2.5L FORD KUGA 2011 1.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1266 of 2057

Differential Case

General EquipmentCable Ties

Removal

All vehicles

1. Refer to: Rear Halfshaft (205-05 Rear Drive

Halfshafts, Removal and Installation).

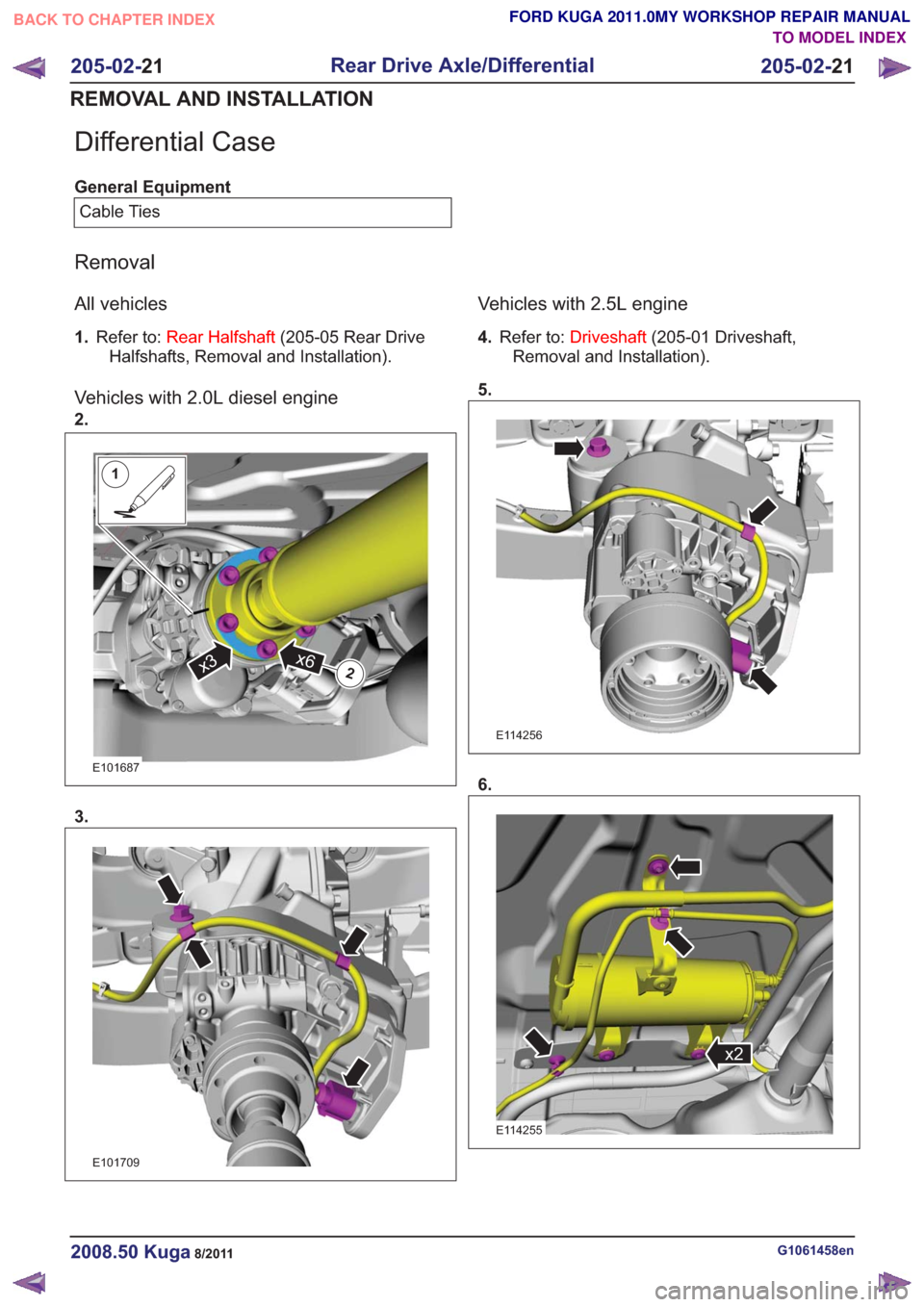

Vehicles with 2.0L diesel engine

2.

1

2x6x3

1

2x6x3

E101687

3.

E101709

Vehicles with 2.5L engine

4. Refer to: Driveshaft (205-01 Driveshaft,

Removal and Installation).

5.

E114256

6.

x2x2

E114255

G1061458en2008.50 Kuga8/2011

205-02- 21

Rear Drive Axle/Differential

205-02- 21

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1269 of 2057

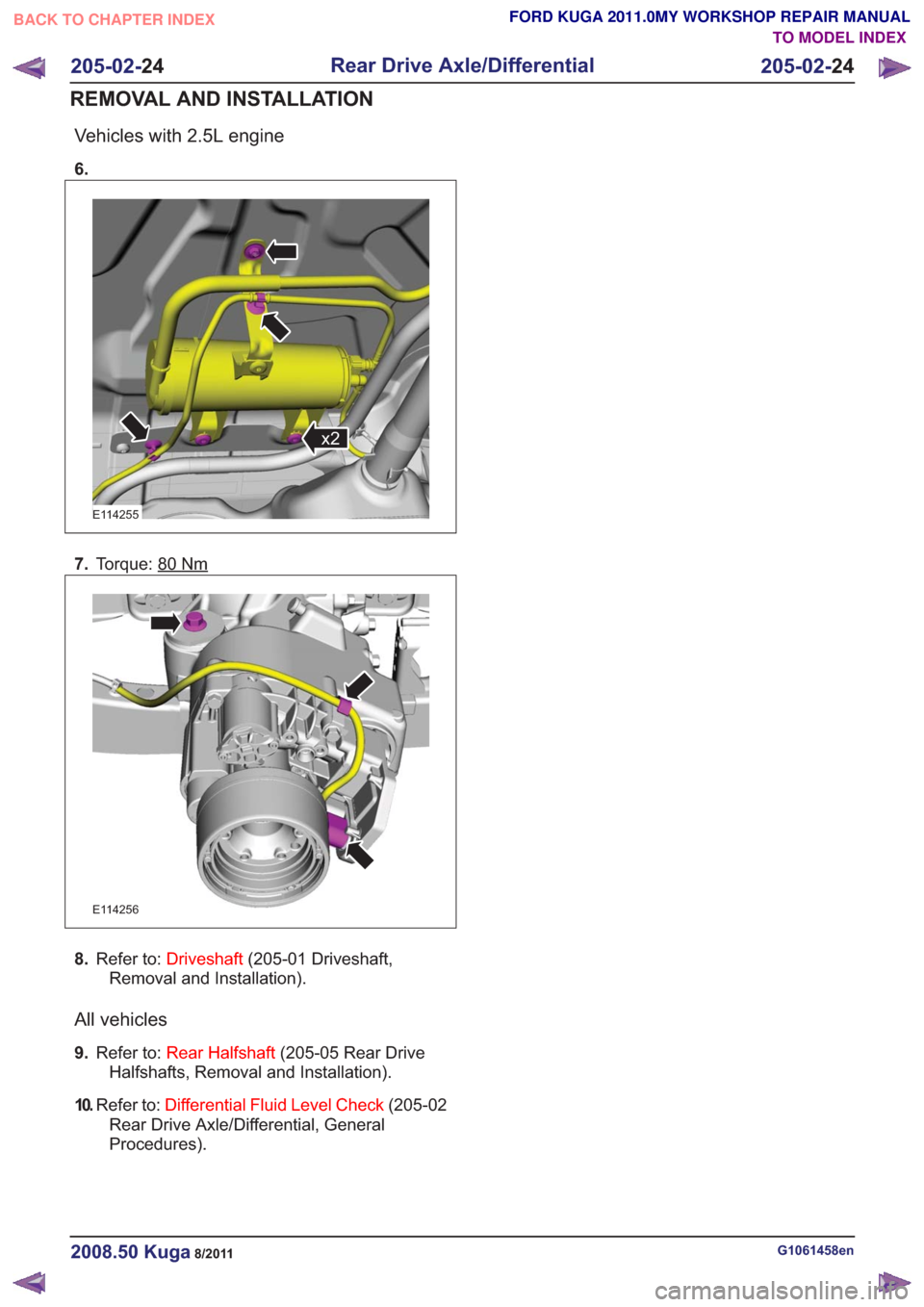

Vehicles with 2.5L engine

6.

x2x2

E114255

7.Torque: 80Nm

E114256

8.Refer to: Driveshaft (205-01 Driveshaft,

Removal and Installation).

All vehicles

9. Refer to: Rear Halfshaft (205-05 Rear Drive

Halfshafts, Removal and Installation).

10. Refer to: Differential Fluid Level Check (205-02

Rear Drive Axle/Differential, General

Procedures).

G1061458en2008.50 Kuga8/2011

205-02- 24

Rear Drive Axle/Differential

205-02- 24

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1271 of 2057

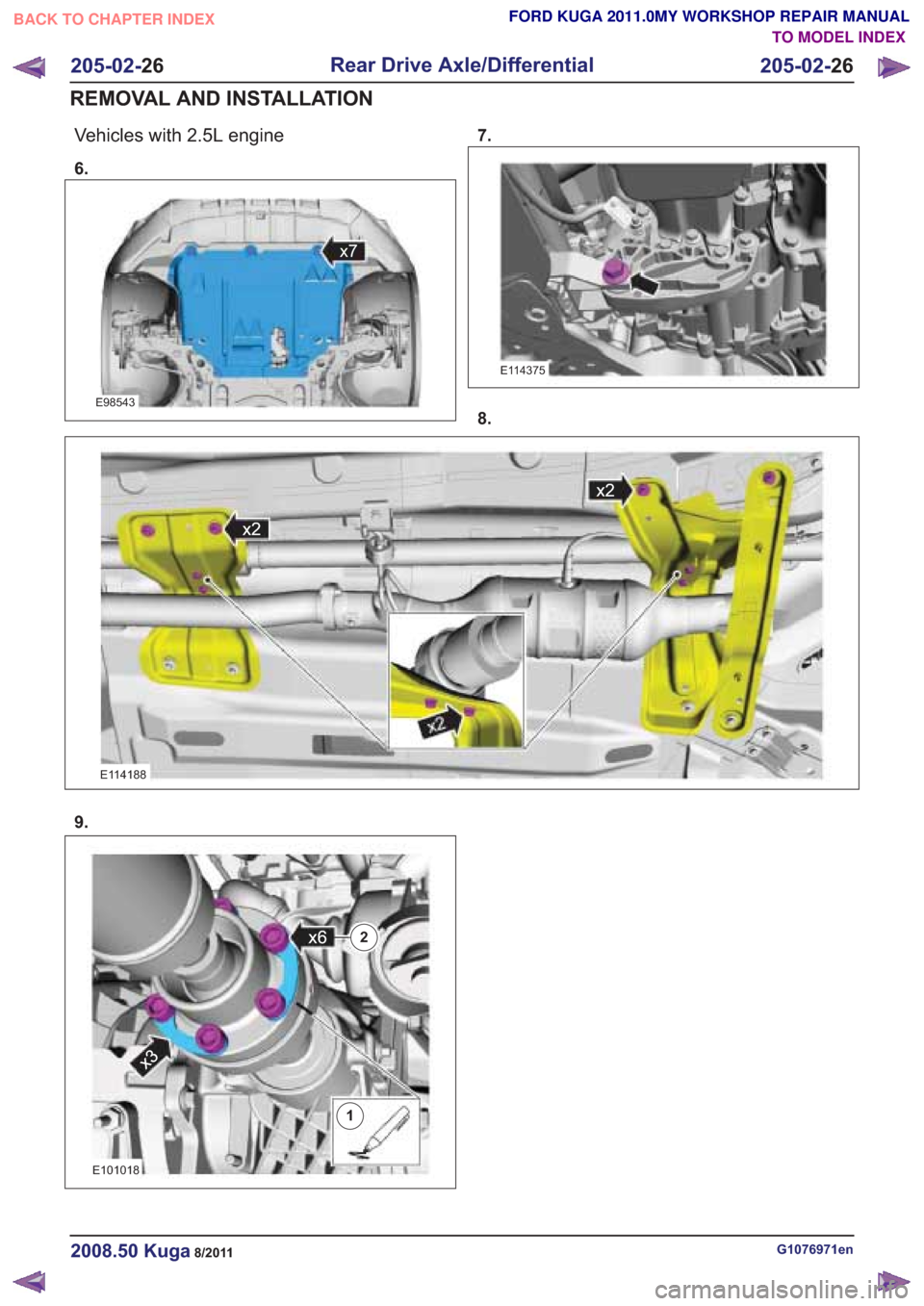

Vehicles with 2.5L engine

6.

E98543

x7

7.

E114375

8.

x2

x2

x2

x2

E114188

9.

1

2x6

x3

1

2x6

x3

E101018

G1076971en2008.50 Kuga8/2011

205-02-26

Rear Drive Axle/Differential

205-02- 26

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1274 of 2057

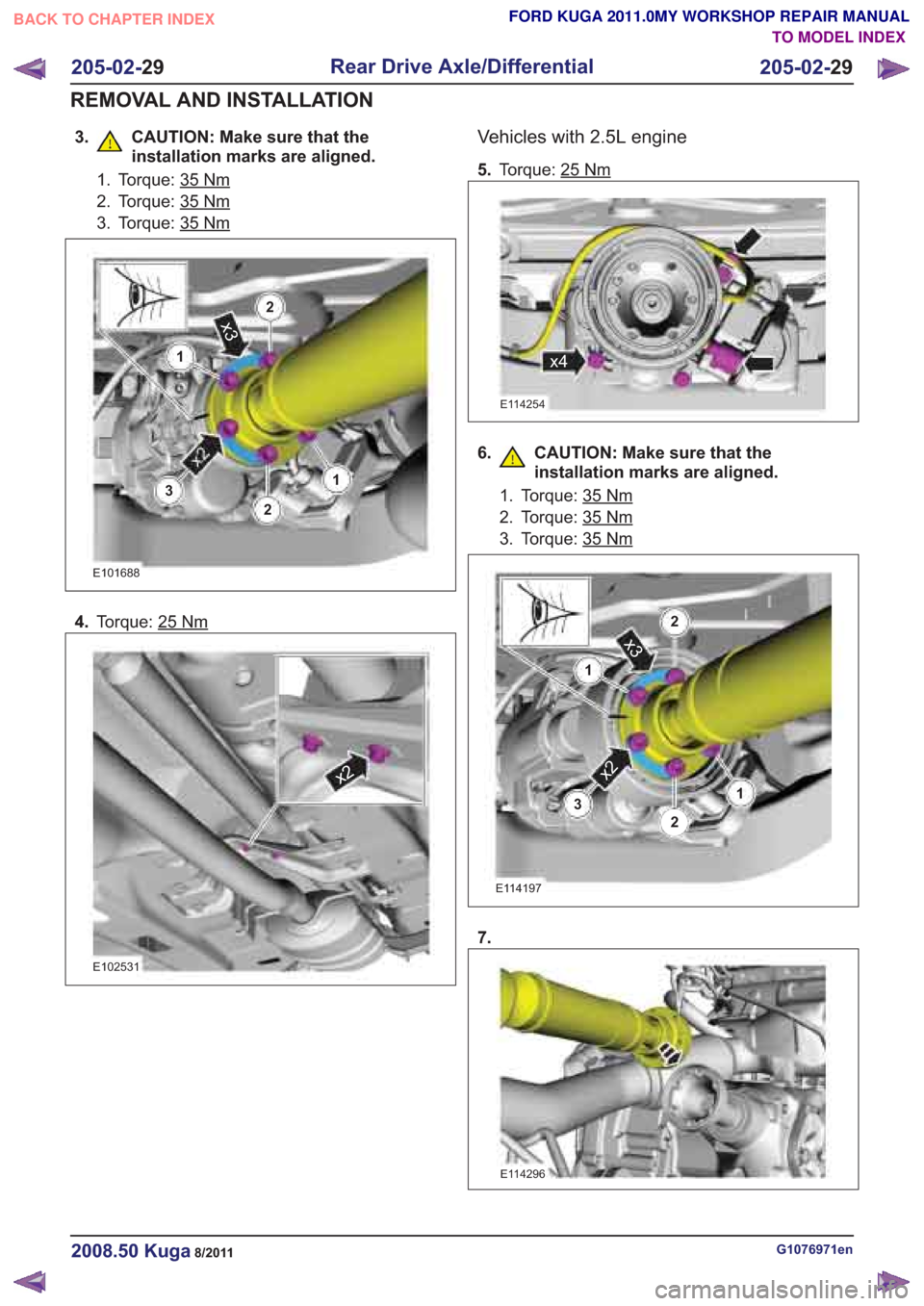

3. CAUTION: Make sure that theinstallation marks are aligned.

2. Torque: 35

E101688

4.Torque: 25Nm

x2

E102531

Vehicles with 2.5L engine

5.Torque: 25

E114254

6. CAUTION: Make sure that the

installation marks are aligned.

1. Torque: 35

2. Torque: 35

3. Torque: 35

E114296

G1076971en2008.50 Kuga8/2011

205-02- 29

Rear Drive Axle/Differential

205-02- 29

REMOVAL AND INSTALLATION

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

TO MODEL INDEX

BACK TO CHAPTER INDEX

1. Torque: 35Nm

Nm

3. Torque: 35Nm

Nm

Nm

Nm

Nm

3

x2

1

2

2

x3

1

E114197

7.

3

1

2

2x3

1

x4

Page 1315 of 2057

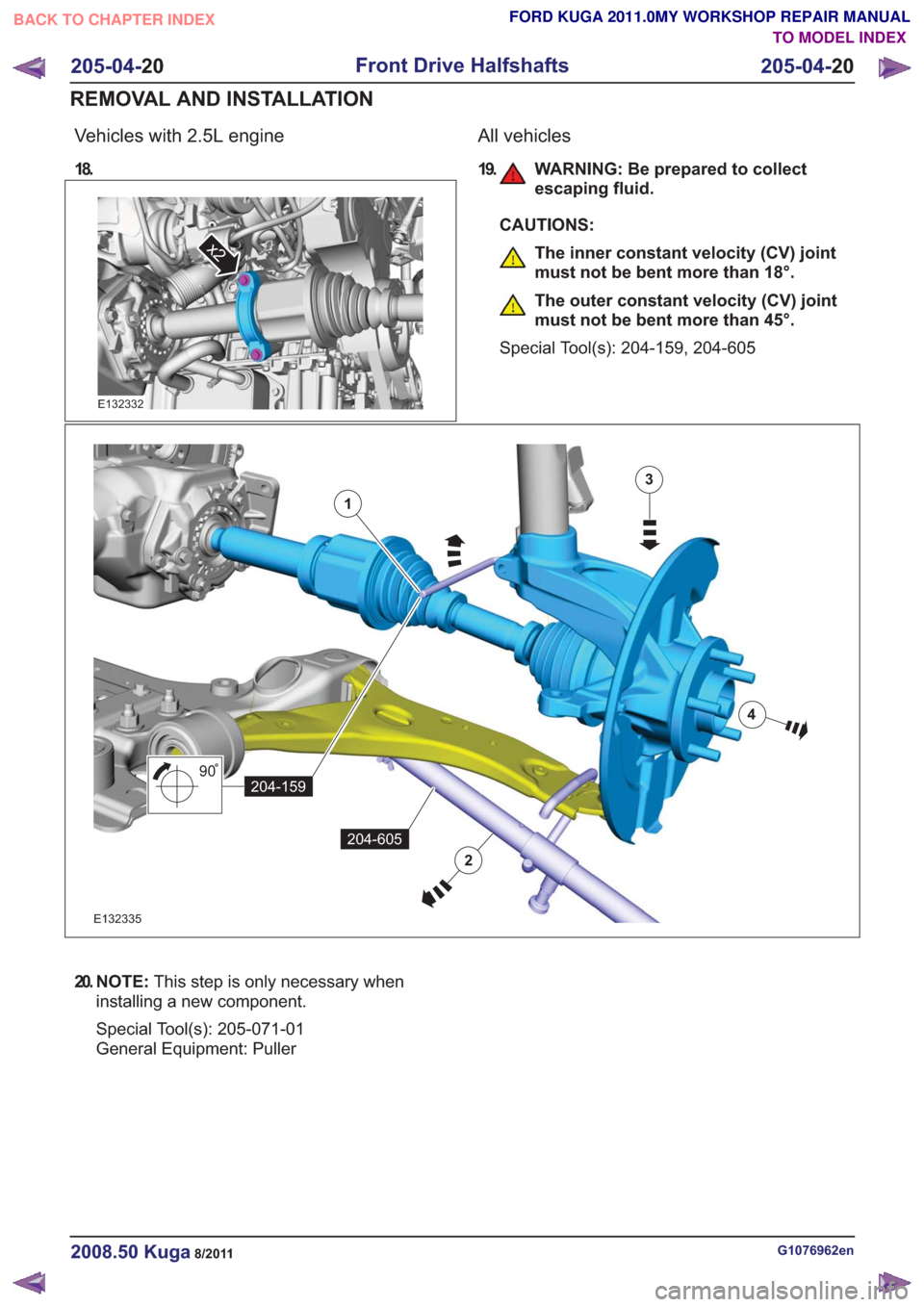

Vehicles with 2.5L engine

18.

x2x2

E132332

All vehicles

19. WARNING: Be prepared to collectescaping fluid.

CAUTIONS:

The inner constant velocity (CV) joint

must not be bent more than 18°.

The outer constant velocity (CV) joint

must not be bent more than 45°.

Special Tool(s): 204-159, 204-605

90

204-159

3

4

1

204-605

2

90

204-159

3

4

1

204-605

2

E132335

20. N O T E : This step is only necessary when

installing a new component.

Special Tool(s): 205-071-01

General Equipment: Puller

G1076962en2008.50 Kuga8/2011

205-04- 20

Front Drive Halfshafts

205-04- 20

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1319 of 2057

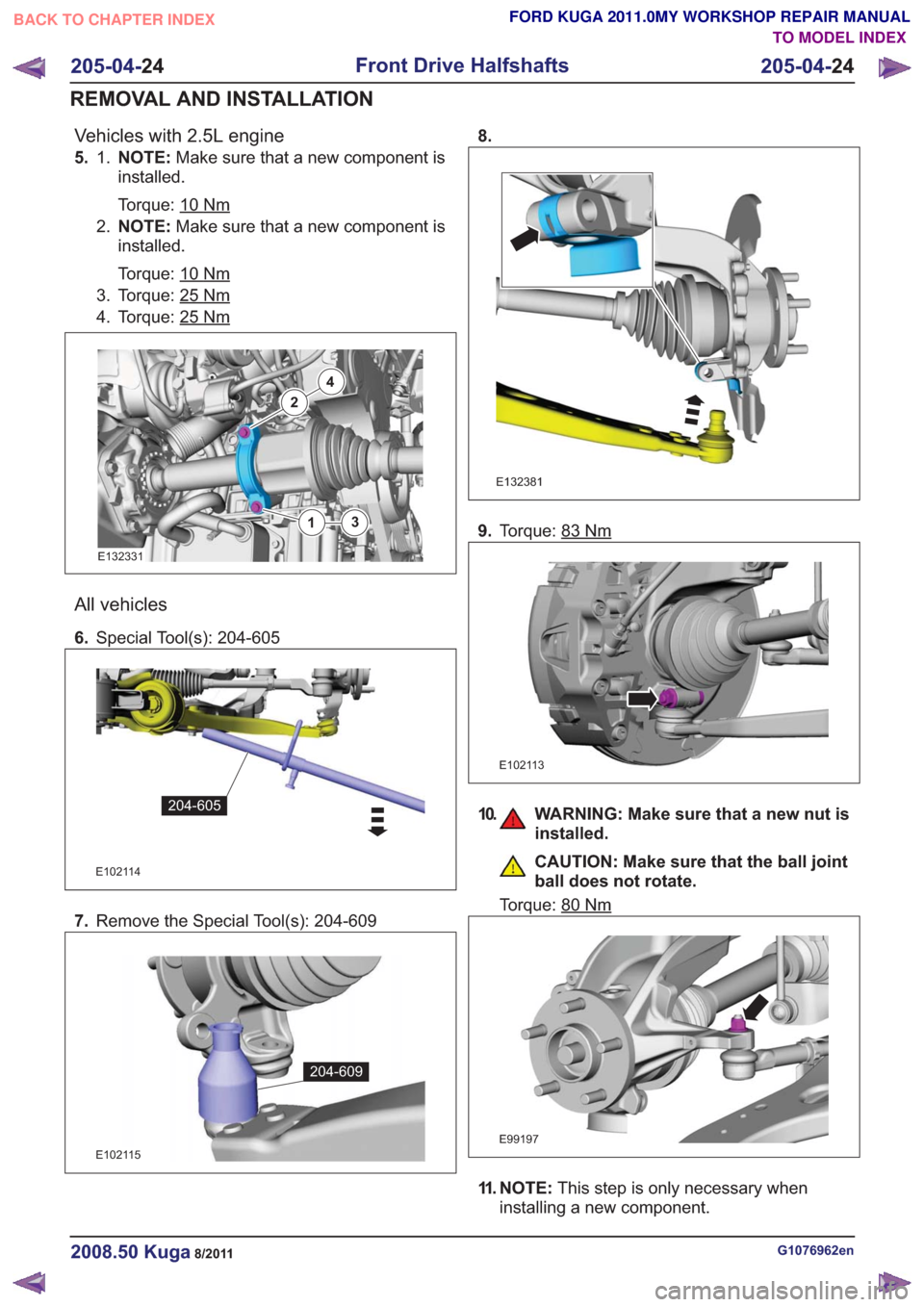

Vehicles with 2.5L engine

5. NOTE:Make sure that a new component is

installed.

Torque: 10

Nm

1.

2. NOTE: Make sure that a new component is

installed.

Torque: 10

Nm

3. Torque: 25Nm

4. Torque: 25Nm

2

4

13

2

4

13

E132331

All vehicles

6. Special Tool(s): 204-605

E102114

204-605

7.Remove the Special Tool(s): 204-609

E102115

204-609

8.

E132381

9.Torque: 83Nm

E102113

10. WARNING: Make sure that a new nut is

installed.

CAUTION: Make sure that the ball joint

ball does not rotate.

Torque: 80

Nm

E99197

11. NOTE: This step is only necessary when

installing a new component.

G1076962en2008.50 Kuga8/2011

205-04- 24

Front Drive Halfshafts

205-04- 24

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1342 of 2057

Action

Possible Sources

Symptom

• INSTALL a new brake mastercylinder.

REFER to: Brake Master

Cylinder - 2.5L Duratec

(147kW/200PS) - VI5 (206-06

Hydraulic Brake Actuation,

Removal and Installation).

• Leaking brake master cylinder

primary piston cup.

• FREE UP and ADJUST theparking brake cable.

REFER to: Parking Brake

Cable Adjustment (206-05

Parking Brake and Actuation,

General Procedures).

INSTALL new components as

necessary.

• Parking brake control not fully

released.

• REFER to:Anti-Lock Control

(206-09 Anti-Lock Control,

Diagnosis and Testing).

• Malfunctioning anti-lock braking

system (ABS).

• REFER to:Instrument Cluster

(413-01 Instrument Cluster,

Diagnosis and Testing).

• Shorted indicator circuit.

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Grease or fluid on the brake

shoes or brake pads; glazed

linings.

• Vibration when the brakes are

applied

• INSTALL new brake shoes orbrake pads.

REFER to: Brake Pads (206-03

Front Disc Brake, Removal

and Installation).

• Worn or damaged brake shoes

or brake pads.

• TIGHTEN the caliper mountingbolt(s).

• Loose caliper mounting bolt(s).

•

• Excessive brake disc thickness

variation or brake disc runout.

• CHECK the tires. BALANCE orINSTALL new tires as neces-

sary.

REFER to: Wheels and Tires

(204-04 Wheels and Tires,

Diagnosis and Testing).

• Wheels and tires.

• TIGHTEN or INSTALL newwheel hub bolts as necessary.

• Loose or missing wheel hub

bolts.

• CARRY OUT a brake discrunout check.

• Worn or damaged brake drums

or brake discs.

G1058975en2008.50 Kuga8/2011

206-00- 6

Brake System - General Information

206-00- 6

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1347 of 2057

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

A2: CHECK FOR BRAKE SYSTEM LEAKS

1 Check for external brake and clutch system

leaks. Refer to Brake Master Cylinder

Component Test in this procedure.

• Are any leaks present?

zYe s REPAIR as necessary. ADD fluid and BLEED

the brake system. REFER to: (206-00 Brake

System - General Information)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General

Procedures),

Component Bleeding (General Procedures).

TEST the system for normal operation.

zNo

GO to A3.

A3: PERFORM A BRAKE MASTER CYLINDER BYPASS CONDITION TEST

1 Carry out a brake master cylinder bypass

Condition Test. Refer to the Brake Master

Cylinder Component Test in this procedure.

• Was a concern found?

zYe s INSTALL a new brake master cylinder.

REFER to: Brake Master Cylinder - 2.5L

Duratec (147kW/200PS) - VI5 (206-06

Hydraulic Brake Actuation, Removal and

Installation).

TEST the system for normal operation.

zNo

VERIFY the customer concern.

PINPOINT TEST B : PEDAL EASES DOWN SLOWLY

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

B1: CHECK THE BRAKE PEDAL OPERATION

1 Depress the brake pedal.

• Does the pedal ease down slowly?

zYe s GO to B2.

zNoRefer to the Brake Master Cylinder

Component Test in this procedure.

G1058975en2008.50 Kuga8/2011

206-00- 11

Brake System - General Information

206-00- 11

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

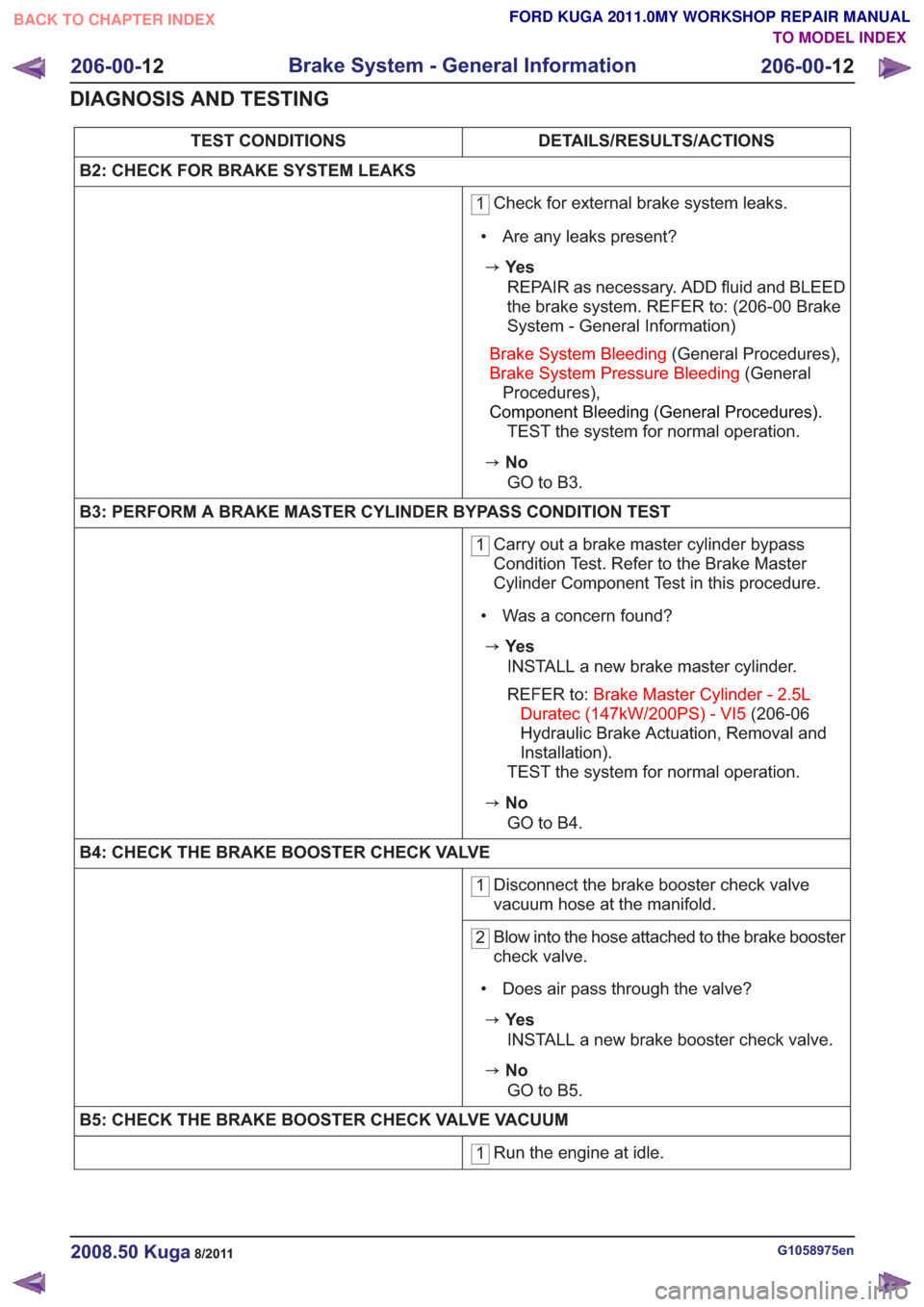

Page 1348 of 2057

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

B2: CHECK FOR BRAKE SYSTEM LEAKS

1 Check for external brake system leaks.

• Are any leaks present?

zYe s REPAIR as necessary. ADD fluid and BLEED

the brake system. REFER to: (206-00 Brake

System - General Information)

Brake System Bleeding (General Procedures),

Brake System Pressure Bleeding (General

Procedures),

Component Bleeding (General Procedures).

TEST the system for normal operation.

zNo

GO to B3.

B3: PERFORM A BRAKE MASTER CYLINDER BYPASS CONDITION TEST

1 Carry out a brake master cylinder bypass

Condition Test. Refer to the Brake Master

Cylinder Component Test in this procedure.

• Was a concern found?

zYe s INSTALL a new brake master cylinder.

REFER to: Brake Master Cylinder - 2.5L

Duratec (147kW/200PS) - VI5 (206-06

Hydraulic Brake Actuation, Removal and

Installation).

TEST the system for normal operation.

zNo

GO to B4.

B4: CHECK THE BRAKE BOOSTER CHECK VALVE

1 Disconnect the brake booster check valve

vacuum hose at the manifold.

2Blow into the hose attached to the brake booster

check valve.

• Does air pass through the valve?

zYe s INSTALL a new brake booster check valve.

zNoGO to B5.

B5: CHECK THE BRAKE BOOSTER CHECK VALVE VACUUM

1 Run the engine at idle.

G1058975en2008.50 Kuga8/2011

206-00-

12

Brake System - General Information

206-00- 12

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1355 of 2057

too close to the fluid level indicator assembly,

or float assembly damage.

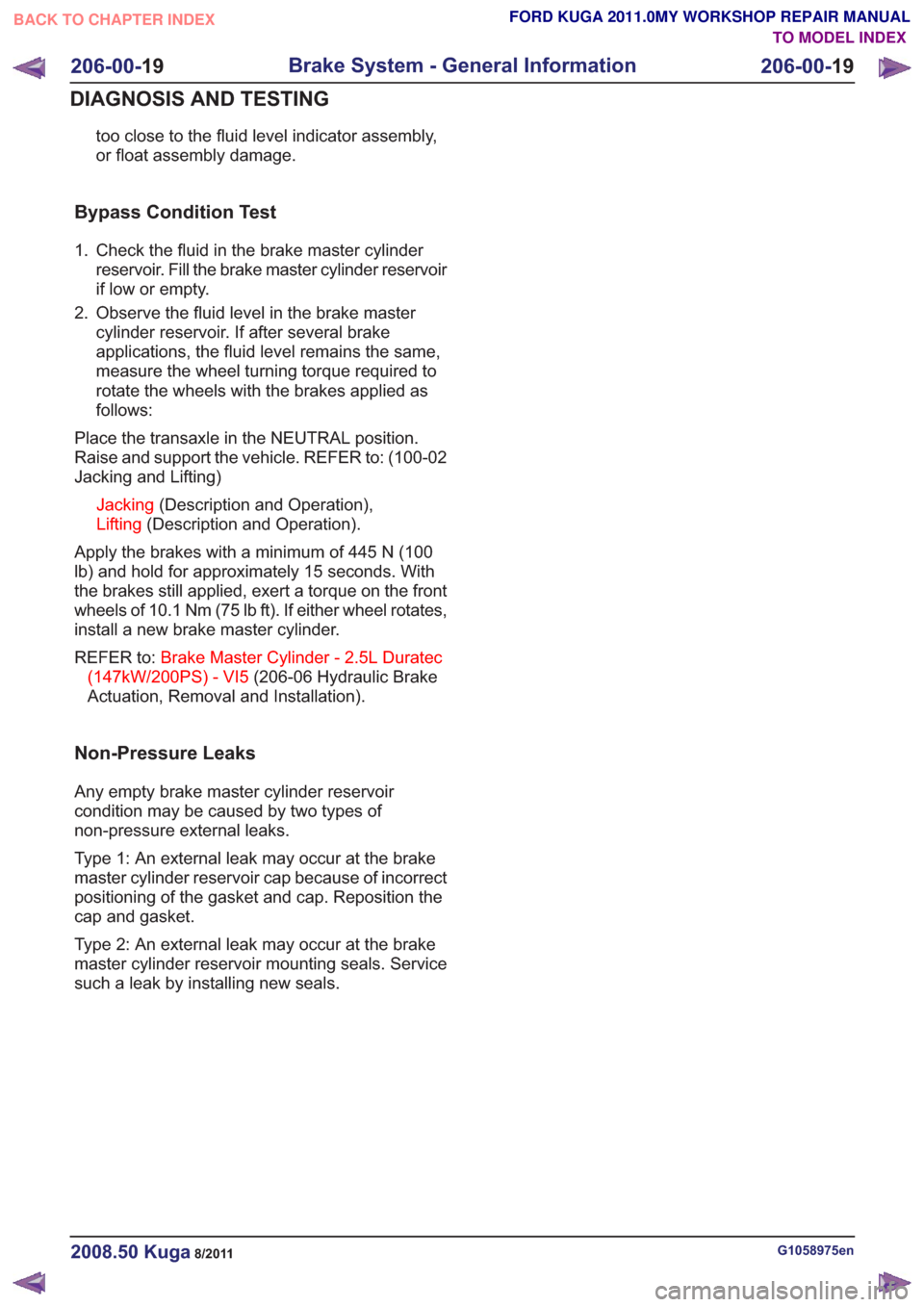

Bypass Condition Test

1. Check the fluid in the brake master cylinderreservoir. Fill the brake master cylinder reservoir

if low or empty.

2. Observe the fluid level in the brake master cylinder reservoir. If after several brake

applications, the fluid level remains the same,

measure the wheel turning torque required to

rotate the wheels with the brakes applied as

follows:

Place the transaxle in the NEUTRAL position.

Raise and support the vehicle. REFER to: (100-02

Jacking and Lifting) Jacking (Description and Operation),

Lifting (Description and Operation).

Apply the brakes with a minimum of 445 N (100

lb) and hold for approximately 15 seconds. With

the brakes still applied, exert a torque on the front

wheels of 10.1 Nm (75 lb ft). If either wheel rotates,

install a new brake master cylinder.

REFER to: Brake Master Cylinder - 2.5L Duratec

(147kW/200PS) - VI5 (206-06 Hydraulic Brake

Actuation, Removal and Installation).

Non-Pressure Leaks

Any empty brake master cylinder reservoir

condition may be caused by two types of

non-pressure external leaks.

Type 1: An external leak may occur at the brake

master cylinder reservoir cap because of incorrect

positioning of the gasket and cap. Reposition the

cap and gasket.

Type 2: An external leak may occur at the brake

master cylinder reservoir mounting seals. Service

such a leak by installing new seals.

G1058975en2008.50 Kuga8/2011

206-00- 19

Brake System - General Information

206-00- 19

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL