fuel consumption FORD KUGA 2011 1.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1795 of 2057

actuated) or opened (actuated). Each cylinder has

its own injector. The injection is accurately dosed

and takes place at a time determined by the PCM.

Injection takes place immediately in front of the

intake valves of the cylinder. The injectors are

actuated ground side via end-stages integrated

into the PCM and using the signal calculated by

the engine management system. Power is supplied

via the Powertrain Control Module relay in the BJB.

The injected fuel quantity depends on the opening

time, the fuel pressure and the diameter of the

nozzle holes.

The fuel metering is determined via open or

closed-loop control.

The open control loop differs from the closed

control loop in that the lambda control is

deactivated.

The PCM switches from closed to open-loop control

if the HO2S cools down to below 600°C or fails, as

well as when accelerating, coasting and at full load.

Regulation of injected fuel quantity via the PCM

involves:

• controlling the fuel pump,

• calculating the required quantity of fuel forengine starting,

• observance of the desired air/fuel ratio,

• calculating air mass,

• and calculating the fuel quantity for the different operating states and corresponding fuel

adjustment measures.

Open loop control

Open loop control is used primarily for fuel

injection, as long as the signals of the HO2S are

not involved in the calculation of the PCM.

The two most important reasons that make it

absolutely essential to run the engine without

lambda control (open-loop control) are the following

operating conditions:

• Cold engine (starting, warm-up phase)

• Full-load operation (WOT (wide open throttle))

Under these operating conditions the engine needs

a rich air/fuel mixture with lambda values below λ

= 1 in order to achieve optimum running or

optimum performance.

It is possible to keep this unregulated range very

small by using a broadband HO2S.

Closed-loop control

Closed loop control ensures strict control of

exhaust emissions in conjunction with the TWC (three-way catalytic converter) and economical fuel

consumption. With closed loop control, the signals

from the HO2S are analyzed by the PCM and the

engine always runs in the optimum range of λ = 1.

In addition to the normal HO2S, the signal from the

monitoring sensor for the catalytic converter is also

included in the control. The lambda control is

optimized on the basis of this data.

Certain factors such as wear, component

tolerances or more minor defects such as air leaks

in the intake system are compensated for by

lambda control. If the deviation occurs for a longer

period of time, this is recorded by the adaptive

(self-learning) function of lambda control. In this

instance, the entire map is shifted by the

corresponding amount, to enable control to

commence once again from the virtual baseline.

These adaptive settings are stored in the PCM and

are also used in open-loop control conditions.

If the adaptive value is too high or too low, an error

is stored in the fault memory of the PCM.

Oxygen sensor (HO2S) and catalyst monitor

sensor

A broadband HO2S is used as the HO2S. The

HO2S is located in front of the TWC. The catalyst

monitor sensor is located in the center of the TWC

so that it can detect any deterioration in the

cleaning performance of the TWC more quickly.

The HO2S measures the residual amount of

oxygen in the exhaust before the TWC.

The catalyst monitor sensor measures the amount

of oxygen in the exhaust gas after or in the TWC.

Both the HO2S and the catalyst monitor sensor

transmit these data to the PCM.

The broadband HO2S works at temperatures of

between 650°C and 900 °C. If the temperature

rises above 1000°C, the oxygen sensor will be

irreparably damaged.

To reach optimum operating temperature as quickly

as possible, an electrically-heated oxygen sensor

is installed. The heating also serves to maintain a

suitable operating temperature while coasting, for

example, when no hot gases are flowing past the

oxygen sensor.

The heating element in the HO2S is a PTC

(positive temperature coefficient) resistor. The

heating element is supplied with battery voltage as

soon as the Powertrain Control Module relay

engages. The HO2S is earthed via the PCM. As

the heating current is high when the element is

cold, it is limited via PWM in the PCM until a certain

G1021908en2008.50 Kuga8/2011

303-14-

21

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

21

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1796 of 2057

current value is reached. The PCM then

permanently connects the heating element to earth.

The catalyst monitor sensor is used by the PCM

to measure the oxygen content in the exhaust gas

in the TWC. If all the conditions for catalyst

diagnostics are met, based on this information the

PCM can check that the TWC is working

satisfactorily. The information is also used to

improve the air/fuel mixture adjustment.

The catalyst monitor sensor is similar in function

to an HO2S. The signal transmitted by the catalyst

monitor sensor changes sharply if the oxygen

content in the exhaust gas changes. For this

reason, catalyst monitor sensors are also called

"jump lambda sensors".

Fuel tank purging

The EVAP purge valve is only actuated by the PCM

if the coolant temperature is at least 60°C.

Actuation is done ground side by means of a PWM

signal. This makes it possible to have the full range

of opening widths, from fully closed to fully open.

The PCM determines from the operating conditions

when and how wide to open the EVAP tank purge

valve. If the EVAP purge valve is opened, the

engine sucks in ambient air through the activated

charcoal in the evaporative emission canister as

a result of the vacuum in the intake manifold. In

this way the adsorbed hydrocarbons are led to the

combustion chamber of the engine.

The EVAP tank purge valve is not actuated and

system cleaning is interrupted if the engine

switches to idle and/or a closed-loop control

process is initiated.

Power (battery voltage) is supplied via the

Powertrain Control Module relay in the BJB. The

solenoid coil resistance is between 17 and 24 ohms

at 20°C.

Engine speed control

The APP sensor provides the PCM with information

about the driver's request for acceleration.

The throttle control unit receives a corresponding

input signal from the PCM. An electric motor then

moves the throttle valve shaft by means of a set

of gears. The position of the throttle is continuously

recorded by the TP sensor. Information on throttle

position is processed and monitored by the PCM.

The TP sensor comprises two potentiometers.

These work in opposite ways to each other. In one

potentiometer, the resistance increases when the

throttle is opened, in the other it decreases. Thisallows the operation of the potentiometers to be

checked. The signal from the TP sensor is

amplified in the lower range (idle to a quarter open)

by the PCM to enable more precise control of the

throttle in this range. This is necessary because

the engine is very sensitive to changes in throttle

angle in this throttle opening range.

With the throttle valve position kept constant, the

ignition angle and the injected fuel quantity are

then varied to meet the torque demands.

Depending on the operating state of the engine, a

change in the position of the throttle flap may not

be necessary when the APP sensor changes.

If a fault develops in the throttle control unit, a

standby function is executed. This standby function

allows a slight opening of the throttle flap, so that

enough air passes through to allow limited engine

operation. For this purpose, there is a throttle flap

adjustment screw on the throttle housing. The

return spring closes the throttle flap until the stop

of the toothed segment touches the stop screw. In

this way a defined throttle flap gap is formed for

limp home mode.

The stop screw has a spring loaded pin, which

holds the throttle flap open for limp home mode.

In normal operating mode, this spring loaded pin

is pushed in by the force of the electric motor when

the throttle flap must be closed past the limp home

position (e.g. for idle speed control or overrun

shutoff).

Oil monitoring

The engine does not have an oil pressure

switch.

The oil level and oil quality are calculated.

Calculating the engine oil level

The oil level is determined by continuous

measurement of the capacitance (i.e. the ability to

store an electrical charge) between the two

capacitive elements of the engine oil

level/temperature/quality sensor. The different oil

levels cause the capacitance between the elements

to change. The data are recorded by the PCM and

converted into an oil level value. Temporary

fluctuations in oil level are automatically filtered out

by the PCM.

Calculating oil quality

The PCM calculates the oil quality from the oil level

measurement and the oil temperature measured

by the sensor, plus the engine speed and the

average fuel consumption. The driver is informed

about when an oil change is due.

G1021908en2008.50 Kuga8/2011

303-14- 22

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

22

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1797 of 2057

Calculation of valve timing adjustment

angle

The 2.5L Duratec (VI5) engine has two camshaft

adjustment units which work independently of each

other.

One camshaft adjustment solenoid is installed for

each intake camshaft and exhaust camshaft.

This allows the PCM to continuously adjust the

intake and exhaust-side camshaft adjustments

independently of one another. The timing is

adjusted by the PCM using curves; adjustment is

primarily done as a function of engine load and

engine speed.

In this way the engine performance is increased

and internal exhaust gas recirculation is realized.

The advantages of camshaft adjustment are as

follows:

• Higher torque and improved torquecharacteristics

• Reduced fuel consumption

• Improved emissions performance

The camshaft adjustment solenoids are actuated

by the PWM by means of a PCM signal.

Continuous adjustment of the camshafts by the

PCM is achieved by means of the camshaft

adjustment solenoids, the camshaft adjustment

units and two CMP sensors. A defined quantity of

engine is oil is supplied to or drained from the

adjustment units via the camshaft adjustment

solenoids. The existing EOP (engine oil pressure)

is taken into account in the process. In this way

the valve timings are adjusted according to the

operating condition of the engine. The camshaft

adjusters work according to the vane-cell principle.

On starting the engine, both camshafts are

mechanically locked in their starting positions. The

intake camshaft is in the maximum late position

and the exhaust camshaft in the maximum early

position.

Control is divided into four main areas:

• Low engine speed and low load

• Partial load

• Low engine speed and high load

• High engine speed and high load

At low engine speed and low load, the exhaust

valves open early and the intake valves open late.

The result is reduced fuel consumption and more

uniform idling. In the partial load range, the exhaust valves and

the intake valves open late. The late opening of

the exhaust valves results in a good utilization of

the expanding gases in the cylinder. Closing the

exhaust valves after Top Dead Center allows

internal exhaust gas recirculation through aspiration

of exhaust gases into the combustion chamber.

Moreover, the intake valves close after Bottom

Dead Centre, allowing the fresh air/fuel mixture

and exhaust gases to flow back into the intake

tract. The result is reduced fuel consumption and

low emissions.

At low engine speed and high engine load, the

exhaust valves open late and the intake valves

open early. Due to the resulting valve opening

overlap at Top Dead Centre, the pulsating gas

column within the combustion chamber is utilized

to achieve better charging of the combustion

chamber. The result is increased torque at lower

RPM.

At high engine speeds and high engine load, the

exhaust valves open early and the intake valves

close late. Because a rapid gas exchange must be

achieved at high engine speeds, the early opening

of the exhaust valves achieves better expulsion of

the exhaust gas and the late closing of the intake

valves improves cylinder charge efficiency.

Optimum power output is achieved.

Many other camshaft positions are possible in

addition to these settings.

In order to avoid a malfunction in the camshaft

adjustment units at excessively low ambient or

engine-oil temperatures, they are activated by the

PCM with a time delay via the camshaft adjustment

solenoids. The PCM receives the information

required for this from the ECT sensor and the

outside air temperature sensor.

When idling and during deceleration, the camshaft

adjustment solenoids are activated repeatedly by

the PCM in order to remove any dirt which may be

on the bore holes and ring grooves.

Boost pressure control

Optimum regulation is achieved by means of an

electronically-controlled solenoid valve, the boost

control solenoid valve.

Refer to:

Turbocharger (303-04 Fuel Charging and

Controls - Turbocharger - 2.5L Duratec

(147kW/200PS) - VI5, Description and

Operation).

G1021908en2008.50 Kuga8/2011

303-14- 23

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

23

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1828 of 2057

E125525

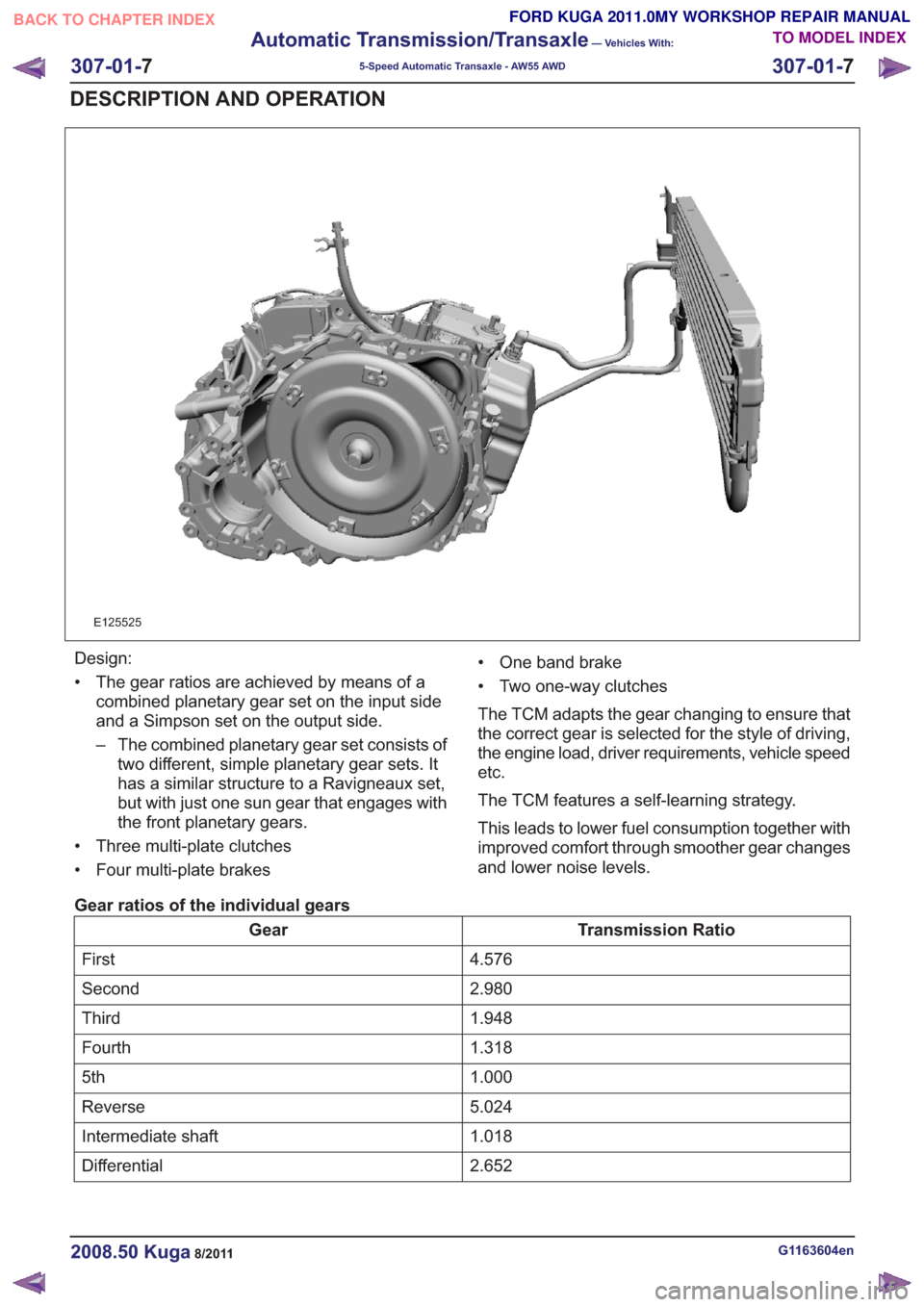

Design:

• The gear ratios are achieved by means of acombined planetary gear set on the input side

and a Simpson set on the output side.

– The combined planetary gear set consists oftwo different, simple planetary gear sets. It

has a similar structure to a Ravigneaux set,

but with just one sun gear that engages with

the front planetary gears.

• Three multi-plate clutches

• Four multi-plate brakes • One band brake

• Two one-way clutches

The TCM adapts the gear changing to ensure that

the correct gear is selected for the style of driving,

the engine load, driver requirements, vehicle speed

etc.

The TCM features a self-learning strategy.

This leads to lower fuel consumption together with

improved comfort through smoother gear changes

and lower noise levels.

Gear ratios of the individual gears

Transmission Ratio

Gear

4.576

First

2.980

Second

1.948

Third

1.318

Fourth

1.000

5th

5.024

Reverse

1.018

Intermediate shaft

2.652

Differential

G1163604en2008.50 Kuga8/2011

307-01- 7

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 7

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1831 of 2057

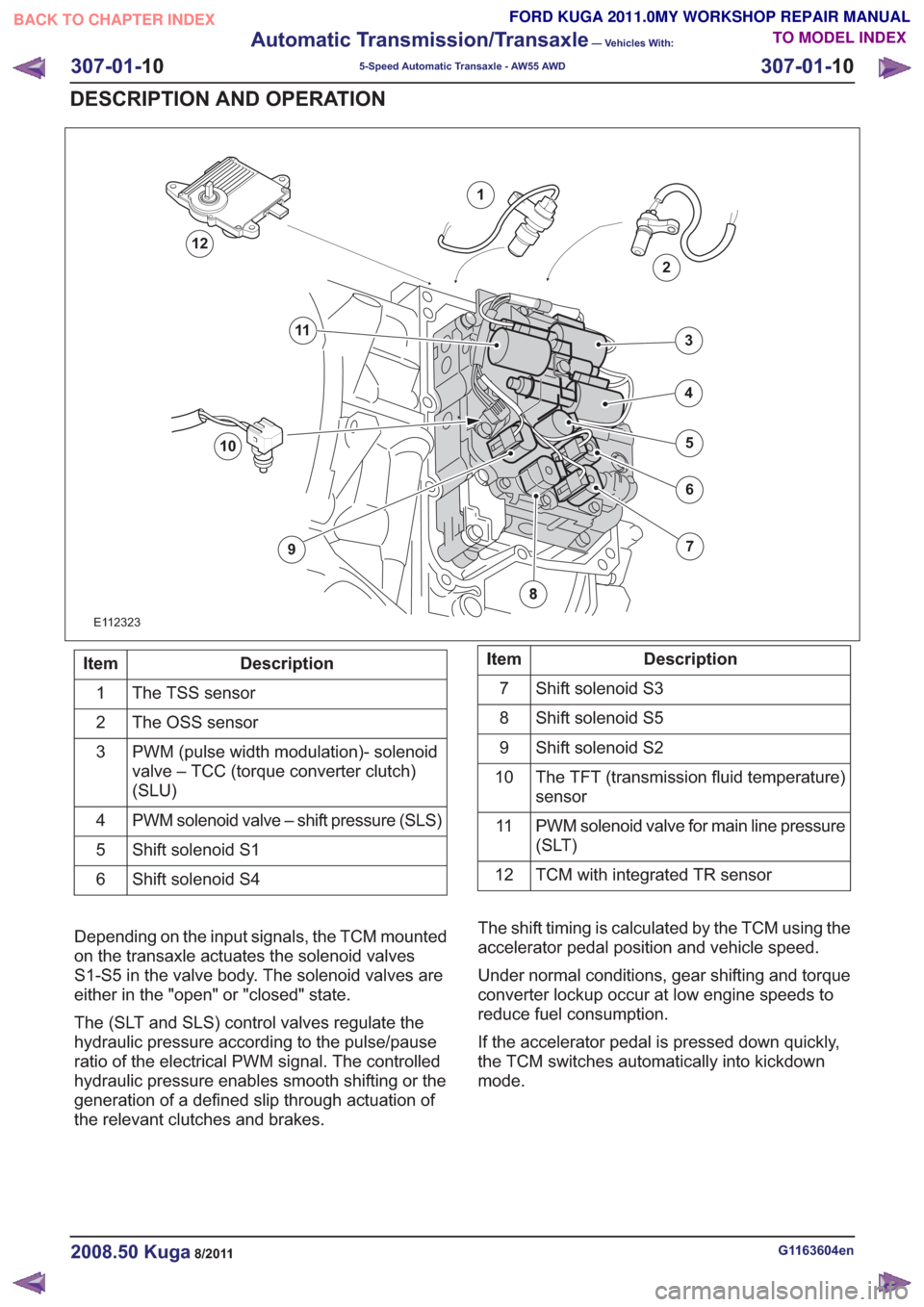

E112323

1

2

7

6

4

5

3

10

9

11

12

Description

Item

The TSS sensor

1

The OSS sensor

2

PWM (pulse width modulation)- solenoid

valve – TCC (torque converter clutch)

(SLU)

3

PWM solenoid valve – shift pressure (SLS)

4

Shift solenoid S1

5

Shift solenoid S4

6Description

Item

Shift solenoid S3

7

Shift solenoid S5

8

Shift solenoid S2

9

The TFT (transmission fluid temperature)

sensor

10

PWM solenoid valve for main line pressure

(SLT)

11

TCM with integrated TR sensor

12

Depending on the input signals, the TCM mounted

on the transaxle actuates the solenoid valves

S1-S5 in the valve body. The solenoid valves are

either in the "open" or "closed" state.

The (SLT and SLS) control valves regulate the

hydraulic pressure according to the pulse/pause

ratio of the electrical PWM signal. The controlled

hydraulic pressure enables smooth shifting or the

generation of a defined slip through actuation of

the relevant clutches and brakes. The shift timing is calculated by the TCM using the

accelerator pedal position and vehicle speed.

Under normal conditions, gear shifting and torque

converter lockup occur at low engine speeds to

reduce fuel consumption.

If the accelerator pedal is pressed down quickly,

the TCM switches automatically into kickdown

mode.

G1163604en2008.50 Kuga8/2011

307-01-

10

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 10

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1847 of 2057

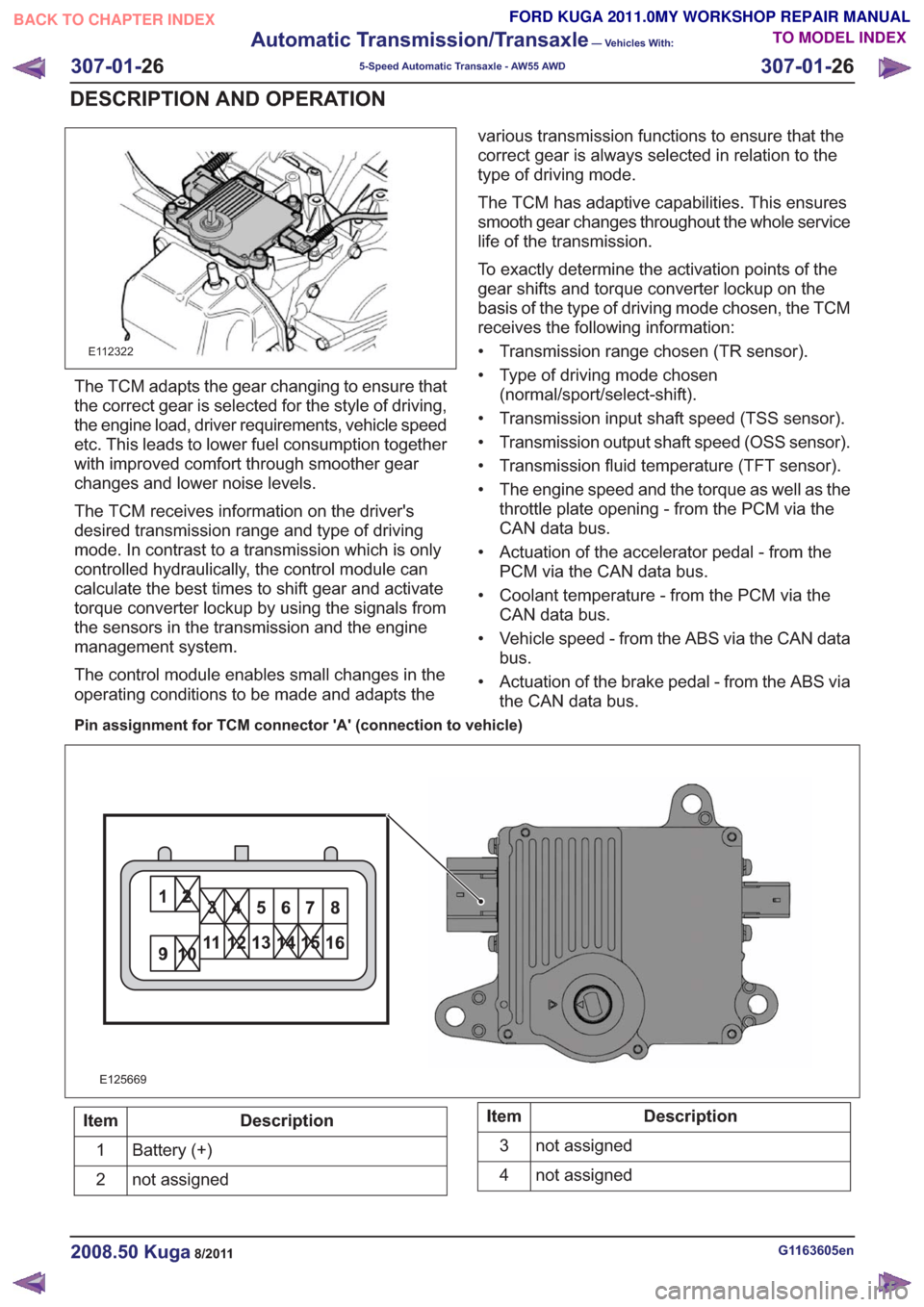

E112322

The TCM adapts the gear changing to ensure that

the correct gear is selected for the style of driving,

the engine load, driver requirements, vehicle speed

etc. This leads to lower fuel consumption together

with improved comfort through smoother gear

changes and lower noise levels.

The TCM receives information on the driver's

desired transmission range and type of driving

mode. In contrast to a transmission which is only

controlled hydraulically, the control module can

calculate the best times to shift gear and activate

torque converter lockup by using the signals from

the sensors in the transmission and the engine

management system.

The control module enables small changes in the

operating conditions to be made and adapts thevarious transmission functions to ensure that the

correct gear is always selected in relation to the

type of driving mode.

The TCM has adaptive capabilities. This ensures

smooth gear changes throughout the whole service

life of the transmission.

To exactly determine the activation points of the

gear shifts and torque converter lockup on the

basis of the type of driving mode chosen, the TCM

receives the following information:

• Transmission range chosen (TR sensor).

• Type of driving mode chosen

(normal/sport/select-shift).

• Transmission input shaft speed (TSS sensor).

• Transmission output shaft speed (OSS sensor).

• Transmission fluid temperature (TFT sensor).

• The engine speed and the torque as well as the throttle plate opening - from the PCM via the

CAN data bus.

• Actuation of the accelerator pedal - from the PCM via the CAN data bus.

• Coolant temperature - from the PCM via the CAN data bus.

• Vehicle speed - from the ABS via the CAN data bus.

• Actuation of the brake pedal - from the ABS via the CAN data bus.

Pin assignment for TCM connector 'A' (connection to vehicle)

11

E125669

Description

Item

Battery (+)

1

not assigned

2Description

Item

not assigned

3

not assigned

4

G1163605en2008.50 Kuga8/2011

307-01- 26

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 26

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1849 of 2057

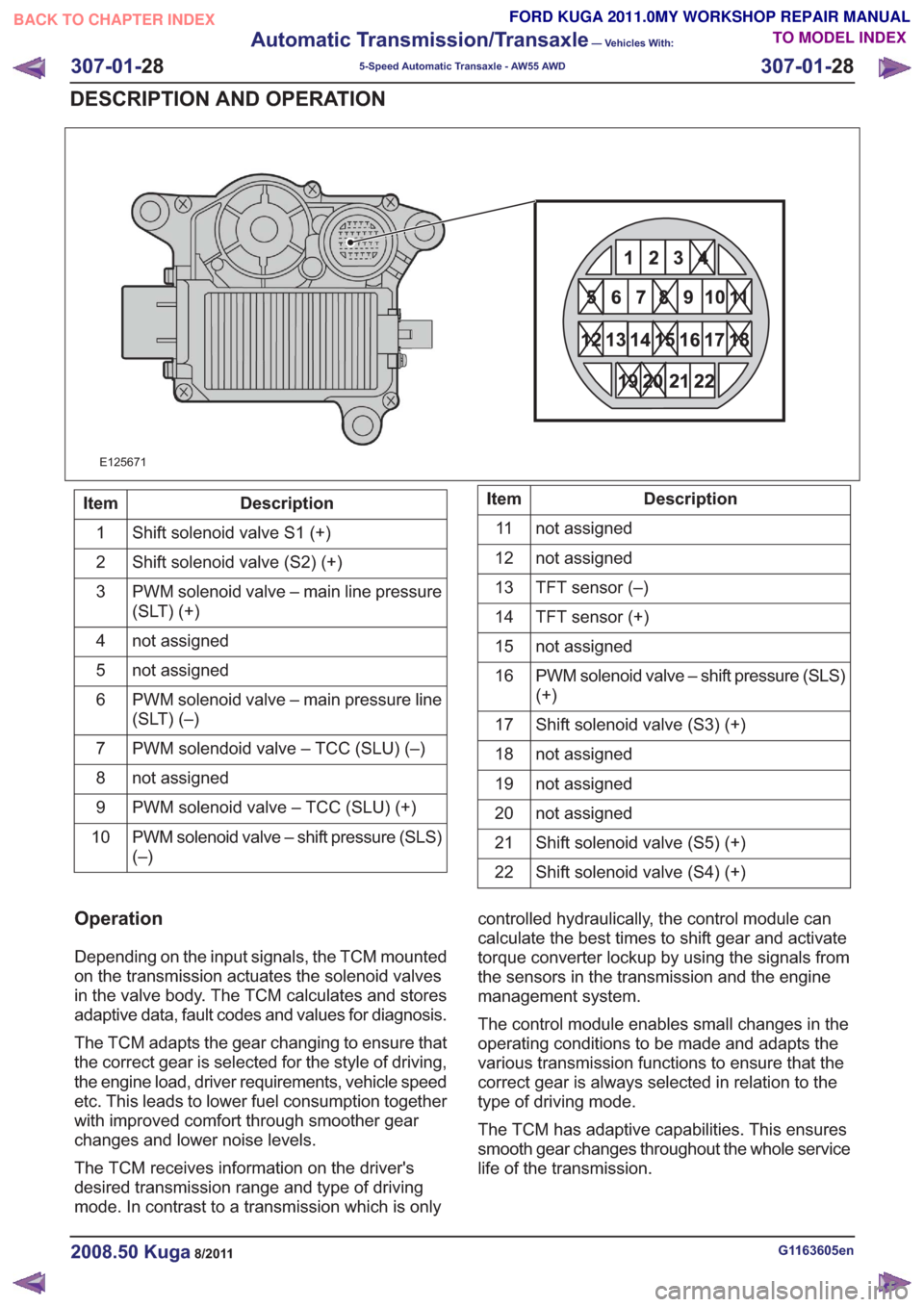

21

22 20 19

15 14 13

161718 12

876

9

10

11 5

3

42121

22 20 19

15 14 13

161718 12

876

9

10

11 5

3

421

E125671

Description

Item

Shift solenoid valve S1 (+)

1

Shift solenoid valve (S2) (+)

2

PWM solenoid valve – main line pressure

(SLT) (+)

3

not assigned

4

not assigned

5

PWM solenoid valve – main pressure line

(SLT) (–)

6

PWM solendoid valve – TCC (SLU) (–)

7

not assigned

8

PWM solenoid valve – TCC (SLU) (+)

9

PWM solenoid valve – shift pressure (SLS)

(–)

10Description

Item

not assigned

11

not assigned

12

TFT sensor (–)

13

TFT sensor (+)

14

not assigned

15

PWM solenoid valve – shift pressure (SLS)

(+)

16

Shift solenoid valve (S3) (+)

17

not assigned

18

not assigned

19

not assigned

20

Shift solenoid valve (S5) (+)

21

Shift solenoid valve (S4) (+)

22

Operation

Depending on the input signals, the TCM mounted

on the transmission actuates the solenoid valves

in the valve body. The TCM calculates and stores

adaptive data, fault codes and values for diagnosis.

The TCM adapts the gear changing to ensure that

the correct gear is selected for the style of driving,

the engine load, driver requirements, vehicle speed

etc. This leads to lower fuel consumption together

with improved comfort through smoother gear

changes and lower noise levels.

The TCM receives information on the driver's

desired transmission range and type of driving

mode. In contrast to a transmission which is only controlled hydraulically, the control module can

calculate the best times to shift gear and activate

torque converter lockup by using the signals from

the sensors in the transmission and the engine

management system.

The control module enables small changes in the

operating conditions to be made and adapts the

various transmission functions to ensure that the

correct gear is always selected in relation to the

type of driving mode.

The TCM has adaptive capabilities. This ensures

smooth gear changes throughout the whole service

life of the transmission.

G1163605en2008.50 Kuga8/2011

307-01-

28

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 28

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1867 of 2057

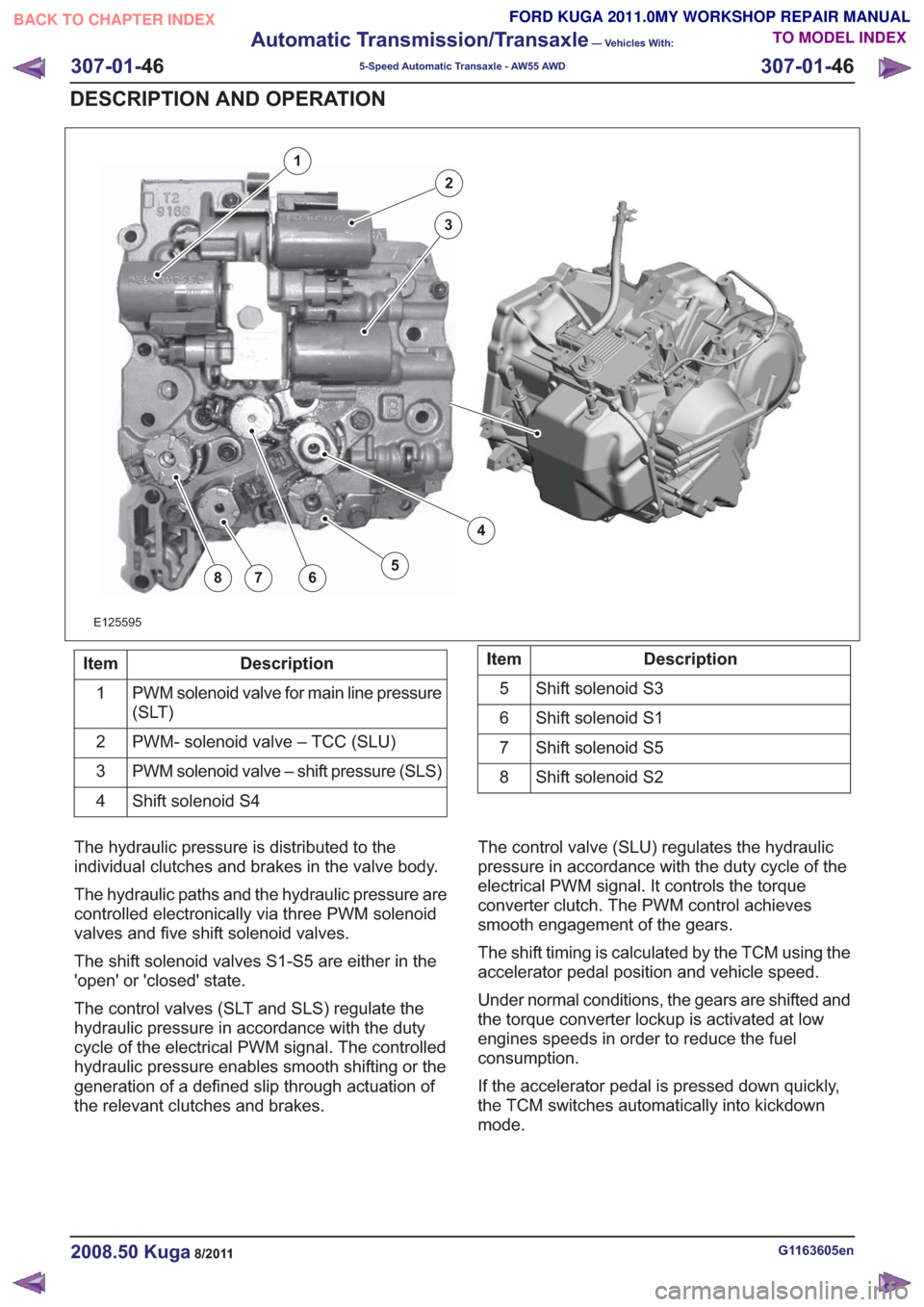

E125595

2

3

4

5678

1

Description

Item

PWM solenoid valve for main line pressure

(SLT)

1

PWM- solenoid valve – TCC (SLU)

2

PWM solenoid valve – shift pressure (SLS)

3

Shift solenoid S4

4Description

Item

Shift solenoid S3

5

Shift solenoid S1

6

Shift solenoid S5

7

Shift solenoid S2

8

The hydraulic pressure is distributed to the

individual clutches and brakes in the valve body.

The hydraulic paths and the hydraulic pressure are

controlled electronically via three PWM solenoid

valves and five shift solenoid valves.

The shift solenoid valves S1-S5 are either in the

'open' or 'closed' state.

The control valves (SLT and SLS) regulate the

hydraulic pressure in accordance with the duty

cycle of the electrical PWM signal. The controlled

hydraulic pressure enables smooth shifting or the

generation of a defined slip through actuation of

the relevant clutches and brakes. The control valve (SLU) regulates the hydraulic

pressure in accordance with the duty cycle of the

electrical PWM signal. It controls the torque

converter clutch. The PWM control achieves

smooth engagement of the gears.

The shift timing is calculated by the TCM using the

accelerator pedal position and vehicle speed.

Under normal conditions, the gears are shifted and

the torque converter lockup is activated at low

engines speeds in order to reduce the fuel

consumption.

If the accelerator pedal is pressed down quickly,

the TCM switches automatically into kickdown

mode.

G1163605en2008.50 Kuga8/2011

307-01-

46

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 46

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1870 of 2057

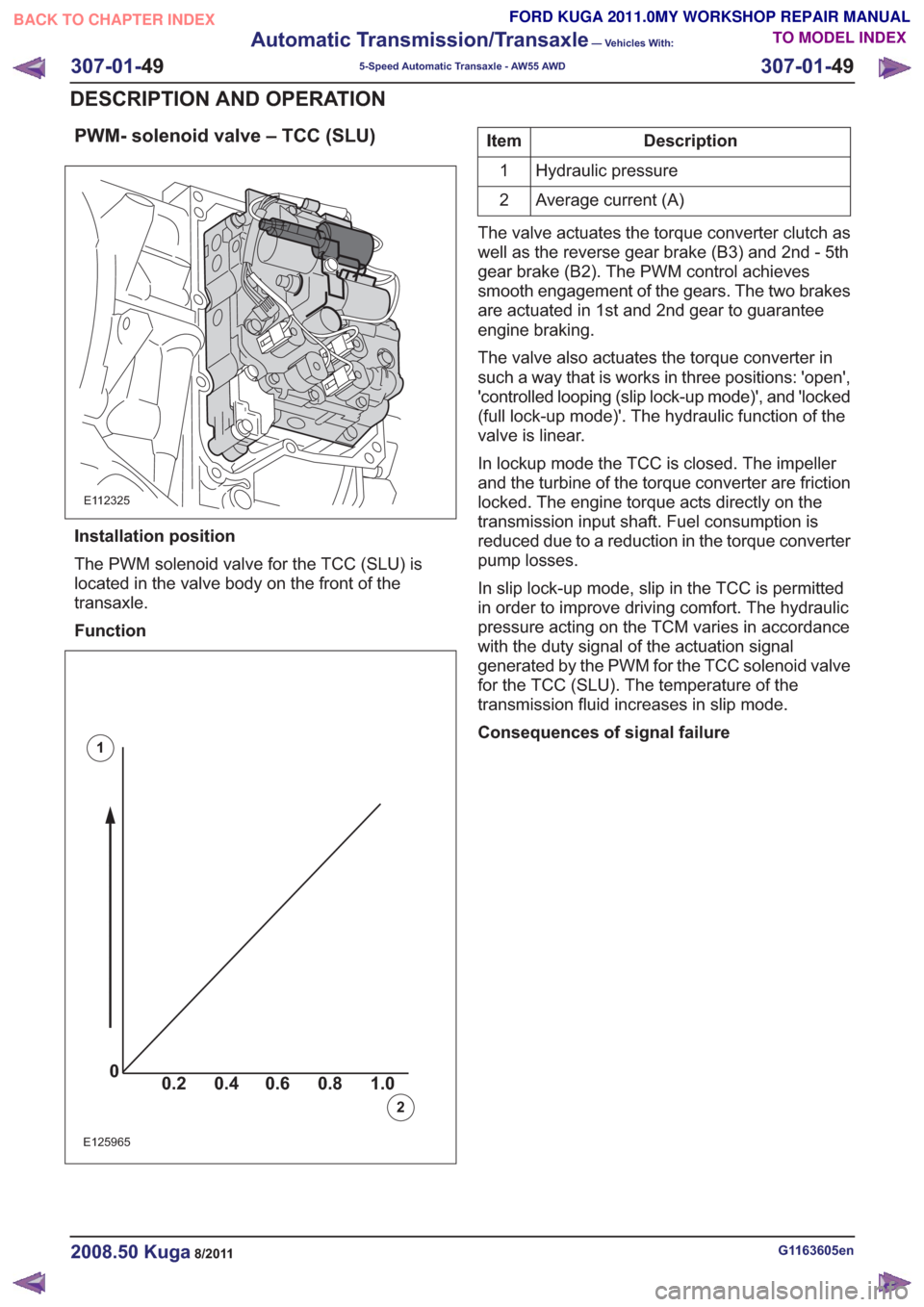

PWM- solenoid valve – TCC (SLU)

E112325

Installation position

The PWM solenoid valve for the TCC (SLU) is

located in the valve body on the front of the

transaxle.

Function

00.2 1.0 0.80.60.4

0

0.2 1.0

0.80.60.4

0

0.2 1.0

0.80.60.40

0.2 1.0 0.80.60.4

E125965

1

2

Description

Item

Hydraulic pressure

1

Average current (A)

2

The valve actuates the torque converter clutch as

well as the reverse gear brake (B3) and 2nd - 5th

gear brake (B2). The PWM control achieves

smooth engagement of the gears. The two brakes

are actuated in 1st and 2nd gear to guarantee

engine braking.

The valve also actuates the torque converter in

such a way that is works in three positions: 'open',

'controlled looping (slip lock-up mode)', and 'locked

(full lock-up mode)'. The hydraulic function of the

valve is linear.

In lockup mode the TCC is closed. The impeller

and the turbine of the torque converter are friction

locked. The engine torque acts directly on the

transmission input shaft. Fuel consumption is

reduced due to a reduction in the torque converter

pump losses.

In slip lock-up mode, slip in the TCC is permitted

in order to improve driving comfort. The hydraulic

pressure acting on the TCM varies in accordance

with the duty signal of the actuation signal

generated by the PWM for the TCC solenoid valve

for the TCC (SLU). The temperature of the

transmission fluid increases in slip mode.

Consequences of signal failure

G1163605en2008.50 Kuga8/2011

307-01- 49

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 49

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1876 of 2057

Description

Item

Drive

3

Intake side

4

Delivery side

5

The fluid pump operates on the principle of a

G-rotor fluid pump.

The fluid pump draws transmission fluid from the

fluid pan, builds up fluid pressure and then supplies

it to the valve body.

The fluid pump is driven by the crankshaft via the

torque converter housing.

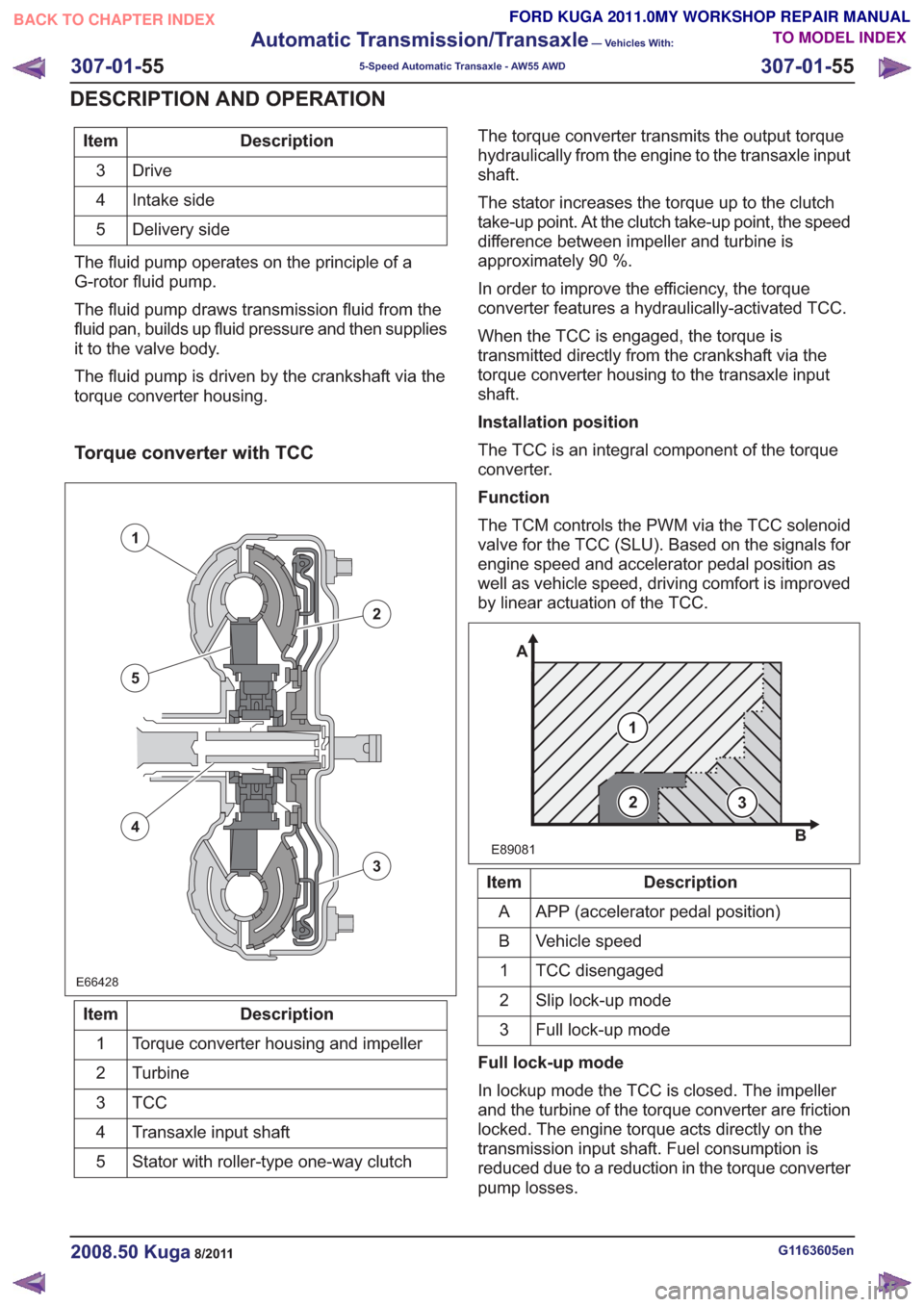

Torque converter with TCC

E66428E66428

1

2

3

5

4

Description

Item

Torque converter housing and impeller

1

Turbine

2

TCC3

Transaxle input shaft

4

Stator with roller-type one-way clutch

5 The torque converter transmits the output torque

hydraulically from the engine to the transaxle input

shaft.

The stator increases the torque up to the clutch

take-up point. At the clutch take-up point, the speed

difference between impeller and turbine is

approximately 90 %.

In order to improve the efficiency, the torque

converter features a hydraulically-activated TCC.

When the TCC is engaged, the torque is

transmitted directly from the crankshaft via the

torque converter housing to the transaxle input

shaft.

Installation position

The TCC is an integral component of the torque

converter.

Function

The TCM controls the PWM via the TCC solenoid

valve for the TCC (SLU). Based on the signals for

engine speed and accelerator pedal position as

well as vehicle speed, driving comfort is improved

by linear actuation of the TCC.

E89081

1

A

B

23

Description

Item

APP (accelerator pedal position)

A

Vehicle speed

B

TCC disengaged

1

Slip lock-up mode

2

Full lock-up mode

3

Full lock-up mode

In lockup mode the TCC is closed. The impeller

and the turbine of the torque converter are friction

locked. The engine torque acts directly on the

transmission input shaft. Fuel consumption is

reduced due to a reduction in the torque converter

pump losses.

G1163605en2008.50 Kuga8/2011

307-01- 55

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 55

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL