Electric FORD KUGA 2011 1.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1430 of 2057

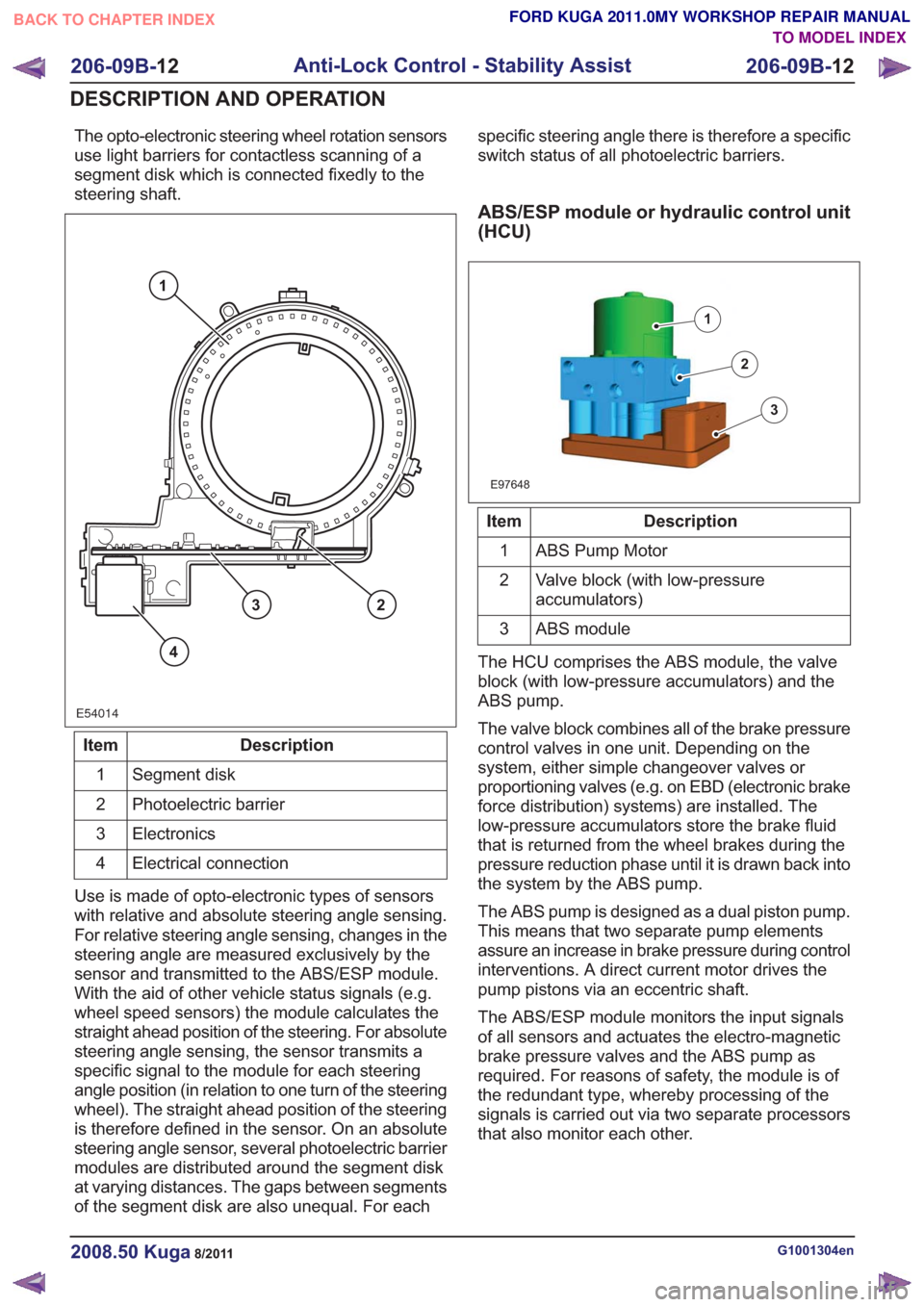

The opto-electronic steering wheel rotation sensors

use light barriers for contactless scanning of a

segment disk which is connected fixedly to the

steering shaft.

E54014

1

23

4

Description

Item

Segment disk

1

Photoelectric barrier

2

Electronics

3

Electrical connection

4

Use is made of opto-electronic types of sensors

with relative and absolute steering angle sensing.

For relative steering angle sensing, changes in the

steering angle are measured exclusively by the

sensor and transmitted to the ABS/ESP module.

With the aid of other vehicle status signals (e.g.

wheel speed sensors) the module calculates the

straight ahead position of the steering. For absolute

steering angle sensing, the sensor transmits a

specific signal to the module for each steering

angle position (in relation to one turn of the steering

wheel). The straight ahead position of the steering

is therefore defined in the sensor. On an absolute

steering angle sensor, several photoelectric barrier

modules are distributed around the segment disk

at varying distances. The gaps between segments

of the segment disk are also unequal. For each specific steering angle there is therefore a specific

switch status of all photoelectric barriers.

ABS/ESP module or hydraulic control unit

(HCU)

E97648

1

2

3

Description

Item

ABS Pump Motor

1

Valve block (with low-pressure

accumulators)

2

ABS module

3

The HCU comprises the ABS module, the valve

block (with low-pressure accumulators) and the

ABS pump.

The valve block combines all of the brake pressure

control valves in one unit. Depending on the

system, either simple changeover valves or

proportioning valves (e.g. on EBD (electronic brake

force distribution) systems) are installed. The

low-pressure accumulators store the brake fluid

that is returned from the wheel brakes during the

pressure reduction phase until it is drawn back into

the system by the ABS pump.

The ABS pump is designed as a dual piston pump.

This means that two separate pump elements

assure an increase in brake pressure during control

interventions. A direct current motor drives the

pump pistons via an eccentric shaft.

The ABS/ESP module monitors the input signals

of all sensors and actuates the electro-magnetic

brake pressure valves and the ABS pump as

required. For reasons of safety, the module is of

the redundant type, whereby processing of the

signals is carried out via two separate processors

that also monitor each other.

G1001304en2008.50 Kuga8/2011

206-09B- 12

Anti-Lock Control - Stability Assist

206-09B- 12

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1443 of 2057

Steering System

Special Tool(s) / General EquipmentAlignment Pins, Subframe

205-316 (15-097A)

15097

Simulator, Driver and

Passenger Air Bags and Side

Air Curtains

501-073 (40-016)

501073

The Ford approved diagnostic tool

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanicalor electrical damage.

Visual Inspection Chart

Electrical

Mechanical

• Battery

• Battery cables

• Steering anglesensor electrical

connector

• Power steering pump control

module electrical

connectors

• Power steering pump control

module ground

cable

• Power steering pump control

module ground

cable retaining

screw

• Steering angle sensor warning

indicator

• Fuse(s)

• Tire pressure(s)

• Loose tie-rod end(s)

• Loose strut and

spring assemblies or

ball joints

• Loose pinch bolts on steering column

shaft flexible coup-

ling

• Wheels and tires

• Power steering line fluid leaks

• Steering gear bellows 3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the diagnostic tab within

the Ford approved diagnostic tool.

Components Tests

Steering Linkage

1. Grasp the steering wheel firmly and move it upand down and to the left and right without

turning the steering wheel to check the steering

column bearing for wear, steering column shaft

for wear, steering wheel for looseness and

steering column for looseness. If the steering

column bearing or the steering column shaft is

worn install a new steering column. If the

steering wheel or the steering column is loose,

tighten the steering wheel or the steering column

retaining bolts.

2. With the road wheels in the straight ahead position, gently turn the steering wheel to the

left and the right to check for free play in the

steering linkage.

3. There should be no excessive free play at the steering wheel rim. If there is excessive free

play, CHECK the tie-rod inner and outer ball

joints, REFER to Tie-Rod Component Test in

this procedure. CHECK the steering column

universal joint, REFER to Steering Column

Universal Joint Component Test in this

procedure. If there is no free play in the tie-rod

and the steering column, install a new steering

gear.

Tie-Rod

CAUTION: Steering gear boots must be

handled carefully to avoid damage. Use

new steering boot clamps when installing

the steering gear boots.

NOTE: Noises such as knocks, which may appear

to originate from the steering linkage, may also be

generated by front suspension components.

REFER to: Noise, Vibration and Harshness (NVH)

(100-04 Noise, Vibration and Harshness,

Diagnosis and Testing).

G1059437en2008.50 Kuga8/2011

211-00- 2

Steering System - General Information

211-00- 2

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1460 of 2057

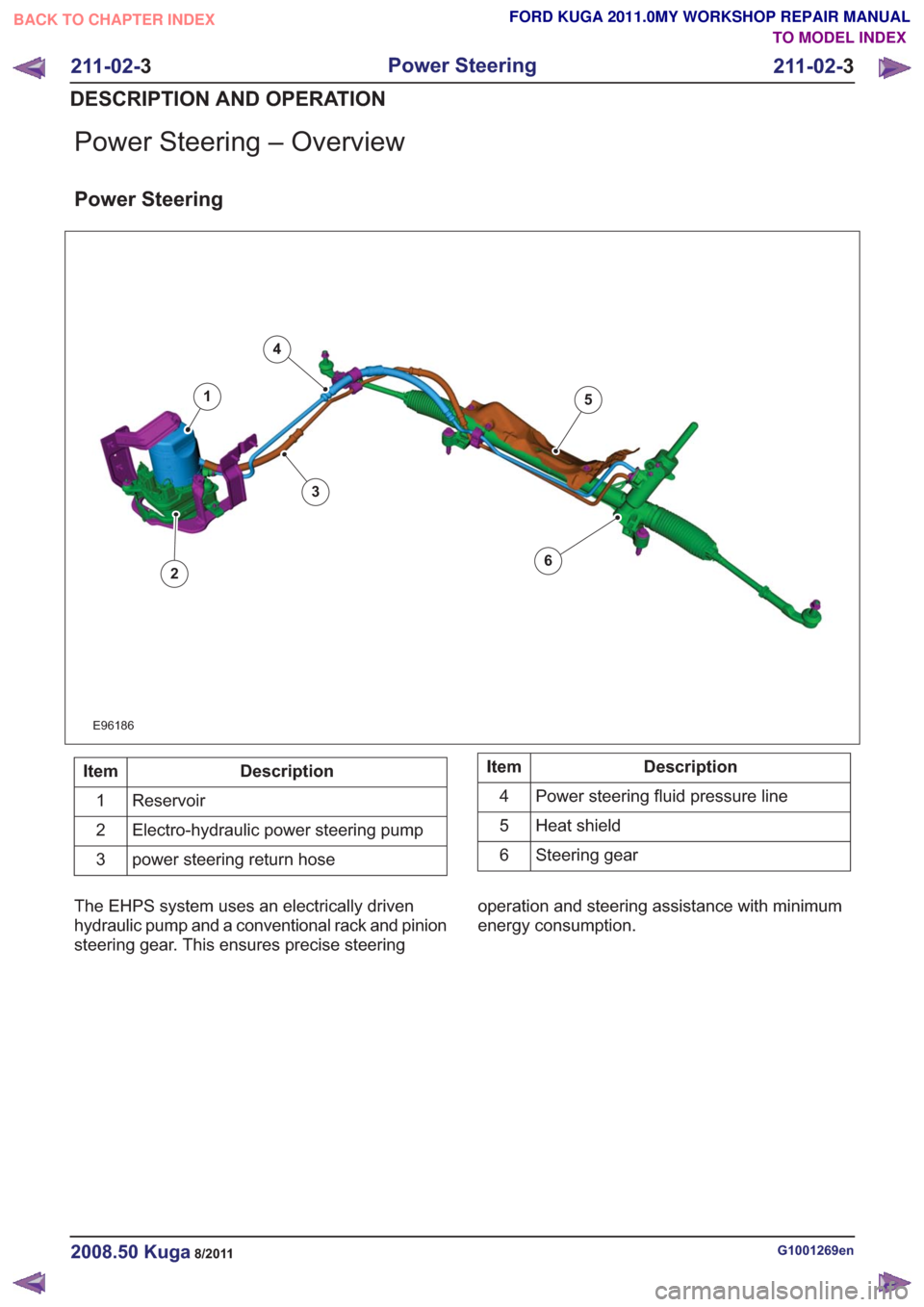

Power Steering – Overview

Power Steering

E96186

1

2

3

4

5

6

Description

Item

Reservoir

1

Electro-hydraulic power steering pump

2

power steering return hose

3Description

Item

Power steering fluid pressure line

4

Heat shield

5

Steering gear

6

The EHPS system uses an electrically driven

hydraulic pump and a conventional rack and pinion

steering gear. This ensures precise steering operation and steering assistance with minimum

energy consumption.

G1001269en2008.50 Kuga8/2011

211-02-

3

Power Steering

211-02- 3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1504 of 2057

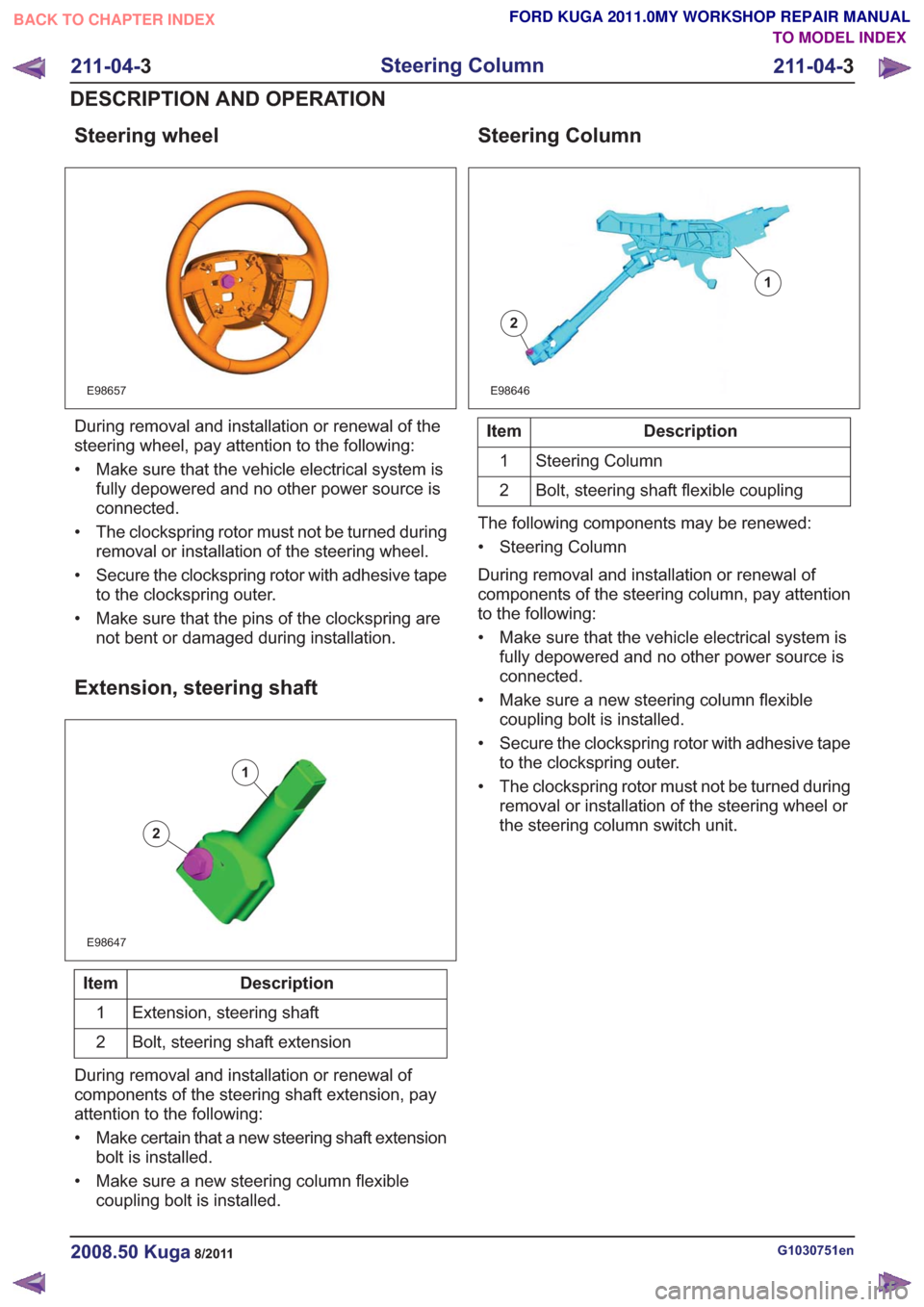

Steering wheel

E98657

During removal and installation or renewal of the

steering wheel, pay attention to the following:

• Make sure that the vehicle electrical system isfully depowered and no other power source is

connected.

• The clockspring rotor must not be turned during removal or installation of the steering wheel.

• Secure the clockspring rotor with adhesive tape to the clockspring outer.

• Make sure that the pins of the clockspring are not bent or damaged during installation.

Extension, steering shaft

E98647

1

2

Description

Item

Extension, steering shaft

1

Bolt, steering shaft extension

2

During removal and installation or renewal of

components of the steering shaft extension, pay

attention to the following:

• Make certain that a new steering shaft extension bolt is installed.

• Make sure a new steering column flexible coupling bolt is installed.

Steering Column

E98646

1

2

Description

Item

Steering Column

1

Bolt, steering shaft flexible coupling

2

The following components may be renewed:

• Steering Column

During removal and installation or renewal of

components of the steering column, pay attention

to the following:

• Make sure that the vehicle electrical system is fully depowered and no other power source is

connected.

• Make sure a new steering column flexible coupling bolt is installed.

• Secure the clockspring rotor with adhesive tape to the clockspring outer.

• The clockspring rotor must not be turned during removal or installation of the steering wheel or

the steering column switch unit.

G1030751en2008.50 Kuga8/2011

211-04- 3

Steering Column

211-04- 3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1506 of 2057

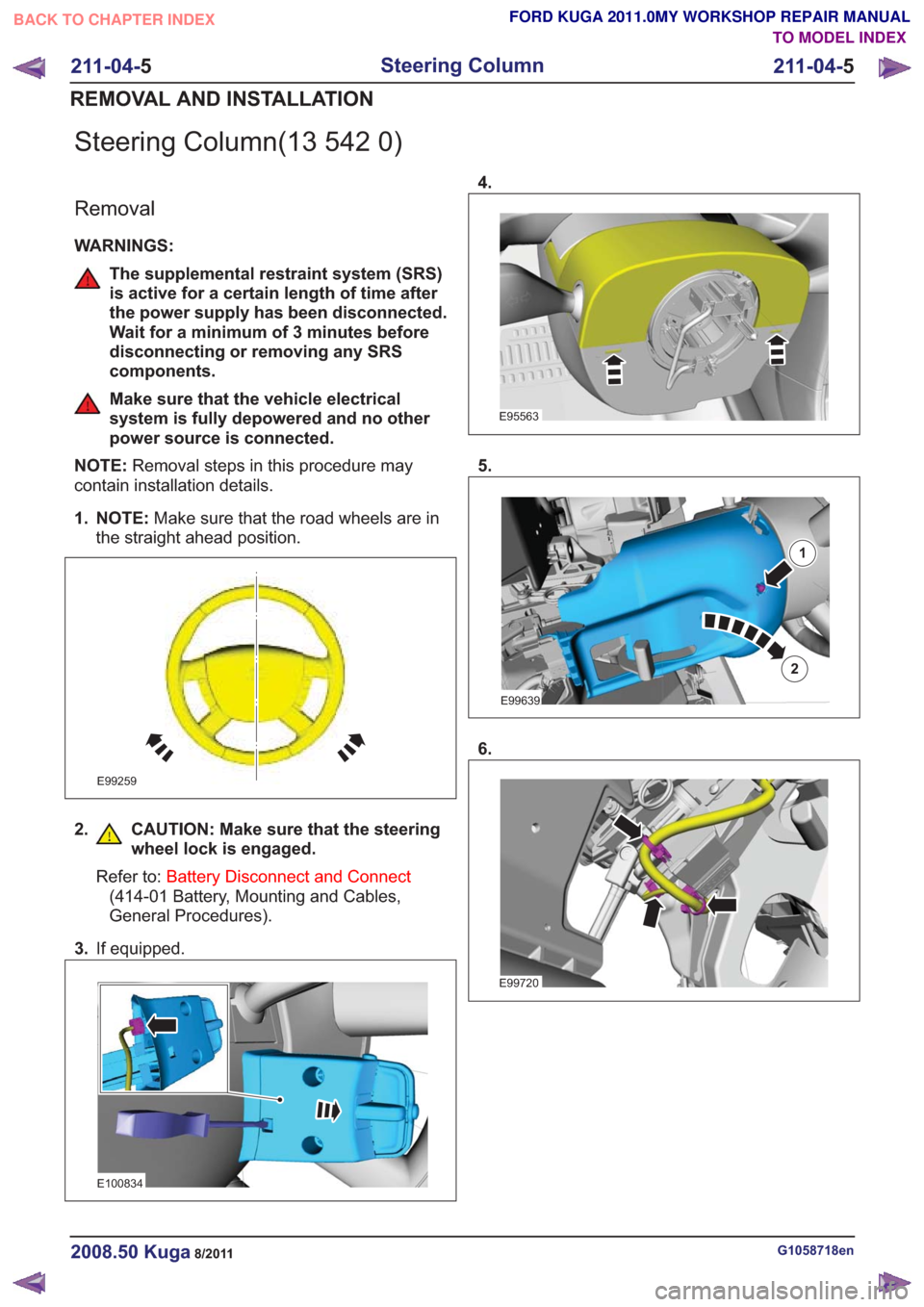

Steering Column(13 542 0)

Removal

WARNINGS:

The supplemental restraint system (SRS)

is active for a certain length of time after

the power supply has been disconnected.

Wait for a minimum of 3 minutes before

disconnecting or removing any SRS

components.

Make sure that the vehicle electrical

system is fully depowered and no other

power source is connected.

NOTE: Removal steps in this procedure may

contain installation details.

1. NOTE: Make sure that the road wheels are in

the straight ahead position.

E99259

2. CAUTION: Make sure that the steering wheel lock is engaged.

Refer to: Battery Disconnect and Connect

(414-01 Battery, Mounting and Cables,

General Procedures).

3. If equipped.

E100834

4.

E95563

5.

E99639

1

2

6.

E99720

G1058718en2008.50 Kuga8/2011

211-04- 5

Steering Column

211-04- 5

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1508 of 2057

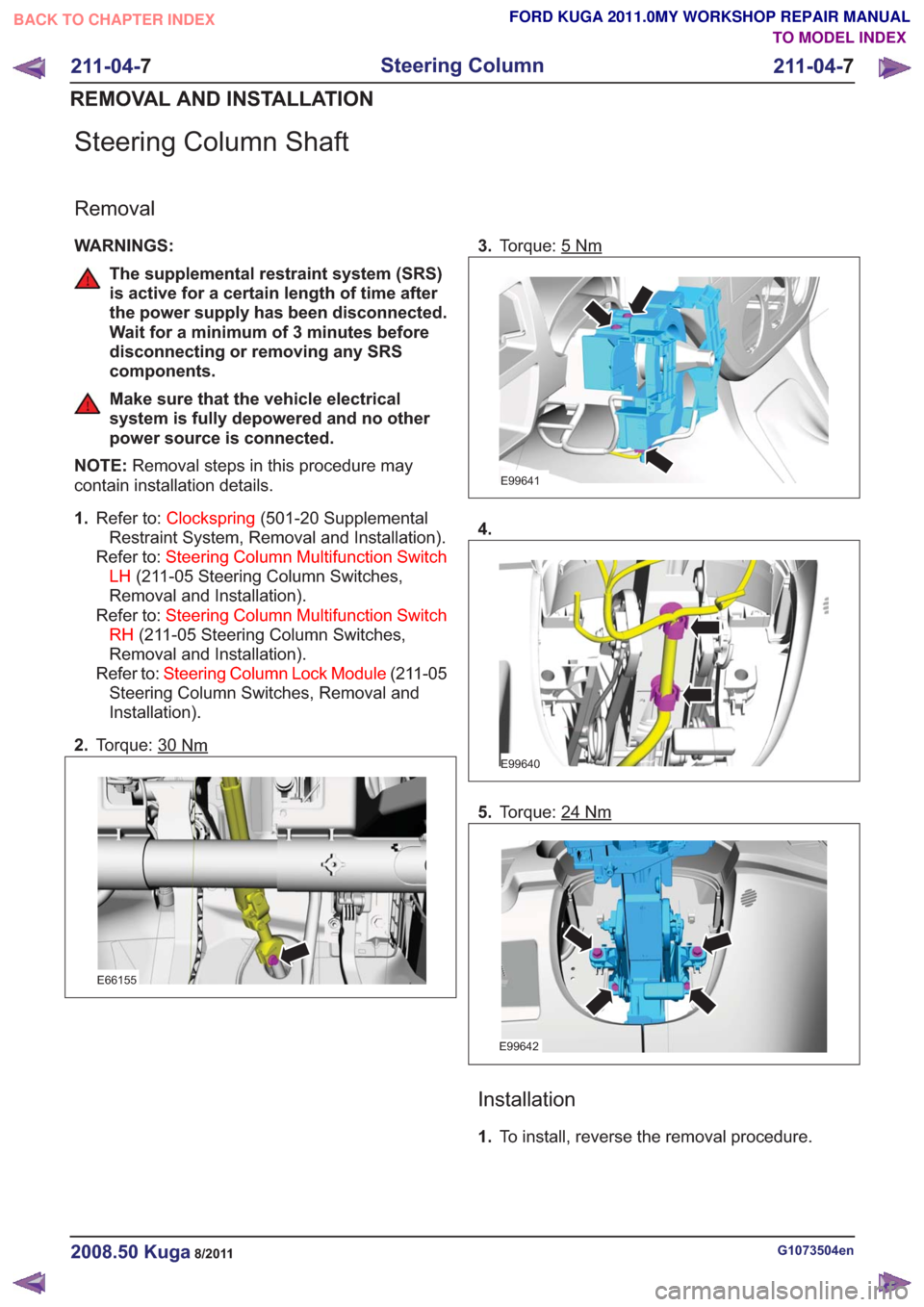

Steering Column Shaft

Removal

WARNINGS:

The supplemental restraint system (SRS)

is active for a certain length of time after

the power supply has been disconnected.

Wait for a minimum of 3 minutes before

disconnecting or removing any SRS

components.

Make sure that the vehicle electrical

system is fully depowered and no other

power source is connected.

NOTE: Removal steps in this procedure may

contain installation details.

1. Refer to: Clockspring (501-20 Supplemental

Restraint System, Removal and Installation).

Refer to: Steering Column Multifunction Switch

LH (211-05 Steering Column Switches,

Removal and Installation).

Refer to: Steering Column Multifunction Switch

RH (211-05 Steering Column Switches,

Removal and Installation).

Refer to: Steering Column Lock Module (211-05

Steering Column Switches, Removal and

Installation).

2. Torque: 30

Nm

E66155

3.Torque: 5Nm

E99641

4.

E99640

5.Torque: 24Nm

E99642

Installation

1.To install, reverse the removal procedure.

G1073504en2008.50 Kuga8/2011

211-04- 7

Steering Column

211-04- 7

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1511 of 2057

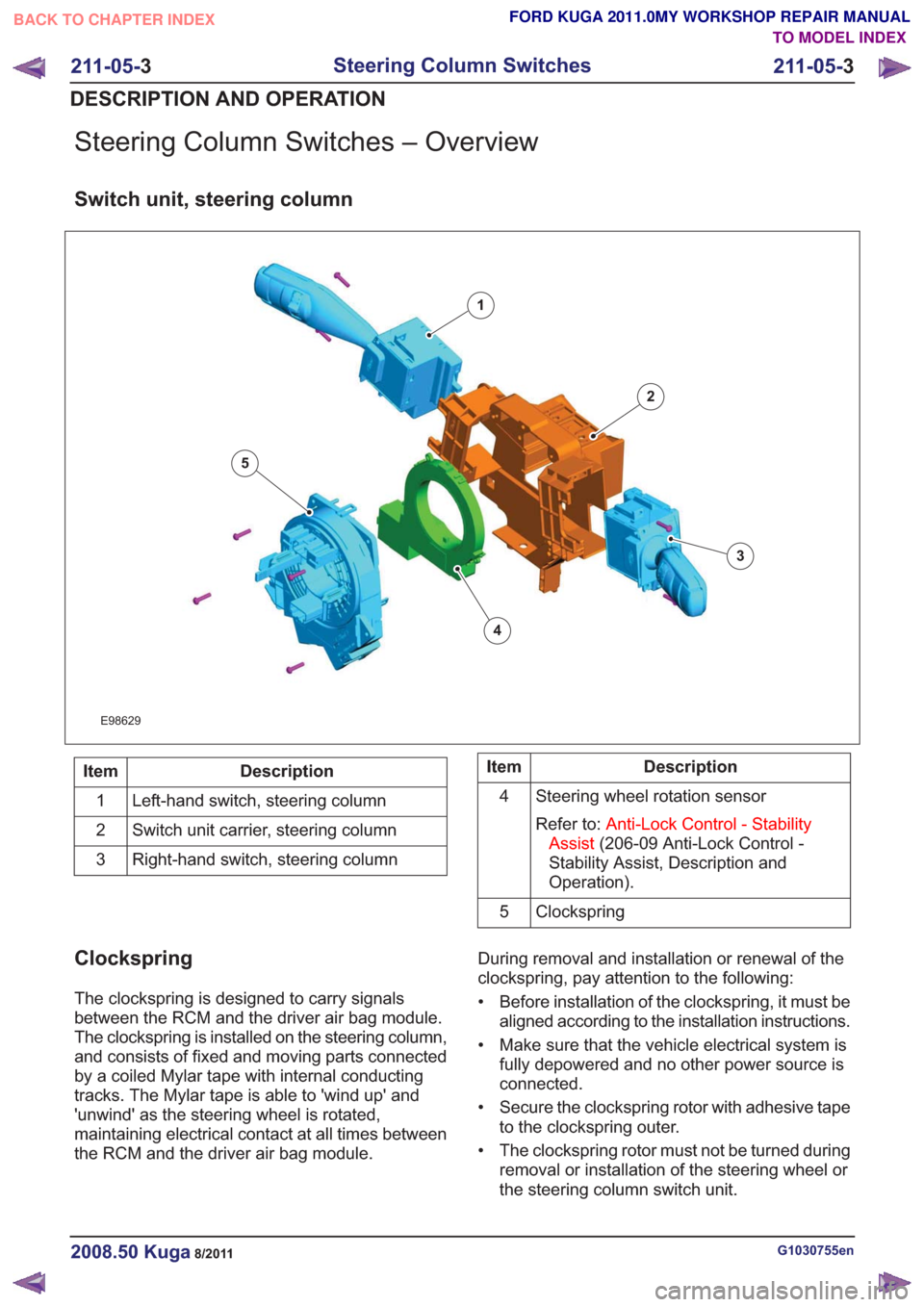

Steering Column Switches – Overview

Switch unit, steering column

E98629

1

2

3

4

5

Description

Item

Left-hand switch, steering column

1

Switch unit carrier, steering column

2

Right-hand switch, steering column

3Description

Item

Steering wheel rotation sensor

Refer to: Anti-Lock Control - Stability

Assist (206-09 Anti-Lock Control -

Stability Assist, Description and

Operation).

4

Clockspring

5

Clockspring

The clockspring is designed to carry signals

between the RCM and the driver air bag module.

The clockspring is installed on the steering column,

and consists of fixed and moving parts connected

by a coiled Mylar tape with internal conducting

tracks. The Mylar tape is able to 'wind up' and

'unwind' as the steering wheel is rotated,

maintaining electrical contact at all times between

the RCM and the driver air bag module. During removal and installation or renewal of the

clockspring, pay attention to the following:

• Before installation of the clockspring, it must be

aligned according to the installation instructions.

• Make sure that the vehicle electrical system is fully depowered and no other power source is

connected.

• Secure the clockspring rotor with adhesive tape to the clockspring outer.

• The clockspring rotor must not be turned during removal or installation of the steering wheel or

the steering column switch unit.

G1030755en2008.50 Kuga8/2011

211-05- 3

Steering Column Switches

211-05- 3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1518 of 2057

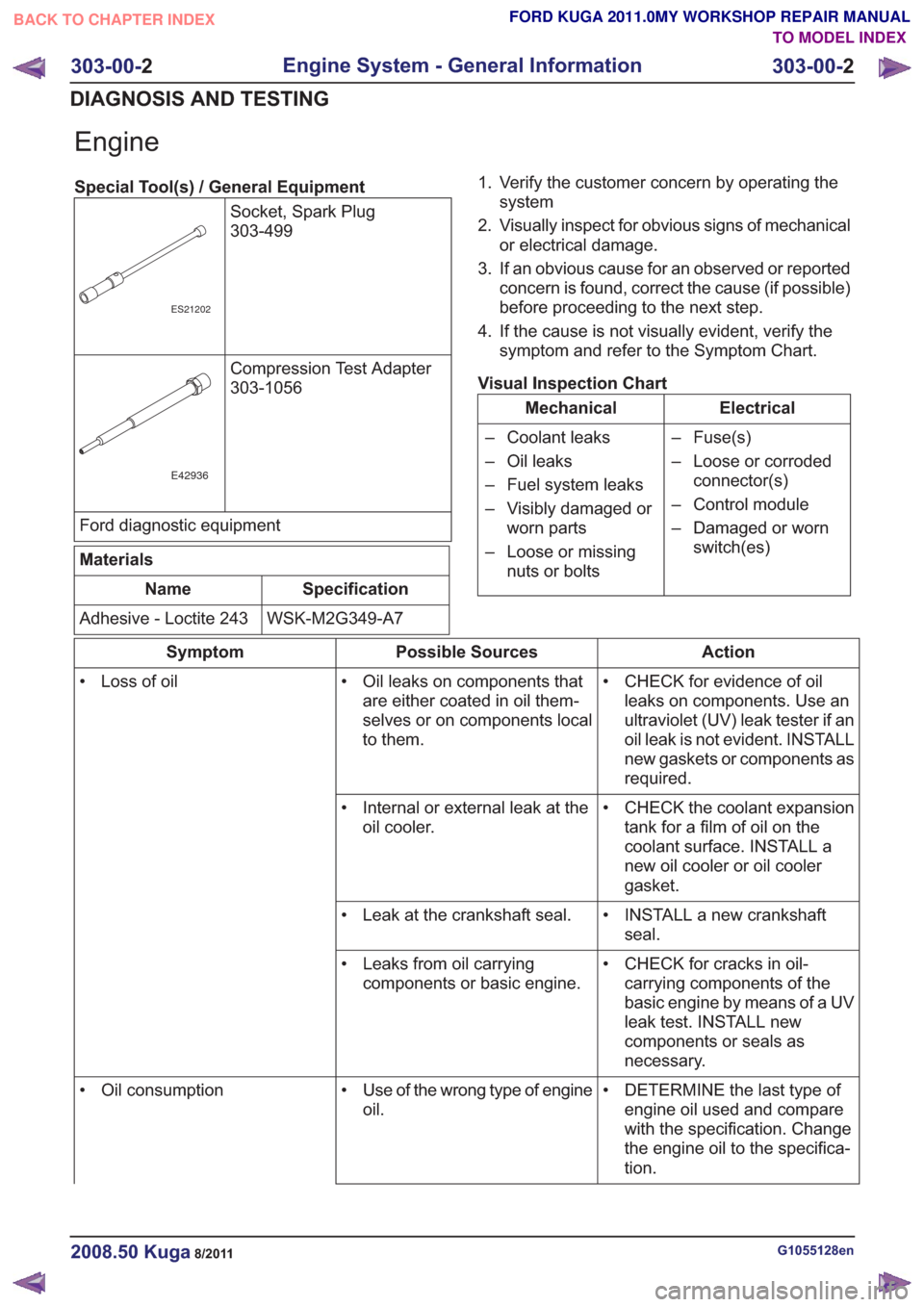

Engine

Special Tool(s) / General EquipmentSocket, Spark Plug

303-499

ES21202

Compression Test Adapter

303-1056

E42936

Ford diagnostic equipment

Materials

Specification

Name

WSK-M2G349-A7

Adhesive - Loctite 243 1. Verify the customer concern by operating the

system

2. Visually inspect for obvious signs of mechanical or electrical damage.

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the Symptom Chart.

Visual Inspection Chart

Electrical

Mechanical

– Fuse(s)

– Loose or corrodedconnector(s)

– Control module

– Damaged or worn switch(es)

– Coolant leaks

– Oil leaks

– Fuel system leaks

– Visibly damaged or

worn parts

– Loose or missing nuts or bolts

Action

Possible Sources

Symptom

• CHECK for evidence of oilleaks on components. Use an

ultraviolet (UV) leak tester if an

oil leak is not evident. INSTALL

new gaskets or components as

required.

• Oil leaks on components that

are either coated in oil them-

selves or on components local

to them.

• Loss of oil

• CHECK the coolant expansiontank for a film of oil on the

coolant surface. INSTALL a

new oil cooler or oil cooler

gasket.

• Internal or external leak at the

oil cooler.

• INSTALL a new crankshaftseal.

• Leak at the crankshaft seal.

• CHECK for cracks in oil-carrying components of the

basic engine by means of a UV

leak test. INSTALL new

components or seals as

necessary.

• Leaks from oil carrying

components or basic engine.

• DETERMINE the last type ofengine oil used and compare

with the specification. Change

the engine oil to the specifica-

tion.

• Use of the wrong type of engine

oil.

• Oil consumption

G1055128en2008.50 Kuga8/2011

303-00-

2

Engine System - General Information

303-00- 2

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1525 of 2057

Action

Possible Sources

Symptom

• CHECK the engine compon-ents for wear or damage. Make

sure that all components are

within specification. INSTALL

new components as necessary.

Engine - 2.5L Duratec-ST (VI5)

-

REFER to: Specifications (303-

01 Engine - 2.5L Duratec

(147kW/200PS) - VI5,

Specifications).

Engine - 2.0L Duratorq-TDCi

(DW) Diesel -

• Engine components

- Pistons.

- Piston rings.

- Connecting rod big end,main bearing or thrust

bearing journals.

- Connecting rods bent or damaged.

• Noisy running or engine noise

Engine - Oil Leaks

NOTE:

Before installing new gaskets or oil seals,

make sure that the fault is clearly established.

If the oil leak cannot be identified clearly by a visual

inspection, carry out an ultraviolet (UV) test:

Ultraviolet (UV) Testing

1. Clean the engine and transmission with a suitable cleaning fluid.

2. Pour the UV-test fluid in accordance with the quantity specified by the manufacturer through

the oil filler neck into the engine and install the

oil filler cap.

WARNING: Vehicles with manual transaxle,

shift the transaxle into Neutral. Failure to

follow this instruction may result in

personal injury.

3. Start the engine and let it run for about five minutes.

4. Switch off the engine.

NOTE: If no leak can be found, road test the

vehicle under various loads and check the engine

for leaks again.

5. Check the engine for oil leaks using a suitable UV lamp.

6. Rectify any leaks found and check the engine for oil leaks.

Measure the compression pressure

NOTE: The powertrain control module (PCM)

receives an error message when the fuel pump

relay is removed or electrical components are disconnected. This error message must be deleted

from the fault memory using the Ford diagnostic

equipment after completing the compression test.

NOTE:

Valve clearance must be set correctly

before performing a compression test. Make sure

the engine is at the normal operating temperature.

NOTE: The varying design of compression

checking devices and fluctuating starter motor

speeds normally only allows for a comparison to

be made of the compression pressures in all

cylinders.

G1055128en2008.50 Kuga8/2011

303-00- 9

Engine System - General Information

303-00- 9

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1528 of 2057

TIE44583

5. Remove the glow plug relay.

6. Lower the vehicle.

7. Remove the cowl panel grille.REFER to: Cowl Panel Grille (501-02 Front End

Body Panels, Removal and Installation).

E50527

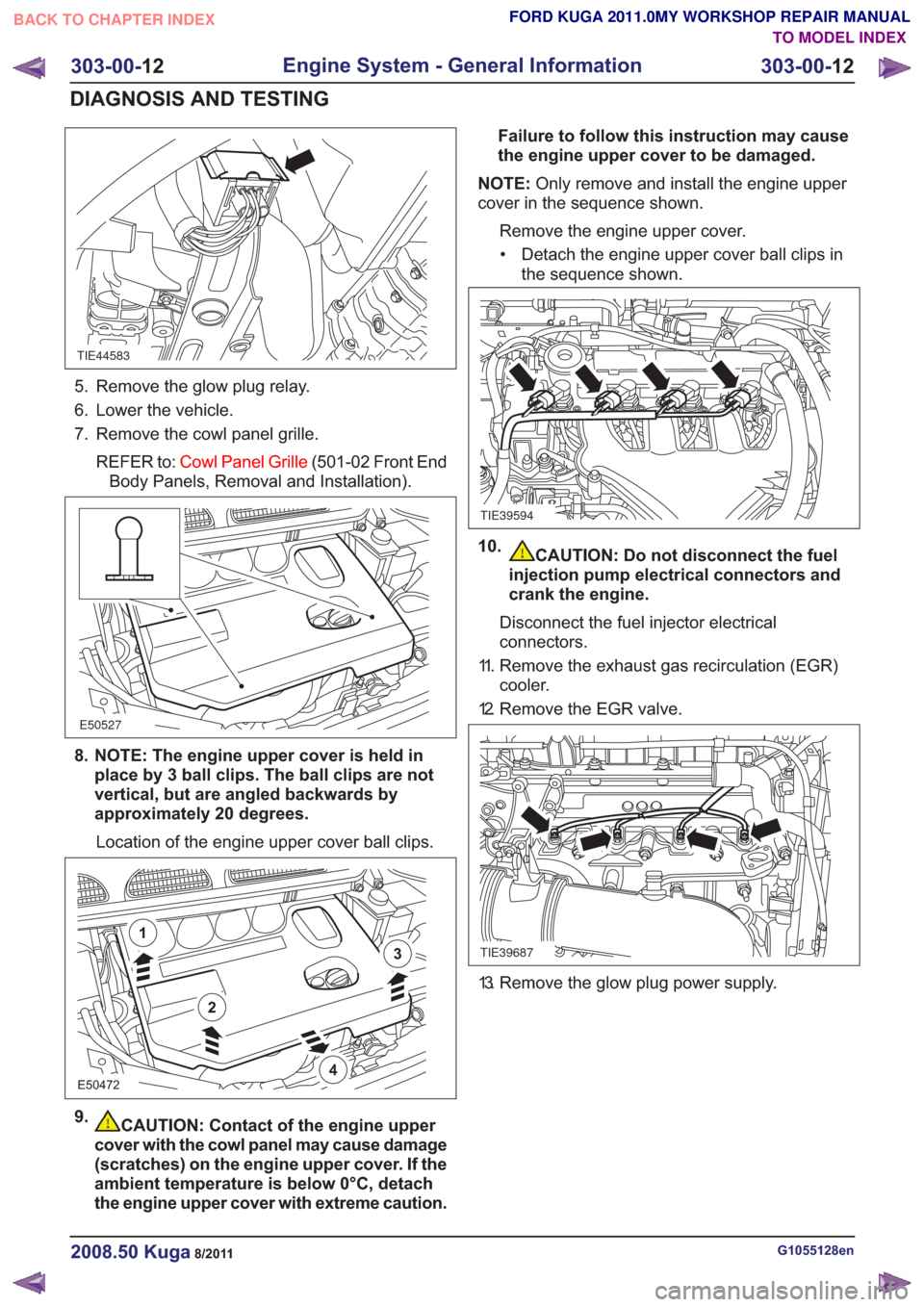

8. NOTE: The engine upper cover is held in place by 3 ball clips. The ball clips are not

vertical, but are angled backwards by

approximately 20 degrees.

Location of the engine upper cover ball clips.

E50472

2

1

3

4

9.CAUTION: Contact of the engine upper

cover with the cowl panel may cause damage

(scratches) on the engine upper cover. If the

ambient temperature is below 0°C, detach

the engine upper cover with extreme caution. Failure to follow this instruction may cause

the engine upper cover to be damaged.

NOTE: Only remove and install the engine upper

cover in the sequence shown.

Remove the engine upper cover.• Detach the engine upper cover ball clips in the sequence shown.

TIE39594

10.CAUTION: Do not disconnect the fuel

injection pump electrical connectors and

crank the engine.

Disconnect the fuel injector electrical

connectors.

11. Remove the exhaust gas recirculation (EGR) cooler.

12. Remove the EGR valve.

TIE39687

13. Remove the glow plug power supply.

G1055128en2008.50 Kuga8/2011

303-00- 12

Engine System - General Information

303-00- 12

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL