roof FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 74 of 2057

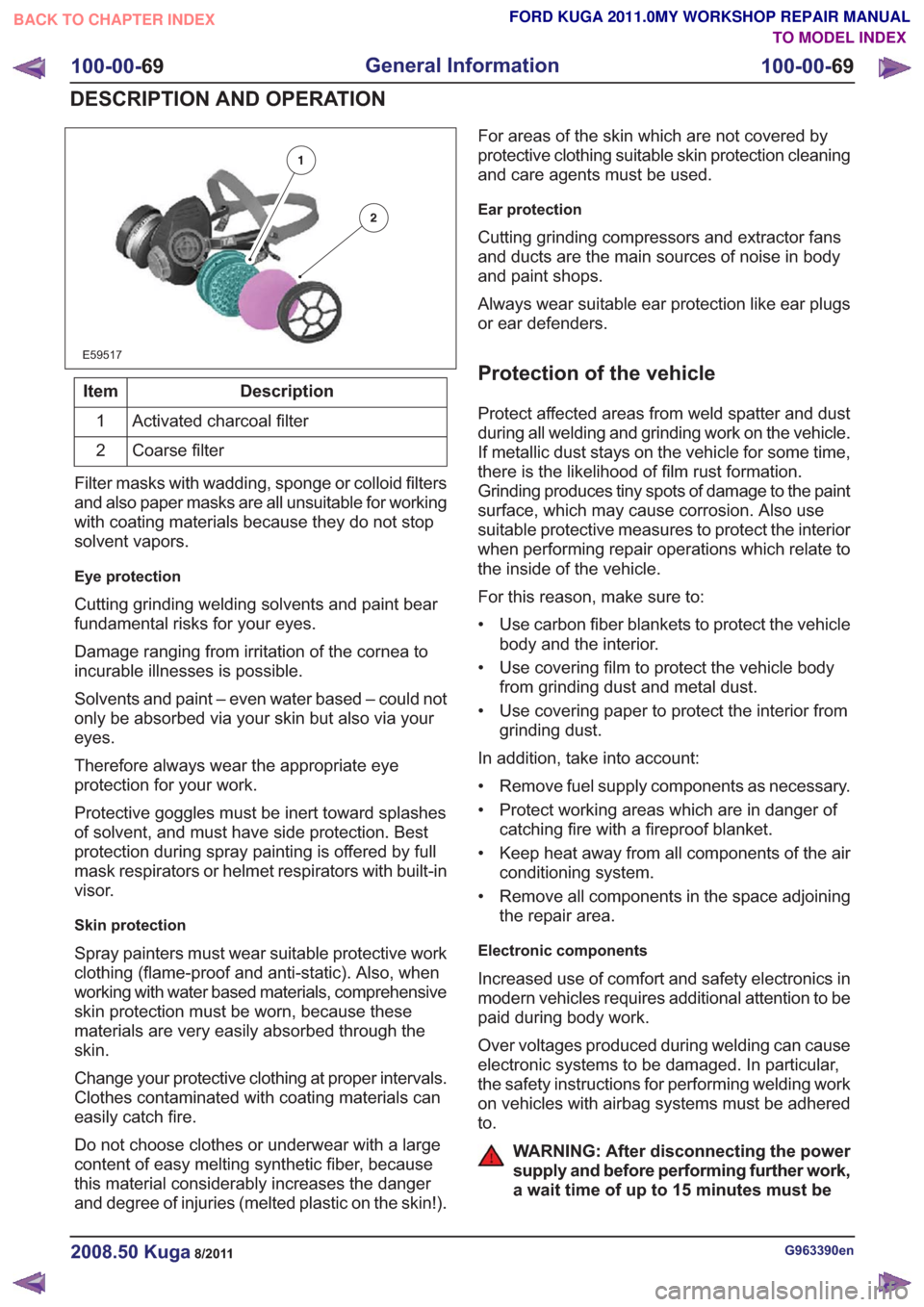

E59517

Description

Item

Activated charcoal filter

1

Coarse filter

2

Filter masks with wadding, sponge or colloid filters

and also paper masks are all unsuitable for working

with coating materials because they do not stop

solvent vapors.

Eye protection

Cutting grinding welding solvents and paint bear

fundamental risks for your eyes.

Damage ranging from irritation of the cornea to

incurable illnesses is possible.

Solvents and paint – even water based – could not

only be absorbed via your skin but also via your

eyes.

Therefore always wear the appropriate eye

protection for your work.

Protective goggles must be inert toward splashes

of solvent, and must have side protection. Best

protection during spray painting is offered by full

mask respirators or helmet respirators with built-in

visor.

Skin protection

Spray painters must wear suitable protective work

clothing (flame-proof and anti-static). Also, when

working with water based materials, comprehensive

skin protection must be worn, because these

materials are very easily absorbed through the

skin.

Change your protective clothing at proper intervals.

Clothes contaminated with coating materials can

easily catch fire.

Do not choose clothes or underwear with a large

content of easy melting synthetic fiber, because

this material considerably increases the danger

and degree of injuries (melted plastic on the skin!). For areas of the skin which are not covered by

protective clothing suitable skin protection cleaning

and care agents must be used.

Ear protection

Cutting grinding compressors and extractor fans

and ducts are the main sources of noise in body

and paint shops.

Always wear suitable ear protection like ear plugs

or ear defenders.

Protection of the vehicle

Protect affected areas from weld spatter and dust

during all welding and grinding work on the vehicle.

If metallic dust stays on the vehicle for some time,

there is the likelihood of film rust formation.

Grinding produces tiny spots of damage to the paint

surface, which may cause corrosion. Also use

suitable protective measures to protect the interior

when performing repair operations which relate to

the inside of the vehicle.

For this reason, make sure to:

• Use carbon fiber blankets to protect the vehicle

body and the interior.

• Use covering film to protect the vehicle body from grinding dust and metal dust.

• Use covering paper to protect the interior from grinding dust.

In addition, take into account:

• Remove fuel supply components as necessary.

• Protect working areas which are in danger of catching fire with a fireproof blanket.

• Keep heat away from all components of the air conditioning system.

• Remove all components in the space adjoining the repair area.

Electronic components

Increased use of comfort and safety electronics in

modern vehicles requires additional attention to be

paid during body work.

Over voltages produced during welding can cause

electronic systems to be damaged. In particular,

the safety instructions for performing welding work

on vehicles with airbag systems must be adhered

to.

WARNING: After disconnecting the power

supply and before performing further work,

a wait time of up to 15 minutes must be

G963390en2008.50 Kuga8/2011

100-00- 69

General Information

100-00- 69

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 81 of 2057

Noise, Vibration and Harshness (NVH)

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanicalor electrical damage.

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the concern is not visually evident, verify the symptom and REFER to the Symptom Chart.

How to Use this Diagnostic Procedure

Section

• Noise, vibration and harshness (NVH) concernshave become more important as vehicles have

become more sensitive to these vibrations. This

section is designed to aid in identifying these

concerns.

• The section provides diagnostic procedures based on symptom. If the condition occurs at

high speed, for instance, the most likely place

to start is under Shake and Vibration While

Driving.

• The road test procedure will tell how to sort the conditions into categories and how to tell a

vibration from a shake.

• A series of Road Test Quick Checks are provided to make sure that a cause is either

pinpointed or eliminated.

• Name the condition, proceed to the appropriate section and locate the correct diagnosis. When

the condition is identified, the job is partly done.

• Follow the diagnostic procedure as outlined.

• Quick Checks are described within the step, while more involved tests and adjustments are

outlined in General Procedures.

• Always follow each step exactly and make notes to recall important findings later.

Customer Interview

The road test and customer interview (if available)

provide information that will help identify the

concern and will provide direction to the correct

starting point for diagnosis.

Identify the Condition

NVH usually occur in four areas:

• tires

• engine accessories

• suspension

• driveline

It is important, therefore, that an NVH concern be

isolated into its specific area(s) as soon as

possible. The easiest and quickest way to do this

is to carry out the Road Test as outlined. To assist

in the diagnosis and testing procedure(s), use a

suitable approved NVH diagnosis tester.

Noise Diagnostic Procedure

Non-Axle Noise

The five most common sources of non-axle noise

are exhaust, tires, roof racks, trim panels and

transmission.

Therefore, make sure that none of the following

conditions are the cause of the noise before

proceeding with a driveline teardown and

diagnosis.

• In certain conditions, the pitch of the exhaustmay sound very much like gear noise. At other

times, it can be mistaken for a wheel bearing

rumble.

• Tires, especially snow tires, can have a high pitched tread whine or roar, similar to gear

noise. Radial tires may have this characteristic.

Also, any non-standard tire with an unusual

tread construction may emit a roar or whine

noise.

• Trim panels can also cause whistling or whining noise.

• Clunk may be a metallic noise heard when the automatic transaxle is engaged in "R"

(REVERSE) or "D" (DRIVE) or it may occur

when the throttle is applied or released. It is

caused by backlash somewhere in the driveline.

• Bearing rumble sounds like marbles being tumbled. This condition is usually caused by a

damaged wheel bearing.

G37349en2008.50 Kuga8/2011

100-04- 2

Noise, Vibration and Harshness

100-04- 2

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 297 of 2057

SECTION 415-01 Information and Entertainment

System

VEHICLE APPLICATION:

2008.50 Kuga

PAGE

CONTENTS

DESCRIPTION AND OPERATION

415-01-2

Audio System (Component Location).................................................................................

415-01-3

Audio System (Overview)...................................................................................................

415-01-3

Keycode entry - vehicle with standard audio system.........................................................

415-01-3

Vehicle Identification Number (VID) - entry - vehicle with standard audio system.............

415-01-3

Self-check routine - vehicles with standard audio system..................................................

415-01-3

Keycode entry - vehicles with upgraded audio system......................................................

415-01-5

Audio System (System Operation and Component Description)........................................

415-01-5

System Diagram.................................................................................................................

415-01-8

System Operation...............................................................................................................

415-01-8

In-car entertainment........................................................................................................

415-01-8

Component Description......................................................................................................

415-01-8

Vehicles with standard audio system..............................................................................

415-01-9

Vehicles with upgraded audio system.............................................................................

415-01-9

DAB radio........................................................................................................................

415-01-9

AUX port.........................................................................................................................

415-01-9

Radio remote control......................................................................................................415-01-10Antenna systems............................................................................................................

415-01-11

Cellular Phone (Component Location)...............................................................................

415-01-12

Cellular Phone (Overview)..................................................................................................

415-01-12

Software update - control module for mobile electronic auxiliary equipment (variant 1)....

415-01-12

Software update - control module for mobile electronic auxiliary equipment (variants 2

and 3)................................................................................................................................ 415-01-13

Cellular Phone (System Operation and Component Description)......................................

415-01-13

System Diagram.................................................................................................................

415-01-17

System Operation...............................................................................................................

415-01-17

Overview .........................................................................................................................

415-01-17

Voice Control...................................................................................................................

415-01-18

Component Description......................................................................................................

415-01-18Control module for mobile electronic auxiliary equipment..............................................

415-01-19Radio remote control......................................................................................................

415-01-19USB port/AUX socket.....................................................................................................

REMOVAL AND INSTALLATION 415-01-20

Audio Unit...........................................................................................................................

415-01-21

Audio Unit Antenna — Vehicles With: Glass Roof Panel...................................................

415-01-22

Audio Unit Antenna — Vehicles Without: Glass Roof Panel..............................................

415-01-23

Audio Unit Antenna to Connector Cable — Vehicles With: Glass Roof Panel...................

415-01-30

Audio Unit Antenna to Connector Cable — Vehicles Without: Glass Roof Panel..............

415-01-32

Connector to Audio Unit Antenna Cable.............................................................................

415-01-35

Compact Disc (CD) Changer..............................................................................................

415-01-37

(33 635 0)

Portable Support Electronics (PSE) Module..................................................

415-01-38

Cellular Phone Microphone................................................................................................ 415-01-1

Information and Entertainment System

415-01-1

.

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 306 of 2057

• Volume adjustment

– To increase the volume, press the top rearbutton on the remote control.

– To lower the volume: Press the bottom rear button on the remote control.

• Search – During radio operation, the station search isstarted upwards or downwards within the

frequency band.

– During CD operation, this skips to the next or previous track.

• Mode –During radio operation, the next saved station

is called up (if pressed briefly).

– During radio operation, to switch wave range

(if pressed and held).

– During CD operation, provided a CD changer

is installed, the next CD is played.

Antenna systems

The antenna systems fitted to the vehicle comprise:

• AM/FM roof antennal

• AM/FM/GPS roof antenna

• Roof antenna for digital radio system (vehicles with DAB radio) G1055647en

2008.50 Kuga 8/2011 415-01-10

Information and Entertainment System

415-01-10

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 317 of 2057

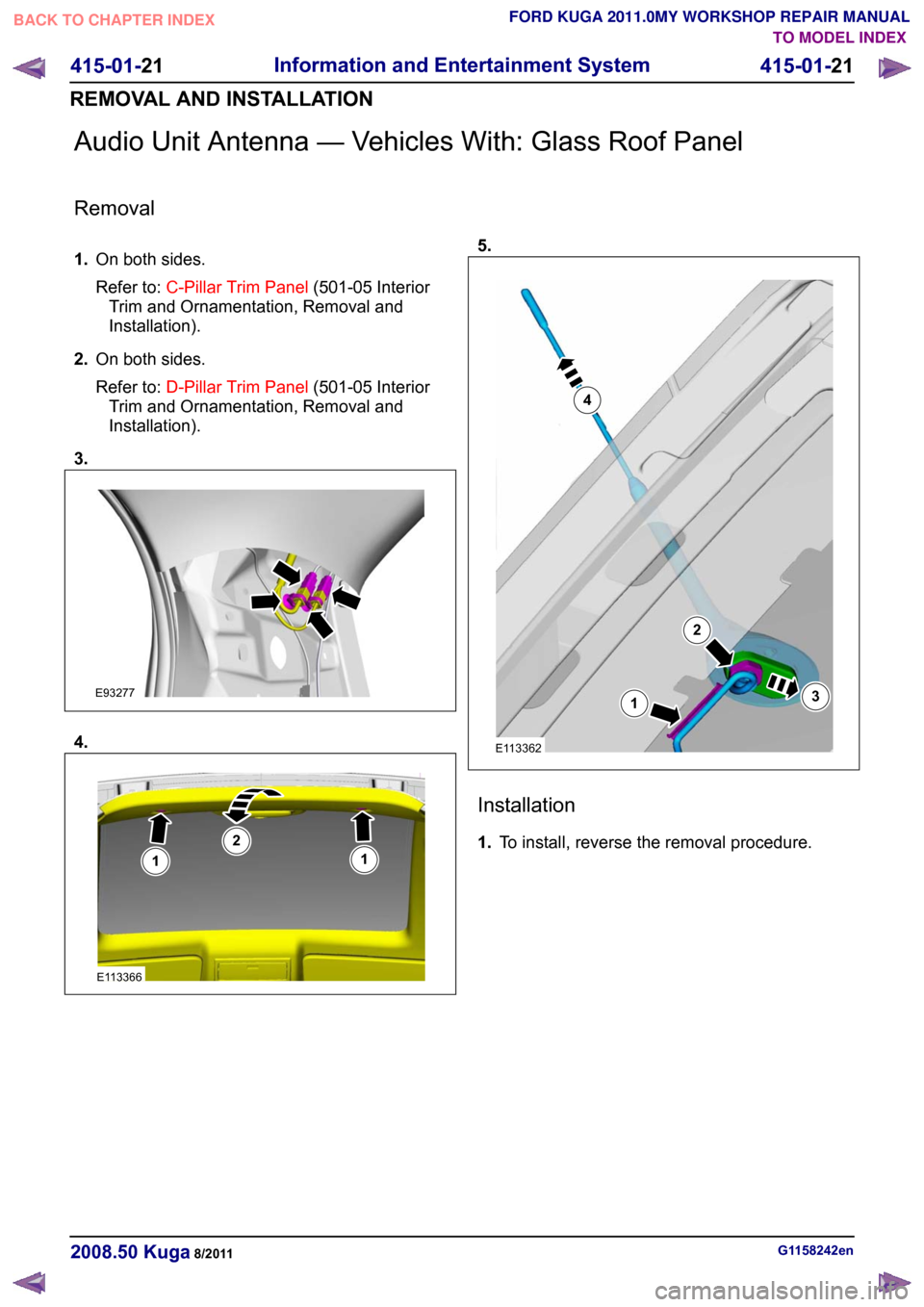

Audio Unit Antenna — Vehicles With: Glass Roof Panel

Removal

1.

On both sides.

Refer to: C-Pillar Trim Panel (501-05 Interior

Trim and Ornamentation, Removal and

Installation).

2. On both sides.

Refer to: D-Pillar Trim Panel (501-05 Interior

Trim and Ornamentation, Removal and

Installation).

3. 4. 5.

Installation

1.

To install, reverse the removal procedure. G1158242en

2008.50 Kuga 8/2011 415-01-21

Information and Entertainment System

415-01-21

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE93277 E113366112 E1133621234

Page 318 of 2057

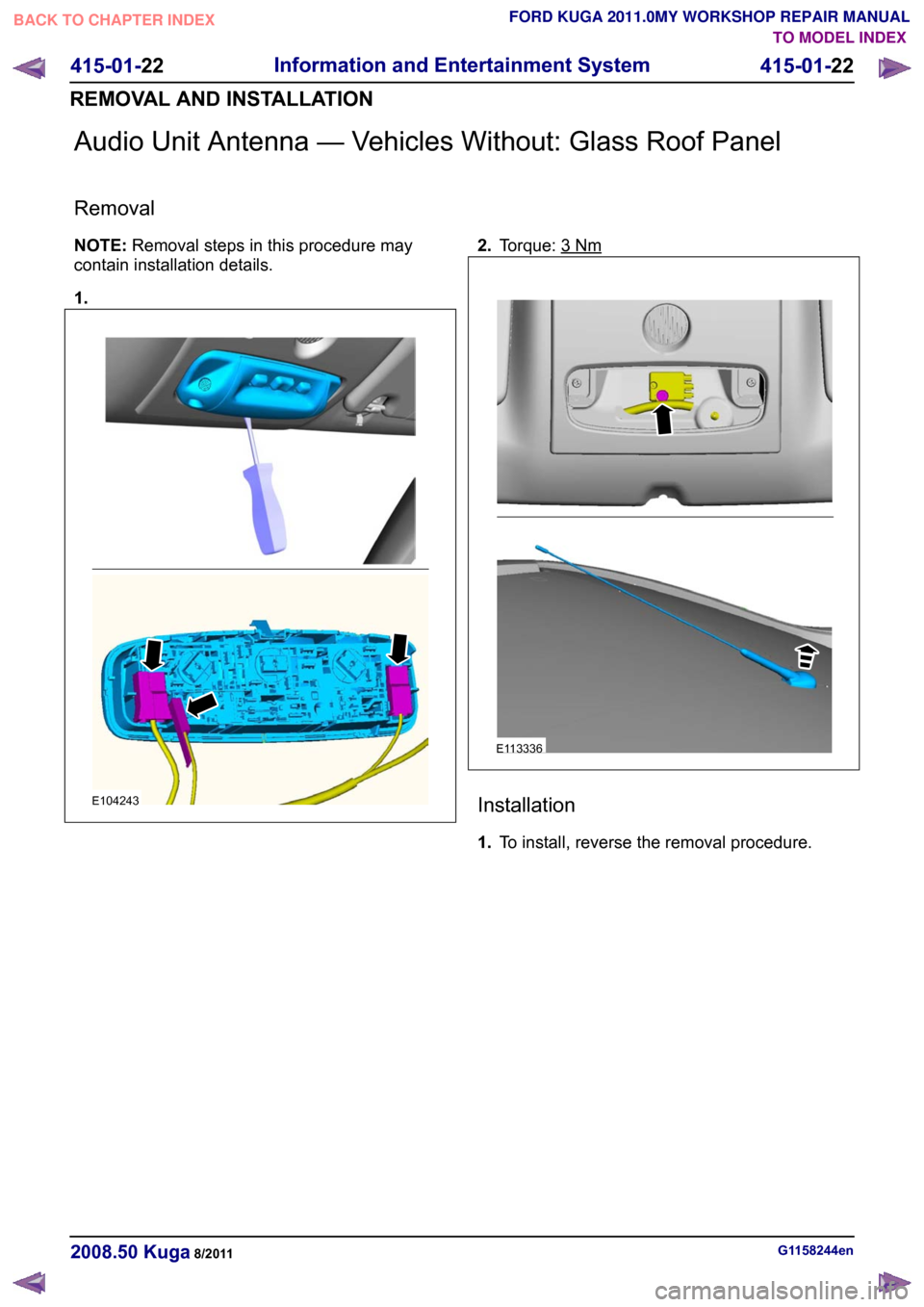

Audio Unit Antenna — Vehicles Without: Glass Roof Panel

Removal

NOTE:

Removal steps in this procedure may

contain installation details.

1. 2.

Torque: 3 Nm

Installation

1.

To install, reverse the removal procedure. G1158244en

2008.50 Kuga 8/2011 415-01-22

Information and Entertainment System

415-01-22

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE104243 E113336

Page 319 of 2057

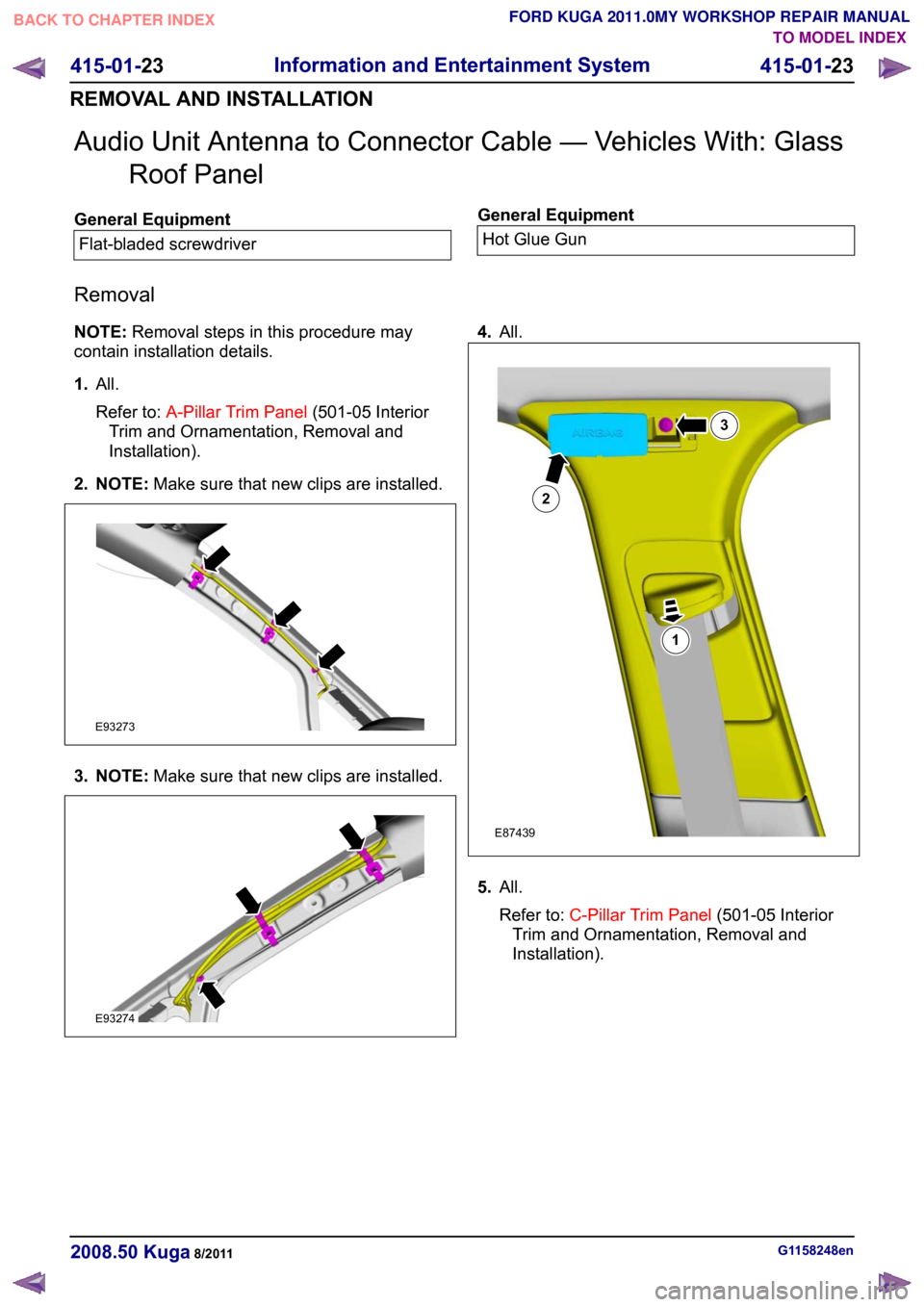

Audio Unit Antenna to Connector Cable — Vehicles With: Glass

Roof Panel General Equipment

Flat-bladed screwdriver General Equipment

Hot Glue Gun

Removal

NOTE: Removal steps in this procedure may

contain installation details.

1. All.

Refer to: A-Pillar Trim Panel (501-05 Interior

Trim and Ornamentation, Removal and

Installation).

2. NOTE: Make sure that new clips are installed.3. NOTE:

Make sure that new clips are installed. 4.

All. 5.

All.

Refer to: C-Pillar Trim Panel (501-05 Interior

Trim and Ornamentation, Removal and

Installation). G1158248en

2008.50 Kuga 8/2011 415-01-23

Information and Entertainment System

415-01-23

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE93273 E93274 123E87439

Page 326 of 2057

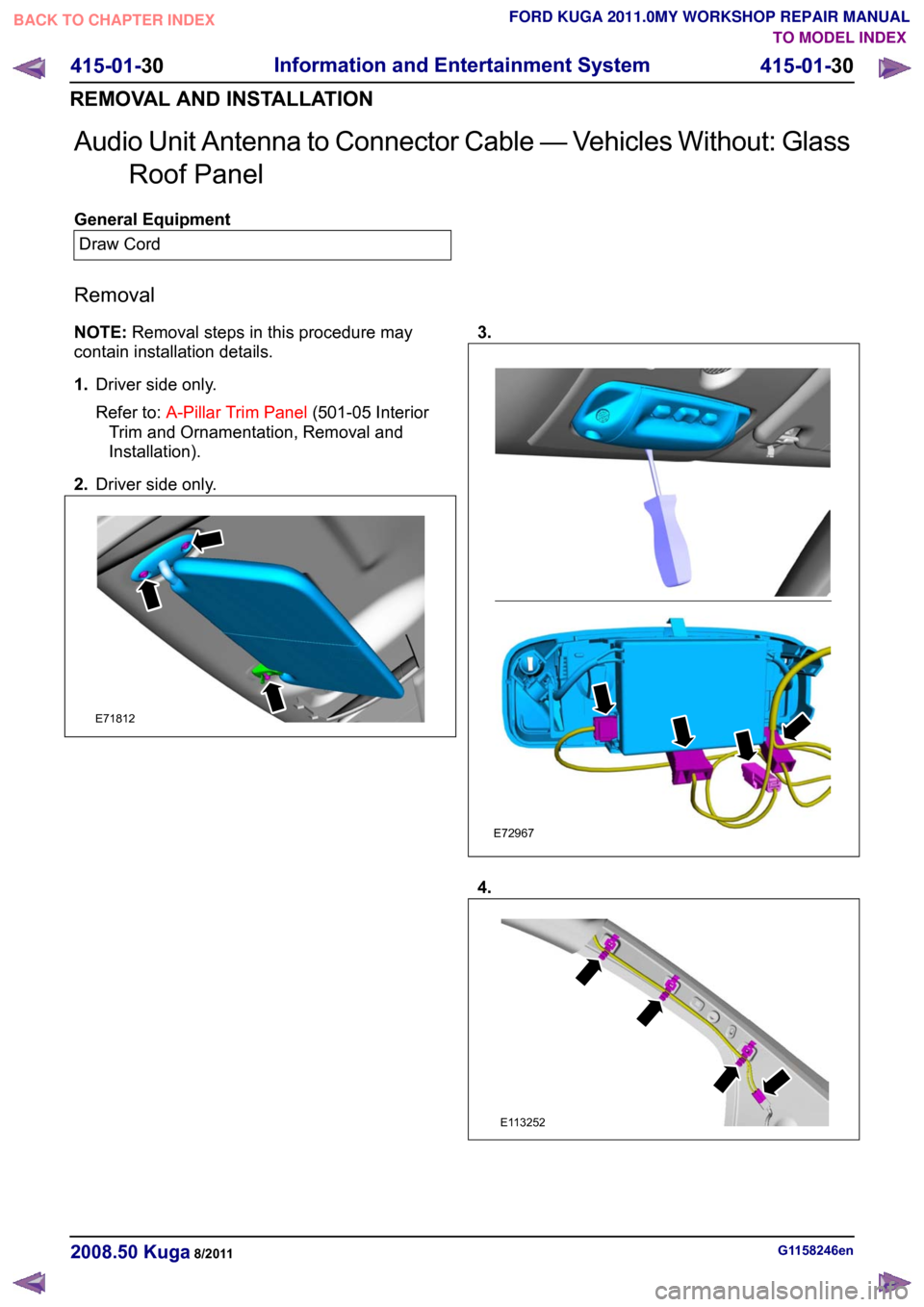

Audio Unit Antenna to Connector Cable — Vehicles Without: Glass

Roof Panel General Equipment

Draw Cord

Removal

NOTE: Removal steps in this procedure may

contain installation details.

1. Driver side only.

Refer to: A-Pillar Trim Panel (501-05 Interior

Trim and Ornamentation, Removal and

Installation).

2. Driver side only. 3.

4.

G1158246en

2008.50 Kuga 8/2011 415-01-30

Information and Entertainment System

415-01-30

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE71812 E72967 E113252

Page 342 of 2057

On some models, the door entry lamps are installed

in the external mirrors.

The door entry lamps should illuminate the ground

in the immediate vicinity of the front doors; they

are equipped with white bulbs, which are installed

in the underside of the mirror.

The door entry illumination is switched on when

one of the doors or the tailgate are opened, or if

an unlocking command is detected and the

following conditions are satisfied:

• Vehicle Ignition is off.

• Reverse gear is not engaged.

• The vehicle speed is below 7 km/h.

The door entry illumination is switched off if one of

the following conditions is satisfied:

• The ignition is selected on.

• Reverse gear is engaged.

• The vehicle speed exceeds 7 km/h.

• More than 25 seconds have elapsed since the

tailgate was closed or a central locking

command was determined.

• The time set for the battery protection function for the interior lighting has elapsed.

• More than 5 seconds have elapsed since the doors and the tailgate were closed.

• More than 5 seconds have elapsed since a central locking command was received and the

all doors and the tailgate were closed. Rear Lighting The rear lamps are each divided into three units.

The reversing lamps are located in the units in the

liftgate.

The outer units in the D-pillars contain the side

lamp as well as the turn signal and stoplamp.

The rear fog lamp is integrated in the lower area

of the bumper.

The high-mounted additional stop lamp is installed

in the middle of the roof spoiler.

Bulb color

Current draw

Bulb

Lamp

Orange

19W

PSY19W

Turn signal indicator

Clear

21W

P21W

Reversing Lamp

Clear

21/5W

W21/5W

Stoplamp/side lamp

Clear

21W

P21W

Rear fog lamp

–

1,4W

1 x LED board

Additional high-mounted

stoplamp G1079626en

2008.50 Kuga 8/2011 417-01-8

Exterior Lighting

417-01-8

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE101618

Page 384 of 2057

must use the same language. This language is

called a protocol.

At present, Ford uses three different data bus

systems. Depending upon model and equipment

level, all three data bus systems are used. Each

of these data bus systems has its own protocol.

Data bus systems

ISO 9141 bus

The International Organisation for Standardisation

ISO 9141 bus. This consists of a single wire and

is used exclusively for communication between the

modules and the Ford diagnostic unit. The fault

memories of the various modules are read out via

the ISO 9141 bus.

Local Interconnect Network (LIN) bus

The LIN bus is a standard specifically designed for

cost-effective communication between intelligent

sensors and actuators in vehicles. The LIN control

unit subnet is used in every situation where the

bandwidth and versatility of CAN is not needed.

The LIN specification comprises the LIN protocol,

a standard format for describing a complete LIN

and the interface between an LIN and the

application. An LIN comprises a LIN master and

one or more LIN slaves. The LIN utilizes the

master/slave principle for the purpose of bus

access control. This has the significant advantage

that few resources (CPU performance, ROM, RAM)

are required for bus management in the slave

module. The master is implemented in a control

module or a gateway which has the necessary

resources. All communication is initiated by the

master. Consequently, a message always consists

of a header, which is generated by the master, and

a response from the slave. The data transfer rate

is in the region of up to 20 Kbit/s. The LIN master

knows the time sequence of all data which are to

be transmitted. These data are transmitted by the

corresponding LIN slaves (e.g. ultrasonic sensors)

if they are requested to do so by the LIN master.

LIN is a single-wire bus, i.e. the data are

transmitted in the cable via one wire. Usually the

same cable is also used to provide the supply

voltage. The ground connection of the supply

voltage also acts as the ground connection of the

data transmission. An LIN does not use a

terminating resistor.

Controller Area Network (CAN) bus

This consists of two twisted wires and operates

serially (data is transmitted sequentially). It is used

for communication between the modules

themselves and between the modules and the Ford

diagnostic unit. The modules are connected to the

data bus in parallel. New modules can be

incorporated easily, without modifying the other

wiring or modules. The transmitted data is received

by every module connected to the control unit

network (CAN). As each data packet has an

identifier (label), in which the priority of the

message is determined as well as the content

identification, each module can detect whether or

not the data is relevant for its own information

processing. This enables several modules to be

addressed with a particular data packet and

supplied with data simultaneously. For this

purpose, it is ensured that important data (for

example from the ABS) is transmitted first. The

other modules are only able to submit their data to

the data bus after the high-priority messages have

been received.

The advantages of the CAN bus are:

• Minimization of wiring requirements

•

High degree of error protection (fault / fail-proof)

• Robustness

• Good extendibility

• Prioritization of messages

• Inexpensive

• Automatic repetition of faulty messages

• Independent system monitoring and the ability to disconnect faulty modules from the data bus

automatically

Due to the increased number of modules and the

resulting continued increase in data transfer, two

different CAN bus systems are used. Essentially,

they only differ in terms of their data transmission

rates and application areas.

To be able to distinguish between the individual

CAN bus systems, the CAN bus system with the

high transfer speed is called the high speed CAN

bus (HS-CAN). The data are transmitted at a baud

rate of 500 kB/s.

The CAN bus system with the medium transfer

speed is called the medium speed CAN bus

(MS-CAN) and is mainly used for communication

in the comfort electronics or the multimedia system.

The data are transmitted at a baud rate of 125 kB/s.

An interface (gateway) is used to exchange data

between the HS-CAN and the MS-CAN. This

provides the connection between the three CAN

databus systems and is installed in the GEM and

in the electronic instrument cluster. The number of

modules which are connected to the three databus G1030779en

2008.50 Kuga 8/2011 418-00-7

Module Communications Network

418-00-7

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL