can FORD KUGA 2011 1.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 205 of 2057

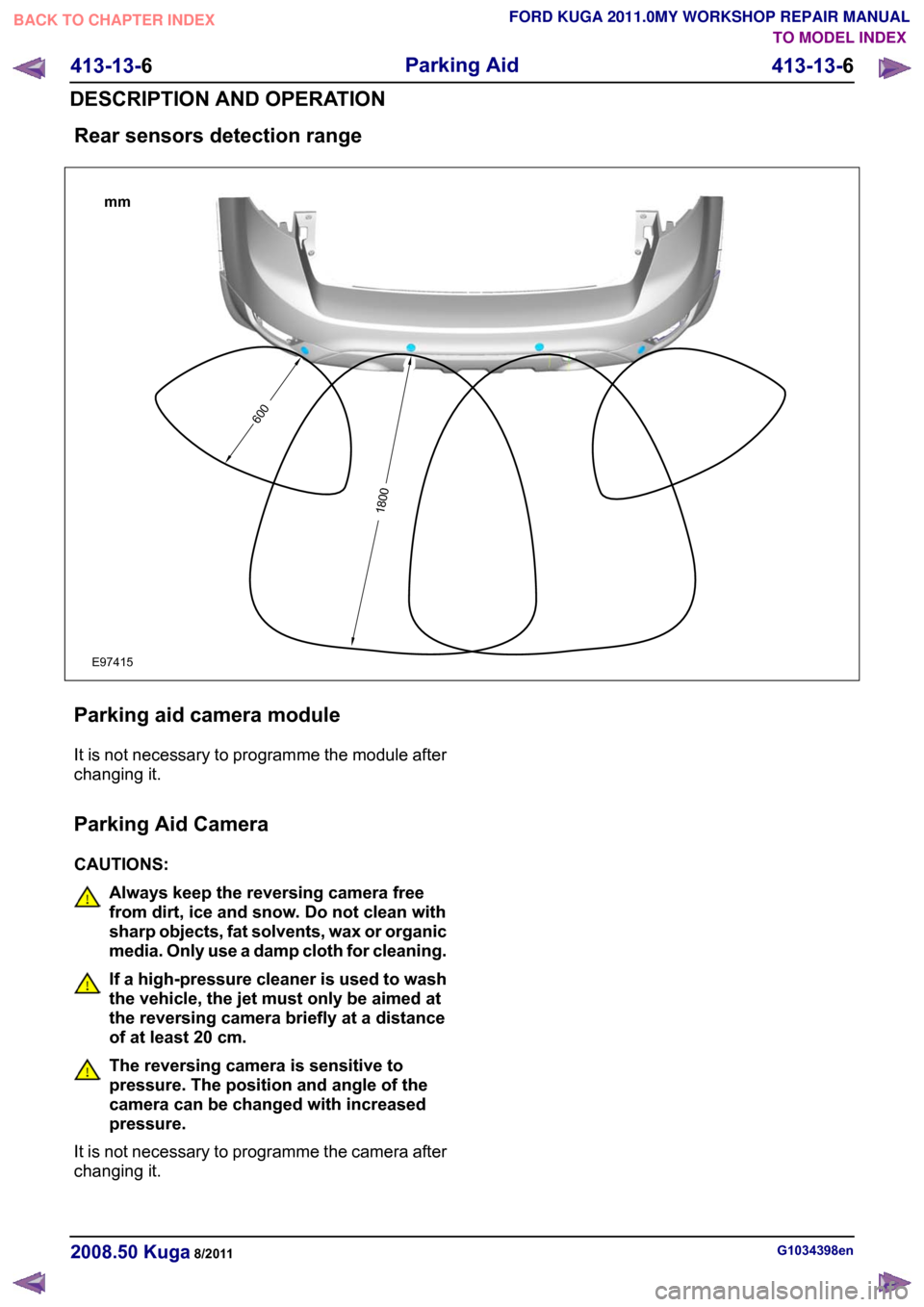

Rear sensors detection range

Parking aid camera module

It is not necessary to programme the module after

changing it.

Parking Aid Camera

CAUTIONS:

Always keep the reversing camera free

from dirt, ice and snow. Do not clean with

sharp objects, fat solvents, wax or organic

media. Only use a damp cloth for cleaning.

If a high-pressure cleaner is used to wash

the vehicle, the jet must only be aimed at

the reversing camera briefly at a distance

of at least 20 cm.

The reversing camera is sensitive to

pressure. The position and angle of the

camera can be changed with increased

pressure.

It is not necessary to programme the camera after

changing it. G1034398en

2008.50 Kuga 8/2011 413-13-6

Parking Aid

413-13-6

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL6001800mmE97415

Page 211 of 2057

Description

Item

Rear parking aid sensorRefer to Component Description: Parking

aid sensors (page ?)

7

Rear parking aid sensorRefer to Component Description: Parking

aid sensors (page ?)

8 Description

Item

Rear parking aid sensorRefer to Component Description: Parking

aid sensors (page ?)

9

steering angle sensor

10

Navigation device

11

System Operation

Parking Aid WARNING: It is the driver's responsibility

to stay alert during reversing procedures.

The system may fail to detect small

children or animals.

CAUTION: The driver is responsible for

detecting obstacles and judging the

distance between these and the vehicle.

The system may fail to detect some

hanging objects, barriers, narrow obstacles

or painted surfaces, which could damage

the vehicle. Always pay attention when

parking.

The parking aid provides an audible warning to the

driver if there are any obstacles in front of or behind

the vehicle during reverse parking maneuvers.

At low speeds, the parking aid module uses the

parking aid sensors to monitor the area around the

vehicle. If an object is detected within a monitored

area, the parking aid module emits a warning tone

using the respective parking aid speaker.

The rear parking aid is switched on with the

ignition. However, it is only enabled when reverse

gear is selected.

The front and rear parking aid is always switched

off when the ignition is switched on. It is switched

on when reverse gear is selected or if the parking

aid switch in the center console is actuated up to

a speed of 16 km/h.

The parking aid is switched off when the vehicle is

travelling forwards at more than 16 km/h or if the

parking aid switch in the center console is actuated

again.

When the parking aid module activates the system,

the parking aid switch LED is illuminated. If the

vehicle is only fitted with the rear parking aid, there

is no switch.

The parking aid sensors emit a series of ultrasonic

impulses and switch to receiver mode to receive the echo reflected by an obstacle within the

detection range. The received echo signals are

amplified and converted from an analog signal to

a digital signal by the sensor. The digital signal is

passed to the parking aid module and compared

with pre-programmed data stored in an EEPROM

within the module. The module calculates the

distance to the obstacle by measuring the time

taken between the emitted and received impulses.

If no objects are detected there are no further

warning tones. If an object is detected, repeated

audible tones are emitted from either parking aid

speaker(s) as appropriate. The time delay between

the tones decreases as the distance between the

object and the vehicle decreases, until at

approximately 250 mm (10 inches), the audible

tone becomes continuous.

If the distance between the obstacle and the

vehicle does not decrease, the warning tone

remains constant if the object has been detected

by an internal parking aid sensor. If the obstacle

was detected by an external sensor and the

distance remains unchanged, the warning tone

stops after 3 seconds.

The parking aid module continues to monitor the

distance and will resume the warning tones if a

decrease in distance is detected.

If a trailer is connected to the vehicle, a signal is

sent to the GEM (generic electronic module) via

the trailer relay. This signal is sent to the parking

aid module via the MS CAN bus. When the parking

aid module detects that a trailer is connected to

the vehicle, the rear parking aid sensors are

disabled to prevent constant warnings due to the

close proximity of the trailer.

G1034399en

2008.50 Kuga 8/2011 413-13-12

Parking Aid

413-13-12

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 212 of 2057

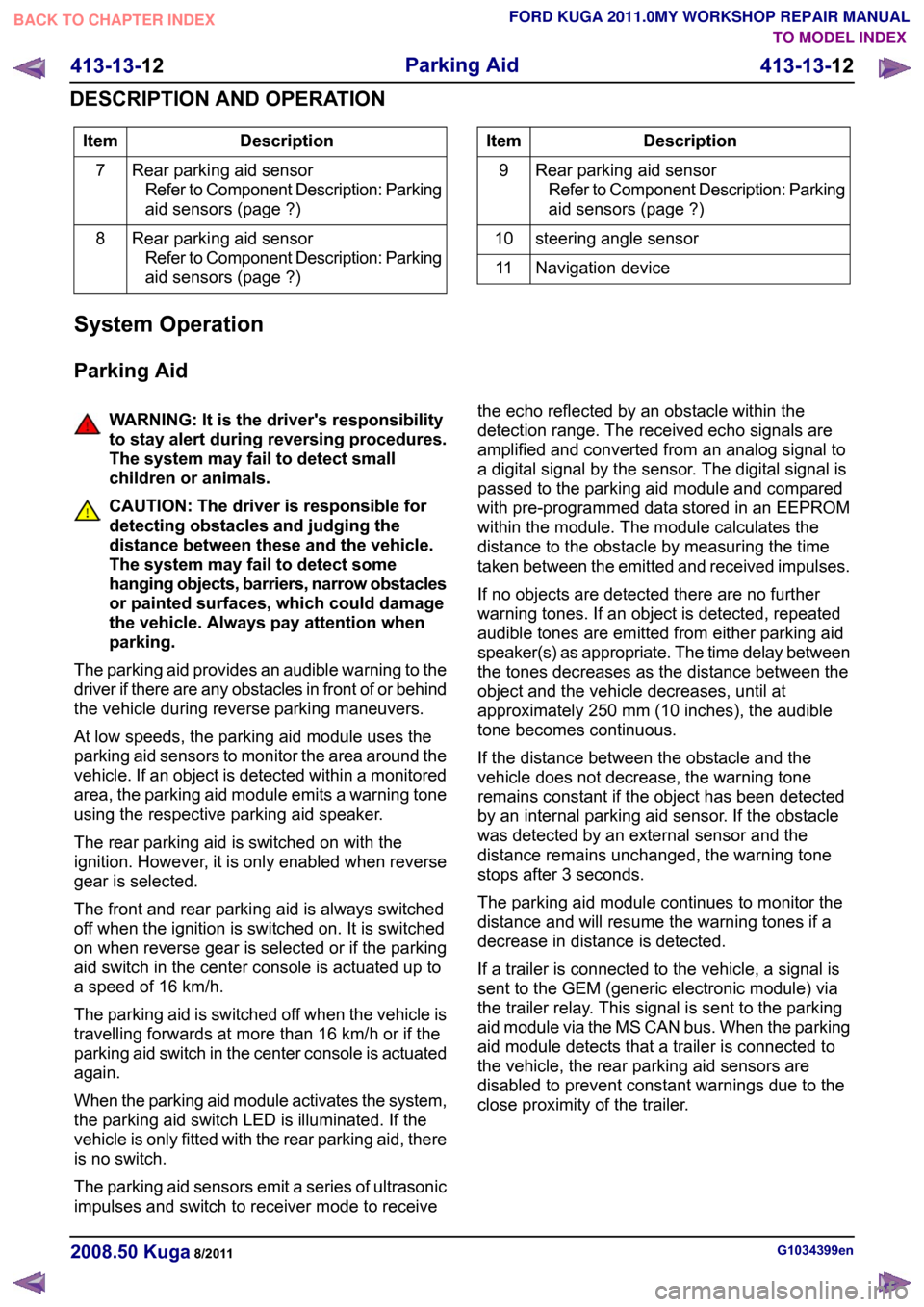

Parking Aid Camera

For vehicles with a DVD navigation system with a

touch screen, the parking aid camera is supplied

as standard. For vehicles with a standard

navigation system, the camera can be ordered as

an optional extra. The system essentially consists

of a camera with a wide angle lens, a control unit

and a wiring harness which is not integrated in the

vehicle wiring harness.

On the navigation display screen, the drivers sees

a video image of the area behind the vehicle.

Guides integrated in the camera images by the

parking aid camera module and displayed on the

screen help the driver to find out about the steering

angle, vehicle width, cornering and driving straight

ahead. The system generates these guides using:

• Vehicle parameters (length, width)

• Steering Angle

• Vehicle position during the parking maneuverDescription

Item

Monitoring angle

1

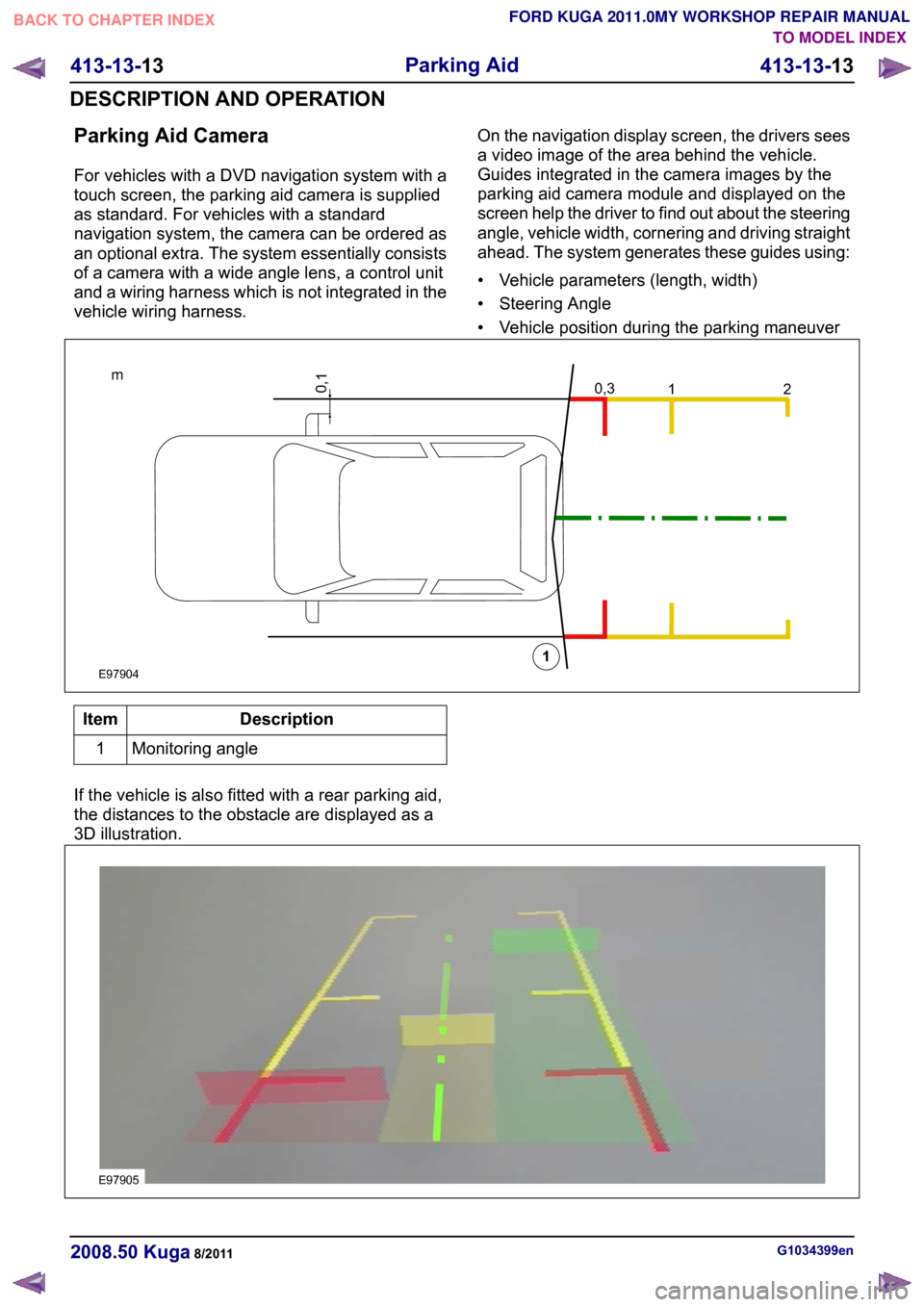

If the vehicle is also fitted with a rear parking aid,

the distances to the obstacle are displayed as a

3D illustration. G1034399en

2008.50 Kuga 8/2011 413-13-13

Parking Aid

413-13-13

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL0,3m120,11E97904 E97905

Page 214 of 2057

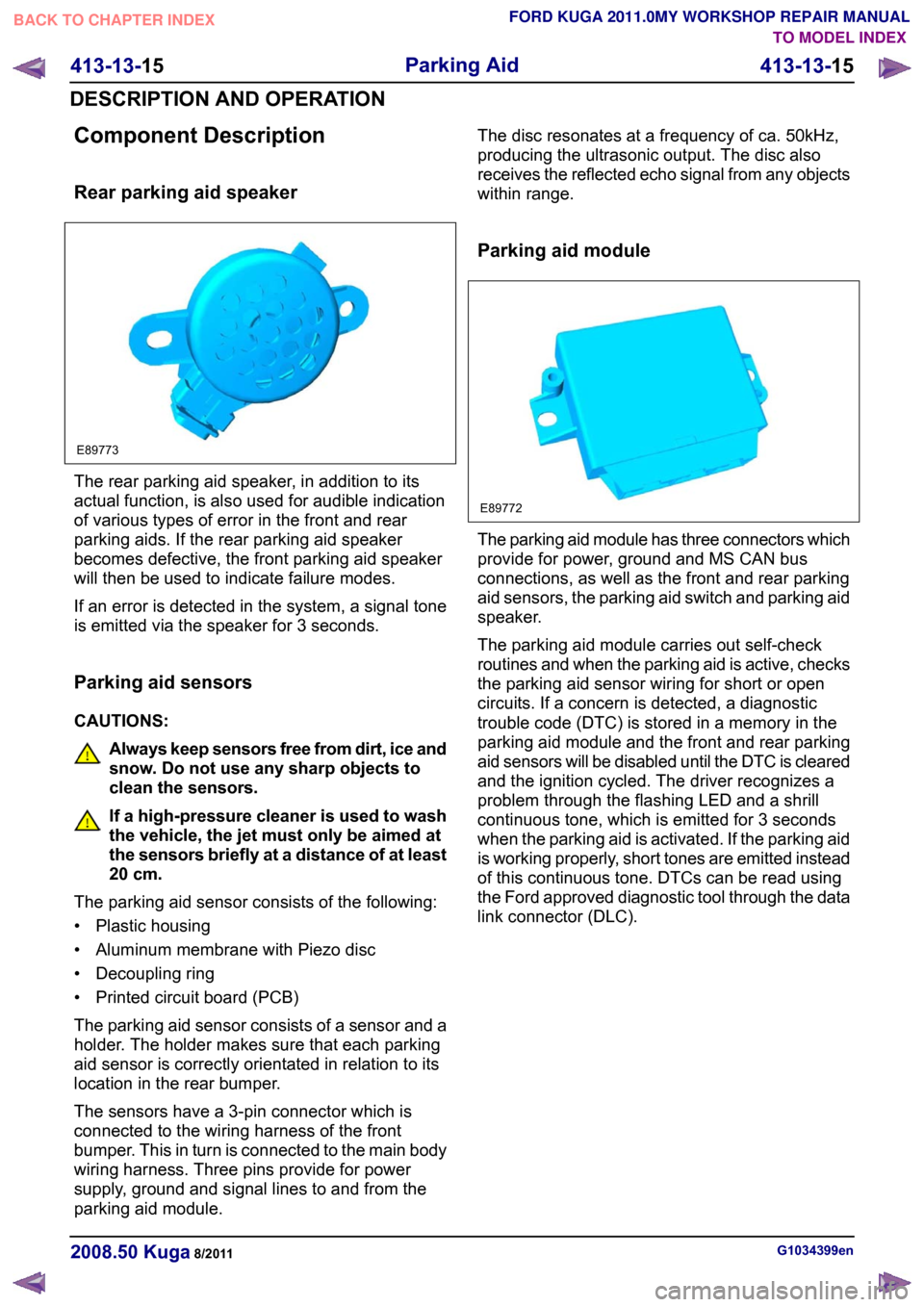

Component Description

Rear parking aid speaker

The rear parking aid speaker, in addition to its

actual function, is also used for audible indication

of various types of error in the front and rear

parking aids. If the rear parking aid speaker

becomes defective, the front parking aid speaker

will then be used to indicate failure modes.

If an error is detected in the system, a signal tone

is emitted via the speaker for 3 seconds.

Parking aid sensors

CAUTIONS:

Always keep sensors free from dirt, ice and

snow. Do not use any sharp objects to

clean the sensors.

If a high-pressure cleaner is used to wash

the vehicle, the jet must only be aimed at

the sensors briefly at a distance of at least

20 cm.

The parking aid sensor consists of the following:

• Plastic housing

• Aluminum membrane with Piezo disc

• Decoupling ring

• Printed circuit board (PCB)

The parking aid sensor consists of a sensor and a

holder. The holder makes sure that each parking

aid sensor is correctly orientated in relation to its

location in the rear bumper.

The sensors have a 3-pin connector which is

connected to the wiring harness of the front

bumper. This in turn is connected to the main body

wiring harness. Three pins provide for power

supply, ground and signal lines to and from the

parking aid module. The disc resonates at a frequency of ca. 50kHz,

producing the ultrasonic output. The disc also

receives the reflected echo signal from any objects

within range.

Parking aid module

The parking aid module has three connectors which

provide for power, ground and MS CAN bus

connections, as well as the front and rear parking

aid sensors, the parking aid switch and parking aid

speaker.

The parking aid module carries out self-check

routines and when the parking aid is active, checks

the parking aid sensor wiring for short or open

circuits. If a concern is detected, a diagnostic

trouble code (DTC) is stored in a memory in the

parking aid module and the front and rear parking

aid sensors will be disabled until the DTC is cleared

and the ignition cycled. The driver recognizes a

problem through the flashing LED and a shrill

continuous tone, which is emitted for 3 seconds

when the parking aid is activated. If the parking aid

is working properly, short tones are emitted instead

of this continuous tone. DTCs can be read using

the Ford approved diagnostic tool through the data

link connector (DLC).

G1034399en

2008.50 Kuga 8/2011 413-13-15

Parking Aid

413-13-15

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE89773 E89772

Page 215 of 2057

Front parking aid speaker

The front parking aid speaker, in addition to its

actual function, is also used for audible indication

of various types of error in the front and rear

parking aids when the rear parking aid speaker

fails.

Parking aid switch

The parking aid switch is a non-locking switch with

an integrated LED for switching the parking aid on

and off. When pressed, the parking aid switch

momentarily connects a ground to the parking aid

module. The LED indicates when the parking aid

is active. The LED is controlled by the parking aid

module.

The parking aid switch allows the driver to disable

the parking aid when reverse gear is selected or

to activate the parking aid sensors when not in

reverse gear.

If a high tone is emitted for 3 seconds and the lights

in the switch flash, this indicates that there is a

fault. The system is then deactivated. Parking aid camera module

The data from the optional parking aid is sent to

the module via the Mid Speed CAN data bus. The

signals from the steering angle sensor are sent to

the module via cable. The module is connected to

the navigation device via a video-in/out cable.

Parking Aid Camera

The wide angle lens camera is fixed in the handle

strip of the tailgate. It is connected to the parking

aid camera module via a separate line.

G1034399en

2008.50 Kuga 8/2011 413-13-16

Parking Aid

413-13-16

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE89773 E97703 E97856 E97857

Page 263 of 2057

Charging System

Refer to Wiring Diagrams Section 414-02, for

schematic and connector information.

General Equipment

Midtronics EXP-1050 battery tester

Midtronics GR590-2

Ford diagnostic equipment

Inspection and Verification

WARNINGS: Batteries contain sulphuric acid. Avoid

contact with skin, eyes, or clothing. Also,

shield your eyes when working near

batteries to protect against possible

splashing of the acid solution. In case of

acid contact with skin or eyes, flush

immediately with water for a minimum of

15 minutes and get prompt medical

attention. If acid is swallowed, call a

physician immediately. Failure to follow

these instructions may result in personal

injury.

Batteries normally produce explosive

gases which can cause personal injury.

Therefore, do not allow flames, sparks or

lighted substances to come near the

battery. When charging or working near a

battery, always shield your face and

protect your eyes. Always provide

ventilation. Failure to follow these

instructions may result in personal injury.

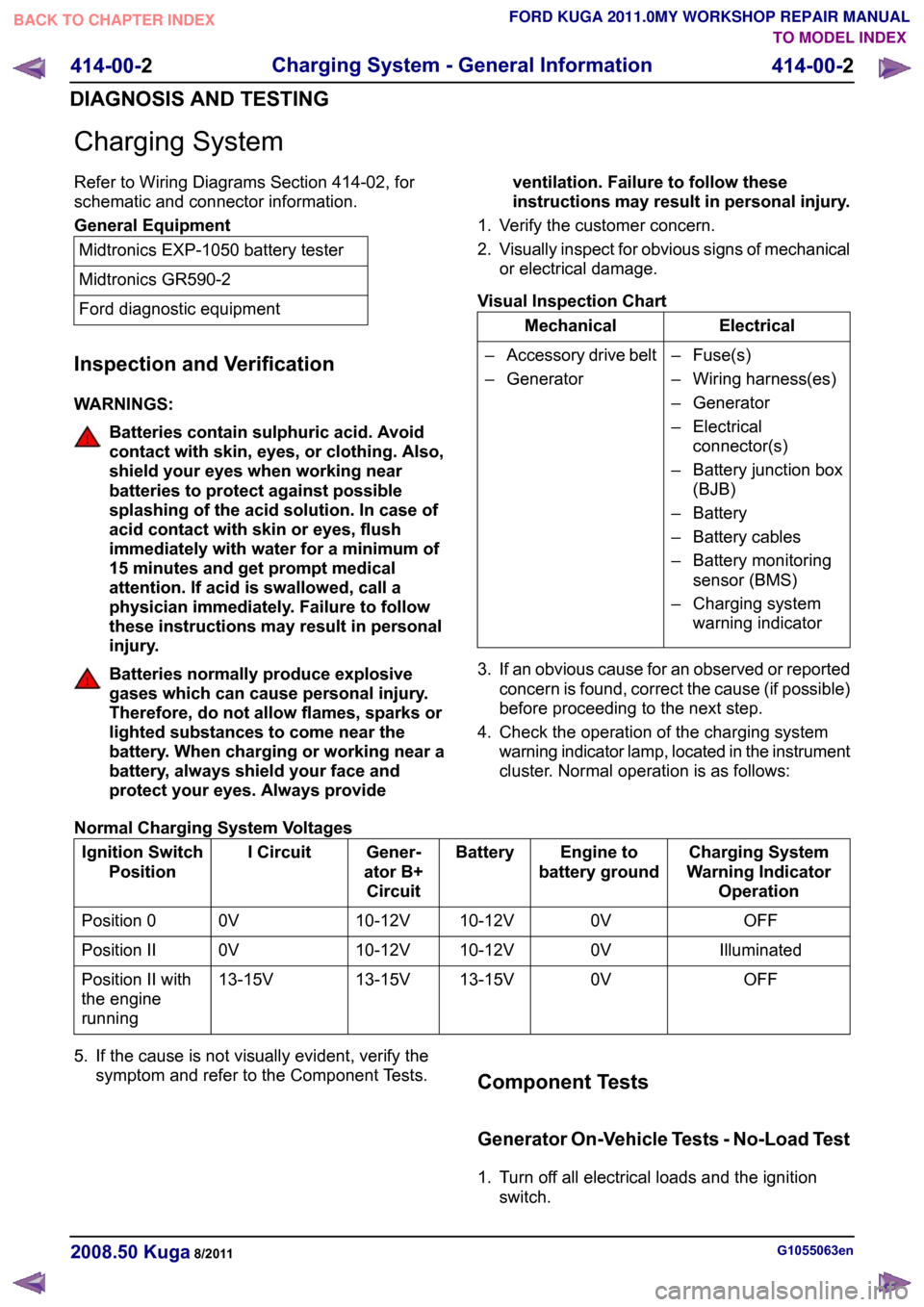

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

Visual Inspection Chart Electrical

Mechanical

– Fuse(s)

– Wiring harness(es)

– Generator

– Electricalconnector(s)

– Battery junction box (BJB)

– Battery

– Battery cables

– Battery monitoring sensor (BMS)

– Charging system warning indicator

–

Accessory drive belt

– Generator

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. Check the operation of the charging system warning indicator lamp, located in the instrument

cluster. Normal operation is as follows:

Normal Charging System Voltages Charging System

Warning Indicator Operation

Engine to

battery ground

Battery

Gener-

ator B+ Circuit

I Circuit

Ignition Switch

Position

OFF

0V

10-12V

10-12V

0V

Position 0

Illuminated

0V

10-12V

10-12V

0V

Position II

OFF

0V

13-15V

13-15V

13-15V

Position II with

the engine

running

5. If the cause is not visually evident, verify the symptom and refer to the Component Tests. Component Tests

Generator On-Vehicle Tests - No-Load Test

1. Turn off all electrical loads and the ignition

switch. G1055063en

2008.50 Kuga 8/2011 414-00-2

Charging System - General Information

414-00-2

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 266 of 2057

• Surface charge removal procedure

• Dynamic Response procedure for refined

decisiveness on battery diagnostics

• Upgradeable by SD card

• Export data feature to send data to infra red printer

• Voltmeter function

• Date and time indication with every test

• 23 languages included within the battery tester

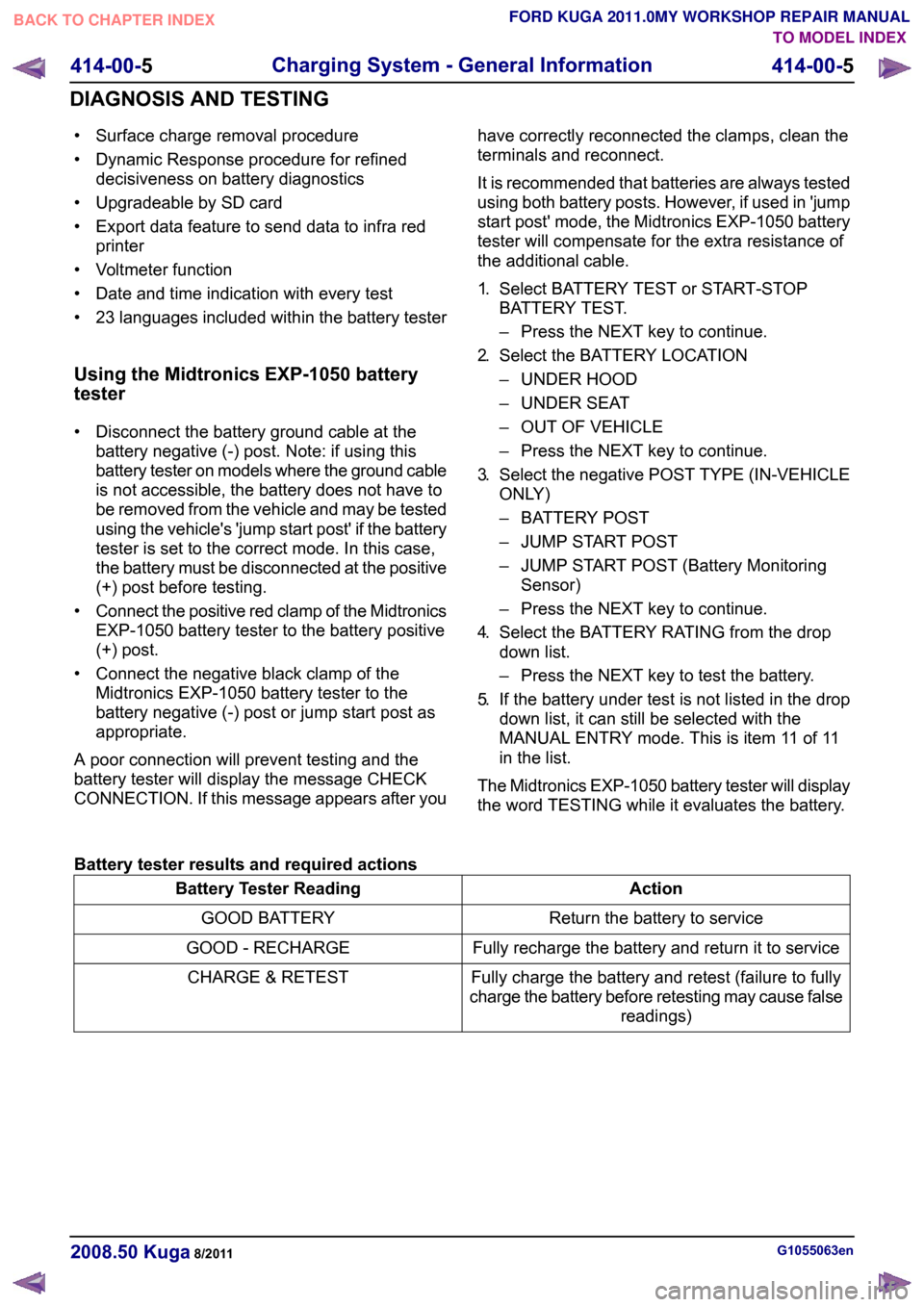

Using the Midtronics EXP-1050 battery

tester

• Disconnect the battery ground cable at the battery negative (-) post. Note: if using this

battery tester on models where the ground cable

is not accessible, the battery does not have to

be removed from the vehicle and may be tested

using the vehicle's 'jump start post' if the battery

tester is set to the correct mode. In this case,

the battery must be disconnected at the positive

(+) post before testing.

• Connect the positive red clamp of the Midtronics

EXP-1050 battery tester to the battery positive

(+) post.

• Connect the negative black clamp of the Midtronics EXP-1050 battery tester to the

battery negative (-) post or jump start post as

appropriate.

A poor connection will prevent testing and the

battery tester will display the message CHECK

CONNECTION. If this message appears after you have correctly reconnected the clamps, clean the

terminals and reconnect.

It is recommended that batteries are always tested

using both battery posts. However, if used in 'jump

start post' mode, the Midtronics EXP-1050 battery

tester will compensate for the extra resistance of

the additional cable.

1.

Select BATTERY TEST or START-STOP

BATTERY TEST.

– Press the NEXT key to continue.

2. Select the BATTERY LOCATION

– UNDER HOOD

– UNDER SEAT

– OUT OF VEHICLE

– Press the NEXT key to continue.

3. Select the negative POST TYPE (IN-VEHICLE

ONLY)

– BATTERY POST

– JUMP START POST

– JUMP START POST (Battery Monitoring

Sensor)

– Press the NEXT key to continue.

4. Select the BATTERY RATING from the drop

down list.

– Press the NEXT key to test the battery.

5. If the battery under test is not listed in the drop

down list, it can still be selected with the

MANUAL ENTRY mode. This is item 11 of 11

in the list.

The Midtronics EXP-1050 battery tester will display

the word TESTING while it evaluates the battery.

Battery tester results and required actions Action

Battery Tester Reading

Return the battery to service

GOOD BATTERY

Fully recharge the battery and return it to service

GOOD - RECHARGE

Fully charge the battery and retest (failure to fully

charge the battery before retesting may cause false readings)

CHARGE & RETEST G1055063en

2008.50 Kuga 8/2011 414-00-5

Charging System - General Information

414-00-5

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 267 of 2057

Action

Battery Tester Reading WARNING: Do not recharge the battery.

Make sure that the surface charge was removed. A "REPLACE BATTERY" result could also mean

a poor connection between the battery cables and the battery. Check the connections are OK and

retest. If the result remains the same, INSTALL a NEW battery

REFER to: Battery(414-01 Battery, Mounting and

Cables, Removal and Installation).

REPLACE BATTERY or BAD CELL BATTERY

In addition it is advisable to check the vehicle electrical system. Check that the generator is functioning

correctly and the vehicle does not have an excessive key-off load (in general this should be under

20mA after 40 minutes of key off).

Midtronics EXP-1050 Battery Tester Test

Code

At the end of the test, use the arrow keys to scroll

down the screens to see additional information.

One of these is the TEST CODE.

The TEST CODE has 11 digits, for example:

0021U-B88WKX.

Using the Midtronics GR-590-2 The Midtronics GR-590-2 is both a battery charger

and battery tester and automatically removes the

surface charge as part of the normal operating

procedure.

The Midtronics GR-590-2 can be used on a battery

in-vehicle or out-of-vehicle.

• Disconnect the battery ground cable.

• Connect the positive red clamp from the

Midtronics GR-590-2 to the battery positive

terminal.

• Connect the negative black clamp from the Midtronics GR-590-2 to the battery negative

terminal.

• Connect the AC power cable to the mains outlet

and switch ON.

• Follow the instructions supplied with the Midtronics GR-590-2 to charge the battery.

• To disconnect the Midtronics GR-590-2, reverse

the connection procedure.

The Midtronics GR-590-2 will automatically carry

out a charge cycle before giving the resulting test

code. It will bring the battery into a serviceable

condition and if required can proceed to fully

charge the battery.

Functions on the front panel of the Midtronics

GR-590-2

• UP and DOWN button: The UP and DOWN buttons allow the operator to scroll through

selections on the display and increase or

decrease values.

• ENTER button: The ENTER button allows the operator to accept a selection and continue to

the next step. G1055063en

2008.50 Kuga 8/2011 414-00-6

Charging System - General Information

414-00-6

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE136266

Page 274 of 2057

Generator

General information

The powertrain control module (PCM) controls the

alternator charging voltage. The connection

between the PCM and the generator is made via

the control module subnetwork (LIN) bus.

If the load on the alternator is high, the PCM can

increase the idle speed.

The alternator is temporarily deactivated during

engine starting so that the engine drag moment is

minimized and it is reactivated again after the

starting procedure.

The PCM controls the charge control lamp in the

instrument cluster via the controller area network

(CAN) bus.

Smart Charge system

In addition to the familiar functions, the Smart

Charge system also performs the following

functions:

•

Automatic deactivation of non-critical high power

electrical consumers when the battery voltage

is low in order to reduce the level of current

drawn.

• Automatic activation of non-critical high power electrical consumers when the battery voltage

is excessively high in order to protect

components which are sensitive to increased

voltages.

The battery charging current is optimized through

continuous calculation of the battery temperature

and monitoring of the alternator output voltage.

By receiving the forwarded alternator load signal,

the PCM is given early warning whenever an

electric consumer is switched on or off. This means

that the PCM receives information about imminent

changes in the torque drawn by the alternator. By

evaluating this information the PCM can provide a

higher level of idling stability.

The two remaining functions of the Smart Charge

System are controlled by the GEM.

Electrical consumers are switched off due to low

voltage when the GEM determines (on the basis

of the message received from the PCM on the CAN

bus via the instrument cluster) that the battery

voltage has dropped below the threshold.

When the threshold for low battery voltage is

reached the GEM automatically deactivates the following consumers - in this order and with a gap

of 5 seconds between each:

• Electric booster heater (vehicles with diesel

engines)

• Heated exterior mirrors

• Heated rear window

• Heated windscreen

If the battery voltage rises back above the lower

threshold then the GEM re-enables all of the

electrical consumers which were previously

disabled. They then have switched off status and

must be switched back on by the driver.

Electrical consumers are switched on due to

excessively high voltage if the GEM determines

that the battery voltage is above the threshold for

overvoltage and the charge control lamp has been

switched on.

When the threshold is reached the GEM

automatically activates the following consumers -

in this order and with a gap of 5 seconds between

each:

• Heated rear window

• Heated exterior mirrors

• Electric booster heater (vehicles with diesel engines)

• Blower motor

If the battery voltage drops back below the

threshold then the GEM automatically deactivates

any consumers that were switched on. However,

if they were switched on by the driver before the

automatic activation, they will then be switched on

again in turn with a 5-second time interval. G964174en

2008.50 Kuga 8/2011 414-02-2

Generator and Regulator

414-02-2

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 279 of 2057

Direct Current/Alternating Current (DC/AC) Inverter – Overview

Function indicator

WARNING: For workshop repairs, it is only

permissible to replace the converter as a

complete unit together with the wiring

harness and the socket. The component

must not be opened, as charged capacitors

inside can still carry dangerously high

residual voltages.

The LED in the socket lights up orange when the

converter is supplying a voltage.

In the event of a fault the system switches off and

indicates the cause of the fault by flashing a trouble

code via the LED in the socket:

• 1x flash – High temperature

• 2x flashes – Overload

• 3x flashes – Internal overvoltage

• 4x flashes – Internal undervoltage

• Continuous flashing – Short circuit to power

If the converter switches off due to high

temperature then it switches back on again

automatically once the temperature has cooled

down sufficiently.

With all of the other faults which are displayed, the

converter can be reset by switching the ignition off

and back on again or by unplugging and reinserting

the consumer in the socket.

If these measures are unsuccessful then there are

no further options for directly influencing the

function yourself. G1055637en

2008.50 Kuga 8/2011 414-05-3

Voltage Converter/Inverter

414-05-3

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL