starter relay FORD KUGA 2011 1.G Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 457 of 2057

Electrical consumers are switched off when the

battery voltage is low if the GEM determines (as a

result of the message received from the PCM on

the CAN bus via the instrument cluster) that the

battery voltage has dropped below the threshold

value.

When the threshold for low battery voltage is

reached the GEM switches off the following

consumers in this order at intervals of 5 seconds:

• Heated windscreen

• Heated rear window

• Electric booster Heater

• A/C system

If the battery voltage increases back above the

lower threshold then all of the consumers which

were previously switched off are reactivated by the

GEM.

Once the electric consumers have been reactivated

their status is "switched off", i.e. the consumers

are switched off and await an input signal provided

from the relevant switch via the GEM; this means

that the driver needs to switch these components

back on again.

Electrical consumers are switched on when the

battery voltage is excessively high if the GEM

determines that the battery voltage has increased

above the threshold for overvoltage and the

charging system warning indicator has come on.

When the threshold is reached the GEM switches

on the following consumers in this order at intervals

of 5 seconds:

• Heated windscreen

• Heated rear window

When these components are deactivated again

their status is "switched off". This means that the

consumers are waiting for an input signal provided

from the relevant switch via the GEM.

Ignition overload protection

The ignition overload protection intermittently

disconnects certain circuits in order to restrict the

current being drawn from the battery while the

starter motor is operating.

The position of the ignition switch is broadcast by

the instrument cluster on the medium speed CAN

bus.

The ignition overload protection relay which is

integrated in the battery junction box is activated

by the GEM if the message "ignition switch in

position III" is received from the instrument cluster.

All of the electric consumers controlled by the

ignition overload protection relay are then switched

off.

The following consumers (among others) are

controlled by the ignition overload protection relay:

• Fog lamps

• Windscreen/rear window wash/wipe systems

• Backup lamps

• Heated washer nozzles

• Heating blower motor

• Seat heating

Headlamp switch-off delay

The headlamp switch-off delay utilizes the low

beam together with the peripheral lights (if

equipped) to illuminate the area surrounding the

vehicle. The function is activated by operating the

high beam lever when the ignition switch is in the

"0" position.

After the last door has been closed, the function

remains active for a further 30 seconds and then

switches off automatically.

When a door or the tailgate is open, the switch-off

time is extended to 180 seconds. After the last door

has been closed, the switch-off time is reset to 30

seconds.

The headlamp switch-off delay can be deactivated

prematurely by operating the high beam lever again

or by switching on the ignition.

The switch-off time is adjusted to set values at the

factory and cannot be re-programmed using the

Ford diagnostic unit.

G1030788en

2008.50 Kuga 8/2011 419-10-7

Multifunction Electronic Modules

419-10-7

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1525 of 2057

Action

Possible Sources

Symptom

• CHECK the engine compon-ents for wear or damage. Make

sure that all components are

within specification. INSTALL

new components as necessary.

Engine - 2.5L Duratec-ST (VI5)

-

REFER to: Specifications (303-

01 Engine - 2.5L Duratec

(147kW/200PS) - VI5,

Specifications).

Engine - 2.0L Duratorq-TDCi

(DW) Diesel -

• Engine components

- Pistons.

- Piston rings.

- Connecting rod big end,main bearing or thrust

bearing journals.

- Connecting rods bent or damaged.

• Noisy running or engine noise

Engine - Oil Leaks

NOTE:

Before installing new gaskets or oil seals,

make sure that the fault is clearly established.

If the oil leak cannot be identified clearly by a visual

inspection, carry out an ultraviolet (UV) test:

Ultraviolet (UV) Testing

1. Clean the engine and transmission with a suitable cleaning fluid.

2. Pour the UV-test fluid in accordance with the quantity specified by the manufacturer through

the oil filler neck into the engine and install the

oil filler cap.

WARNING: Vehicles with manual transaxle,

shift the transaxle into Neutral. Failure to

follow this instruction may result in

personal injury.

3. Start the engine and let it run for about five minutes.

4. Switch off the engine.

NOTE: If no leak can be found, road test the

vehicle under various loads and check the engine

for leaks again.

5. Check the engine for oil leaks using a suitable UV lamp.

6. Rectify any leaks found and check the engine for oil leaks.

Measure the compression pressure

NOTE: The powertrain control module (PCM)

receives an error message when the fuel pump

relay is removed or electrical components are disconnected. This error message must be deleted

from the fault memory using the Ford diagnostic

equipment after completing the compression test.

NOTE:

Valve clearance must be set correctly

before performing a compression test. Make sure

the engine is at the normal operating temperature.

NOTE: The varying design of compression

checking devices and fluctuating starter motor

speeds normally only allows for a comparison to

be made of the compression pressures in all

cylinders.

G1055128en2008.50 Kuga8/2011

303-00- 9

Engine System - General Information

303-00- 9

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1526 of 2057

Measure the compression pressure

(Engine - 2.5L Duratec-ST (VI5))

TIE44608

1. Remove the central junction box (CJB) cover.

TIE44609

2. Open the CJB and remove the fuel pump relay.

3. NOTE: The engine will start, run for a fewseconds and then stop.

Start the engine.

4. Remove the ignition coil-on-plug.

REFER to: Ignition Coil-On-Plug (303-07 Engine

Ignition - 2.5L Duratec (147kW/200PS) - VI5,

Removal and Installation). 5. Connect the battery ground cable.

REFER to: Battery Disconnect and Connect

(414-01 Battery, Mounting and Cables,

General Procedures).

E68679

x5

6. Using Special Tool 303-499, remove the spark plugs.

E68434

NOTE: Operate the starter motor with wide open

throttle until the pointer on the measuring device

stops rising.

7. Carry out the measurement in accordance with the instructions supplied with the measuring

device on every cylinder using a suitable

compression pressure recorder with a suitable

adapter.

E68680

28 Nm

8. Using Special Tool 303-499, install the sparkplugs.

G1055128en2008.50 Kuga8/2011

303-00- 10

Engine System - General Information

303-00- 10

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1748 of 2057

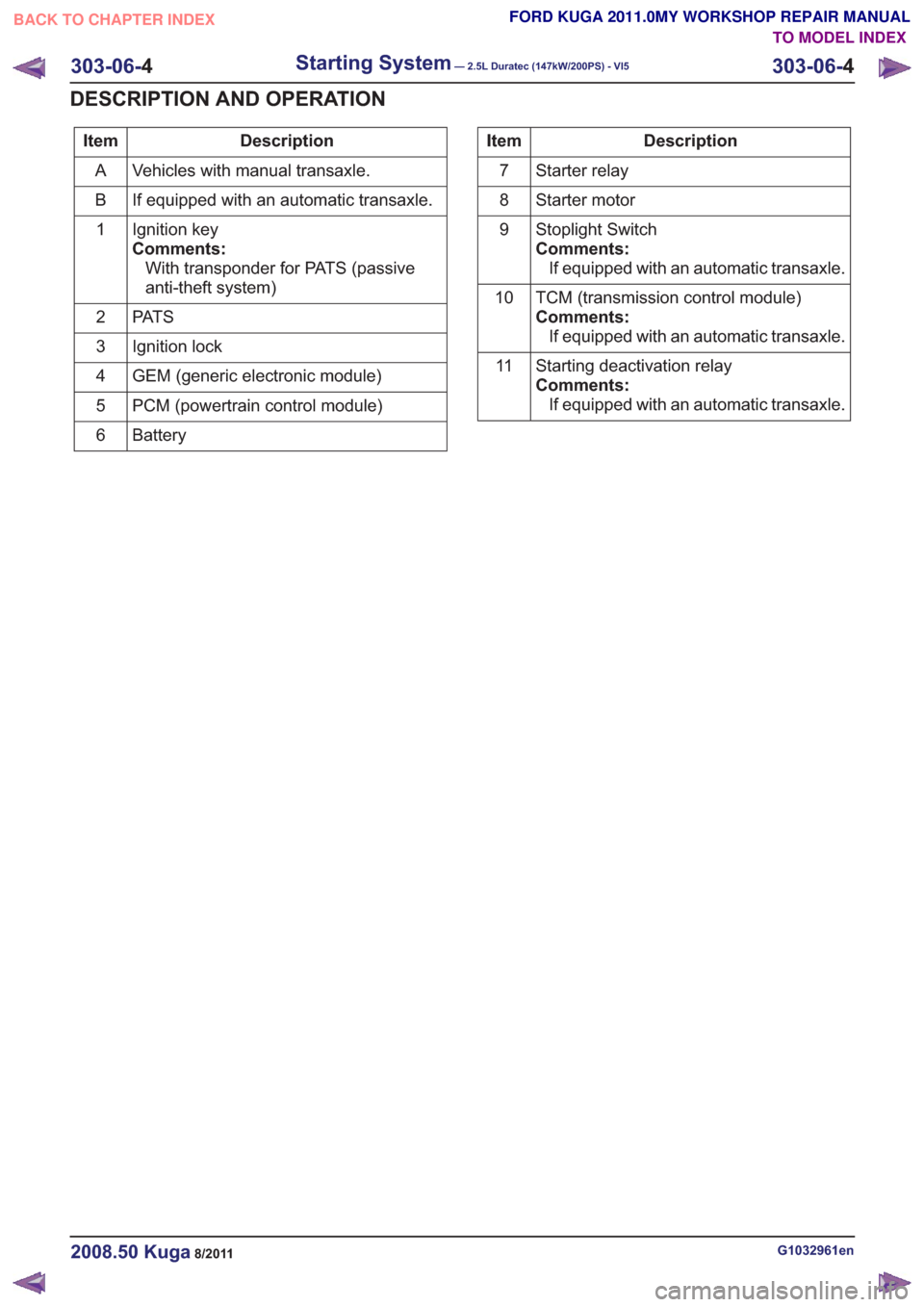

Description

Item

Vehicles with manual transaxle.

A

If equipped with an automatic transaxle.

B

Ignition key

Comments:With transponder for PATS (passive

anti-theft system)

1

PAT S

2

Ignition lock

3

GEM (generic electronic module)

4

PCM (powertrain control module)

5

Battery

6Description

Item

Starter relay

7

Starter motor

8

Stoplight Switch

Comments:If equipped with an automatic transaxle.

9

TCM (transmission control module)

Comments:If equipped with an automatic transaxle.

10

Starting deactivation relay

Comments:If equipped with an automatic transaxle.

11

G1032961en2008.50 Kuga8/2011

303-06-

4

Starting System— 2.5L Duratec (147kW/200PS) - VI5303-06-

4

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1750 of 2057

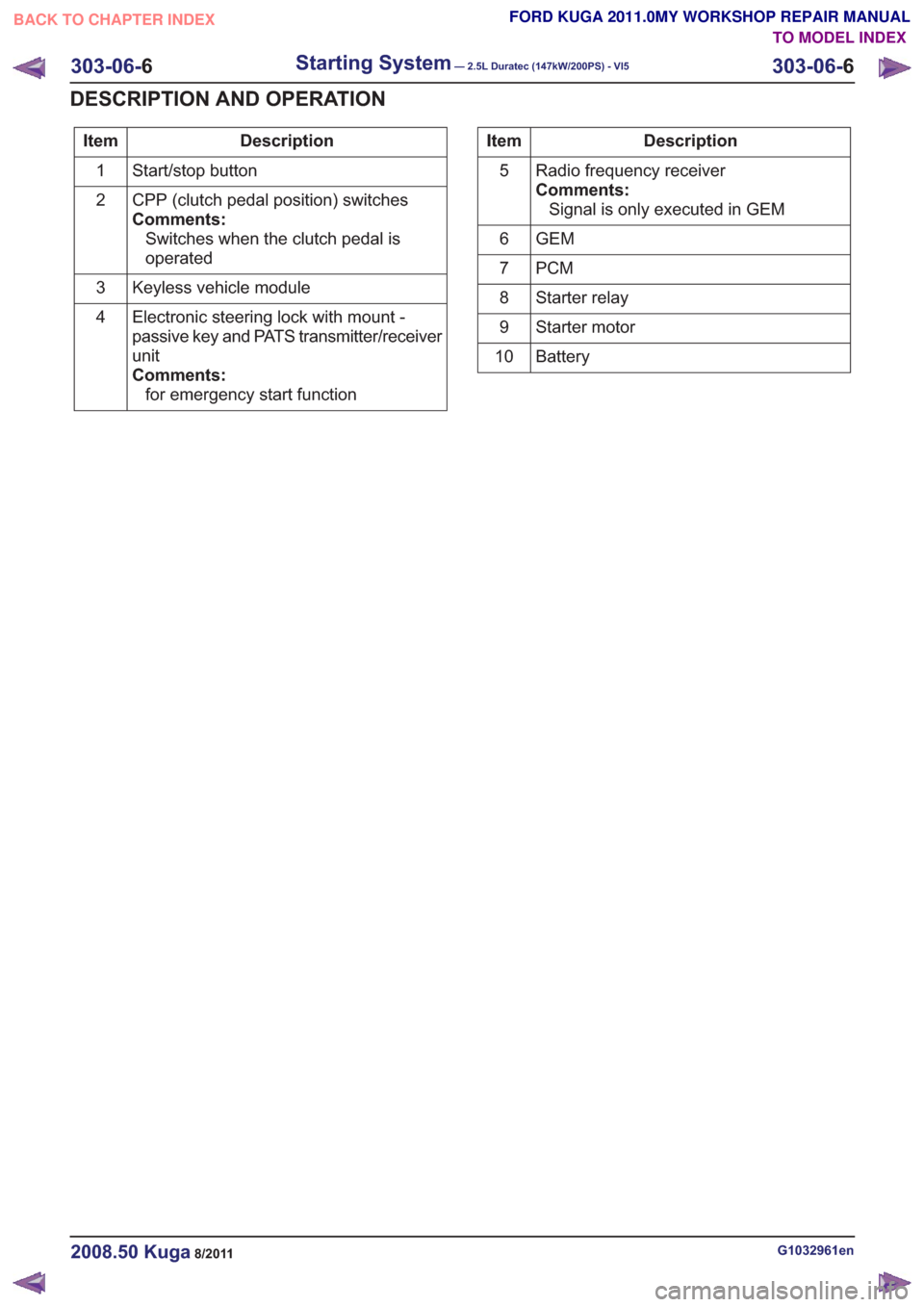

Description

Item

Start/stop button

1

CPP (clutch pedal position) switches

Comments:Switches when the clutch pedal is

operated

2

Keyless vehicle module

3

Electronic steering lock with mount -

passive key and PATS transmitter/receiver

unit

Comments:for emergency start function

4Description

Item

Radio frequency receiver

Comments:Signal is only executed in GEM

5

GEM

6

PCM

7

Starter relay

8

Starter motor

9

Battery

10

G1032961en2008.50 Kuga8/2011

303-06- 6

Starting System— 2.5L Duratec (147kW/200PS) - VI5303-06-

6

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1752 of 2057

Description

Item

Start/stop button

1

Keyless vehicle module

2

Electronic steering lock with mount -

passive key and PATS transmitter/receiver

unit

Comments:for emergency start function

3

Radio frequency receiver

Comments:Signal is only executed in GEM

4Description

Item

GEM

5

Stoplight Switch

6

TCM7

Starting deactivation relay

8

PCM

9

Starter relay

10

Starter motor

11

Battery

12

System Operation

Smart Start

The PCM enables the starting process when a key

providing a valid code is read via the PATS. This

code is then verified in the GEM and compared

with the saved code. If this code is recognized as

correct, synchronization with other modules is

carried out. After successful synchronization, the

engine is cleared to start in the PCM. The PCM

connects earth to the starter relay, which then

connects power to the starter solenoid. As soon

as the engine reaches a certain speed, the PCM

disconnects the starter relay and so turns off the

starter. This protects the starter.

If the engine does not turn or turns only slowly, the

starting process is aborted by the PCM.

The starter is notactivated if:

• the engine is running (i.e. the engine speed is above a particular value),

• the PATS does not permit the engine to be started,

• the clutch pedal is not operated (vehicles with manual transmission),

• the gear selector level is not set to P or N (vehicles with automatic transmission),

• the brake pedal is not operated (vehicles with automatic transmission).

Emergency starting function

If the keyless vehicle system is unable to recognize

the passive key, the vehicle can be started via the

emergency starting function. In this case, there is a passive key mount on the

steering wheel. A PATS transmission/reception

unit is attached to this.

To start the engine, the passive key must be

inserted into the passive key mount. The Start/Stop

button can then be used to turn on the ignition and

start the engine as normal. To deactivate the

PATS, a transponder is fitted in the passive key,

which is read by the transmission/reception unit.

G1032961en2008.50 Kuga8/2011

303-06-

8

Starting System— 2.5L Duratec (147kW/200PS) - VI5303-06-

8

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1753 of 2057

Starting System

Refer toWiring Diagrams Section 303-06, for

schematic and connector information.

General Equipment

Ford diagnostic equipment

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of electrical damage.

Visual Inspection Chart

Electrical

• Fuse(s)

• Wiring harness

• Electrical connector(s)

• Relay

• Switch(es)

• Battery junction box (BJB)

• Engine junction box (EJB)

• Central junction box (CJB)

• Keyless vehicle module (KVM) (if equipped)

• Battery

• Starter motor

• Powertrain Control Module (PCM)

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the symptom and refer to the diagnostictab within

the Ford diagnostic equipment .

G1183444en2008.50 Kuga8/2011

303-06-9

Starting System— 2.5L Duratec (147kW/200PS) - VI5303-06-

9

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1790 of 2057

Description

Item

Medium speed CAN data bus (MS-CAN)

1

DLC

2

GEM

Comments:Serves as a gateway between the two

CAN databus systems.

3

High speed CAN data bus (HS-CAN)

4

PCMRefertoComponentDescription:(page

8)

5

LIN (local interconnect network) databus

6

Alternator

7

Heating element - broadband HO2S

8

Catalyst monitor sensor heating element

9

Powertrain Control Module relay

10

Starter Relay

11

FPDM

Comments:Refer to: Fuel Tank and Lines - 2.5L

Duratec (147kW/200PS) - VI5 (310-01

Fuel Tank and Lines, Description and

Operation).

12

Fuel pump

13

injectorsRefertoComponentDescription:(page

?)

Comments: 5x

14Description

Item

Air conditioning clutch relay

Comments:Refer to: Climate Control (412-01

Climate Control, Description and

Operation).

15

EVAP valve

Comments:

16

VCT oil control solenoid, exhaust camshaftRefer to Component Description:

solenoids(page26)

17

VCT oil control solenoid, intake camshaftRefer to Component Description:

solenoids(page26)

18

Cooling fan module

Comments:Refer to: Engine Cooling - 2.5L Duratec

(147kW/200PS) - VI5 (303-03 Engine

Cooling, Description and Operation).

19

Wastegate control valve

Comments:Refer to: Turbocharger (303-04 Fuel

Charging and Controls - Turbocharger

- 2.5L Duratec (147kW/200PS) - VI5,

Description and Operation).

20

Ignition coil-on-plugRefertoComponentDescription:(page

10)

Comments: 5x

21

Throttle control unitRefertoComponentDescription:(page

30)

Comments: Actuator motor unit

22

System Operation

The engine is controlled by the PCM. For this

purpose, the PCM uses information from the

sensors, sender units and switches. In addition,

the PCM receives information from other control

modules via the CAN data bus. All the information

is processed in the PCM and is used to control or

regulate the different actuators.

These are:

• the throttle control unit,

• the fuel injectors, • the camshaft adjustment,

• the boost control solenoid valve

• and the ignition coils.

Some values are sent via the CAN databus to other

systems.

The following functions are regulated or controlled

by the PCM:

G1021908en2008.50 Kuga8/2011

303-14-

16

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

16

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 1791 of 2057

• Starting process

• Engine running– Fuel supply to the engine including lambdacontrol

– Ignition setting including knock control

– Idle speed control

– Boost pressure control

– Valve timing via the camshaft adjuster for the intake and exhaust camshafts (including

internal exhaust gas recirculation)

• Refrigerant compressor (activation, deactivation and delivery)

• EVAP purge valve

• Charging system

Fuel is supplied to the engine via a sequential

multi-point injection system. Ignition is performed

by a distributor-less ignition system with one

ignition coil unit for each cylinder.

The PCM optimizes engine power and emissions

at all times by processing the sensor signals and

information received via the CAN databus and

using these for open or closed loop control of the

different variables.

The PCM contains part of the PATS (passive

anti-theft system).

The PCM is supplied with battery voltage via a fuse

in the BJB (battery junction box). This power supply

is needed to ensure that saved data is not lost

when the engine is switched off.

For other power supply requirements, the PCM

switches on a relay in the BJB which is responsible

for supplying power to the PCM and to some

sensors and actuators. Each of these are protected

by fuses in the BJB.

To guarantee optimum engine running at all times,

the PCM has several adaptive (self-learning)

functions. These adapt the output signals to

changing circumstances, such as wear or system

faults.

In some cases a faulty signal is replaced with a

substitute value or limited. A substitute value can

be calculated from other signals or it can be

predefined by the PCM. The substitute value allows

the vehicle to keep on running without the emission

values changing unduly. Depending on the signal

failure, the PCM operates in emergency mode. In

this mode, the engine power and/or the engine

speed is reduced to prevent further damage.

Depending on the faulty signal, a fault code is

stored in the error memory of the PCM. These can be read out using IDS (Integrated Diagnostic

System) via the DLC.

The PCM processes and evaluates the signals

from the sensors. The following sensors send

signals to the PCM:

• CMP sensors

• CKP sensor

• MAF sensor

•KS

• ECT sensor

• TP sensor

• APP sensor

• Broadband HO2S

• Catalyst monitor sensor

• MAPT sensor

• Air conditioning (A/C) pressure sensor

• Alternator

• Fuel temperature and fuel pressure sensor

• Engine oil level, temperature and quality sensor

• Outside air temperature sensor

The following components receive signals from the

PCM:

• Powertrain Control Module relay

• A/C clutch relay

• injectors

• Direct ignition coils

• Cooling fan module

• Throttle control unit

• Camshaft adjuster solenoid valve

• Starter Relay

• EVAP purge valve

• Alternator

• Heating element - broadband HO2S

• Catalyst monitor sensor heating element

• FPDM

• Wastegate control valve

• Air conditioning compressor

The PCM receives the following signals via the

CAN databus:

• APP

•CPP

• BPP

• Vehicle speed.

• Refrigerant compressor request

• PAT S

G1021908en2008.50 Kuga8/2011

303-14-

17

Electronic Engine Controls— 2.5L Duratec (147kW/200PS) - VI5303-14-

17

DESCRIPTION AND OPERATION

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL