instrument FORD KUGA 2011 1.G Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 1387 of 2057

Parking Brake

Inspection and Verification

1. Verify the customer concern by operating theparking brake system.

2. Visually inspect for obvious signs of mechanical or electrical damage.

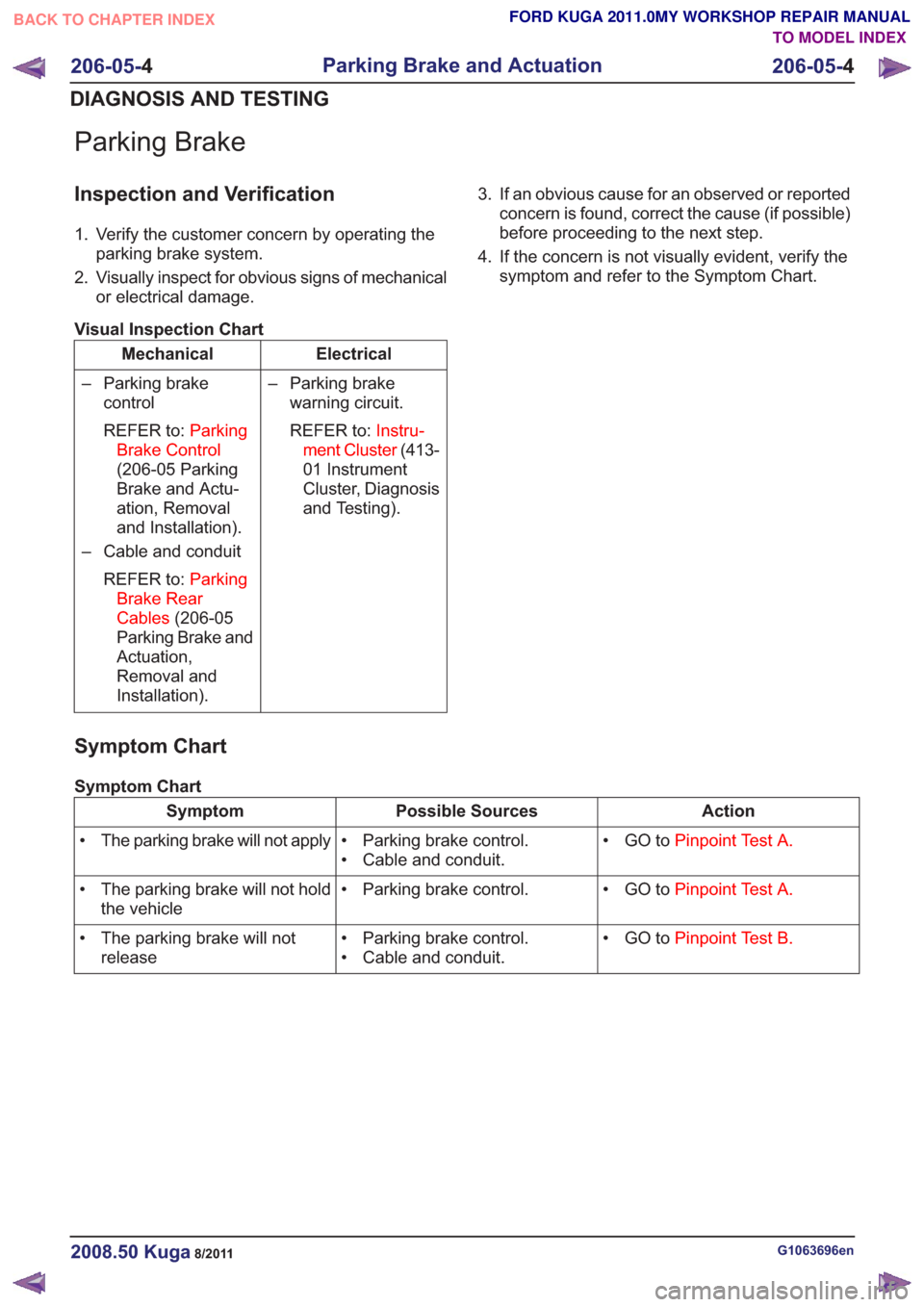

Visual Inspection Chart

Electrical

Mechanical

– Parking brakewarning circuit.

REFER to: Instru-

ment Cluster (413-

01 Instrument

Cluster, Diagnosis

and Testing).

– Parking brake

control

REFER to: Parking

Brake Control

(206-05 Parking

Brake and Actu-

ation, Removal

and Installation).

– Cable and conduit

REFER to: Parking

Brake Rear

Cables (206-05

Parking Brake and

Actuation,

Removal and

Installation). 3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the concern is not visually evident, verify the symptom and refer to the Symptom Chart.

Symptom Chart

Symptom Chart

Action

Possible Sources

Symptom

• GO toPinpoint Test A.

• Parking brake control.

• Cable and conduit.

• The parking brake will not apply

• GO toPinpoint Test A.

• Parking brake control.

• The parking brake will not hold

the vehicle

• GO toPinpoint Test B.

• Parking brake control.

• Cable and conduit.

• The parking brake will not

release

G1063696en2008.50 Kuga8/2011

206-05- 4

Parking Brake and Actuation

206-05- 4

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1394 of 2057

Parking Brake Control(12 664 0)

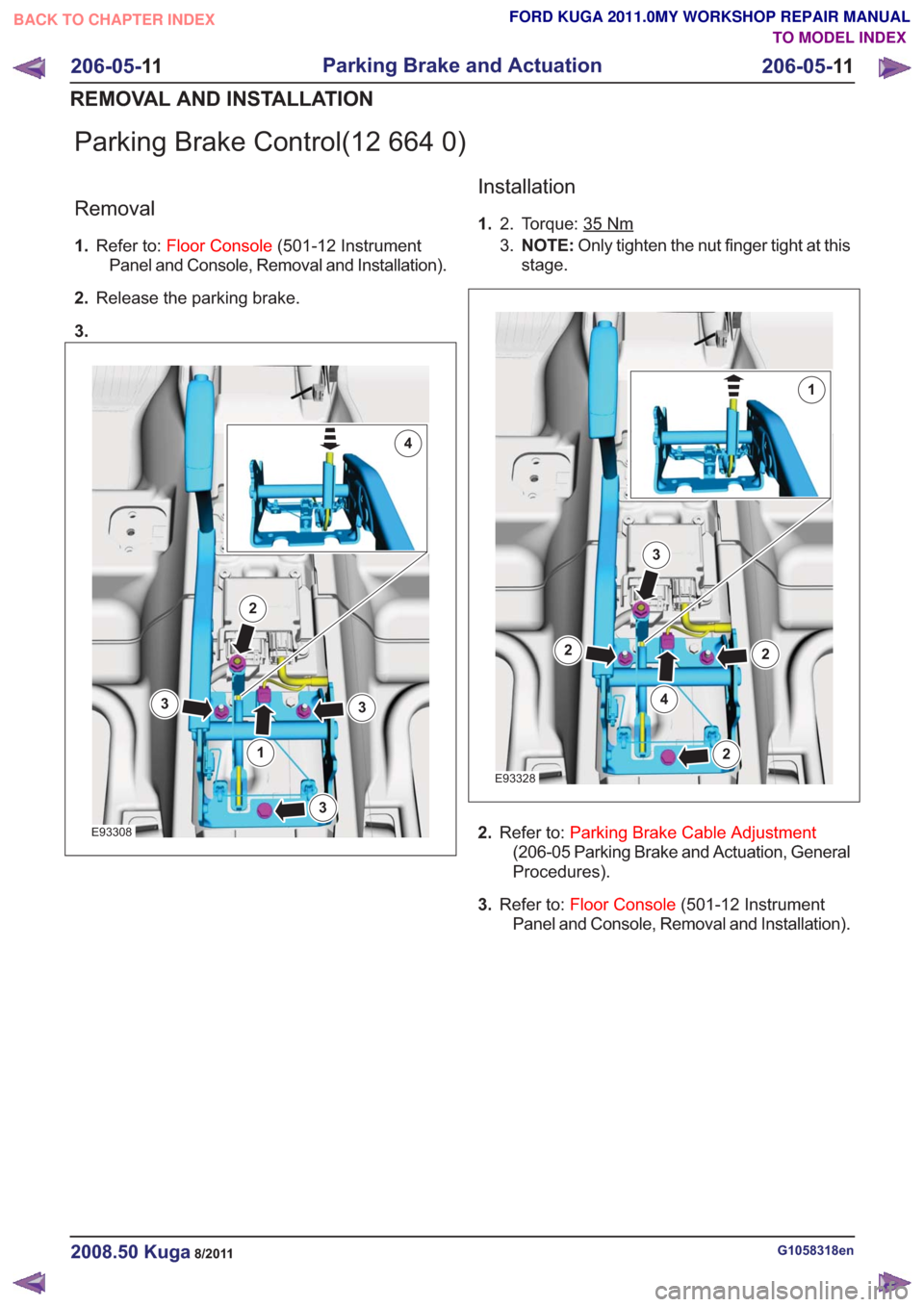

Removal

1.Refer to: Floor Console (501-12 Instrument

Panel and Console, Removal and Installation).

2. Release the parking brake.

3.

3

33

2

1

4

E93308

Installation

1. Torque: 35Nm2.

3.NOTE: Only tighten the nut finger tight at this

stage.

2

22

3

4

1

E93328

2. Refer to: Parking Brake Cable Adjustment

(206-05 Parking Brake and Actuation, General

Procedures).

3. Refer to: Floor Console (501-12 Instrument

Panel and Console, Removal and Installation).

G1058318en2008.50 Kuga8/2011

206-05- 11

Parking Brake and Actuation

206-05- 11

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1399 of 2057

Brake Pedal and Bracket — RHD 4WD/RHD FWD

Removal

NOTE:Removal steps in this procedure may

contain installation details.

Panel and Console, Removal and Installation).

2.

E101395

G1065459en2008.50 Kuga8/2011

206-06- 2

Hydraulic Brake Actuation

206-06- 2

REMOVAL AND INSTALLATION

BACK TO CHAPTER INDEXFORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

TO MODEL INDEX

1. Refer to: Floor Console Extension - Vehicles

With: Center Armrest (501-12 Instrument

Page 1424 of 2057

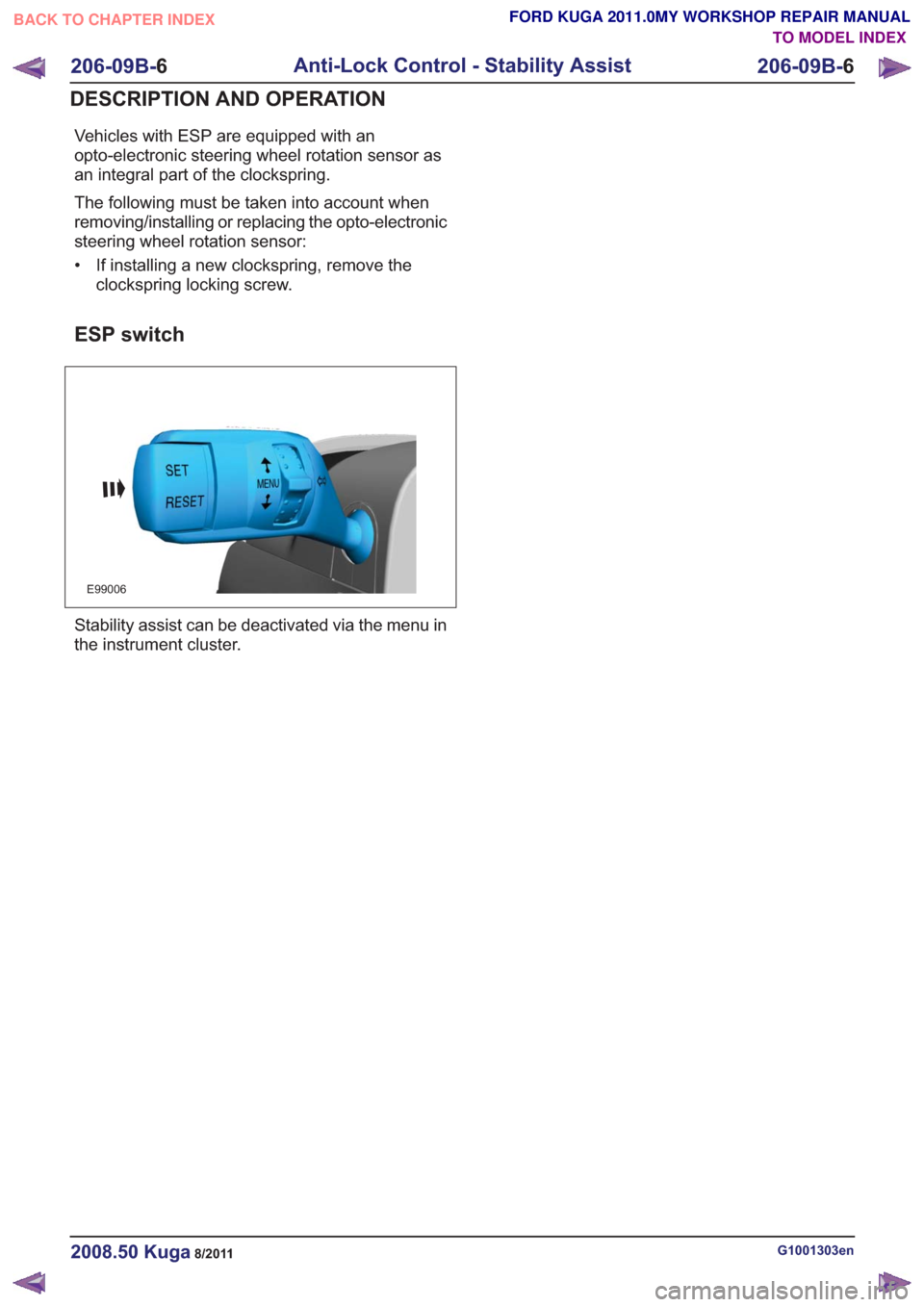

Vehicles with ESP are equipped with an

opto-electronic steering wheel rotation sensor as

an integral part of the clockspring.

The following must be taken into account when

removing/installing or replacing the opto-electronic

steering wheel rotation sensor:

• If installing a new clockspring, remove theclockspring locking screw.

ESP switch

E99006

Stability assist can be deactivated via the menu in

the instrument cluster.

G1001303en2008.50 Kuga8/2011

206-09B- 6

Anti-Lock Control - Stability Assist

206-09B- 6

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1428 of 2057

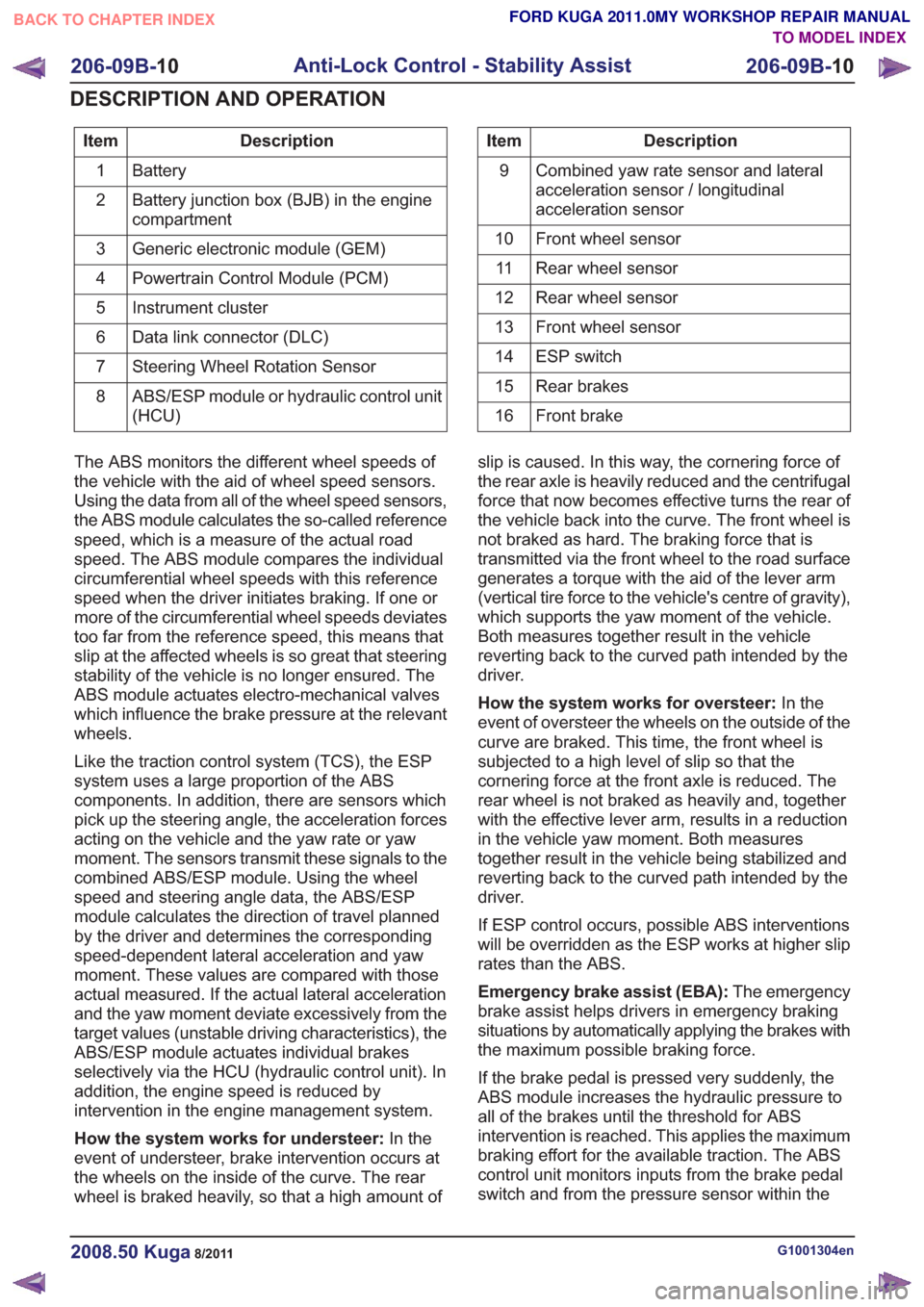

Description

Item

Battery

1

Battery junction box (BJB) in the engine

compartment

2

Generic electronic module (GEM)

3

Powertrain Control Module (PCM)

4

Instrument cluster

5

Data link connector (DLC)

6

Steering Wheel Rotation Sensor

7

ABS/ESP module or hydraulic control unit

(HCU)

8Description

Item

Combined yaw rate sensor and lateral

acceleration sensor / longitudinal

acceleration sensor

9

Front wheel sensor

10

Rear wheel sensor

11

Rear wheel sensor

12

Front wheel sensor

13

ESP switch

14

Rear brakes

15

Front brake

16

The ABS monitors the different wheel speeds of

the vehicle with the aid of wheel speed sensors.

Using the data from all of the wheel speed sensors,

the ABS module calculates the so-called reference

speed, which is a measure of the actual road

speed. The ABS module compares the individual

circumferential wheel speeds with this reference

speed when the driver initiates braking. If one or

more of the circumferential wheel speeds deviates

too far from the reference speed, this means that

slip at the affected wheels is so great that steering

stability of the vehicle is no longer ensured. The

ABS module actuates electro-mechanical valves

which influence the brake pressure at the relevant

wheels.

Like the traction control system (TCS), the ESP

system uses a large proportion of the ABS

components. In addition, there are sensors which

pick up the steering angle, the acceleration forces

acting on the vehicle and the yaw rate or yaw

moment. The sensors transmit these signals to the

combined ABS/ESP module. Using the wheel

speed and steering angle data, the ABS/ESP

module calculates the direction of travel planned

by the driver and determines the corresponding

speed-dependent lateral acceleration and yaw

moment. These values are compared with those

actual measured. If the actual lateral acceleration

and the yaw moment deviate excessively from the

target values (unstable driving characteristics), the

ABS/ESP module actuates individual brakes

selectively via the HCU (hydraulic control unit). In

addition, the engine speed is reduced by

intervention in the engine management system.

How the system works for understeer: In the

event of understeer, brake intervention occurs at

the wheels on the inside of the curve. The rear

wheel is braked heavily, so that a high amount of slip is caused. In this way, the cornering force of

the rear axle is heavily reduced and the centrifugal

force that now becomes effective turns the rear of

the vehicle back into the curve. The front wheel is

not braked as hard. The braking force that is

transmitted via the front wheel to the road surface

generates a torque with the aid of the lever arm

(vertical tire force to the vehicle's centre of gravity),

which supports the yaw moment of the vehicle.

Both measures together result in the vehicle

reverting back to the curved path intended by the

driver.

How the system works for oversteer:

In the

event of oversteer the wheels on the outside of the

curve are braked. This time, the front wheel is

subjected to a high level of slip so that the

cornering force at the front axle is reduced. The

rear wheel is not braked as heavily and, together

with the effective lever arm, results in a reduction

in the vehicle yaw moment. Both measures

together result in the vehicle being stabilized and

reverting back to the curved path intended by the

driver.

If ESP control occurs, possible ABS interventions

will be overridden as the ESP works at higher slip

rates than the ABS.

Emergency brake assist (EBA): The emergency

brake assist helps drivers in emergency braking

situations by automatically applying the brakes with

the maximum possible braking force.

If the brake pedal is pressed very suddenly, the

ABS module increases the hydraulic pressure to

all of the brakes until the threshold for ABS

intervention is reached. This applies the maximum

braking effort for the available traction. The ABS

control unit monitors inputs from the brake pedal

switch and from the pressure sensor within the

G1001304en2008.50 Kuga8/2011

206-09B- 10

Anti-Lock Control - Stability Assist

206-09B- 10

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1429 of 2057

HCU to check for sudden actuation of the brakes.

With the brake pedal pressed, the ABS module

triggers emergency braking if the rate of increase

of hydraulic pressure exceeds the predetermined

limit.

If the brake pedal is pressed so hard that the ABS

becomes active on the front wheels then the ABS

control unit increases the pressure to the rear

wheel brakes up to the ABS intervention threshold.

EBA operation continues until the driver releases

the brake pedal sufficiently for the hydraulic

pressure in the HCU to drop below a threshold

value stored in the ABS module.

Trailer stability control:If the vehicle is ordered

with a trailer coupling then the Trailer Stability

Control function is integrated in the ESP. The ESP

detects snaking when driving with a trailer and

reduces the speed of the vehicle and trailer through

adapted braking and, if necessary, by also reducing

the engine output until the snaking movement of

the trailer is corrected.

Roll-over protection: The ESP dynamically

determines the tipping tendency of the vehicle and

works in conjunction with the EBA system to

prevent the vehicle from tipping over during

dynamic maneuvers like lane changing or while

negotiating bends.

Emergency brake light: The emergency brake

light automatically switches on the hazard flasher

system to warn drivers of other vehicles that

emergency braking is being initiated. Based on a

defined delay value, the ABS/ESP module sends

a signal to the generic electronic module (GEM)

via the CAN data bus. The GEM activates the

hazard flasher system, that then flashes 7 times.

Prerequisites for activation of the emergency brake

light are:

• The speed is higher than 50 km/h.

• The brake pedal is being actuated.

• The deceleration is greater than 9 m/s².

To prevent activation on snow or ice, for example,

the following prerequisites must be met:

• The speed is higher than 50 km/h.

• The brake pedal is being actuated.

• ABS regulation takes place.

• The deceleration is greater than 6 m/s².

Tire pressure monitoring system: The tire

pressure monitoring system used in the Kuga is

able to detect loss of air in a tire at an early stage

and warn the driver. Because it can only compare

the behaviour of the tyres with each other, it is not possible to draw conclusions about the absolute

tyre pressure. It is also not possible to monitor the

spare tyre pressure. In order for the system to

operate correctly, the tyre pressures must be

regularly checked and corrected and the system

subsequently initialised (see below).

The tire pressure monitoring system used here,

depending on the equipment level, is built into the

anti-lock braking system (ABS) as an extra function

and therefore does not have its own sensors.

The ABS module measures the loss of pressure

in the tyres by calculation using the wheel speed

sensors of the ABS system. If a tyre loses

pressure, its diameter decreases and the speed of

the wheel therefore increases. If the ABS module

detects such a loss in pressure, it sends a signal

to the instrument cluster via the CAN bus and a

warning message is displayed in the message

centre. The warning threshold depends among

other things on the dimension of the tyres being

used, the vehicle operating conditions and the

status at the last initialisation. Since neither the

absolute tyre pressure nor the position of the tyre

is known, the pressure of all the tyres must be

checked and the system re-initialised after a tyre

pressure warning. If necessary, the cause of the

loss of pressure must be investigated.

Regular tyre pressure checks are still necessary.

The system must be initialised after a tyre is

changed, winter or summer tyres fitted, the

pressures corrected or adjusted to suit the vehicle

load. This can be done by the driver using the

driver information system. For further information,

see: Owner’s Manual.

Component Description

Opto-electronic steering wheel rotation

sensor

E80158

G1001304en2008.50 Kuga8/2011

206-09B-

11

Anti-Lock Control - Stability Assist

206-09B- 11

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1431 of 2057

ESP switch

E99006

Stability assist can be deactivated via the menu in

the instrument cluster. The stability assist functions

are deactivated when the Set switch is actuated.

The ABS control module makes the stability assist

functions available once more when the Set switch

is actuated again. The stability assist function is

automatically reactivated when the ignition is

switched on.

The electronic EBA is a constant function and will

remain active even if the ESP has been switched

off.

Combined yaw rate sensor and lateral

acceleration sensor / longitudinal

acceleration sensor

E96822

The heart of the combined yaw rate sensor and

lateral acceleration sensor/longitudinal acceleration

sensor is a small, double-sided tuning fork made

of a piezo crystal (A). The exciter side of this tuning

fork is set to a resonance of 11 kHz with the aid of

an alternating current. The measuring side of the

tuning fork features a resonance frequency of 11.33

kHz and therefore does not vibrate (B). Since,

under influence of an external accelerating force,

a vibrating mass reacts slower than a comparable

mass that is not vibrating, the tuning fork twists

within itself with rotational movement being

imparted on the sensor (C). This rotation results

in a change in the charge distribution in the Piezo

element, which is subsequently picked up and

converted into an electronic signal by electronics

integrated into the sensor. This electronic signal is

then sent to the ESP module. The ESP module

evaluates these data and takes into account the

other input data (vehicle speed, wheel speed)

before deciding whether the ESP function is

required.

G1001304en2008.50 Kuga8/2011

206-09B-13

Anti-Lock Control - Stability Assist

206-09B- 13

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

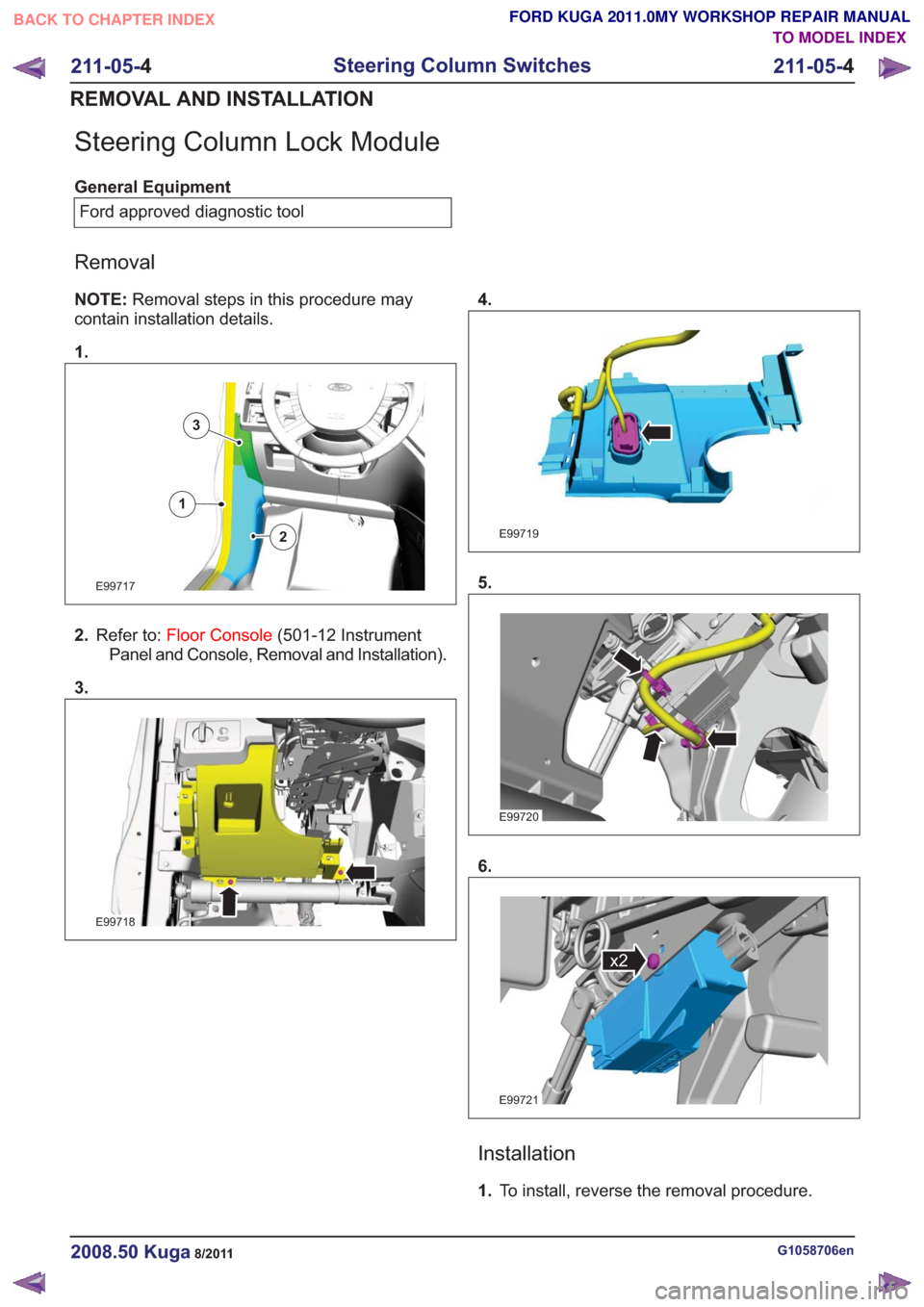

Page 1512 of 2057

Steering Column Lock Module

General EquipmentFord approved diagnostic tool

Removal

NOTE: Removal steps in this procedure may

contain installation details.

1.

E99717

1

2

3

2. Refer to: Floor Console (501-12 Instrument

Panel and Console, Removal and Installation).

3.

E99718

4.

E99719

5.

E99720

6.

E99721

x2

Installation

1. To install, reverse the removal procedure.

G1058706en2008.50 Kuga8/2011

211-05- 4

Steering Column Switches

211-05- 4

REMOVAL AND INSTALLATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

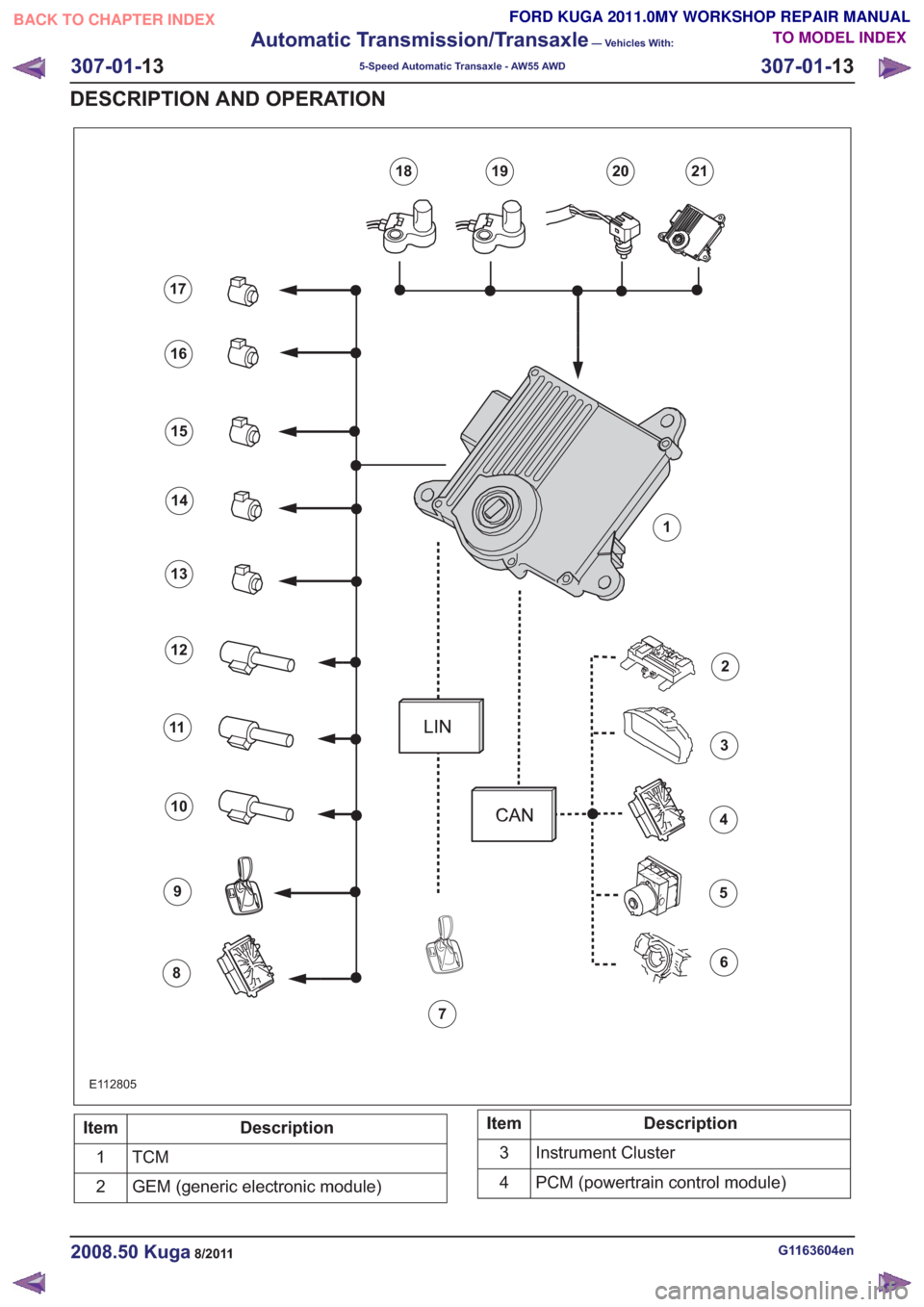

Page 1834 of 2057

E112805

59

13

2

6

10

14

3

7

11

15

4

8

12

16

17

19202118

1

Description

Item

TCM1

GEM (generic electronic module)

2Description

Item

Instrument Cluster

3

PCM (powertrain control module)

4

G1163604en2008.50 Kuga8/2011

307-01- 13

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 13

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1843 of 2057

transmission range or gear (in select-shift mode)

is indicated to the driver in the instrument panel.

In selector lever position "S", the driver can

manually select the gears (select-shift mode). Up

(+) and down (-) shifts are made by moving the

selector lever in the appropriate direction.

Hydraulic limp home modes maintain limited

operation in the event of failure of important

electrical components.Under normal conditions, the transmission fluid is

filled for the service life of the transaxle and does

not need to be changed.

A dipstick is used to check the fluid level in the

transmission.

Functionality overview

G1163605en2008.50 Kuga8/2011

307-01-

22

Automatic Transmission/Transaxle

— Vehicles With:

5-Speed Automatic Transaxle - AW55 AWD

307-01- 22

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL