Transmission FORD KUGA 2011 1.G Owner's Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1233 of 2057

Wheels and Tires

Inspection and Verification

Visual Inspection Chart

MechanicalWheel(s)Tire(s)

Tire pressure(s) * Wheel nuts

Wheel studs

* Vehicles equipped with a tire deflation detection system (DDS) must be inspected for correct operation using the Ford approved diagnostic tool.

To maximize tire performance, inspect the tires for

signs of incorrect inflation and uneven wear which

may indicate a need for balancing, rotation or

suspension alignment. Tires should also be

checked frequently for cuts, stone bruises,

abrasions, blisters and for objects that may have

become embedded in the tread. More frequent

inspections are recommended when rapid or

extreme temperature changes occur or when road

surfaces are rough or occasionally littered with

foreign material.

As a further visible check of tire condition, tread

wear indicators are molded into the bottom of the

tread grooves. When these indicator bands become

visible, new tires must be installed.

Tire Wear Diagnosis

Uneven wear is usually caused by either excessive

camber or excessive toe on tires.

Sometimes incorrect toe settings or worn struts will

cause severe `cupping' or `scalloped' tire wear on

non-driven wheels.

Severely incorrect toe settings will also cause other

unusual wear patterns.

Tire Vibration Diagnosis

A tire vibration diagnostic procedure always begins

with a road test. The road test and customer

interview (if available) will provide much of the

information needed to find the source of a vibration. During the road test, drive the vehicle on a road

that is smooth and free of undulations. If vibration

is apparent, note and record the following:

– the speed at which the vibration occurs.

– what type of vibration occurs in each speed

range.

– mechanical or audible

– how the vibration is affected by changes in the following:

– engine torque

– vehicle speed

– engine speed

– type of vibration - sensitivity: – torque sensitive

– vehicle speed sensitive

– engine speed sensitive

The following explanations help isolate the source

of the vibration.

Torque Sensitive

This means that the condition can be improved or

made worse by accelerating, decelerating,

coasting, maintaining a steady vehicle speed or

applying engine torque.

Vehicle Speed Sensitive

This means that the vibration always occurs at the

same vehicle speed and is not affected by engine

torque, engine speed or the transmission gear

selected.

G1061329en2008.50 Kuga8/2011

204-04- 6

Wheels and Tires

204-04- 6

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1234 of 2057

Engine Speed Sensitive

This means that the vibration occurs at varying

vehicle speeds when a different transmission gear

is selected. It can sometimes be isolated by

increasing or decreasing engine speed with the

transmission in NEUTRAL or by stall testing with

the transmission in gear. If the condition is engine

speed sensitive, the cause is probably not related

to the tires.

If the road test indicates that there is tire whine,

but no shake or vibration, the noise originates with

the contact between the tire and the road surface.A thumping noise usually means that the tire is flat

or has soft spots making a noise as they slap the

roadway. Tire whine can be distinguished from axle

noise. Tire whine remains the same over a range

of speeds.

A complete road test procedure is described in

Section 100-04.

REFER to:

Noise, Vibration and Harshness (NVH)

(100-04 Noise, Vibration and Harshness,

Diagnosis and Testing).

Symptom Chart

Action

Possible Sources

Symptom

• ADJUST the tire pressure andreset the DDS. For additional

information REFER to the

owners guide.

• Loss of tire pressure.

• DDS warning lamp illuminated

• REFER to the DDS resetprocedure. For additional

information REFER to the

owners guide.

• The DDS reset procedure was

not carried out after adjustment

of the tire pressure.

• DDS warning lamp illuminated

with the correct tire pressure

• ADJUST the tire pressure andreset the DDS. For additional

information REFER to the

owners guide.

• The DDS reset procedure was

carried out under incorrect tire

conditions.

• DDS warning lamp not illumin-

ated when one or more tire(s)

have the incorrect tire pressure

• REFER to the DDS resetprocedure. For additional

information REFER to the

owners guide.

• The DDS reset procedure was

not completed.

• DDS reset command was not

confirmed

• REFER to the Ford approveddiagnostic tool.

• Anti-lock brake system (ABS)

module.

• DDS failure warning display

• ADJUST the tire pressure(s).

• Tire(s) under-inflated.

• Tire(s) show excess wear on

edge of tread

• CORRECT as necessary.

• Vehicle overloaded.

• ADJUST the wheel alignment.REFER to: Suspension System

(204-00 Suspension System

- General Information,

Diagnosis and Testing).

• Incorrect wheel alignment.

• ADJUST the tire pressure(s).

• Tire(s) over-inflated.

• Tire(s) show excess wear in

center of tread

• ADJUST the tire pressure(s).

• Incorrect tire pressure(s).

