brake FORD KUGA 2011 1.G Service Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1236 of 2057

Action

Possible Sources

Symptom

• CHECK or INSTALL new wheelbearings as necessary.

REFER to: Front Wheel

Bearing (204-01 Front

Suspension, Removal and

Installation).

• Front wheel bearing.

• CHECK or INSTALL newsuspension components as

necessary.

• Suspension components.

• Excessive vehicle vibration,

rough steering

• ADJUST the tire pressure(s).

• Incorrect tire pressure(s).

• Vehicle vibrations from wheels

and tires

• BALANCE the wheel and tireassemblies.

• Wheel or tire imbalance.

• INSTALL a new tire(s) asnecessary.

REFER to: Wheel and Tire

(204-04 Wheels and Tires,

Removal and Installation).

• Uneven tire wear.

• CHECK the brake disc forforeign material.

• Brake disc imbalance.

• REMOVE the water.

• Water in tire(s).

• INSTALL a new wheel and tireassembly.

REFER to: Wheel and Tire

(204-04 Wheels and Tires,

Removal and Installation).

• Bent wheel.

• SPIN the wheel on the vehicle.EXAMINE the area where the

tire and the wheel meet. If that

section of the tire appears to

waver while being rotated, the

tire bead may not be correctly

seated on the wheel. REMOVE

the tire and CLEAN the bead

seat areas on both wheel and

tire.

• Incorrectly seated tire bead.

• BALANCE the wheel and tireassemblies. Using a suitable

dial indicator gauge and holding

fixture, CHECK the lateral and

radial runout of the wheel and

tire assemblies. INSTALL new

wheel and tire assemblies as

necessary.

REFER to: Wheel and Tire

(204-04 Wheels and Tires,

Removal and Installation).

• Excessive lateral or radial

runout of wheel or tire.

G1061329en2008.50 Kuga8/2011

204-04- 9

Wheels and Tires

204-04- 9

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1298 of 2057

Front Drive Halfshafts

Inspection and Verification

NOTE:New front wheel drive halfshafts should not

be installed unless disassembly and inspection

reveals unusual wear.

1. Inspect front wheel driveshaft joint boots for evidence of cracks, tears or splits.

NOTE: While inspecting the front wheel driveshaft

CV joint boots, watch for indentations (dimples) in

the boot convolutions. If an indentation is observed,

it must be removed.

2. Inspect the underbody for any indication of grease splatter in the vicinity of the front wheel

driveshaft CV joint boots outboard and inboard

locations, which is an indication of front wheel

driveshaft CV joint boot and/or front wheel

driveshaft CV joint boot clamp damage. 3. Inspect for inboard CV joint stub shaft pilot

bearing housing seal leakage at the front wheel

driveshaft CV joint.

4. Make sure front axle wheel hub retainer is the correct prevailing torque type.

5. The silicone front wheel driveshaft CV joint boot will sweat during operation, causing a light film

of grease to show on the outside of the front

wheel driveshaft CV joint boot. This condition

is normal.

NOTE: Halfshafts are not balanced and do not

contribute to rotational vibration.

6. If the concerns remain after the inspection, determine the symptoms and go to the Symptom

Chart. For additional Noise, Vibration and

Harshness (NVH). REFER to Section 100-04

[Noise, Vibration and Harshness] .

Symptom Chart

Action

Possible Sources

Symptom

• INSPECT, CLEAN andLUBRICATE as necessary.

• Inadequate or contaminated

lube in outboard/inboard front

wheel driveshaft CV joint.

• Clicking, Popping or Grinding

Noises While Turning

• INSPECT and REPAIR asnecessary.

• Another component contacting

driveshaft assembly.

• INSPECT and REPAIR asnecessary. REFER to

Section 204-00 [Suspension

System - General Information]

/ 206-00 [Brake System -

General Information] /211-00

[Steering System - General

Information] .

• Wheel bearings, brakes,

suspension or steering

components.

• REPAIR or INSTALL new asnecessary. REFER to

Section 204-04 [Wheels and

Tires] .

• Out of balance front wheels or

tires.

• Vibration at Highway Speeds

• REPAIR or INSTALL new asnecessary. REFER to

Section 204-04 [Wheels and

Tires] .

• Out-of-round tires.

• REPAIR or INSTALL new asnecessary.

REFER to Halfshaft Disas-

semblv and Assembly in this

section.

• Incorrectly seated outboard

front wheel driveshaft CV joint

in front wheel hub.

G17442en2008.50 Kuga8/2011

205-04- 3

Front Drive Halfshafts

205-04- 3

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1301 of 2057

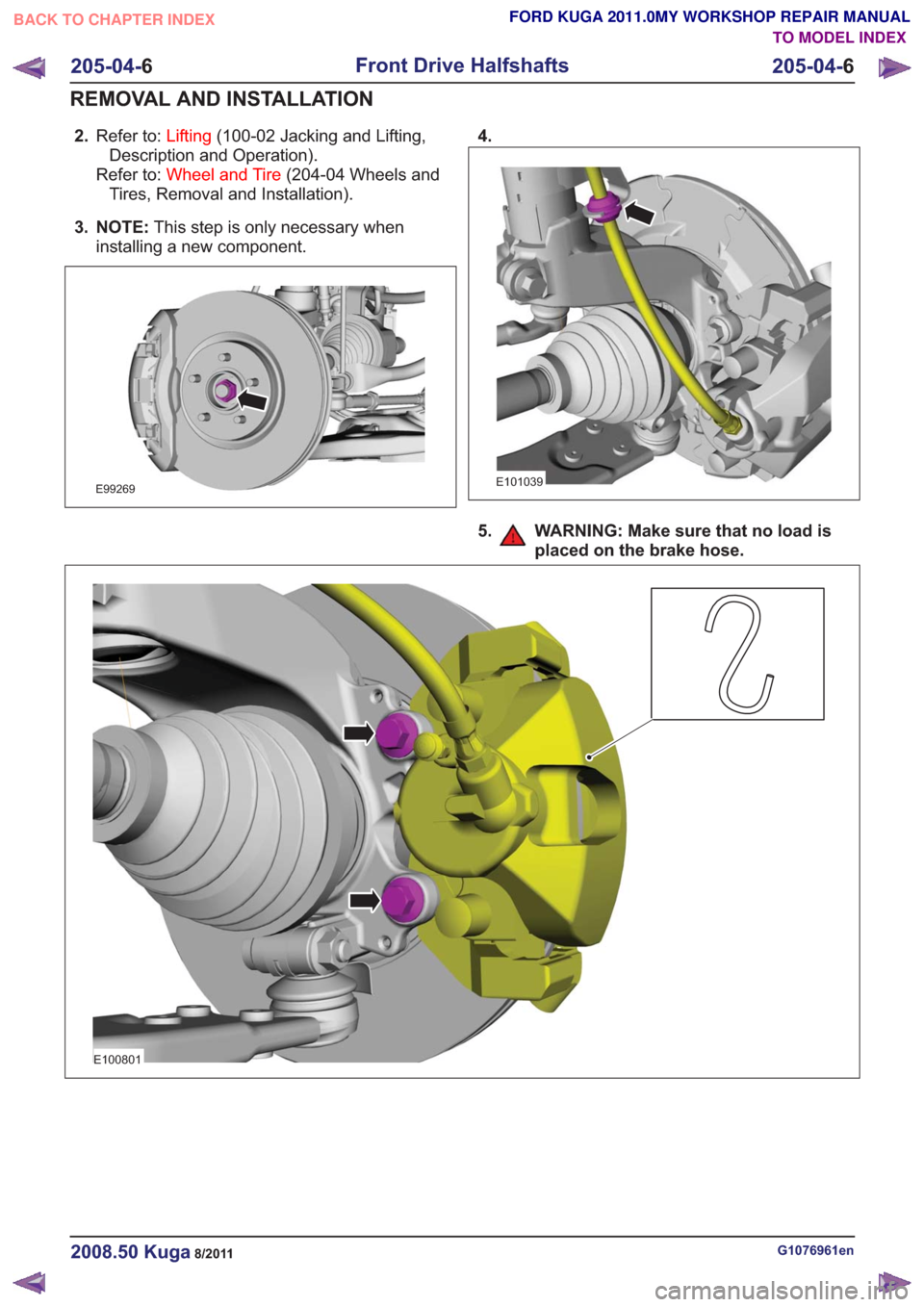

2.Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

3. NOTE: This step is only necessary when

installing a new component.

E99269

4.

E101039

5. WARNING: Make sure that no load is placed on the brake hose.

E100801

G1076961en2008.50 Kuga8/2011

205-04- 6

Front Drive Halfshafts

205-04- 6

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1312 of 2057

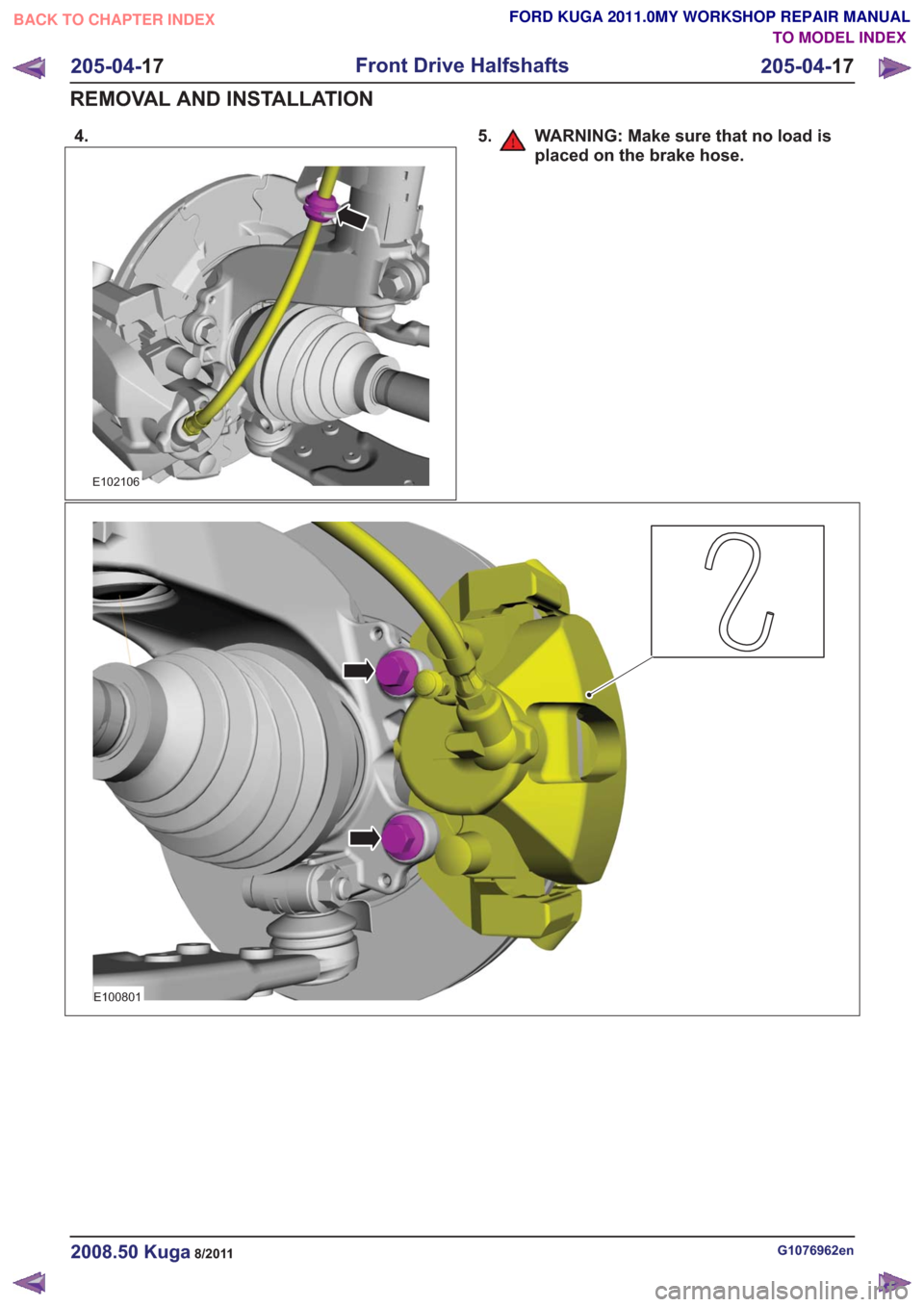

4.

E102106

5. WARNING: Make sure that no load isplaced on the brake hose.

E100801

G1076962en2008.50 Kuga8/2011

205-04- 17

Front Drive Halfshafts

205-04- 17

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1330 of 2057

Rear Halfshaft

Special Tool(s) / General Equipment308-759

Remover, Rear Driveshaft

E100143

Cable Ties

Special Tool(s) / General EquipmentTire Lever

Transmission Jack

Materials

Specification

Name

WSK-M2G349-A8 /

9U7J-M2G349-AA

Sealant LGN

Removal

1.

On both sides.

Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

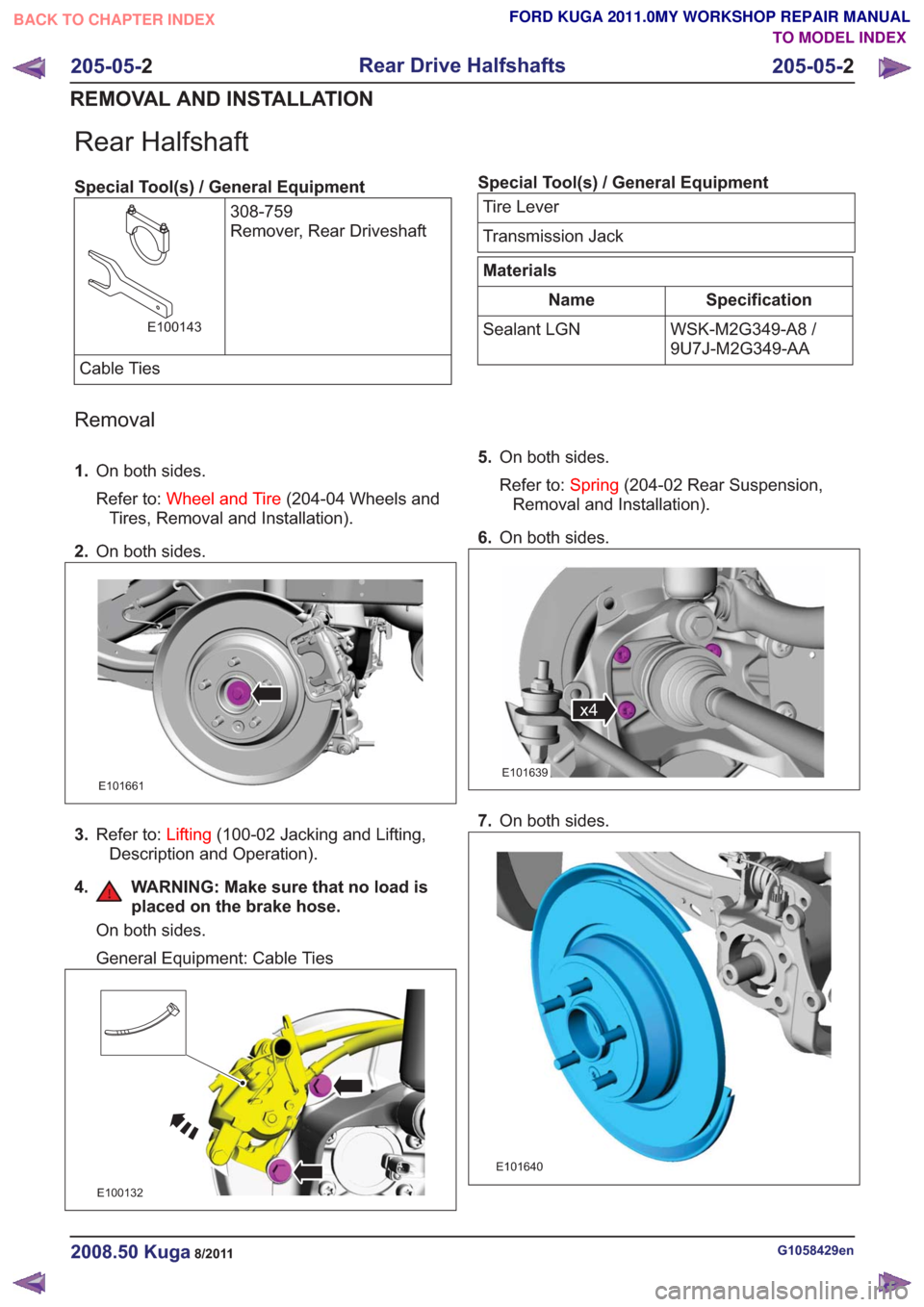

2. On both sides.

E101661

3.Refer to: Lifting(100-02 Jacking and Lifting,

Description and Operation).

4. WARNING: Make sure that no load is placed on the brake hose.

On both sides.

General Equipment: Cable Ties

E100132

5.On both sides.

Refer to: Spring(204-02 Rear Suspension,

Removal and Installation).

6. On both sides.

x4x4

E101639

7.On both sides.

E101640

G1058429en2008.50 Kuga8/2011

205-05- 2

Rear Drive Halfshafts

205-05- 2

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1335 of 2057

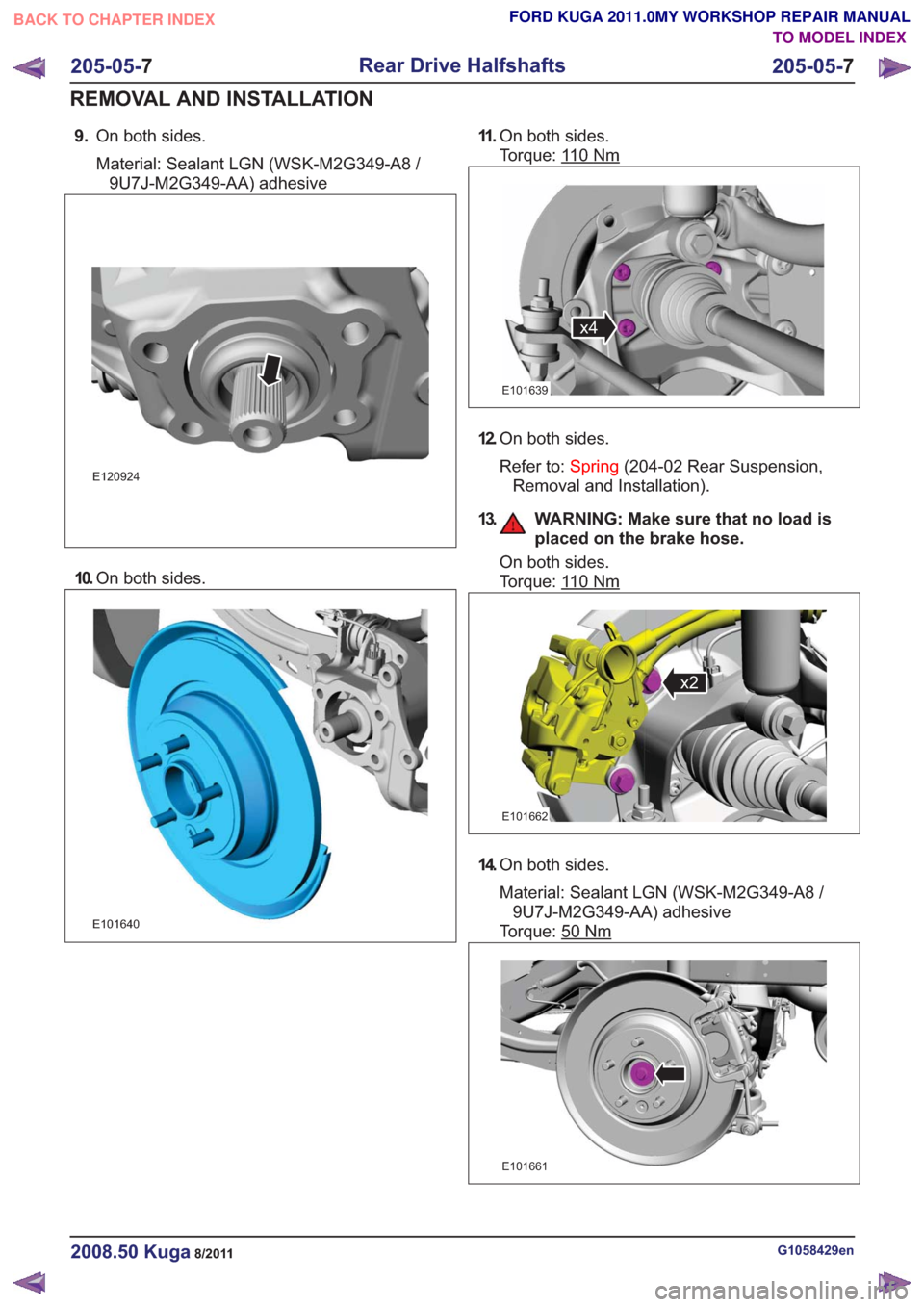

9.On both sides.

Material: Sealant LGN (WSK-M2G349-A8 /

9U7J-M2G349-AA) adhesive

E120924

10. On both sides.

E101640

11 .On both sides.

Torque: 1

10Nm

x4x4

E101639

12.On both sides.

Refer to: Spring(204-02 Rear Suspension,

Removal and Installation).

13. WARNING: Make sure that no load is placed on the brake hose.

On both sides.

Torque: 1

10Nm

x2x2

E101662

14.On both sides.

Material: Sealant LGN (WSK-M2G349-A8 /

9U7J-M2G349-AA) adhesive

Torque: 50

Nm

E101661

G1058429en2008.50 Kuga8/2011

205-05- 7

Rear Drive Halfshafts

205-05- 7

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1337 of 2057

SECTION 206-00 Brake System - General Information

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

SPECIFICATIONS

206-00-2

Specifications ........................................................................\

..............................................

206-00-2

Front Brake Disc Specification ........................................................................\

................

206-00-2

Rear Disc Brake Specification ........................................................................\

................

DESCRIPTION AND OPERATION 206-00-3

Brake System (Overview) ........................................................................\

...........................

206-00-3

Brake System ........................................................................\

.............................................

DIAGNOSIS AND TESTING 206-00-4

Brake System ........................................................................\

.............................................

206-00-4

Inspection and Verification ........................................................................\

..........................

206-00-4

Road Test ........................................................................\

...................................................

206-00-10

Pinpoint Tests ........................................................................\

.............................................

206-00-17

Component Tests ........................................................................\

........................................

206-00-17

Brake System Check ........................................................................\

..................................

206-00-17

Brake Booster Functional Test ........................................................................\

....................

GENERAL PROCEDURES 206-00-20

(12 221 0)

Brake Disc Runout Check ........................................................................\

......

206-00-20

Check ........................................................................\

.........................................................

206-00-22

Component Bleeding ........................................................................\

..................................

206-00-27

Brake System Bleeding ........................................................................\

..............................

206-00-32

(12 154 0;

12 154 4)

Brake System Draining and Filling

.................................................................

206-00-35

Brake System Pressure Bleeding ........................................................................\

...............

206-00-1

Brake System - General Information

206-00- 1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1338 of 2057

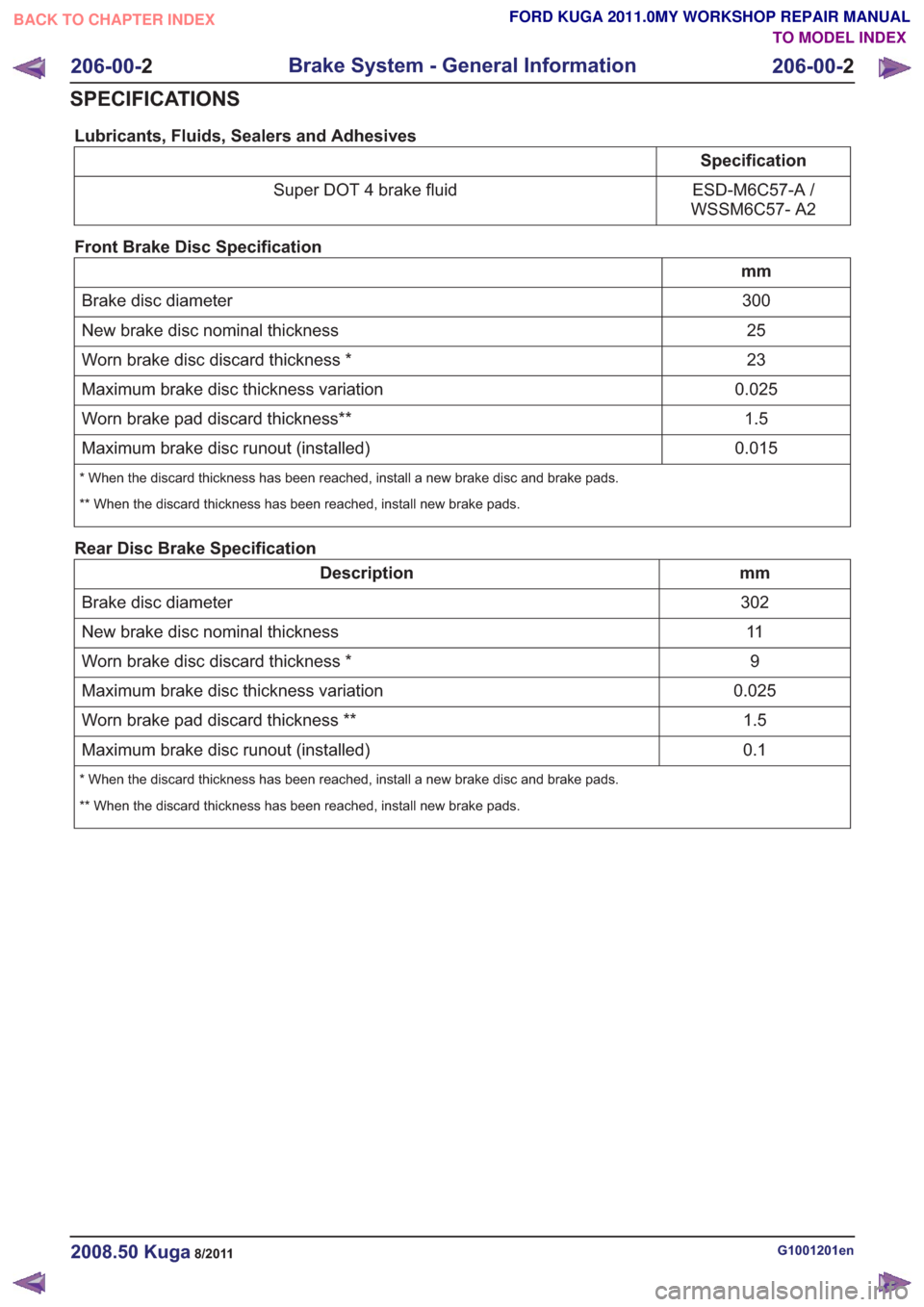

Lubricants, Fluids, Sealers and Adhesives

Specification

ESD-M6C57-A /

WSSM6C57- A2

Super DOT 4 brake fluid

Front Brake Disc Specification

mm 300

Brake disc diameter

25

New brake disc nominal thickness

23

Worn brake disc discard thickness *

0.025

Maximum brake disc thickness variation

1.5

Worn brake pad discard thickness**

0.015

Maximum brake disc runout (installed)

* When the discard thickness has been reached, install a new brake disc and brake pads.

** When the discard thickness has been reached, install new brake pads.

Rear Disc Brake Specification

mm

Description

302

Brake disc diameter

11

New brake disc nominal thickness

9

Worn brake disc discard thickness *

0.025

Maximum brake disc thickness variation

1.5

Worn brake pad discard thickness **

0.1

Maximum brake disc runout (installed)

* When the discard thickness has been reached, install a new brake disc and brake pads.

** When the discard thickness has been reached, install new brake pads.

G1001201en2008.50 Kuga8/2011

206-00- 2

Brake System - General Information

206-00- 2

SPECIFICATIONS

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1339 of 2057

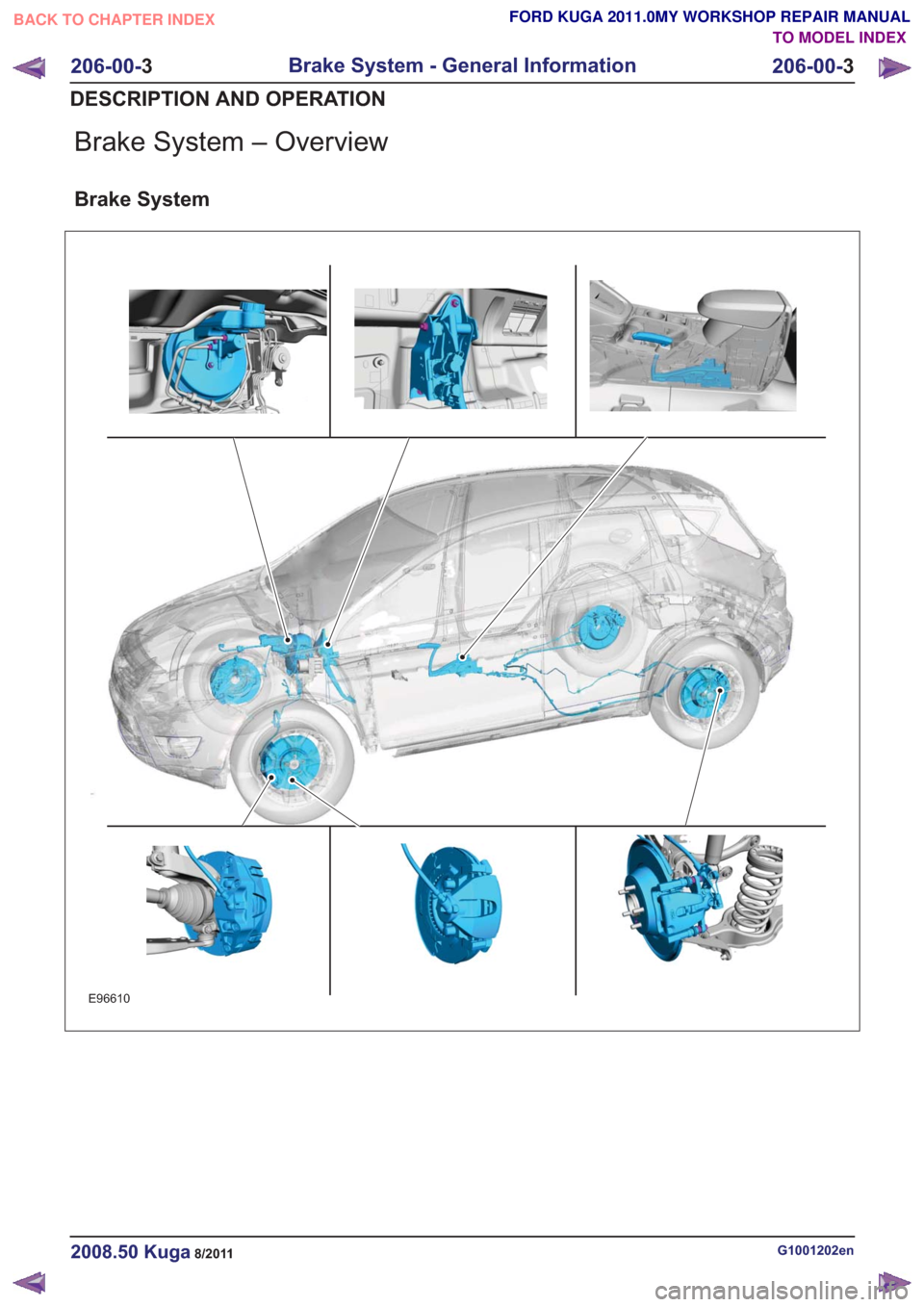

Brake System – Overview

Brake System

E96610

G1001202en2008.50 Kuga8/2011

206-00-3

Brake System - General Information

206-00- 3

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1340 of 2057

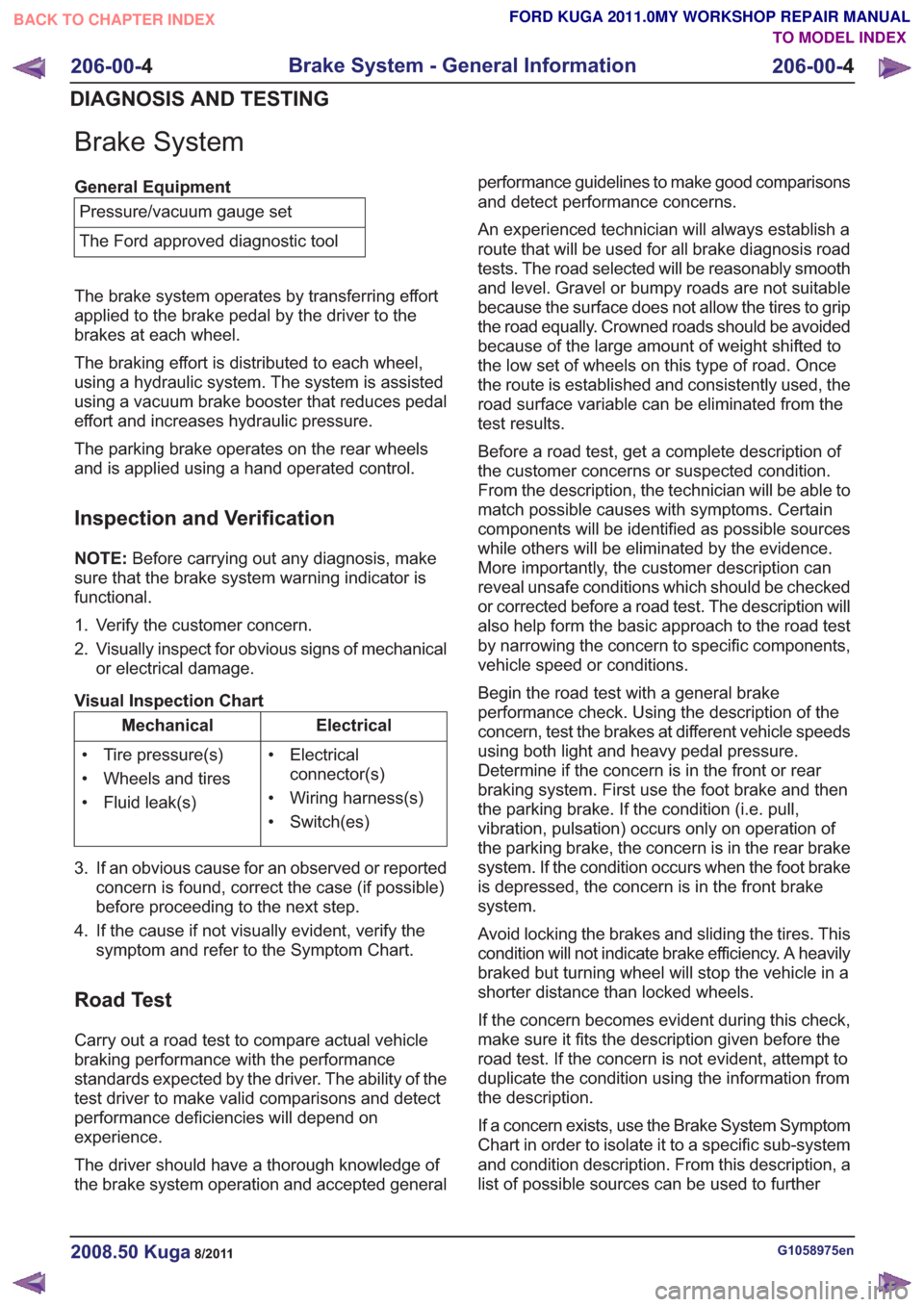

Brake System

General EquipmentPressure/vacuum gauge set

The Ford approved diagnostic tool

The brake system operates by transferring effort

applied to the brake pedal by the driver to the

brakes at each wheel.

The braking effort is distributed to each wheel,

using a hydraulic system. The system is assisted

using a vacuum brake booster that reduces pedal

effort and increases hydraulic pressure.

The parking brake operates on the rear wheels

and is applied using a hand operated control.

Inspection and Verification

NOTE: Before carrying out any diagnosis, make

sure that the brake system warning indicator is

functional.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection Chart

Electrical

Mechanical

• Electricalconnector(s)

• Wiring harness(s)

• Switch(es)

• Tire pressure(s)

• Wheels and tires

• Fluid leak(s)

3. If an obvious cause for an observed or reported concern is found, correct the case (if possible)

before proceeding to the next step.

4. If the cause if not visually evident, verify the symptom and refer to the Symptom Chart.

Road Test

Carry out a road test to compare actual vehicle

braking performance with the performance

standards expected by the driver. The ability of the

test driver to make valid comparisons and detect

performance deficiencies will depend on

experience.

The driver should have a thorough knowledge of

the brake system operation and accepted general performance guidelines to make good comparisons

and detect performance concerns.

An experienced technician will always establish a

route that will be used for all brake diagnosis road

tests. The road selected will be reasonably smooth

and level. Gravel or bumpy roads are not suitable

because the surface does not allow the tires to grip

the road equally. Crowned roads should be avoided

because of the large amount of weight shifted to

the low set of wheels on this type of road. Once

the route is established and consistently used, the

road surface variable can be eliminated from the

test results.

Before a road test, get a complete description of

the customer concerns or suspected condition.

From the description, the technician will be able to

match possible causes with symptoms. Certain

components will be identified as possible sources

while others will be eliminated by the evidence.

More importantly, the customer description can

reveal unsafe conditions which should be checked

or corrected before a road test. The description will

also help form the basic approach to the road test

by narrowing the concern to specific components,

vehicle speed or conditions.

Begin the road test with a general brake

performance check. Using the description of the

concern, test the brakes at different vehicle speeds

using both light and heavy pedal pressure.

Determine if the concern is in the front or rear

braking system. First use the foot brake and then

the parking brake. If the condition (i.e. pull,

vibration, pulsation) occurs only on operation of

the parking brake, the concern is in the rear brake

system. If the condition occurs when the foot brake

is depressed, the concern is in the front brake

system.

Avoid locking the brakes and sliding the tires. This

condition will not indicate brake efficiency. A heavily

braked but turning wheel will stop the vehicle in a

shorter distance than locked wheels.

If the concern becomes evident during this check,

make sure it fits the description given before the

road test. If the concern is not evident, attempt to

duplicate the condition using the information from

the description.

If a concern exists, use the Brake System Symptom

Chart in order to isolate it to a specific sub-system

and condition description. From this description, a

list of possible sources can be used to further

G1058975en2008.50 Kuga8/2011

206-00-

4

Brake System - General Information

206-00- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL