wheel torque FORD KUGA 2011 1.G Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1238 of 2057

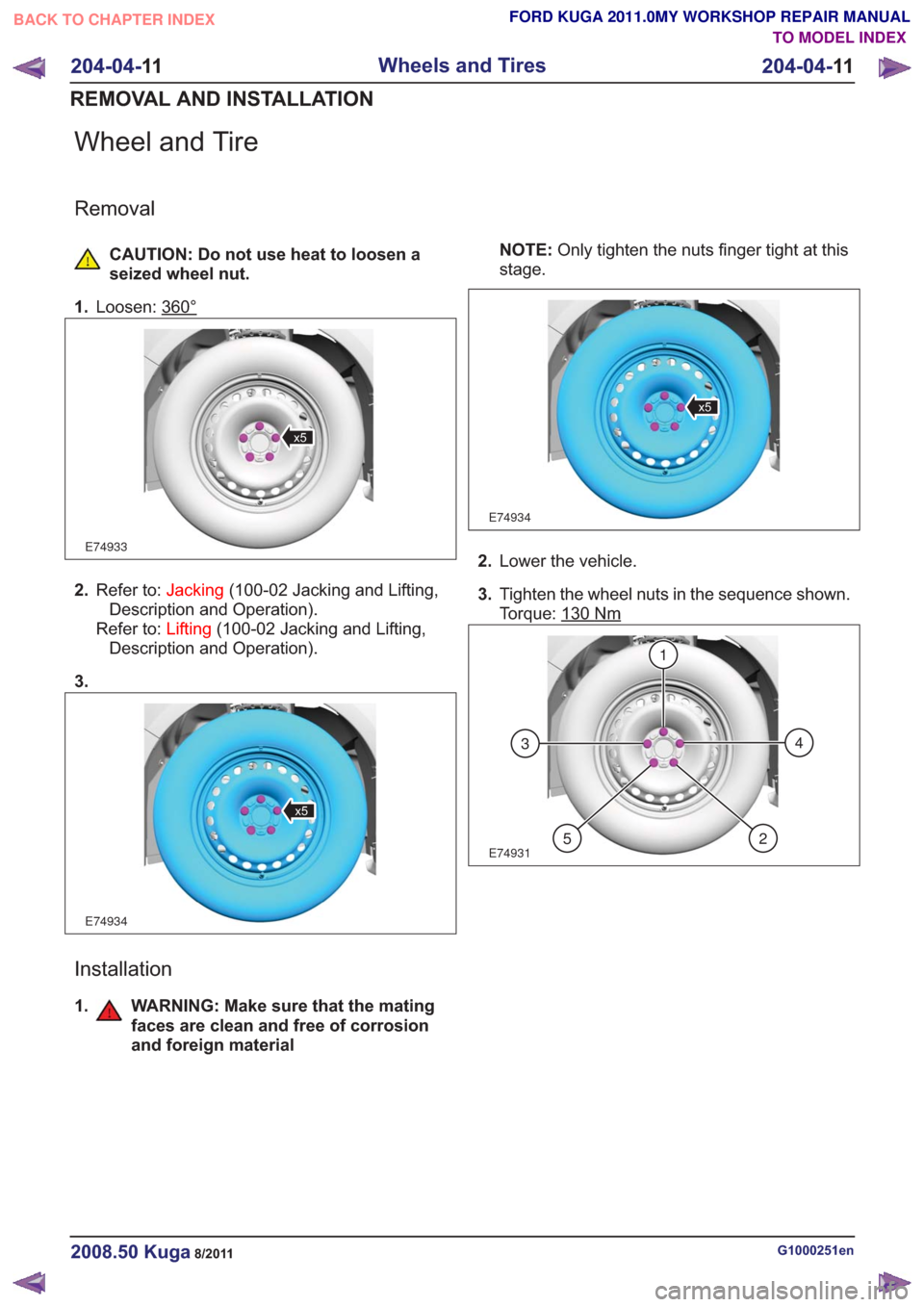

Wheel and Tire

Removal

CAUTION: Do not use heat to loosen a

seized wheel nut.

1. Loosen: 360°

E74933

x5

2.Refer to: Jacking(100-02 Jacking and Lifting,

Description and Operation).

Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

3.

E74934

x5

Installation

1. WARNING: Make sure that the mating faces are clean and free of corrosion

and foreign material

NOTE: Only tighten the nuts finger tight at this

stage.

E74934

x5

2. Lower the vehicle.

3. Tighten the wheel nuts in the sequence shown.

Torque: 130

Nm

E74931

1

43

25

G1000251en2008.50 Kuga8/2011

204-04- 11

Wheels and Tires

204-04- 11

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1251 of 2057

Rear Drive Axle and Differential – System Operation andComponent Description

System Operation

General Information

The powertrain with all-wheel drive consists of the

following main components:

• engine

• transaxle with front axle differential

• transfer box

• halfshafts and driveshafts

• Haldex clutch

• rear axle differential

The Haldex clutch guarantees continuous variable

torque transmission to the rear axle under all

driving conditions. The Haldex clutch reacts

immediately and equally quickly with slow or fast

wheel slip.

A difference in angle of rotation of 90° between the

input and output shafts is required to build up

maximum pressure at the multi-plate clutch or to

transmit maximum torque.

The advantage of vehicles with all-wheel drive is

that they distribute the drive between all four

wheels. They therefore have a higher tractive

power. They feature improved cornering behaviour,

as the grip at all four wheels can be better utilised.

Thus, the wheels contribute to a greater degree

towards cornering stability.

The engine torque is transmitted from the transfer

box to the rear axle via a driveshaft. The driveshaft

is flange-mounted to the input side of the Haldex

clutch.

Driving situations

Pulling away and accelerating

• When pulling away and accelerating, as muchall-wheel drive as necessary must be available

immediately in the short-term. During

acceleration, the electronic system detects slip

at the front axle. This slip is counter-controlled

and thus the propulsive force optimally

distributed to the two axes.

Cornering • A sporty driving style, in particular dynamic

cornering, demands stable cornering behaviour.

The all-wheel system distributes the propulsive

force to all four wheels and by so doing boosts

the high cornering forces so that the vehicle

makes optimum contact with the road surface.

Snow and black ice

• Snow and black ice require particularly high grip. Under these conditions, the Haldex clutch

always distributes the propulsive force to the

axle with the better traction. The all-wheel

system reacts intelligently and quickly to all

driving situations.

Trailer operation

• When driving with a trailer, the trailer weight (support load) is transmitted to the rear axle via

the towbar. This reduces the load on the front

wheels, which means they can slip. The

electronic system detects this difference and

distributes most of the propulsive force to the

rear axle.

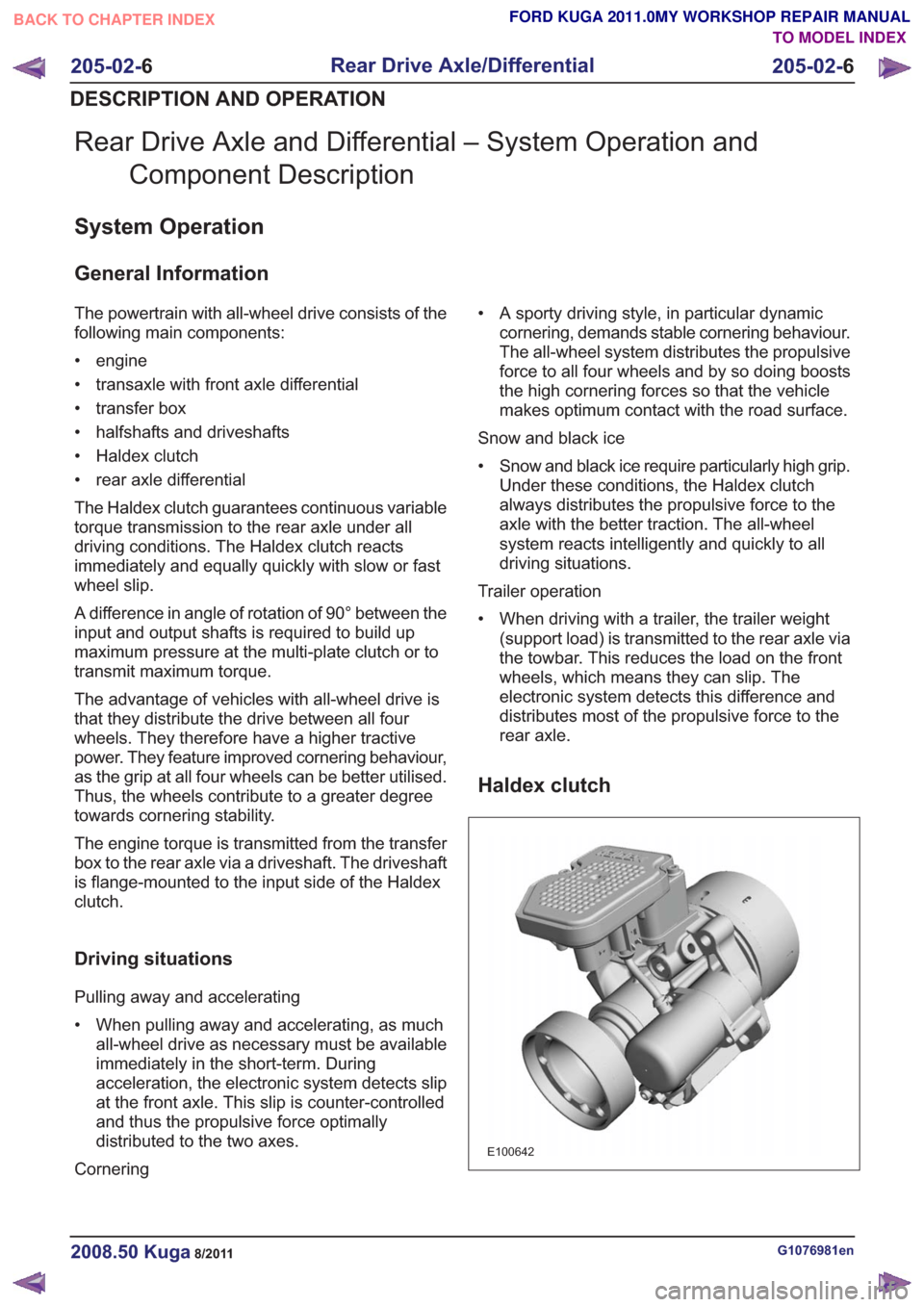

Haldex clutch

E100642

G1076981en2008.50 Kuga8/2011

205-02- 6

Rear Drive Axle/Differential

205-02- 6

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1252 of 2057

General overview

Haldex clutches of the 3rd and 4th generations are

used in the Ford Kuga.

The development of the third generation Haldex

clutch represents a big step forward in modern

all-wheel technology. The Haldex clutch is

electro-hydraulically controlled. Additional

information is taken into consideration during

control tasks via the all-wheel drive control unit.

Slip alone is no longer decisive for the distribution

of the propulsive forces; the vehicle's driving

dynamics are also taken into consideration. The

control unit accesses the driving-related data via

the data bus. With this data, the control unit has

all the essential information about speed, cornering,

coasting or traction operation, and can optimally

react to every driving situation.

Compared with the previous generation, the 4th

generation Haldex clutches operate with higher

pressure and achieve shorter response times when

distributing the drive forces.

Advantages of the Haldex clutch:

• Permanent all-wheel drive withelectronically-controlled multi-plate clutch

• Fast response

• No straining when parking and manoeuvring

• Compatible with different tyres (e.g. emergency spare wheel)

• Fully combinable with driving dynamic control systems

The driveshaft is connected to the input shaft of

the Haldex clutch. Within the Haldex clutch, the

input shaft is separated from the output shaft to

the rear axle differential by means of a multi-plate

clutch. Torque is only transmitted to the rear axle

differential when the plate assembly of the Haldex

clutch is closed.

The multi-plate clutch is electro-hydraulically

controlled via the all-wheel drive control unit. For

ecological driving, the torque to the rear axle is reduced to a minimum up to a throttle position of

approx. 50%. A prerequisite for this is that there is

no difference in speed in the Haldex clutch between

the input and output shafts.

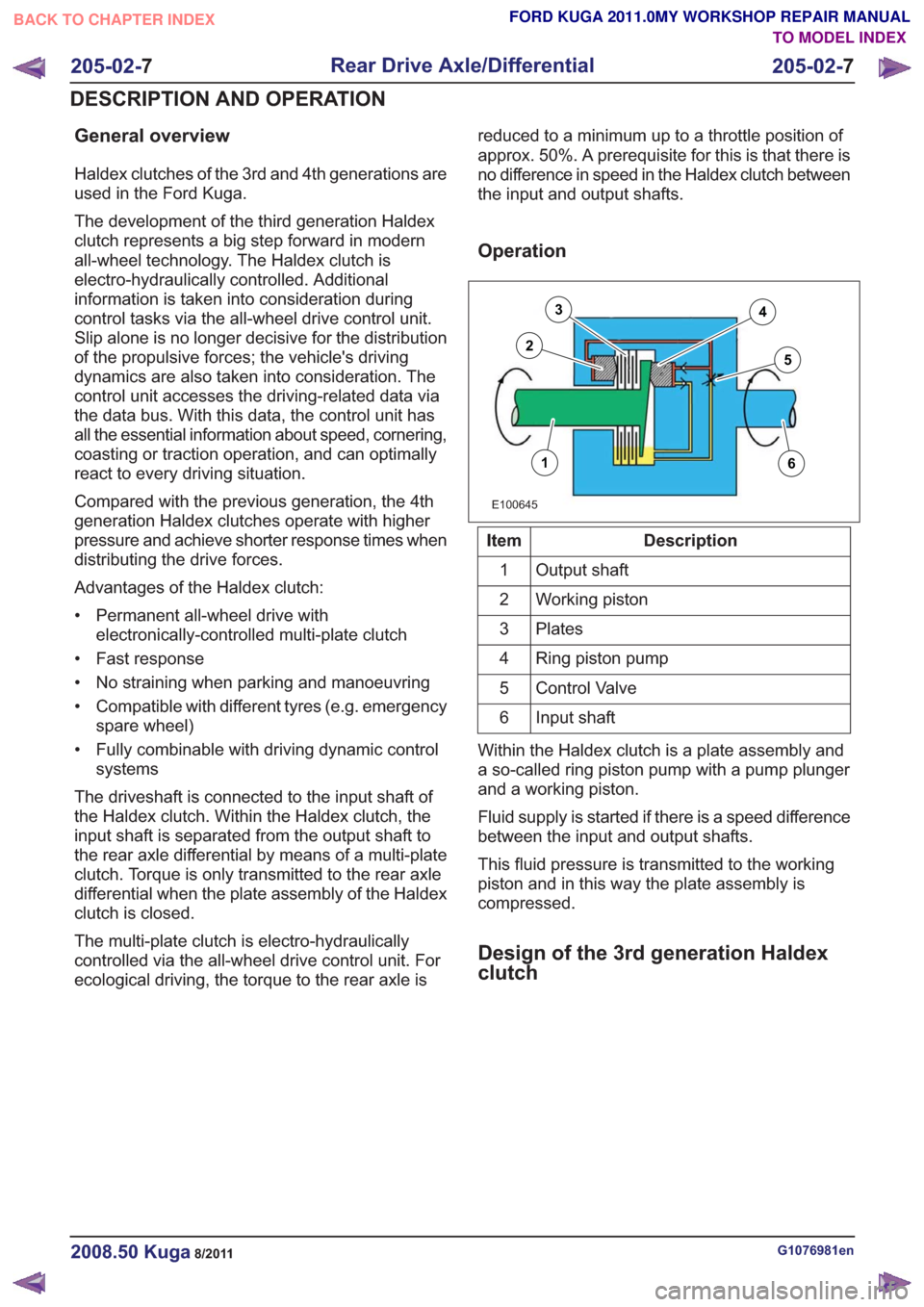

Operation

E100645

16

3

25

4

Description

Item

Output shaft

1

Working piston

2

Plates

3

Ring piston pump

4

Control Valve

5

Input shaft

6

Within the Haldex clutch is a plate assembly and

a so-called ring piston pump with a pump plunger

and a working piston.

Fluid supply is started if there is a speed difference

between the input and output shafts.

This fluid pressure is transmitted to the working

piston and in this way the plate assembly is

compressed.

Design of the 3rd generation Haldex

clutch

G1076981en2008.50 Kuga8/2011

205-02- 7

Rear Drive Axle/Differential

205-02- 7

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1254 of 2057

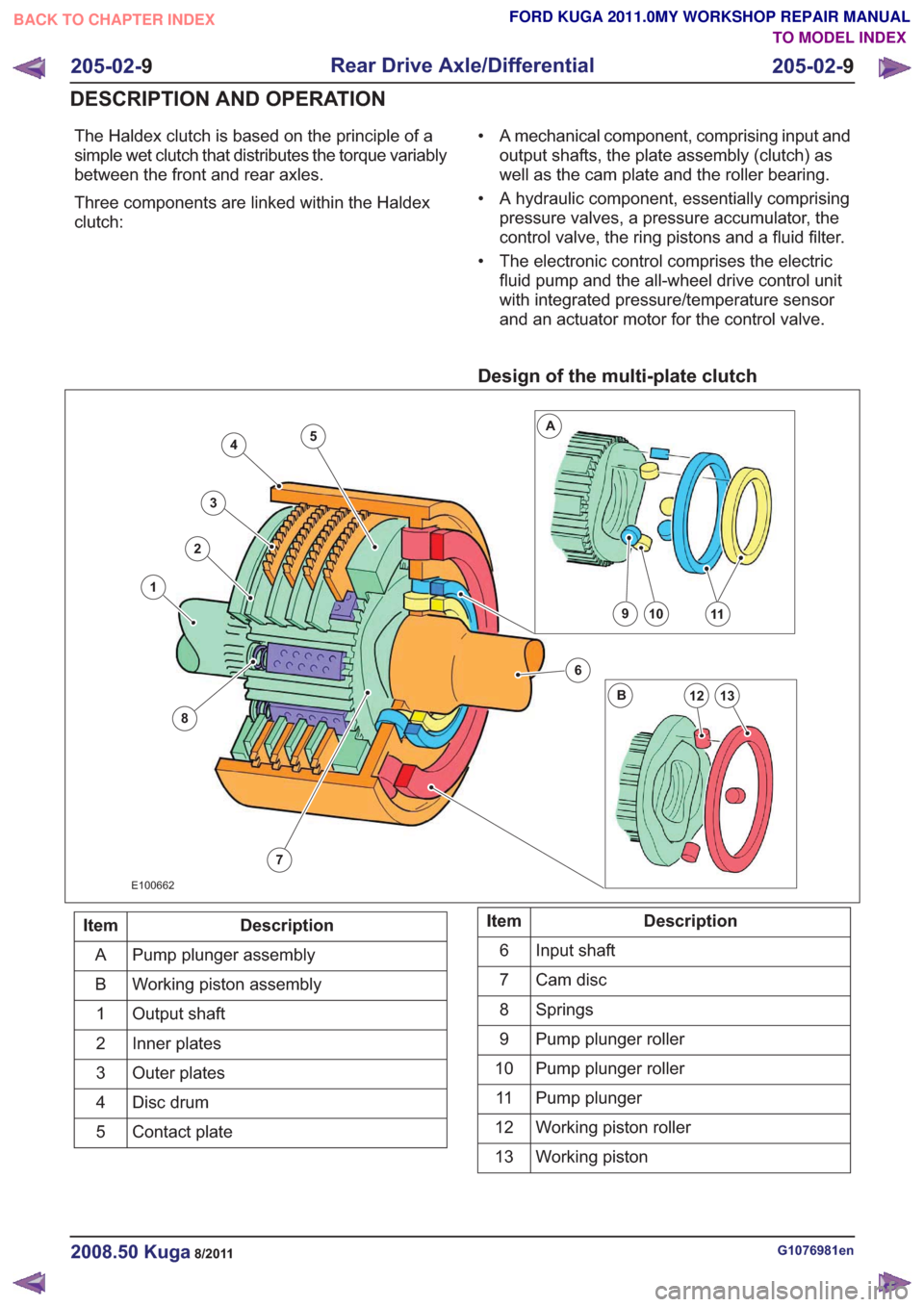

The Haldex clutch is based on the principle of a

simple wet clutch that distributes the torque variably

between the front and rear axles.

Three components are linked within the Haldex

clutch:• A mechanical component, comprising input and

output shafts, the plate assembly (clutch) as

well as the cam plate and the roller bearing.

• A hydraulic component, essentially comprising pressure valves, a pressure accumulator, the

control valve, the ring pistons and a fluid filter.

• The electronic control comprises the electric fluid pump and the all-wheel drive control unit

with integrated pressure/temperature sensor

and an actuator motor for the control valve.

Design of the multi-plate clutch

7

4

3

2

8

1

6

10911

13

A

B12

5

E100662

Description

Item

Pump plunger assembly

A

Working piston assembly

B

Output shaft

1

Inner plates

2

Outer plates

3

Disc drum

4

Contact plate

5Description

Item

Input shaft

6

Cam disc

7

Springs

8

Pump plunger roller

9

Pump plunger roller

10

Pump plunger

11

Working piston roller

12

Working piston

13

G1076981en2008.50 Kuga8/2011

205-02- 9

Rear Drive Axle/Differential

205-02- 9

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1255 of 2057

All-wheel drive control unit

E100663

14

3

2

5

Description

Item

Electronic Control Unit

1

Control valve

2

Pressure/temperature sensor

3

Electrical connection CAN (controller area

network) databus

4

Electric feed pump connection

5

The all-wheel drive control unit is bolted directly to

the housing of the Haldex clutch.

It forms one unit made up of the control valve, a

pressure/temperature sensor, and a control

module. It receives signals from the PCM and from

the ABS control module via the CAN data bus. The

control module in the control unit uses these

signals to determine the fluid pressure that is

needed to actuate the clutch plates depending on

the requirement. This determines how much torque

should be transmitted to the rear wheels. All-wheel

drive is deactivated if a fault occurs in the all-wheel

drive control unit.

A preload of approx. 80 Nm is always present at

the Haldex clutch. The temperature sensor of the Haldex clutch is

installed near the control valve in the control unit

and is surrounded by the hydraulic fluid. The

temperature is transmitted to the control module

and is used for adaptation to the changing viscosity

of the hydraulic fluid. If the hydraulic fluid is cold,

the control valve has to be opened slightly more

than requested. This allowance has to be reduced

as the temperature increases. The normal working

temperature of the hydraulic fluid is between +40

°C and +60 °C. If the temperature rises above 100

°C, the clutch is depressurised; if the temperature

falls below 95 °C, the clutch is pressurised again.

All-wheel drive is deactivated and a diagnostic

trouble code set if a fault occurs in the temperature

sensor.

With Haldex Generations I and II, the control valve

was actuated via a stepper motor. With Haldex

Generation III, the stepper motor has been omitted.

The control valve is now actuated via a solenoid

valve. The solenoid valve is actuated by the control

module in the all-wheel drive control unit by means

of pulse width modulation. The pulse width

modulation determines the position of the

adjustment spindle and thus the opening cross

section of the return hole. This is how the pressure

at the working piston of the plates is determined.

If the return hole is fully closed, maximum pressure

is applied to the plates. If the return hole is fully

open, the plates are unpressurized.

Electric feed pump

The electric feed pump is installed in the clutch

unit. It works according to the gerotor principle.

The main purpose of the feed pump is to fill the

pressure accumulator and the space behind the

pump plunger with hydraulic fluid, thereby ensuring

a fast response time of the Haldex clutch. The feed

pump used in the third generation is designed to

achieve an even higher pressure than the base

pressure of 4 bar. It is supplied with current by the

control module in the all-wheel drive control unit

when the engine is running above approx. 400 rpm.

Pressure control - 3rd generation

Haldex clutch

G1076981en2008.50 Kuga8/2011

205-02-

10

Rear Drive Axle/Differential

205-02- 10

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1261 of 2057

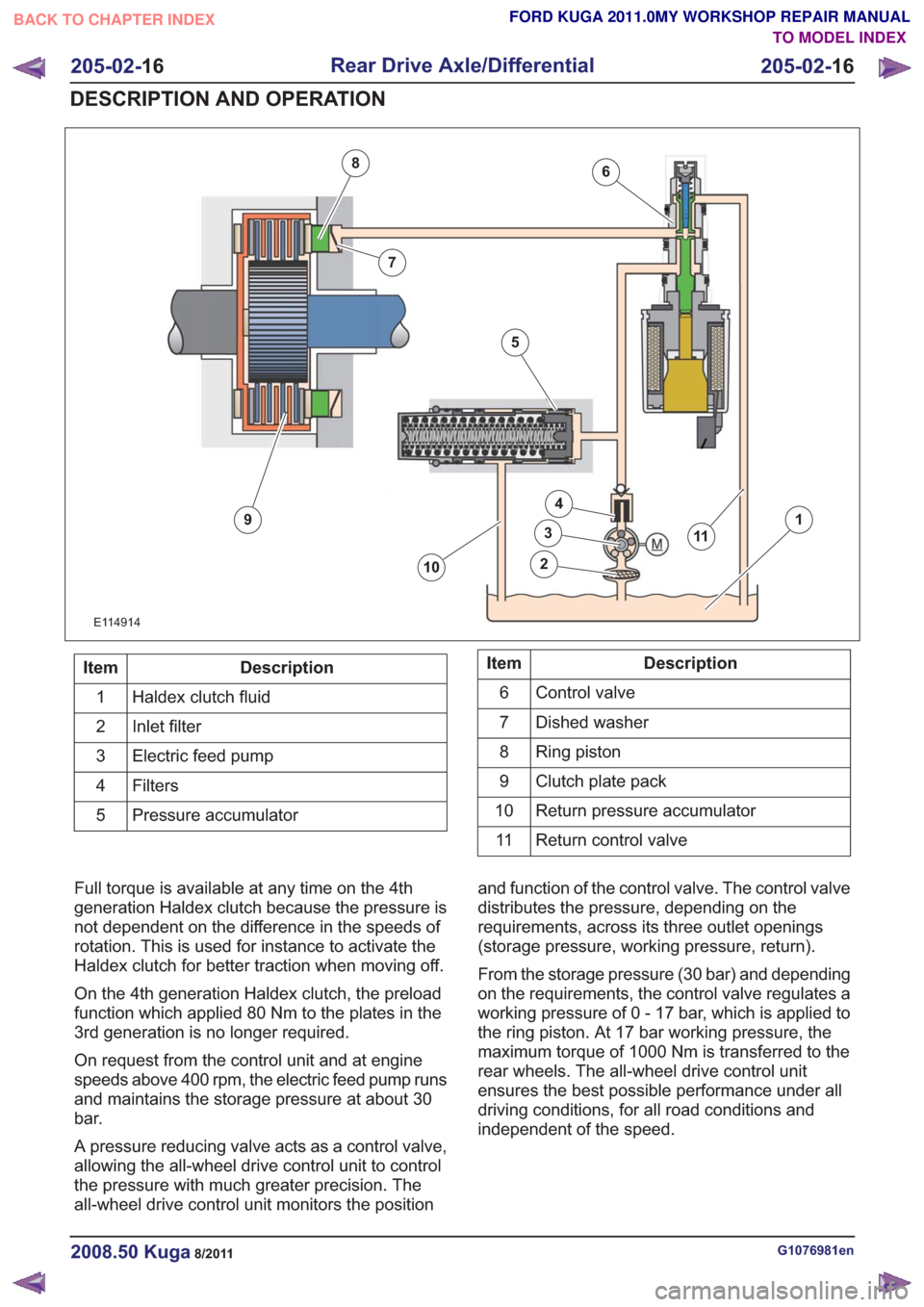

6

7

8

9

10

11

1

2

3

4

5

6

7

8

9

10

11

E114914

Description

Item

Haldex clutch fluid

1

Inlet filter

2

Electric feed pump

3

Filters4

Pressure accumulator

5Description

Item

Control valve

6

Dished washer

7

Ring piston

8

Clutch plate pack

9

Return pressure accumulator

10

Return control valve

11

Full torque is available at any time on the 4th

generation Haldex clutch because the pressure is

not dependent on the difference in the speeds of

rotation. This is used for instance to activate the

Haldex clutch for better traction when moving off.

On the 4th generation Haldex clutch, the preload

function which applied 80 Nm to the plates in the

3rd generation is no longer required.

On request from the control unit and at engine

speeds above 400 rpm, the electric feed pump runs

and maintains the storage pressure at about 30

bar.

A pressure reducing valve acts as a control valve,

allowing the all-wheel drive control unit to control

the pressure with much greater precision. The

all-wheel drive control unit monitors the position and function of the control valve. The control valve

distributes the pressure, depending on the

requirements, across its three outlet openings

(storage pressure, working pressure, return).

From the storage pressure (30 bar) and depending

on the requirements, the control valve regulates a

working pressure of 0 - 17 bar, which is applied to

the ring piston. At 17 bar working pressure, the

maximum torque of 1000 Nm is transferred to the

rear wheels. The all-wheel drive control unit

ensures the best possible performance under all

driving conditions, for all road conditions and

independent of the speed.

G1076981en2008.50 Kuga8/2011

205-02-

16

Rear Drive Axle/Differential

205-02- 16

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1298 of 2057

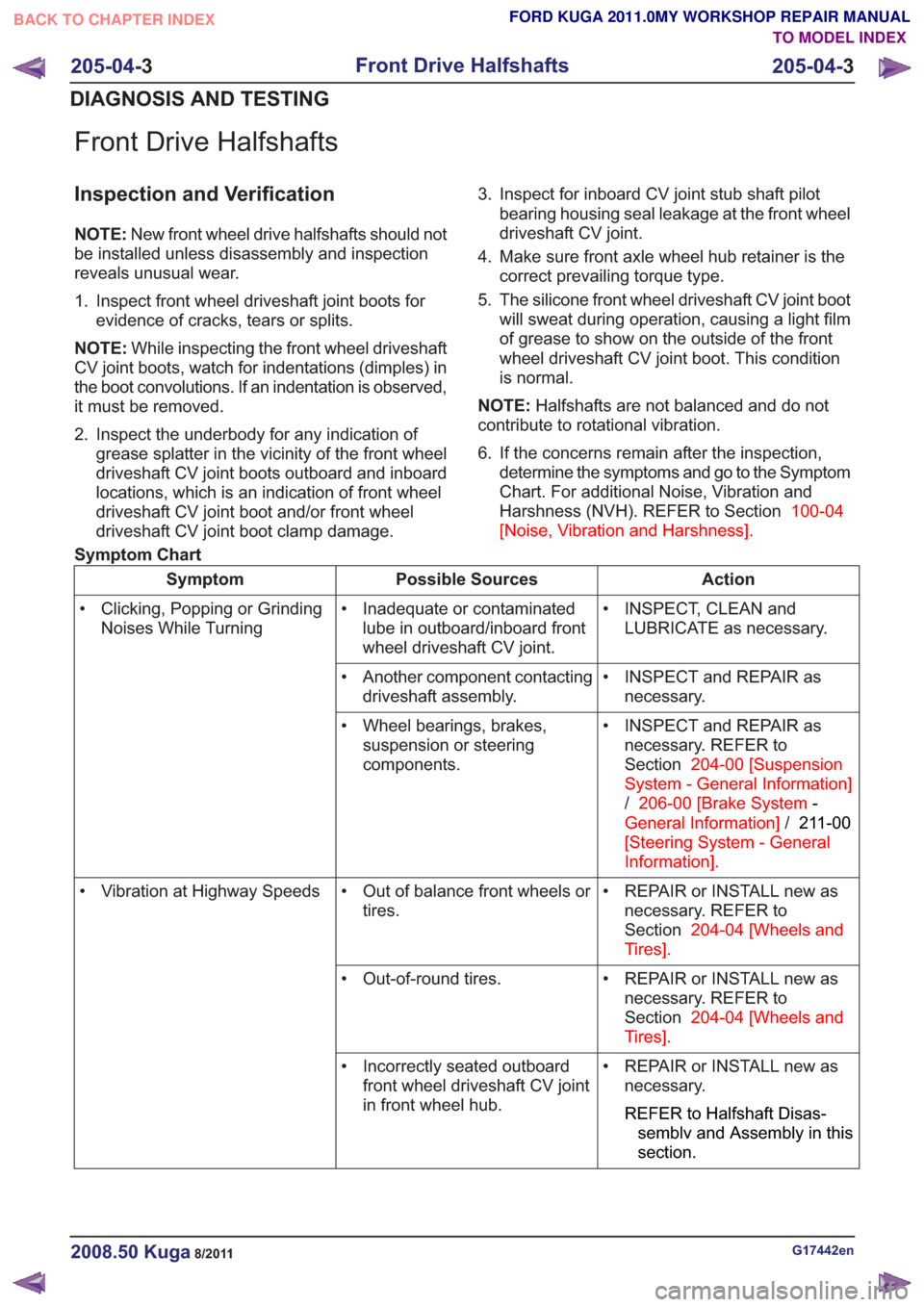

Front Drive Halfshafts

Inspection and Verification

NOTE:New front wheel drive halfshafts should not

be installed unless disassembly and inspection

reveals unusual wear.

1. Inspect front wheel driveshaft joint boots for evidence of cracks, tears or splits.

NOTE: While inspecting the front wheel driveshaft

CV joint boots, watch for indentations (dimples) in

the boot convolutions. If an indentation is observed,

it must be removed.

2. Inspect the underbody for any indication of grease splatter in the vicinity of the front wheel

driveshaft CV joint boots outboard and inboard

locations, which is an indication of front wheel

driveshaft CV joint boot and/or front wheel

driveshaft CV joint boot clamp damage. 3. Inspect for inboard CV joint stub shaft pilot

bearing housing seal leakage at the front wheel

driveshaft CV joint.

4. Make sure front axle wheel hub retainer is the correct prevailing torque type.

5. The silicone front wheel driveshaft CV joint boot will sweat during operation, causing a light film

of grease to show on the outside of the front

wheel driveshaft CV joint boot. This condition

is normal.

NOTE: Halfshafts are not balanced and do not

contribute to rotational vibration.

6. If the concerns remain after the inspection, determine the symptoms and go to the Symptom

Chart. For additional Noise, Vibration and

Harshness (NVH). REFER to Section 100-04

[Noise, Vibration and Harshness] .

Symptom Chart

Action

Possible Sources

Symptom

• INSPECT, CLEAN andLUBRICATE as necessary.

• Inadequate or contaminated

lube in outboard/inboard front

wheel driveshaft CV joint.

• Clicking, Popping or Grinding

Noises While Turning

• INSPECT and REPAIR asnecessary.

• Another component contacting

driveshaft assembly.

• INSPECT and REPAIR asnecessary. REFER to

Section 204-00 [Suspension

System - General Information]

/ 206-00 [Brake System -

General Information] /211-00

[Steering System - General

Information] .

• Wheel bearings, brakes,

suspension or steering

components.

• REPAIR or INSTALL new asnecessary. REFER to

Section 204-04 [Wheels and

Tires] .

• Out of balance front wheels or

tires.

• Vibration at Highway Speeds

• REPAIR or INSTALL new asnecessary. REFER to

Section 204-04 [Wheels and

Tires] .

• Out-of-round tires.

• REPAIR or INSTALL new asnecessary.

REFER to Halfshaft Disas-

semblv and Assembly in this

section.

• Incorrectly seated outboard

front wheel driveshaft CV joint

in front wheel hub.

G17442en2008.50 Kuga8/2011

205-04- 3

Front Drive Halfshafts

205-04- 3

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1310 of 2057

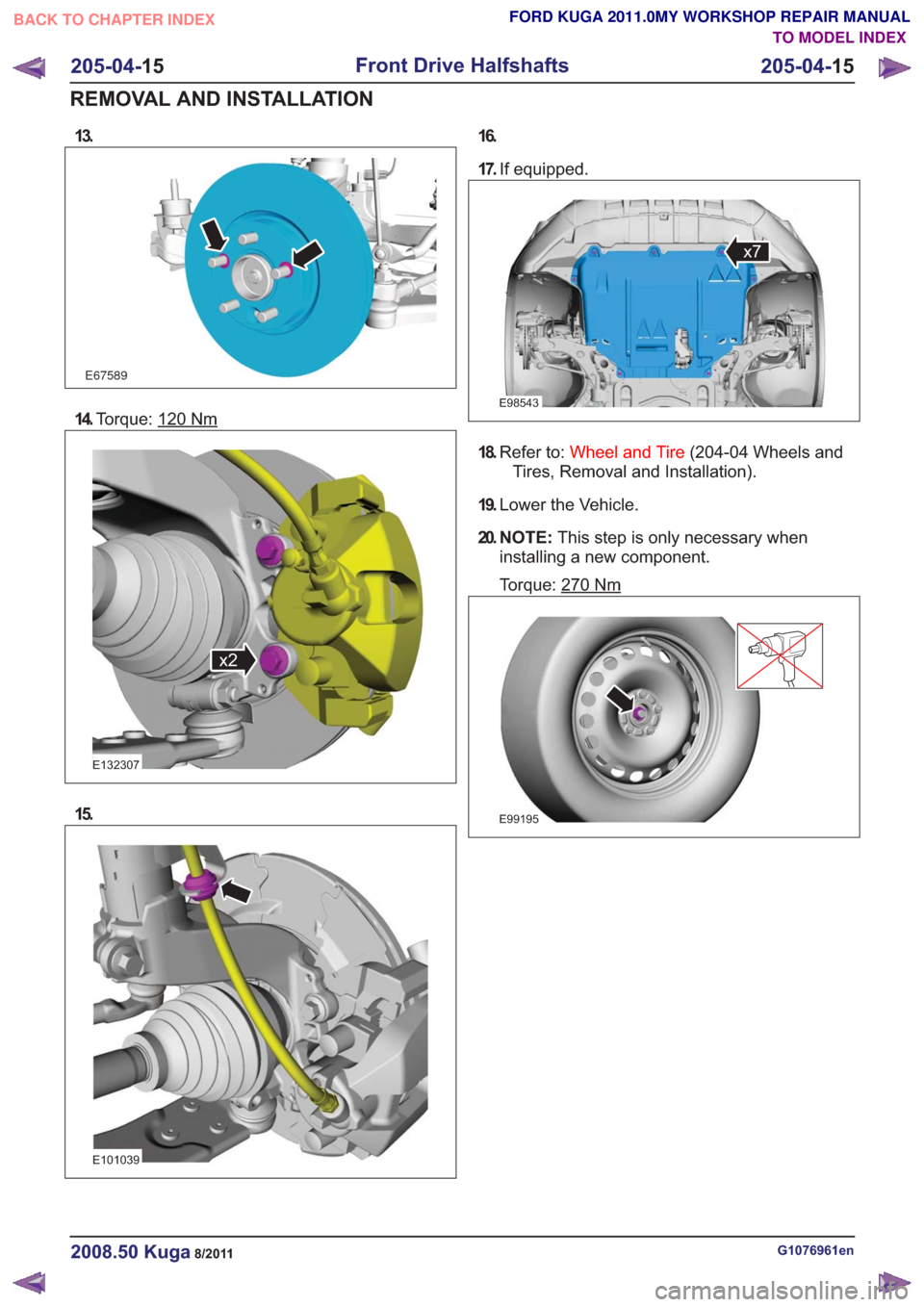

13.

E67589

14.Torque: 120Nm

x2x2

E132307

15.

E101039

16.

17.If equipped.

E98543

x7

18.Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

19. Lower the Vehicle.

20. N O T E : This step is only necessary when

installing a new component.

Torque: 270

Nm

E99195

G1076961en2008.50 Kuga8/2011

205-04- 15

Front Drive Halfshafts

205-04- 15

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1321 of 2057

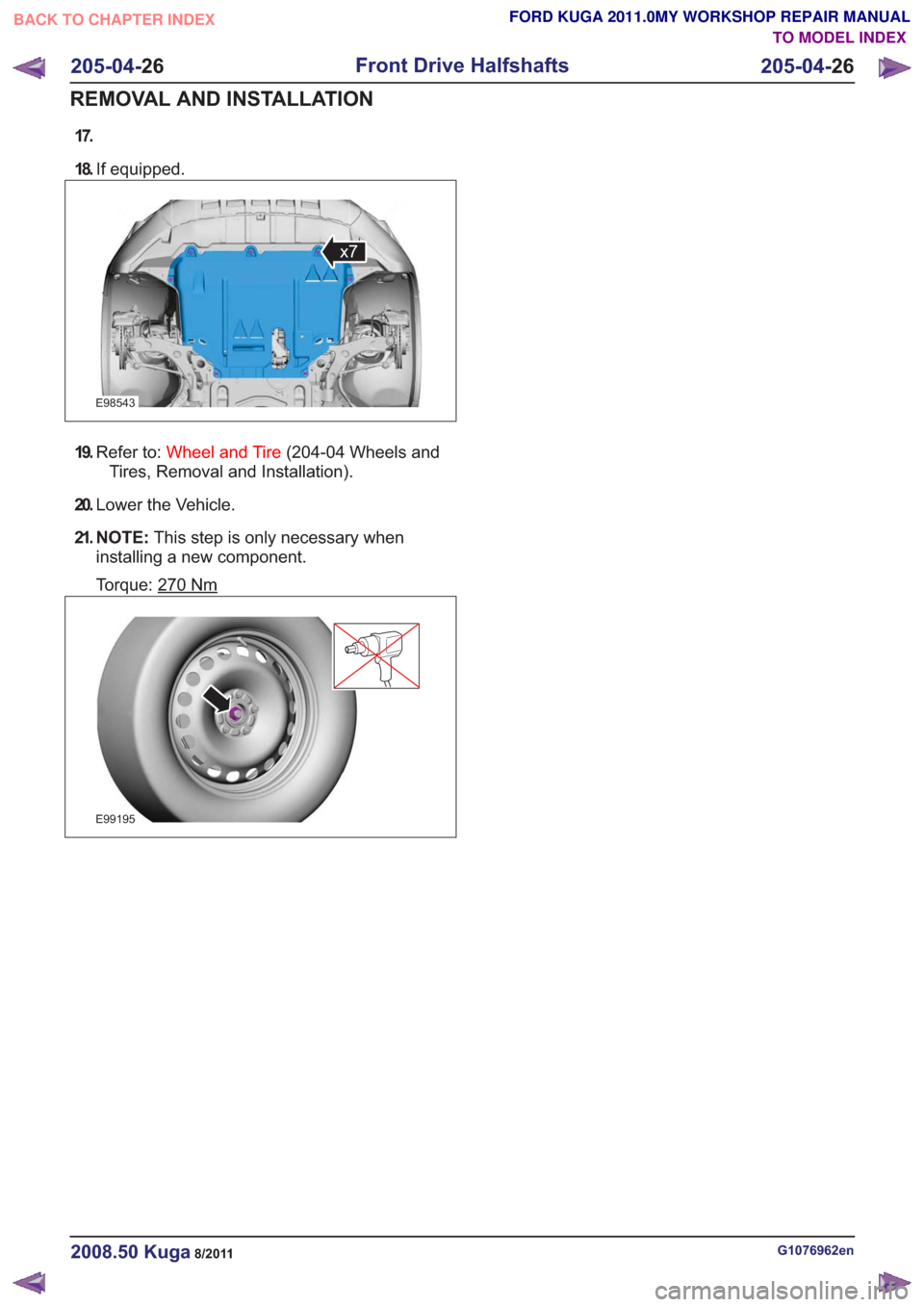

17.

18.If equipped.

E98543

x7

19.Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

20. Lower the Vehicle.

21. N O T E : This step is only necessary when

installing a new component.

Torque: 270

Nm

E99195

G1076962en2008.50 Kuga8/2011

205-04- 26

Front Drive Halfshafts

205-04- 26

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1355 of 2057

too close to the fluid level indicator assembly,

or float assembly damage.

Bypass Condition Test

1. Check the fluid in the brake master cylinderreservoir. Fill the brake master cylinder reservoir

if low or empty.

2. Observe the fluid level in the brake master cylinder reservoir. If after several brake

applications, the fluid level remains the same,

measure the wheel turning torque required to

rotate the wheels with the brakes applied as

follows:

Place the transaxle in the NEUTRAL position.

Raise and support the vehicle. REFER to: (100-02

Jacking and Lifting) Jacking (Description and Operation),

Lifting (Description and Operation).

Apply the brakes with a minimum of 445 N (100

lb) and hold for approximately 15 seconds. With

the brakes still applied, exert a torque on the front

wheels of 10.1 Nm (75 lb ft). If either wheel rotates,

install a new brake master cylinder.

REFER to: Brake Master Cylinder - 2.5L Duratec

(147kW/200PS) - VI5 (206-06 Hydraulic Brake

Actuation, Removal and Installation).

Non-Pressure Leaks

Any empty brake master cylinder reservoir

condition may be caused by two types of

non-pressure external leaks.

Type 1: An external leak may occur at the brake

master cylinder reservoir cap because of incorrect

positioning of the gasket and cap. Reposition the

cap and gasket.

Type 2: An external leak may occur at the brake

master cylinder reservoir mounting seals. Service

such a leak by installing new seals.

G1058975en2008.50 Kuga8/2011

206-00- 19

Brake System - General Information

206-00- 19

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL