ASSEMBLY FORD KUGA 2011 1.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1295 of 2057

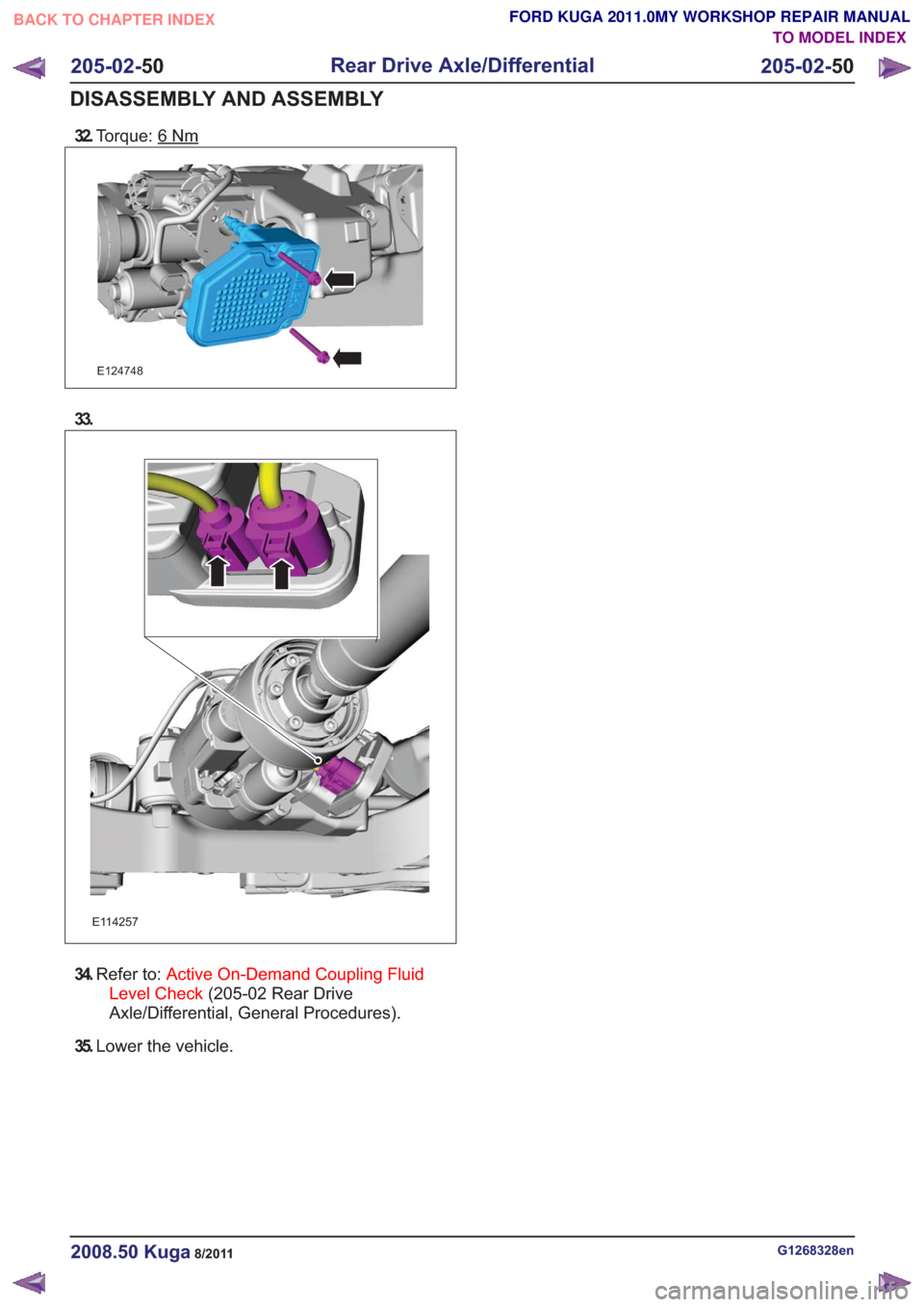

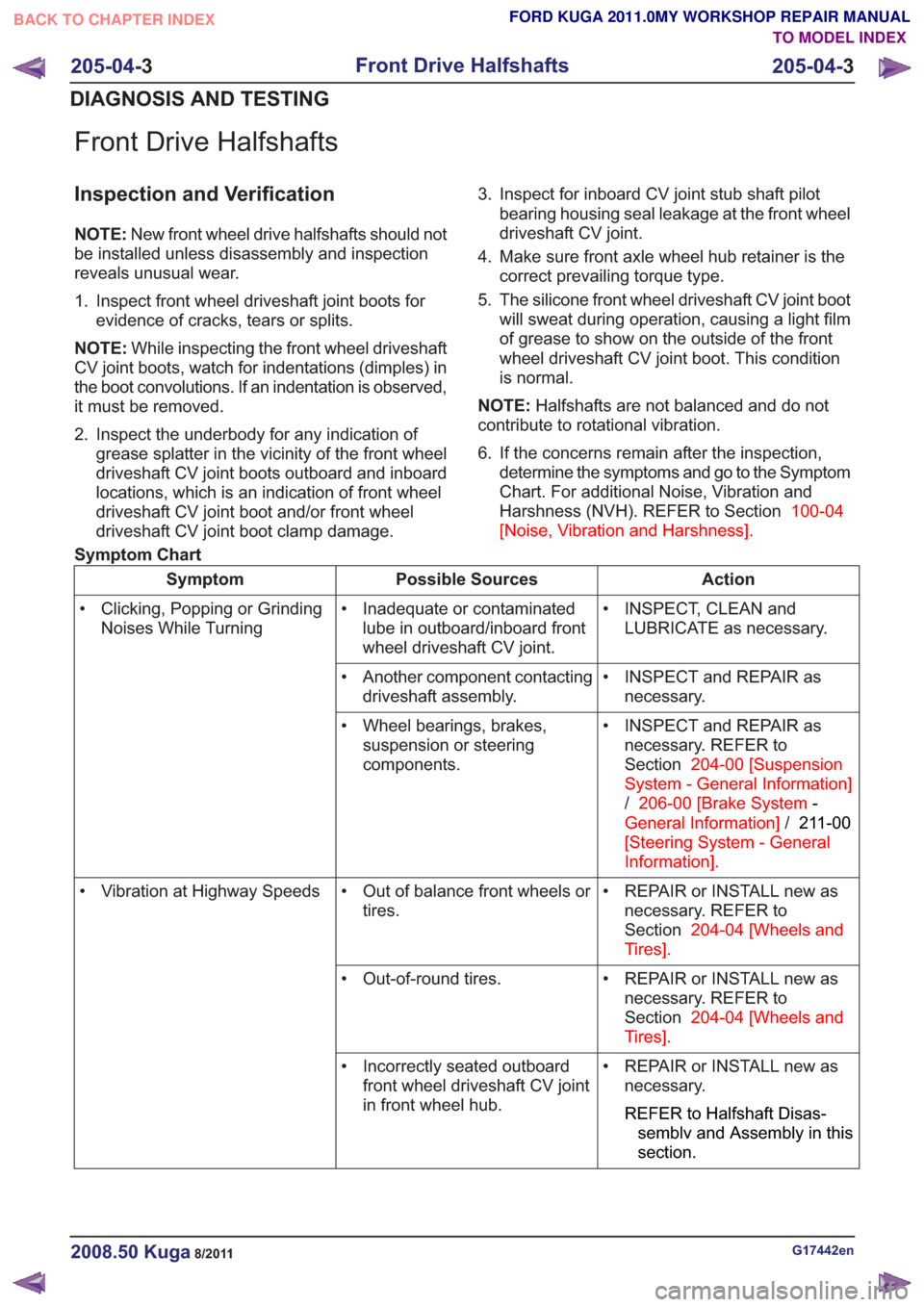

32.Torque: 6Nm

E124748

33.

E114257

34.Refer to: Active On-Demand Coupling Fluid

Level Check (205-02 Rear Drive

Axle/Differential, General Procedures).

35. Lower the vehicle.

G1268328en2008.50 Kuga8/2011

205-02- 50

Rear Drive Axle/Differential

205-02- 50

DISASSEMBLY AND ASSEMBLY

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1298 of 2057

Front Drive Halfshafts

Inspection and Verification

NOTE:New front wheel drive halfshafts should not

be installed unless disassembly and inspection

reveals unusual wear.

1. Inspect front wheel driveshaft joint boots for evidence of cracks, tears or splits.

NOTE: While inspecting the front wheel driveshaft

CV joint boots, watch for indentations (dimples) in

the boot convolutions. If an indentation is observed,

it must be removed.

2. Inspect the underbody for any indication of grease splatter in the vicinity of the front wheel

driveshaft CV joint boots outboard and inboard

locations, which is an indication of front wheel

driveshaft CV joint boot and/or front wheel

driveshaft CV joint boot clamp damage. 3. Inspect for inboard CV joint stub shaft pilot

bearing housing seal leakage at the front wheel

driveshaft CV joint.

4. Make sure front axle wheel hub retainer is the correct prevailing torque type.

5. The silicone front wheel driveshaft CV joint boot will sweat during operation, causing a light film

of grease to show on the outside of the front

wheel driveshaft CV joint boot. This condition

is normal.

NOTE: Halfshafts are not balanced and do not

contribute to rotational vibration.

6. If the concerns remain after the inspection, determine the symptoms and go to the Symptom

Chart. For additional Noise, Vibration and

Harshness (NVH). REFER to Section 100-04

[Noise, Vibration and Harshness] .

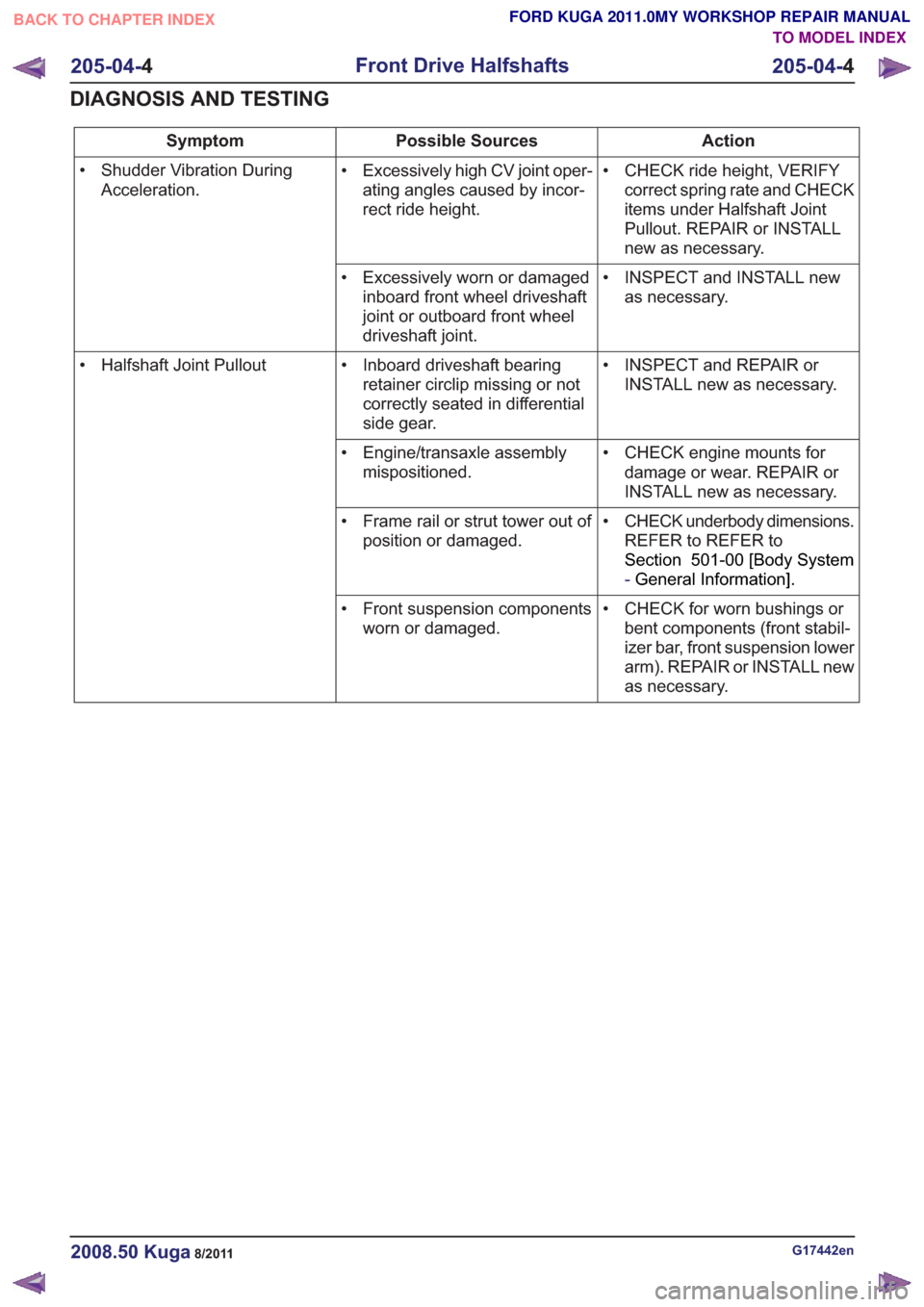

Symptom Chart

Action

Possible Sources

Symptom

• INSPECT, CLEAN andLUBRICATE as necessary.

• Inadequate or contaminated

lube in outboard/inboard front

wheel driveshaft CV joint.

• Clicking, Popping or Grinding

Noises While Turning

• INSPECT and REPAIR asnecessary.

• Another component contacting

driveshaft assembly.

• INSPECT and REPAIR asnecessary. REFER to

Section 204-00 [Suspension

System - General Information]

/ 206-00 [Brake System -

General Information] /211-00

[Steering System - General

Information] .

• Wheel bearings, brakes,

suspension or steering

components.

• REPAIR or INSTALL new asnecessary. REFER to

Section 204-04 [Wheels and

Tires] .

• Out of balance front wheels or

tires.

• Vibration at Highway Speeds

• REPAIR or INSTALL new asnecessary. REFER to

Section 204-04 [Wheels and

Tires] .

• Out-of-round tires.

• REPAIR or INSTALL new asnecessary.

REFER to Halfshaft Disas-

semblv and Assembly in this

section.

• Incorrectly seated outboard

front wheel driveshaft CV joint

in front wheel hub.

G17442en2008.50 Kuga8/2011

205-04- 3

Front Drive Halfshafts

205-04- 3

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1299 of 2057

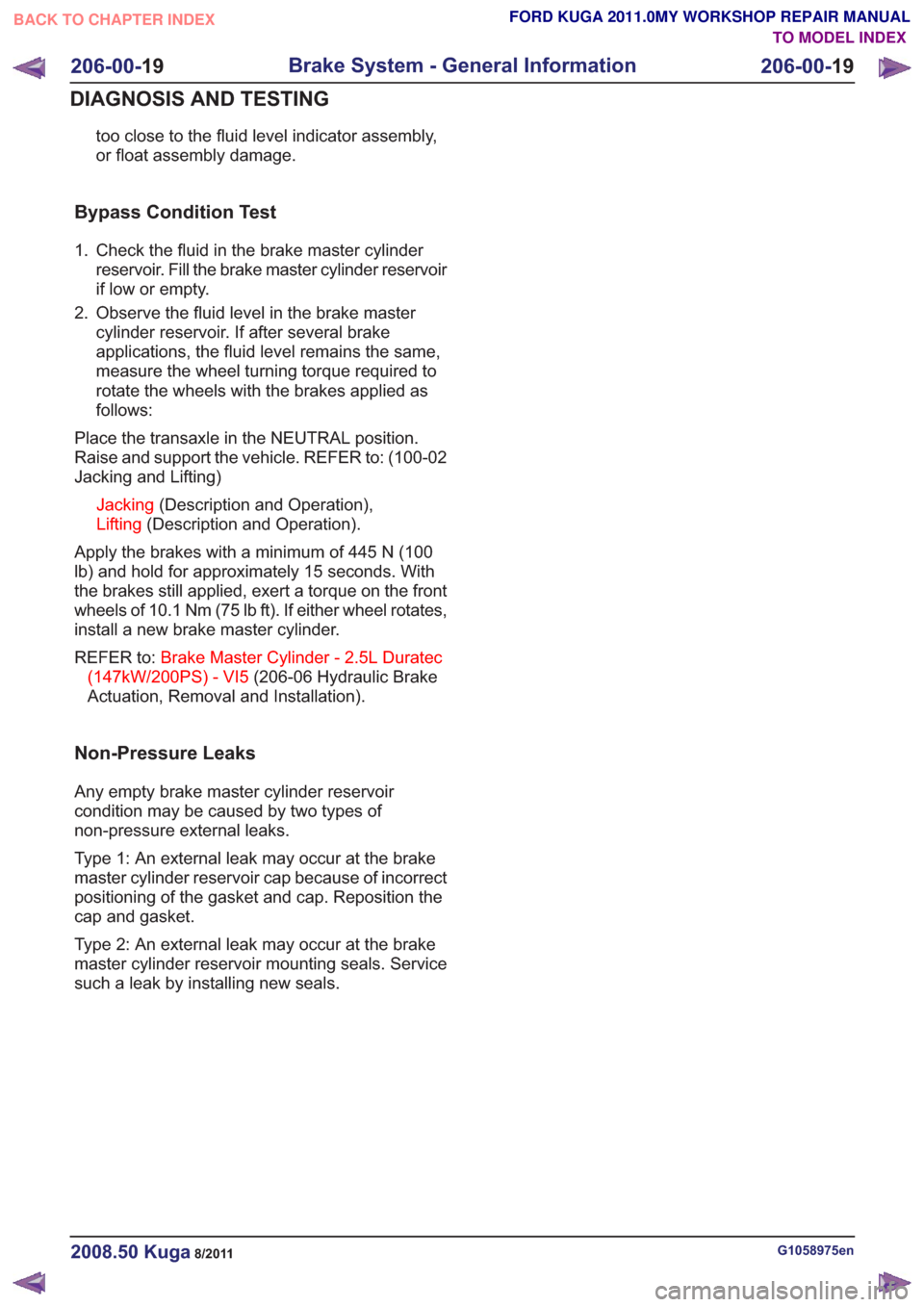

Action

Possible Sources

Symptom

• CHECK ride height, VERIFYcorrect spring rate and CHECK

items under Halfshaft Joint

Pullout. REPAIR or INSTALL

new as necessary.

• Excessively high CV joint oper-

ating angles caused by incor-

rect ride height.

• Shudder Vibration During

Acceleration.

• INSPECT and INSTALL newas necessary.

• Excessively worn or damaged

inboard front wheel driveshaft

joint or outboard front wheel

driveshaft joint.

• INSPECT and REPAIR orINSTALL new as necessary.

• Inboard driveshaft bearing

retainer circlip missing or not

correctly seated in differential

side gear.

• Halfshaft Joint Pullout

• CHECK engine mounts fordamage or wear. REPAIR or

INSTALL new as necessary.

• Engine/transaxle assembly

mispositioned.

• CHECK underbody dimensions.REFER to REFER to

Section 501-00 [Body System

-General Information] .

• Frame rail or strut tower out of

position or damaged.

• CHECK for worn bushings orbent components (front stabil-

izer bar, front suspension lower

arm). REPAIR or INSTALL new

as necessary.

• Front suspension components

worn or damaged.

G17442en2008.50 Kuga8/2011

205-04- 4

Front Drive Halfshafts

205-04- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1355 of 2057

too close to the fluid level indicator assembly,

or float assembly damage.

Bypass Condition Test

1. Check the fluid in the brake master cylinderreservoir. Fill the brake master cylinder reservoir

if low or empty.

2. Observe the fluid level in the brake master cylinder reservoir. If after several brake

applications, the fluid level remains the same,

measure the wheel turning torque required to

rotate the wheels with the brakes applied as

follows:

Place the transaxle in the NEUTRAL position.

Raise and support the vehicle. REFER to: (100-02

Jacking and Lifting) Jacking (Description and Operation),

Lifting (Description and Operation).

Apply the brakes with a minimum of 445 N (100

lb) and hold for approximately 15 seconds. With

the brakes still applied, exert a torque on the front

wheels of 10.1 Nm (75 lb ft). If either wheel rotates,

install a new brake master cylinder.

REFER to: Brake Master Cylinder - 2.5L Duratec

(147kW/200PS) - VI5 (206-06 Hydraulic Brake

Actuation, Removal and Installation).

Non-Pressure Leaks

Any empty brake master cylinder reservoir

condition may be caused by two types of

non-pressure external leaks.

Type 1: An external leak may occur at the brake

master cylinder reservoir cap because of incorrect

positioning of the gasket and cap. Reposition the

cap and gasket.

Type 2: An external leak may occur at the brake

master cylinder reservoir mounting seals. Service

such a leak by installing new seals.

G1058975en2008.50 Kuga8/2011

206-00- 19

Brake System - General Information

206-00- 19

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1391 of 2057

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

B4: CHECK REAR PARKING BRAKE CABLES

1 Disconnect the parking brake at the rear brakes,

one at a time.

– Rotate the wheel affected by the disconnected parking brake.

• Did the wheel turn freely?

zYe s INSTALL a new parking brake control lever

on the rear drum brakes or caliper assembly

on rear disc brakes.

REFER to: Parking Brake Control (206-05

Parking Brake and Actuation, Removal and

Installation)

/ Brake Caliper (206-04 Rear Disc Brake,

Removal and Installation).

TEST the system for normal operation.

zNo

REFER to: Brake System (206-00 Brake

System - General Information, Diagnosis

and Testing).

G1063696en2008.50 Kuga8/2011

206-05- 8

Parking Brake and Actuation

206-05- 8

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1422 of 2057

Description

Item

Front wheel sensor, right-hand side

8Description

Item

9 ESP switch

Testing the brakes on a roller dynamometer

- 4X4 vehicles only

On 4X4 vehicles a brake test on a roller

dynamometer must only be performed under the

following conditions.

• The brake test must not exceed a duration of 1 minute.

• Ignition key in position 0.

• The roller speed must not exceed 5 km/h.

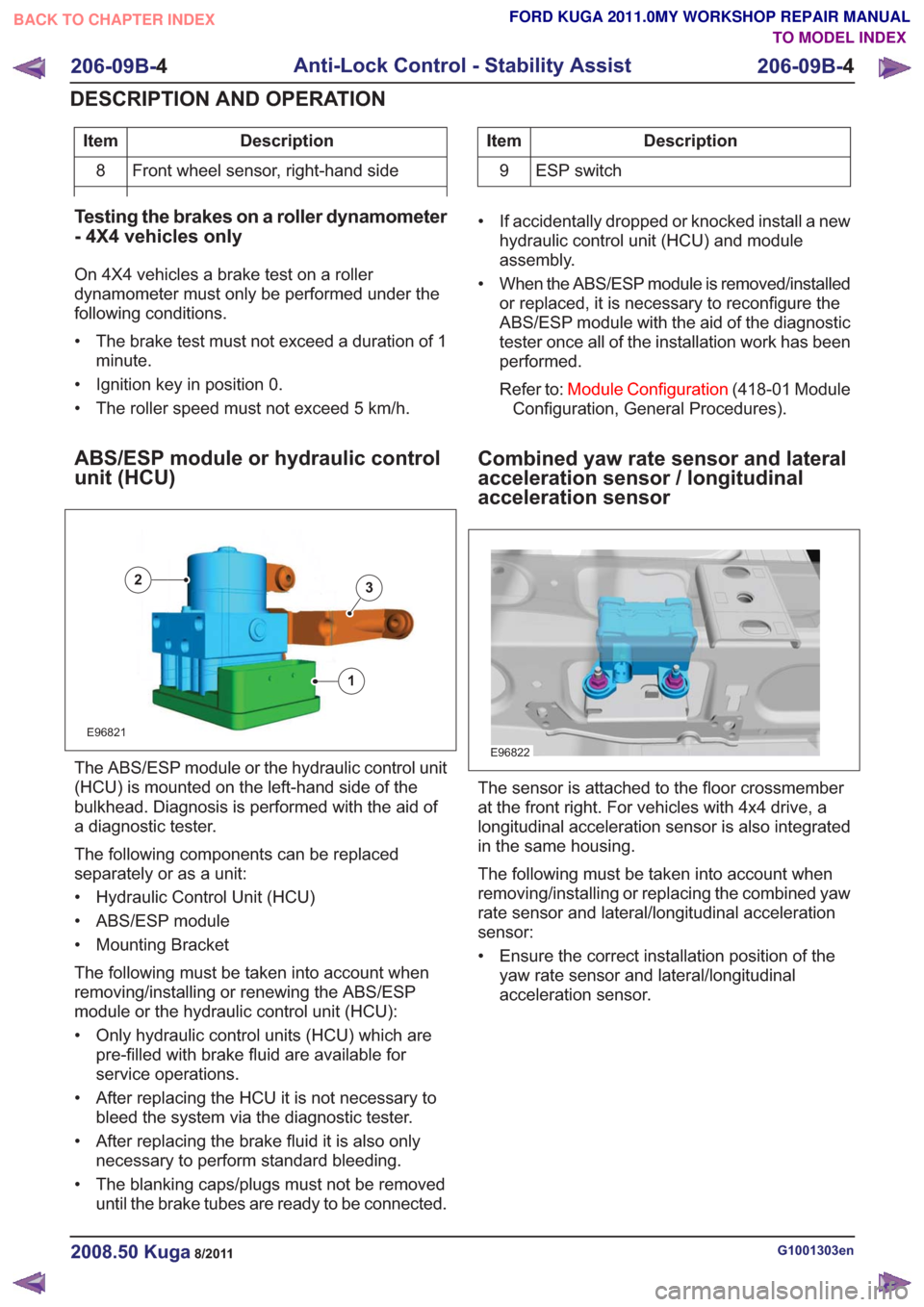

ABS/ESP module or hydraulic control

unit (HCU)

E96821

1

23

The ABS/ESP module or the hydraulic control unit

(HCU) is mounted on the left-hand side of the

bulkhead. Diagnosis is performed with the aid of

a diagnostic tester.

The following components can be replaced

separately or as a unit:

• Hydraulic Control Unit (HCU)

• ABS/ESP module

• Mounting Bracket

The following must be taken into account when

removing/installing or renewing the ABS/ESP

module or the hydraulic control unit (HCU):

• Only hydraulic control units (HCU) which are pre-filled with brake fluid are available for

service operations.

• After replacing the HCU it is not necessary to bleed the system via the diagnostic tester.

• After replacing the brake fluid it is also only necessary to perform standard bleeding.

• The blanking caps/plugs must not be removed until the brake tubes are ready to be connected. • If accidentally dropped or knocked install a new

hydraulic control unit (HCU) and module

assembly.

• When the ABS/ESP module is removed/installed or replaced, it is necessary to reconfigure the

ABS/ESP module with the aid of the diagnostic

tester once all of the installation work has been

performed.

Refer to: Module Configuration (418-01 Module

Configuration, General Procedures).

Combined yaw rate sensor and lateral

acceleration sensor / longitudinal

acceleration sensor

E96822

The sensor is attached to the floor crossmember

at the front right. For vehicles with 4x4 drive, a

longitudinal acceleration sensor is also integrated

in the same housing.

The following must be taken into account when

removing/installing or replacing the combined yaw

rate sensor and lateral/longitudinal acceleration

sensor:

• Ensure the correct installation position of the yaw rate sensor and lateral/longitudinal

acceleration sensor.

G1001303en2008.50 Kuga8/2011

206-09B- 4

Anti-Lock Control - Stability Assist

206-09B- 4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1458 of 2057

SECTION 211-02 Power Steering

VEHICLE APPLICATION:2008.50 Kuga

PA G E

CONTENTS

DESCRIPTION AND OPERATION

211-02-2

Power Steering (Component Location) ........................................................................\

......

211-02-3

Power Steering (Overview) ........................................................................\

.........................

211-02-3

Power Steering ........................................................................\

...........................................

211-02-4

Steering gear ........................................................................\

..............................................

211-02-5

Electro-hydraulic power steering pump ........................................................................\

......

211-02-6

Pressure and return lines ........................................................................\

...........................

211-02-7

Power Steering (System Operation and Component Description) .....................................

211-02-7

System Diagram ........................................................................\

.........................................

211-02-8

System Operation ........................................................................\

.......................................

211-02-8

Electronic principle of operation ........................................................................\

..............

211-02-9

Hydraulic principle of operation ........................................................................\

..............

211-02-9

Component Description ........................................................................\

..............................

211-02-9

Electro-hydraulic power steering pump ........................................................................\

..

211-02-10

Integrated steering angle sensor - vehicles built up to 09/2009 .....................................

211-02-11

Brushless DC motor with integral power steering module..............................................

REMOVAL AND INSTALLATION

211-02-13

(13 443 0)

Power Steering Pressure Line and Return Line Assembly — 2.5L Duratec

(147kW/200PS) - VI5 ........................................................................\

............

211-02-18

(13 434 0)

Power Steering Pump — 2.5L Duratec (147kW/200PS) - VI5 .......................

211-02-21

(13 440 0;

13 443 0)

Power Steering Pump to Steering Gear Pressure Line — 2.5L Duratec

(147kW/200PS) - VI5 ........................................................................\

............

211-02-25

(13 116 0)

Steering Gear ........................................................................\

.........................

211-02-36

(13 439 0)

Steering Gear to Power Steering Fluid Reservoir Return Line — 2.5L Duratec

(147kW/200PS) - VI5 ........................................................................\

............

211-02-1

Power Steering

211-02- 1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1470 of 2057

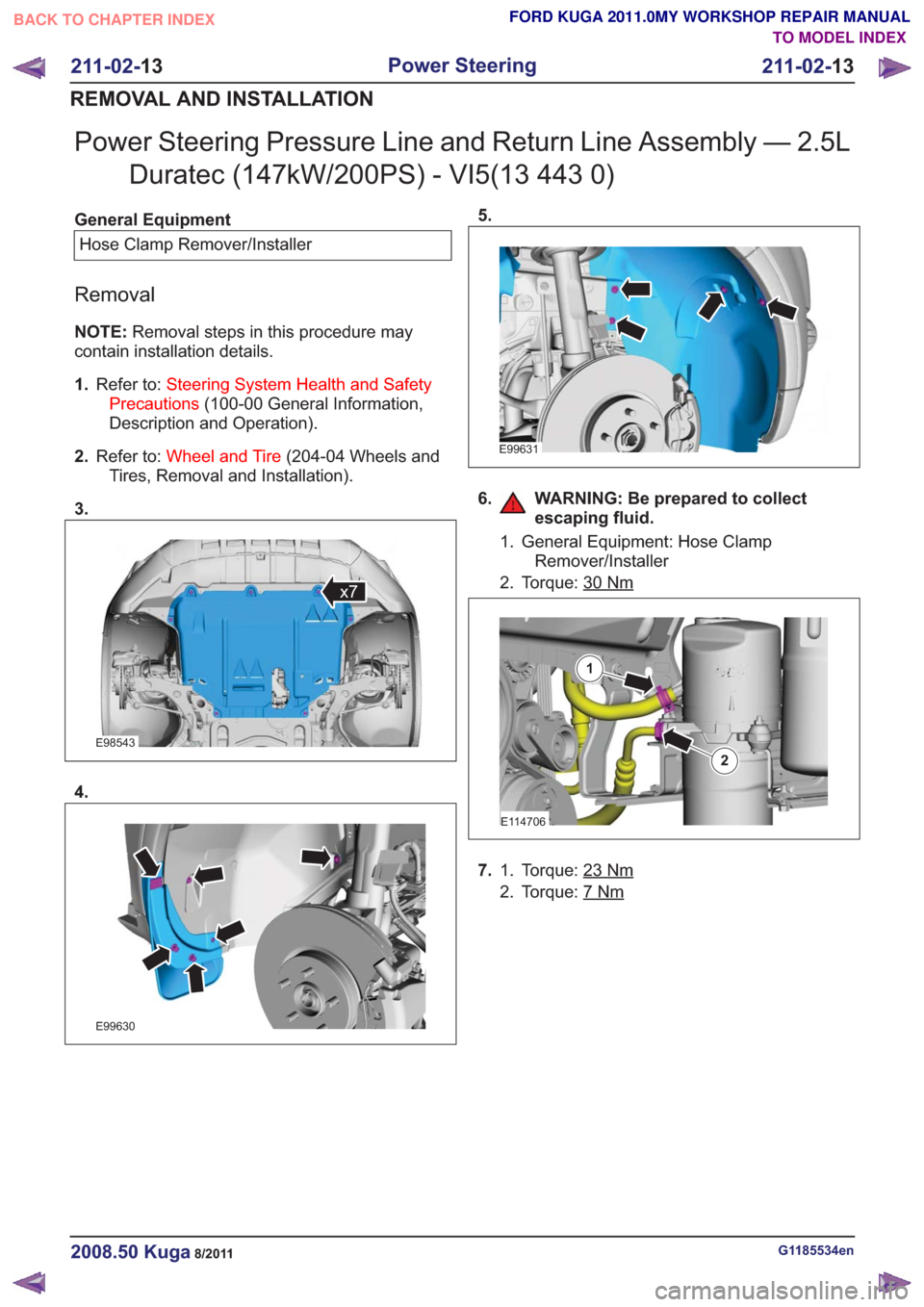

Power Steering Pressure Line and Return Line Assembly — 2.5LDuratec (147kW/200PS) - VI5(13 443 0)

General Equipment

Hose Clamp Remover/Installer

Removal

NOTE: Removal steps in this procedure may

contain installation details.

1. Refer to: Steering System Health and Safety

Precautions (100-00 General Information,

Description and Operation).

2. Refer to: Wheel and Tire (204-04 Wheels and

Tires, Removal and Installation).

3.

E98543

x7

4.

E99630

5.

E99631

6. WARNING: Be prepared to collect escaping fluid.

1. General Equipment: Hose ClampRemover/Installer

2. Torque: 30

Nm

E114706

1

2

7. Torque: 23Nm1.

2. Torque: 7

Nm

G1185534en2008.50 Kuga8/2011

211-02- 13

Power Steering

211-02- 13

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1535 of 2057

DISASSEMBLY303-01-84

(21 134 8)

Engine ........................................................................\

....................................

DISASSEMBLY AND ASSEMBLY OF SUBASSEMBLIES 303-01-93

(21 165 6)

Cylinder Head ........................................................................\

.........................

ASSEMBLY 303-01-94

(21 134 8)

Engine ........................................................................\

....................................

INSTALLATION 303-01-112

(21 139 4)

Engine Accessories ........................................................................\

................

303-01-119

(21 132 0;

21 132 6;

21 132 7)

Engine — Vehicles With: 5-Speed Automatic Transaxle (AW55)

...................

303-01-2

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

2

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

PAGE 2 OF 2 FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1549 of 2057

Engine – System Operation and Component Description

System Operation

The variable camshaft timing occurs

electro-hydraulically and individually for both

camshafts.

The camshaft adjusters work according to the vane

cell principle and have an adjustment range of 52°

crank angle on the intake side and 47° crank angle

on the exhaust side. On starting the engine and

during idling, both camshafts are mechanically

locked in their starting positions. The exhaust

camshaft is in the early position and the intake

camshaft is in the late position. The camshaftadjuster on the exhaust side has a torsion spring

which compensates the camshaft drive torque.

This ensures that the assembly can return to the

starting position under all operating conditions and

when the engine is turned off.

Internal exhaust gas recirculation can be realized

through continuous adjustment of the timings. This

results in better fuel consumption and more

favorable combustion temperatures which produce

less pollutants. This means that pollutant level IV

can be adhered to with a 3-way catalytic converter.

The variable timings also make it possible to

optimize performance with wide open throttle.

G1032416en2008.50 Kuga8/2011

303-01-

16

Engine— 2.5L Duratec (147kW/200PS) - VI5303-01-

16

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL