front FORD KUGA 2011 1.G Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1205 of 2057

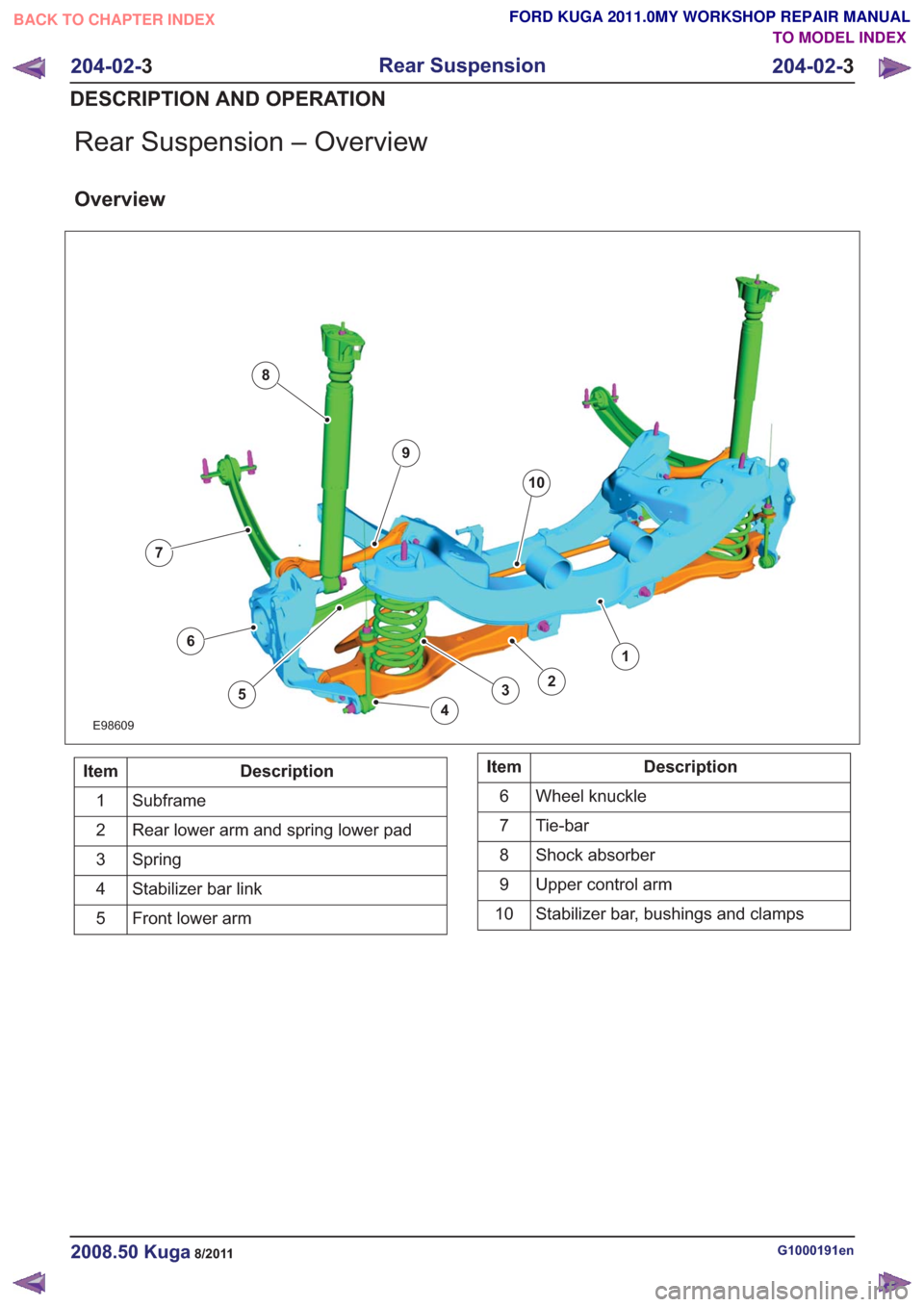

Rear Suspension – Overview

Overview

E98609

1

23

4

5

7

6

8

9

10

Description

Item

Subframe

1

Rear lower arm and spring lower pad

2

Spring

3

Stabilizer bar link

4

Front lower arm

5Description

Item

Wheel knuckle

6

Tie-bar

7

Shock absorber

8

Upper control arm

9

Stabilizer bar, bushings and clamps

10

G1000191en2008.50 Kuga8/2011

204-02- 3

Rear Suspension

204-02- 3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1206 of 2057

Upper control arm

E98616

The following components may be renewed:

• Lower arms

During removal and installation or renewal of the

lower arm, pay attention to the following:

• After completing the work, the suspensiongeometry of the vehicle must be checked and

corrected as necessary.

Rear lower arm and spring lower pad

E98615

The following components may be renewed:

• Lower arms

During removal and installation or renewal of the

lower arm, pay attention to the following:

• After completing the work, the suspensiongeometry of the vehicle must be checked and

corrected as necessary.

Front lower arm

E98614

The following components may be renewed:

• Lower arms

During removal and installation or renewal of the

lower arm, pay attention to the following:

• After completing the work, the suspensiongeometry of the vehicle must be checked and

corrected as necessary.

G1000191en2008.50 Kuga8/2011

204-02- 4

Rear Suspension

204-02- 4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1213 of 2057

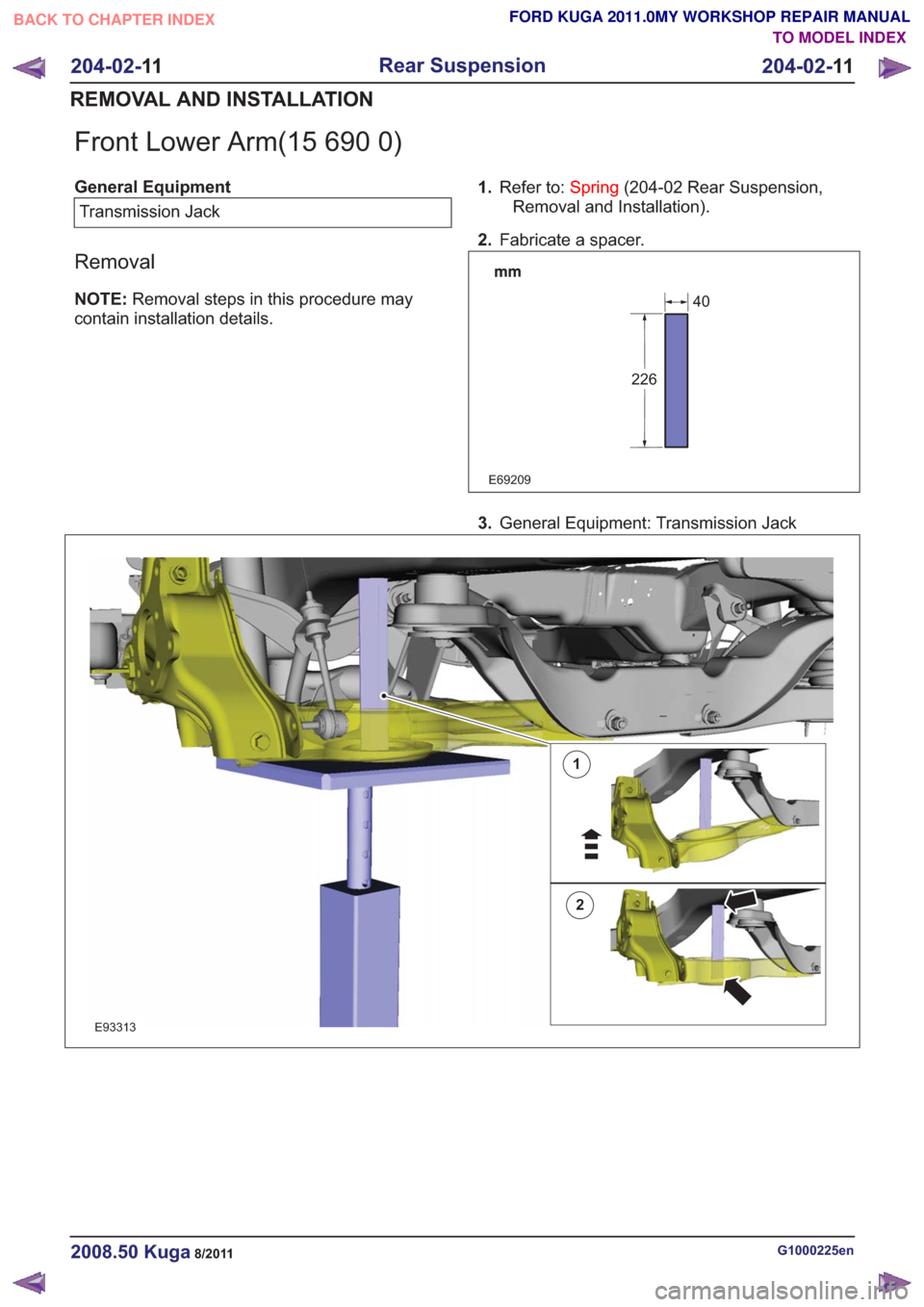

Front Lower Arm(15 690 0)

General EquipmentTransmission Jack

Removal

NOTE: Removal steps in this procedure may

contain installation details. 1.

Refer to: Spring(204-02 Rear Suspension,

Removal and Installation).

2. Fabricate a spacer.

E69209

226

40

3.General Equipment: Transmission Jack

1

2

E93313

G1000225en2008.50 Kuga8/2011

204-02- 11

Rear Suspension

204-02- 11

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

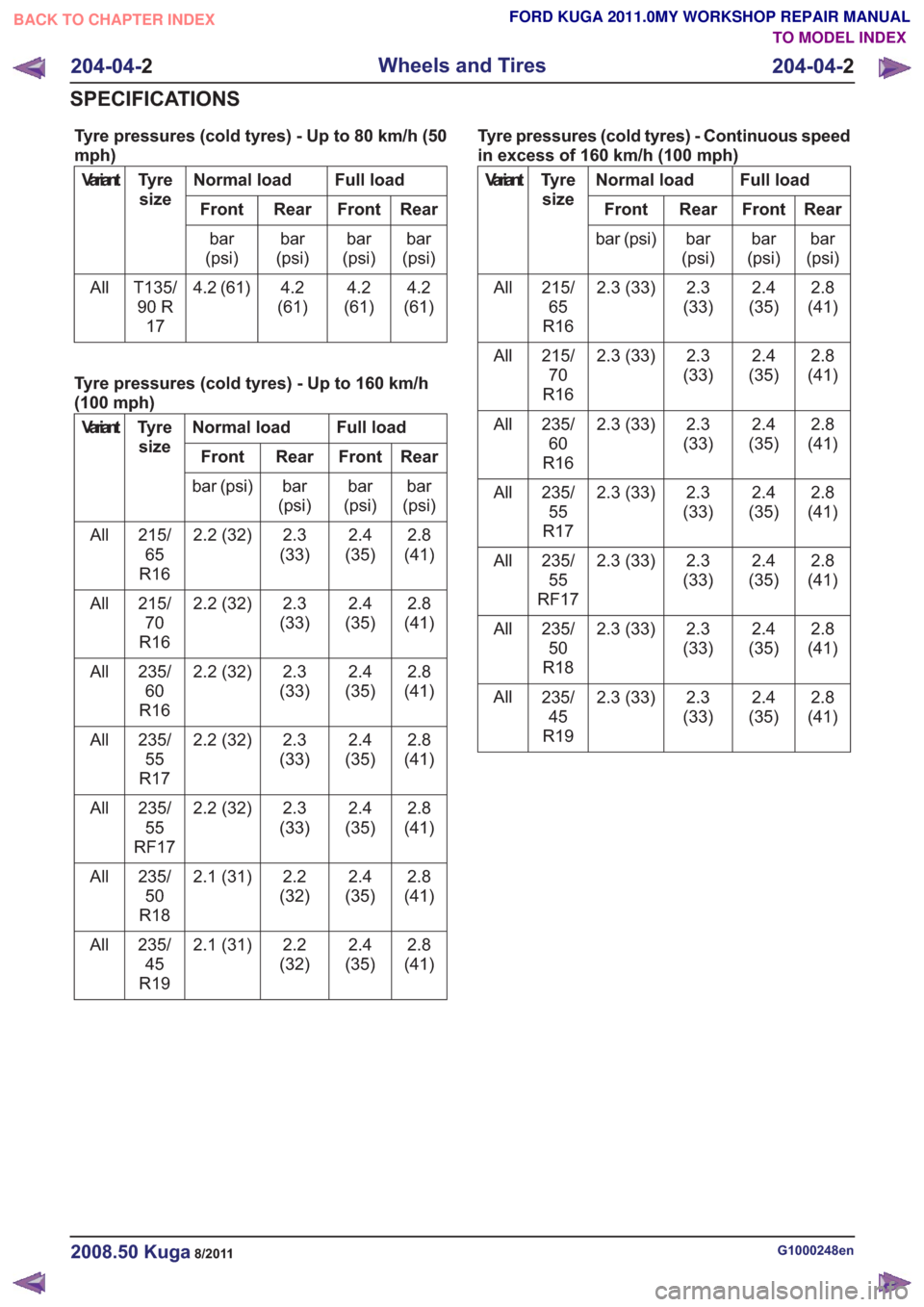

Page 1229 of 2057

Tyre pressures (cold tyres) - Up to 80 km/h (50

mph)

Full load

Normal load

Tyre

size

Variant

Rear

Front

Rear

Front

bar

(psi)

bar

(psi)

bar

(psi)

bar

(psi)

4.2

(61)

4.2

(61)

4.2

(61)

4.2 (61)

T135/

90 R 17

All

Tyre pressures (cold tyres) - Up to 160 km/h

(100 mph)

Full load

Normal load

Tyre

size

Variant

Rear

Front

Rear

Front

bar

(psi)

bar

(psi)

bar

(psi)

bar (psi)

2.8

(41)

2.4

(35)

2.3

(33)

2.2 (32)

215/

65

R16

All

2.8

(41)

2.4

(35)

2.3

(33)

2.2 (32)

215/

70

R16

All

2.8

(41)

2.4

(35)

2.3

(33)

2.2 (32)

235/

60

R16

All

2.8

(41)

2.4

(35)

2.3

(33)

2.2 (32)

235/

55

R17

All

2.8

(41)

2.4

(35)

2.3

(33)

2.2 (32)

235/

55

RF17

All

2.8

(41)

2.4

(35)

2.2

(32)

2.1 (31)

235/

50

R18

All

2.8

(41)

2.4

(35)

2.2

(32)

2.1 (31)

235/

45

R19

All Tyre pressures (cold tyres) - Continuous speed

in excess of 160 km/h (100 mph)

Full load

Normal load

Tyre

size

Variant

Rear

Front

Rear

Front

bar

(psi)

bar

(psi)

bar

(psi)

bar (psi)

2.8

(41)

2.4

(35)

2.3

(33)

2.3 (33)

215/

65

R16

All

2.8

(41)

2.4

(35)

2.3

(33)

2.3 (33)

215/

70

R16

All

2.8

(41)

2.4

(35)

2.3

(33)

2.3 (33)

235/

60

R16

All

2.8

(41)

2.4

(35)

2.3

(33)

2.3 (33)

235/

55

R17

All

2.8

(41)

2.4

(35)

2.3

(33)

2.3 (33)

235/

55

RF17

All

2.8

(41)

2.4

(35)

2.3

(33)

2.3 (33)

235/

50

R18

All

2.8

(41)

2.4

(35)

2.3

(33)

2.3 (33)

235/

45

R19

All

G1000248en2008.50 Kuga8/2011

204-04-

2

Wheels and Tires

204-04- 2

SPECIFICATIONS

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1235 of 2057

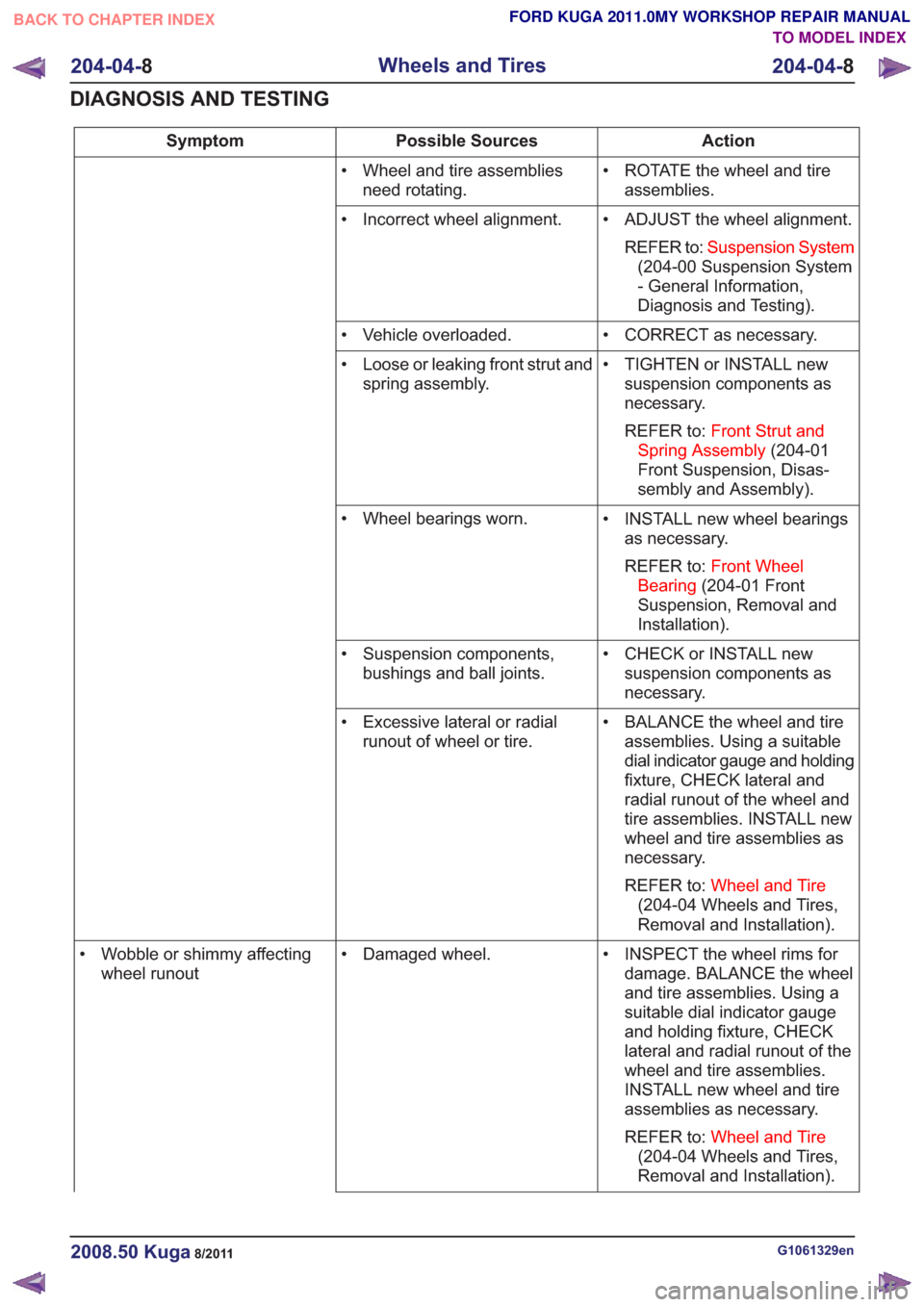

Action

Possible Sources

Symptom

• ROTATE the wheel and tireassemblies.

• Wheel and tire assemblies

need rotating.

• ADJUST the wheel alignment.REFER to: Suspension System

(204-00 Suspension System

- General Information,

Diagnosis and Testing).

• Incorrect wheel alignment.

• CORRECT as necessary.

• Vehicle overloaded.

• TIGHTEN or INSTALL newsuspension components as

necessary.

REFER to: Front Strut and

Spring Assembly (204-01

Front Suspension, Disas-

sembly and Assembly).

• Loose or leaking front strut and

spring assembly.

• INSTALL new wheel bearingsas necessary.

REFER to: Front Wheel

Bearing (204-01 Front

Suspension, Removal and

Installation).

• Wheel bearings worn.

• CHECK or INSTALL newsuspension components as

necessary.

• Suspension components,

bushings and ball joints.

• BALANCE the wheel and tireassemblies. Using a suitable

dial indicator gauge and holding

fixture, CHECK lateral and

radial runout of the wheel and

tire assemblies. INSTALL new

wheel and tire assemblies as

necessary.

REFER to: Wheel and Tire

(204-04 Wheels and Tires,

Removal and Installation).

• Excessive lateral or radial

runout of wheel or tire.

• INSPECT the wheel rims fordamage. BALANCE the wheel

and tire assemblies. Using a

suitable dial indicator gauge

and holding fixture, CHECK

lateral and radial runout of the

wheel and tire assemblies.

INSTALL new wheel and tire

assemblies as necessary.

REFER to: Wheel and Tire

(204-04 Wheels and Tires,

Removal and Installation).

• Damaged wheel.

• Wobble or shimmy affecting

wheel runout

G1061329en2008.50 Kuga8/2011

204-04- 8

Wheels and Tires

204-04- 8

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1236 of 2057

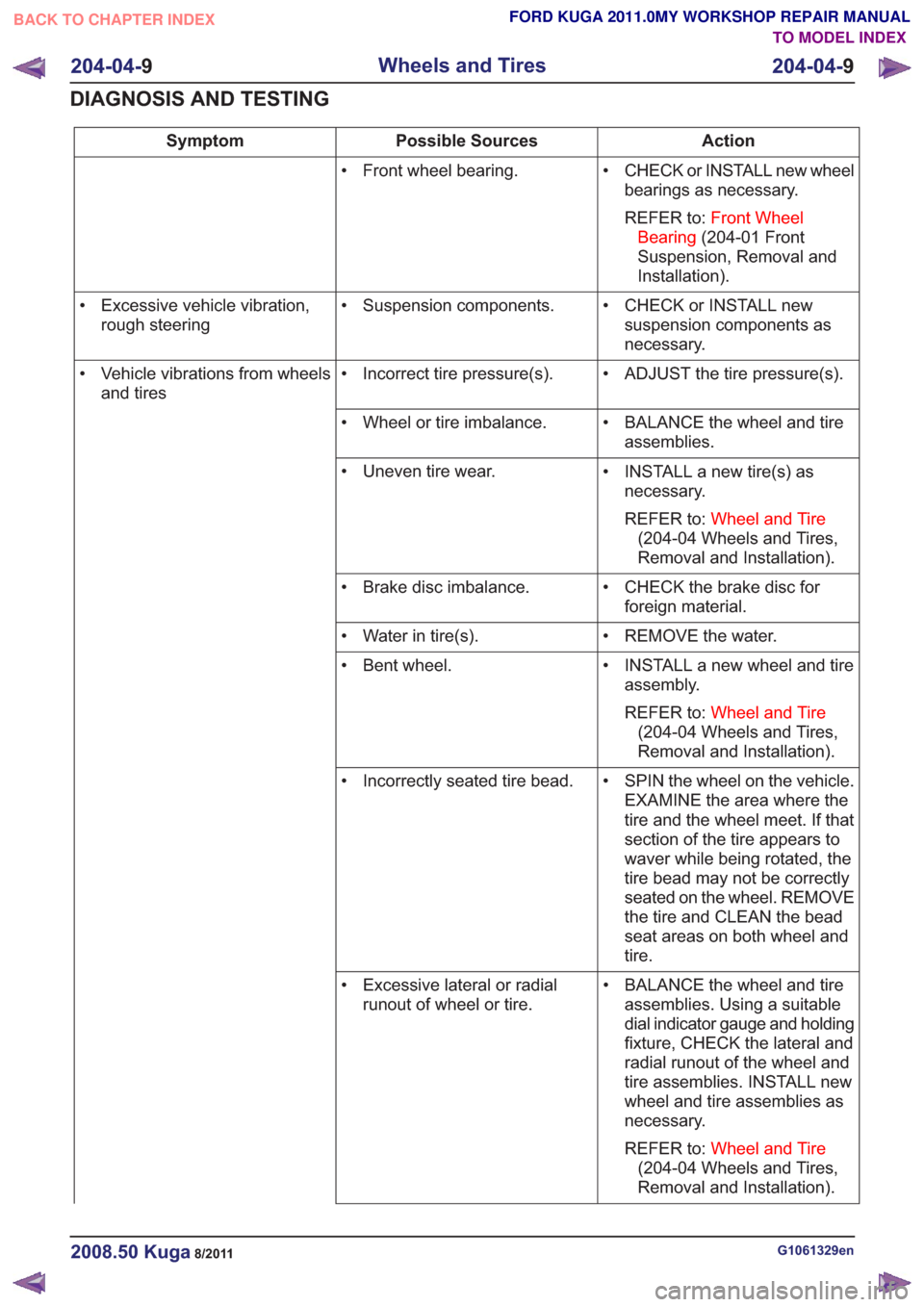

Action

Possible Sources

Symptom

• CHECK or INSTALL new wheelbearings as necessary.

REFER to: Front Wheel

Bearing (204-01 Front

Suspension, Removal and

Installation).

• Front wheel bearing.

• CHECK or INSTALL newsuspension components as

necessary.

• Suspension components.

• Excessive vehicle vibration,

rough steering

• ADJUST the tire pressure(s).

• Incorrect tire pressure(s).

• Vehicle vibrations from wheels

and tires

• BALANCE the wheel and tireassemblies.

• Wheel or tire imbalance.

• INSTALL a new tire(s) asnecessary.

REFER to: Wheel and Tire

(204-04 Wheels and Tires,

Removal and Installation).

• Uneven tire wear.

• CHECK the brake disc forforeign material.

• Brake disc imbalance.

• REMOVE the water.

• Water in tire(s).

• INSTALL a new wheel and tireassembly.

REFER to: Wheel and Tire

(204-04 Wheels and Tires,

Removal and Installation).

• Bent wheel.

• SPIN the wheel on the vehicle.EXAMINE the area where the

tire and the wheel meet. If that

section of the tire appears to

waver while being rotated, the

tire bead may not be correctly

seated on the wheel. REMOVE

the tire and CLEAN the bead

seat areas on both wheel and

tire.

• Incorrectly seated tire bead.

• BALANCE the wheel and tireassemblies. Using a suitable

dial indicator gauge and holding

fixture, CHECK the lateral and

radial runout of the wheel and

tire assemblies. INSTALL new

wheel and tire assemblies as

necessary.

REFER to: Wheel and Tire

(204-04 Wheels and Tires,

Removal and Installation).

• Excessive lateral or radial

runout of wheel or tire.

G1061329en2008.50 Kuga8/2011

204-04- 9

Wheels and Tires

204-04- 9

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1237 of 2057

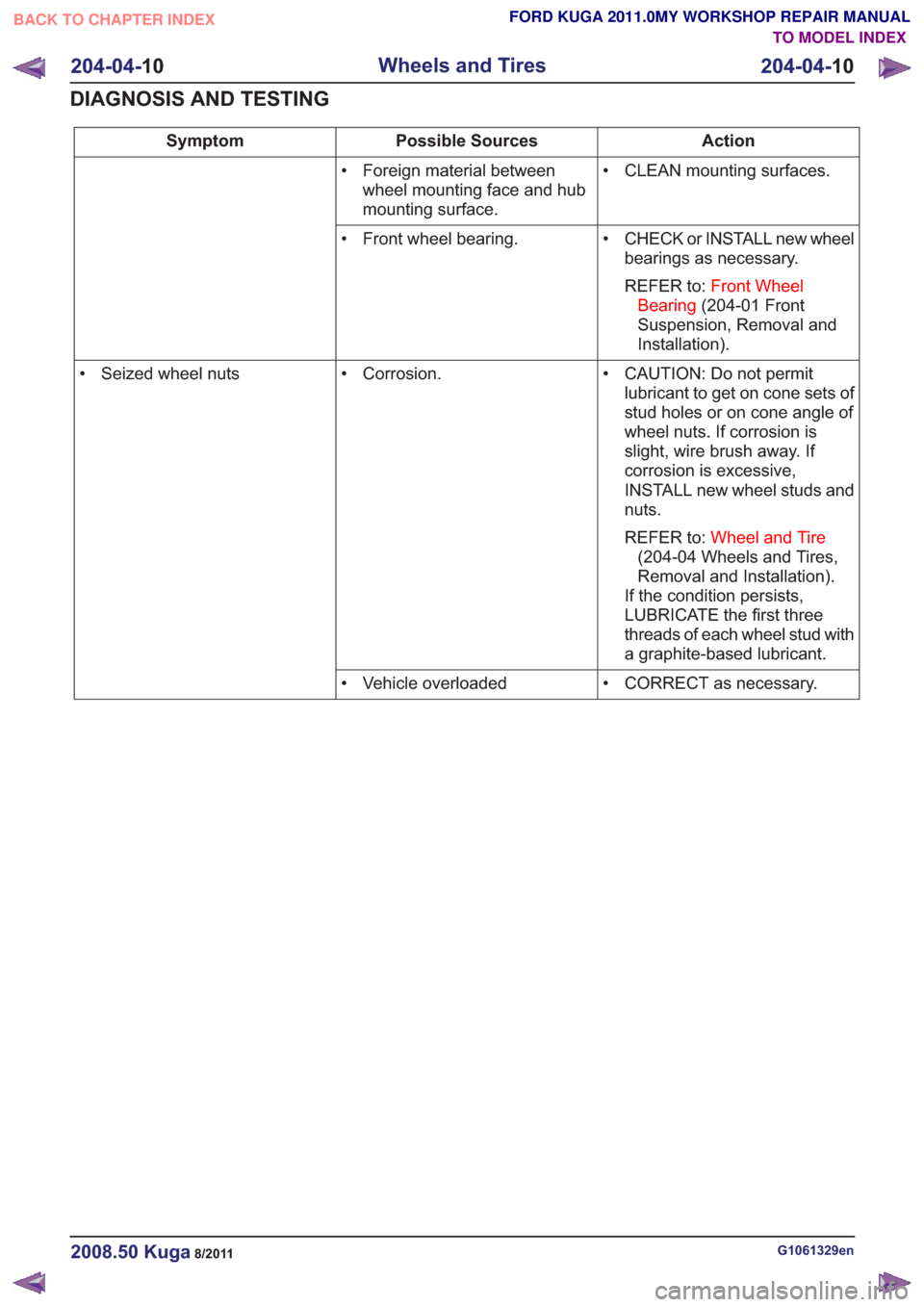

Action

Possible Sources

Symptom

• CLEAN mounting surfaces.

• Foreign material between

wheel mounting face and hub

mounting surface.

• CHECK or INSTALL new wheelbearings as necessary.

REFER to: Front Wheel

Bearing (204-01 Front

Suspension, Removal and

Installation).

• Front wheel bearing.

• CAUTION: Do not permitlubricant to get on cone sets of

stud holes or on cone angle of

wheel nuts. If corrosion is

slight, wire brush away. If

corrosion is excessive,

INSTALL new wheel studs and

nuts.

REFER to: Wheel and Tire

(204-04 Wheels and Tires,

Removal and Installation).

If the condition persists,

LUBRICATE the first three

threads of each wheel stud with

a graphite-based lubricant.

• Corrosion.

• Seized wheel nuts

• CORRECT as necessary.

• Vehicle overloaded

G1061329en2008.50 Kuga8/2011

204-04- 10

Wheels and Tires

204-04- 10

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1247 of 2057

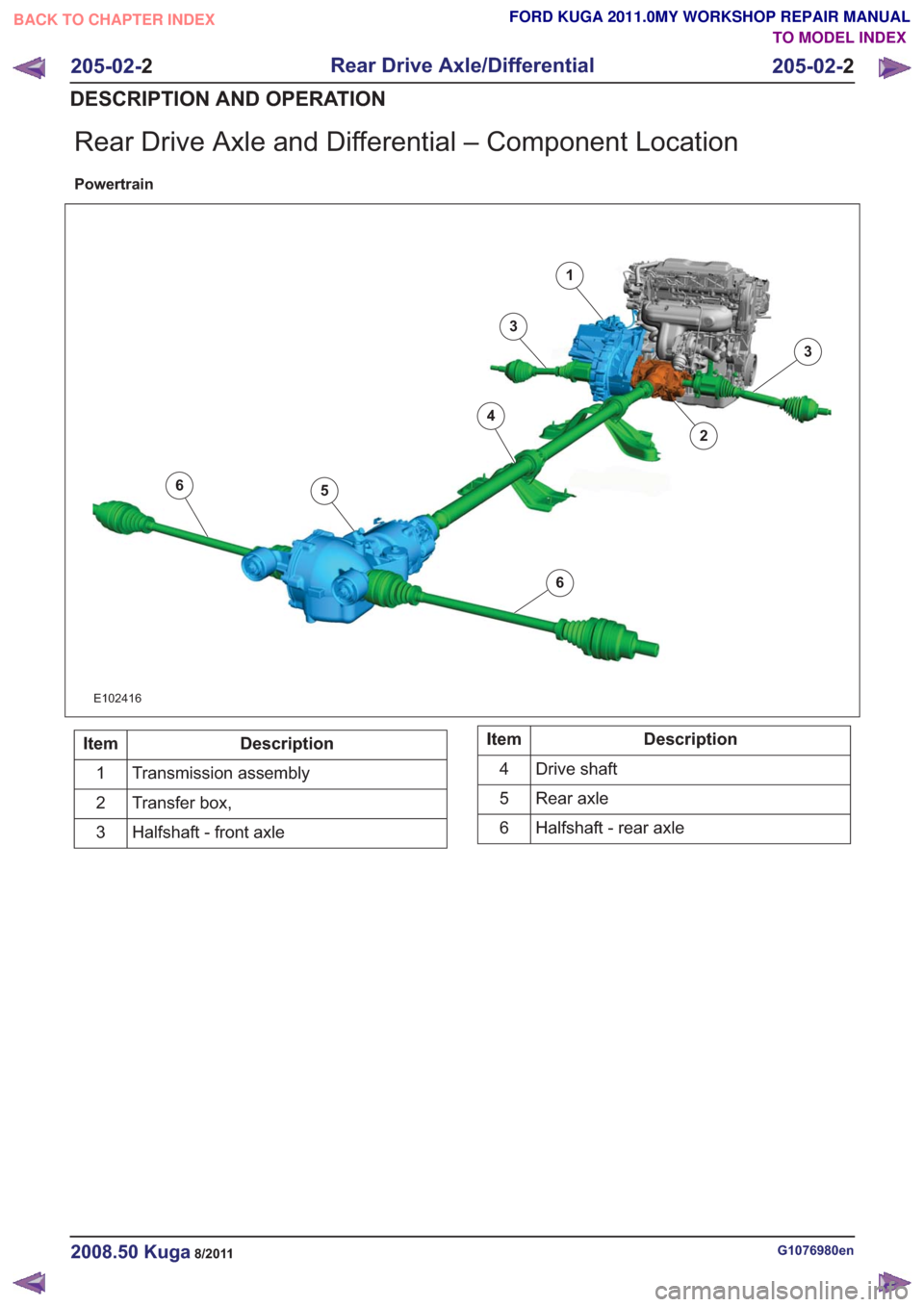

Rear Drive Axle and Differential – Component Location

Powertrain

6

6

1

2

3

3

4

5

6

6

E102416

Description

Item

Transmission assembly

1

Transfer box,

2

Halfshaft - front axle

3Description

Item

Drive shaft

4

Rear axle

5

Halfshaft - rear axle

6

G1076980en2008.50 Kuga8/2011

205-02- 2

Rear Drive Axle/Differential

205-02- 2

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1251 of 2057

Rear Drive Axle and Differential – System Operation andComponent Description

System Operation

General Information

The powertrain with all-wheel drive consists of the

following main components:

• engine

• transaxle with front axle differential

• transfer box

• halfshafts and driveshafts

• Haldex clutch

• rear axle differential

The Haldex clutch guarantees continuous variable

torque transmission to the rear axle under all

driving conditions. The Haldex clutch reacts

immediately and equally quickly with slow or fast

wheel slip.

A difference in angle of rotation of 90° between the

input and output shafts is required to build up

maximum pressure at the multi-plate clutch or to

transmit maximum torque.

The advantage of vehicles with all-wheel drive is

that they distribute the drive between all four

wheels. They therefore have a higher tractive

power. They feature improved cornering behaviour,

as the grip at all four wheels can be better utilised.

Thus, the wheels contribute to a greater degree

towards cornering stability.

The engine torque is transmitted from the transfer

box to the rear axle via a driveshaft. The driveshaft

is flange-mounted to the input side of the Haldex

clutch.

Driving situations

Pulling away and accelerating

• When pulling away and accelerating, as muchall-wheel drive as necessary must be available

immediately in the short-term. During

acceleration, the electronic system detects slip

at the front axle. This slip is counter-controlled

and thus the propulsive force optimally

distributed to the two axes.

Cornering • A sporty driving style, in particular dynamic

cornering, demands stable cornering behaviour.

The all-wheel system distributes the propulsive

force to all four wheels and by so doing boosts

the high cornering forces so that the vehicle

makes optimum contact with the road surface.

Snow and black ice

• Snow and black ice require particularly high grip. Under these conditions, the Haldex clutch

always distributes the propulsive force to the

axle with the better traction. The all-wheel

system reacts intelligently and quickly to all

driving situations.

Trailer operation

• When driving with a trailer, the trailer weight (support load) is transmitted to the rear axle via

the towbar. This reduces the load on the front

wheels, which means they can slip. The

electronic system detects this difference and

distributes most of the propulsive force to the

rear axle.

Haldex clutch

E100642

G1076981en2008.50 Kuga8/2011

205-02- 6

Rear Drive Axle/Differential

205-02- 6

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1254 of 2057

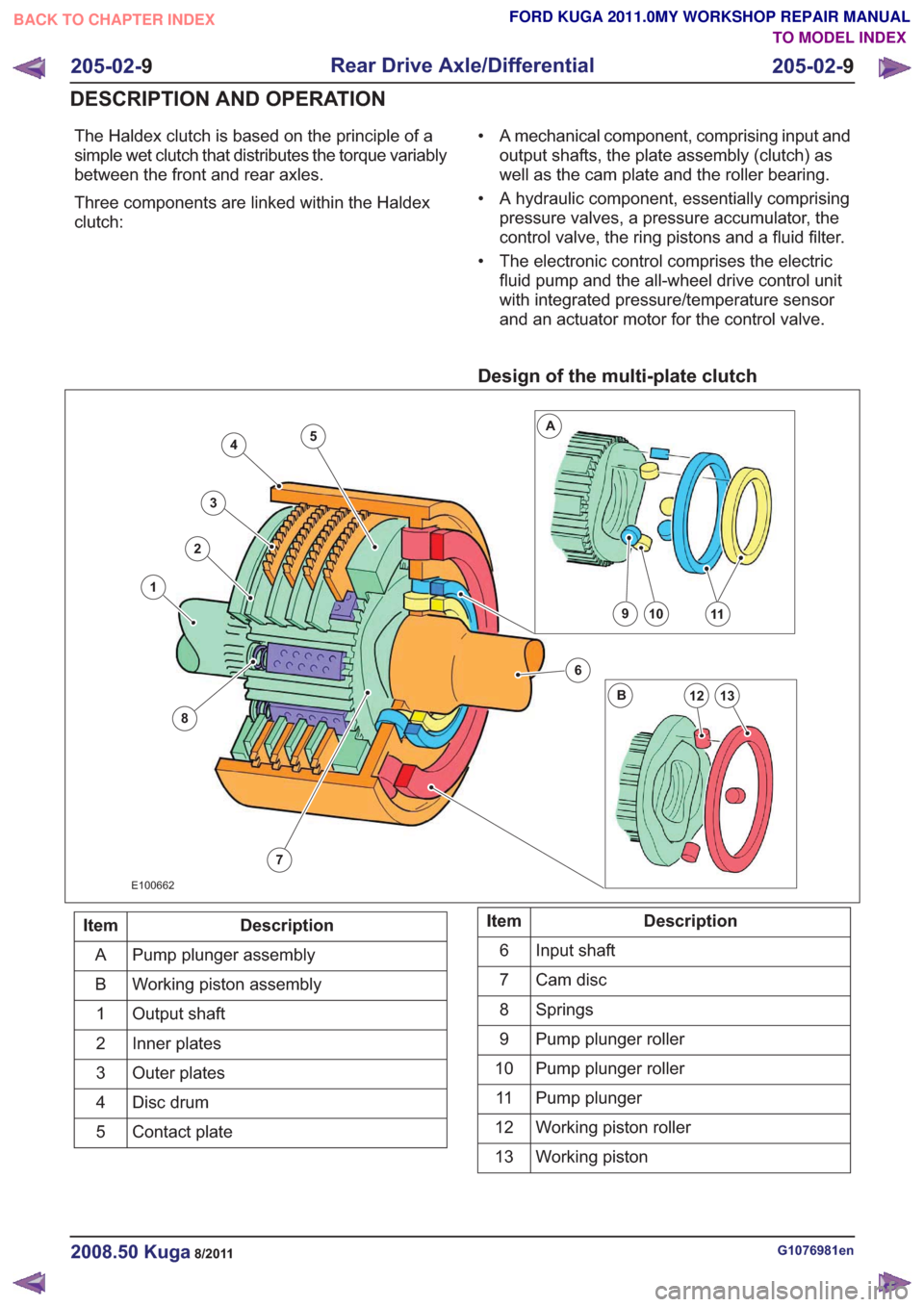

The Haldex clutch is based on the principle of a

simple wet clutch that distributes the torque variably

between the front and rear axles.

Three components are linked within the Haldex

clutch:• A mechanical component, comprising input and

output shafts, the plate assembly (clutch) as

well as the cam plate and the roller bearing.

• A hydraulic component, essentially comprising pressure valves, a pressure accumulator, the

control valve, the ring pistons and a fluid filter.

• The electronic control comprises the electric fluid pump and the all-wheel drive control unit

with integrated pressure/temperature sensor

and an actuator motor for the control valve.

Design of the multi-plate clutch

7

4

3

2

8

1

6

10911

13

A

B12

5

E100662

Description

Item

Pump plunger assembly

A

Working piston assembly

B

Output shaft

1

Inner plates

2

Outer plates

3

Disc drum

4

Contact plate

5Description

Item

Input shaft

6

Cam disc

7

Springs

8

Pump plunger roller

9

Pump plunger roller

10

Pump plunger

11

Working piston roller

12

Working piston

13

G1076981en2008.50 Kuga8/2011

205-02- 9

Rear Drive Axle/Differential

205-02- 9

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL