brakes FORD GRANADA 1985 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 21 of 255

12Place a piece of wood in the caliper jaws

to limit piston travel. Keep your fingers clear of

the piston. Have the assistant depress the

brake pedal gentlyin order to move the

caliper piston out.

13With the pedal held depressed, slacken

the bleed screw on the right-hand caliper and

again depress the piston. Tighten the bleed

screw when the piston is retracted. The pedal

can now be released.

14Disconnect the bleed tube. Refit the right-hand brake pad and caliper.

15Remove the left-hand caliper and inboard

pad again. Carry out the operations described

in paragraphs 10 to 14 on the left-hand

caliper.

16Bleed the rear brakes as described in

Chapter 10.

17Refit the front wheels, lower the vehicle

and tighten the wheel nuts.

18Pump the brake pedal to bring the pads

up to the discs, then make a final check of thehydraulic fluid level. Top-up and refit the

reservoir cap.

Camshaft drivebelt renewal is

recommended as a precautionary measure.

Refer to Chapter 2, Part A, Sections 13 and 45

for the full renewal procedure.

45Camshaft drivebelt renewal -

SOHC engines

1Before proceeding, note the precautions

given in Chapter 3, Section 1.

2Disconnect the battery negative lead.

3Remove the expansion tank cap. Take

precautions against scalding if the system is

hot.

4Place a drain pan of adequate capacity

beneath the radiator drain plug. Unscrew the

plug, without removing it, and allow the

coolant to drain (see illustration). On OHC

engines, release the hose clip and remove the

rubber cap from the bleed spigot on top of the

thermostat housing (see illustration). On V6

engines, remove the bleed screw (if fitted)

from the radiator top hose.

5Place another drain pan below the cylinder

block drain plug, which is located on the right-

hand side of the engine (except DOHC engine

which has no plug). Remove the drain plug

and allow the coolant to drain from the block.

6Dispose of the old coolant safely, or keep it

in a covered container if it is to be re-used.7Flushing should not be necessary unless

periodic renewal of the coolant has been

neglected, or unless plain water has been

used as coolant. In either case the coolant will

appear rusty and dark in colour. Flushing is

then required and should be carried out as

follows.

8Drain the system and disconnect the top

hose from the radiator. Insert a garden hose

into the radiator and run water into the radiator

until it flows clear from the drain plug.

9Run the hose into the expansion tank (OHC

engines) or into the radiator top hose (V6

engines) until clean water comes out of the

cylinder block drain plug. On DOHC engines

there is no drain plug in the cylinder block, so

the engine should be flushed until water runs

clear from the radiator bottom hose.

10If, after a reasonable period the water still

does not run clear, the radiator can be flushed

with a good proprietary cleaning agent.

11Flush the heater matrix by disconnecting

one of the heater hoses and running the hose

into that.

12In severe cases of contamination the

radiator should be removed, inverted andflushed in the reverse direction to normal flow,

ie with the water going in at the bottom and

out at the top. Shake the radiator gently while

doing this to dislodge any deposits.

13Refit any hoses which were disturbed,

making sure that they and their clips are in

good condition. Refit the cylinder block drain

plug and tighten the radiator drain plug.

14On OHC engines, make sure that the

bleed spigot cap is still removed (not DOHC).

On V6 engines, check, if applicable, that the

bleed screw is still removed.

15Pour coolant in through the expansion

tank filler hole until the level is up to the MAX

line.

16Refit the bleed spigot cap or screw when

coolant starts to emerge from the spigot.

Tighten the clip.

17Squeeze the radiator hoses to help

disperse airlocks. Top-up the coolant further if

necessary, then refit and tighten the expansion

tank cap.

18Run the engine up to operating

temperature, checking for coolant leaks. Stop

the engine and allow it to cool, then top-up the

coolant again to the MAX mark if necessary.

46Engine coolant renewal

1•20Every 2 years

46.4b Releasing the bleed spigot cap -

OHC engine46.4a Radiator drain plug (arrowed) -

OHC engine

Every 2 years (regardless of mileage)

procarmanuals.com

Page 22 of 255

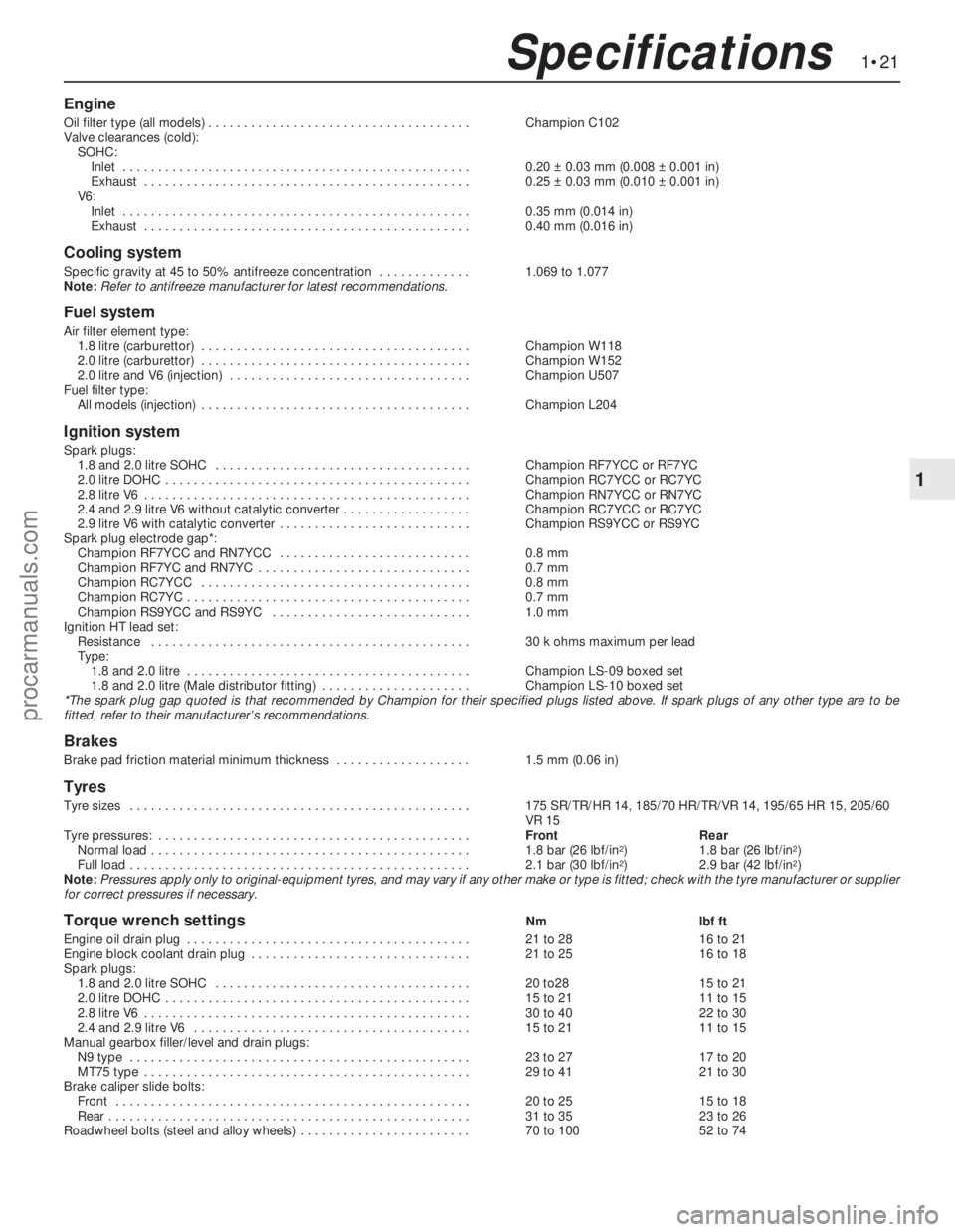

Engine

Oil filter type (all models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion C102

Valve clearances (cold):

SOHC:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.20 ±0.03 mm (0.008 ±0.001 in)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.25 ±0.03 mm (0.010 ±0.001 in)

V6:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.35 mm (0.014 in)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.40 mm (0.016 in)

Cooling system

Specific gravity at 45 to 50% antifreeze concentration . . . . . . . . . . . . .1.069 to 1.077

Note:Refer to antifreeze manufacturer for latest recommendations.

Fuel system

Air filter element type:

1.8 litre (carburettor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion W118

2.0 litre (carburettor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion W152

2.0 litre and V6 (injection) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion U507

Fuel filter type:

All models (injection) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion L204

Ignition system

Spark plugs:

1.8 and 2.0 litre SOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RF7YCC or RF7YC

2.0 litre DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RC7YCC or RC7YC

2.8 litre V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RN7YCC or RN7YC

2.4 and 2.9 litre V6 without catalytic converter . . . . . . . . . . . . . . . . . .Champion RC7YCC or RC7YC

2.9 litre V6 with catalytic converter . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RS9YCC or RS9YC

Spark plug electrode gap*:

Champion RF7YCC and RN7YCC . . . . . . . . . . . . . . . . . . . . . . . . . . .0.8 mm

Champion RF7YC and RN7YC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.7 mm

Champion RC7YCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.8 mm

Champion RC7YC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.7 mm

Champion RS9YCC and RS9YC . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.0 mm

Ignition HT lead set:

Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 k ohms maximum per lead

Type:

1.8 and 2.0 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion LS-09 boxed set

1.8 and 2.0 litre (Male distributor fitting) . . . . . . . . . . . . . . . . . . . . .Champion LS-10 boxed set

*The spark plug gap quoted is that recommended by Champion for their specified plugs listed above. If spark plugs of any other type are to be

fitted, refer to their manufacturer’s recommendations.

Brakes

Brake pad friction material minimum thickness . . . . . . . . . . . . . . . . . . .1.5 mm (0.06 in)

Tyres

Tyre sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175 SR/TR/HR 14, 185/70 HR/TR/VR 14,195/65 HR 15, 205/60

VR 15

Tyre pressures: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FrontRear

Normal load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.8 bar (26 lbf/in

2)1.8 bar (26 lbf/in2)

Full load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.1 bar (30 lbf/in2)2.9 bar (42 lbf/in2)

Note:Pressures apply only to original-equipment tyres, and may vary if any other make or type is fitted; check with the tyre manufacturer or supplier

for correct pressures if necessary.

Torque wrench settingsNmlbf ft

Engine oil drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2816 to 21

Engine block coolant drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2516 to 18

Spark plugs:

1.8 and 2.0 litre SOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to2815 to 21

2.0 litre DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 to 2111 to 15

2.8 litre V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 to 4022 to 30

2.4 and 2.9 litre V6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 to 2111 to 15

Manual gearbox filler/level and drain plugs:

N9 type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 to 2717 to 20

MT75 type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29 to 4121 to 30

Brake caliper slide bolts:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 to 3523 to 26

Roadwheel bolts (steel and alloy wheels) . . . . . . . . . . . . . . . . . . . . . . . .70 to 10052 to 74

1•21

1

Specifications

procarmanuals.com

Page 131 of 255

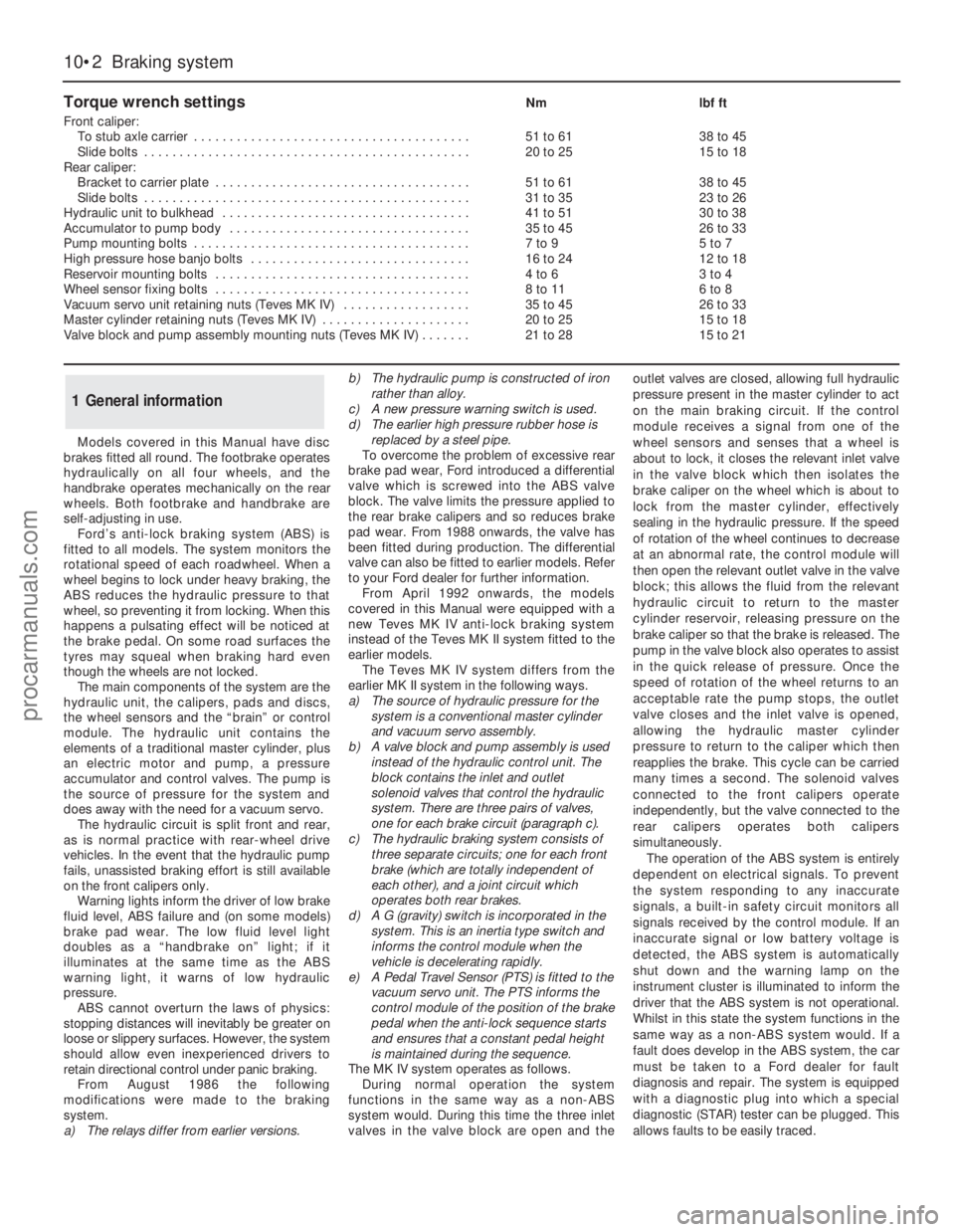

Models covered in this Manual have disc

brakes fitted all round. The footbrake operates

hydraulically on all four wheels, and the

handbrake operates mechanically on the rear

wheels. Both footbrake and handbrake are

self-adjusting in use.

Ford’s anti-lock braking system (ABS) is

fitted to all models. The system monitors the

rotational speed of each roadwheel. When a

wheel begins to lock under heavy braking, the

ABS reduces the hydraulic pressure to that

wheel, so preventing it from locking. When this

happens a pulsating effect will be noticed at

the brake pedal. On some road surfaces the

tyres may squeal when braking hard even

though the wheels are not locked.

The main components of the system are the

hydraulic unit, the calipers, pads and discs,

the wheel sensors and the “brain” or control

module. The hydraulic unit contains the

elements of a traditional master cylinder, plus

an electric motor and pump, a pressure

accumulator and control valves. The pump is

the source of pressure for the system and

does away with the need for a vacuum servo.

The hydraulic circuit is split front and rear,

as is normal practice with rear-wheel drive

vehicles. In the event that the hydraulic pump

fails, unassisted braking effort is still available

on the front calipers only.

Warning lights inform the driver of low brake

fluid level, ABS failure and (on some models)

brake pad wear. The low fluid level light

doubles as a “handbrake on” light; if it

illuminates at the same time as the ABS

warning light, it warns of low hydraulic

pressure.

ABS cannot overturn the laws of physics:

stopping distances will inevitably be greater on

loose or slippery surfaces. However, the system

should allow even inexperienced drivers to

retain directional control under panic braking.

From August 1986 the following

modifications were made to the braking

system.

a)The relays differ from earlier versions.b)The hydraulic pump is constructed of iron

rather than alloy.

c)A new pressure warning switch is used.

d)The earlier high pressure rubber hose is

replaced by a steel pipe.

To overcome the problem of excessive rear

brake pad wear, Ford introduced a differential

valve which is screwed into the ABS valve

block.The valve limits the pressure applied to

the rear brake calipers and so reduces brake

pad wear. From 1988 onwards, the valve has

been fitted during production. The differential

valve can also be fitted to earlier models. Refer

to your Ford dealer for further information.

From April 1992 onwards, the models

covered in this Manual were equipped with a

new Teves MK IV anti-lock braking system

instead of the Teves MK II system fitted to the

earlier models.

The Teves MK IV system differs from the

earlier MK II system in the following ways.

a)The source of hydraulic pressure for the

system is a conventional master cylinder

and vacuum servo assembly.

b)A valve block and pump assembly is used

instead of the hydraulic control unit. The

block contains the inlet and outlet

solenoid valves that control the hydraulic

system. There are three pairs of valves,

one for each brake circuit (paragraph c).

c)The hydraulic braking system consists of

three separate circuits; one for each front

brake (which are totally independent of

each other), and a joint circuit which

operates both rear brakes.

d)A G (gravity) switch is incorporated in the

system. This is an inertia type switch and

informs the control module when the

vehicle is decelerating rapidly.

e)A Pedal Travel Sensor (PTS) is fitted to the

vacuum servo unit. The PTS informs the

control module of the position of the brake

pedal when the anti-lock sequence starts

and ensures that a constant pedal height

is maintained during the sequence.

The MK IV system operates as follows.

During normal operation the system

functions in the same way as a non-ABS

system would. During this time the three inlet

valves in the valve block are open and theoutlet valves are closed, allowing full hydraulic

pressure present in the master cylinder to act

on the main braking circuit. If the control

module receives a signal from one of the

wheel sensors and senses that a wheel is

about to lock, it closes the relevant inlet valve

in the valve block which then isolates the

brake caliper on the wheel which is about to

lock from the master cylinder, effectively

sealing in the hydraulic pressure. If the speed

of rotation of the wheel continues to decrease

at an abnormal rate, the control module will

then open the relevant outlet valve in the valve

block; this allows the fluid from the relevant

hydraulic circuit to return to the master

cylinder reservoir, releasing pressure on the

brake caliper so that the brake is released. The

pump in the valve block also operates to assist

in the quick release of pressure. Once the

speed of rotation of the wheel returns to an

acceptable rate the pump stops, the outlet

valve closes and the inlet valve is opened,

allowing the hydraulic master cylinder

pressure to return to the caliper which then

reapplies the brake. This cycle can be carried

many times a second. The solenoid valves

connected to the front calipers operate

independently, but the valve connected to the

rear calipers operates both calipers

simultaneously.

The operation of the ABS system is entirely

dependent on electrical signals. To prevent

the system responding to any inaccurate

signals, a built-in safety circuit monitors all

signals received by the control module. If an

inaccurate signal or low battery voltage is

detected, the ABS system is automatically

shut down and the warning lamp on the

instrument cluster is illuminated to inform the

driver that the ABS system is not operational.

Whilst in this state the system functions in the

same way as a non-ABS system would. If a

fault does develop in the ABS system, the car

must be taken to a Ford dealer for fault

diagnosis and repair. The system is equipped

with a diagnostic plug into which a special

diagnostic (STAR) tester can be plugged. This

allows faults to be easily traced.

1General information

10•2Braking system

Torque wrench settingsNmlbf ft

Front caliper:

To stub axle carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51 to 6138 to 45

Slide bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Rear caliper:

Bracket to carrier plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51 to 6138 to 45

Slide bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 to 3523 to 26

Hydraulic unit to bulkhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41 to 5130 to 38

Accumulator to pump body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 to 4526 to 33

Pump mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 to 95 to 7

High pressure hose banjo bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 to 2412 to 18

Reservoir mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 to 63 to 4

Wheel sensor fixing bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Vacuum servo unit retaining nuts (Teves MK IV) . . . . . . . . . . . . . . . . . .35 to 4526 to 33

Master cylinder retaining nuts (Teves MK IV) . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Valve block and pump assembly mounting nuts (Teves MK IV) . . . . . . .21 to 2815 to 21

procarmanuals.com

Page 132 of 255

Note: Hydraulic fluid is poisonous; wash off

immediately and thoroughly in the case of skin

contact and seek immediate medical advice if

any fluid is swallowed or gets into the eyes.

Certain types of hydraulic fluid are inflammable

and may ignite when allowed into contact with

hot components; when servicing any hydraulic

system it is safest to assume that the fluid is

inflammable and to take precautions against

the risk of fire as though it is petrol that is

being handled. Finally, it is hygroscopic (it

absorbs moisture from the air) old fluid may be

contaminated and unfit for further use. When

topping-up or renewing the fluid, always use

the recommended type and ensure that it

comes from a freshly-opened sealed container

1Bleeding is necessary whenever air has

entered the hydraulic system - for instance

after component renewal. Because the

hydraulic circuits are split, if only the front or

rear circuit has been disturbed it will normally

only be necessary to bleed the front or rear

calipers. If the hydraulic unit has been

disturbed or the fluid level has been allowed to

fall so low that air has entered the system,

both front and rear circuits must be bled,

starting with the front

2The services of an assistant will be required.

As far as is known, pressure bleeding or other

“one-man” equipment cannot be used. In

addition a supply of fresh brake fluid of the

correct type will be needed, together with a

length of flexible tube to fit the bleed screws

and a clean glass or plastic container.

3Do not allow the hydraulic unit pump motor

to run for more than two minutes at a time. The

motor must be allowed to cool (with the

ignition off) for at least ten minutes after each

two minute spell of running.

4Remember that brake fluid is poisonous and

that the rear brake hydraulic system may be

under considerable pressure. Take care not to

allow hydraulic fluid to spray into the face or

eyes.

5Keep the reservoir topped up to the MAX

mark during bleeding.

6Discard the fluid bled out of the system as it

is unfit for re-use.

Models before April 1992

Front brakes

7Remove the dust cap (if fitted) from the left-

hand caliper bleed screw. Slacken the bleed

screw, then nip it up again. Make sure that the

ignition is off.8Fit the bleed tube over the bleed screw.

Place the other end of the tube in the bleed jar

(glass or plastic container). Pour sufficient

brake fluid into the jar to cover the end of the

tube.

9Open the bleed screw one full turn. Have

the assistant depress the brake pedal as far as

it will go, and hold it depressed. Tighten the

bleed screw, then tell the assistant to release

the pedal.

10Repeat paragraph 9 until clean fluid, free

of air bubbles, flows from the bleed screw

during the downstrokes. Remember to keep

the fluid reservoir topped up.

11Repeat the operations on the right-hand

caliper. Refit the bleed screw dust caps (if

applicable) on completion.

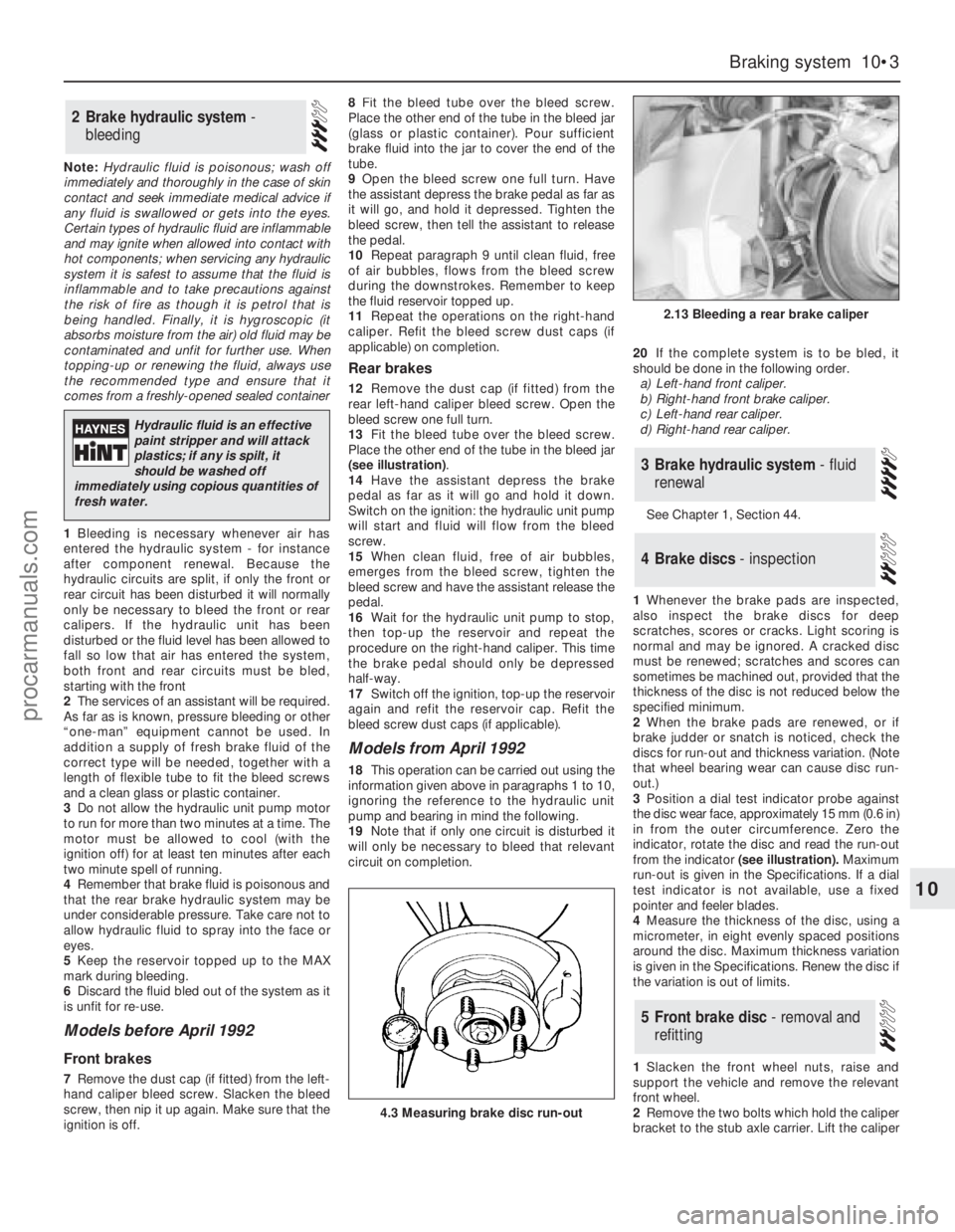

Rear brakes

12Remove the dust cap (if fitted) from the

rear left-hand caliper bleed screw. Open the

bleed screw one full turn.

13Fit the bleed tube over the bleed screw.

Place the other end of the tube in the bleed jar

(see illustration).

14Have the assistant depress the brake

pedal as far as it will go and hold it down.

Switch on the ignition: the hydraulic unit pump

will start and fluid will flow from the bleed

screw.

15When clean fluid, free of air bubbles,

emerges from the bleed screw, tighten the

bleed screw and have the assistant release the

pedal.

16Wait for the hydraulic unit pump to stop,

then top-up the reservoir and repeat the

procedure on the right-hand caliper. This time

the brake pedal should only be depressed

half-way.

17Switch off the ignition, top-up the reservoir

again and refit the reservoir cap. Refit the

bleed screw dust caps (if applicable).

Models from April 1992

18This operation can be carried out using the

information given above inparagraphs 1 to 10,

ignoring the reference to the hydraulic unit

pump and bearing in mind the following.

19Note that if only one circuit is disturbed it

will only be necessary to bleed that relevant

circuit on completion.20If the complete system is to be bled, it

should be done in the following order.

a)Left-hand front caliper.

b)Right-hand front brake caliper.

c)Left-hand rear caliper.

d)Right-hand rear caliper.

See Chapter 1, Section 44.

1Whenever the brake pads are inspected,

also inspect the brake discs for deep

scratches, scores or cracks. Light scoring is

normal and may be ignored. A cracked disc

must be renewed; scratches and scores can

sometimes be machined out, provided that the

thickness of the disc is not reduced below the

specified minimum.

2When the brake pads are renewed, or if

brake judder or snatch is noticed, check the

discs for run-out and thickness variation. (Note

that wheel bearing wear can cause disc run-

out.)

3Position a dial test indicator probe against

the disc wear face, approximately 15 mm (0.6 in)

in from the outer circumference. Zero the

indicator, rotate the disc and read the run-out

from the indicator(see illustration).Maximum

run-out is given in the Specifications. If a dial

test indicator is not available, use a fixed

pointer and feeler blades.

4Measure the thickness of the disc, using a

micrometer, in eight evenly spaced positions

around the disc. Maximum thickness variation

is given in the Specifications. Renew the disc if

the variation is out of limits.

1Slacken the front wheel nuts, raise and

support the vehicle and remove the relevant

front wheel.

2Remove the two bolts which hold the caliper

bracket to the stub axle carrier. Lift the caliper

5Front brake disc - removal and

refitting

4Brake discs - inspection

3Brake hydraulic system - fluid

renewal

2Brake hydraulic system -

bleeding

Braking system 10•3

10

2.13 Bleeding a rear brake caliper

4.3 Measuring brake disc run-out

Hydraulic fluid is an effective

paint stripper and will attack

plastics; if any is spilt, it

should be washed off

immediately using copious quantities of

fresh water.

procarmanuals.com

Page 240 of 255

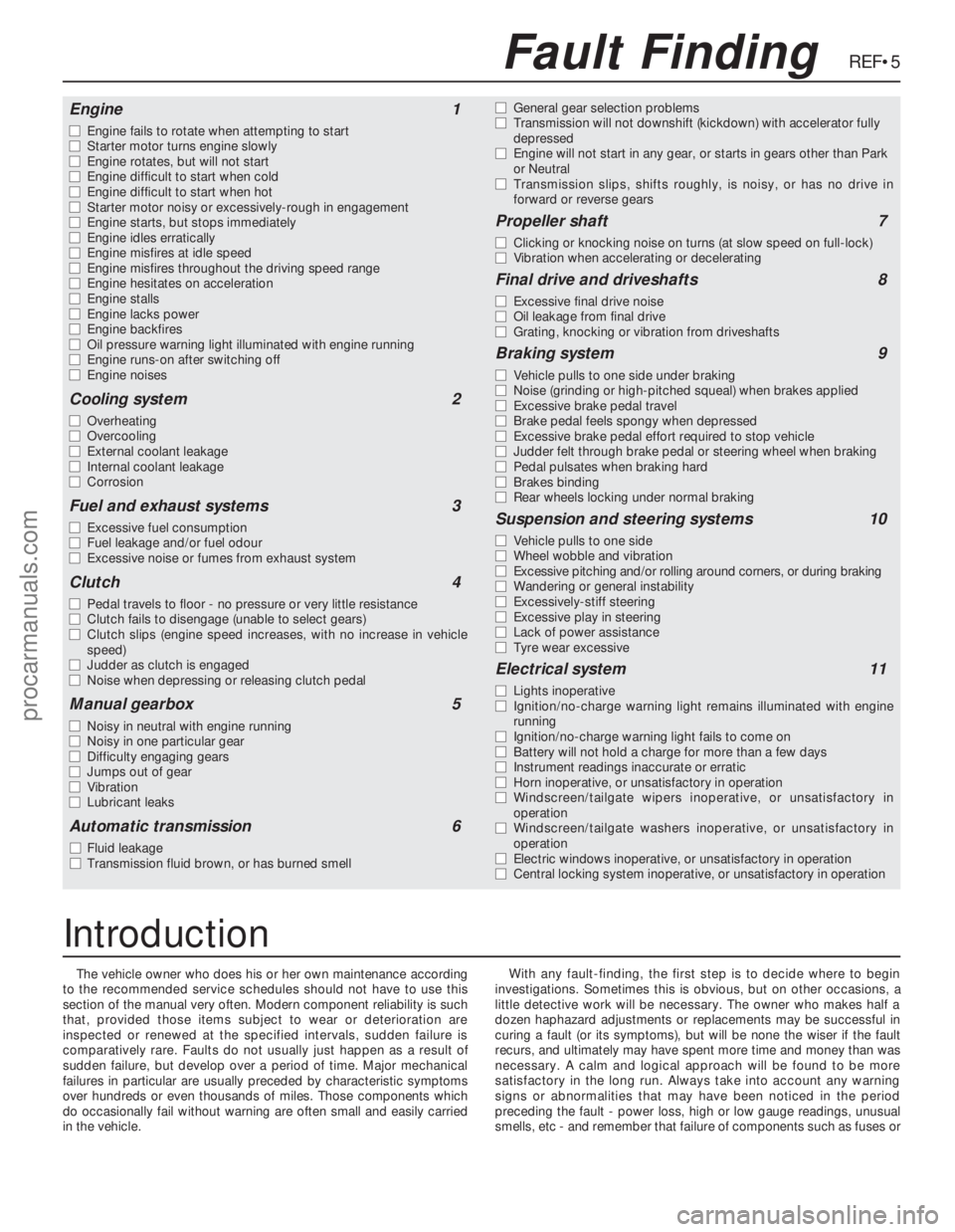

The vehicle owner who does his or her own maintenance according

to the recommended service schedules should not have to use this

section of the manual very often. Modern component reliability is such

that, provided those items subject to wear or deterioration are

inspected or renewed at the specified intervals, sudden failure is

comparatively rare. Faults do not usually just happen as a result of

sudden failure, but develop over a period of time. Major mechanical

failures in particular are usually preceded by characteristic symptoms

over hundreds or even thousands of miles. Those components which

do occasionally fail without warning are often small and easily carried

in the vehicle.With any fault-finding, the first step is to decide where to begin

investigations. Sometimes this is obvious, but on other occasions, a

little detective work will be necessary. The owner who makes half a

dozen haphazard adjustments or replacements may be successful in

curing a fault (or its symptoms), but will be none the wiser if the fault

recurs, and ultimately may have spent more time and money than was

necessary. A calm and logical approach will be found to be more

satisfactory in the long run. Always take into account any warning

signs or abnormalities that may have been noticed in the period

preceding the fault - power loss, high or low gauge readings, unusual

smells, etc - and remember that failure of components such as fuses or

REF•5Fault Finding

Engine1

m mEngine fails to rotate when attempting to start

m mStarter motor turns engine slowly

m mEngine rotates, but will not start

m mEngine difficult to start when cold

m mEngine difficult to start when hot

m mStarter motor noisy or excessively-rough in engagement

m mEngine starts, but stops immediately

m mEngine idles erratically

m mEngine misfires at idle speed

m mEngine misfires throughout the driving speed range

m mEngine hesitates on acceleration

m mEngine stalls

m mEngine lacks power

m mEngine backfires

m mOil pressure warning light illuminated with engine running

m mEngine runs-on after switching off

m mEngine noises

Cooling system2

m

mOverheating

m mOvercooling

m mExternal coolant leakage

m mInternal coolant leakage

m mCorrosion

Fuel and exhaust systems3

m

mExcessive fuel consumption

m mFuel leakage and/or fuel odour

m mExcessive noise or fumes from exhaust system

Clutch4

m

mPedal travels to floor - no pressure or very little resistance

m mClutch fails to disengage (unable to select gears)

m mClutch slips (engine speed increases, with no increase in vehicle

speed)

m mJudder as clutch is engaged

m mNoise when depressing or releasing clutch pedal

Manual gearbox5

m

mNoisy in neutral with engine running

m mNoisy in one particular gear

m mDifficulty engaging gears

m mJumps out of gear

m mVibration

m mLubricant leaks

Automatic transmission6

m

mFluid leakage

m mTransmission fluid brown, or has burned smellm mGeneral gear selection problems

m mTransmission will not downshift (kickdown) with accelerator fully

depressed

m mEngine will not start in any gear, or starts in gears other than Park

or Neutral

m mTransmission slips, shifts roughly, is noisy, or has no drive in

forward or reverse gears

Propeller shaft7

m

mClicking or knocking noise on turns (at slow speed on full-lock)

m mVibration when accelerating or decelerating

Final drive and driveshafts8

m

mExcessive final drive noise

m mOil leakage from final drive

m mGrating, knocking or vibration from driveshafts

Braking system9

m

mVehicle pulls to one side under braking

m mNoise (grinding or high-pitched squeal) when brakes applied

m mExcessive brake pedal travel

m mBrake pedal feels spongy when depressed

m mExcessive brake pedal effort required to stop vehicle

m mJudder felt through brake pedal or steering wheel when braking

m mPedal pulsates when braking hard

m mBrakes binding

m mRear wheels locking under normal braking

Suspension and steering systems10

m

mVehicle pulls to one side

m mWheel wobble and vibration

m mExcessive pitching and/or rolling around corners, or during braking

m mWandering or general instability

m mExcessively-stiff steering

m mExcessive play in steering

m mLack of power assistance

m mTyre wear excessive

Electrical system11

m

mLights inoperative

m mIgnition/no-charge warning light remains illuminated with engine

running

m mIgnition/no-charge warning light fails to come on

m mBattery will not hold a charge for more than a few days

m mInstrument readings inaccurate or erratic

m mHorn inoperative, or unsatisfactory in operation

m mWindscreen/tailgate wipers inoperative, or unsatisfactory in

operation

m mWindscreen/tailgate washers inoperative, or unsatisfactory in

operation

m mElectric windows inoperative, or unsatisfactory in operation

m mCentral locking system inoperative, or unsatisfactory in operation

Introduction

procarmanuals.com

Page 242 of 255

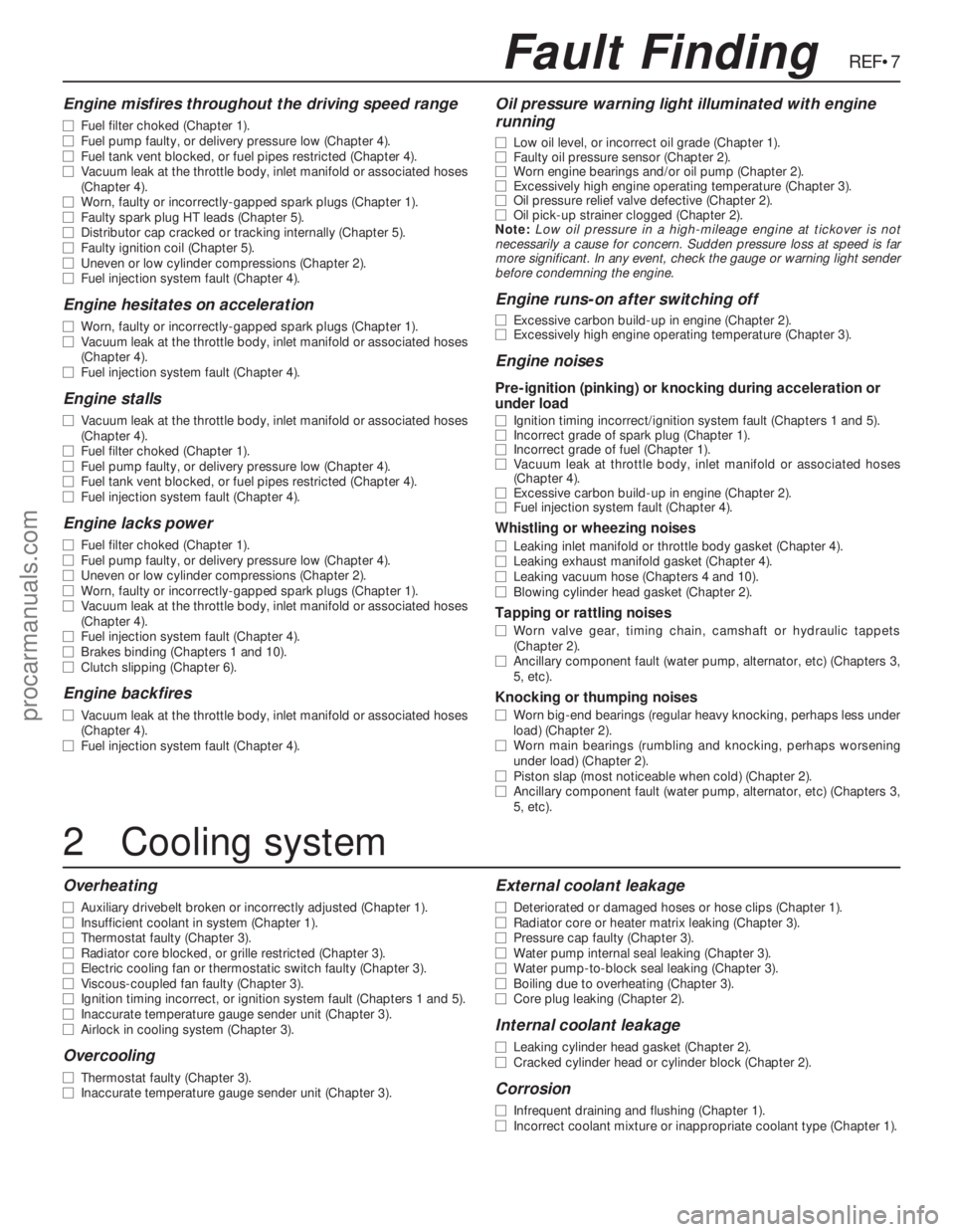

Engine misfires throughout the driving speed range

m mFuel filter choked (Chapter 1).

m mFuel pump faulty, or delivery pressure low (Chapter 4).

m mFuel tank vent blocked, or fuel pipes restricted (Chapter 4).

m mVacuum leak at the throttle body, inlet manifold or associated hoses

(Chapter 4).

m mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m mFaulty spark plug HT leads (Chapter 5).

m mDistributor cap cracked or tracking internally (Chapter 5).

m mFaulty ignition coil (Chapter 5).

m mUneven or low cylinder compressions (Chapter 2).

m mFuel injection system fault (Chapter 4).

Engine hesitates on acceleration

m

mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m mVacuum leak at the throttle body, inlet manifold or associated hoses

(Chapter 4).

m mFuel injection system fault (Chapter 4).

Engine stalls

m

mVacuum leak at the throttle body, inlet manifold or associated hoses

(Chapter 4).

m mFuel filter choked (Chapter 1).

m mFuel pump faulty, or delivery pressure low (Chapter 4).

m mFuel tank vent blocked, or fuel pipes restricted (Chapter 4).

m mFuel injection system fault (Chapter 4).

Engine lacks power

m

mFuel filter choked (Chapter 1).

m mFuel pump faulty, or delivery pressure low (Chapter 4).

m mUneven or low cylinder compressions (Chapter 2).

m mWorn, faulty or incorrectly-gapped spark plugs (Chapter 1).

m mVacuum leak at the throttle body, inlet manifold or associated hoses

(Chapter 4).

m mFuel injection system fault (Chapter 4).

m mBrakes binding (Chapters 1 and 10).

m mClutch slipping (Chapter 6).

Engine backfires

m

mVacuum leak at the throttle body, inlet manifold or associated hoses

(Chapter 4).

m mFuel injection system fault (Chapter 4).

Oil pressure warning light illuminated with engine

running

m mLow oil level, or incorrect oil grade (Chapter 1).

m mFaulty oil pressure sensor (Chapter 2).

m mWorn engine bearings and/or oil pump (Chapter 2).

m mExcessively high engine operating temperature (Chapter 3).

m mOil pressure relief valve defective (Chapter 2).

m mOil pick-up strainer clogged (Chapter 2).

Note:Low oil pressure in a high-mileage engine at tickover is not

necessarily a cause for concern. Sudden pressure loss at speed is far

more significant. In any event, check the gauge or warning light sender

before condemning the engine.

Engine runs-on after switching off

m mExcessive carbon build-up in engine (Chapter 2).

m mExcessively high engine operating temperature (Chapter 3).

Engine noises

Pre-ignition (pinking) or knocking during acceleration or

under load

m mIgnition timing incorrect/ignition system fault (Chapters 1 and 5).

m mIncorrect grade of spark plug (Chapter 1).

m mIncorrect grade of fuel (Chapter 1).

m mVacuum leak at throttle body, inlet manifold or associated hoses

(Chapter 4).

m mExcessive carbon build-up in engine (Chapter 2).

m mFuel injection system fault (Chapter 4).

Whistling or wheezing noises

m

mLeaking inlet manifold or throttle body gasket (Chapter 4).

m mLeaking exhaust manifold gasket (Chapter 4).

m mLeaking vacuum hose (Chapters 4 and 10).

m mBlowing cylinder head gasket (Chapter 2).

Tapping or rattling noises

m

mWorn valve gear, timing chain, camshaft or hydraulic tappets

(Chapter 2).

m mAncillary component fault (water pump, alternator, etc) (Chapters 3,

5, etc).

Knocking or thumping noises

m mWorn big-end bearings (regular heavy knocking, perhaps less under

load) (Chapter 2).

m mWorn main bearings (rumbling and knocking, perhaps worsening

under load) (Chapter 2).

m mPiston slap (most noticeable when cold) (Chapter 2).

m mAncillary component fault (water pump, alternator, etc) (Chapters 3,

5, etc).

REF•7Fault Finding

2Cooling system

Overheating

m

mAuxiliary drivebelt broken or incorrectly adjusted (Chapter 1).

m mInsufficient coolant in system (Chapter 1).

m mThermostat faulty (Chapter 3).

m mRadiator core blocked, or grille restricted (Chapter 3).

m mElectric cooling fan or thermostatic switch faulty (Chapter 3).

m mViscous-coupled fan faulty (Chapter 3).

m mIgnition timing incorrect, or ignition system fault (Chapters 1 and 5).

m mInaccurate temperature gauge sender unit (Chapter 3).

m mAirlock in cooling system (Chapter 3).

Overcooling

m

mThermostat faulty (Chapter 3).

m mInaccurate temperature gauge sender unit (Chapter 3).

External coolant leakage

m

mDeteriorated or damaged hoses or hose clips (Chapter 1).

m mRadiator core or heater matrix leaking (Chapter 3).

m mPressure cap faulty (Chapter 3).

m mWater pump internal seal leaking (Chapter 3).

m mWater pump-to-block seal leaking (Chapter 3).

m mBoiling due to overheating (Chapter 3).

m mCore plug leaking (Chapter 2).

Internal coolant leakage

m

mLeaking cylinder head gasket (Chapter 2).

m mCracked cylinder head or cylinder block (Chapter 2).

Corrosion

m

mInfrequent draining and flushing (Chapter 1).

m mIncorrect coolant mixture or inappropriate coolant type (Chapter 1).

procarmanuals.com

Page 243 of 255

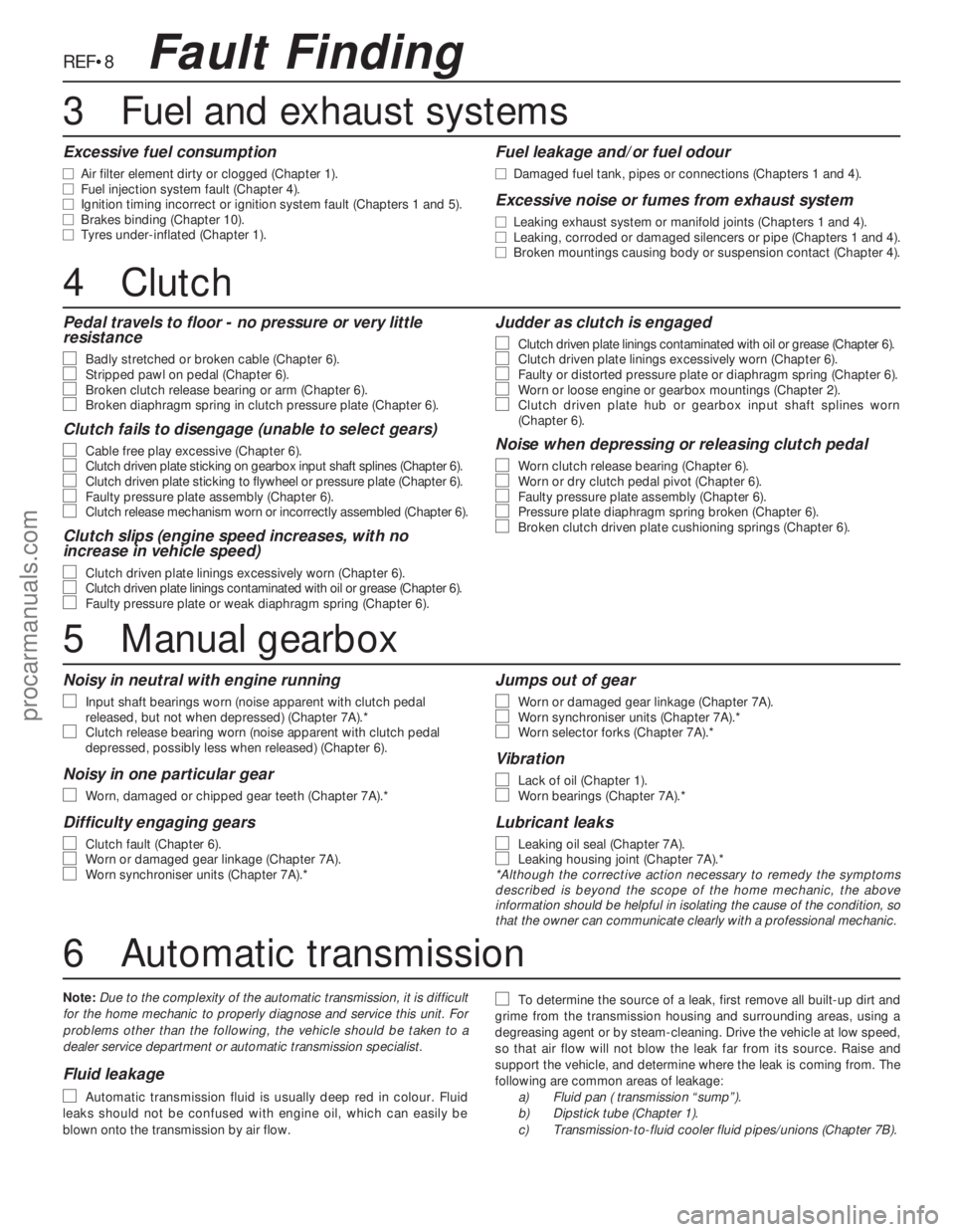

REF•8

Pedal travels to floor - no pressure or very little

resistance

m m

Badly stretched or broken cable (Chapter 6).m

mStripped pawl on pedal (Chapter 6).m

mBroken clutch release bearing or arm (Chapter 6).m

mBroken diaphragm spring in clutch pressure plate (Chapter 6).

Clutch fails to disengage (unable to select gears)

m m

Cable free play excessive (Chapter 6).m

mClutch driven plate sticking on gearbox input shaft splines (Chapter 6).m

mClutch driven plate sticking to flywheel or pressure plate (Chapter 6).m

mFaulty pressure plate assembly (Chapter 6).m

mClutch release mechanism worn or incorrectly assembled (Chapter 6).

Clutch slips (engine speed increases, with no

increase in vehicle speed)

m m

Clutch driven plate linings excessively worn (Chapter 6).m

mClutch driven plate linings contaminated with oil or grease (Chapter 6).m

mFaulty pressure plate or weak diaphragm spring (Chapter 6).

Judder as clutch is engaged

m m

Clutch driven plate linings contaminated with oil or grease (Chapter 6).m

mClutch driven plate linings excessively worn (Chapter 6).m

mFaulty or distorted pressure plate or diaphragm spring (Chapter 6).m

mWorn or loose engine or gearbox mountings (Chapter 2).m

mClutch driven plate hub or gearbox input shaft splines worn

(Chapter 6).

Noise when depressing or releasing clutch pedal

m m

Worn clutch release bearing (Chapter 6).m

mWorn or dry clutch pedal pivot (Chapter 6).m

mFaulty pressure plate assembly (Chapter 6).m

mPressure plate diaphragm spring broken (Chapter 6).m

mBroken clutch driven plate cushioning springs (Chapter 6).

Excessive fuel consumption

m

mAir filter element dirty or clogged (Chapter 1).

m mFuel injection system fault (Chapter 4).

m mIgnition timing incorrect or ignition system fault (Chapters 1 and 5).

m mBrakes binding (Chapter 10).

m mTyres under-inflated (Chapter 1).

Fuel leakage and/or fuel odour

m

mDamaged fuel tank, pipes or connections (Chapters 1 and 4).

Excessive noise or fumes from exhaust system

m

mLeaking exhaust system or manifold joints (Chapters 1 and 4).

m mLeaking, corroded or damaged silencers or pipe (Chapters 1 and 4).

m mBroken mountings causing body or suspension contact (Chapter 4).

Fault Finding

4Clutch

5Manual gearbox

Noisy in neutral with engine running

m m

Input shaft bearings worn (noise apparent with clutch pedal

released, but not when depressed) (Chapter 7A).*

m mClutch release bearing worn (noise apparent with clutch pedal

depressed, possibly less when released) (Chapter 6).

Noisy in one particular gear

m m

Worn, damaged or chipped gear teeth (Chapter 7A).*

Difficulty engaging gears

m m

Clutch fault (Chapter 6).m

mWorn or damaged gear linkage (Chapter 7A).m

mWorn synchroniser units (Chapter 7A).*

Jumps out of gear

m m

Worn or damaged gear linkage (Chapter 7A).m

mWorn synchroniser units (Chapter 7A).*m

mWorn selector forks (Chapter 7A).*

Vibration

m m

Lack of oil (Chapter 1).m

mWorn bearings (Chapter 7A).*

Lubricant leaks

m m

Leaking oil seal (Chapter 7A).m

mLeaking housing joint (Chapter 7A).*

*Although the corrective action necessary to remedy the symptoms

described is beyond the scope of the home mechanic, the above

information should be helpful in isolating the cause of the condition, so

that the owner can communicate clearly with a professional mechanic.

6Automatic transmission

Note:Due to the complexity of the automatic transmission, it is difficult

for the home mechanic to properly diagnose and service this unit. For

problems other than the following, the vehicle should be taken to a

dealer service department or automatic transmission specialist.

Fluid leakage

m m

Automatic transmission fluid is usually deep red in colour. Fluid

leaks should not be confused with engine oil, which can easily be

blown onto the transmission by air flow.

m mTo determine the source of a leak, first remove all built-up dirt and

grime from the transmission housing and surrounding areas, using a

degreasing agent or by steam-cleaning. Drive the vehicle at low speed,

so that air flow will not blow the leak far from its source. Raise and

support the vehicle, and determine where the leak is coming from. The

following are common areas of leakage:

a)Fluid pan ( transmission “sump”).

b)Dipstick tube (Chapter 1).

c)Transmission-to-fluid cooler fluid pipes/unions (Chapter 7B).

3Fuel and exhaust systems

procarmanuals.com

Page 244 of 255

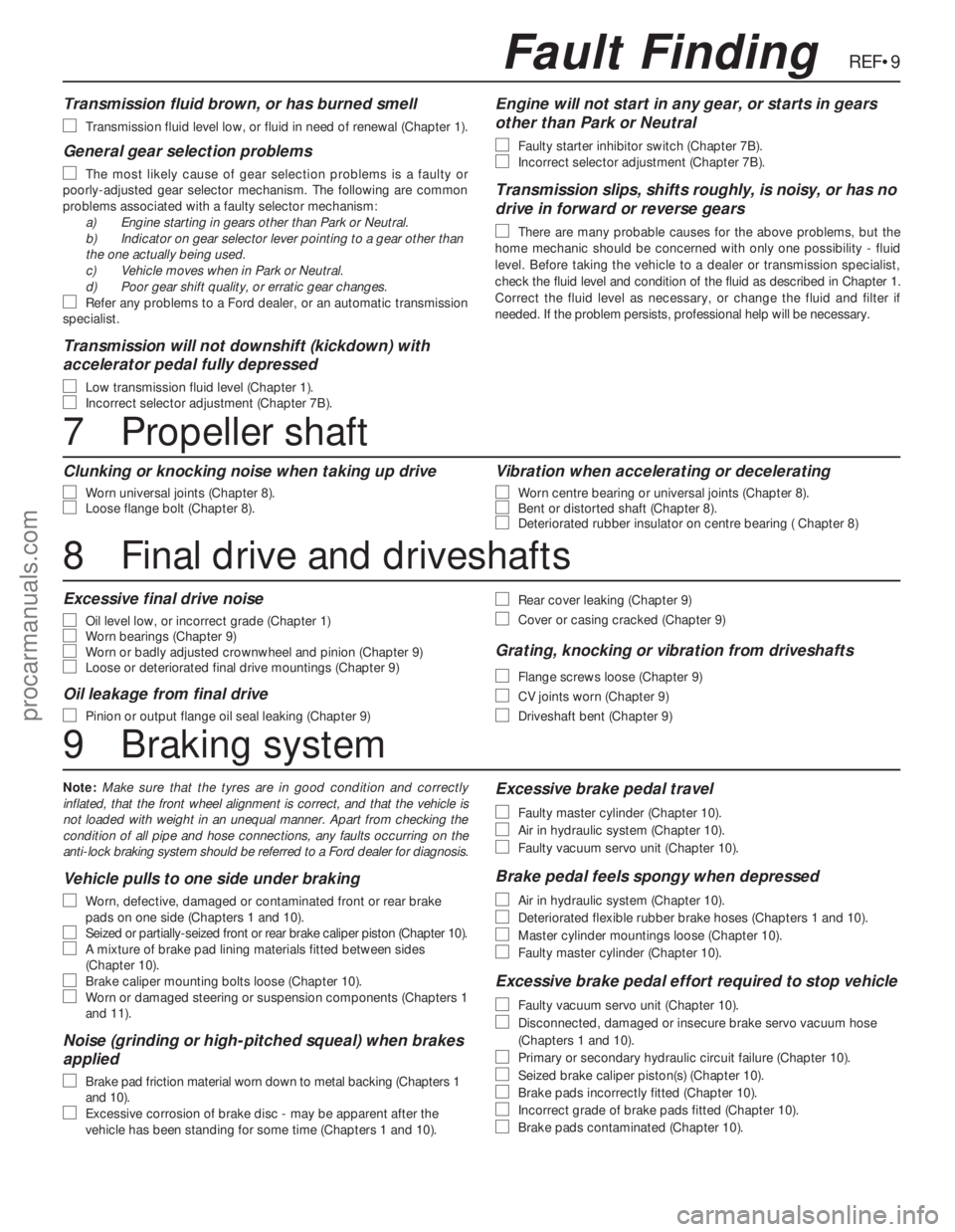

Transmission fluid brown, or has burned smell

m m

Transmission fluid level low, or fluid in need of renewal (Chapter 1).

General gear selection problems

m m

The most likely cause of gear selection problems is a faulty or

poorly-adjusted gear selector mechanism. The following are common

problems associated with a faulty selector mechanism:

a)Engine starting in gears other than Park or Neutral.

b)Indicator on gear selector lever pointing to a gear other than

the one actually being used.

c)Vehicle moves when in Park or Neutral.

d)Poor gear shift quality, or erratic gear changes.

m

mRefer any problems to a Ford dealer, or an automatic transmission

specialist.

Transmission will not downshift (kickdown) with

accelerator pedal fully depressed

m m

Low transmission fluid level (Chapter 1).

m

mIncorrect selector adjustment (Chapter 7B).

Engine will not start in any gear, or starts in gears

other than Park or Neutral

m m

Faulty starter inhibitor switch (Chapter 7B).

m

mIncorrect selector adjustment (Chapter 7B).

Transmission slips, shifts roughly, is noisy, or has no

drive in forward or reverse gears

m m

There are many probable causes for the above problems, but the

home mechanic should be concerned with only one possibility - fluid

level. Before taking the vehicle to a dealer or transmission specialist,

check the fluid level and condition of the fluid as described in Chapter 1.

Correct the fluid level as necessary, or change the fluid and filter if

needed. If the problem persists, professional help will be necessary.

REF•9Fault Finding

7Propeller shaft

Clunking or knocking noise when taking up drive

m m

Worn universal joints (Chapter 8).m

mLoose flange bolt (Chapter 8).

Vibration when accelerating or decelerating

m m

Worn centre bearing or universal joints (Chapter 8).m

mBent or distorted shaft (Chapter 8).m

mDeteriorated rubber insulator on centre bearing ( Chapter 8)

8Final drive and driveshafts

Excessive final drive noise

m m

Oil level low, or incorrect grade (Chapter 1)m

mWorn bearings (Chapter 9)m

mWorn or badly adjusted crownwheel and pinion (Chapter 9)m

mLoose or deteriorated final drive mountings (Chapter 9)

Oil leakage from final drive

m m

Pinion or output flange oil seal leaking (Chapter 9)

m

mRear cover leaking (Chapter 9)

m

mCover or casing cracked (Chapter 9)

Grating, knocking or vibration from driveshafts

m m

Flange screws loose (Chapter 9)

m

mCV joints worn (Chapter 9)

m

mDriveshaft bent (Chapter 9)

9Braking system

Note:Make sure that the tyres are in good condition and correctly

inflated, that the front wheel alignment is correct, and that the vehicle is

not loaded with weight in an unequal manner. Apart from checking the

condition of all pipe and hose connections, any faults occurring on the

anti-lock braking system should be referred to a Ford dealer for diagnosis.

Vehicle pulls to one side under braking

m m

Worn, defective, damaged or contaminated front or rear brake

pads on one side (Chapters 1 and 10).

m mSeized or partially-seized front or rear brake caliper piston (Chapter 10).m

mA mixture of brake pad lining materials fitted between sides

(Chapter 10).

m mBrake caliper mounting bolts loose (Chapter 10).m

mWorn or damaged steering or suspension components (Chapters 1

and 11).

Noise (grinding or high-pitched squeal) when brakes

applied

m m

Brake pad friction material worn down to metal backing (Chapters 1

and 10).

m mExcessive corrosion of brake disc - may be apparent after the

vehicle has been standing for some time (Chapters 1 and 10).

Excessive brake pedal travel

m m

Faulty master cylinder (Chapter 10).

m

mAir in hydraulic system (Chapter 10).

m

mFaulty vacuum servo unit (Chapter 10).

Brake pedal feels spongy when depressed

m m

Air in hydraulic system (Chapter 10).

m

mDeteriorated flexible rubber brake hoses (Chapters 1 and 10).

m

mMaster cylinder mountings loose (Chapter 10).

m

mFaulty master cylinder (Chapter 10).

Excessive brake pedal effort required to stop vehicle

m m

Faulty vacuum servo unit (Chapter 10).

m

mDisconnected, damaged or insecure brake servo vacuum hose

(Chapters 1 and 10).

m mPrimary or secondary hydraulic circuit failure (Chapter 10).

m

mSeized brake caliper piston(s) (Chapter 10).

m

mBrake pads incorrectly fitted (Chapter 10).

m

mIncorrect grade of brake pads fitted (Chapter 10).

m

mBrake pads contaminated (Chapter 10).

procarmanuals.com

Page 245 of 255

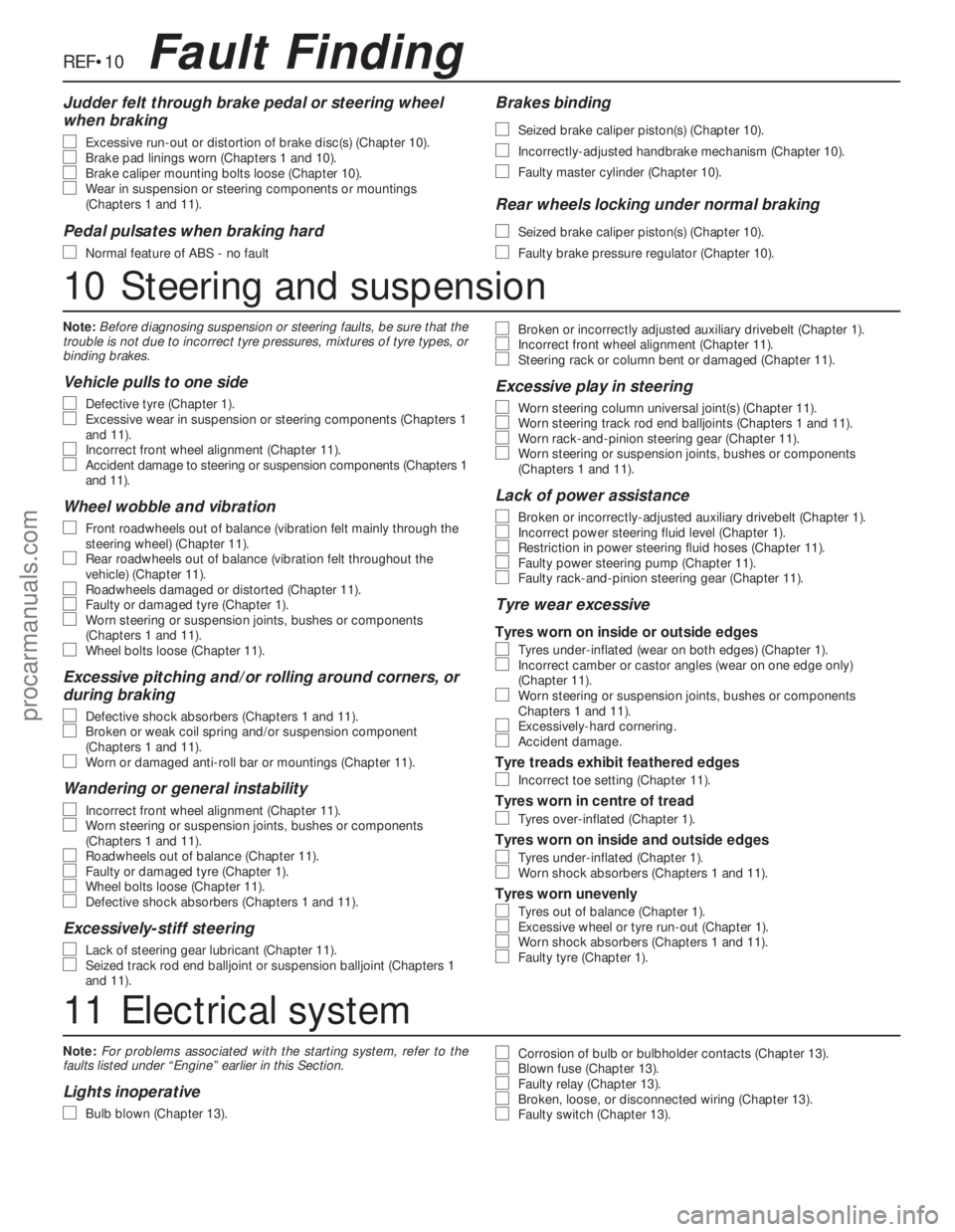

Note:For problems associated with the starting system, refer to the

faults listed under “Engine” earlier in this Section.

Lights inoperative

m m

Bulb blown (Chapter 13).

m

mCorrosion of bulb or bulbholder contacts (Chapter 13).m

mBlown fuse (Chapter 13).m

mFaulty relay (Chapter 13).m

mBroken, loose, or disconnected wiring (Chapter 13).m

mFaulty switch (Chapter 13).

REF•10Fault Finding

Judder felt through brake pedal or steering wheel

when braking

m m

Excessive run-out or distortion of brake disc(s) (Chapter 10).m

mBrake pad linings worn (Chapters 1 and 10).m

mBrake caliper mounting bolts loose (Chapter 10).m

mWear in suspension or steering components or mountings

(Chapters 1 and 11).

Pedal pulsates when braking hard

m m

Normal feature of ABS - no fault

Brakes binding

m m

Seized brake caliper piston(s) (Chapter 10).

m

mIncorrectly-adjusted handbrake mechanism (Chapter 10).

m

mFaulty master cylinder (Chapter 10).

Rear wheels locking under normal braking

m m

Seized brake caliper piston(s) (Chapter 10).

m

mFaulty brake pressure regulator (Chapter 10).

10Steering and suspension

Note:Before diagnosing suspension or steering faults, be sure that the

trouble is not due to incorrect tyre pressures, mixtures of tyre types, or

binding brakes.

Vehicle pulls to one side

m m

Defective tyre (Chapter 1).m

mExcessive wear in suspension or steering components (Chapters 1

and 11).

m mIncorrect front wheel alignment (Chapter 11).m

mAccident damage to steering or suspension components (Chapters 1

and 11).

Wheel wobble and vibration

m m

Front roadwheels out of balance (vibration felt mainly through the

steering wheel) (Chapter 11).

m mRear roadwheels out of balance (vibration felt throughout the

vehicle) (Chapter 11).

m mRoadwheels damaged or distorted (Chapter 11).m

mFaulty or damaged tyre (Chapter 1).m

mWorn steering or suspension joints, bushes or components

(Chapters 1 and 11).

m mWheel bolts loose (Chapter 11).

Excessive pitching and/or rolling around corners, or

during braking

m m

Defective shock absorbers (Chapters 1 and 11).m

mBroken or weak coil spring and/or suspension component

(Chapters 1 and 11).

m mWorn or damaged anti-roll bar or mountings (Chapter 11).

Wandering or general instability

m m

Incorrect front wheel alignment (Chapter 11).m

mWorn steering or suspension joints, bushes or components

(Chapters 1 and 11).

m mRoadwheels out of balance (Chapter 11).m

mFaulty or damaged tyre (Chapter 1).m

mWheel bolts loose (Chapter 11).m

mDefective shock absorbers (Chapters 1 and 11).

Excessively-stiff steering

m m

Lack of steering gear lubricant (Chapter 11).m

mSeized track rod end balljoint or suspension balljoint (Chapters 1

and 11).

m mBroken or incorrectly adjusted auxiliary drivebelt (Chapter 1).m

mIncorrect front wheel alignment (Chapter 11).m

mSteering rack or column bent or damaged (Chapter 11).

Excessive play in steering

m m

Worn steering column universal joint(s) (Chapter 11).m

mWorn steering track rod end balljoints (Chapters 1 and 11).m

mWorn rack-and-pinion steering gear (Chapter 11).m

mWorn steering or suspension joints, bushes or components

(Chapters 1 and 11).

Lack of power assistance

m m

Broken or incorrectly-adjusted auxiliary drivebelt (Chapter 1).m

mIncorrect power steering fluid level (Chapter 1).m

mRestriction in power steering fluid hoses (Chapter 11).m

mFaulty power steering pump (Chapter 11).m

mFaulty rack-and-pinion steering gear (Chapter 11).

Tyre wear excessive

Tyres worn on inside or outside edges

m

mTyres under-inflated (wear on both edges) (Chapter 1).m

mIncorrect camber or castor angles (wear on one edge only)

(Chapter 11).

m mWorn steering or suspension joints, bushes or components

Chapters 1 and 11).

m mExcessively-hard cornering.m

mAccident damage.

Tyre treads exhibit feathered edges

m

mIncorrect toe setting (Chapter 11).

Tyres worn in centre of tread

m

mTyres over-inflated (Chapter 1).

Tyres worn on inside and outside edges

m

mTyres under-inflated (Chapter 1).m

mWorn shock absorbers (Chapters 1 and 11).

Tyres worn unevenly

m

mTyres out of balance (Chapter 1).m

mExcessive wheel or tyre run-out (Chapter 1).m

mWorn shock absorbers (Chapters 1 and 11).m

mFaulty tyre (Chapter 1).

11Electrical system

procarmanuals.com

Page 247 of 255

REF•12Glossary of Technical Terms

A

ABS (Anti-lock brake system)A system,

usually electronically controlled, that senses

incipient wheel lockup during braking and

relieves hydraulic pressure at wheels that are

about to skid.

Air bag An inflatable bag hidden in the

steering wheel (driver’s side) or the dash or

glovebox (passenger side). In a head-on

collision, the bags inflate, preventing the

driver and front passenger from being thrown

forward into the steering wheel or windscreen.

Air cleanerA metal or plastic housing,

containing a filter element, which removes

dust and dirt from the air being drawn into the

engine.

Air filter elementThe actual filter in an air

cleaner system, usually manufactured from

pleated paper and requiring renewal at regular

intervals.

Allen keyA hexagonal wrench which fits into

a recessed hexagonal hole.

Alligator clipA long-nosed spring-loaded

metal clip with meshing teeth. Used to make

temporary electrical connections.

AlternatorA component in the electrical

system which converts mechanical energy

from a drivebelt into electrical energy to

charge the battery and to operate the starting

system, ignition system and electrical

accessories.

Ampere (amp)A unit of measurement for the

flow of electric current. One amp is the

amount of current produced by one volt

acting through a resistance of one ohm.

Anaerobic sealerA substance used to

prevent bolts and screws from loosening.

Anaerobic means that it does not require

oxygen for activation. The Loctite brand is

widely used.

AntifreezeA substance (usually ethylene

glycol) mixed with water, and added to a

vehicle’s cooling system, to prevent freezing

of the coolant in winter. Antifreeze also

contains chemicals to inhibit corrosion and

the formation of rust and other deposits that

would tend to clog the radiator and coolant

passages and reduce cooling efficiency.

Anti-seize compoundA coating that

reduces the risk of seizing on fasteners that

are subjected to high temperatures, such as

exhaust manifold bolts and nuts.

AsbestosA natural fibrous mineral with great

heat resistance, commonly used in the

composition of brake friction materials.Asbestos is a health hazard and the dust

created by brake systems should never be

inhaled or ingested.

AxleA shaft on which a wheel revolves, or

which revolves with a wheel. Also, a solid

beam that connects the two wheels at one

end of the vehicle. An axle which also

transmits power to the wheels is known as a

live axle.

AxleshaftA single rotating shaft, on either

side of the differential, which delivers power

from the final drive assembly to the drive

wheels. Also called a driveshaft or a halfshaft.

BBall bearingAn anti-friction bearing

consisting of a hardened inner and outer race

with hardened steel balls between two races.

BearingThe curved surface on a shaft or in a

bore, or the part assembled into either, that

permits relative motion between them with

minimum wear and friction.

Big-end bearingThe bearing in the end of

the connecting rod that’s attached to the

crankshaft.

Bleed nippleA valve on a brake wheel

cylinder, caliper or other hydraulic component

that is opened to purge the hydraulic system

of air. Also called a bleed screw.

Brake bleedingProcedure for removing air

from lines of a hydraulic brake system.

Brake discThe component of a disc brake

that rotates with the wheels.Brake drumThe component of a drum brake

that rotates with the wheels.

Brake liningsThe friction material which

contacts the brake disc or drum to retard the

vehicle’s speed. The linings are bonded or

riveted to the brake pads or shoes.

Brake padsThe replaceable friction pads

that pinch the brake disc when the brakes are

applied. Brake pads consist of a friction

material bonded or riveted to a rigid backing

plate.

Brake shoeThe crescent-shaped carrier to

which the brake linings are mounted and

which forces the lining against the rotating

drum during braking.

Braking systemsFor more information on

braking systems, consult the Haynes

Automotive Brake Manual.

Breaker barA long socket wrench handle

providing greater leverage.

BulkheadThe insulated partition between

the engine and the passenger compartment.

CCaliperThe non-rotating part of a disc-brake

assembly that straddles the disc and carries

the brake pads. The caliper also contains the

hydraulic components that cause the pads to

pinch the disc when the brakes are applied. A

caliper is also a measuring tool that can be set

to measure inside or outside dimensions of an

object.

CamshaftA rotating shaft on which a series

of cam lobes operate the valve mechanisms.

The camshaft may be driven by gears, by

sprockets and chain or by sprockets and a

belt.

CanisterA container in an evaporative

emission control system; contains activated

charcoal granules to trap vapours from the

fuel system.

CarburettorA device which mixes fuel with

air in the proper proportions to provide a

desired power output from a spark ignition

internal combustion engine.

CastellatedResembling the parapets along

the top of a castle wall. For example, a

castellated balljoint stud nut.

CastorIn wheel alignment, the backward or

forward tilt of the steering axis. Castor is

positive when the steering axis is inclined

rearward at the top.

Canister

Brake bleeding

Bearing

Air filter

procarmanuals.com