tailgate FORD MONDEO 1993 Service Owner's Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1993, Model line: MONDEO, Model: FORD MONDEO 1993Pages: 279, PDF Size: 12.71 MB

Page 222 of 279

headlamp washer pump, from the reservoir

(see illustration).

7Remove the rubber seals.

Washer nozzle (windscreen)

8With the bonnet supported in its open

position, carefully disconnect the washer tube

from the bottom of the nozzle.

9Using a screwdriver and working from

under the bonnet, carefully prise out the

nozzle. Where necessary, disconnect the

wiring for the nozzle heater.

Washer nozzle (rear window)

10With the tailgate open, carefully pull off

the inner trim panel from the top of the

tailgate.

11Pull the washer tube from the bottom of

the nozzle (see illustration).

12Carefully prise the nozzle out of the

tailgate glass, then prise out the rubber

grommet (see illustrations). Where

necessary, disconnect the wiring for the

nozzle heater.

Refitting

13Refitting is a reversal of the removal

procedure. In the case of the washer nozzles,

press them in until they are fully engaged. The

rear window washer nozzle must rest against

the rubber seal.

Note:Special tools are required to remove the

radio.

Coding

1If a Ford “Keycode” unit is fitted, and the

unit and/or the battery is disconnected, the

unit will not function again on reconnection

until the correct security code is entered.

Details of this procedure are given in the

“Ford Audio Systems Operating Guide”

supplied with the vehicle when new, with the

code itself being given in a “Radio Passport”

and/or a “Keycode Label” at the same time.

2For obvious security reasons, the re-coding

procedure is not given in this manual - if youdo not have the code or details of the correct

procedure, but can supply proof of ownership

and a legitimate reason for wanting this

information, the vehicle’s selling dealer may

be able to help.

3Note that these units will allow only ten

attempts at entering the code - any further

attempts will render the unit permanently

inoperative until it has been reprogrammed by

Ford themselves. At first, three consecutive

attempts are allowed; if all three are incorrect,

a 30-minute delay is required before another

attempt can be made. Each of any

subsequent attempts (up to the maximum of

ten) can be made only after a similar delay.

Removal

4Disconnect the battery negative (earth)

lead.

5Where fitted, prise the cover/surround from

the front of the radio/cassette player. Note

that the cover is not fitted to all models.

6In order to release the radio retaining clips,

two U-shaped rods must be inserted into the

special holes on each side of the radio (see

illustration). If possible, it is preferable to

obtain purpose-made rods from an audio

specialist, as these have cut-outs which snap

firmly into the clips so that the radio can be

pulled out. Pull the unit squarely from its

aperture, or it may jam. If the unit proves

difficult to withdraw, remove the cassette tray

(or where applicable, the CD player) frombeneath the unit, then reach through the

aperture and ease it out from behind.

7With the radio partly withdrawn, disconnect

the feed, earth, aerial and speaker leads.

Where applicable, also detach and remove

the plastic support bracket from the rear of

the unit.

Refitting

6Refitting is a reversal of removal. With the

leads reconnected to the rear of the unit,

press it into position until the retaining clips

are felt to engage. Reactivate the unit by

entering the correct code in accordance with

the maker’s instructions.

Removal

1Disconnect the battery negative (earth)

lead. See Chapter 5, Section 1.

2Unscrew the screws and remove the lower

facia panel.

3The radio/cassette player power amplifier is

located beneath the facia.

4Unscrew the cross-head screws, dis-

connect the wiring and remove the amplifier.

Refitting

5Refitting is a reversal of the removal

procedure.

24 Radio/cassette player

power amplifier -

removal and refitting

23 Radio/cassette player -

coding, removal and refitting

Body electrical system 12•21

12

22.12B . . . and prise out the rubber

grommet23.6 Using the special U-shaped rods to

remove the radio

22.6 Pulling the windscreen washer pump

from the reservoir22.11 Pull the washer tube from the

bottom of the nozzle22.12A Remove the nozzle from the

tailgate glass . . .

procarmanuals.com

Page 265 of 279

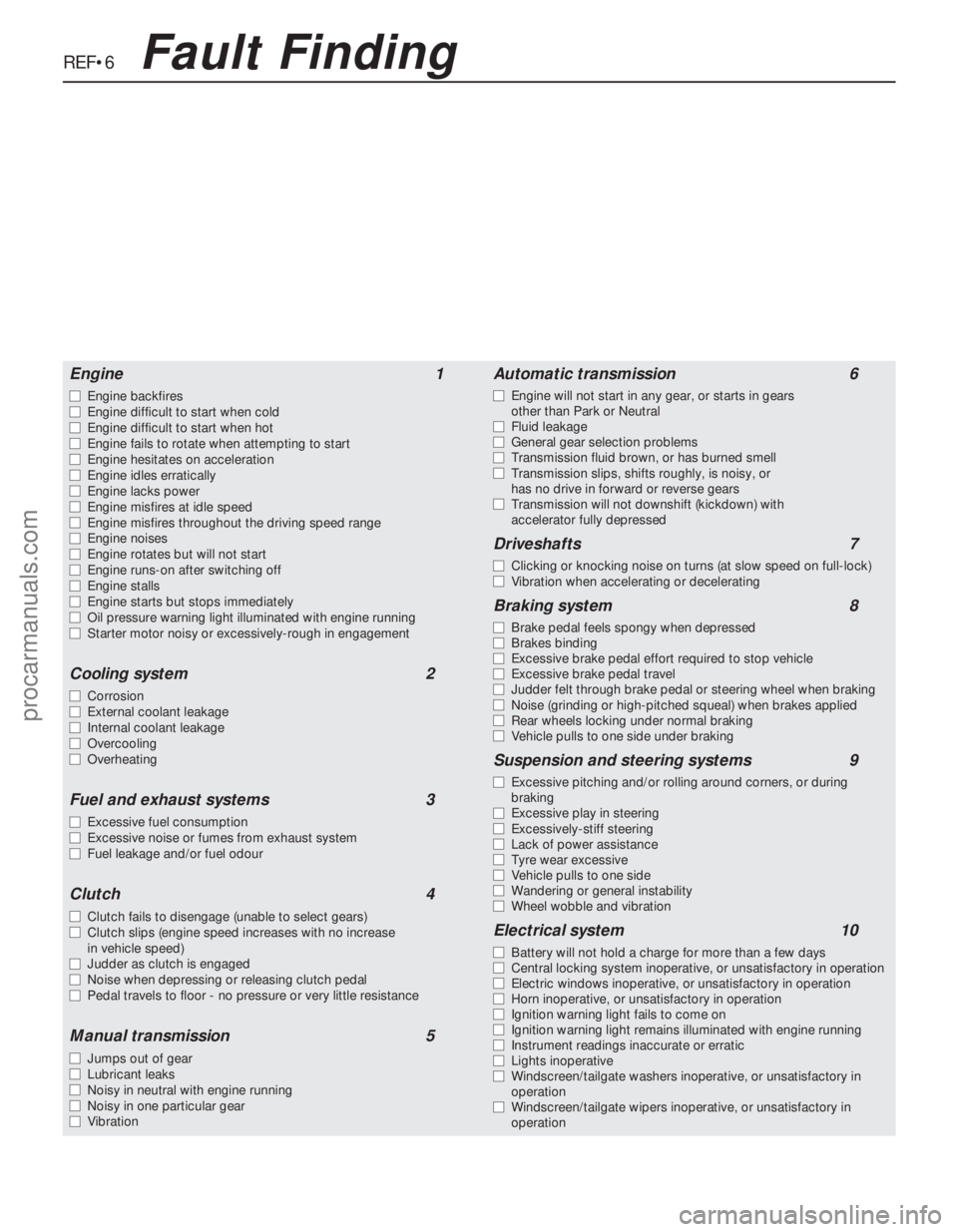

REF•6Fault Finding

Engine 1

m mEngine backfires

m mEngine difficult to start when cold

m mEngine difficult to start when hot

m mEngine fails to rotate when attempting to start

m mEngine hesitates on acceleration

m mEngine idles erratically

m mEngine lacks power

m mEngine misfires at idle speed

m mEngine misfires throughout the driving speed range

m mEngine noises

m mEngine rotates but will not start

m mEngine runs-on after switching off

m mEngine stalls

m mEngine starts but stops immediately

m mOil pressure warning light illuminated with engine running

m mStarter motor noisy or excessively-rough in engagement

Cooling system 2

m

mCorrosion

m mExternal coolant leakage

m mInternal coolant leakage

m mOvercooling

m mOverheating

Fuel and exhaust systems 3

m

mExcessive fuel consumption

m mExcessive noise or fumes from exhaust system

m mFuel leakage and/or fuel odour

Clutch 4

m

mClutch fails to disengage (unable to select gears)

m mClutch slips (engine speed increases with no increase

in vehicle speed)

m mJudder as clutch is engaged

m mNoise when depressing or releasing clutch pedal

m mPedal travels to floor - no pressure or very little resistance

Manual transmission 5

m

mJumps out of gear

m mLubricant leaks

m mNoisy in neutral with engine running

m mNoisy in one particular gear

m mVibration

Automatic transmission 6

m

mEngine will not start in any gear, or starts in gears

other than Park or Neutral

m mFluid leakage

m mGeneral gear selection problems

m mTransmission fluid brown, or has burned smell

m mTransmission slips, shifts roughly, is noisy, or

has no drive in forward or reverse gears

m mTransmission will not downshift (kickdown) with

accelerator fully depressed

Driveshafts 7

m mClicking or knocking noise on turns (at slow speed on full-lock)

m mVibration when accelerating or decelerating

Braking system 8

m

mBrake pedal feels spongy when depressed

m mBrakes binding

m mExcessive brake pedal effort required to stop vehicle

m mExcessive brake pedal travel

m mJudder felt through brake pedal or steering wheel when braking

m mNoise (grinding or high-pitched squeal) when brakes applied

m mRear wheels locking under normal braking

m mVehicle pulls to one side under braking

Suspension and steering systems 9

m

mExcessive pitching and/or rolling around corners, or during

braking

m mExcessive play in steering

m mExcessively-stiff steering

m mLack of power assistance

m mTyre wear excessive

m mVehicle pulls to one side

m mWandering or general instability

m mWheel wobble and vibration

Electrical system 10

m

mBattery will not hold a charge for more than a few days

m mCentral locking system inoperative, or unsatisfactory in operation

m mElectric windows inoperative, or unsatisfactory in operation

m mHorn inoperative, or unsatisfactory in operation

m mIgnition warning light fails to come on

m mIgnition warning light remains illuminated with engine running

m mInstrument readings inaccurate or erratic

m mLights inoperative

m mWindscreen/tailgate washers inoperative, or unsatisfactory in

operation

m mWindscreen/tailgate wipers inoperative, or unsatisfactory in

operation

procarmanuals.com

Page 271 of 279

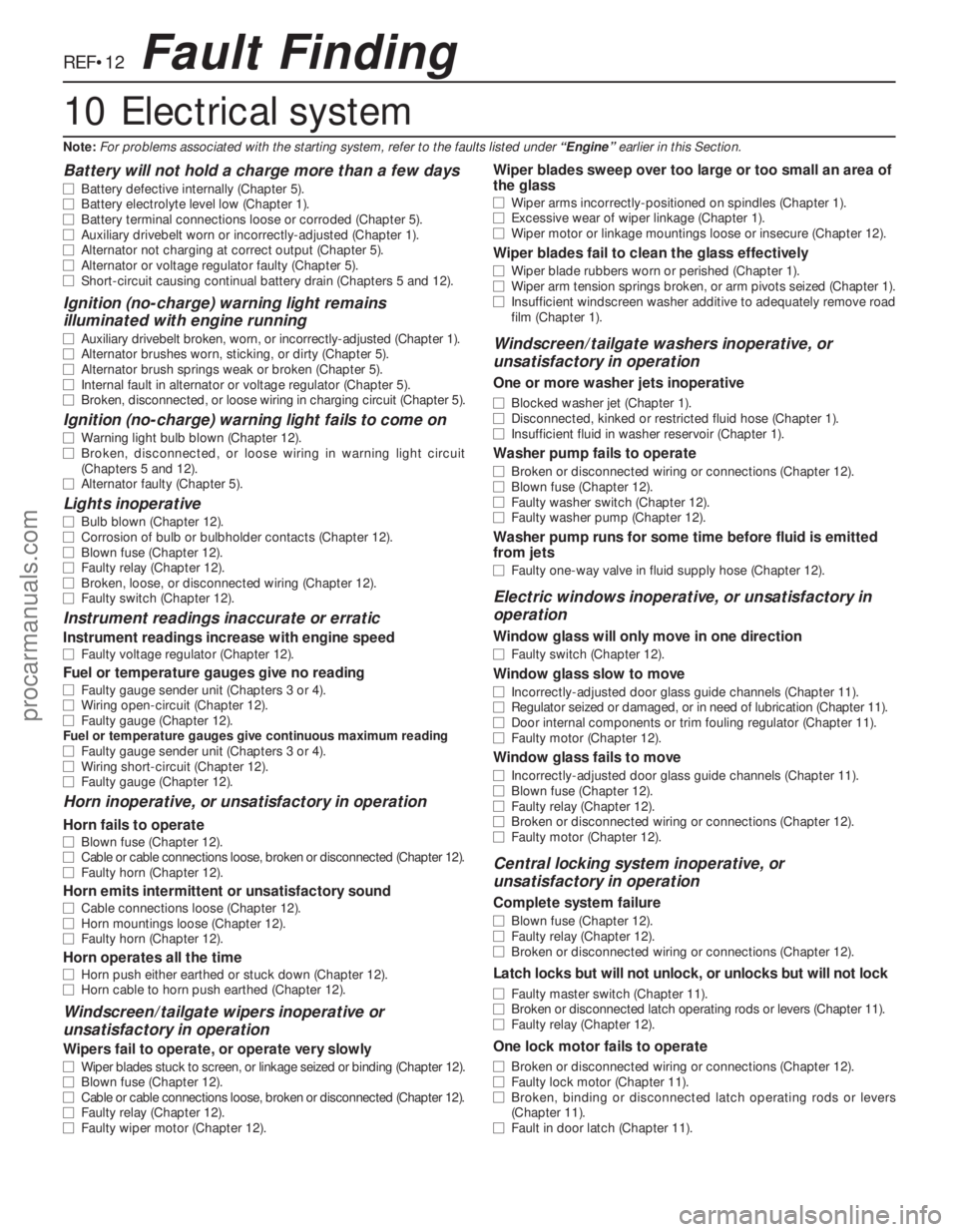

REF•12

Battery will not hold a charge more than a few days

m mBattery defective internally (Chapter 5).

m mBattery electrolyte level low (Chapter 1).

m mBattery terminal connections loose or corroded (Chapter 5).

m mAuxiliary drivebelt worn or incorrectly-adjusted (Chapter 1).

m mAlternator not charging at correct output (Chapter 5).

m mAlternator or voltage regulator faulty (Chapter 5).

m mShort-circuit causing continual battery drain (Chapters 5 and 12).

Ignition (no-charge) warning light remains

illuminated with engine running

m mAuxiliary drivebelt broken, worn, or incorrectly-adjusted (Chapter 1).

m mAlternator brushes worn, sticking, or dirty (Chapter 5).

m mAlternator brush springs weak or broken (Chapter 5).

m mInternal fault in alternator or voltage regulator (Chapter 5).

m mBroken, disconnected, or loose wiring in charging circuit (Chapter 5).

Ignition (no-charge) warning light fails to come on

m

mWarning light bulb blown (Chapter 12).

m mBroken, disconnected, or loose wiring in warning light circuit

(Chapters 5 and 12).

m mAlternator faulty (Chapter 5).

Lights inoperative

m

mBulb blown (Chapter 12).

m mCorrosion of bulb or bulbholder contacts (Chapter 12).

m mBlown fuse (Chapter 12).

m mFaulty relay (Chapter 12).

m mBroken, loose, or disconnected wiring (Chapter 12).

m mFaulty switch (Chapter 12).

Instrument readings inaccurate or erratic

Instrument readings increase with engine speed

m

mFaulty voltage regulator (Chapter 12).

Fuel or temperature gauges give no reading

m

mFaulty gauge sender unit (Chapters 3 or 4).

m mWiring open-circuit (Chapter 12).

m mFaulty gauge (Chapter 12).

Fuel or temperature gauges give continuous maximum reading

m mFaulty gauge sender unit (Chapters 3 or 4).

m mWiring short-circuit (Chapter 12).

m mFaulty gauge (Chapter 12).

Horn inoperative, or unsatisfactory in operation

Horn fails to operate

m

mBlown fuse (Chapter 12).

m mCable or cable connections loose, broken or disconnected (Chapter 12).

m mFaulty horn (Chapter 12).

Horn emits intermittent or unsatisfactory sound

m

mCable connections loose (Chapter 12).

m mHorn mountings loose (Chapter 12).

m mFaulty horn (Chapter 12).

Horn operates all the time

m

mHorn push either earthed or stuck down (Chapter 12).

m mHorn cable to horn push earthed (Chapter 12).

Windscreen/tailgate wipers inoperative or

unsatisfactory in operation

Wipers fail to operate, or operate very slowly

m mWiper blades stuck to screen, or linkage seized or binding (Chapter 12).

m mBlown fuse (Chapter 12).

m mCable or cable connections loose, broken or disconnected (Chapter 12).

m mFaulty relay (Chapter 12).

m mFaulty wiper motor (Chapter 12).

Wiper blades sweep over too large or too small an area of

the glass

m mWiper arms incorrectly-positioned on spindles (Chapter 1).

m mExcessive wear of wiper linkage (Chapter 1).

m mWiper motor or linkage mountings loose or insecure (Chapter 12).

Wiper blades fail to clean the glass effectively

m

mWiper blade rubbers worn or perished (Chapter 1).

m mWiper arm tension springs broken, or arm pivots seized (Chapter 1).

m mInsufficient windscreen washer additive to adequately remove road

film (Chapter 1).

Windscreen/tailgate washers inoperative, or

unsatisfactory in operation

One or more washer jets inoperative

m mBlocked washer jet (Chapter 1).

m mDisconnected, kinked or restricted fluid hose (Chapter 1).

m mInsufficient fluid in washer reservoir (Chapter 1).

Washer pump fails to operate

m

mBroken or disconnected wiring or connections (Chapter 12).

m mBlown fuse (Chapter 12).

m mFaulty washer switch (Chapter 12).

m mFaulty washer pump (Chapter 12).

Washer pump runs for some time before fluid is emitted

from jets

m mFaulty one-way valve in fluid supply hose (Chapter 12).

Electric windows inoperative, or unsatisfactory in

operation

Window glass will only move in one direction

m mFaulty switch (Chapter 12).

Window glass slow to move

m

mIncorrectly-adjusted door glass guide channels (Chapter 11).

m mRegulator seized or damaged, or in need of lubrication (Chapter 11).

m mDoor internal components or trim fouling regulator (Chapter 11).

m mFaulty motor (Chapter 12).

Window glass fails to move

m

mIncorrectly-adjusted door glass guide channels (Chapter 11).

m mBlown fuse (Chapter 12).

m mFaulty relay (Chapter 12).

m mBroken or disconnected wiring or connections (Chapter 12).

m mFaulty motor (Chapter 12).

Central locking system inoperative, or

unsatisfactory in operation

Complete system failure

m mBlown fuse (Chapter 12).

m mFaulty relay (Chapter 12).

m mBroken or disconnected wiring or connections (Chapter 12).

Latch locks but will not unlock, or unlocks but will not lock

m

mFaulty master switch (Chapter 11).

m mBroken or disconnected latch operating rods or levers (Chapter 11).

m mFaulty relay (Chapter 12).

One lock motor fails to operate

m

mBroken or disconnected wiring or connections (Chapter 12).

m mFaulty lock motor (Chapter 11).

m mBroken, binding or disconnected latch operating rods or levers

(Chapter 11).

m mFault in door latch (Chapter 11).

Fault Finding

10 Electrical system

Note:For problems associated with the starting system, refer to the faults listed under “Engine”earlier in this Section.

procarmanuals.com

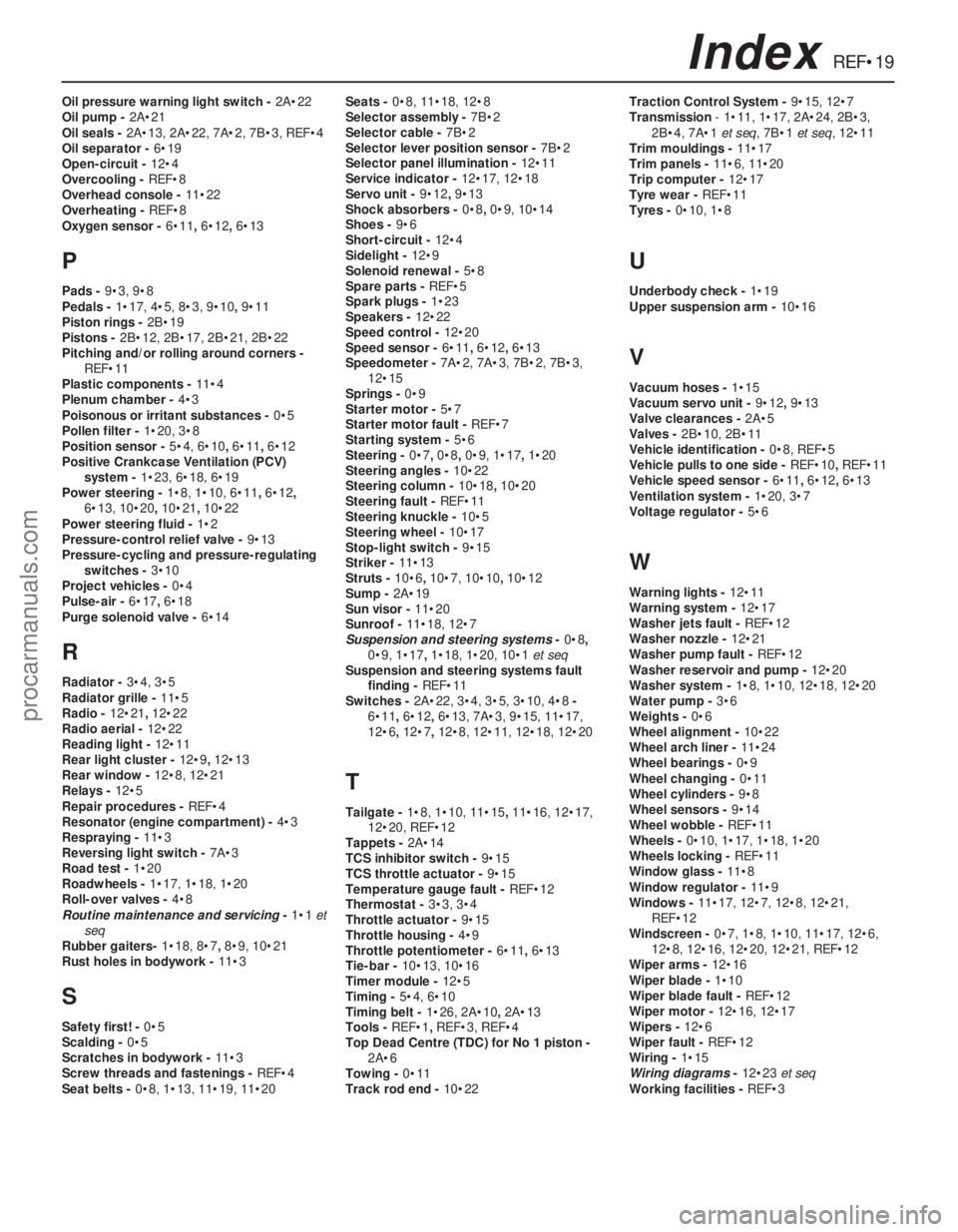

Page 278 of 279

REF•19Index

Oil pressure warning light switch - 2A•22

Oil pump - 2A•21

Oil seals - 2A•13, 2A•22, 7A•2, 7B•3, REF•4

Oil separator - 6•19

Open-circuit - 12•4

Overcooling - REF•8

Overhead console - 11•22

Overheating - REF•8

Oxygen sensor - 6•11, 6•12, 6•13

P

Pads - 9•3, 9•8

Pedals - 1•17, 4•5, 8•3, 9•10, 9•11

Piston rings - 2B•19

Pistons - 2B•12, 2B•17, 2B•21, 2B•22

Pitching and/or rolling around corners -

REF•11

Plastic components - 11•4

Plenum chamber - 4•3

Poisonous or irritant substances - 0•5

Pollen filter - 1•20, 3•8

Position sensor - 5•4, 6•10, 6•11, 6•12

Positive Crankcase Ventilation (PCV)

system - 1•23, 6•18, 6•19

Power steering - 1•8, 1•10, 6•11, 6•12,

6•13, 10•20, 10•21, 10•22

Power steering fluid - 1•2

Pressure-control relief valve - 9•13

Pressure-cycling and pressure-regulating

switches - 3•10

Project vehicles - 0•4

Pulse-air - 6•17, 6•18

Purge solenoid valve - 6•14

R

Radiator - 3•4, 3•5

Radiator grille - 11•5

Radio - 12•21, 12•22

Radio aerial - 12•22

Reading light - 12•11

Rear light cluster - 12•9, 12•13

Rear window - 12•8, 12•21

Relays - 12•5

Repair procedures - REF•4

Resonator (engine compartment) - 4•3

Respraying - 11•3

Reversing light switch - 7A•3

Road test - 1•20

Roadwheels - 1•17, 1•18, 1•20

Roll-over valves - 4•8

Routine maintenance and servicing- 1•1et

seq

Rubber gaiters- 1•18, 8•7, 8•9, 10•21

Rust holes in bodywork - 11•3

S

Safety first! - 0•5

Scalding - 0•5

Scratches in bodywork - 11•3

Screw threads and fastenings - REF•4

Seat belts - 0•8, 1•13, 11•19, 11•20Seats - 0•8, 11•18, 12•8

Selector assembly - 7B•2

Selector cable - 7B•2

Selector lever position sensor - 7B•2

Selector panel illumination - 12•11

Service indicator - 12•17, 12•18

Servo unit - 9•12, 9•13

Shock absorbers - 0•8, 0•9, 10•14

Shoes - 9•6

Short-circuit - 12•4

Sidelight - 12•9

Solenoid renewal - 5•8

Spare parts - REF•5

Spark plugs - 1•23

Speakers - 12•22

Speed control - 12•20

Speed sensor - 6•11, 6•12, 6•13

Speedometer - 7A•2, 7A•3, 7B•2, 7B•3,

12•15

Springs - 0•9

Starter motor - 5•7

Starter motor fault - REF•7

Starting system - 5•6

Steering - 0•7, 0•8, 0•9, 1•17, 1•20

Steering angles - 10•22

Steering column - 10•18, 10•20

Steering fault - REF•11

Steering knuckle - 10•5

Steering wheel - 10•17

Stop-light switch - 9•15

Striker - 11•13

Struts - 10•6, 10•7, 10•10, 10•12

Sump - 2A•19

Sun visor - 11•20

Sunroof - 11•18, 12•7

Suspension and steering systems- 0•8,

0•9, 1•17, 1•18, 1•20, 10•1et seq

Suspension and steering systems fault

finding - REF•11

Switches - 2A•22, 3•4, 3•5, 3•10, 4•8-

6•11, 6•12, 6•13, 7A•3, 9•15, 11•17,

12•6, 12•7, 12•8, 12•11, 12•18, 12•20

T

Tailgate - 1•8, 1•10, 11•15, 11•16, 12•17,

12•20, REF•12

Tappets - 2A•14

TCS inhibitor switch - 9•15

TCS throttle actuator - 9•15

Temperature gauge fault - REF•12

Thermostat - 3•3, 3•4

Throttle actuator - 9•15

Throttle housing - 4•9

Throttle potentiometer - 6•11, 6•13

Tie-bar - 10•13, 10•16

Timer module - 12•5

Timing - 5•4, 6•10

Timing belt - 1•26, 2A•10, 2A•13

Tools - REF•1, REF•3, REF•4

Top Dead Centre (TDC) for No 1 piston -

2A•6

Towing - 0•11

Track rod end - 10•22Traction Control System - 9•15, 12•7

Transmission- 1•11, 1•17, 2A•24, 2B•3,

2B•4, 7A•1 et seq, 7B•1 et seq, 12•11

Trim mouldings - 11•17

Trim panels - 11•6, 11•20

Trip computer - 12•17

Tyre wear - REF•11

Tyres - 0•10, 1•8

U

Underbody check - 1•19

Upper suspension arm - 10•16

V

Vacuum hoses - 1•15

Vacuum servo unit - 9•12, 9•13

Valve clearances - 2A•5

Valves - 2B•10, 2B•11

Vehicle identification - 0•8, REF•5

Vehicle pulls to one side - REF•10, REF•11

Vehicle speed sensor - 6•11, 6•12, 6•13

Ventilation system - 1•20, 3•7

Voltage regulator - 5•6

W

Warning lights - 12•11

Warning system - 12•17

Washer jets fault - REF•12

Washer nozzle - 12•21

Washer pump fault - REF•12

Washer reservoir and pump - 12•20

Washer system - 1•8, 1•10, 12•18, 12•20

Water pump - 3•6

Weights - 0•6

Wheel alignment - 10•22

Wheel arch liner - 11•24

Wheel bearings - 0•9

Wheel changing - 0•11

Wheel cylinders - 9•8

Wheel sensors - 9•14

Wheel wobble - REF•11

Wheels - 0•10, 1•17, 1•18, 1•20

Wheels locking - REF•11

Window glass - 11•8

Window regulator - 11•9

Windows - 11•17, 12•7, 12•8, 12•21,

REF•12

Windscreen - 0•7, 1•8, 1•10, 11•17, 12•6,

12•8, 12•16, 12•20, 12•21, REF•12

Wiper arms - 12•16

Wiper blade - 1•10

Wiper blade fault - REF•12

Wiper motor - 12•16, 12•17

Wipers - 12•6

Wiper fault - REF•12

Wiring - 1•15

Wiring diagrams- 12•23et seq

Working facilities - REF•3

procarmanuals.com