• Other excessive tire wear

concerns

G1061329en2008.50 Kuga8/2011

204-04- 7

Wheels and Tires

204-04- 7

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1247 of 2057

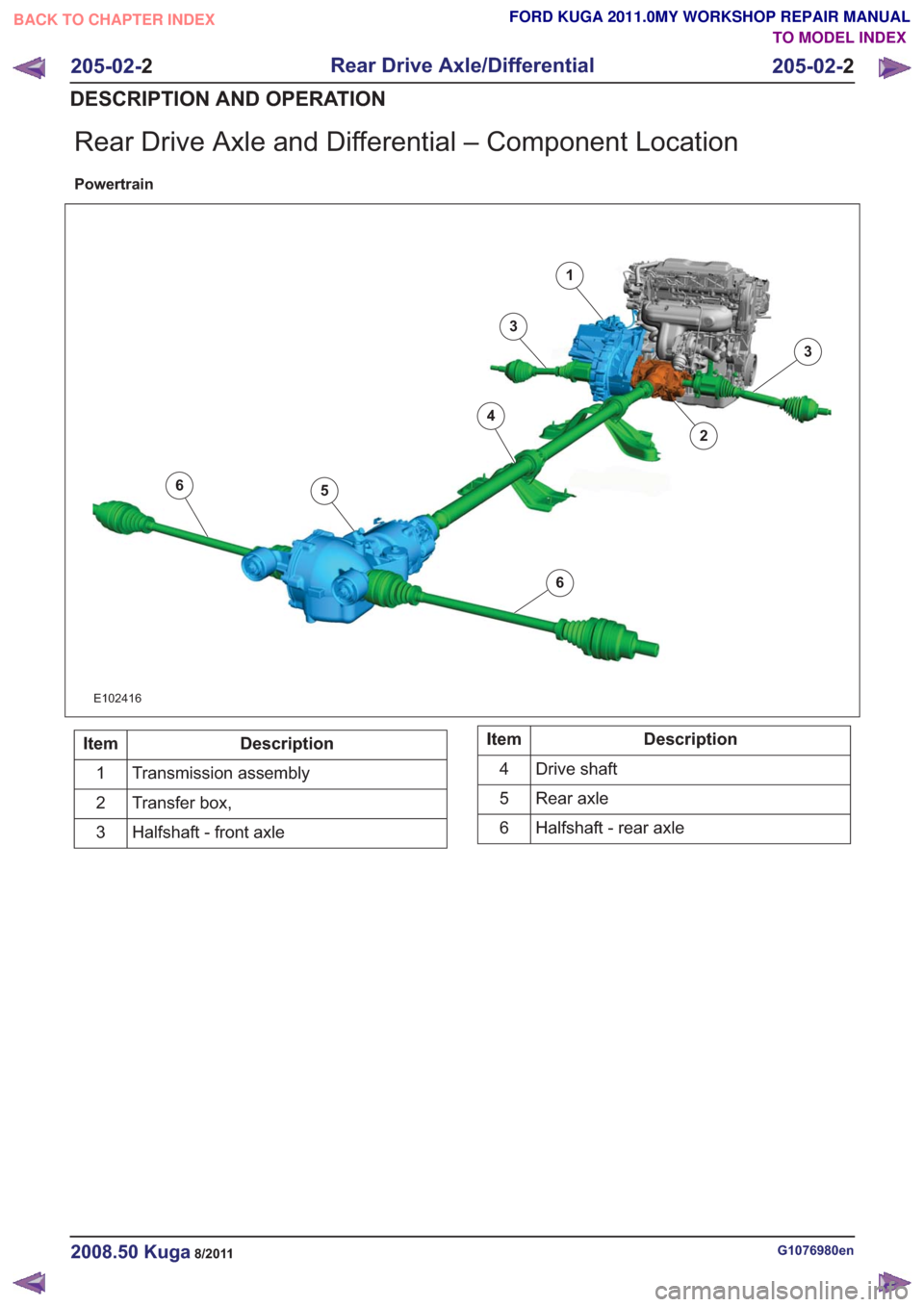

Rear Drive Axle and Differential – Component Location

Powertrain

6

6

1

2

3

3

4

5

6

6

E102416

Description

Item

Transmission assembly

1

Transfer box,

2

Halfshaft - front axle

3Description

Item

Drive shaft

4

Rear axle

5

Halfshaft - rear axle

6

G1076980en2008.50 Kuga8/2011

205-02- 2

Rear Drive Axle/Differential

205-02- 2

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1251 of 2057

Rear Drive Axle and Differential – System Operation andComponent Description

System Operation

General Information

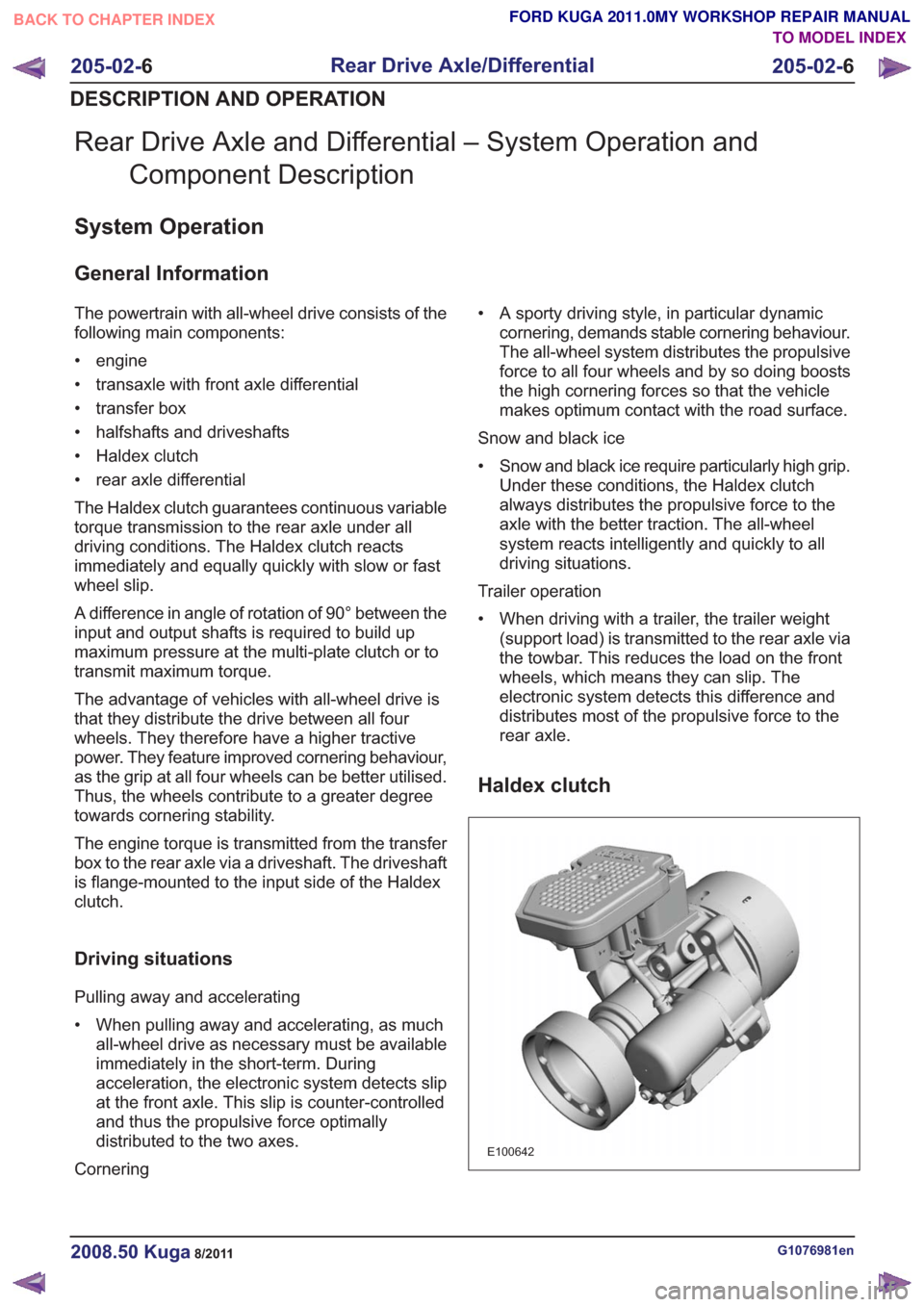

The powertrain with all-wheel drive consists of the

following main components:

• engine

• transaxle with front axle differential

• transfer box

• halfshafts and driveshafts

• Haldex clutch

• rear axle differential

The Haldex clutch guarantees continuous variable

torque transmission to the rear axle under all

driving conditions. The Haldex clutch reacts

immediately and equally quickly with slow or fast

wheel slip.

A difference in angle of rotation of 90° between the

input and output shafts is required to build up

maximum pressure at the multi-plate clutch or to

transmit maximum torque.

The advantage of vehicles with all-wheel drive is

that they distribute the drive between all four

wheels. They therefore have a higher tractive

power. They feature improved cornering behaviour,

as the grip at all four wheels can be better utilised.

Thus, the wheels contribute to a greater degree

towards cornering stability.

The engine torque is transmitted from the transfer

box to the rear axle via a driveshaft. The driveshaft

is flange-mounted to the input side of the Haldex

clutch.

Driving situations

Pulling away and accelerating

• When pulling away and accelerating, as muchall-wheel drive as necessary must be available

immediately in the short-term. During

acceleration, the electronic system detects slip

at the front axle. This slip is counter-controlled

and thus the propulsive force optimally

distributed to the two axes.

Cornering • A sporty driving style, in particular dynamic

cornering, demands stable cornering behaviour.

The all-wheel system distributes the propulsive

force to all four wheels and by so doing boosts

the high cornering forces so that the vehicle

makes optimum contact with the road surface.

Snow and black ice

• Snow and black ice require particularly high grip. Under these conditions, the Haldex clutch

always distributes the propulsive force to the

axle with the better traction. The all-wheel

system reacts intelligently and quickly to all

driving situations.

Trailer operation

• When driving with a trailer, the trailer weight (support load) is transmitted to the rear axle via

the towbar. This reduces the load on the front

wheels, which means they can slip. The

electronic system detects this difference and

distributes most of the propulsive force to the

rear axle.

Haldex clutch

E100642

G1076981en2008.50 Kuga8/2011

205-02- 6

Rear Drive Axle/Differential

205-02- 6

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1258 of 2057

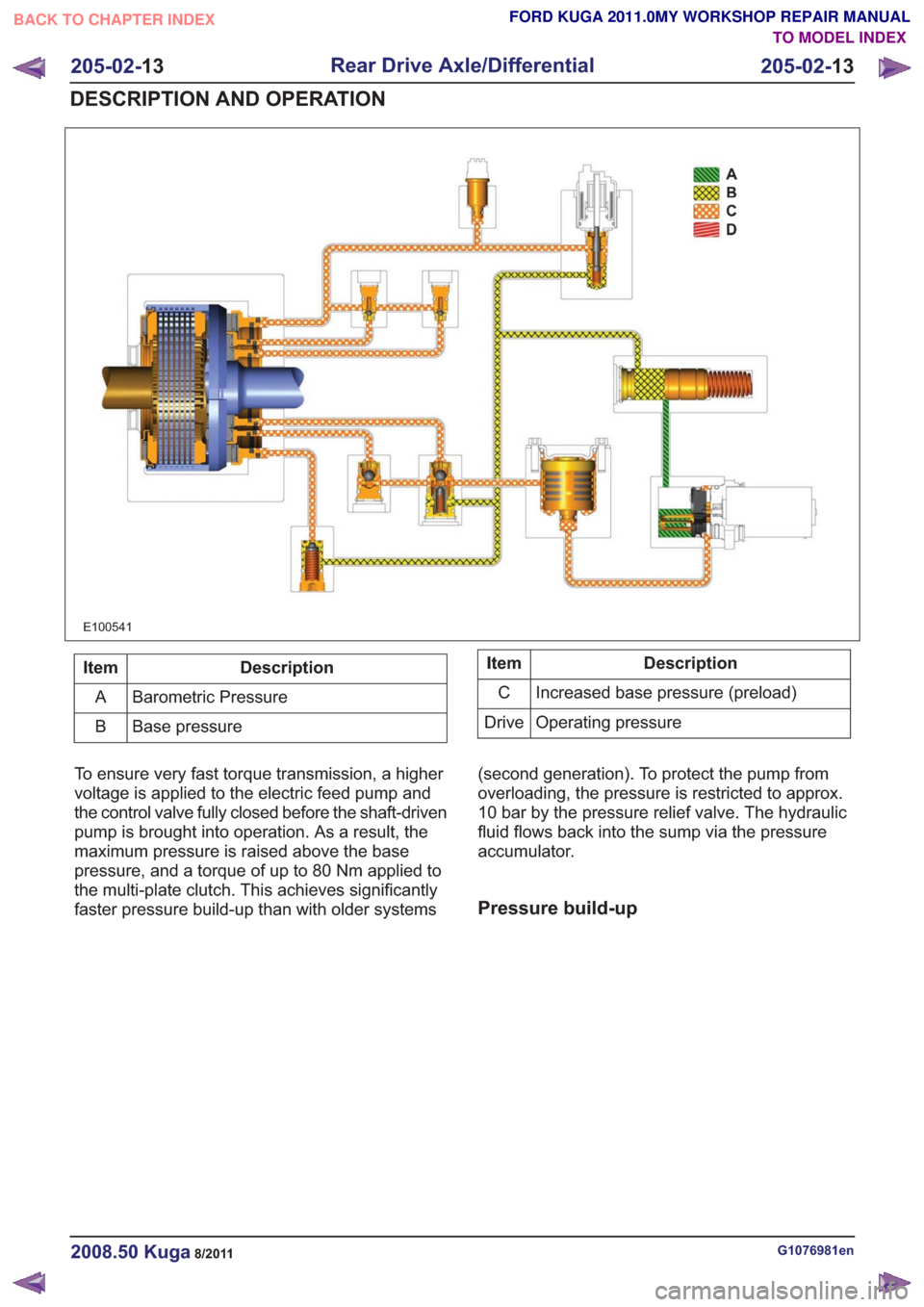

E100541

Description

Item

Barometric Pressure

A

Base pressure

BDescription

Item

Increased base pressure (preload)

C

Operating pressure

Drive

To ensure very fast torque transmission, a higher

voltage is applied to the electric feed pump and

the control valve fully closed before the shaft-driven

pump is brought into operation. As a result, the

maximum pressure is raised above the base

pressure, and a torque of up to 80 Nm applied to

the multi-plate clutch. This achieves significantly

faster pressure build-up than with older systems (second generation). To protect the pump from

overloading, the pressure is restricted to approx.

10 bar by the pressure relief valve. The hydraulic

fluid flows back into the sump via the pressure

accumulator.

Pressure build-up

G1076981en2008.50 Kuga8/2011

205-02-

13

Rear Drive Axle/Differential

205-02- 13

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1262 of 2057

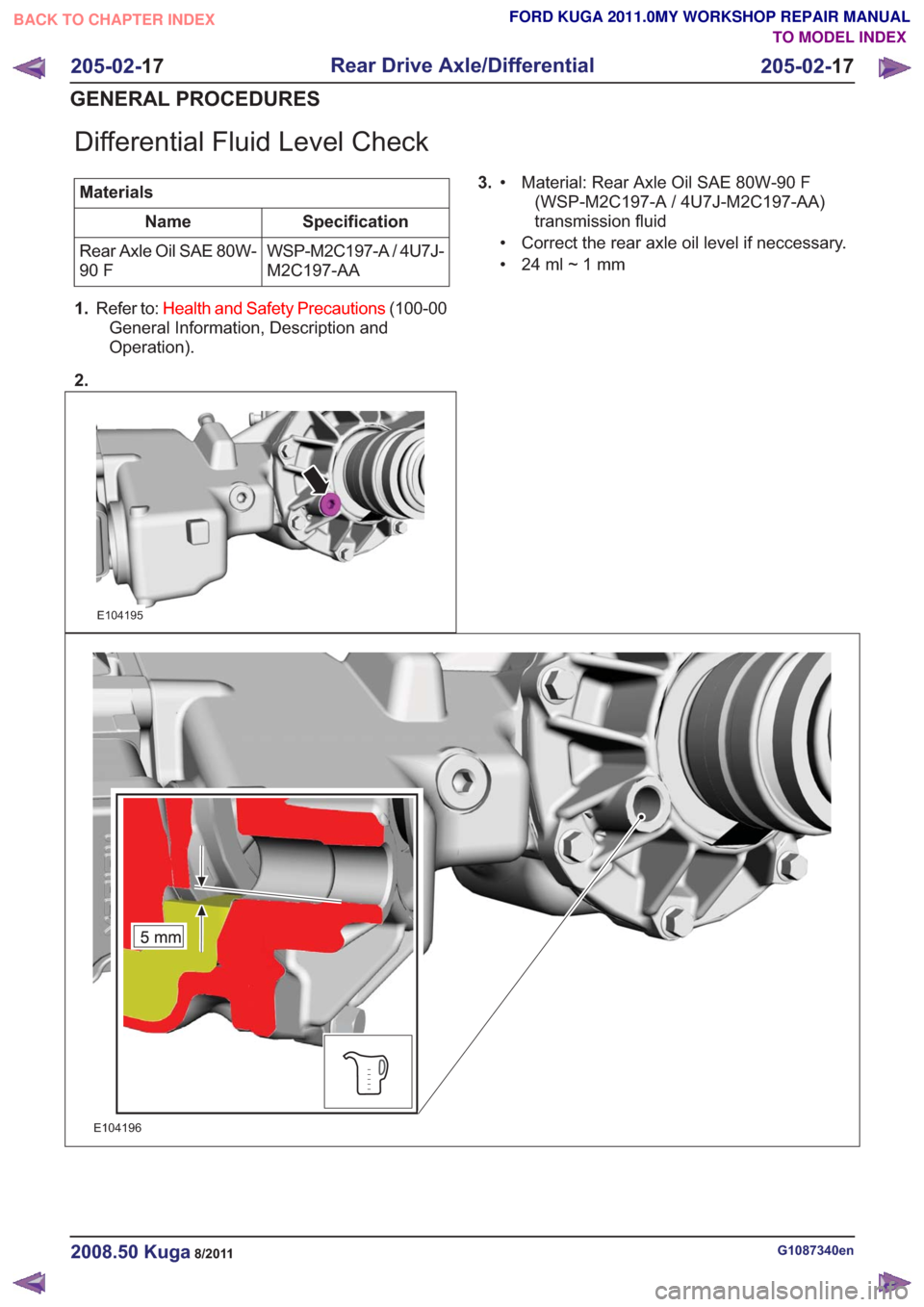

Differential Fluid Level Check

MaterialsSpecification

Name

WSP-M2C197-A / 4U7J-

M2C197-AA

Rear Axle Oil SAE 80W-

90 F

1. Refer to: Health and Safety Precautions (100-00

General Information, Description and

Operation).

2.

E104195

3. Material: Rear Axle Oil SAE 80W-90 F

(WSP-M2C197-A / 4U7J-M2C197-AA)

transmission fluid

•

• Correct the rear axle oil level if neccessary.

• 24ml~1mm

E104196

G1087340en2008.50 Kuga8/2011

205-02-

17

Rear Drive Axle/Differential

205-02- 17

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1264 of 2057

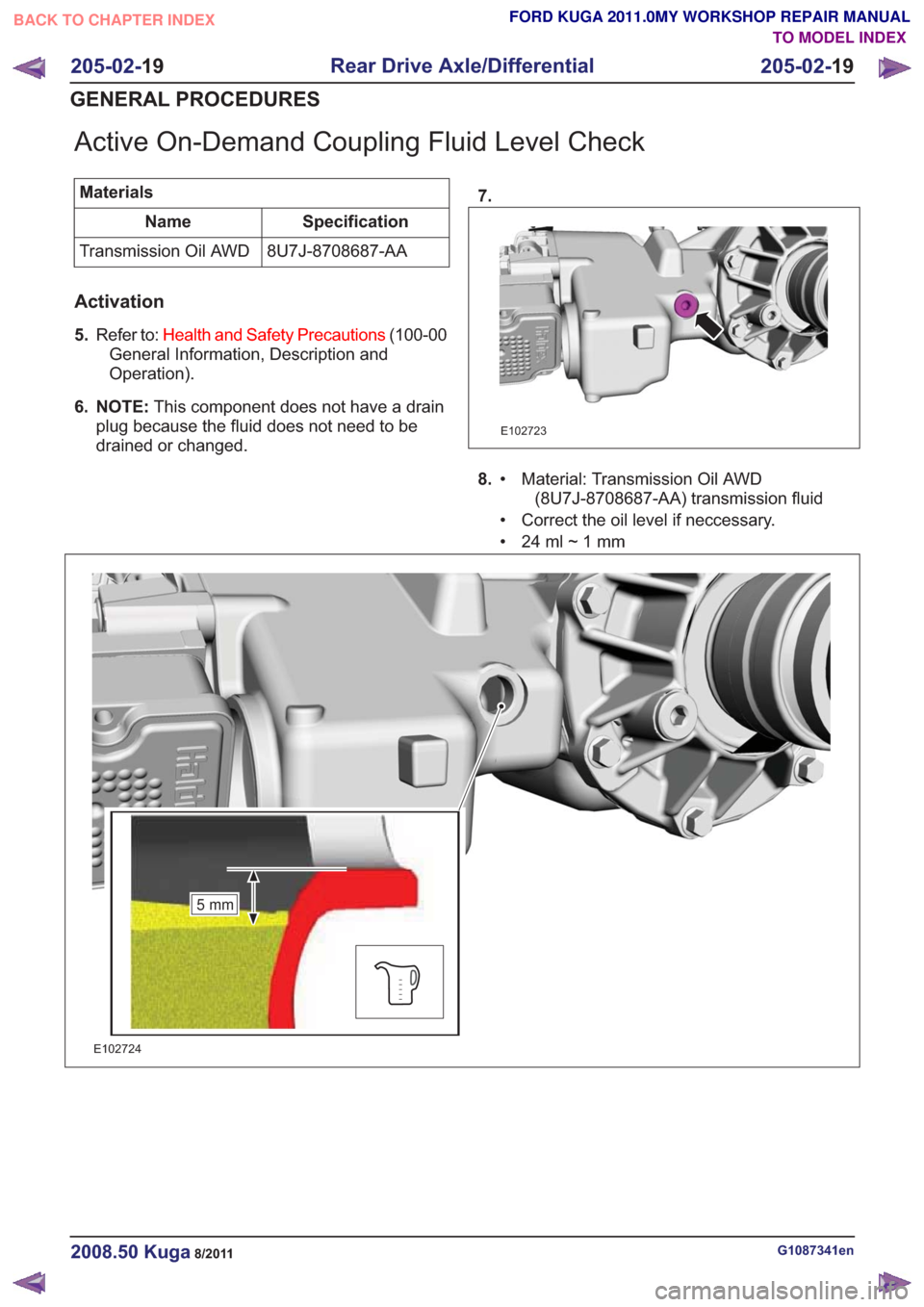

Active On-Demand Coupling Fluid Level Check

MaterialsSpecification

Name

8U7J-8708687-AA

Transmission Oil AWD

Activation

5. Refer to: Health and Safety Precautions (100-00

General Information, Description and

Operation).

6. NOTE: This component does not have a drain

plug because the fluid does not need to be

drained or changed. 7.

E102723

8.

Material: Transmission Oil AWD

(8U7J-8708687-AA) transmission fluid

•

• Correct the oil level if neccessary.

• 24ml~1mm

5mm5mm

E102724

G1087341en2008.50 Kuga8/2011

205-02-

19

Rear Drive Axle/Differential

205-02- 19

GENERAL PROCEDURES

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1270 of 2057

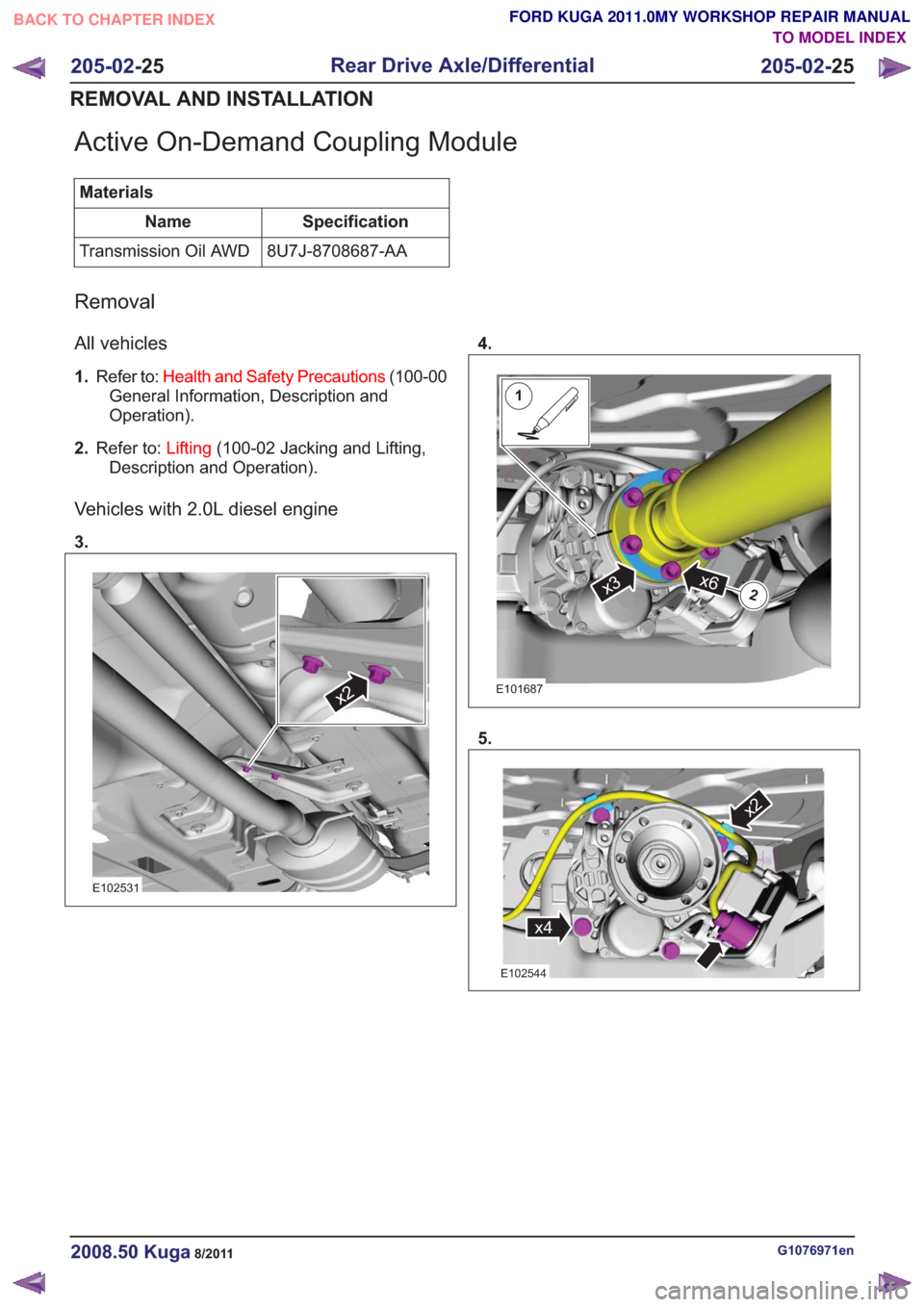

Active On-Demand Coupling Module

MaterialsSpecification

Name

8U7J-8708687-AA

Transmission Oil AWD

Removal

All vehicles

1. Refer to: Health and Safety Precautions (100-00

General Information, Description and

Operation).

2. Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

Vehicles with 2.0L diesel engine

3.

x2x2

E102531

4.

1

2x6x3

1

2x6x3

E101687

5.

x4

x2

x4

x2

E102544

G1076971en2008.50 Kuga8/2011

205-02- 25

Rear Drive Axle/Differential

205-02- 25

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1273 of 2057

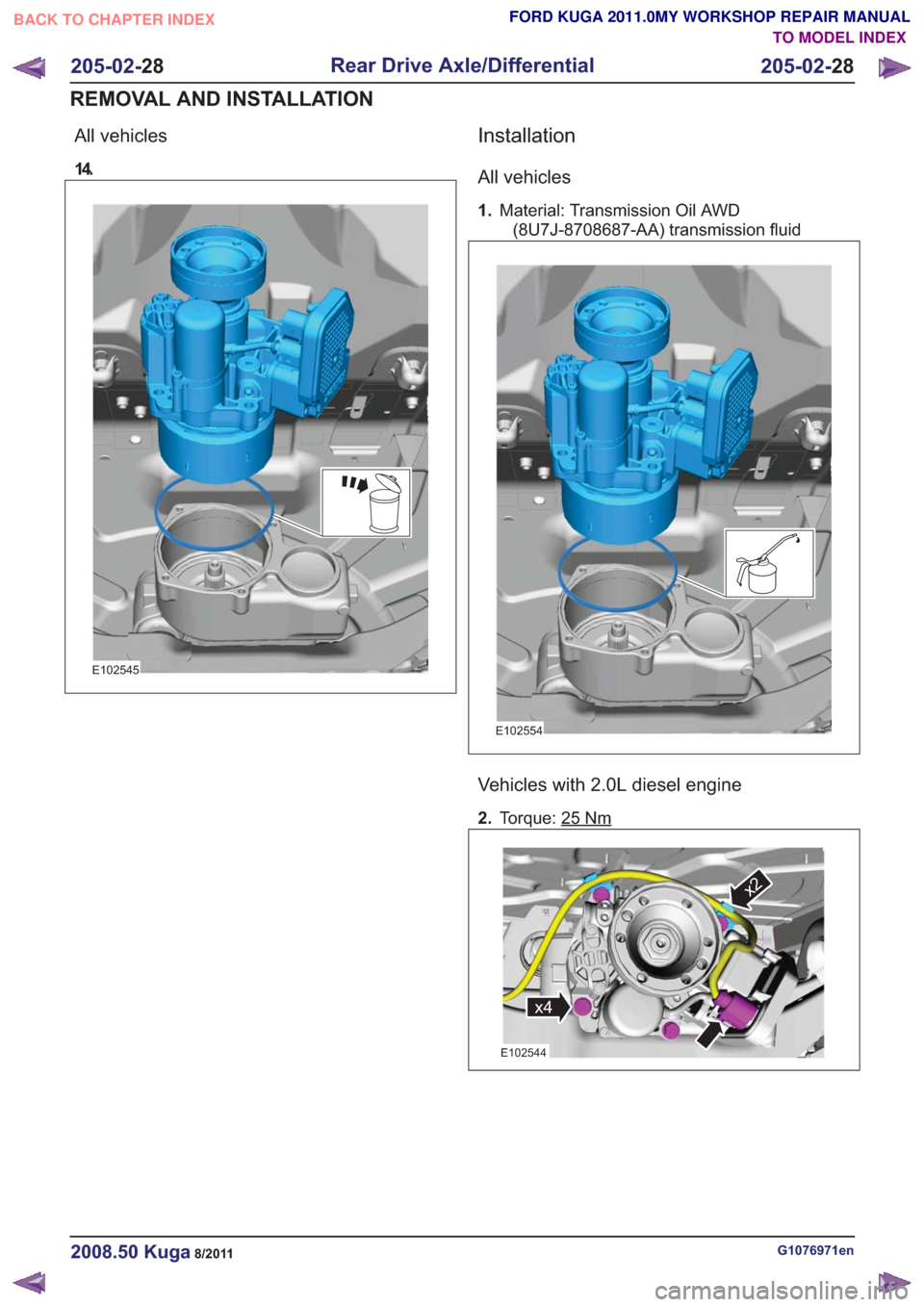

All vehicles

14.

E102545

Installation

All vehicles

1.Material: Transmission Oil AWD

(8U7J-8708687-AA) transmission fluid

E102554

Vehicles with 2.0L diesel engine

2. Torque: 25Nm

x4

x2

x4

x2

E102544

G1076971en2008.50 Kuga8/2011

205-02- 28

Rear Drive Axle/Differential

205-02- 28

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1279 of 2057

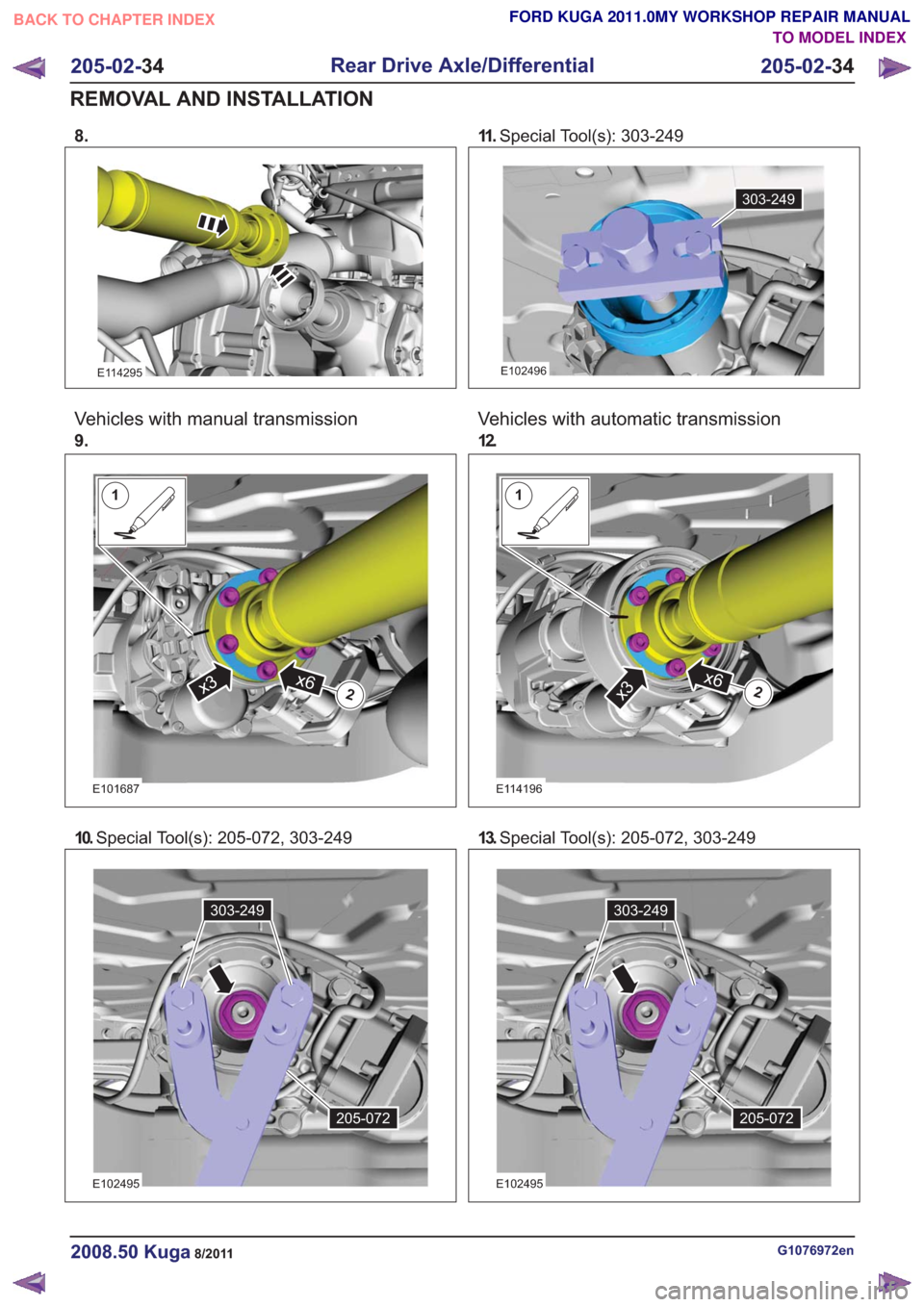

8.

E114295

Vehicles with manual transmission

9.

1

2x6x3

1

2x6x3

E101687

10.Special Tool(s): 205-072, 303-249

205-072

303-249

205-072

303-249

E102495

11 .Special Tool(s): 303-249

303-249303-249

E102496

Vehicles with automatic transmission

12.

1

2x6

x3

1

2x6

x3

E114196

13.Special Tool(s): 205-072, 303-249

205-072

303-249

205-072

303-249

E102495

G1076972en2008.50 Kuga8/2011

205-02- 34

Rear Drive Axle/Differential

205-02- 34

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL