Index FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 382 of 2057

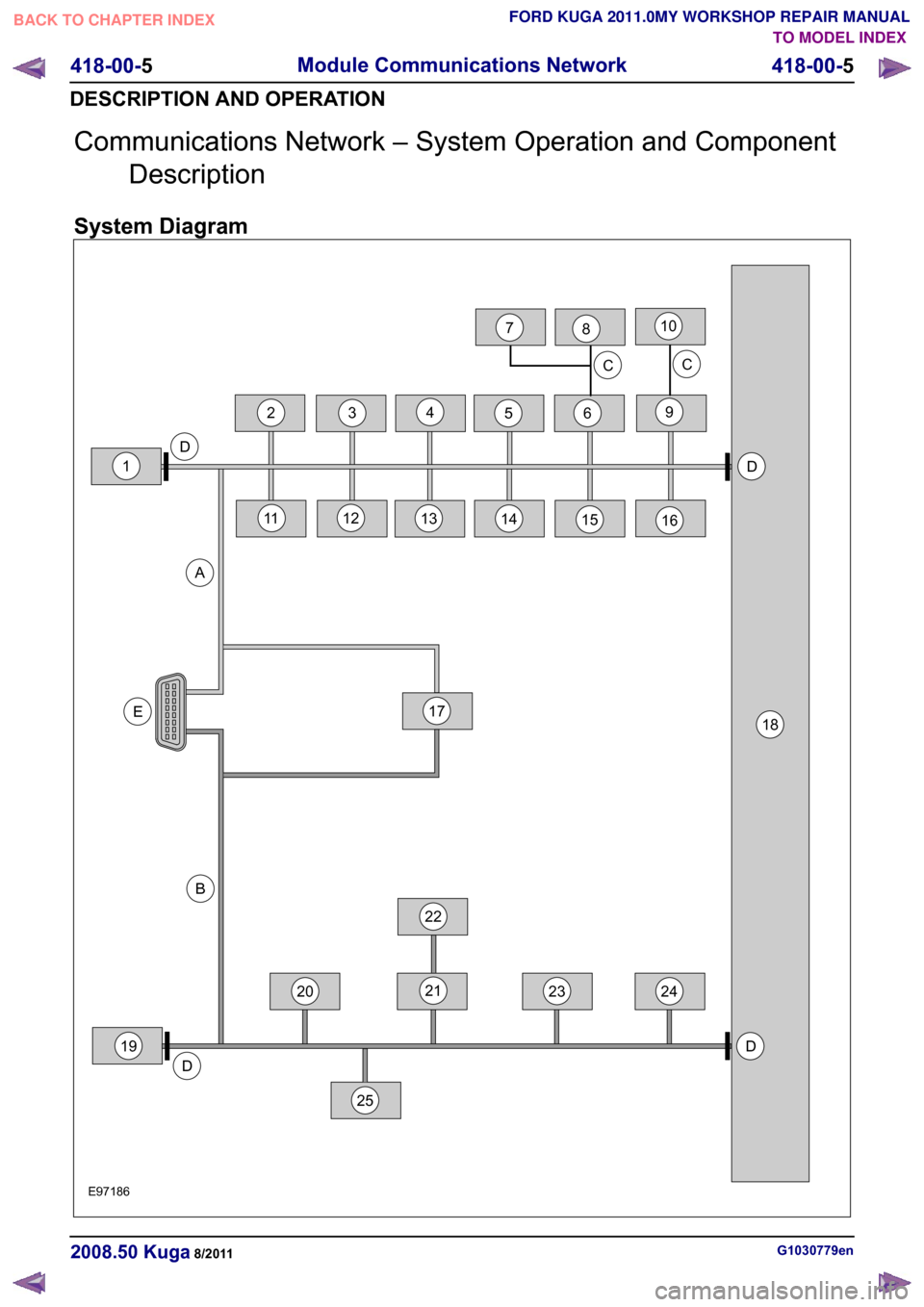

Communications Network – System Operation and Component

Description

System Diagram G1030779en

2008.50 Kuga 8/2011 418-00-5

Module Communications Network

418-00-5

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE971864522DD18E20212319DAB3242513141516D1917C1011126C782

Page 383 of 2057

Description

Item

Medium speed CAN (controller area

network) bus (MS-CAN)

A

High speed CAN bus (HS-CAN)

B

LIN (local interconnect network) bus

C

Terminating resistors

Drive

DLC (data link connector)

E

GEMRefer to Component Description: ABS

(page ?)

1

Fuel fired booster heater /programmable

fuel fired booster heater

2

The EATC control module

3

Reversing camera module (RVC)

4

Parking aid module (PAM)

5

DDM6

Front driver's side switch unit

7

Driver's side RDM

8

PDM (Passenger Door Module)

9

Passenger side RDM

10

Audio unit/navigation unit

11

CD changer

12 Description

Item

Navigation system module - vehicles

equipped with DVD navigation system with

touch screen (not communicating with the

diagnostic unit)

13

Navigation system display - vehicles

equipped with DVD navigation system with

touch screen (not communicating with the

diagnostic unit)

14

Control module for electronic auxiliary

equipment (BVC)

15

RCM16

Keyless vehicle module (KVM)

17

Instrument Cluster

18

PCM19

Fuel additive system module.

20

ABS module or electronic stability program

module

21

Yaw rate sensor/lateral acceleration

sensor

22

Headlamp Leveling Module

23

All-wheel drive control unit

24

Electrohydraulic power steering module

25

System Operation

General

In a communications network (data bus system),

various modules of different systems are connected

to one another via one or several lines.

The data bus system is used exclusively for

transmitting data between the connected modules,

as well as between the connected modules and

the Ford diagnostic unit.

In a data bus system, complete data blocks are

transmitted instead of single on/off pulses. In

addition to the actual information, these data blocks

also contain data regarding the address of the

module to be addressed, the size of the data block

and information for monitoring the content of each

individual data block.

Data bus systems offer various advantages: • Simplified data transmission between the

modules due to a standardized protocol

• Fewer sensors and connectors

• Improved diagnostic options

• Lower costs

The DLC is connected to the various data bus

systems and to the power supply via the standard

16-pin GEM. The signal for the module

programming is also transferred via the DLC.

In a data bus system, if there is a break in one or

both lines or there is a short to ground or to voltage,

then communication between the modules and

with the Ford diagnostic unit is disturbed or is no

longer possible at all.

In order to be able to establish communication with

one another, the modules of the individual systems G1030779en

2008.50 Kuga 8/2011 418-00-6

Module Communications Network

418-00-6

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 384 of 2057

must use the same language. This language is

called a protocol.

At present, Ford uses three different data bus

systems. Depending upon model and equipment

level, all three data bus systems are used. Each

of these data bus systems has its own protocol.

Data bus systems

ISO 9141 bus

The International Organisation for Standardisation

ISO 9141 bus. This consists of a single wire and

is used exclusively for communication between the

modules and the Ford diagnostic unit. The fault

memories of the various modules are read out via

the ISO 9141 bus.

Local Interconnect Network (LIN) bus

The LIN bus is a standard specifically designed for

cost-effective communication between intelligent

sensors and actuators in vehicles. The LIN control

unit subnet is used in every situation where the

bandwidth and versatility of CAN is not needed.

The LIN specification comprises the LIN protocol,

a standard format for describing a complete LIN

and the interface between an LIN and the

application. An LIN comprises a LIN master and

one or more LIN slaves. The LIN utilizes the

master/slave principle for the purpose of bus

access control. This has the significant advantage

that few resources (CPU performance, ROM, RAM)

are required for bus management in the slave

module. The master is implemented in a control

module or a gateway which has the necessary

resources. All communication is initiated by the

master. Consequently, a message always consists

of a header, which is generated by the master, and

a response from the slave. The data transfer rate

is in the region of up to 20 Kbit/s. The LIN master

knows the time sequence of all data which are to

be transmitted. These data are transmitted by the

corresponding LIN slaves (e.g. ultrasonic sensors)

if they are requested to do so by the LIN master.

LIN is a single-wire bus, i.e. the data are

transmitted in the cable via one wire. Usually the

same cable is also used to provide the supply

voltage. The ground connection of the supply

voltage also acts as the ground connection of the

data transmission. An LIN does not use a

terminating resistor.

Controller Area Network (CAN) bus

This consists of two twisted wires and operates

serially (data is transmitted sequentially). It is used

for communication between the modules

themselves and between the modules and the Ford

diagnostic unit. The modules are connected to the

data bus in parallel. New modules can be

incorporated easily, without modifying the other

wiring or modules. The transmitted data is received

by every module connected to the control unit

network (CAN). As each data packet has an

identifier (label), in which the priority of the

message is determined as well as the content

identification, each module can detect whether or

not the data is relevant for its own information

processing. This enables several modules to be

addressed with a particular data packet and

supplied with data simultaneously. For this

purpose, it is ensured that important data (for

example from the ABS) is transmitted first. The

other modules are only able to submit their data to

the data bus after the high-priority messages have

been received.

The advantages of the CAN bus are:

• Minimization of wiring requirements

•

High degree of error protection (fault / fail-proof)

• Robustness

• Good extendibility

• Prioritization of messages

• Inexpensive

• Automatic repetition of faulty messages

• Independent system monitoring and the ability to disconnect faulty modules from the data bus

automatically

Due to the increased number of modules and the

resulting continued increase in data transfer, two

different CAN bus systems are used. Essentially,

they only differ in terms of their data transmission

rates and application areas.

To be able to distinguish between the individual

CAN bus systems, the CAN bus system with the

high transfer speed is called the high speed CAN

bus (HS-CAN). The data are transmitted at a baud

rate of 500 kB/s.

The CAN bus system with the medium transfer

speed is called the medium speed CAN bus

(MS-CAN) and is mainly used for communication

in the comfort electronics or the multimedia system.

The data are transmitted at a baud rate of 125 kB/s.

An interface (gateway) is used to exchange data

between the HS-CAN and the MS-CAN. This

provides the connection between the three CAN

databus systems and is installed in the GEM and

in the electronic instrument cluster. The number of

modules which are connected to the three databus G1030779en

2008.50 Kuga 8/2011 418-00-7

Module Communications Network

418-00-7

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 385 of 2057

systems depends on the equipment level of the

vehicle.

In order to guarantee a high degree of error

protection, two 120 Ohm terminating resistors are

installed in the CAN. These are integrated in the

first module connected to the CAN and in the last

module connected to the CAN respectively and

are used for suppression as well as the elimination

of voltage peaks. In order to ensure correct

functioning of the data bus system, the modules

must always be connected with an integral

terminating resistor. In order to enable

communication between the modules on the

HS-CAN and the modules on the MS-CAN, one

module is connected to both data bus systems.

The connection of both data bus systems is

designated as a gateway. In this gateway, the

received data is converted to the transmission rate

required for the relevant data bus and is

transmitted. This ensures an optimal distribution

of information between both data bus systems.

Component Description

ABS

The GEM is integrated in the CJB (central junction

box) and cannot be replaced as a separate unit.

G1030779en

2008.50 Kuga 8/2011 418-00-8

Module Communications Network

418-00-8

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 386 of 2057

Communications Network

Special Tool(s) / General Equipment

Terminal Probe Kit

418-S035Digital multimeter

The Ford approved diagnostic tool

Inspection and Checking

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

NOTE: Ensure correct locking of wiring harness

connectors.

Visual Inspection Chart Electrical

- Fuse(s)

- Wiring harness - Connector

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the diagnostic tab within

the Ford approved diagnostic tool. G1055035en

2008.50 Kuga 8/2011 418-00-9

Module Communications Network

418-00-9

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL29011A

Page 387 of 2057

SECTION 418-01 Module Configuration

VEHICLE APPLICATION:

2008.50 Kuga

PAGE

CONTENTS

GENERAL PROCEDURES

418-01-2

Module Configuration ..........................................................................................................

418-01-3

Programmable Module Installation ..................................................................................... 418-01-1

Module Configuration

418-01-1

.TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 388 of 2057

Module Configuration

Activation

1.

Install the most up-to-date software version in

the integrated diagnostic system (IDS).

2. In IDS, select the "Module reprogramming"

submenu in the "Module programming" menu

tool box and then follow the instructions.

3. Transfer a new software version (if available)

to the powertrain control module (PCM) using

IDS, if a module-reprogramming of the PCM

may be required in the case of engine running

concerns.

4. Following installation of a wheel/tire

combination, for which the tire-tread

circumference does not correspond to that of

standard tires, the tire size must be changed in

the PCM using IDS. Therefore select the

"Programmable parameters" submenu and enter

the corresponding tire size under the "tire size"

menu item. G1158256en

2008.50 Kuga 8/2011 418-01-2

Module Configuration

418-01-2

GENERAL PROCEDURESTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 389 of 2057

Programmable Module Installation

Activation

5.

Install the most up-to-date software version in

IDS.

6. If, before replacing a module, it was not possible

to read out the vehicle-specific data using the

integrated diagnostic system (IDS) (the module

to be replaced does not respond) then, during

programming of the new module, the

vehicle-specific data must be entered manually

via a selection list in IDS or via a code which

can be obtained from the Technical Hotline.

7. In order to program, select the "Install

programmable module" submenu in the "Module

programming" menu tool box and then follow

the instructions.

8. The following modules must be programmed

after replacement:

•

• Anti-lock braking system module (ABS)

• Audio system module (ACM)

• CD player (CDP)

• Driver's door control unit (D-DCU)

• Passenger's door control unit (P-DCU)

• Rear left door control unit (RL-DCU)

• Rear right door control unit (RR-DCU)

• Electrical power steering (EPS)

• Generic Display Module (GDM) (vehicles

with DVD navigation system with

touchscreen)

• Generic electronic module (GEM)

• Headlamp control module (HCM) (vehicles with gas discharge headlamps)

• Instrument cluster (IC)

• Navigation system (NAV) (vehicles with navigation system)

• Parking aid module(PAM)

• Powertrain control module (PCM)

• Restraint control module (RCM)

• Rear entertainment system module (RETM) (vehicles with rear seat entertainment

system)

9. In order to configure the PCM, select the

"Programmable parameters" submenu in the

"Module programming" menu tool box and then

follow the instructions.

10. For vehicles with anti-lock braking system and

electronic stability program, these must also be configured using IDS following replacement of

the lateral acceleration sensor, yaw rate sensor

or pressure sensor. Configuration is performed

in the "Programmable parameters" menu tool

box.

G1158258en

2008.50 Kuga 8/2011 418-01-3

Module Configuration

418-01-3

GENERAL PROCEDURESTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 390 of 2057

SECTION 418-02 Wiring Harnesses

VEHICLE APPLICATION:

2008.50 Kuga

PAGE

CONTENTS

DIAGNOSIS AND TESTING

418-02-2

Wiring Harness...................................................................................................................

418-02-2

Inspection and Verification..................................................................................................

REMOVAL AND INSTALLATION 418-02-4

Passenger Compartment Wiring Harness..........................................................................

418-02-24

Instrument Panel Wiring Harness.......................................................................................

418-02-37

Engine Compartment Wiring Harness................................................................................ 418-02-1

Wiring Harnesses

418-02-1

.TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 391 of 2057

Wiring Harness

General Equipment

Ford approved diagnostic tool

Inspection and Verification

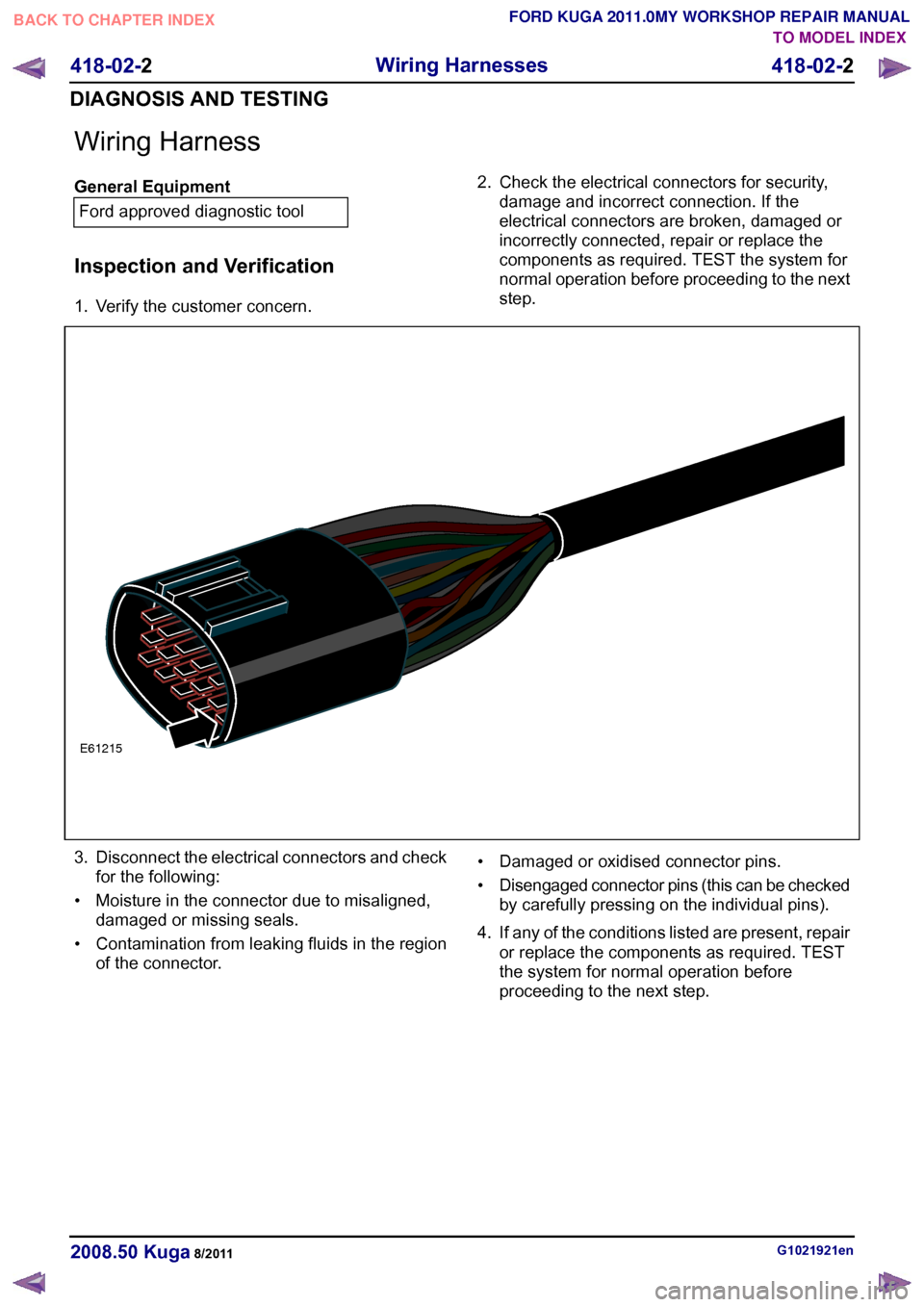

1. Verify the customer concern. 2. Check the electrical connectors for security,

damage and incorrect connection. If the

electrical connectors are broken, damaged or

incorrectly connected, repair or replace the

components as required. TEST the system for

normal operation before proceeding to the next

step. 3. Disconnect the electrical connectors and check

for the following:

• Moisture in the connector due to misaligned, damaged or missing seals.

• Contamination from leaking fluids in the region of the connector. • Damaged or oxidised connector pins.

•

Disengaged connector pins (this can be checked

by carefully pressing on the individual pins).

4. If any of the conditions listed are present, repair or replace the components as required. TEST

the system for normal operation before

proceeding to the next step. G1021921en

2008.50 Kuga 8/2011 418-02-2

Wiring Harnesses

418-02-2

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE61215