ignition switch FORD KUGA 2011 1.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 211 of 2057

Description

Item

Rear parking aid sensorRefer to Component Description: Parking

aid sensors (page ?)

7

Rear parking aid sensorRefer to Component Description: Parking

aid sensors (page ?)

8 Description

Item

Rear parking aid sensorRefer to Component Description: Parking

aid sensors (page ?)

9

steering angle sensor

10

Navigation device

11

System Operation

Parking Aid WARNING: It is the driver's responsibility

to stay alert during reversing procedures.

The system may fail to detect small

children or animals.

CAUTION: The driver is responsible for

detecting obstacles and judging the

distance between these and the vehicle.

The system may fail to detect some

hanging objects, barriers, narrow obstacles

or painted surfaces, which could damage

the vehicle. Always pay attention when

parking.

The parking aid provides an audible warning to the

driver if there are any obstacles in front of or behind

the vehicle during reverse parking maneuvers.

At low speeds, the parking aid module uses the

parking aid sensors to monitor the area around the

vehicle. If an object is detected within a monitored

area, the parking aid module emits a warning tone

using the respective parking aid speaker.

The rear parking aid is switched on with the

ignition. However, it is only enabled when reverse

gear is selected.

The front and rear parking aid is always switched

off when the ignition is switched on. It is switched

on when reverse gear is selected or if the parking

aid switch in the center console is actuated up to

a speed of 16 km/h.

The parking aid is switched off when the vehicle is

travelling forwards at more than 16 km/h or if the

parking aid switch in the center console is actuated

again.

When the parking aid module activates the system,

the parking aid switch LED is illuminated. If the

vehicle is only fitted with the rear parking aid, there

is no switch.

The parking aid sensors emit a series of ultrasonic

impulses and switch to receiver mode to receive the echo reflected by an obstacle within the

detection range. The received echo signals are

amplified and converted from an analog signal to

a digital signal by the sensor. The digital signal is

passed to the parking aid module and compared

with pre-programmed data stored in an EEPROM

within the module. The module calculates the

distance to the obstacle by measuring the time

taken between the emitted and received impulses.

If no objects are detected there are no further

warning tones. If an object is detected, repeated

audible tones are emitted from either parking aid

speaker(s) as appropriate. The time delay between

the tones decreases as the distance between the

object and the vehicle decreases, until at

approximately 250 mm (10 inches), the audible

tone becomes continuous.

If the distance between the obstacle and the

vehicle does not decrease, the warning tone

remains constant if the object has been detected

by an internal parking aid sensor. If the obstacle

was detected by an external sensor and the

distance remains unchanged, the warning tone

stops after 3 seconds.

The parking aid module continues to monitor the

distance and will resume the warning tones if a

decrease in distance is detected.

If a trailer is connected to the vehicle, a signal is

sent to the GEM (generic electronic module) via

the trailer relay. This signal is sent to the parking

aid module via the MS CAN bus. When the parking

aid module detects that a trailer is connected to

the vehicle, the rear parking aid sensors are

disabled to prevent constant warnings due to the

close proximity of the trailer.

G1034399en

2008.50 Kuga 8/2011 413-13-12

Parking Aid

413-13-12

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 214 of 2057

Component Description

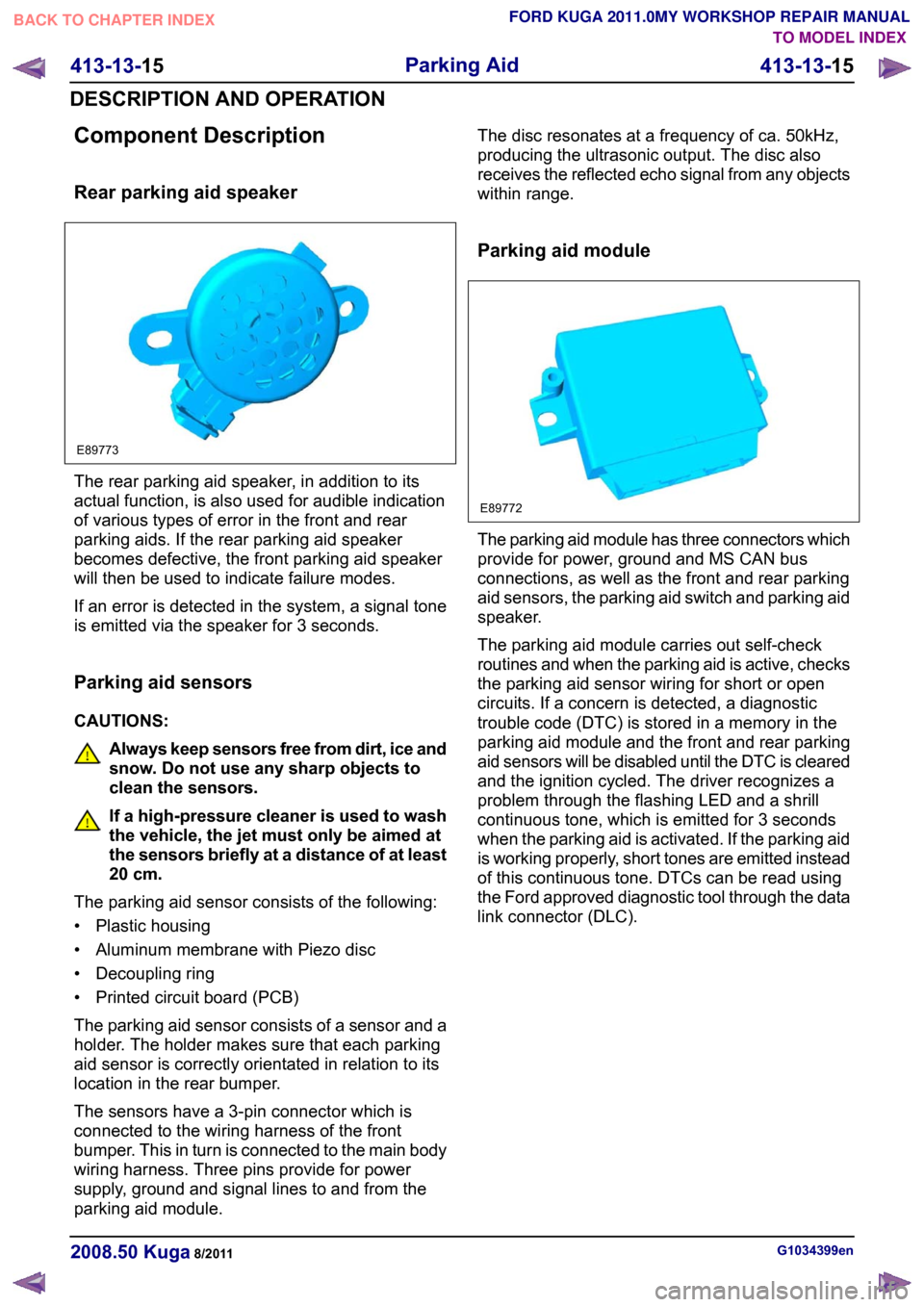

Rear parking aid speaker

The rear parking aid speaker, in addition to its

actual function, is also used for audible indication

of various types of error in the front and rear

parking aids. If the rear parking aid speaker

becomes defective, the front parking aid speaker

will then be used to indicate failure modes.

If an error is detected in the system, a signal tone

is emitted via the speaker for 3 seconds.

Parking aid sensors

CAUTIONS:

Always keep sensors free from dirt, ice and

snow. Do not use any sharp objects to

clean the sensors.

If a high-pressure cleaner is used to wash

the vehicle, the jet must only be aimed at

the sensors briefly at a distance of at least

20 cm.

The parking aid sensor consists of the following:

• Plastic housing

• Aluminum membrane with Piezo disc

• Decoupling ring

• Printed circuit board (PCB)

The parking aid sensor consists of a sensor and a

holder. The holder makes sure that each parking

aid sensor is correctly orientated in relation to its

location in the rear bumper.

The sensors have a 3-pin connector which is

connected to the wiring harness of the front

bumper. This in turn is connected to the main body

wiring harness. Three pins provide for power

supply, ground and signal lines to and from the

parking aid module. The disc resonates at a frequency of ca. 50kHz,

producing the ultrasonic output. The disc also

receives the reflected echo signal from any objects

within range.

Parking aid module

The parking aid module has three connectors which

provide for power, ground and MS CAN bus

connections, as well as the front and rear parking

aid sensors, the parking aid switch and parking aid

speaker.

The parking aid module carries out self-check

routines and when the parking aid is active, checks

the parking aid sensor wiring for short or open

circuits. If a concern is detected, a diagnostic

trouble code (DTC) is stored in a memory in the

parking aid module and the front and rear parking

aid sensors will be disabled until the DTC is cleared

and the ignition cycled. The driver recognizes a

problem through the flashing LED and a shrill

continuous tone, which is emitted for 3 seconds

when the parking aid is activated. If the parking aid

is working properly, short tones are emitted instead

of this continuous tone. DTCs can be read using

the Ford approved diagnostic tool through the data

link connector (DLC).

G1034399en

2008.50 Kuga 8/2011 413-13-15

Parking Aid

413-13-15

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE89773 E89772

Page 216 of 2057

Parking Aid — Vehicles With: Front Parking Aid

Refer to Wiring Diagrams Section 413-13, for

schematic and connector information.

General Equipment

Ford diagnostic equipment

Principles of Operation

The ultrasonic parking aid system activates when

the ignition switch is turned to the RUN and when

the parking brake is OFF. If a front parking aid

switch is fitted the system will be de-activated and

a light emitting diode (LED) will indicate the state

of the system. A lit LED will indicate that the system

is currently deactivated. The parking aid system

will be disabled if a fault is detected in one of the

four front parking aid sensors, the parking aid

speaker or the parking aid module. An error tone

approximately 3 seconds long will be emitted from

the rear parking aid speaker if a fault is detected.

If the rear parking aid speaker is inoperative the

error tone will sound from the front parking aid

speaker.

Inspection and Verification

1. Verify the customer concern. 2. Visually inspect for obvious signs of electrical

damage.

Visual Inspection Chart Electrical

– Fuse(s)

– Wiring harness(s)

– Electrical connector(s)

– Battery junction box (BJB)

– Front parking aid sensor(s)

– Front parking aid speaker

– Parking aid module

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step

4. If the cause is not visually evident, connect the Ford diagnostic equipment to the data link

connector (DLC) and select the vehicle system

to be tested from the diagnostic menu.

5. Retrieve the Diagnostic Trouble Code (DTC)s and refer to the DTC Index.

6. If no DTCs are retrieved or there is no communication with the module, proceed to the

Symptom Chart to continue diagnostics.

Diagnostic Trouble Codes (DTC) Index

DTC Index Action

Possible Source

Description

DTC

Check the circuit 8-GN9

(WH/GN) for short to battery.

IF the circuit is OK, INSTALL

a new parking aid module.

REFER to:Parking Aid

Module (413-13 Parking

Aid, Removal and Installa-

tion).

TEST the system for normal

operation.

• Parking aid sensor signal

circuit.

• Parking aid module.

Front outer left sensor signal

circuit short to battery

C1711

GO toPinpoint Test C.

• Parking aid sensor signal

circuit.

• Parking aid sensor.

• Parking aid module.

Front outer left sensor signal

circuit open or short to

ground

C1712 G325369en

2008.50 Kuga 8/2011 413-13-17

Parking Aid

413-13-17

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 228 of 2057

Parking Aid — Vehicles With: Rear Parking Aid

Refer to

Wiring Diagrams Section 413-13, for

schematic and connector information. General Equipment

Ford diagnostic equipment

Principles of Operation

NOTE: The rear parking aid system will be

de-activated when a Ford rear trailer tow module

is attached to the vehicle.

The ultrasonic parking aid system will default to

enabled when the ignition switch is turned to the

RUN position, the system is activated by selecting

reverse gear. The parking aid system will be

disabled if a fault is detected in one of the four rear

parking aid sensors, the parking aid speaker or the

parking aid module. An error tone approximately

3 seconds long will be emitted from the rear parking

aid speaker if a fault is detected. The rear parking

aid speaker will also sound for approximately 3

seconds if an error is detected at each ignition

cycle or if an error is detected when the system

has been activated.

Inspection and Verification

1. Verify the customer concern. 2. Visually inspect for obvious signs of electrical

damage.

Visual Inspection Chart Electrical

– Fuse(s)

– Wiring harness(s)

– Electrical connector(s)

– Battery junction box (BJB)

– Rear parking aid sensor(s)

– Rear parking aid speaker

– Parking aid module

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step

4. If the cause is not visually evident, connect the Ford diagnostic equipment to the data link

connector (DLC) and select the vehicle system

to be tested from the diagnostic menu.

5. Retrieve the Diagnostic Trouble Code (DTC)s and refer to the DTC Index.

6. If no DTCs are retrieved or there is no communication with the module, proceed to the

Symptom Chart to continue diagnostics.

Diagnostic Trouble Codes (DTC) Index

DTC Index Action

Possible Source

Description

DTC

Check the circuit 8-GN22

(WH/GN) for short to battery.

IF the circuit is OK, INSTALL

a new parking aid module.

REFER to:Parking Aid

Module (413-13 Parking

Aid, Removal and Installa-

tion).

TEST the system for normal

operation.

• Parking aid sensor signal

circuit.

• Parking aid module.

Rear outer left sensor signal

circuit short to battery

C1699

GO toPinpoint Test C.

• Parking aid sensor signal

circuit.

• Parking aid sensor.

• Parking aid module.

Rear outer left sensor signal

circuit open or short to

ground

C1700 G295937en

2008.50 Kuga 8/2011 413-13-29

Parking Aid

413-13-29

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 263 of 2057

Charging System

Refer to Wiring Diagrams Section 414-02, for

schematic and connector information.

General Equipment

Midtronics EXP-1050 battery tester

Midtronics GR590-2

Ford diagnostic equipment

Inspection and Verification

WARNINGS: Batteries contain sulphuric acid. Avoid

contact with skin, eyes, or clothing. Also,

shield your eyes when working near

batteries to protect against possible

splashing of the acid solution. In case of

acid contact with skin or eyes, flush

immediately with water for a minimum of

15 minutes and get prompt medical

attention. If acid is swallowed, call a

physician immediately. Failure to follow

these instructions may result in personal

injury.

Batteries normally produce explosive

gases which can cause personal injury.

Therefore, do not allow flames, sparks or

lighted substances to come near the

battery. When charging or working near a

battery, always shield your face and

protect your eyes. Always provide

ventilation. Failure to follow these

instructions may result in personal injury.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

Visual Inspection Chart Electrical

Mechanical

– Fuse(s)

– Wiring harness(es)

– Generator

– Electricalconnector(s)

– Battery junction box (BJB)

– Battery

– Battery cables

– Battery monitoring sensor (BMS)

– Charging system warning indicator

–

Accessory drive belt

– Generator

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. Check the operation of the charging system warning indicator lamp, located in the instrument

cluster. Normal operation is as follows:

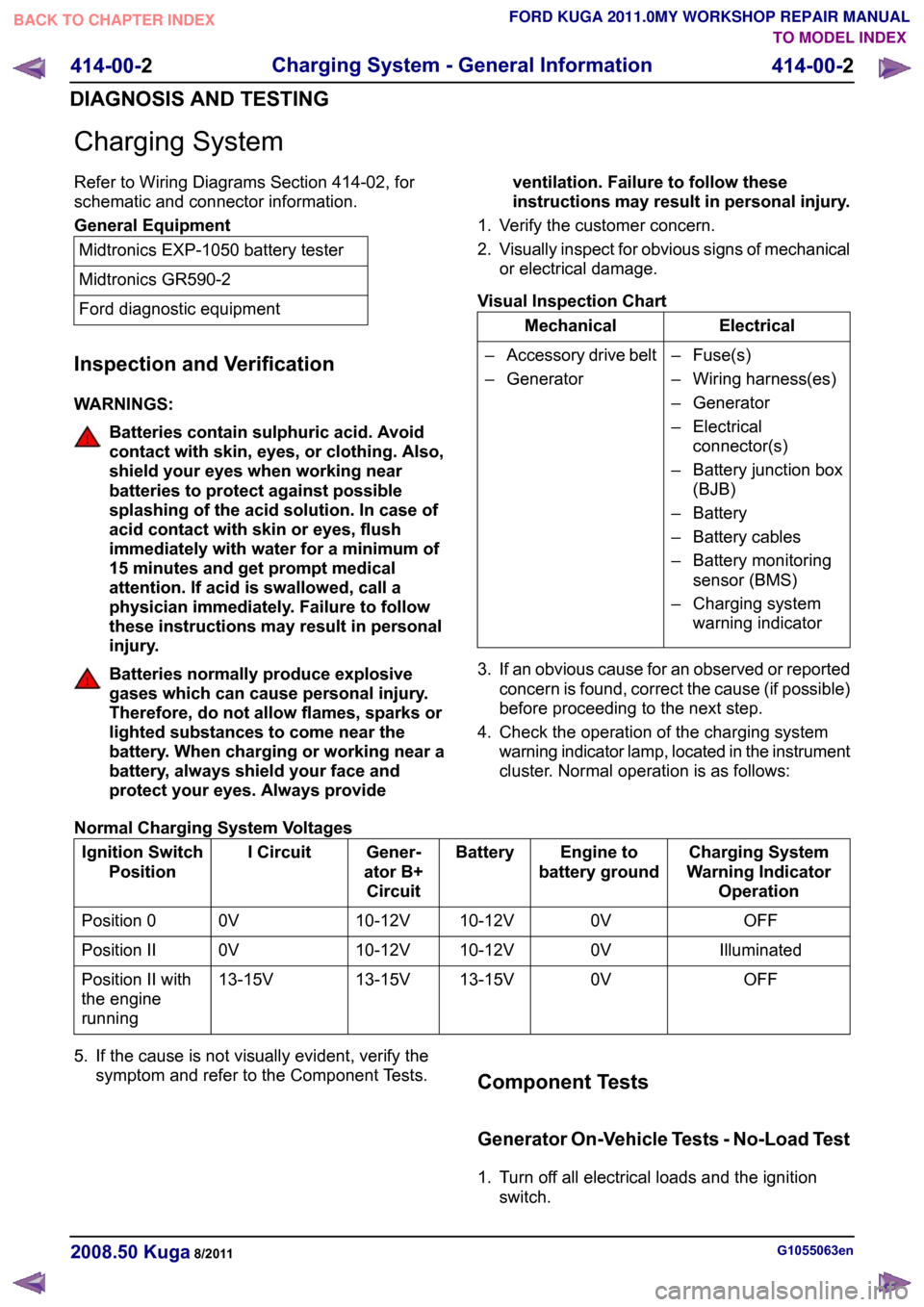

Normal Charging System Voltages Charging System

Warning Indicator Operation

Engine to

battery ground

Battery

Gener-

ator B+ Circuit

I Circuit

Ignition Switch

Position

OFF

0V

10-12V

10-12V

0V

Position 0

Illuminated

0V

10-12V

10-12V

0V

Position II

OFF

0V

13-15V

13-15V

13-15V

Position II with

the engine

running

5. If the cause is not visually evident, verify the symptom and refer to the Component Tests. Component Tests

Generator On-Vehicle Tests - No-Load Test

1. Turn off all electrical loads and the ignition

switch. G1055063en

2008.50 Kuga 8/2011 414-00-2

Charging System - General Information

414-00-2

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 279 of 2057

Direct Current/Alternating Current (DC/AC) Inverter – Overview

Function indicator

WARNING: For workshop repairs, it is only

permissible to replace the converter as a

complete unit together with the wiring

harness and the socket. The component

must not be opened, as charged capacitors

inside can still carry dangerously high

residual voltages.

The LED in the socket lights up orange when the

converter is supplying a voltage.

In the event of a fault the system switches off and

indicates the cause of the fault by flashing a trouble

code via the LED in the socket:

• 1x flash – High temperature

• 2x flashes – Overload

• 3x flashes – Internal overvoltage

• 4x flashes – Internal undervoltage

• Continuous flashing – Short circuit to power

If the converter switches off due to high

temperature then it switches back on again

automatically once the temperature has cooled

down sufficiently.

With all of the other faults which are displayed, the

converter can be reset by switching the ignition off

and back on again or by unplugging and reinserting

the consumer in the socket.

If these measures are unsuccessful then there are

no further options for directly influencing the

function yourself. G1055637en

2008.50 Kuga 8/2011 414-05-3

Voltage Converter/Inverter

414-05-3

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 280 of 2057

Direct Current/Alternating Current (DC/AC) Inverter – System

Operation and Component Description

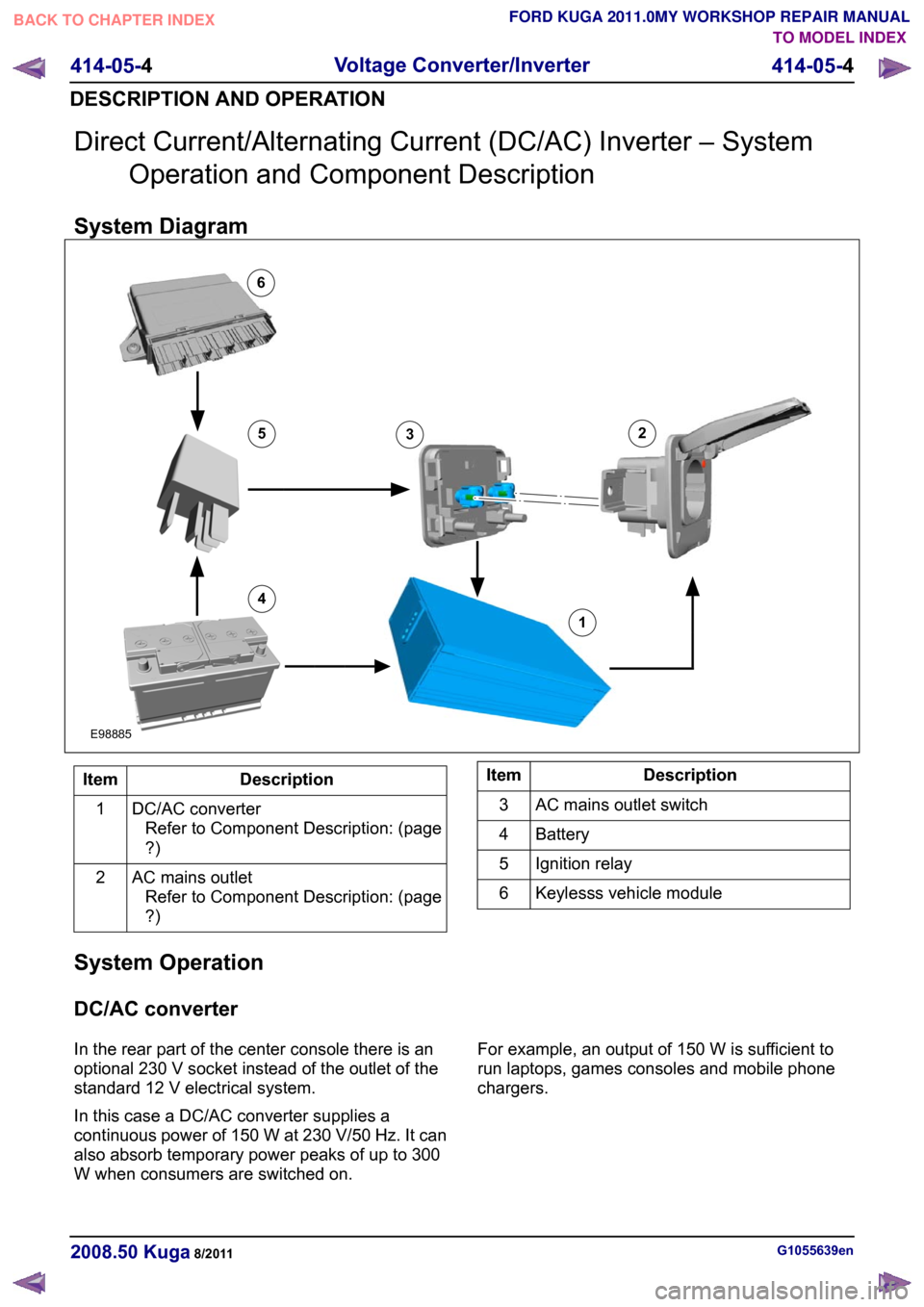

System Diagram Description

Item

DC/AC converterRefer to Component Description: (page

?)

1

AC mains outletRefer to Component Description: (page

?)

2 Description

Item

AC mains outlet switch

3

Battery

4

Ignition relay

5

Keylesss vehicle module

6

System Operation

DC/AC converter

In the rear part of the center console there is an

optional 230 V socket instead of the outlet of the

standard 12 V electrical system.

In this case a DC/AC converter supplies a

continuous power of 150 W at 230 V/50 Hz. It can

also absorb temporary power peaks of up to 300

W when consumers are switched on. For example, an output of 150 W is sufficient to

run laptops, games consoles and mobile phone

chargers.

G1055639en

2008.50 Kuga 8/2011 414-05-4

Voltage Converter/Inverter

414-05-4

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL12456E988853

Page 281 of 2057

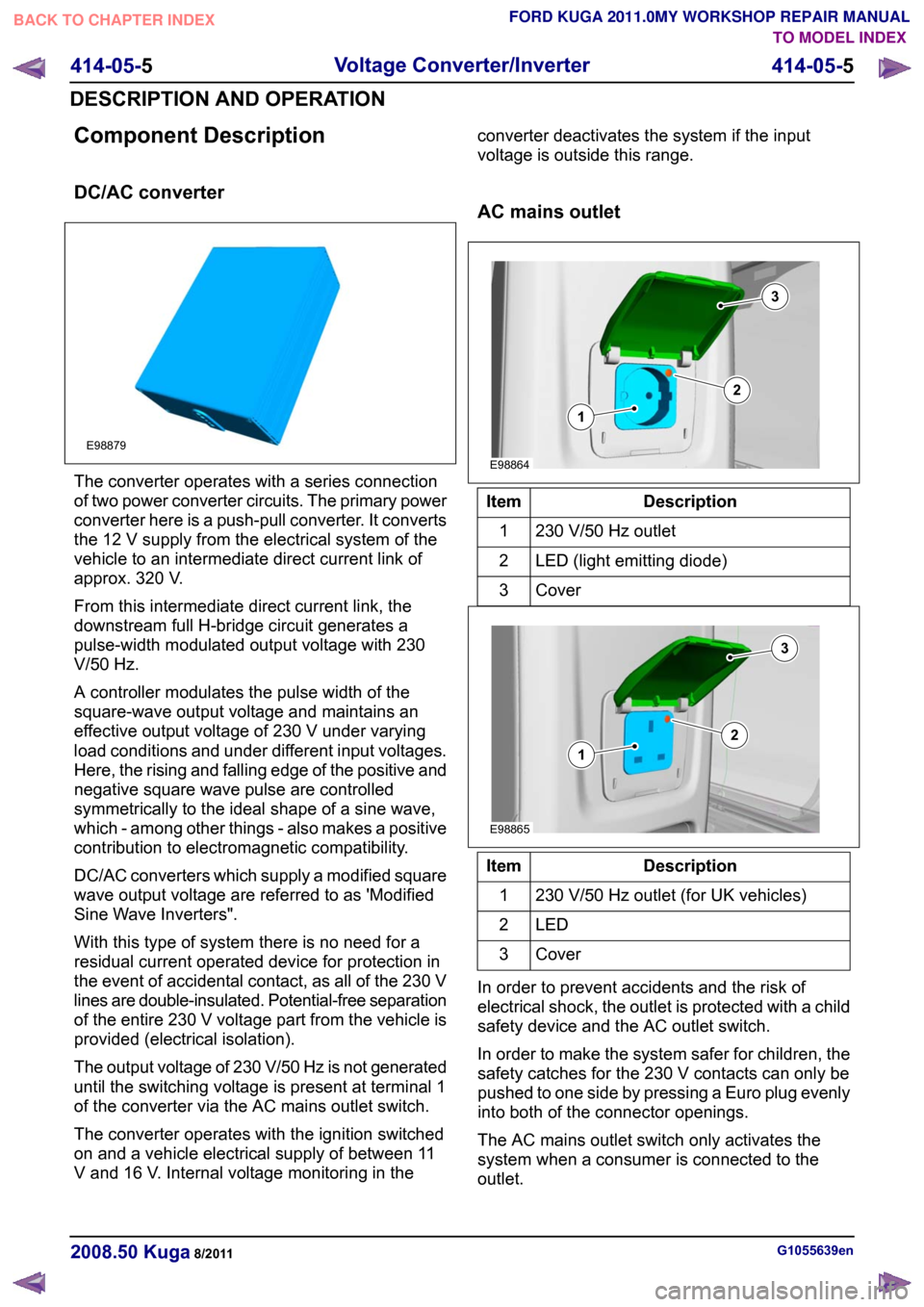

Component Description

DC/AC converter

The converter operates with a series connection

of two power converter circuits. The primary power

converter here is a push-pull converter. It converts

the 12 V supply from the electrical system of the

vehicle to an intermediate direct current link of

approx. 320 V.

From this intermediate direct current link, the

downstream full H-bridge circuit generates a

pulse-width modulated output voltage with 230

V/50 Hz.

A controller modulates the pulse width of the

square-wave output voltage and maintains an

effective output voltage of 230 V under varying

load conditions and under different input voltages.

Here, the rising and falling edge of the positive and

negative square wave pulse are controlled

symmetrically to the ideal shape of a sine wave,

which - among other things - also makes a positive

contribution to electromagnetic compatibility.

DC/AC converters which supply a modified square

wave output voltage are referred to as 'Modified

Sine Wave Inverters".

With this type of system there is no need for a

residual current operated device for protection in

the event of accidental contact, as all of the 230 V

lines are double-insulated. Potential-free separation

of the entire 230 V voltage part from the vehicle is

provided (electrical isolation).

The output voltage of 230 V/50 Hz is not generated

until the switching voltage is present at terminal 1

of the converter via the AC mains outlet switch.

The converter operates with the ignition switched

on and a vehicle electrical supply of between 11

V and 16 V. Internal voltage monitoring in the converter deactivates the system if the input

voltage is outside this range.

AC mains outlet

Description

Item

230 V/50 Hz outlet

1

LED (light emitting diode)

2

Cover3 Description

Item

230 V/50 Hz outlet (for UK vehicles)

1

LED2

Cover3

In order to prevent accidents and the risk of

electrical shock, the outlet is protected with a child

safety device and the AC outlet switch.

In order to make the system safer for children, the

safety catches for the 230 V contacts can only be

pushed to one side by pressing a Euro plug evenly

into both of the connector openings.

The AC mains outlet switch only activates the

system when a consumer is connected to the

outlet. G1055639en

2008.50 Kuga 8/2011 414-05-5

Voltage Converter/Inverter

414-05-5

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE98879 E98864312 E98865312

Page 299 of 2057

Audio System – Overview

Keycode entry - vehicle with standard

audio system

The keycode is entered via the MENU button and

the arrow buttons. The keycode is then confirmed

with the rotary/pushbutton in the middle of the unit.

Only a limited number of attempts to enter the

correct keycode are allowed. The number of

attempts already made is shown in the display.

Following every subsequent unsuccessful attempt,

an uninterrupted waiting period must be observed

before a further attempt can be made.

The display then shows "WAIT XX" and counts

down to "0", provided the ignition remains switched

on. Once this time has expired, a new attempt can

be made to enter the keycode.

After a certain number of unsuccessful attempts

at entering the keycode, the display will show

"LOCKED" or "SAFE". The customer will now be

unable to switch on the device.

The authorized Ford dealer can remove the lock

and can make up to three further attempts.

Vehicle Identification Number (VID) -

entry - vehicle with standard audio

system

It is often extremely difficult to return stolen audio

units which have been seized by the police to their

owners.

Therefore, many Ford audio units offer the option

of, for example, entering a vehicle identification

number into the unit.

For Ford audio systems, the abbreviation VID is

used to refer to the Vehicle Identification Number.

The VIN (chassis number) or, for instance, the number plate number can be entered and this

fulfills the security function.

The VIN is programmed ex works. If the unit is

replaced, the VIN is automatically transferred by

the diagnostics system during configuration.

Self-check routine - vehicles with

standard audio system.

The audio unit must be in radio mode before

entering the Self-Diagnostic Mode.

To enter the audio unit Self-Diagnostic Mode,

switch the audio unit ON. Press pre-set buttons 3

and 6 simultaneously and then release them again.

Keycode entry - vehicles with upgraded

audio system

The station keys are used to enter the keycode.

Station key 5 is used to confirm the keycode.

Only a limited number of attempts to enter the

correct keycode are allowed. The number of

attempts already made is shown in the display.

After the second unsuccessful attempt, the person

entering the keycode will have to wait for an

uninterrupted period of time before making the next

attempt.

The display then shows "WAIT XX" and counts

down to "0", provided the ignition remains switched

on. Once this time has expired, a new attempt can

be made to enter the keycode.

After a certain number of unsuccessful attempts

at entering the keycode, the display will show

"LOCKED" or "SAFE". The customer will now be

unable to switch on the device.

G1055645en

2008.50 Kuga 8/2011 415-01-3

Information and Entertainment System

415-01-3

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE99206 E99207

Page 341 of 2057

Combined rain sensor/light sensor

CAUTIONS:

On vehicles with autolamps, retrofitting

with daytime running lamps is not

permissible, as otherwise, the engine

cannot be stopped when the lighting is

switched on.

On vehicles with autolamps, the daytime

running lamp fuse must not be fitted, as

otherwise, the engine cannot be stopped

when the lighting is switched on.

The combined rain sensor/light sensor is located

behind the interior rear view mirror.

autolamps The low beams, side lamps, license plate lamps

as well as the instrument cluster and instrument

panel illumination are switched on automatically if

all the following conditions are met:

• Ignition ON

• Light switch in the "AUTO" position

•

Detected ambient light conditions below a stored

threshold value

These are switched on and off by the GEM (generic

electronic module) in accordance with the input

signals from the combined rain/light sensor.

Headlamp switch-off delay

In vehicles with mid to high-end equipment, the

headlamp switch-off delay uses the dipped beam

headlamps and the door entry illumination (if

equipped) to illuminate the vehicle surroundings.

This function is activated by operating the main

beam headlamp lever with the ignition switched

off. After the last door has been closed, the function

remains active for a further 30 seconds and then

switches off automatically.

When a door or the tailgate is open, the switch-off

time is extended to 180 seconds. After the last door

has been closed, the switch-off time is reset to 30

seconds.

The headlamp switch-off delay can be deactivated

prematurely by operating the high beam lever again

or by switching on the ignition.

The switch-off time is adjusted to fixed values at

the factory and can

notbe re-programmed using

WDS.

Turn signals The turn signals and the warning lamp flash at a

specified frequency and, in the case of failure of a

turn signal, the frequency is doubled.

The turn signal lamps also have a one-touch lane

change function. If the multifunction lever is

pressed just slightly then the relevant turn signal

lamp is actuated 3 times.

Door entry illumination

G1079626en

2008.50 Kuga 8/2011 417-01-7

Exterior Lighting

417-01-7

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE101615 E101616 E101617