Lock FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1611 of 2057

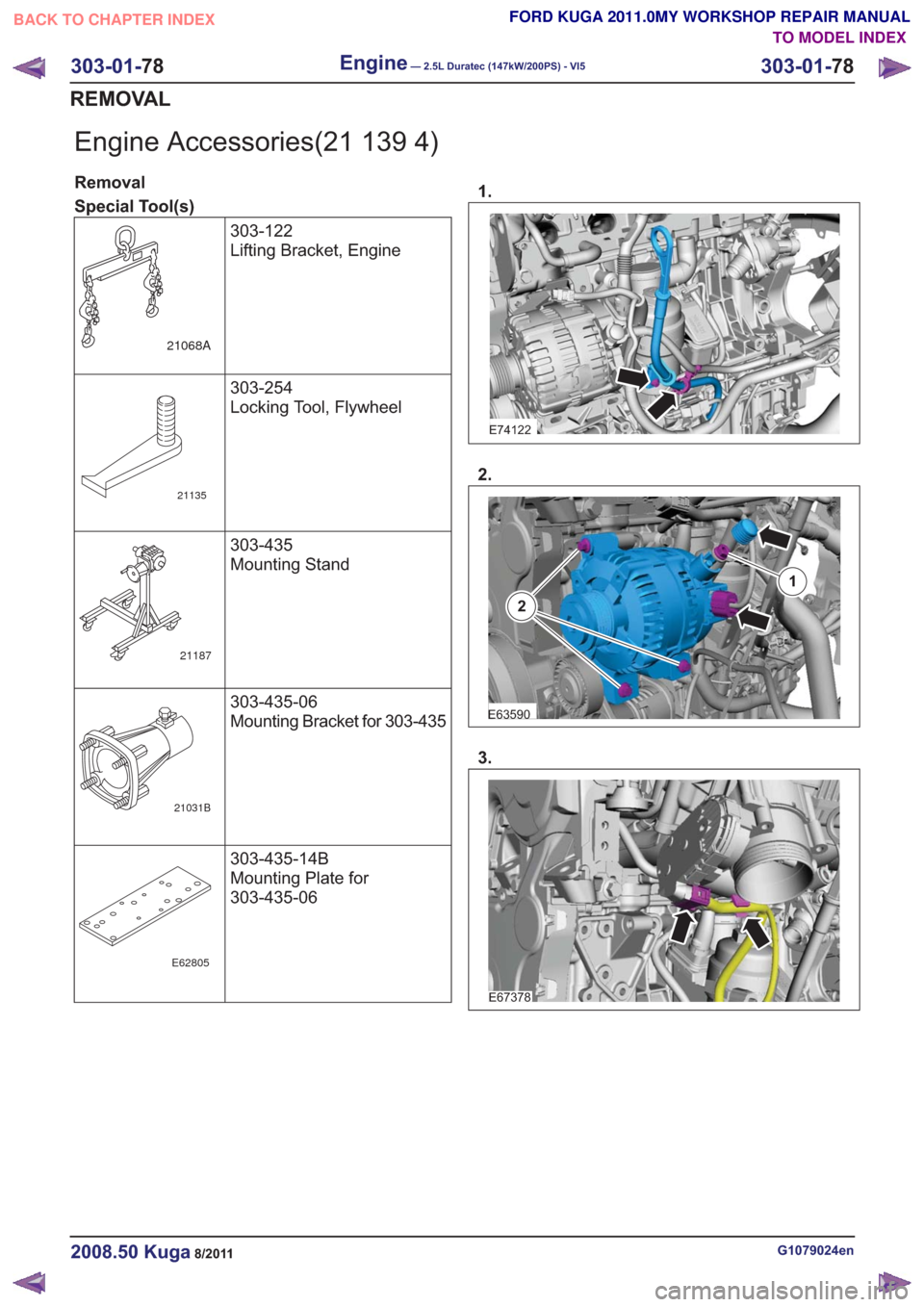

Engine Accessories(21 139 4)

Removal

Special Tool(s)303-122

Lifting Bracket, Engine

21068A

303-254

Locking Tool, Flywheel

21135

303-435

Mounting Stand

21187

303-435-06

Mounting Bracket for 303-435

21031B

303-435-14B

Mounting Plate for

303-435-06

E62805

1.

E74122

2.

E63590

2

1

3.

E67378

G1079024en2008.50 Kuga8/2011

303-01-78

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

78

REMOVAL

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1617 of 2057

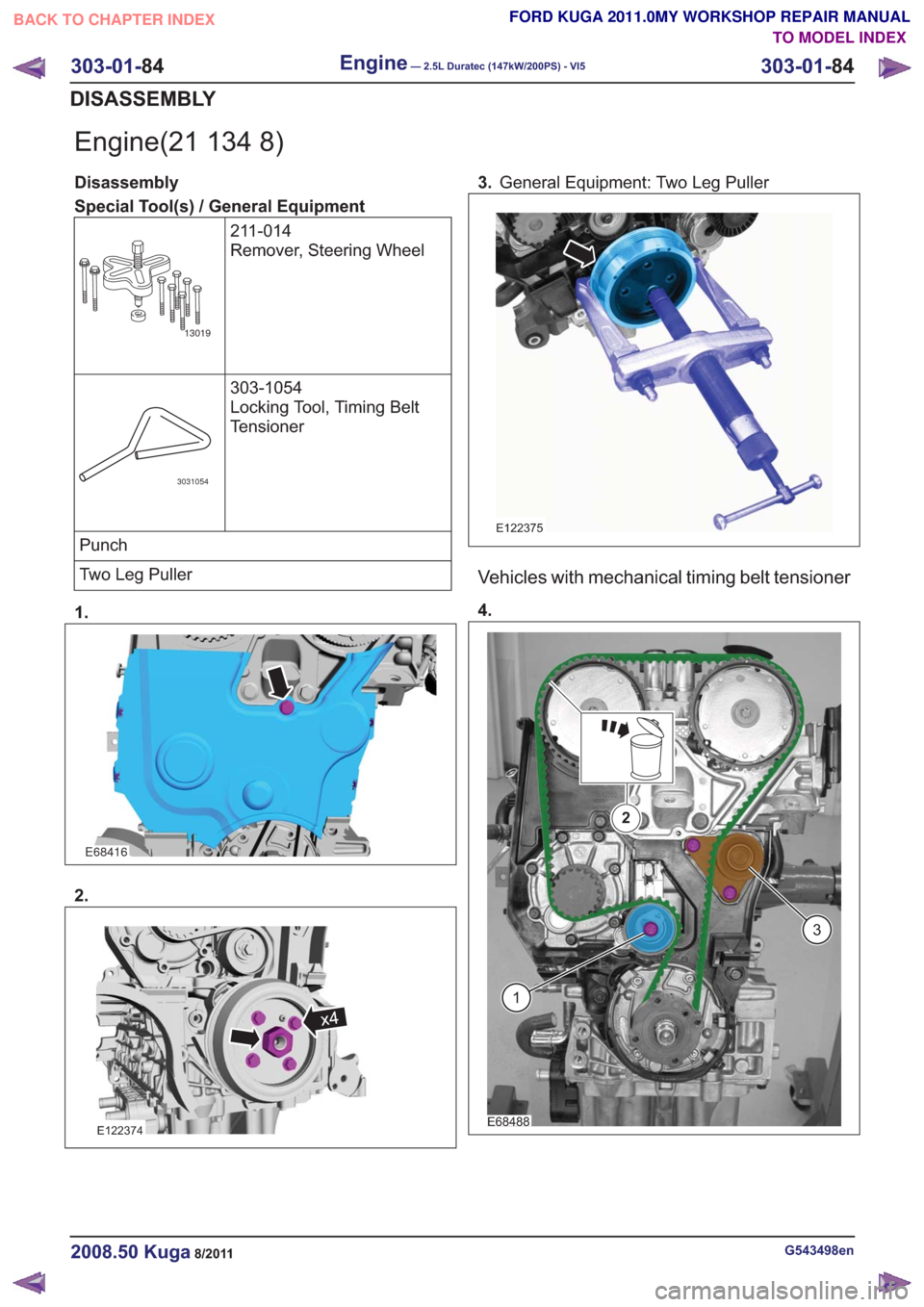

Engine(21 134 8)

Disassembly

Special Tool(s) / General Equipment211-014

Remover, Steering Wheel

13019

303-1054

Locking Tool, Timing Belt

Tensioner

3031054

Punch

Two Leg Puller

1.

E68416

2.

E122374

x4

3. General Equipment: Two Leg Puller

E122375

Vehicles with mechanical timing belt tensioner

4.

E68488

1

3

2

G543498en2008.50 Kuga8/2011

303-01- 84

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

84

DISASSEMBLY

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1627 of 2057

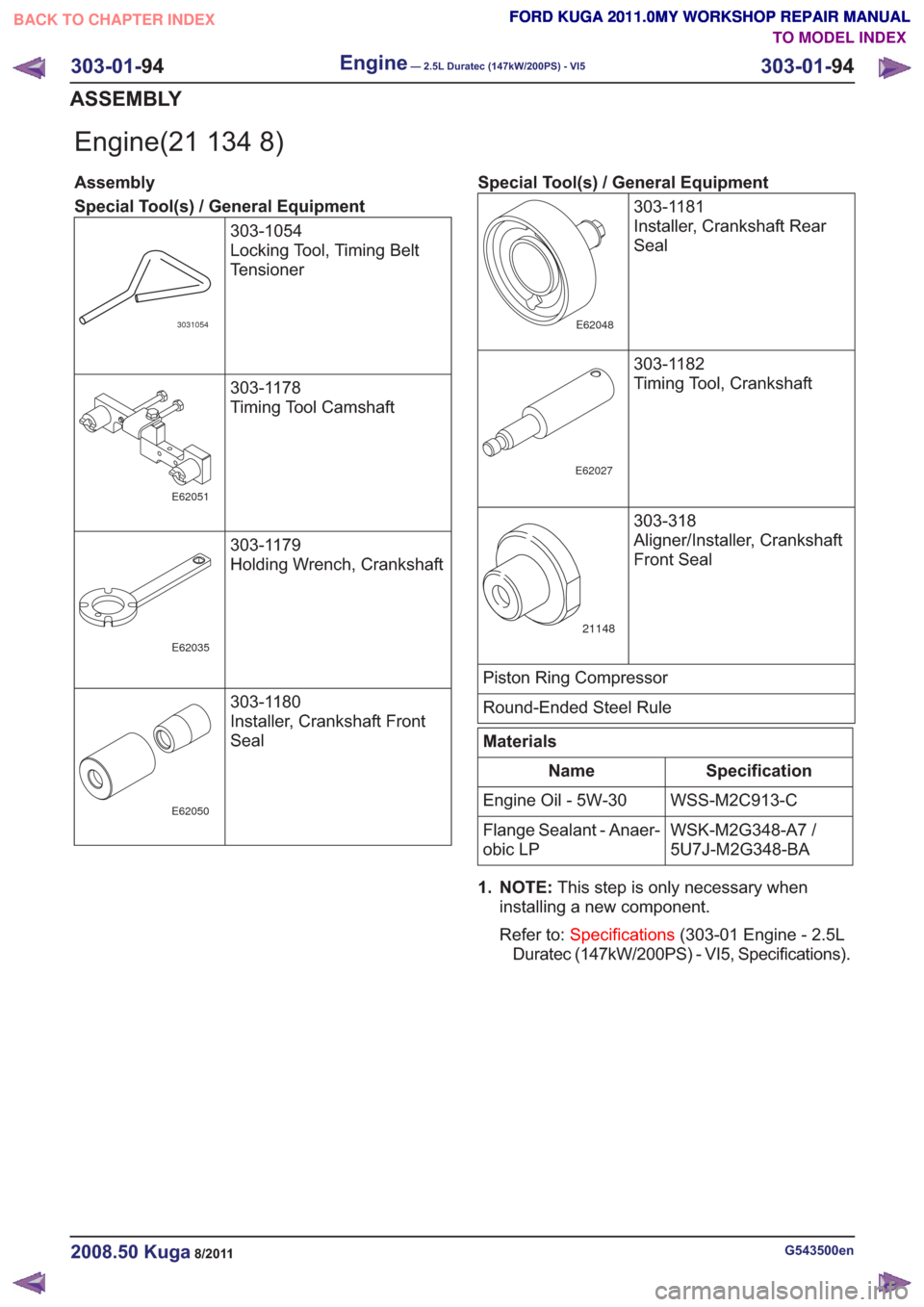

Engine(21 134 8)

Assembly

Special Tool(s) / General Equipment303-1054

Locking Tool, Timing Belt

Tensioner

3031054

303-1178

Timing Tool Camshaft

E62051

303-1179

Holding Wrench, Crankshaft

E62035

303-1180

Installer, Crankshaft Front

Seal

E62050

Special Tool(s) / General Equipment303-1181

Installer, Crankshaft Rear

Seal

E62048

303-1182

Timing Tool, Crankshaft

E62027

303-318

Aligner/Installer, Crankshaft

Front Seal

21148

Piston Ring Compressor

Round-Ended Steel Rule

Materials

Specification

Name

WSS-M2C913-C

Engine Oil - 5W-30

WSK-M2G348-A7 /

5U7J-M2G348-BA

Flange Sealant - Anaer-

obic LP

1. NOTE: This step is only necessary when

installing a new component.

Refer to: Specifications (303-01 Engine - 2.5L

Duratec (147kW/200PS) - VI5, Specifications).

G543500en2008.50 Kuga8/2011

303-01- 94

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

94

ASSEMBLY

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1640 of 2057

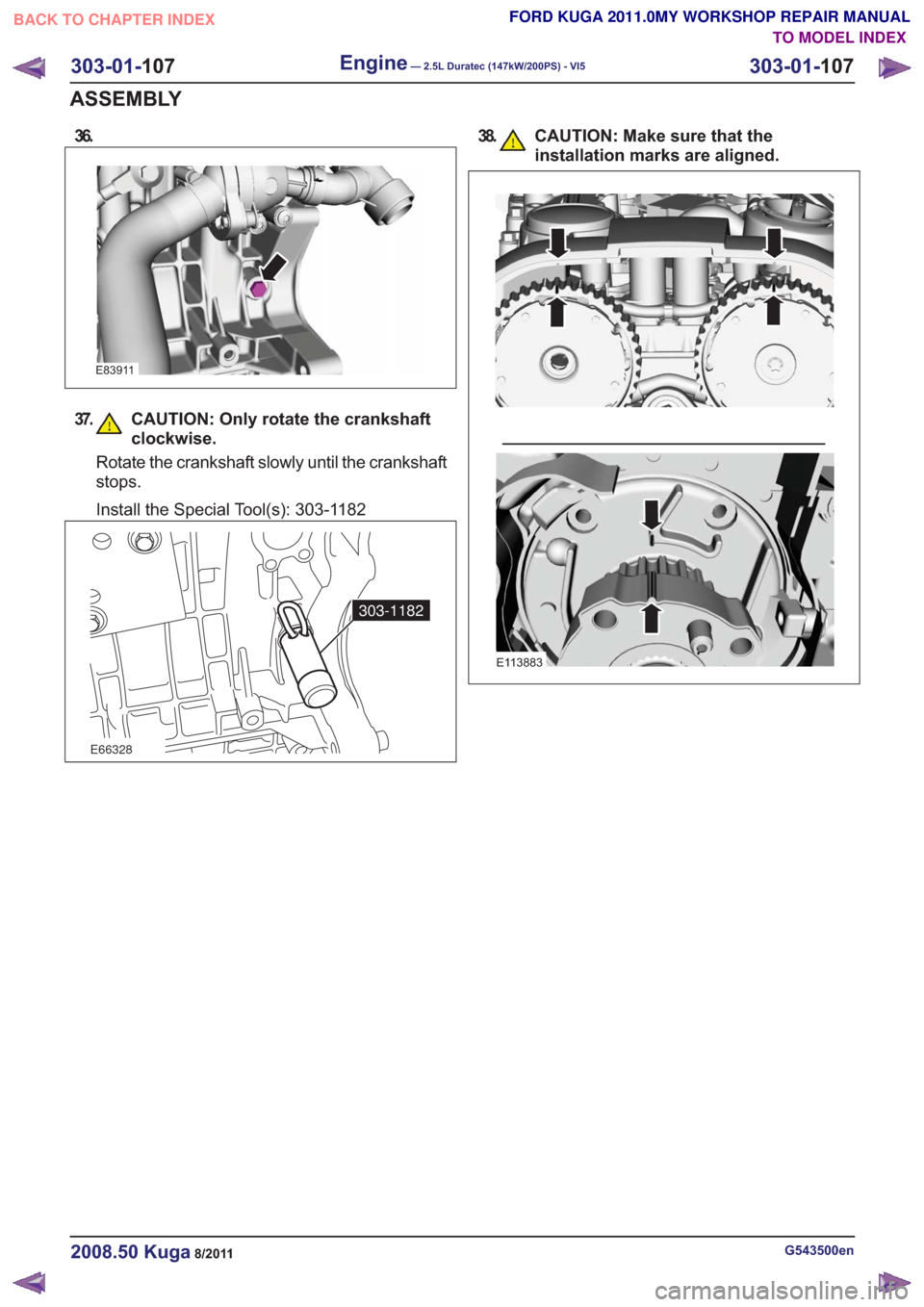

36.

E83911

37. CAUTION: Only rotate the crankshaftclockwise.

Rotate the crankshaft slowly until the crankshaft

stops.

Install the Special Tool(s): 303-1182

E66328

303-1182

38. CAUTION: Make sure that theinstallation marks are aligned.

E113883

G543500en2008.50 Kuga8/2011

303-01- 107

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

107

ASSEMBLY

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1642 of 2057

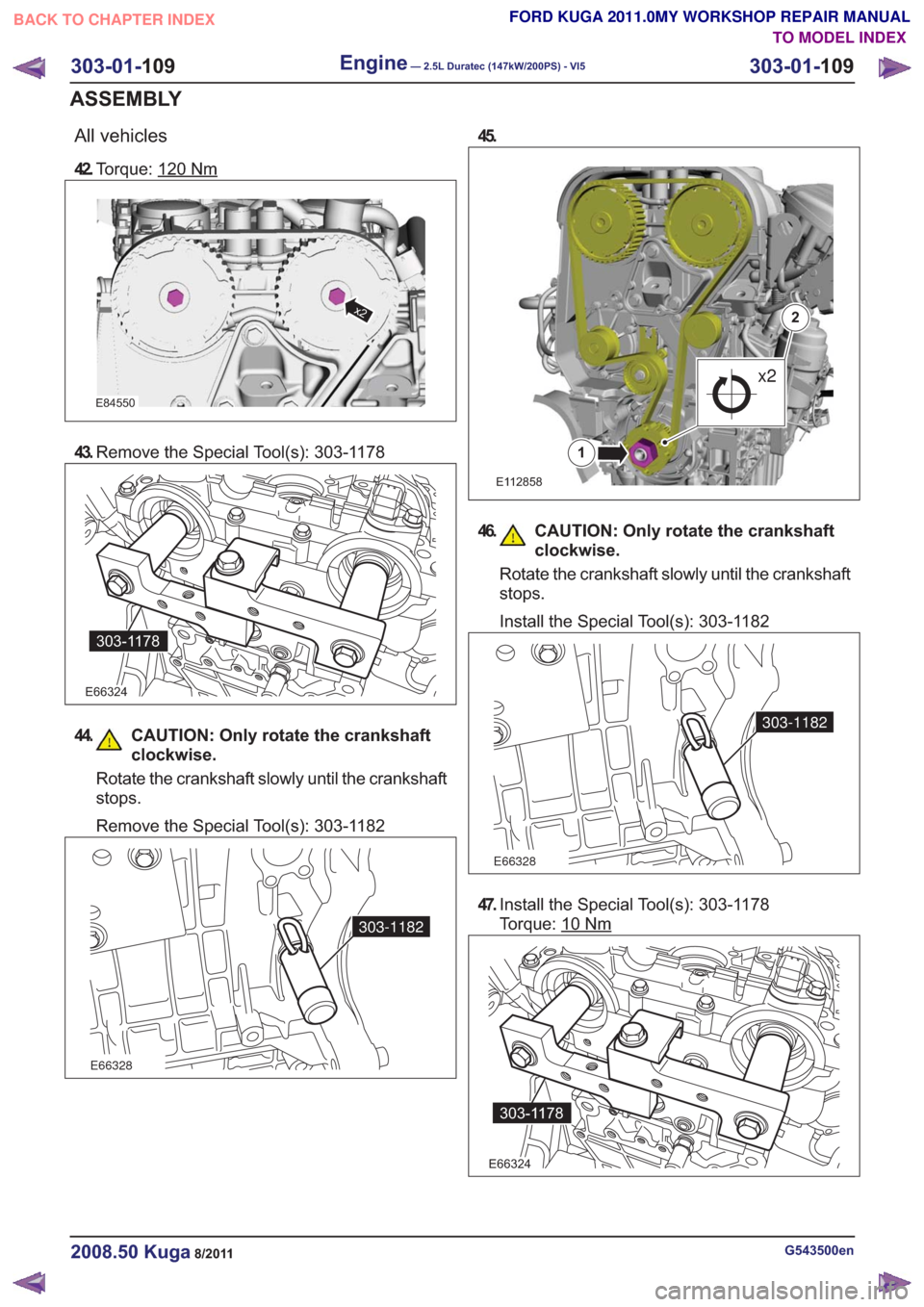

All vehicles

42.Torque: 120Nm

E84550

x2

43.Remove the Special Tool(s): 303-1178

E66324

303-1178

44. CAUTION: Only rotate the crankshaft

clockwise.

Rotate the crankshaft slowly until the crankshaft

stops.

Remove the Special Tool(s): 303-1182

E66328

303-1182

45.

E112858

1

x2

2

46. CAUTION: Only rotate the crankshaftclockwise.

Rotate the crankshaft slowly until the crankshaft

stops.

Install the Special Tool(s): 303-1182

E66328

303-1182

47.Install the Special Tool(s): 303-1178

Torque: 10

Nm

E66324

303-1178

G543500en2008.50 Kuga8/2011

303-01- 109

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

109

ASSEMBLY

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1645 of 2057

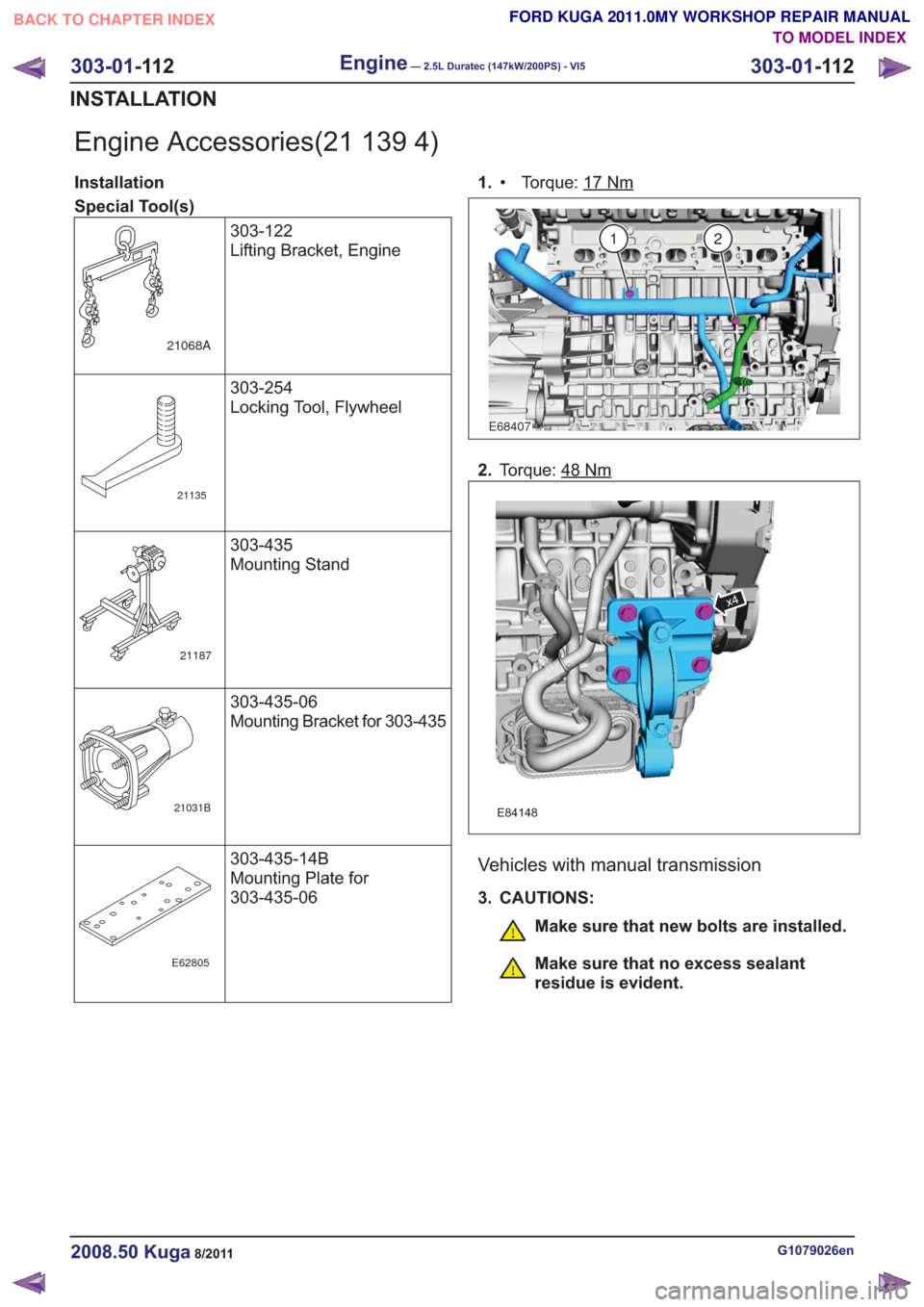

Engine Accessories(21 139 4)

Installation

Special Tool(s)303-122

Lifting Bracket, Engine

21068A

303-254

Locking Tool, Flywheel

21135

303-435

Mounting Stand

21187

303-435-06

Mounting Bracket for 303-435

21031B

303-435-14B

Mounting Plate for

303-435-06

E62805

1.Torque: 17Nm•

E68407

12

2.Torque: 48Nm

E84148

x4

Vehicles with manual transmission

3. CAUTIONS:

Make sure that new bolts are installed.

Make sure that no excess sealant

residue is evident.

G1079026en2008.50 Kuga8/2011

303-01- 11 2

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

11 2

INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1652 of 2057

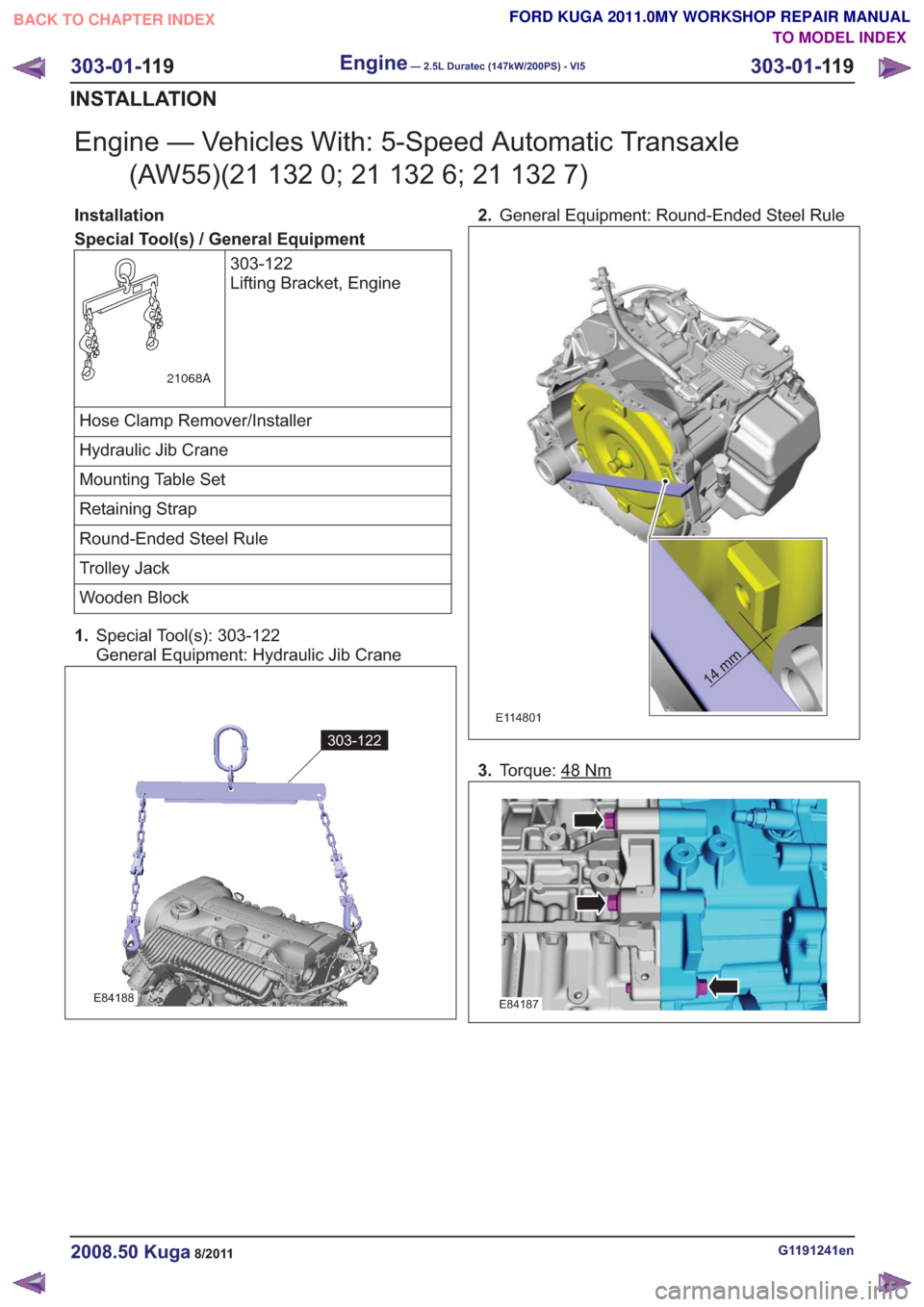

Engine — Vehicles With: 5-Speed Automatic Transaxle(AW55)(21 132 0; 21 132 6; 21 132 7)

Installation

Special Tool(s) / General Equipment

303-122

Lifting Bracket, Engine

21068A

Hose Clamp Remover/Installer

Hydraulic Jib Crane

Mounting Table Set

Retaining Strap

Round-Ended Steel Rule

Trolley Jack

Wooden Block

1. Special Tool(s): 303-122

General Equipment: Hydraulic Jib Crane

E84188

303-122

2.General Equipment: Round-Ended Steel Rule

14 mm14 mm

E114801

3.Torque: 48Nm

E84187

G1191241en2008.50 Kuga8/2011

303-01- 11 9

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

11 9

INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1653 of 2057

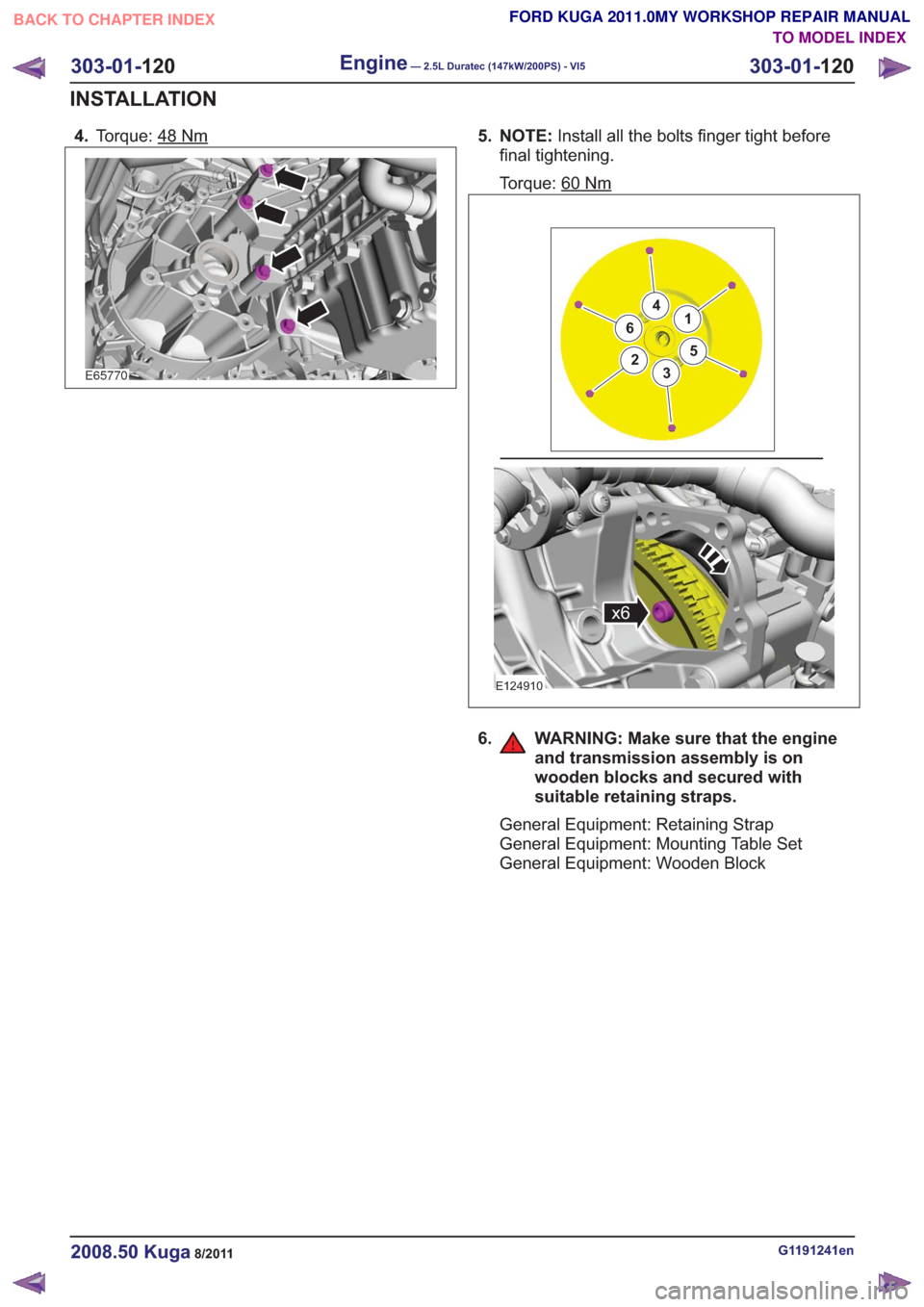

4.Torque: 48Nm

E65770

5. NOTE: Install all the bolts finger tight before

final tightening.

Torque: 60

Nm

6

5

3

4

2

1

x6

6

5

3

4

2

1

x6

E124910

6. WARNING: Make sure that the engine and transmission assembly is on

wooden blocks and secured with

suitable retaining straps.

General Equipment: Retaining Strap

General Equipment: Mounting Table Set

General Equipment: Wooden Block

G1191241en2008.50 Kuga8/2011

303-01- 120

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

120

INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1681 of 2057

Coolant Pump — 2.5L Duratec (147kW/200PS) - VI5(24 404 0)

General EquipmentTrolley Jack

Removal

NOTE: Removal steps in this procedure may

contain installation details.

1. Drain the cooling system.

Refer to: Cooling System Draining and Vacuum

Filling (303-03 Engine Cooling, General

Procedures).

2. Remove the timing belt.

Refer to: Timing Belt (303-01 Engine - 2.5L

Duratec (147kW/200PS) - VI5, Removal and

Installation).

3. CAUTION: Use a wooden block to protect the oil pan when supporting the

engine.

Position the trolley jack with the wooden block

under the oil pan. Raise the trolley jack until the

front of the engine is free from load and the

coolant pump bolts can be accessed.

General Equipment: Trolley Jack

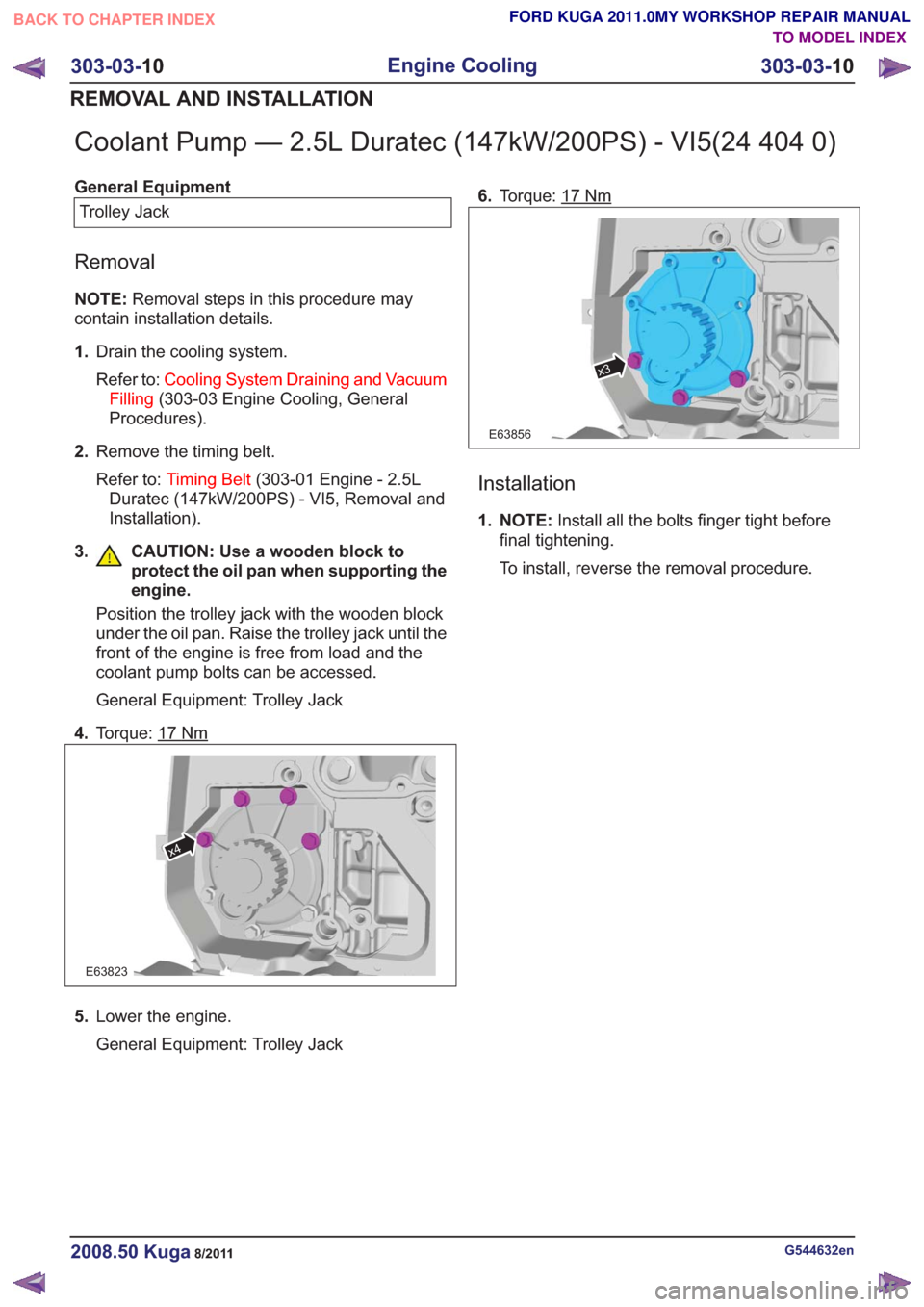

4. Torque: 17

Nm

E63823

x4

5.Lower the engine.

General Equipment: Trolley Jack 6.

Torque: 17

Nm

x3

E63856

Installation

1. NOTE: Install all the bolts finger tight before

final tightening.

To install, reverse the removal procedure.

G544632en2008.50 Kuga8/2011

303-03- 10

Engine Cooling

303-03- 10

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1695 of 2057

Fuel Charging and Controls

General EquipmentFord diagnostic equipment

Inspection and Verification

1. Verify the customer concern by operating the system.

2. Visually inspect for obvious signs of mechanical or electrical damage. Visual Inspection Chart

Electrical

Mechanical

– Loose or corrodedconnector(s)

– Wiring harness

– Fuel injector(s)

– Fuel leaks

– Blocked or contamin-

ated fuel filter

– Damaged fuel supply manifold

– Damaged fuel line connections

– Damaged vacuum hoses

– Fuel rail pressure sensor

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the concern is not visually evident, verify the symptom and refer to the Ford diagnostic

equipment .

Symptom Chart

Action

Possible Sources

Symptom

• CHECK the PATS LED extin-guishes within 3 seconds when

the ignition is turned on.

REFER to: Anti-Theft - Passive

(419-01 Anti-Theft - Passive,

Diagnosis and Testing).

• PAT S .

• Engine does not crank

• REFER to:Starting System

(303-06 Starting System -

2.5L Duratec (147kW/200PS)

- VI5, Diagnosis and Testing).

• Starting system.

• REFER to the Wiring Diagrams.

• Ignition switch.

• Carry out a full enginediagnosis using the guided

diagnostic menu in the Ford

diagnostic equipment.

• Powertrain control module

(PCM).

• RESET the IFS switch.

• Inertia fuel shutoff (IFS) switch.

• Engine cranks but does not

start

• Check the fuel system pres-sure.

• Low fuel system pressure.

G1183441en2008.50 Kuga8/2011

303-04A-

4

Fuel Charging and Controls

— 2.5L Duratec (147kW/200PS) -

VI5

303-04A- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL