft

j)Removal and refitting of the flywheel

The engine must be removed from the

vehicle for the following operations:

a)Renewal of the crankshaft main bearings

b)Removal and refitting of the crankshaft

The engine may be lifted out either on its

own or together with the gearbox. Unless work

is also necessary on the gearbox it is

recommended that the engine is removed on

its own. Where automatic transmission is

fitted, the engine should be removed on its

own owing to the additional weight. If the

engine and gearbox are removed together,

they will have to be tilted at a very steep angle;

make sure that the range of the lifting tackle is

adequate.1Disconnect the battery negative lead.

2Remove the bonnet.

3On carburettor models, remove the air

cleaner. On fuel-injection models, remove the

air cleaner cover, vane airflow meter and air

inlet trunking.

4If a splash guard is fitted, remove it.

5Release the securing clips and bolts and

remove the upper half of the fan shroud. On

carburettor models remove the lower half of

the shroud too.

6Drain the cooling system.

7Disconnect the radiator top and bottom

hoses from the thermostat housing and water

pump. Disconnect the top hose spur from the

expansion tank and unclip it.

8Disconnect the heater hoses from the water

pump and from the inlet manifold or automatic

choke housing. Unclip the hoses.

9On models with power steering, remove the

steering pump.

10Disconnect the vacuum pipe(s) from the

inlet manifold, labelling them if there is any

possibility of confusion.

11Disconnect the following wiring, as

applicable:

a)Alternator

b)Temperature gauge sender

c)Engine management temperature sensor

d)Distributor

e)Oil pressure switch

f)Automatic choke and thermo-switch

g)Carburettor stepper motor

h)Fuel-injection system sub-harness

j)Inlet manifold heater

12Disconnect the HT lead from the coil.

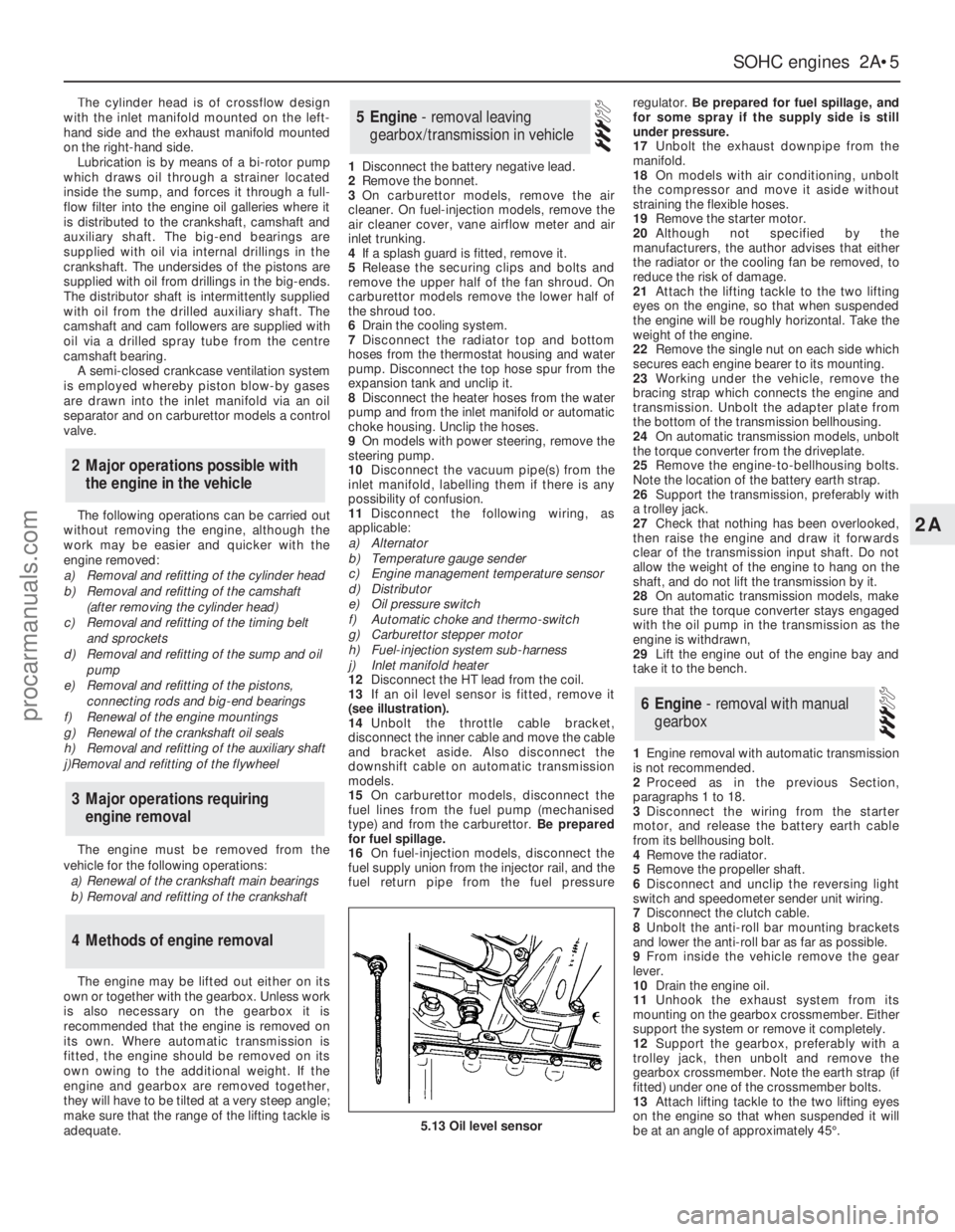

13If an oil level sensor is fitted, remove it

(see illustration).

14Unbolt the throttle cable bracket,

disconnect the inner cable and move the cable

and bracket aside. Also disconnect the

downshift cable on automatic transmission

models.

15On carburettor models, disconnect the

fuel lines from the fuel pump (mechanised

type) and from the carburettor. Be prepared

for fuel spillage.

16On fuel-injection models, disconnect the

fuel supply union from the injector rail, and the

fuel return pipe from the fuel pressureregulator. Be prepared for fuel spillage, and

for some spray if the supply side is still

under pressure.

17Unbolt the exhaust downpipe from the

manifold.

18On models with air conditioning, unbolt

the compressor and move it aside without

straining the flexible hoses.

19Remove the starter motor.

20Although not specified by the

manufacturers, the author advises that either

the radiator or the cooling fan be removed, to

reduce the risk of damage.

21Attach the lifting tackle to the two lifting

eyes on the engine, so that when suspended

the engine will be roughly horizontal. Take the

weight of the engine.

22Remove the single nut on each side which

secures each engine bearer to its mounting.

23Working under the vehicle, remove the

bracing strap which connects the engine and

transmission. Unbolt the adapter plate from

the bottom of the transmission bellhousing.

24On automatic transmission models, unbolt

the torque converter from the driveplate.

25Remove the engine-to-bellhousing bolts.

Note the location of the battery earth strap.

26Support the transmission, preferably with

a trolley jack.

27Check that nothing has been overlooked,

then raise the engine and draw it forwards

clear of the transmission input shaft. Do not

allow the weight of the engine to hang on the

shaft, and do not lift the transmission by it.

28On automatic transmission models, make

sure that the torque converter stays engaged

with the oil pump in the transmission as the

engine is withdrawn,

29Lift the engine out of the engine bay and

take it to the bench.

1Engine removal with automatic transmission

is not recommended.

2Proceed as in the previous Section,

paragraphs 1 to 18.

3Disconnect the wiring from the starter

motor, and release the battery earth cable

from its bellhousing bolt.

4Remove the radiator.

5Remove the propeller shaft.

6Disconnect and unclip the reversing light

switch and speedometer sender unit wiring.

7Disconnect the clutch cable.

8Unbolt the anti-roll bar mounting brackets

and lower the anti-roll bar as far as possible.

9From inside the vehicle remove the gear

lever.

10Drain the engine oil.

11Unhook the exhaust system from its

mounting on the gearbox crossmember. Either

support the system or remove it completely.

12Support the gearbox, preferably with a

trolley jack, then unbolt and remove the

gearbox crossmember. Note the earth strap (if

fitted) under one of the crossmember bolts.

13Attach lifting tackle to the two lifting eyes

on the engine so that when suspended it will

be at an angle of approximately 45°.

6Engine - removal with manual

gearbox

5Engine - removal leaving

gearbox/transmission in vehicle

4Methods of engine removal

3Major operations requiring

engine removal

2Major operations possible with

the engine in the vehicle

SOHCengines 2A•5

2A

5.13 Oil level sensor

procarmanuals.com

Page 170 of 255

6Disconnect the glovebox arms and hinges.

Withdraw the hinge pins and remove the lid.

7Slide the auxiliary fuse panel off its

mounting and remove the glovebox light

(when fitted).

8Remove the ABS and ESC/EEC modules

(Chapter 13). Remove the two nuts and

washers from inside the glovebox.

9Remove the radio, stowage box or graphic

equaliser, ashtray, cigarette lighter panel and

(when applicable) the gear lever gaiter.

10Remove the centre console, disconnecting

switches, rear heater controls etc as

necessary.

11Remove the six screws which secure the

passenger’s side lower panel. Remove the

panel. 12Refit by reversing the removal operations,

transferring the brackets, captive nuts or other

fittings to any new panels being fitted.

Models from April 1992

13Disconnect the battery negative terminal.

14Remove the centre console.

15Remove the radio, amplifier unit and

(where necessary) the CD player.

16Remove the instrument cluster.

17Remove the steering wheel and then the

steering column direction indicator/headlight

flasher switch and windscreen wipe/wash

switch.

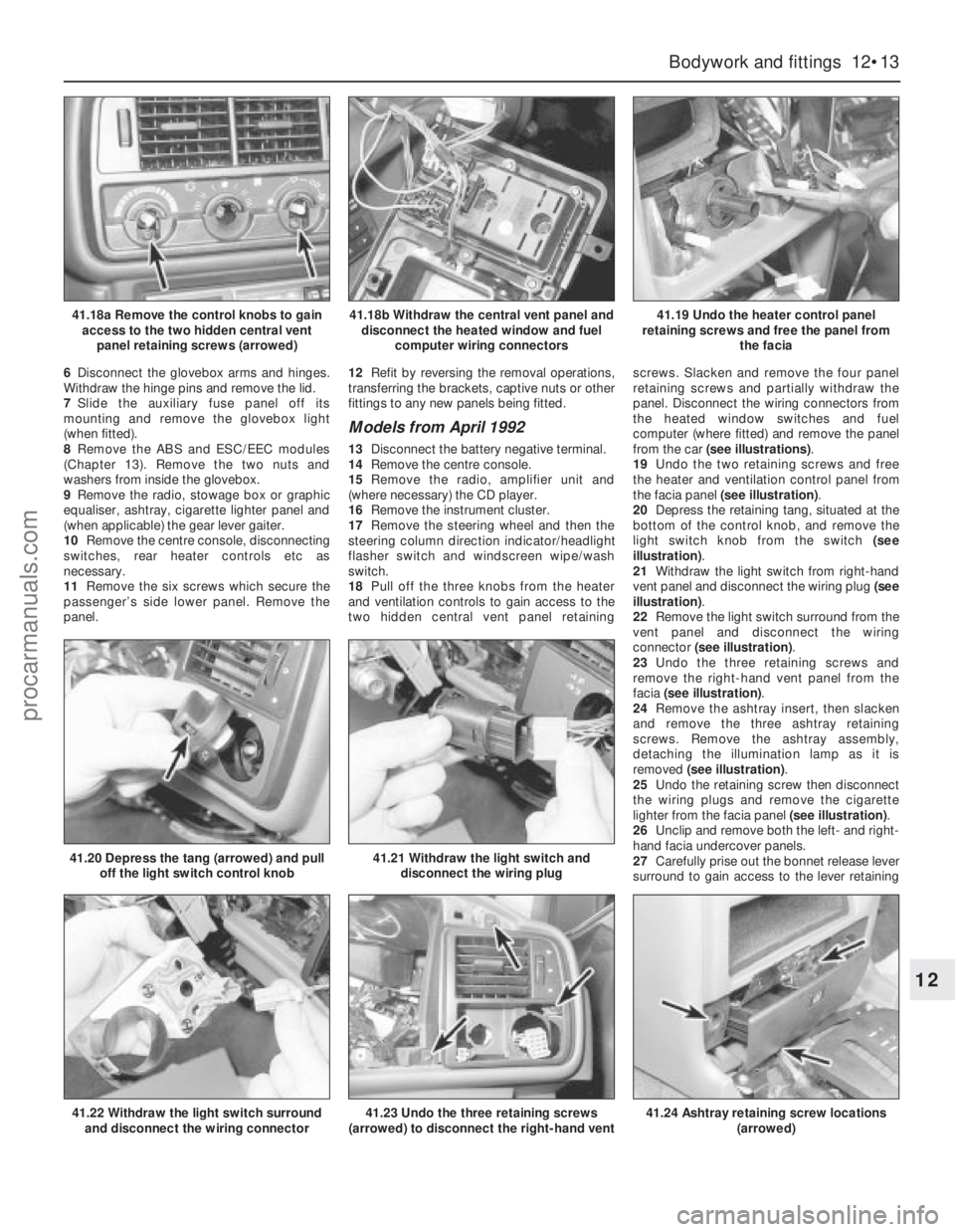

18Pull off the three knobs from the heater

and ventilation controls to gain access to the

two hidden central vent panel retainingscrews. Slacken and remove the four panel

retaining screws and partially withdraw the

panel. Disconnect the wiring connectors from

the heated window switches and fuel

computer (where fitted) and remove the panel

from the car (see illustrations).

19Undo the two retaining screws and free

the heater and ventilation control panel from

the facia panel (see illustration).

20Depress the retaining tang, situated at the

bottom of the control knob, and remove the

light switch knob from the switch (see

illustration).

21Withdraw the light switch from right-hand

vent panel and disconnect the wiring plug (see

illustration).

22Remove the light switch surround from the

vent panel and disconnect the wiring

connector (see illustration).

23Undo the three retaining screws and

remove the right-hand vent panel from the

facia (see illustration).

24Remove the ashtray insert, then slacken

and remove the three ashtray retaining

screws. Remove the ashtray assembly,

detaching the illumination lamp as it is

removed (see illustration).

25Undo the retaining screw then disconnect

the wiring plugs and remove the cigarette

lighter from the facia panel (see illustration).

26Unclip and remove both the left- and right-

hand facia undercover panels.

27Carefully prise out the bonnet release lever

surround to gain access to the lever retaining

Bodywork and fittings 12•13

12

41.18a Remove the control knobs to gain

access to the two hidden central vent

panel retaining screws (arrowed)41.18b Withdraw the central vent panel and

disconnect the heated window and fuel

computer wiring connectors41.19 Undo the heater control panel

retaining screws and free the panel from

the facia

41.22 Withdraw the light switch surround

and disconnect the wiring connector

41.20 Depress the tang (arrowed) and pull

off the light switch control knob41.21 Withdraw the light switch and

disconnect the wiring plug

41.23 Undo the three retaining screws

(arrowed) to disconnect the right-hand vent41.24 Ashtray retaining screw locations

(arrowed)

procarmanuals.com

Page 189 of 255

20When refitting, check the switch for

correct operation before refitting the shrouds

and steering wheel centre cover. When fitting

the shrouds, be careful not to trap the switch

rubber gaiter.

Models from April 1992

21Note that if access to the switch retaining

screws cannot be gained with the steering

wheel in position, then the steering wheel

must first be removed.

Windscreen wipe/wash switch

Models before April 1992

22Proceed as described in the previous sub-

section for the direction indicator switch.

Depending on equipment, the wipe/wash

switch may have more than one multi-plug

connected to it.

Models from April 1992

23Note that if access to the switch retaining

screws cannot be gained with the steering

wheel in position, then the steering wheel

must first be removed.

Door pillar switch (for courtesy

light)

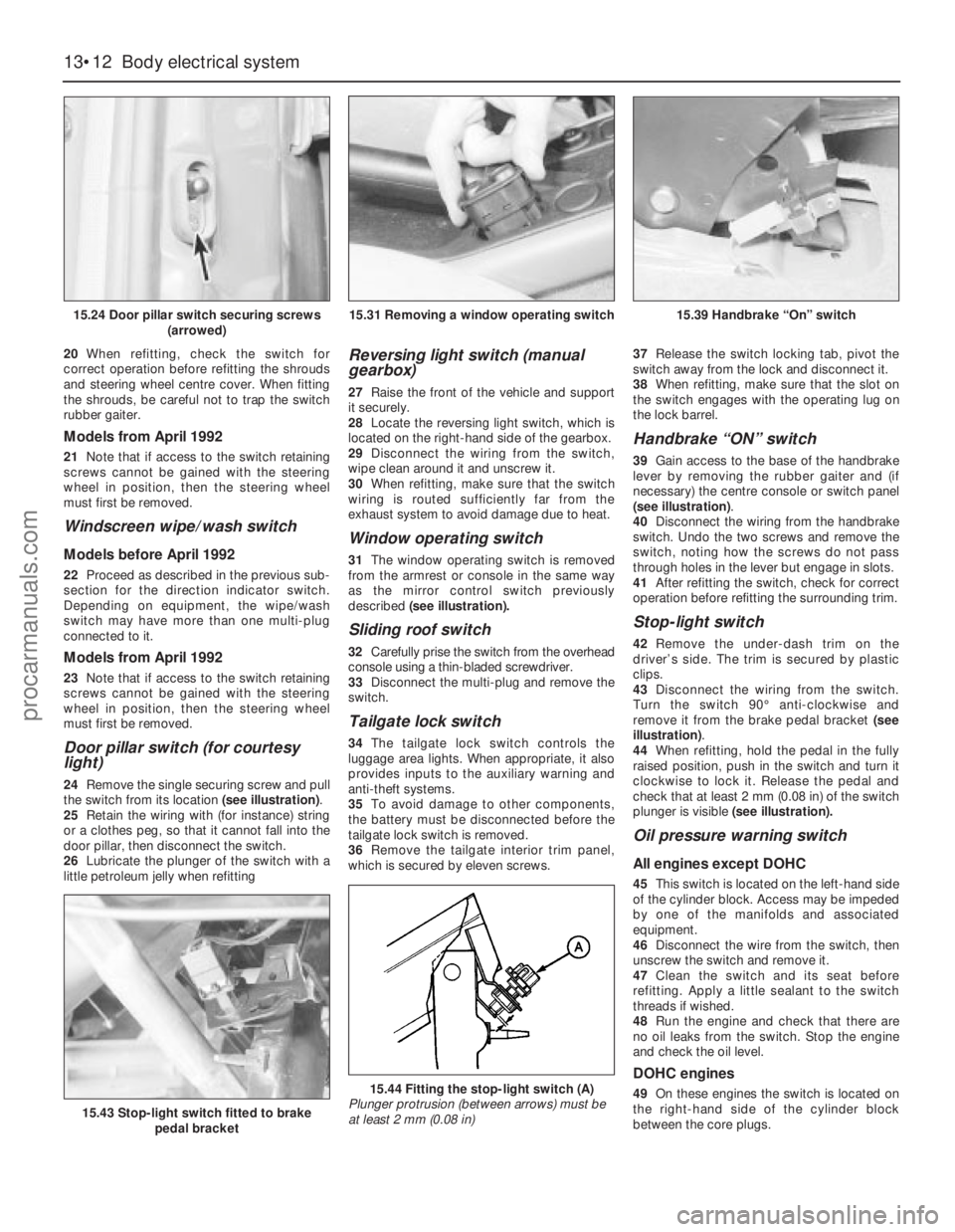

24Remove the single securing screw and pull

the switch from its location (see illustration).

25Retain the wiring with (for instance) string

or a clothes peg, so that it cannot fall into the

door pillar, then disconnect the switch.

26Lubricate the plunger of the switch with a

little petroleum jelly when refitting

Reversing light switch (manual

gearbox)

27Raise the front of the vehicle and support

it securely.

28Locate the reversing light switch, which is

located on the right-hand side of the gearbox.

29Disconnect the wiring from the switch,

wipe clean around it and unscrew it.

30When refitting, make sure that the switch

wiring is routed sufficiently far from the

exhaust system to avoid damage due to heat.

Window operating switch

31The window operating switch is removed

from the armrest or console in the same way

as the mirror control switch previously

described (see illustration).

Sliding roof switch

32Carefully prise the switch from the overhead

console using a thin-bladed screwdriver.

33Disconnect the multi-plug and remove the

switch.

Tailgate lock switch

34The tailgate lock switch controls the

luggage area lights. When appropriate, it also

provides inputs to the auxiliary warning and

anti-theft systems.

35To avoid damage to other components,

the battery must be disconnected before the

tailgate lock switch is removed.

36Remove the tailgate interior trim panel,

which is secured by eleven screws.37Release the switch locking tab, pivot the

switch away from the lock and disconnect it.

38When refitting, make sure that the slot on

the switch engages with the operating lug on

the lock barrel.

Handbrake “ON” switch

39Gain access to the base of the handbrake

lever by removing the rubber gaiter and (if

necessary) the centre console or switch panel

(see illustration).

40Disconnect the wiring from the handbrake

switch. Undo the two screws and remove the

switch, noting how the screws do not pass

through holes in the lever but engage in slots.

41After refitting the switch, check for correct

operation before refitting the surrounding trim.

Stop-light switch

42Remove the under-dash trim on the

driver’s side. The trim is secured by plastic

clips.

43Disconnect the wiring from the switch.

Turn the switch 90°anti-clockwise and

remove it from the brake pedal bracket (see

illustration).

44When refitting, hold the pedal in the fully

raised position, push in the switch and turn it

clockwise to lock it. Release the pedal and

check that at least 2 mm (0.08 in) of the switch

plunger is visible (see illustration).

Oil pressure warning switch

All engines except DOHC

45This switch is located on the left-hand side

of the cylinder block. Access may be impeded

by one of the manifolds and associated

equipment.

46Disconnect the wire from the switch, then

unscrew the switch and remove it.

47Clean the switch and its seat before

refitting. Apply a little sealant to the switch

threads if wished.

48Run the engine and check that there are

no oil leaks from the switch. Stop the engine

and check the oil level.

DOHC engines

49On these engines the switch is located on

the right-hand side of the cylinder block

between the core plugs.

13•12Body electrical system

15.24 Door pillar switch securing screws

(arrowed)

15.43 Stop-light switch fitted to brake

pedal bracket

15.44 Fitting the stop-light switch (A)

Plunger protrusion (between arrows) must be

at least 2 mm (0.08 in)

15.31 Removing a window operating switch15.39 Handbrake “On” switch

procarmanuals.com

Page 190 of 255

Heated rear window switch

Models before April 1992

50Remove the instrument panel surround,

which is secured by four screws.

51Carefully prise the switch from its location,

disconnect the multi-plug and remove it.

Models from April 1992

52Using a small flat-bladed screwdriver,

carefully prise the switch out of the centre

facia vent panel and disconnect the wiring

connector.

53On refitting, reconnect the wiring

connector and push the switch in until it clicks

into position.

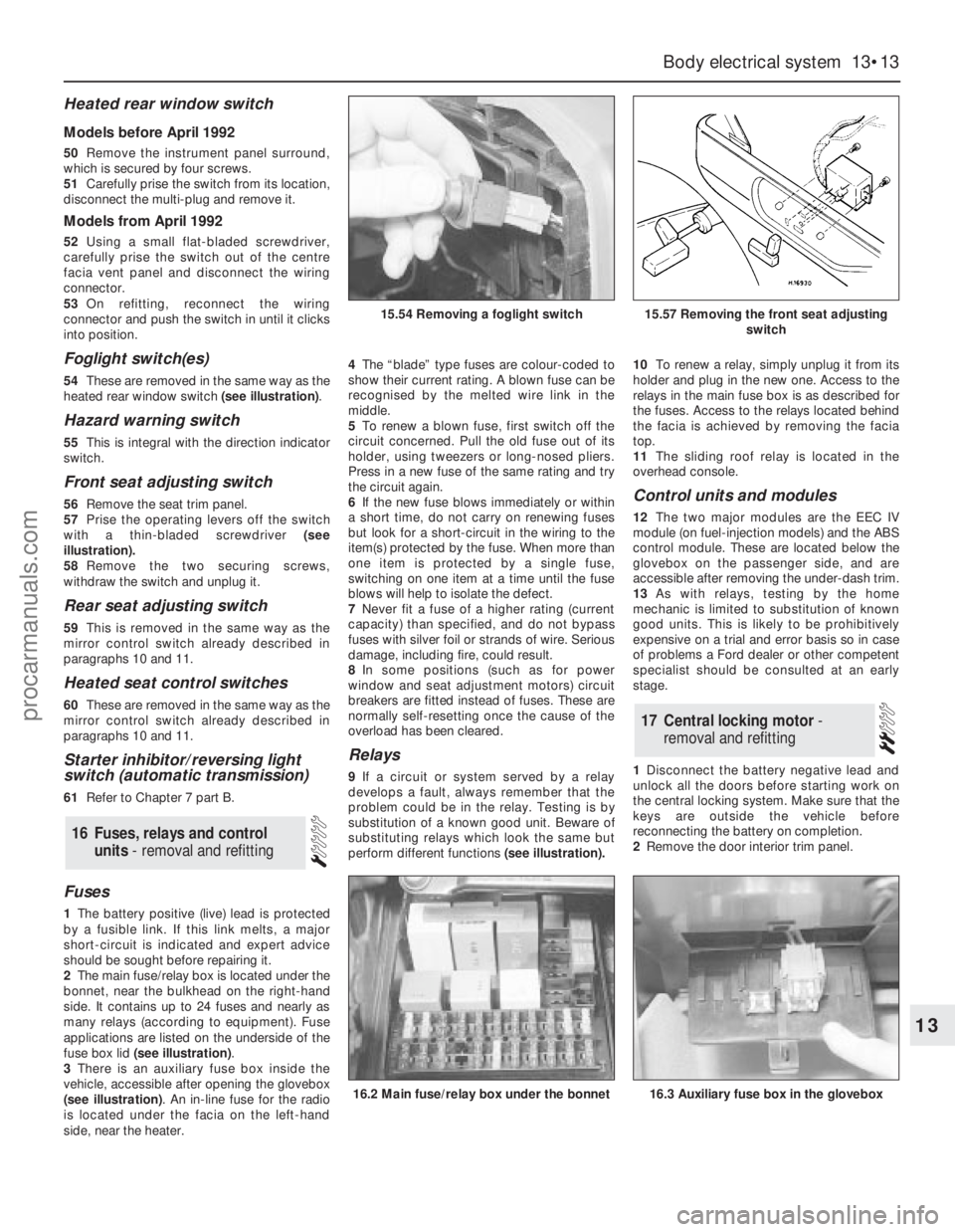

Foglight switch(es)

54These are removed in the same way as the

heated rear window switch (see illustration).

Hazard warning switch

55This is integral with the direction indicator

switch.

Front seat adjusting switch

56Remove the seat trim panel.

57Prise the operating levers off the switch

with a thin-bladed screwdriver (see

illustration).

58Remove the two securing screws,

withdraw the switch and unplug it.

Rear seat adjusting switch

59This is removed in the same way as the

mirror control switch already described in

paragraphs 10 and 11.

Heated seat control switches

60These are removed in the same way as the

mirror control switch already described in

paragraphs 10 and 11.

Starter inhibitor/reversing light

switch (automatic transmission)

61Refer to Chapter 7 part B.

Fuses

1The battery positive (live) lead is protected

by a fusible link. If this link melts, a major

short-circuit is indicated and expert advice

should be sought before repairing it.

2The main fuse/relay box is located under the

bonnet, near the bulkhead on the right-hand

side. It contains up to 24 fuses and nearly as

many relays (according to equipment). Fuse

applications are listed on the underside of the

fuse box lid (see illustration).

3There is an auxiliary fuse box inside the

vehicle, accessible after opening the glovebox

(see illustration). An in-line fuse for the radio

is located under the facia on the left-hand

side, near the heater.4The“blade” type fuses are colour-coded to

show their current rating. A blown fuse can be

recognised by the melted wire link in the

middle.

5To renew a blown fuse, first switch off the

circuit concerned. Pull the old fuse out of its

holder, using tweezers or long-nosed pliers.

Press in a new fuse of the same rating and try

the circuit again.

6If the new fuse blows immediately or within

a short time, do not carry on renewing fuses

but look for a short-circuit in the wiring to the

item(s) protected by the fuse. When more than

one item is protected by a single fuse,

switching on one item at a time until the fuse

blows will help to isolate the defect.

7Never fit a fuse of a higher rating (current

capacity) than specified, and do not bypass

fuses with silver foil or strands of wire. Serious

damage, including fire, could result.

8In some positions (such as for power

window and seat adjustment motors) circuit

breakers are fitted instead of fuses. These are

normally self-resetting once the cause of the

overload has been cleared.

Relays

9If a circuit or system served by a relay

develops a fault, always remember that the

problem could be in the relay. Testing is by

substitution of a known good unit. Beware of

substituting relays which look the same but

perform different functions(see illustration).10To renew a relay, simply unplug it from its

holder and plug in the new one. Access to the

relays in the main fuse box is as described for

the fuses. Access to the relays located behind

the facia is achieved by removing the facia

top.

11The sliding roof relay is located in the

overhead console.

Control units and modules

12The two major modules are the EEC IV

module (on fuel-injection models) and the ABS

control module. These are located below the

glovebox on the passenger side, and are

accessible after removing the under-dash trim.

13As with relays, testing by the home

mechanic is limited to substitution of known

good units. This is likely to be prohibitively

expensive on a trial and error basis so in case

of problems a Ford dealer or other competent

specialist should be consulted at an early

stage.

1Disconnect the battery negative lead and

unlock all the doors before starting work on

the central locking system. Make sure that the

keys are outside the vehicle before

reconnecting the battery on completion.

2Remove the door interior trim panel.

17Central locking motor -

removal and refitting

16Fuses, relays and control

units - removal and refitting

Body electrical system 13•13

13

15.54 Removing a foglight switch15.57 Removing the front seat adjusting

switch

16.2 Main fuse/relay box under the bonnet16.3 Auxiliary fuse box in the glovebox

procarmanuals.com

Page 195 of 255

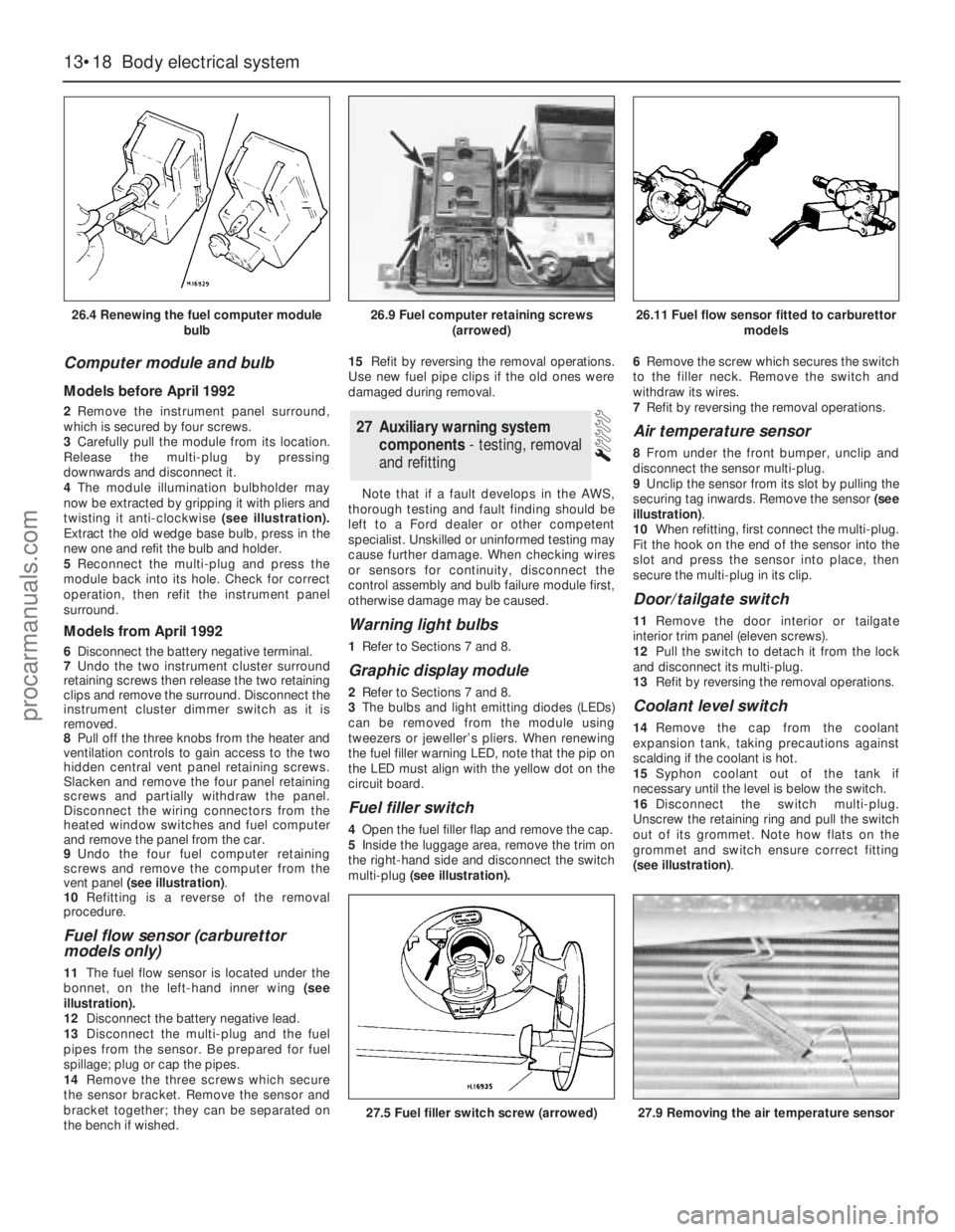

Computer module and bulb

Models before April 1992

2Remove the instrument panel surround,

which is secured by four screws.

3Carefully pull the module from its location.

Release the multi-plug by pressing

downwards and disconnect it.

4The module illumination bulbholder may

now be extracted by gripping it with pliers and

twisting it anti-clockwise (see illustration).

Extract the old wedge base bulb, press in the

new one and refit the bulb and holder.

5Reconnect the multi-plug and press the

module back into its hole. Check for correct

operation, then refit the instrument panel

surround.

Models from April 1992

6Disconnect the battery negative terminal.

7Undo the two instrument cluster surround

retaining screws then release the two retaining

clips and remove the surround. Disconnect the

instrument cluster dimmer switch as it is

removed.

8Pull off the three knobs from the heater and

ventilation controls to gain access to the two

hidden central vent panel retaining screws.

Slacken and remove the four panel retaining

screws and partially withdraw the panel.

Disconnect the wiring connectors from the

heated window switches and fuel computer

and remove the panel from the car.

9Undo the four fuel computer retaining

screws and remove the computer from the

vent panel (see illustration).

10Refitting is a reverse of the removal

procedure.

Fuel flow sensor (carburettor

models only)

11The fuel flow sensor is located under the

bonnet, on the left-hand inner wing (see

illustration).

12Disconnect the battery negative lead.

13Disconnect the multi-plug and the fuel

pipes from the sensor. Be prepared for fuel

spillage; plug or cap the pipes.

14Remove the three screws which secure

the sensor bracket. Remove the sensor and

bracket together; they can be separated on

the bench if wished.15Refit by reversing the removal operations.

Use new fuel pipe clips if the old ones were

damaged during removal.

Note that if a fault develops in the AWS,

thorough testing and fault finding should be

left to a Ford dealer or other competent

specialist. Unskilled or uninformed testing may

cause further damage. When checking wires

or sensors for continuity, disconnect the

control assembly and bulb failure module first,

otherwise damage may be caused.

Warning light bulbs

1Refer to Sections 7 and 8.

Graphic display module

2Refer to Sections 7 and 8.

3The bulbs and light emitting diodes (LEDs)

can be removed from the module using

tweezers or jeweller’s pliers. When renewing

the fuel filler warning LED, note that the pip on

the LED must align with the yellow dot on the

circuit board.

Fuel filler switch

4Open the fuel filler flap and remove the cap.

5Inside the luggage area, remove the trim on

the right-hand side and disconnect the switch

multi-plug(see illustration).6Remove the screw which secures the switch

to the filler neck. Remove the switch and

withdraw its wires.

7Refit by reversing the removal operations.

Air temperature sensor

8From under the front bumper, unclip and

disconnect the sensor multi-plug.

9Unclip the sensor from its slot by pulling the

securing tag inwards. Remove the sensor (see

illustration).

10When refitting, first connect the multi-plug.

Fit the hook on the end of the sensor into the

slot and press the sensor into place, then

secure the multi-plug in its clip.

Door/tailgate switch

11Remove the door interior ortailgate

interior trim panel (eleven screws).

12Pull the switch to detach it from the lock

and disconnect its multi-plug.

13Refit by reversing the removal operations.

Coolant level switch

14Remove the cap from the coolant

expansion tank, taking precautions against

scalding if the coolant is hot.

15Syphon coolant out of the tank if

necessary until the level is below the switch.

16Disconnect the switch multi-plug.

Unscrew the retaining ring and pull the switch

out of its grommet. Note how flats on the

grommet and switch ensure correct fitting

(see illustration).

27Auxiliary warning system

components - testing, removal

and refitting

13•18Body electrical system

26.4 Renewing the fuel computer module

bulb

27.5 Fuel filler switch screw (arrowed)27.9 Removing the air temperature sensor

26.9 Fuel computer retaining screws

(arrowed)26.11 Fuel flow sensor fitted to carburettor

models

procarmanuals.com