automatic FORD KUGA 2011 1.G Owner's Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 380 of 2057

Description

Item

Reversing camera module (RVC)

10

Keyless vehicle module (KVM)

11

All-wheel drive control unit

12

RDM - Driver's side

13

RCM (restraints control module)

14

DDM (driver door module)

15

Instrument Cluster

16 Description

Item

High intensity discharge headlamp module

(optional)

17

ABS (anti-lock brake system) module or

electronic stability program module

18

PCM (powertrain control module)

19

The EATC (electronic automatic

temperature control) control module

20

Electrohydraulic power steering module

21 G1072290en

2008.50 Kuga 8/2011 418-00-3

Module Communications Network

418-00-3

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 384 of 2057

must use the same language. This language is

called a protocol.

At present, Ford uses three different data bus

systems. Depending upon model and equipment

level, all three data bus systems are used. Each

of these data bus systems has its own protocol.

Data bus systems

ISO 9141 bus

The International Organisation for Standardisation

ISO 9141 bus. This consists of a single wire and

is used exclusively for communication between the

modules and the Ford diagnostic unit. The fault

memories of the various modules are read out via

the ISO 9141 bus.

Local Interconnect Network (LIN) bus

The LIN bus is a standard specifically designed for

cost-effective communication between intelligent

sensors and actuators in vehicles. The LIN control

unit subnet is used in every situation where the

bandwidth and versatility of CAN is not needed.

The LIN specification comprises the LIN protocol,

a standard format for describing a complete LIN

and the interface between an LIN and the

application. An LIN comprises a LIN master and

one or more LIN slaves. The LIN utilizes the

master/slave principle for the purpose of bus

access control. This has the significant advantage

that few resources (CPU performance, ROM, RAM)

are required for bus management in the slave

module. The master is implemented in a control

module or a gateway which has the necessary

resources. All communication is initiated by the

master. Consequently, a message always consists

of a header, which is generated by the master, and

a response from the slave. The data transfer rate

is in the region of up to 20 Kbit/s. The LIN master

knows the time sequence of all data which are to

be transmitted. These data are transmitted by the

corresponding LIN slaves (e.g. ultrasonic sensors)

if they are requested to do so by the LIN master.

LIN is a single-wire bus, i.e. the data are

transmitted in the cable via one wire. Usually the

same cable is also used to provide the supply

voltage. The ground connection of the supply

voltage also acts as the ground connection of the

data transmission. An LIN does not use a

terminating resistor.

Controller Area Network (CAN) bus

This consists of two twisted wires and operates

serially (data is transmitted sequentially). It is used

for communication between the modules

themselves and between the modules and the Ford

diagnostic unit. The modules are connected to the

data bus in parallel. New modules can be

incorporated easily, without modifying the other

wiring or modules. The transmitted data is received

by every module connected to the control unit

network (CAN). As each data packet has an

identifier (label), in which the priority of the

message is determined as well as the content

identification, each module can detect whether or

not the data is relevant for its own information

processing. This enables several modules to be

addressed with a particular data packet and

supplied with data simultaneously. For this

purpose, it is ensured that important data (for

example from the ABS) is transmitted first. The

other modules are only able to submit their data to

the data bus after the high-priority messages have

been received.

The advantages of the CAN bus are:

• Minimization of wiring requirements

•

High degree of error protection (fault / fail-proof)

• Robustness

• Good extendibility

• Prioritization of messages

• Inexpensive

• Automatic repetition of faulty messages

• Independent system monitoring and the ability to disconnect faulty modules from the data bus

automatically

Due to the increased number of modules and the

resulting continued increase in data transfer, two

different CAN bus systems are used. Essentially,

they only differ in terms of their data transmission

rates and application areas.

To be able to distinguish between the individual

CAN bus systems, the CAN bus system with the

high transfer speed is called the high speed CAN

bus (HS-CAN). The data are transmitted at a baud

rate of 500 kB/s.

The CAN bus system with the medium transfer

speed is called the medium speed CAN bus

(MS-CAN) and is mainly used for communication

in the comfort electronics or the multimedia system.

The data are transmitted at a baud rate of 125 kB/s.

An interface (gateway) is used to exchange data

between the HS-CAN and the MS-CAN. This

provides the connection between the three CAN

databus systems and is installed in the GEM and

in the electronic instrument cluster. The number of

modules which are connected to the three databus G1030779en

2008.50 Kuga 8/2011 418-00-7

Module Communications Network

418-00-7

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 448 of 2057

Description

Item

Passive key (radio remote control with

integrated emergency key)Refer to Component Description: (page

?)

4

RF receiverRefer to Component Description: (page

?)

5

PCM6 Description

Item

Transceiver of passive anti-theft system

(emergency start function)Refer to Component Description: (page

?)

7

Instrument clusterRefer to Component Description: (page

?)

8

System Operation

Passive Anti-theft System

The passive anti-theft system PATS (passive

anti-theft system) is based on an electronic engine

immobiliser.

The driver does not need to intervene in any way

to protect the vehicle, since PATS is automatically

activated when the ignition is switched off.

Component Description

Keyless vehicle module (KVM) The PATS functionality is saved in the KVM. After

pressing the start/stop button, the KVM activates

the interior antennas, which then transmit a signal.

If there is a valid passive key in the vehicle interior,

it sends an encrypted signal to the radio frequency

receiver. The radio receiver forwards this signal to

the KVM via a fixed wire. The KVM then forwards

a corresponding identification query via the HS

CAN (controller area network) to the PCM.

If a valid code was received to this query, then the

engine can be started. Interior antennas

The four interior antennas transmit an LF signal

which is identified by the passive key.

Passive key (radio remote control with

integrated emergency key)

G1065785en

2008.50 Kuga 8/2011 419-01B-5

Anti-Theft - Passive

419-01B-5

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE100587 E100793 E87065132

Page 451 of 2057

SECTION 419-10 Multifunction Electronic Modules

VEHICLE APPLICATION:

2008.50 Kuga

PAGE

CONTENTS

DESCRIPTION AND OPERATION

419-10-2

Module Controlled Functions (Overview)...........................................................................

419-10-2

Generic electronics module (GEM)....................................................................................

419-10-2

Emergency function............................................................................................................

419-10-2

Service mode......................................................................................................................

419-10-4

Module Controlled Functions (System Operation and Component Description)................

419-10-4

System Diagram.................................................................................................................

419-10-6

System Operation...............................................................................................................

419-10-6

GEM. ...............................................................................................................................

419-10-6

Component Description......................................................................................................

419-10-6

Battery charging (Smart Charge)....................................................................................

419-10-7

Ignition overload protection.............................................................................................

419-10-7

Headlamp switch-off delay..............................................................................................

419-10-8

Turn signals....................................................................................................................

419-10-8

Interior lighting................................................................................................................

419-10-8

Heated windscreen.........................................................................................................

419-10-9

Heated rear window and heated external mirrors...........................................................

419-10-9

Ambient air temperature.................................................................................................

419-10-9

Brake fluid level...............................................................................................................

419-10-9

Automatic headlamps.....................................................................................................

419-10-9

Combined rain sensor/light sensor.................................................................................419-10-10Windshield wash/wipe system........................................................................................

419-10-10Anti-theft ..........................................................................................................................

419-10-10Electric booster Heater...................................................................................................

419-10-10Climate control................................................................................................................

DIAGNOSIS AND TESTING 419-10-11

Generic Electronic Module (GEM)......................................................................................

419-10-11

Description of operation......................................................................................................

419-10-12

Inspection and Checking....................................................................................................

REMOVAL AND INSTALLATION 419-10-14

Generic Electronic Module (GEM)......................................................................................

419-10-15

Lighting Control Module (LCM)........................................................................................... 419-10-1

Multifunction Electronic Modules

419-10-1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 453 of 2057

• Reversing lamp

• Liftgate release

• Folding liftgate release

• Ignition switch, terminal 15 (turn key to 0

position, then turn key to II position.)

An acoustic signal sounds and the turn signal

lamps flash to indicate receipt of each input signal

by the generic electronic module.

Test the windshield wiper "intermittent mode"

stage input signal (only vehicles with adjustable

intermittent mode):

The windshield wiper switch must be switched to

"intermittent mode" in order to test the input signal.

The delay times of the input signals can then be

tested by operating the rotary switch. Each change

of the rotary switch position is indicated by an

acoustic signal and illumination of the turn signals.

Output signals

SWITCH the wiper switch to the "Intermittent"

position to test the output signals. PRESSING the

heated rear window switch activates the output

signals in the following order:

• Left-hand turn signal

• Right-hand turn signal

• Main beam

• Dipped beam

• Windshield wiper stage I

• Windshield wiper stage II

• Heated rear window

• Heater blower motor

• Headlamp washer system (vehicles with HID headlamps)

• Electric booster heater (if fitted)

• Autolamps (if fitted)

• Alarm horn (vehicles with alarm system)

• Rear window wiper

• Heated rear window relay

When the heated rear window switch is pressed

again, the test of the relevant signal is terminated.

When the heated rear window switch is pressed

once more, the test for the next signal in the list is

started.

Ending the service mode

The GEM automatically ends service mode 20

seconds after the last input or at a driving speed

of over 7km/h. However, service mode can be

manually ended at any time by proceeding as

follows: •

OPERATE the switch of the heated rear window

and HOLD IT THERE

• Switch off the ignition.

• RELEASE the switch of the heated rear window

3 signals sound and the turn signal lamps illuminate

to indicate that service mode has ended.

Resetting service mode

If, after completion of service mode, some functions

do not operate or do not operate properly, check

the following functions:

• Instrument cluster illumination, side marker lamps (side lights) and licence plate lamp in

automatic headlamps mode

• Rear wiper

• Headlamp washer assembly

• Electric booster heater

• Alarm horn

• Heated windshield

If one or more of the listed functions is not OK, it's

possible that the cause of the fault is due to not

exiting service mode properly. To reactivate the

functions correctly, perform the following steps:

1. Switch off the ignition.

2. SWITCH OFF the switch for the windscreen wash/wipe system

3. OPERATE the switch of the heated rear window

and HOLD IT THERE

4. SWITCH ON the ignition.

5. RELEASE the heated rear window switch (an acoustic signal will sound if activation has been

performed correctly)

6. SWITCH the windscreen wash/wipe switch to the "Intermittent wipe" position

7. OPERATE the heated rear window switch 6 times (the main beam headlamps switch on and

off automatically)

8. SWITCH OFF the switch for the windscreen wash/wipe system

9. OPERATE the switch of the heated rear window

and HOLD IT THERE

10. Switch off the ignition.

11. RELEASE the heated rear window switch (three

acoustic signals will sound if activation has been

performed correctly)

After completion of the work, check all the

functions. G1030787en

2008.50 Kuga 8/2011 419-10-3

Multifunction Electronic Modules

419-10-3

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 456 of 2057

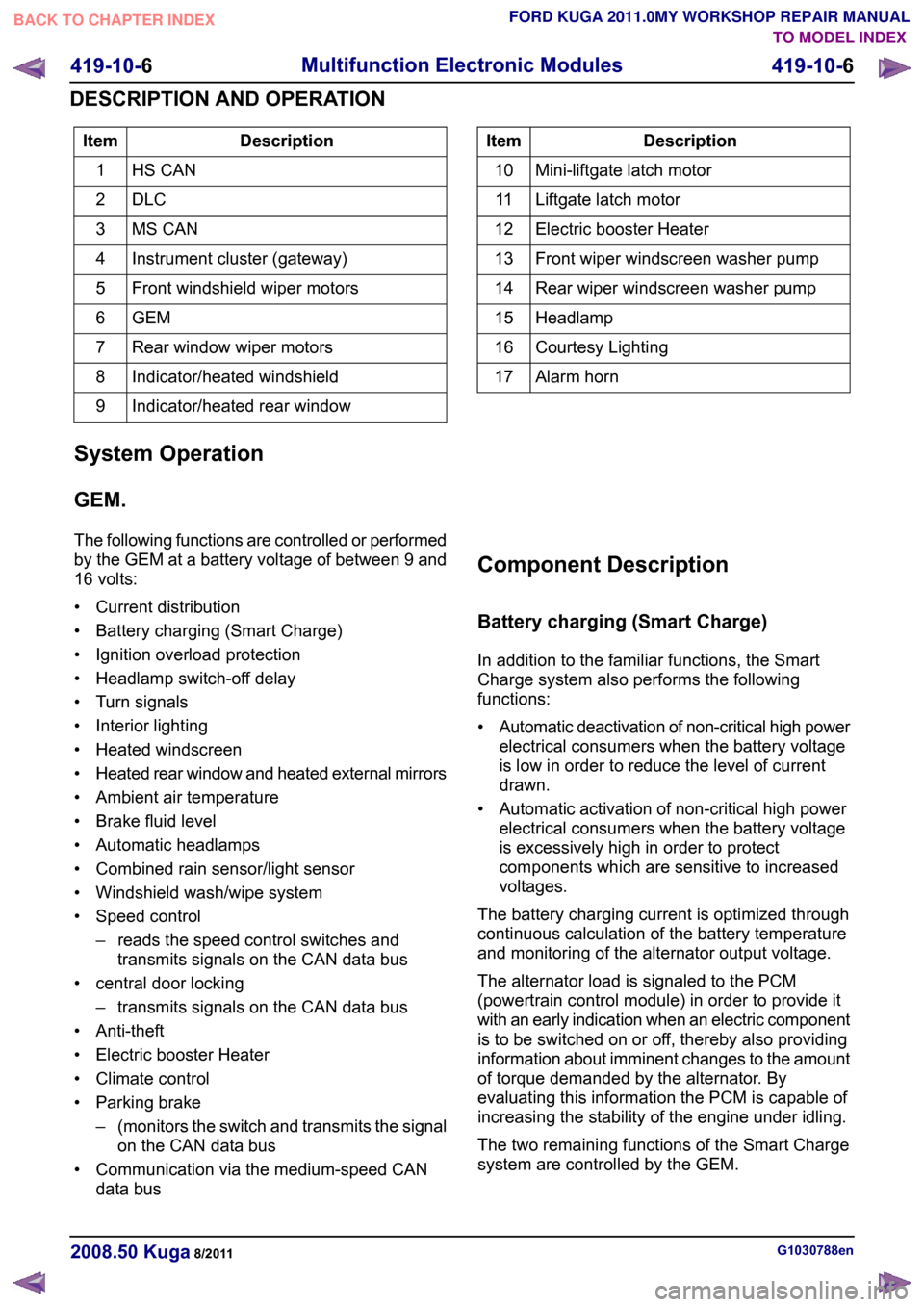

Description

Item

HS CAN

1

DLC2

MS CAN

3

Instrument cluster (gateway)

4

Front windshield wiper motors

5

GEM6

Rear window wiper motors

7

Indicator/heated windshield

8

Indicator/heated rear window

9 Description

Item

Mini-liftgate latch motor

10

Liftgate latch motor

11

Electric booster Heater

12

Front wiper windscreen washer pump

13

Rear wiper windscreen washer pump

14

Headlamp

15

Courtesy Lighting

16

Alarm horn

17

System Operation

GEM.

The following functions are controlled or performed

by the GEM at a battery voltage of between 9 and

16 volts:

• Current distribution

• Battery charging (Smart Charge)

• Ignition overload protection

• Headlamp switch-off delay

• Turn signals

• Interior lighting

• Heated windscreen

• Heated rear window and heated external mirrors

• Ambient air temperature

• Brake fluid level

• Automatic headlamps

• Combined rain sensor/light sensor

• Windshield wash/wipe system

• Speed control – reads the speed control switches andtransmits signals on the CAN data bus

• central door locking – transmits signals on the CAN data bus

• Anti-theft

• Electric booster Heater

• Climate control

• Parking brake –(monitors the switch and transmits the signal

on the CAN data bus

• Communication via the medium-speed CAN data bus Component Description

Battery charging (Smart Charge)

In addition to the familiar functions, the Smart

Charge system also performs the following

functions:

•

Automatic deactivation of non-critical high power

electrical consumers when the battery voltage

is low in order to reduce the level of current

drawn.

• Automatic activation of non-critical high power electrical consumers when the battery voltage

is excessively high in order to protect

components which are sensitive to increased

voltages.

The battery charging current is optimized through

continuous calculation of the battery temperature

and monitoring of the alternator output voltage.

The alternator load is signaled to the PCM

(powertrain control module) in order to provide it

with an early indication when an electric component

is to be switched on or off, thereby also providing

information about imminent changes to the amount

of torque demanded by the alternator. By

evaluating this information the PCM is capable of

increasing the stability of the engine under idling.

The two remaining functions of the Smart Charge

system are controlled by the GEM. G1030788en

2008.50 Kuga 8/2011 419-10-6

Multifunction Electronic Modules

419-10-6

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 457 of 2057

Electrical consumers are switched off when the

battery voltage is low if the GEM determines (as a

result of the message received from the PCM on

the CAN bus via the instrument cluster) that the

battery voltage has dropped below the threshold

value.

When the threshold for low battery voltage is

reached the GEM switches off the following

consumers in this order at intervals of 5 seconds:

• Heated windscreen

• Heated rear window

• Electric booster Heater

• A/C system

If the battery voltage increases back above the

lower threshold then all of the consumers which

were previously switched off are reactivated by the

GEM.

Once the electric consumers have been reactivated

their status is "switched off", i.e. the consumers

are switched off and await an input signal provided

from the relevant switch via the GEM; this means

that the driver needs to switch these components

back on again.

Electrical consumers are switched on when the

battery voltage is excessively high if the GEM

determines that the battery voltage has increased

above the threshold for overvoltage and the

charging system warning indicator has come on.

When the threshold is reached the GEM switches

on the following consumers in this order at intervals

of 5 seconds:

• Heated windscreen

• Heated rear window

When these components are deactivated again

their status is "switched off". This means that the

consumers are waiting for an input signal provided

from the relevant switch via the GEM.

Ignition overload protection

The ignition overload protection intermittently

disconnects certain circuits in order to restrict the

current being drawn from the battery while the

starter motor is operating.

The position of the ignition switch is broadcast by

the instrument cluster on the medium speed CAN

bus.

The ignition overload protection relay which is

integrated in the battery junction box is activated

by the GEM if the message "ignition switch in

position III" is received from the instrument cluster.

All of the electric consumers controlled by the

ignition overload protection relay are then switched

off.

The following consumers (among others) are

controlled by the ignition overload protection relay:

• Fog lamps

• Windscreen/rear window wash/wipe systems

• Backup lamps

• Heated washer nozzles

• Heating blower motor

• Seat heating

Headlamp switch-off delay

The headlamp switch-off delay utilizes the low

beam together with the peripheral lights (if

equipped) to illuminate the area surrounding the

vehicle. The function is activated by operating the

high beam lever when the ignition switch is in the

"0" position.

After the last door has been closed, the function

remains active for a further 30 seconds and then

switches off automatically.

When a door or the tailgate is open, the switch-off

time is extended to 180 seconds. After the last door

has been closed, the switch-off time is reset to 30

seconds.

The headlamp switch-off delay can be deactivated

prematurely by operating the high beam lever again

or by switching on the ignition.

The switch-off time is adjusted to set values at the

factory and cannot be re-programmed using the

Ford diagnostic unit.

G1030788en

2008.50 Kuga 8/2011 419-10-7

Multifunction Electronic Modules

419-10-7

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 459 of 2057

• 4 minutes have elapsed since the button for the

heated windshield was pressed.

• The ignition switch is turned to the "I" or "0" position.

• The "Defrost" function is deactivated or the switch for the heated windscreen is pressed

again while the heated windscreen is still

switched on.

• The charging system warning indicator is switched on.

• The battery voltage falls below the threshold value for low battery voltage for more than 20

seconds (power management strategy). Manual

requests for switching on the heated windshield

by pressing the switch are ignored at this time.

• More than 4 minutes have passed since starting

the engine.

Heated rear window and heated external

mirrors

The GEM transmits a request signal via the CAN

bus to the door modules to switch on the heated

exterior mirrors.

The heated rear window and the heated exterior

mirrors are switched on by the GEM under the

following conditions:

• The switch for the heated rear window is pressed and the ignition switch is in the "II"

position.

• The "defrost" function of the air conditioning is activated and the ignition switch is in the position

"II".

• The battery voltage has exceeded 16 V for more

than 20 seconds (power management strategy).

Manual requests to switch off the heated rear

window by pressing the button are ignored at

this time.

• The engine was started at an outside air temperature below 4°C and an engine

temperature below 65°. Manual requests for

switching off the heated rear window by pressing

the switch are accepted.

NOTE: If the battery voltage returns to the normal

range then the disabling of the heated rear window

is cancelled - the heated rear window is then in a

switched-off state.

The GEM transmits a request signal via the CAN

bus to the door modules to switch off the heated

exterior mirrors. The heated rear window and the heated exterior

mirrors are switched off by the GEM under the

following conditions

• 14 minutes have elapsed since the button for

the heated rear window was pressed.

• The ignition switch is turned to the position "0", "I" or "III".

• The switch for the heated rear window is pressed or the "defrost" function of the air

conditioning is deactivated while the heated rear

window is switched on.

• The battery voltage has dropped below 10.3 V for more than 20 seconds (power management

strategy). Manual requests for switching on the

heated rear window by pressing the switch are

ignored at this time.

• More than 14 minutes have passed since starting the engine.

Ambient air temperature

The ambient air temperature sensor is connected

via a cable to the GEM. It measures the outside

air temperature to an accuracy of around ±0.5 °C.

The GEM broadcasts the ambient air temperature

on the medium speed CAN bus, where it can be

evaluated by various systems.

Brake fluid level

The brake fluid level switch is connected via a

cable to the GEM.

The GEM transmits a message on the medium

speed CAN bus. The instrument cluster then

transfers this message to the high speed CAN bus

where it is made available for various other

functions.

Automatic headlamps

Refer to: Exterior Lighting (417-01 Exterior Lighting,

Description and Operation).

Combined rain sensor/light sensor

Refer to: Exterior Lighting (417-01 Exterior Lighting,

Description and Operation). G1030788en

2008.50 Kuga 8/2011 419-10-9

Multifunction Electronic Modules

419-10-9

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 462 of 2057

Output signals

SWITCH the wiper switch to the "intermittent""

position to test the output signals. PRESSING the

heated rear window switch activates the output

signals in the following order:

a.

Left-hand turn signal

b. Right-hand turn signal

c. Main beam

d. Dipped beam

e. Windshield wiper stage I

f. Windshield wiper stage II

g. Heated rear windshield

h. Heater blower motor

i. Headlamp washer system (vehicles with HID headlamps)

j. Electric booster heater (if fitted)

k. Autolamps (position lamps only if fitted)

l. Alarm horn (vehicles with alarm system)

m. Rear window wiper

n. Heated front window relay

When the heated rear window switch is pressed

again, the test of the relevant signal is terminated.

When the heated rear window switch is pressed

once more, the test for the next signal in the list is

started.

End service mode

The GEM automatically ends service mode 20

seconds after the last input or at a driving speed

of over 7km/h. However, service mode can be

manually ended at any time by proceeding as

follows:

• PRESS and HOLD the switch of the heated rear

window

• SWITCH OFF the ignition.

• RELEASE the switch of the heated rear window

3 signals sound and the turn signal lamps illuminate

to indicate that service mode has ended.

Reset service mode

If, after completion of service mode, some functions

do not operate or do not operate properly, check

the following functions:

• Instrument cluster illumination, side marker lamps (side lights) and licence plate lamp in

automatic headlamps mode

• Rear wiper

• Headlamp washer assembly

• Electric booster heater • Alarm horn

• Heated windshield

If one or more of the listed functions is not OK, it's

possible that the cause of the fault is due to not

exiting service mode properly. To reactivate the

functions correctly, perform the following steps:

1. Switch off the ignition.

2. SWITCH OFF the switch for the windscreen

wash/wipe system

3. OPERATE the switch of the heated rear window

and HOLD IT THERE

4. SWITCH ON the ignition.

5. RELEASE the heated rear window switch (an acoustic signal will sound if activation has been

performed correctly)

6. SWITCH the windscreen wash/wipe switch to the "Intermittent wipe" position

7. OPERATE the heated rear window switch 6 times (the main beam headlamps switch on and

off automatically)

8. SWITCH OFF the switch for the windscreen wash/wipe system

9. OPERATE the switch of the heated rear window

and HOLD IT THERE

10. Switch off the ignition.

11. RELEASE the heated rear window switch (three

acoustic signals will sound if activation has been

performed correctly)

After completion of the work, check all the

functions.

Inspection and Checking

NOTE: The generic electronic module (GEM) is

integrated into the central junction box (CJB).

1. VERIFY customer concern.

2. Visually CHECK for any obvious mechanical or electrical damage.

NOTE: Ensure correct locking of the wiring harness

connector.

Visual Inspection Electrical

Fuses

Wiring harness Connectors G1055084en

2008.50 Kuga 8/2011 419-10-12

Multifunction Electronic Modules

419-10-12

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1246 of 2057

SECTION 205-02 Rear Drive Axle/Differential

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

DESCRIPTION AND OPERATION

205-02-2

Rear Drive Axle and Differential (Component Location) .....................................................

205-02-6

Rear Drive Axle and Differential (System Operation and Component Description) ...........

205-02-6

System Operation ........................................................................\

.......................................

205-02-6

General Information ........................................................................\

................................

205-02-6

Driving situations ........................................................................\

....................................

205-02-6

Haldex clutch ........................................................................\

..........................................

205-02-7

General overview ........................................................................\

....................................

205-02-7

Operation ........................................................................\

................................................

205-02-7

Design of the 3rd generation Haldex clutch ....................................................................

205-02-9

Design of the multi-plate clutch ........................................................................\

...............

205-02-10

All-wheel drive control unit ........................................................................\

......................

205-02-10

Electric feed pump ........................................................................\

..................................

205-02-10

Pressure control - 3rd generation Haldex clutch .............................................................

205-02-11

Base pressure ........................................................................\

.........................................

205-02-12

Increased base pressure (preload) ........................................................................\

.........

205-02-13

Pressure build-up ........................................................................\

....................................

205-02-14

Design of the 4th generation Haldex clutch ...................................................................

205-02-14

General overview ........................................................................\

....................................

205-02-15

Pressure control - 4th generation Haldex clutch .............................................................

GENERAL PROCEDURES 205-02-17

Differential Fluid Level Check ........................................................................\

.....................

205-02-19

Active On-Demand Coupling Fluid Level Check ................................................................

REMOVAL AND INSTALLATION 205-02-21

Differential Case ........................................................................\

.........................................

205-02-25

Active On-Demand Coupling Module ........................................................................\

.........

205-02-32

Differential Input Shaft Seal ........................................................................\

........................

205-02-38

Differential Support Insulator ........................................................................\

......................

205-02-39

Rear Halfshaft Seal ........................................................................\

.....................................

205-02-41

Drive Pinion Seal ........................................................................\

........................................

DISASSEMBLY AND ASSEMBLY

205-02-42

Active On-Demand Coupling — Vehicles With: 5-Speed Automatic Transaxle - AW55

AWD/6-Speed Automatic Transaxle - 6DCT450 ...............................................................

205-02-1

Rear Drive Axle/Differential

205-02- 1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL