bus FORD KUGA 2011 1.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1299 of 2057

Action

Possible Sources

Symptom

• CHECK ride height, VERIFYcorrect spring rate and CHECK

items under Halfshaft Joint

Pullout. REPAIR or INSTALL

new as necessary.

• Excessively high CV joint oper-

ating angles caused by incor-

rect ride height.

• Shudder Vibration During

Acceleration.

• INSPECT and INSTALL newas necessary.

• Excessively worn or damaged

inboard front wheel driveshaft

joint or outboard front wheel

driveshaft joint.

• INSPECT and REPAIR orINSTALL new as necessary.

• Inboard driveshaft bearing

retainer circlip missing or not

correctly seated in differential

side gear.

• Halfshaft Joint Pullout

• CHECK engine mounts fordamage or wear. REPAIR or

INSTALL new as necessary.

• Engine/transaxle assembly

mispositioned.

• CHECK underbody dimensions.REFER to REFER to

Section 501-00 [Body System

-General Information] .

• Frame rail or strut tower out of

position or damaged.

• CHECK for worn bushings orbent components (front stabil-

izer bar, front suspension lower

arm). REPAIR or INSTALL new

as necessary.

• Front suspension components

worn or damaged.

G17442en2008.50 Kuga8/2011

205-04- 4

Front Drive Halfshafts

205-04- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1322 of 2057

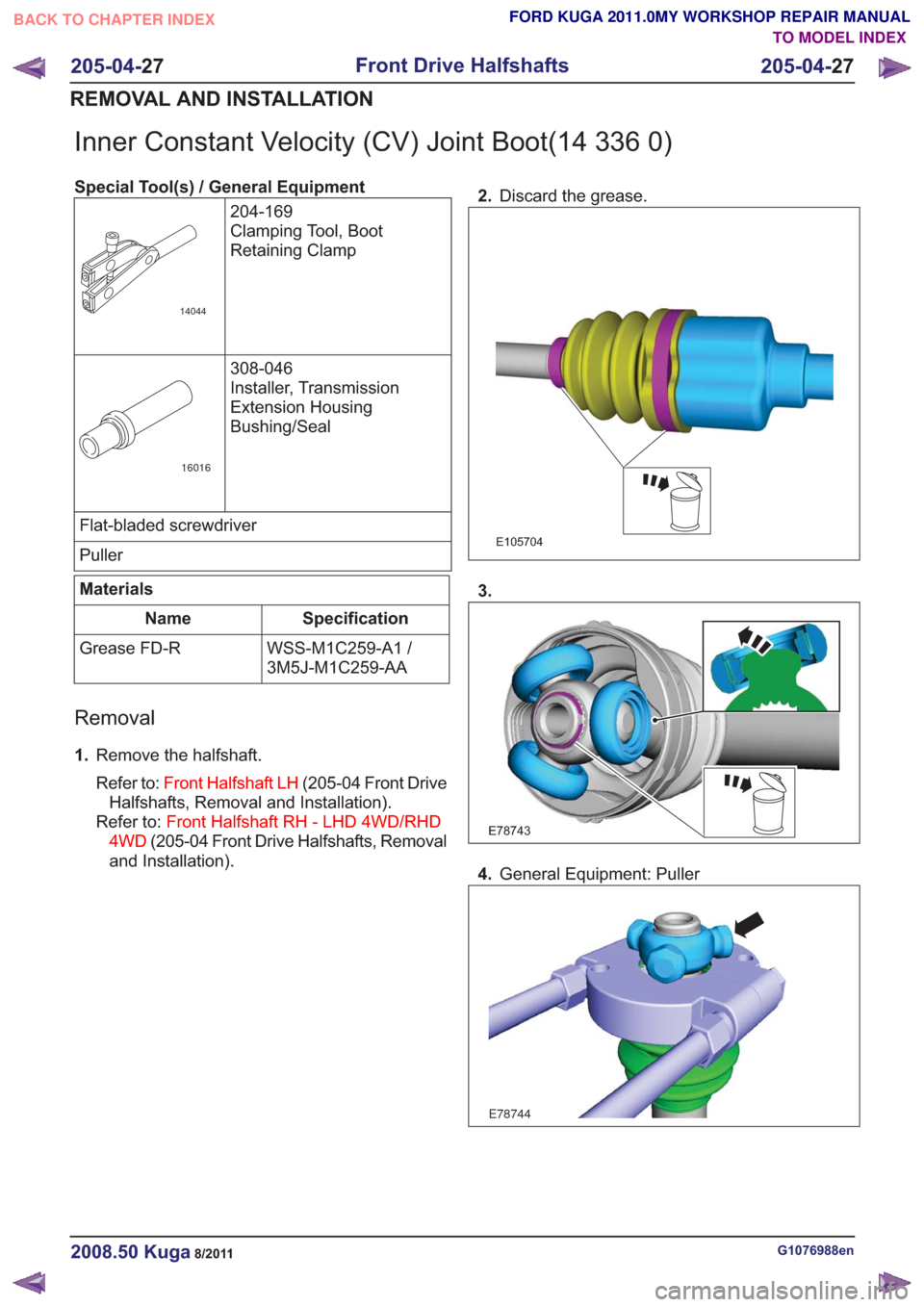

Inner Constant Velocity (CV) Joint Boot(14 336 0)

Special Tool(s) / General Equipment204-169

Clamping Tool, Boot

Retaining Clamp

14044

308-046

Installer, Transmission

Extension Housing

Bushing/Seal

16016

Flat-bladed screwdriver

Puller

Materials

Specification

Name

WSS-M1C259-A1 /

3M5J-M1C259-AA

Grease FD-R

Removal

1.

Remove the halfshaft.

Refer to: Front Halfshaft LH (205-04 Front Drive

Halfshafts, Removal and Installation).

Refer to: Front Halfshaft RH - LHD 4WD/RHD

4WD (205-04 Front Drive Halfshafts, Removal

and Installation). 2.

Discard the grease.

E105704

3.

E78743

4.General Equipment: Puller

E78744

G1076988en2008.50 Kuga8/2011

205-04- 27

Front Drive Halfshafts

205-04- 27

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1350 of 2057

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

D2: CHECK THE BRAKE BOOSTER FOR LEAKS

1 Run the engine at approximately 1000 rpm,

release the accelerator pedal and turn the

engine off. Wait 90 seconds and apply the

brakes. Two or more brake applications should

be power assisted.

• Does the brake booster work?

zYe s VERIFY the customer concern.

zNoGO to D4 .

D3: CHECK THE BRAKE PEDAL LINKAGE

1 Disconnect the actuator rod from the pedal pin

and fully depress the brake pedal.

• Did the pedal move freely?

zYe s VERIFY the customer concern.

zNoINSTALL new brake pedal bushings. TEST

the system for normal operation.

D4: CHECK THE BRAKE BOOSTER CHECK VALVE

1 Disconnect the brake booster check valve

vacuum hose at the manifold.

2Blow into the hose attached to the brake booster

check valve.

• Does air pass through the valve?

zYe s INSTALL a new brake booster check valve.

TEST the system for normal operation.

zNoGO to D5 .

D5: CHECK THE BRAKE BOOSTER CHECK VALVE VACUUM

1 Run the engine at idle.

G1058975en2008.50 Kuga8/2011

206-00-

14

Brake System - General Information

206-00- 14

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1353 of 2057

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

F2: CHECK FOR BRAKE PEDAL BINDING

1 Check the brake pedal for free operation.

• Did the brake pedal operate freely?

zYe s INSTALL a new brake booster. TEST the

system for normal operation.

zNoINSTALL new brake pedal bushings. TEST

the system for normal operation.

Component Tests

Hydraulic Leak Check

NOTE: There is a common clutch and brake fluid

reservoir, therefore it is possible that a clutch leak

can lead to reduction in the reservoir level.

It is possible that all evidence of fluid leakage may

have washed off if the vehicle has been operated

in rain or snow, as brake fluid is water-soluble.

Refill the system, bleed then apply the brakes

several times. Examine the system to verify that

the reservoir fluid level is actually dropping. Locate

and repair the external leak. If the fluid level drops

and no external leak can be found, check for a

brake master cylinder bore end seal leak.

Brake System Check

Brake Pedal Reserve Check

Where a low brake pedal or the feel of a

bottomed-out condition exists, check for brake

pedal reserve.

1. Operate the engine at idle with the transaxle in the NEUTRAL position.

2. Apply the brake pedal lightly three or four times.

3. Allow 15 seconds for the vacuum to replenish the brake booster.

NOTE: This increased resistance may feel like

something has bottomed out.

4. Apply the brake pedal until it stops moving downward or an increased resistance to the

pedal travel occurs. 5. Hold the brake pedal in the applied position and

raise the engine speed to approximately 2000

rpm.

NOTE: The additional movement of the brake pedal

is the result of the increased engine manifold

vacuum which exerts more force on the brake

booster during engine rundown. This means that

additional stroke is available in the brake master

cylinder and the brake system is not bottoming out.

6. Release the accelerator pedal and observe that the brake pedal moves downward as the engine

returns to idle speed.

Brake Booster Functional Test

Inspect all hoses and connections. All unused

vacuum connectors should be capped. Hoses and

their connections should be correctly secured and

in good condition with no holes and no collapsed

areas. Inspect the check valve on the brake booster

for damage.

Brake Booster Operation Check

1. Check the hydraulic brake system for leaks orlow fluid.

2. With the transaxle in the NEUTRAL position, stop the engine and apply the parking brake.

Apply the brake pedal several times to exhaust

all the vacuum in the system.

3. With the engine turned off and the vacuum in the system exhausted, apply the brake pedal

and hold it down. Start the engine. If the vacuum

system is operating, the brake pedal will tend

to move downward under constant foot

pressure. If no motion is felt, the vacuum

booster system is not functioning.

G1058975en2008.50 Kuga8/2011

206-00- 17

Brake System - General Information

206-00- 17

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1429 of 2057

HCU to check for sudden actuation of the brakes.

With the brake pedal pressed, the ABS module

triggers emergency braking if the rate of increase

of hydraulic pressure exceeds the predetermined

limit.

If the brake pedal is pressed so hard that the ABS

becomes active on the front wheels then the ABS

control unit increases the pressure to the rear

wheel brakes up to the ABS intervention threshold.

EBA operation continues until the driver releases

the brake pedal sufficiently for the hydraulic

pressure in the HCU to drop below a threshold

value stored in the ABS module.

Trailer stability control:If the vehicle is ordered

with a trailer coupling then the Trailer Stability

Control function is integrated in the ESP. The ESP

detects snaking when driving with a trailer and

reduces the speed of the vehicle and trailer through

adapted braking and, if necessary, by also reducing

the engine output until the snaking movement of

the trailer is corrected.

Roll-over protection: The ESP dynamically

determines the tipping tendency of the vehicle and

works in conjunction with the EBA system to

prevent the vehicle from tipping over during

dynamic maneuvers like lane changing or while

negotiating bends.

Emergency brake light: The emergency brake

light automatically switches on the hazard flasher

system to warn drivers of other vehicles that

emergency braking is being initiated. Based on a

defined delay value, the ABS/ESP module sends

a signal to the generic electronic module (GEM)

via the CAN data bus. The GEM activates the

hazard flasher system, that then flashes 7 times.

Prerequisites for activation of the emergency brake

light are:

• The speed is higher than 50 km/h.

• The brake pedal is being actuated.

• The deceleration is greater than 9 m/s².

To prevent activation on snow or ice, for example,

the following prerequisites must be met:

• The speed is higher than 50 km/h.

• The brake pedal is being actuated.

• ABS regulation takes place.

• The deceleration is greater than 6 m/s².

Tire pressure monitoring system: The tire

pressure monitoring system used in the Kuga is

able to detect loss of air in a tire at an early stage

and warn the driver. Because it can only compare

the behaviour of the tyres with each other, it is not possible to draw conclusions about the absolute

tyre pressure. It is also not possible to monitor the

spare tyre pressure. In order for the system to

operate correctly, the tyre pressures must be

regularly checked and corrected and the system

subsequently initialised (see below).

The tire pressure monitoring system used here,

depending on the equipment level, is built into the

anti-lock braking system (ABS) as an extra function

and therefore does not have its own sensors.

The ABS module measures the loss of pressure

in the tyres by calculation using the wheel speed

sensors of the ABS system. If a tyre loses

pressure, its diameter decreases and the speed of

the wheel therefore increases. If the ABS module

detects such a loss in pressure, it sends a signal

to the instrument cluster via the CAN bus and a

warning message is displayed in the message

centre. The warning threshold depends among

other things on the dimension of the tyres being

used, the vehicle operating conditions and the

status at the last initialisation. Since neither the

absolute tyre pressure nor the position of the tyre

is known, the pressure of all the tyres must be

checked and the system re-initialised after a tyre

pressure warning. If necessary, the cause of the

loss of pressure must be investigated.

Regular tyre pressure checks are still necessary.

The system must be initialised after a tyre is

changed, winter or summer tyres fitted, the

pressures corrected or adjusted to suit the vehicle

load. This can be done by the driver using the

driver information system. For further information,

see: Owner’s Manual.

Component Description

Opto-electronic steering wheel rotation

sensor

E80158

G1001304en2008.50 Kuga8/2011

206-09B-

11

Anti-Lock Control - Stability Assist

206-09B- 11

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1433 of 2057

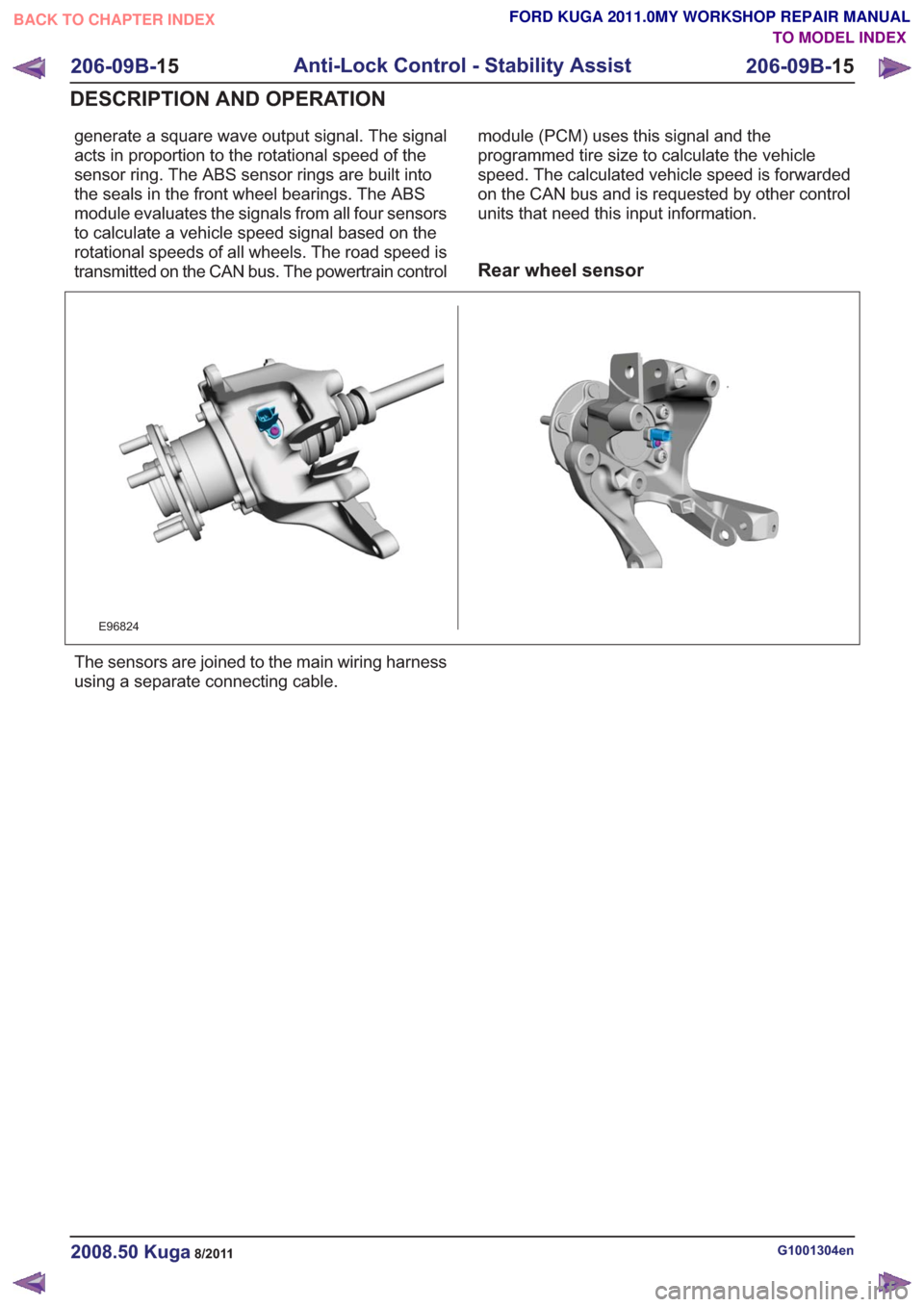

generate a square wave output signal. The signal

acts in proportion to the rotational speed of the

sensor ring. The ABS sensor rings are built into

the seals in the front wheel bearings. The ABS

module evaluates the signals from all four sensors

to calculate a vehicle speed signal based on the

rotational speeds of all wheels. The road speed is

transmitted on the CAN bus. The powertrain controlmodule (PCM) uses this signal and the

programmed tire size to calculate the vehicle

speed. The calculated vehicle speed is forwarded

on the CAN bus and is requested by other control

units that need this input information.

Rear wheel sensor

E96824

The sensors are joined to the main wiring harness

using a separate connecting cable.

G1001304en2008.50 Kuga8/2011

206-09B-

15

Anti-Lock Control - Stability Assist

206-09B- 15

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1461 of 2057

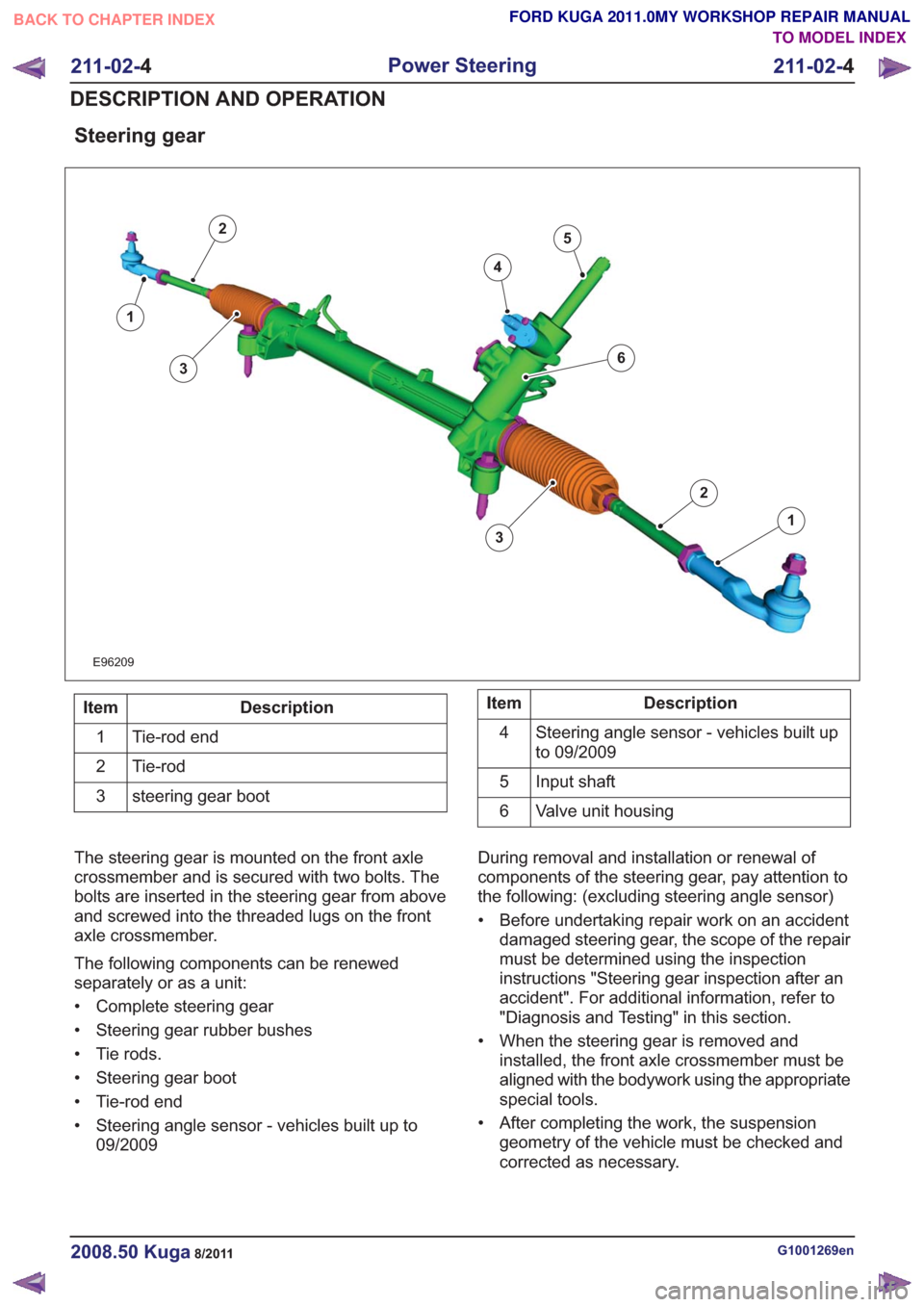

Steering gear

E96209

1

2

3

4

5

1

2

63

Description

Item

Tie-rod end

1

Tie-rod

2

steering gear boot

3Description

Item

Steering angle sensor - vehicles built up

to 09/2009

4

Input shaft

5

Valve unit housing

6

The steering gear is mounted on the front axle

crossmember and is secured with two bolts. The

bolts are inserted in the steering gear from above

and screwed into the threaded lugs on the front

axle crossmember.

The following components can be renewed

separately or as a unit:

• Complete steering gear

• Steering gear rubber bushes

• Tie rods.

• Steering gear boot

• Tie-rod end

• Steering angle sensor - vehicles built up to 09/2009 During removal and installation or renewal of

components of the steering gear, pay attention to

the following: (excluding steering angle sensor)

• Before undertaking repair work on an accident

damaged steering gear, the scope of the repair

must be determined using the inspection

instructions "Steering gear inspection after an

accident". For additional information, refer to

"Diagnosis and Testing" in this section.

• When the steering gear is removed and installed, the front axle crossmember must be

aligned with the bodywork using the appropriate

special tools.

• After completing the work, the suspension geometry of the vehicle must be checked and

corrected as necessary.

G1001269en2008.50 Kuga8/2011

211-02- 4

Power Steering

211-02- 4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1462 of 2057

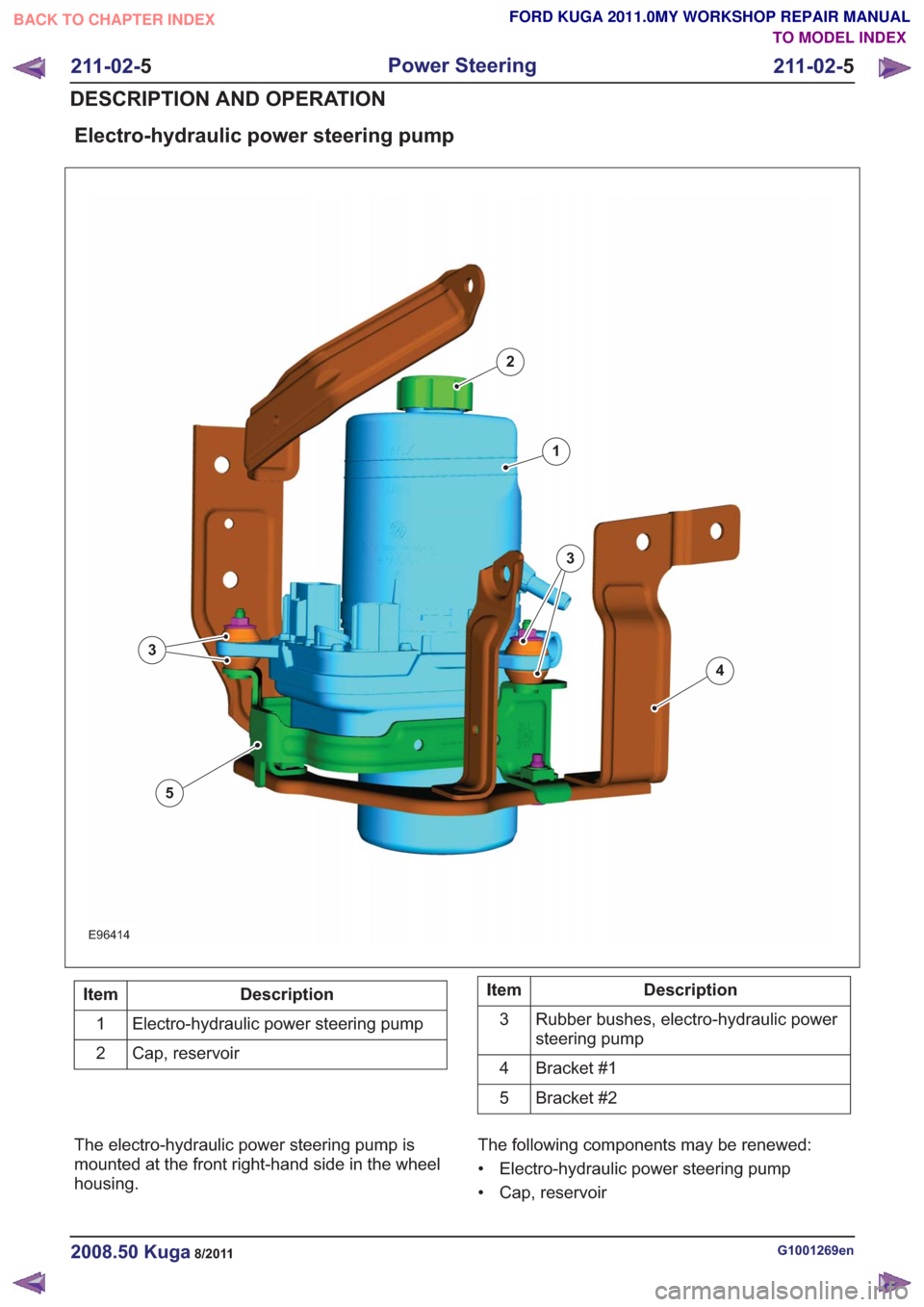

Electro-hydraulic power steering pump

E96414

1

2

3

4

5

3

Description

Item

Electro-hydraulic power steering pump

1

Cap, reservoir

2Description

Item

Rubber bushes, electro-hydraulic power

steering pump

3

Bracket #1

4

Bracket #2

5

The electro-hydraulic power steering pump is

mounted at the front right-hand side in the wheel

housing. The following components may be renewed:

• Electro-hydraulic power steering pump

• Cap, reservoir

G1001269en2008.50 Kuga8/2011

211-02-

5

Power Steering

211-02- 5

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1463 of 2057

• Rubber bushes, electro-hydraulic power steeringpump

• Bracket #1

• Bracket #2

During removal and installation or renewal of

components of the electro-hydraulic power steering

pump, pay attention to the following:

• Before starting work to renew the electro-hydraulic power steering pump, the

program code of the electro-hydraulic power steering must be read out using the diagnostic

unit and noted.

• After the work to renew the electro-hydraulic power steering pump is completed, the

electro-hydraulic power steering must be

reconfigured using the diagnostic unit. For

further information, see: Module Configuration

(418-01 Module Configuration, General

Procedures).

• The electro-hydraulic power steering pump must be filled and vented as specified.

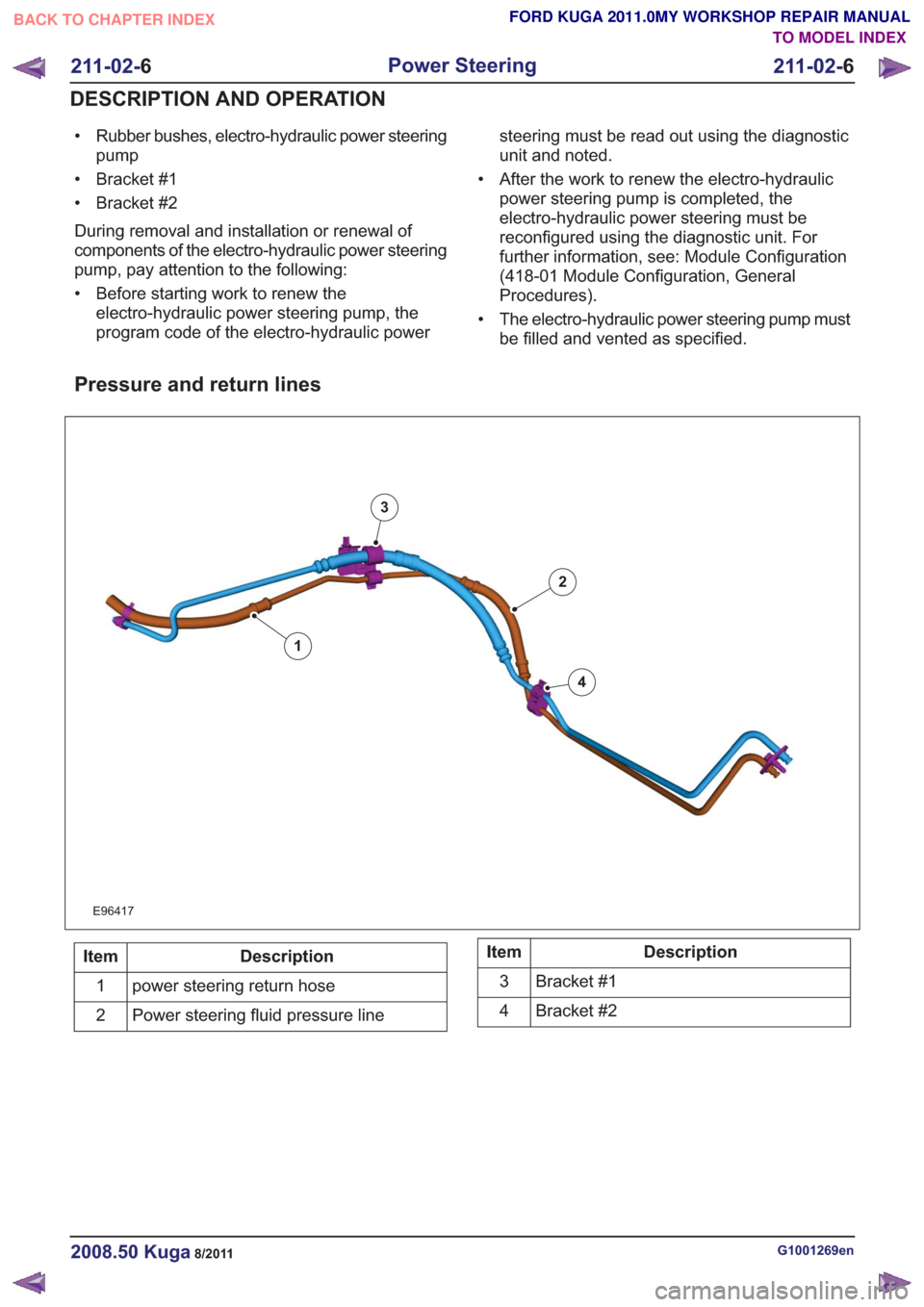

Pressure and return lines

E96417

1

2

3

4

Description

Item

power steering return hose

1

Power steering fluid pressure line

2Description

Item

Bracket #1

3

Bracket #2

4

G1001269en2008.50 Kuga8/2011

211-02- 6

Power Steering

211-02- 6

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1465 of 2057

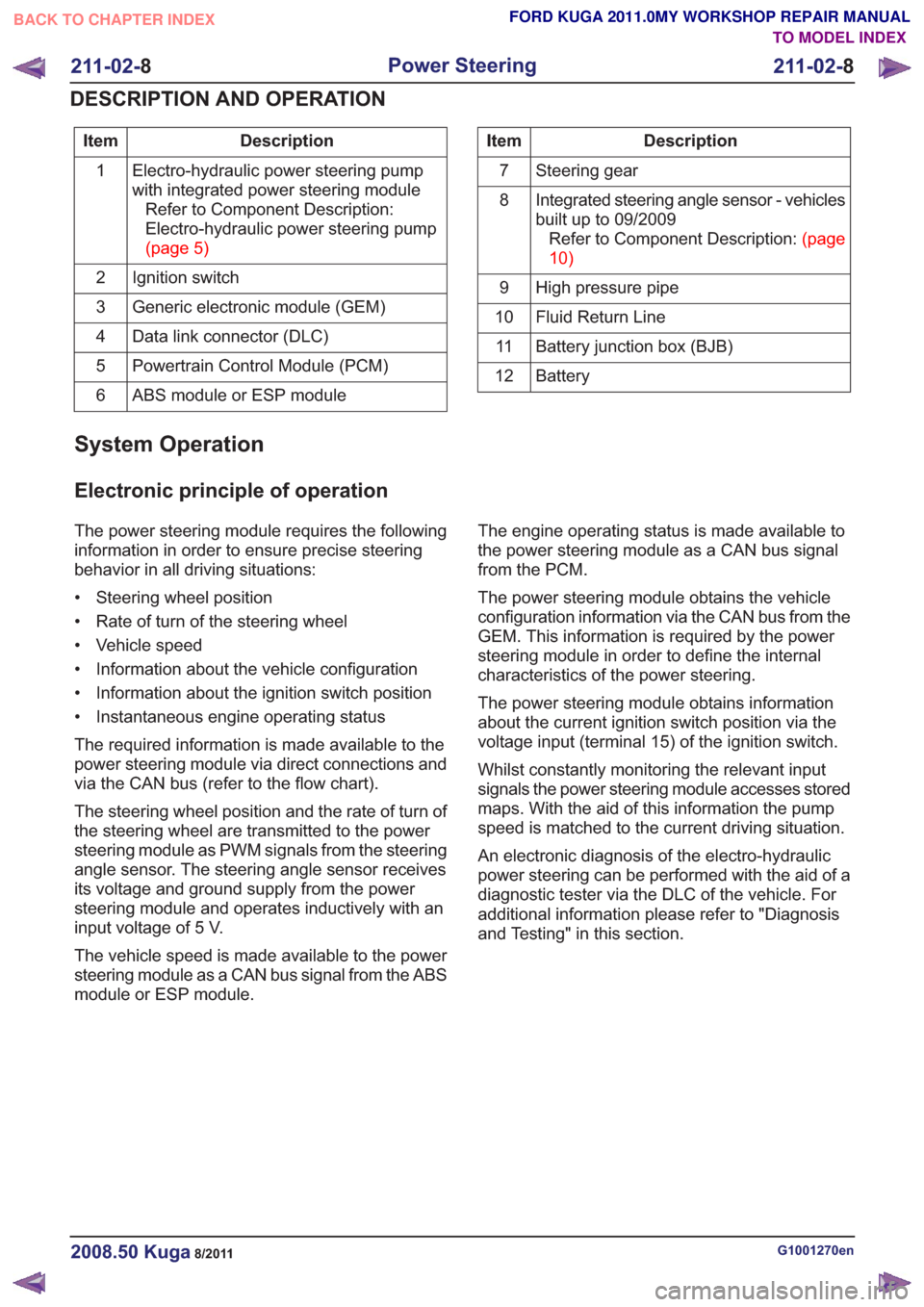

Description

Item

Electro-hydraulic power steering pump

with integrated power steering moduleRefer to Component Description:

Electro-hydraulic power steering pump

(page5)

1

Ignition switch

2

Generic electronic module (GEM)

3

Data link connector (DLC)

4

Powertrain Control Module (PCM)

5

ABS module or ESP module

6Description

Item

Steering gear

7

Integrated steering angle sensor - vehicles

built up to 09/2009RefertoComponentDescription:(page

10)

8

High pressure pipe

9

Fluid Return Line

10

Battery junction box (BJB)

11

Battery

12

System Operation

Electronic principle of operation

The power steering module requires the following

information in order to ensure precise steering

behavior in all driving situations:

• Steering wheel position

• Rate of turn of the steering wheel

• Vehicle speed

• Information about the vehicle configuration

• Information about the ignition switch position

• Instantaneous engine operating status

The required information is made available to the

power steering module via direct connections and

via the CAN bus (refer to the flow chart).

The steering wheel position and the rate of turn of

the steering wheel are transmitted to the power

steering module as PWM signals from the steering

angle sensor. The steering angle sensor receives

its voltage and ground supply from the power

steering module and operates inductively with an

input voltage of 5 V.

The vehicle speed is made available to the power

steering module as a CAN bus signal from the ABS

module or ESP module. The engine operating status is made available to

the power steering module as a CAN bus signal

from the PCM.

The power steering module obtains the vehicle

configuration information via the CAN bus from the

GEM. This information is required by the power

steering module in order to define the internal

characteristics of the power steering.

The power steering module obtains information

about the current ignition switch position via the

voltage input (terminal 15) of the ignition switch.

Whilst constantly monitoring the relevant input

signals the power steering module accesses stored

maps. With the aid of this information the pump

speed is matched to the current driving situation.

An electronic diagnosis of the electro-hydraulic

power steering can be performed with the aid of a

diagnostic tester via the DLC of the vehicle. For

additional information please refer to "Diagnosis

and Testing" in this section.

G1001270en2008.50 Kuga8/2011

211-02-

8

Power Steering

211-02- 8

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL